Abstract

High amylose rice (HAR) and carboxymethyl cellulose (CMC) are the preferred choices for enhancement of resistant starch content and lowering of glycemic index in dairy desserts. The effects of different levels of skimmed milk powder (SMP): HAR flour (45:55 to 75:25) and CMC (0.1 to 1%) were investigated on physical characteristics of dry-mix and on texture profile parameters, resistant starch (RS), predicted glycemic index (pGI), glycemic load (GL) and overall acceptability of phirni (a traditional milk pudding). Design expert predicted SMP (70): HAR (30) and CMC (0.8%) as optimum levels for reducing the pGI and maximizing the RS content and other quality characteristics in phirni. RS content of phirni (4.38%) prepared from optimized dry-mix (ODM) was higher while pGI (48.12) and GL (7.50) were lower as compared to phirni prepared from market dry-mix (MDM). The visco-thermal properties of ODM and MDM also showed significant variations. Storage modulus (Gʹ) and loss modulus (Gʹʹ) indicated that ODM phirni was less solid than MDM phirni. Scanning electron micrographs showed fused structures in ODM, while coarse sheet like structures were observed across the surface of MDM. Thus, ODM can be a promising substitute for the available milk desserts for diabetic patients.

Similar content being viewed by others

Introduction

Traditional dairy based desserts have deep cultural preferences, but their manufacturing has been restricted to non-industrial sector only. Phirni—a classic creamy sweet pudding, is one of the most famous traditional dairy based dessert relished in Northern India, especially on festive and social occasions. Phirni is usually prepared from rice flour or semolina and milk with the addition of sugar, and flavoring agents. It is cooked to semi-solid or pasty consistency, by heat desiccation and consumed after brief refrigeration or cooling1. Kheer is used as a synonym for phirni in literature but the principal difference between the two is use of pregelatinized rice grains in former and rice flour in latter2. Dairy based traditional desserts have a very short shelf life without refrigeration, which has prompted researchers to develop technologies for making milk-cereal based pre-mixes with instant reconstitution. Jha et al.2 prepared ready-to reconstitute Kheer pre-mix from milk-rice slurry through spray drying. Different variants of Kheer mix have been prepared by substituting milk with skimmed milk (SMP)/whole milk powders (WMP)/soymilk and rice with other cereals besides addition of various functional ingredients3,4. Kumar et al.5 formulated phirni mix from pregelatinzed rice flour, sugar, cardamom powder and WMP:SMP in the ratio of 18, 31, 1 and 50:50%. The authors standardized cooking time of 10 min for preparation of phirnion the basis of sensory score and rheological parameters.

The global demand for low GI foods has increased many-folds due to increased prevalence of diabetes mellitus. The prevalence of diabetes mellitusis high with about 463 M people suffering from diabetes worldwide6. Rice serves as the main daily caloric source for more than half of the population worldwide, while its high increases the risk of diabetes mellitusdue to its high GI7. Although various low GI foods have been developed, but the efforts to develop low GI desserts are rare8.Phirni is a rich source of proteins and minerals. Also being semi-solid in nature, it is highly recommended for patients with swallowing difficulties. Rice is categorized as high GI food with GI score ranging from 40 to 100. However, rice starch having high amylose content (> 25%) usually tends to elicit a lower GI9. Gelling polysaccharides and gums are usually added to milk-based puddings for improvement of body and structure10,11. Zahidi et al.10 studied the effects of soy milk (10–100%) and CMC (0, 0.5%) on color and rheological properties of soy dessert. Samples containing CMC showed high consistency coefficient. Arancibia et al.11 studied the effect of CMC at concentrations ≤ 0.9 w/w on rheology and microstructure of soy protein desserts and concluded that texture and rheological characteristics of high protein desserts could be altered by adding thickeners. Carboxymethylcellulose (CMC)—a linear chain polymer of D-glucopyranose and anionic carboxylate groups is one such gelling polysaccharide. It has a unique property to limit availability of water which reduces gelatinization of starch12. The gelatinization behaviour of starch is directly influenced by the chemical and morphological structure of the gum present in the starch gel matrix, the swelling power of the granules, and the electrostatic interactions between starch granules and hydrocolloid molecules13. The interaction between starch and hydrocolloids can alter food texture, structure, and viscosity, thereby changing the accessibility of enzymes to starch granules14. Hydrocolloids have the potential effect to increase the viscosity of food products and alter the accessibility of starch granules to the α-amylase. Blending starch with hydrocolloids decreases the rate of starch digestion. Some previous studies have also reported that hydrocolloids decreased starch hydrolysis in rice starch15; corn starch16; maize and wheat starch mixtures17. Srikaeo and Paphonyanyong18 reported that addition of 1% hydrocolloids exhibited lower starch digestion rate in cooked rice samples. Oh et al.19 also reported that addition of 0.4% CMC altered the starch digestibility of dry heat treated high amylose rice.

Despite the increasing demand for low GI foods, no study has been conducted so far on starch digestibility and glycemic response of traditional dairy based dessert like phirni. Thus, the aim of this study was to a) investigate the effect of different levels of high amylose rice (HAR), skimmed milk powder (SMP) and carboxymethyl cellulose (CMC) on physical attributes of instant phirni dry-mix as well as on the textural parameters, resistant starch, glycemic index, glycemic load and overall acceptability of phirni reconstituted thereof, and b) compare the pasting, thermal, rheological and morphological properties of optimized dry-mix (ODM) and market dry-mix (MDM). The hypothesis postulated in the study was that low GI traditional rice pudding “phirni” with improved quality characteristics can be prepared with ingredient alterations.

Material and methods

Raw material

Broken white grains of HAR (var Lalat) were ground in a laboratory mill (Perten, USA) to obtain rice flour that passed through 60 mesh sieve size. Moisture, protein, fat, crude fiber, dietary fiber, ash content and amylose content of rice flour were recorded as 11.30%, 10.15%, 1.25%, 1.09%, 3.90% and 0.56%, and 28.31%, respectively. The raw material was procured from the registered seed centers, and all the methods used in this work are in compliance with the institutional guidelines. Food grade CMC was procured from Sigma Aldrich, while SMP (Sifti, India), and market dry mix (MDM)were procured from the departmental store in Srinagar, India. In MDM, the ingredients were rice flour, milk powder, sugar, almonds and preservatives.

Experimental design

The 5-level-2-factor central composite rotatable design (CCRD) was used to investigate the effects of different levels of SMP: HAR and CMC on physical characteristics of instant phirni dry mix, as well as on texture profile parameters, resistant starch (RS), predicted glycemic index (pGI), glycemic load (GL) and overall acceptability of phirni re-constituted from dry-mix. The experimental ranges of independent variables and their coded levels are illustrated in Table 1. Least square regression method was used to analyze the data and second order polynomial models were established using statistical software Design-Expert 9 (Stat-Ease Inc, Minnneapolis, MN, USA).

where \(y_{i}\) = response variable, xi (i = 1, and 2), xi2 and xixj are linear, quadratic and interaction effects of the independent variables and bo, bi, bii and bij are regression coefficients for intercept, linear, quadratic and interactive effects, respectively. From ANOVA, the F-values were used to test the adequacy of models, while the model terms having “Prob > F” less than 0.05 were considered as significant terms20,21.

Preparation of instant phirni dry mix

All the dry ingredients i.e., HAR flour, SMP and CMC were mixed and homogenized in a planetary mixer (Phillips, India) in various proportions as per the experimental design (Table 1). Sucralose was added @ 680 mg/100 g dry mix weight in all the formulations20,21.

Reconstitution of instant phirni dry-mix

The contents of phirni dry mix samples were mixed with potable boiled water in the ratio of 1:5 (phirni dry mix: water)4 in an open pan and subjected to cooking at low heat (80–85 °C) with constant stirring for 15-20 min till desired consistency was achieved. Reconstituted phirni was poured into plastic cups and kept at 4 ± 2 °C under refrigerated conditions for 12 h prior to analysis.

Determination of physical attributes of instant phirni dry-mix

Bulk density, true density and solubility

Bulk density (\(\rho_{B}\)) and true density (\(\rho_{T}\)) were calculated by the method described by Raigar and Mishra22. Porosity was calculated using the standard formula2. The solubility percentage was calculated as per the procedure reported by Seth et al.23.

Determination of textural, chemical and sensory properties of reconstituted phirni samples

Texture profile analysis

Texture profile analysis of the phirni samples was done using the texture analyzer, TA-XT2i (Stable Microsystems, Surrey, UK). The two-cycle penetration test at a penetration speed of 2 mm s−1, up to a depth of 5 mm was carried out with a 0.05 N load cell and P-20 stainless steel cylindrical probe24. The parameters recorded were hardness, cohesiveness (COH) and adhesiveness (ADH).

Resistant starch

The reconstituted phirni samples were freeze dried in a laboratory freeze drier (Leybold-Heraeus, GT 2A, Germany) and subjected to fine grinding. Grinded samples (100 mg) were incubated in a shaking water bath with pepsin (Roche, Germany), pancreatic alpha-amylase (Sigma-Aldrich, UK) and amyloglucosidase (Megazyme, 3,300U/mL) for 16 h at 37 °C as per the detailed protocol reported by Naseer et al.21. Resistant starch content was measured using Megazyme Assay Kit (Megazyme International, Wicklow, Ireland)25 and RS was calculated from the formula given in the instruction manual.

Predicted glycemic index and glycemic load

The procedure reported by Naseer et al.21 was followed to determine the in-vitro digestibility of different freeze dried phirni samples. The rate of starch digestion was expressed as the percentage of total starch (TS) hydrolyzed at different time intervals. Hydrolysis index (HI) was calculated using the starch digestion rate curve (glucose release). The area under the curve for the experimental sample divided by the area under the curve of the control sample (white bread) was taken as HI and predicted glycemic index (pGI) was calculated using the standard formula26

Glycemic load (GL) of the samples was calculated using the following equation

where available carbohydrate (CHO)/serving size of 50 g was calculated by subtracting the dietary fiber content from total carbohydrate content.

Overall acceptability

Sensory evaluation of different reconstituted phirni samples was carried out on 9-point hedonic scale (9—liked extremely and 1—disliked extremely)27 by a jury of 30 trained judges. Samples were randomly coded and presented to the judges in separate partitioned booths. The judges evaluated the samples for different sensory attributes (appearance, consistency, flavor and lumpiness) according to the rating criteria and overall acceptability (OA) was determined as average of different sensory attributes. The judges used potable water for palate cleaning before evaluating each sample.

Process optimization and validation

Specific goals were allocated to all the analyzed parameters to optimize the process for preparation of instant phirni dry-mix using desirability function approach. Among the physical and textural attributes, BD, TD, hardness, and cohesiveness were minimized; whereas, porosity, solubility, adhesiveness, and OA were maximized. RS content was also maximized, while pGI and GL were minimized. Out of different generated solutions, the solution with highest desirability value was selected for the preparation of instant phirni dry-mix. The actual values of physico-chemical, textural and sensory properties determined after evaluating the instant phirni dry-mix prepared from optimized ingredient levels were compared with the predicted values generated by the software to validate the optimization process. Percentage prediction error was calculated using the equation given by Scheuer et al.28.

Quality evaluation of optimized dry-mix (ODM) and market dry-mix (MDM)

Physico-chemical analysis

Moisture, protein, ash, crude fiber, dietary fiber and fat contents were determined according to the standard methods of AOAC29. Water activity was measured with the help of water activity meter (Pre‐Aqua Lab, India). Carbohydrate content was estimated by difference method, and caloric value was calculated using Atwater factors. Total solids were estimated by gravimetric and total sugars were estimated using Lane- Eynon method as described by FSSAI30. Standard AACC25 method was followed to measure the total starch content using the total starch assay kit (K-TSTA, Megazyme, Bray, Ireland). Standard protocol was followed to determine the amylose content using the Megazyme assay kit (K-AMYL 06/18).

Visco-thermal properties

Pasting properties of different samples (3.50 g dry mix, 25 mL deionized water) were measured using rapid visco analyzer (RVA Starch TM, New Port, Scientific Warrie Wood, Australia) as per the procedure described by Pracham and Thaiudom24. The thermal properties were studied with a Differential Scanning Calorimeter (DSC-1 STARe 167 System, Mettler-Toledo). 10 mg of dry sample was placed in an aluminum pan and 50 µl deionized water was added. An empty aluminum pan was used as a reference. The pans were sealed hermetically and heated at 10 °C/min from 20 to 150 °C heating regime.

Rheological properties

Dynamic rheological properties were measured by Modular Compact Rheometer (MCR-101, Anton Paar, Austria), equipped with a parallel-plate geometry (50 mm diameter) using the procedure given by Thaiudomand Pracham31 with slight modification. The sample was placed on the ram of the rheometer with a spatula, spread uniformly andtrimmed wherever required. Storage modulus (G´), loss modulus (G´´), and loss tangent (tan δ) were analyzed by performing frequency sweep test from 0.1–100 rad/s, with a gap of 1 mm at 25 °C.The strain was kept constant at 2% for all the measurements which were in conformity with the Linear Viscoelastic Range.

Scanning electron microscopy

Morphology of the samples was analyzed by scanning electron microscope (Hitachi S-3400 N, Tokyo Japan) at 1.50 kX magnification. The samples were fixed on aluminum stubs using double sided adhesive tape. The fixed samples were covered with a thin layer of gold–palladium sputter coating and examined under voltage of 20 kV.

Statistical analysis

Experiments were conducted in triplicate and results presented were average of three replications ± standard deviation. Statistical significance of physico-chemical, textural, pasting, and thermal properties was determined by Students t-test using SPSS software. Mean values were compared by Duncan’s Multiple Range test at p < 0.05 level of significance.

Results and discussions

Fit summary for ANOVA

For bulk density, true density, hardness, cohesiveness, resistant starch, predicted glycemic index, quadratic models were suggested; while for porosity, adhesiveness, glycemic load and overall acceptability linear modelswere suggested by output of fit summary statistics (Table 2). R2 values (0.834–0.990) recorded for different parameters indicated fair fit of developed models with the actual values. Models generated for different quality attributes of instant phirni dry mix were highly significant (p ≤ 0.0001). The difference in predicted and adjusted R2 was less than 0.2 in all the models which indicated that they are in reasonable agreement with each other32. F-values obtained (25.29 to 144.12) further demonstrated the validity of the models and there could be 0.01% possibility only that these F-values could be noise based. Range of coefficient of variation (CV = 0.22–10.97%) also confirmed the reproducibility of the developed models. The adequate precision values recorded for different parameters were considered desirable33. Lack of fit (LOF) was non-significant in all the selected parameters, indicating good correlation between second-order polynomial models and the measured data.

Physical properties of instant phirni mix

Bulk density, true density and porosity

Bulk density (BD), true density (TD) and porosity (\(\emptyset ) \) are important functional parameters of instant powders from commercial point of view34. For different experimental runs, BD, TD and \(\emptyset \) of phirni mix ranged from 610 to 685 kg/m3, 710 to 817 kg/m3 and55.64 to 56.82% respectively (Fig. 1a–c). Fitted regression models for BD, TD and \(\emptyset\) are depicted below, where, A indicates proportion of SMP in relation to HAR flour

(a–d) Demonstrates the effect of skimmed milk powder (SMP): high amylose rice (HAR) and CMC on physical attributes of instant dry mix; (e–k) demonstrates the effect of SMP: HAR and CMC on textural parameters, resistant starch, kinetics of starch digestion and overall acceptability of instant dry mix phirni, and (l) optimization plot.

Fitted regression Eqs. (4–6) shown above indicated that SMP incorporation (A) had significant negative linear and quadratic effects on bulk density and true density of phirni mix. However, linear effects of SMP were predominant over quadratic effects in both BD and TD. SMP had significant (p < 0.05) linear effect on porosity of phirni mix as well. As the concentration of SMP was increased, BD and TD were decreased, while ϕ increased (Fig. 1a–c). SMP has lower density than rice flour, which might have reduced the BD of phirni mix samples containing higher proportion of SMP. Thus, agglomeration of particles was more in the phirni mix samples containing higher proportion of SMP which justified the inverse and direct relationships of SMP with density and porosity, respectively. The density values of phirni mix recorded in the present study were lower, while porosity percentage was higher than that reported by Jha et al.2 for kheer mix, likely due to compositional and ingredient variation.

Solubility

Solubility is also one of the important quality attributes of instant powders. Solubility of different phirni mix samples varied from 83.3 to 95.2% (Fig. 1d). Fitted regression model for solubility is depicted below, where, A indicates proportion of SMP in relation to HAR flour and B is concentration of CMC

Regression Eq. (7) exhibited positive linear relationships of A and B and a negative quadratic relationship of A with solubility. As the concentration of SMP was increased from 45 to 60%, solubility increased from 83.3 to 95.16%. However, upon further increase in SMP concentration (60 to 75%), the solubility of phirni mix decreased from 95.16 to 88.18%, respectively (Fig. 1d). Solubilization of instant dairy mix is governed by structural organization of casein proteins and its interactions with water35. SMP has higher dispersibility and porosity and thus, produces lower sediment value as compared to rice flour, which may have increased the solubility of phirni mix developed from blends containing 45–60% SMP. However, higher incorporation of SMP increases the protein content of the blends, which might have decreased the solubility of phirni mix containing greater than 60% SMP, due to hydrophobic protein–protein interactions36,37 and protein-hydroxyl interactions of SMP and CMC38. McSweeney et al.36 also reported inverse effect of protein content on solubility of milk concentrates. Moreover, BD and solubility have inverse relationship39 and same trend was noticed in the present study as well (Eq. 4 and Eq. (7), respectively). Equation (7) and Fig. 1d also demonstrated the significant positive linear effect of CMC concentration on solubility of dry mix. As the concentration of CMC was increased from 0.1 to 1%, solubility increased from 90.31 to 95.21%, respectively (Fig. 1d). The presence of hydroxyl groups facilitates the bonding between CMC and neighboring water molecules, which may have increased the solubility of phirni mix samples containing higher levels of CMC. Although CMC is highly hygroscopic in nature, however, interaction of proteins and hydroxyl groups induce some conformational changes which may have led to difference in sensitivity of phirni mix to hydration and binding of water molecules38.

Physico-chemical properties of reconstituted phirni

Texture profile analysis

Hardness

Hardness of different reconstituted phirni samples ranged from 0.24 to 0.80 N (Fig. 1e). Fitted regression model for H is depicted below:

Regression Eq. (8) indicated that A had a significant negative linear effect on hardness. As the concentration of SMP increased from 45 to 75%, hardness decreased from 0.80 to 0.24 N, respectively (Fig. 1e). Incorporation of SMP lowered the starch content of the formulation which may have decreased the hardness of phirni prepared from such samples. At the highest concentration of rice flour (55%), maximum hardness was recorded highest (0.80 N), which could be attributed to interaction of SMP proteins with leached components of starch in phirni during cooling40. Amylose has an ability to form rigid gel, which may have caused interaction starch and milk causing positive affect on the firmness of puddings41. Figure 1e shows that B also had significant negative linear effect on hardness. As the concentration of CMC was increased from 0.1 to 0.5%, hardness decreased from 0.75 to 0.36 N. CMC has good holding capacity and thus decreases the gel hardness during cooking which subsequently leads to the production of soft puddings42.

Adhesiveness and cohesiveness

Adhesiveness (ADH) indicates the ability of the product to adhere to the palate during swallowing43 while cohesiveness (COH) measures the strength of internal bonds and the degree to which a food can be deformed before it breakdowns44. Both ADH and COH are important factors which govern the acceptability of milk desserts. ADH of different phirni samples ranged between (−) 0.309 to (−) 0.628 N and COH from 0.455 to 0.910, respectively (Fig. 1f,g). Fitted regression models for ADH and COH are depicted below:

Both the independent variables (A and B) exhibited positive linear relationships with ADH (Eq. 9). Figure 1f indicated that as the SMP and CMC concentrations increased from 45 to 75% and 0.1 to 1%, the ADH of phirni samples increased from (−) 0.341 to (−) 0.563 N and (−) 0.309 to (−) 0.628 N, respectively. Higher ADH implies softer texture, which is a desirable trait in milk desserts. Casein—a dominant protein in SMP forms protein gel upon gentle heating and stirring and thus imparts body and texture to phirni45. Higher SMP reduces the consistency of phirni due to formation of liquid bridges, which increases the ADH. Furthermore, lactose act as a plasticizer in the presence of water due to its hygroscopic nature and thus, depresses the glass transition of amorphous sugars46, which also justifies the increase in ADH upon increase in SMP level in phirni. Guimarães et al.47 also reported a significant increase in ADH of instant dessert with the increase in addition of milk powder in relation to rice flour. The positive relationship of CMC and ADH recorded in phirni samples can be attributed to CMC-calcium ion interaction. Coronato et al.48 reported that with increase in gum concentration, the adhesiveness of milk-gum suspension also increased.

Regression Eq. (10) indicated inverse relationship of A and direct relationship of B with COH. The perusal of the results depicted in Fig. 1g demonstrate that increase in concentration of SMP from 45 to 75% decreased the COH from 0.651 to 0.455, while increase in concentration of CMC from 0.1 to 1% increased the COH from 0.721 to 0.910, respectively. Decrease in COH with the increase in SMP level can be attributed to dilution of starch network and weakening of interparticle bonding49 caused by easy dissolution of SMP in water. In contrast, CMC imposed a thickening effect in phirni which may have lead to increase in COH50 due to starch-milk interaction. Zhang et al.51 also reported that addition of gums increased the consistency and cohesiveness of the low-fat fermented skimmed milk.

Resistant starch

Resistant starch (RS) is an important contributor of glycemic response offered by carbohydrate-rich food; hence, lot of research is going on to enhance the RS content in processed foods due to its health benefits52. RS content of different phirni samples ranged from 1.53 to 4.72% (Fig. 1h). Fitted regression model for RS is depicted below:

Both the independent variables exhibited significant positive relationships with RS content (Eq. 11). Interactive effect of A and B on RS content was also found to be significantly positive. The data depicted in Fig. 1h indicated that as the increase of SMP increased from 60 to 75%, the RS content increased from 2.25 to 3.44%, while as upon increase in CMC concentration from 0.1 to 1%, RS content increased from 1.53 to 4.62%, in different phirni samples respectively. Milk proteins interact with the rice starch granules through adsorption and hydrophobic linkages53. Adsorption of protein aggregates fill the voids inside starch granules which restrict the diffusion of water and thus, limit the starch hydrolysis and digestion. Further, heating induces protein–protein aggregation, and formation of amylose–lipid complexes which may reduce the accessibility to hydrolysis54. CMC exhibited a dominant effect on RS content as compared to SMP due to its thickening effect. A prominent increase in RS content with the increase in CMC concentration is evident in Fig. 1h. CMC binds to the surface of proteins due to the electrostatic attraction between the positive charge on casein micelles and anionic groups on the CMC molecules due to which enzyme–substrate interactions during enzymatic hydrolysis gets reduced. In addition, electrostatic interaction also leads to protein-polysaccharide complex formation which are relatively resistant to digestion55. Elmstahl56 also reported an increase in RS content in semolina porridge due to starch-protein interactions.

Predicted glycemic index and glycemic load

Low-GI foods are recommended by the American Diabetic Association for the long-term management of diabetes mellitus57. pGI and GL of different phirni samples ranged from 47.15 to 51.78 and 7.15 to 11.18, respectively (Fig. 1i–j). Fitted regression models for pGI and GL are depicted below:

Both the independent variables exhibited significant negative relationships with pGI and GL (Eq. 12 and 13). In case of pGI, the interactive effect of A and B was also significantly negative. The data depicted in Fig. 1i–j indicated that pGI of phirni samples decreased from 51.55 to 49.64 as the SMP concentration increased from 60 to 75%; while as upon increase in CMC concentration from 0.1 to 1%, pGI decreased from 51.78 to 47.18, respectively. At the same time, the increase in SMP concentration from 45 to 75% decreased the GL from 11.18 to 7.15 and increase in CMC concentration from 0.1 to 1%, decreased the GL from 8.96 to 8.22 in different phirni samples (Fig. 1i–j). Milk proteins located in the interfaces of starch granules limit the water diffusion inside the granules which restrict the gelatinization of the starch40. Proteins and partially/ungelatinized starch granules are less susceptible to hydrolysis and are thus involved in starch-protein interaction which lowers the glycemic response and glycemic load upon their co-ingestion58. Milk proteins are also known to have insulinotropic properties and thus, reduce the glycemic response59.Sugiyama et al.60 also reported that the consumption of rice and milk attenuates; Sun et al.58 also reported that co-ingestion of soymilk and dairy milk with bread significantly lowered the blood glucose levels. Out of two independent variables, CMC exhibited a dominant effect on pGI as compared to SMP (Eq. 12). Hydroxyl groups of CMC interact with starch granules—via—hydrogen bonding and form thermally stable structures. The decrease in pGI and GL could also be accorded to the enhanced structural stability of starch induced due to immobilization of water and crosslinking of CMC with glycosidic linkages during heating. Further, the hydrophilic polysaccharides due to its linear structure and ionic charge assist in formation of retrograded starch61 during cooling of phirni. Jung et al.62 also reported that glycemic index of segoami rice gels decreased significantly as the concentration of gums was increased from 0.3 to 0.7%.

Overall acceptability

The SMP and CMC formulations significantly affected the sensory attributes of phirnisamples. For different phirni samples, overall acceptability (OA) ranged from 7.10 to 8.58 (Fig. 1k). Fitted regression model for OA is given below:

The Eq. (14) depicts significant positive relationships of A and B with OA. Figure 1k also indicated an increasing trend in OA with the increase in concentration of SMP and CMC. SMP improved the flavor of phirni, possibly due to presence of milk sugar while CMC improved the sensory attributes like texture and viscosity, due to its thickening effect. Also, the starch gets gelatinized during cooking and interacts with milk proteins and hydrocolloid which may have further imparted the desired texture and mouthfeel to phirni5.

Optimization

Design expert predicted high amylose rice flour (70): SMP (30) and CMC 0.85% as optimum ingredient levels for preparation of low GI phirni. The desirability value for the selected solution was 0.70 (Fig. 1l). The BD, TD, porosity, S, H, ADH, COH, RS, pGI, GL and OA of phirni prepared from optimized ingredient levels were recorded as 634.15 kg/m3, 745.10 kg/m3, 55.16%, 94.24%, 0.311 N, (−) 0.642 N, 0.724, 4.38%, 48.12, 7.50, 8.39, respectively. The actual values of dependent variables matched the predicted values well with a variation of ≤ 3.66% which confirmed the predicted pattern of the developed models.

Chemical composition

Physico-chemical composition of optimized drymix (ODM) and market dry mix (MDM) is depicted in Table 3. Moisture, water activity, and total solid content of ODM and MDM differed non-significantly with each other. The values of these parameters were more or less similar to the values reported by Jha et al.2 and Vashistha et al.63 in different types of dairy dry-mixes. Protein content was significantly higher, while fat content was significantly lower in ODM as compared to MDM, possible due to ingredient difference. Higher ash content of ODM as compared MDM was presumable due to SMP. Crude and dietary fiber contents were also significantly higher in ODM than MDM, which might be attributed to incorporation of CMC in ODM. However, carbohydrate content was significantly lower in ODM as compared to MDM. Significant reduction in carbohydrate content of ODM was probably due to its higher protein, and fiber content, besides the lower total sugar content. In case of MDM, sucrose is usually added as a taste enhancer, while in case of ODM, lactose was the major sugar present due to SMP incorporation. Lactose has a GI score of 43 and falls under the low GI category, while sucrose has a GI score of 60 and falls under the moderate GI category64. Energy value of ODM was significantly lower than that of MDM, likely due to lesser sugar, fat and carbohydrate contents in the former. Significantly higher starch content of ODM than that of MDM might be because of high proportion of rice flour in ODM. Since high amylose rice flour was used as base material for preparation of ODM, which may have led to its high amylose content as compared to MDM. Variation in SMP, rice flour and other ingredients possibly led to observed disparities in compositional analysis of ODM andMDM. Higher RS content (4.38%) was recorded in phirni reconstituted from ODM as compared to MDM phirni (0.50%), which can be attributed to high amylose content and CMC incorporation in ODM. Due to linear chain structure, amylose is more susceptible to retrogradation during heating–cooling cycle, which might have increased the RS content in ODM phirni. In addition, various chemical changes take place during phirni preparation, which may have facilitated protein denaturation and formation of complexes between starch and non-starch components that are resistant to amylolytic hydrolysis65. The lower glycemic response of ODM phirni (48.12) relative to MDM phirni (60.20), was possibly due to its higher RS and dietary fiber content. The presence of sucrose may possibly have spiked the pGI of MDM phirni as well. Variation in glycemic index of phirni reconstituted from ODM relative to MDM highlighted the importance of rice and sugar type including the effect of hydrocolloid on postprandial hyperglycemic effect.

Texture profile analysis

TPA of phirni reconstituted from ODM and MDM is shown in Table 3. Hardness and cohesiveness (COH) were higher in phirni reconstituted from MDM as compared to that reconstituted from ODM. Higher protein content reduces the leaching of amylose possibly leading to reduction of the hardness of ODM phirni. It can be presumed that network of casein micelles dominated the texture of ODM phirni. Equation (8) also indicated that SMP had dominant negative effect on hardness of phirni as compared to the positive effect of CMC. Further, due to presence of additional ingredients, MDM upon heating produced viscous pastes which converted into firm gel after cooling. In contrast, ODM during reconstitution produced liquid like consistency and thus, formed firm gel after cooling, which might have reduced the COH of ODM phirni. However, ODM phirni had higher ADH as compared to MDM phirni, possibly due to its softer texture and presence of lactose owing to high SMP (70%) incorporation46.

Pasting properties

The pasting properties of ODM and MDM are depicted in Table 4. ODM showed significantly higher pasting temperature than MDM suggesting that starch crystallites formed in ODM were resistant to melting. Also, starch-hydrocolloid interaction might have created some stable structures, which require higher temperature to disorganize66. Noisuwan et al.40 reported that proteins adsorb onto the starch granules and restrict the diffusion of water into the starch granules during pasting, which may increase the pasting temperature of ODM. However, peak viscosity and hold viscosity were higher in MDM as compared to ODM (Table 4). Presence of sucrose in MDM may have contributed to its higher peak and hold viscosities, which is in agreement with the results of Pongsawatmanit et al.67 for sucrose incorporated starch suspensions. However, higher amylose content (15.31%) in ODM may have restricted the development of viscous paste and thus, significantly lowered its peak and hold viscosities. In addition, due to high protein content (25.12%), the protein molecules in ODM tend to encircle the starch granules in the matrix which hinders its water absorption. One of the possible mechanisms which can explain the influence of SMP on pasting behaviour of rice flour could be that proteins compete for water during gelatinization of starch and thus, restrict the swelling of granules. At the same time, lactose and salt diffuses into starch granules which affects the leaching of amylose into continuous phase by anti-plasticizing effect of lactose and stabilizing effect of cations on starch structure, respectively24. The paste has lower breakdown viscosity (BDV) and has better stability against shearing, which is a desirable trait for puddings68. The lower BDV of ODM indicated higher reinforcing effect of protein matrixes on starch-protein interaction, possibly due to disulfide bonding, which may have improved the shear resistance of ODM as compared to MDM. Final viscosity (FV) and setback viscosity (SBV) of ODM were significantly higher than that of MDM (Table 4). The higher FV of ODM can be attributed to the presence of CMC. The interaction between negatively charged CMC molecules and positively charged casein miscelles, controlled by electrostatic repulsion69 may have led to increase in FV. The results of pasting properties were almost in agreement with the results of Pracham and Thaiudom24 reported for jasmine rice pudding. Higher SBV recorded in case of ODM indicated its higher retrogradation tendency which was possibly due to its high amylose content. Ye et al.70 and Naseer et al.71 have also reported higher SBV for high amyloses rice.

Thermal behaviour

Differential Scanning Calorimetric (DSC) results presented in Table 4 showed that ODM had significantly higher peak, end-set temperatures and enthalpy of gelatinization (∆Hgel) than MDM. However, onset temperatures recorded for both the samples showed non-significant difference. CMC, protein and amylose molecules compete with each other for water72, which may have enhanced the peak and end-set temperatures of ODM. Furthermore, high amylose starches also exhibit higher gelatinization temperatures73,74. Uthumporn et al.72 also reported that protein and starch granules compete for water molecules which results in inhibited swelling and increased gelatinization temperature. Higher ∆Hgel suggested that more organized amylose structures were present in ODM as compared to MDM and thus, higher energy was required to break the hydrogen bonds between the monomers in case of ODM.

Microstructure analysis

Scanning electron micrographs given in Fig. 2a demonstrated the presence of fused structures in ODM. The starch granules possibly fused with protein molecules and formed aggregated complexes which appeared as fused structures. Further, the casein micelles linked to each other with inter-micellar bridges seemed to appear like balls in micrographs of ODM (Fig. 2a). Fine spikes around these casein aggregates can be attributed to the presence of polysaccharide/fibrous materials75. Overall, it appeared as if the surface of ODM was dominated by the proteins and different constituents of rice were encased by protein miscelles. Further, the interaction of CMC and casein particles may also have resulted in the agglomeration of particles, which may have acted as a physical barrier to enzymatic hydrolysis76. In contrast, coarse sheet like structures were observed in MDM (Fig. 2b). Some irregular shaped components and spherical protein bodies were found dispersed all over the surface of MDM, which could be attributed to difference of ingredients and processing conditions adopted for preparation of market sample. Borad et al.77 also reported coarse sheet like structures in different kheer samples.

Rheological properties

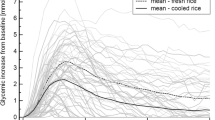

Due to the presence of multiple components like proteins, sugar, additives and stabilizers, rice-milk desserts usually show somewhat complex rheological behaviour. Both ODM and MDM Phirni samples had G′ > G" and tan δ < 1 over entire range of studied frequency (Fig. 3a,b). These trends indicate a typical soft gel behaviour and have been observed with milk puddings24,68. Higher storage (G′) and loss modulii (G") were recorded for MDM phirni which indicated its more solid like behaviour as compared to ODM phirni. Due to flavoring agents and additives, the ingredient interaction was probably stronger in MDM phirni which might have increased its G′ and G". Therefore, it was presumed that total solids and other particulate matter exhibited the dominant affect on pudding structure and gel strength. Lower G′ and G" of ODM phirni indicated its less firm structure as compared to MDM phirni sample. Although, ODM was prepared from high amylose rice flour with CMC incorporation (0.85%), but the G′ and G" values indicated that ODM phirni was less solid-like as compared to MDM phirni. At low concentration (≤ 4%), hydrated CMC molecular chains act as “diluent” and disperse around amylose molecules, thereby, prevent the amylose-amylose interaction which may reduce the rigidity of the pastes78. Further, due to high SMP percentage, the casein micelles in ODM may also have restricted the interaction between amylose and other ingredients. It is likely possible that either amylose leaching may have been inhibited by casein aggregates or leached amylose granules would have been encased by casein network40. El-Garaway and Salam 79 also described that high protein concentration imposed hinderance on formation of strong gel network between amylose-amylopectin and CMC. Tan δ of ODM phirni was higher than MDM phirni (Fig. 3b), which also indicated that at high protein content, CMC indisposed the amylose network and reduced the rigidity of the paste. Milk proteins also prevent the molecular reorganization of high amylose starch and thus reduce the rigidity of gels as compared to low amylose ones. Carvalho et al.80 also suggested that casein micelles act as inactive fillers in starch granules and thus, produce weak gels. Since sucrose was present in MDM, that has tendency to create preferential exclusion of sugar and proteins which increases the effective concentration of sugars in bulk volume and therefore, increases the firmness and viscosity. However, in case of ODM, co-adsorption of rice flour components may have altered the surface charge of proteins. This may have reduced the protein–protein interaction and subsequently the gel strength of ODM phirni81. Pracham and Thaiddum24 also reported that high protein puddings exhibited weak gel structure as compared to low protein puddings. The rheological and texture profile results recorded for ODM and MDM phirni samples in the present study were in synchronization with each other. Similar trends were reported by Prachamand Thaiddum24 in milk based puddings.

Conclusions

Perusal of the results revealed that addition of CMC can play a predominant role in enhancing the RS and lowering the pGI of traditional milk-based rice pudding-phirni. Physical attributes of optimized dry mix were dominantly affected by SMP, while RS and pGI were mainly controlled by CMC. However, both SMP and CMC seemed to work in synergy with high amylose rice in increasing the resistant starch and lowering the pGI of reconstituted phirni. Milk proteins played a vital role in pasting and thermal behaviour of optimized dry mix, which was validated by scanning electron microscopy as well. The elastic (G') and viscous (G") components confirmed that phirni reconstituted from both ODM and MDM exhibited soft gel behaviour. However, ODM phirni had less firm texture than MDM phirni. Texture profile analysis also indicated that ODM phirni had lower hardness but higher adhesiveness and cohesiveness as compared to MDM phirni. The outcome of the present study can help to prepare a low GI diet for people suffering from diabetes and swallowing difficult. However, this is the first reported study which investigated the glycemic index, glycemic load and resistant starch content of traditional dessert-phirni. Therefore, prior to its commercialization, there is a need to conduct in-vivo testing of such product among the target population in future to validate its impact on glycemia.

Data availability

The datasets analysed during the current study shall be made available from the corresponding author on reasonable request.

References

Arora, S. K. & Patel, A. A. Effect of fiber blends, total solids, heat treatment, whey protein concentrate and stage of sugar incorporation on dietary fiber-fortified Kheer. J. Food Sci. Technol. 54(11), 3512–3520 (2017).

Jha, A., Patel, A. A. & Singh, R. R. B. Physico-chemical properties of instant kheer mix. Lait 82(4), 501–513 (2002).

Aneja, R. P., Mathur, B. N., Chauhan, R. C. & Banerjee, A. K. Technology of Indian milk products. Ist Edn. A Dairy India, Delhi, 199 (2002).

Bunkar, D. S., Jha, A. & Mahajan, A. Optimization of the formulation and technology of pearl millet based ‘ready-to-reconstitute’kheer mix powder. J. Food Sci. Technol. 51(10), 2404–2414 (2014).

Kumar, S., Paul, S. C. & Kumar, S. Effect of varying level of dried milk proportion on formulation and reconstitution of Phirni mix powder. J. Food Sci. Technol. 52(2), 1206–1211 (2015).

International Diabetes Federation. (2019). IDF diabetes atlas (the 9th ed.) (2019) Retrieved from https://www.diabetesatlas.org/en/GoogleScholar.

Jukanti, A. K., Pautong, P. A., Liu, Q. & Sreenivasulu, N. Low glycemic index rice—A desired trait in starchy staples. Trends Food Sci. Technol. 106, 132–149 (2020).

Suttireung, P. et al. Riceberry rice puddings: Rice-based low glycemic dysphagia diets. Asia Pac. J. Clin. Nutr. 28(3), 467–475 (2019).

Kumar, A. et al. Addition of pulses, cooking oils, and vegetables enhances resistant starch and lowers the glycemic index of rice (Oryza sativa L.). Starch-Stärke 72, 1900081 (2020).

Zahedi, A., Mohammad, H., Javad, K. & Mohammad, A. S. Soy milk effects and CMC on soy dessert and its rheological properties. Int. J. Farm. All. Sci. 2–7, 148–152 (2013).

Arancibia, C., Bayarri, S. & Costell, E. Effect of hydrocolloid on rheology and microstructure of high-protein soy desserts. J. Food Sci. Technol. 52(10), 6435–6444 (2015).

Chen, M. et al. The effect of viscous soluble dietary fiber on nutrient digestion and metabolic responses I: In vitro digestion process. Food Hydrocolloids 107, 105971 (2020).

Chaisawang, M. & Suphantharika, M. Effects of guar gum and xanthan gum additions on physical and rheological properties of cationic tapioca starch. Carbohydr. Polym. 61, 288–295 (2005).

Brennan, C. S. Dietary fibre, glycaemic response, and diabetes. Mol. Nutr. Food Res. 49(6), 560–570 (2005).

Sasaki, T. & Kohyama, K. Effect of non-starch polysaccharides on the in vitro digestibility and rheological properties of rice starch gel. Food Chem. 127(2), 541–546 (2011).

Zhou, S. et al. Effect of heat-moisture treatment on the in vitro digestibility and physicochemical properties of starch-hydrocolloid complexes. Food Hydrocolloids 104, 105736 (2020).

Tester, R. F. & Sommerville, M. D. The effects of non-starch polysaccharides on the extent of gelatinisation, swelling and α-amylase hydrolysis of maize and wheat starches. Food Hydrocolloids 17(1), 41–54 (2003).

Srikaeo, K. & Paphonyanyong, W. Texture, microstructure and in-vitro starch digestibility of waxy rice cooked with hydrocolloids. Food Res. 4(4), 1089–1097 (2020).

Bae, I. Y. & Lee, H. G. Complexation of high amylose rice starch and hydrocolloid through dry heat treatment: Physical property and in vitro starch digestibility. J. Cereal Sci. 79, 341–347 (2018).

Naseer, B., Naik, H. R., Hussain, S. Z., Bhat, T. & Nazir, N. Development of instant phirni mix (a traditional dairy dessert) from high amylose rice, skim milk powder and carboxymethyl cellulose-resistant starch, predicted glycemic index and stability during storage. Food Biosci. 42, 101213 (2021).

Naseer, B. et al. Effect of carboxymethyl cellulose and baking conditions on in-vitro starch digestibility and physico-textural characteristics of low Glycemic Index gluten-free rice cookies. LWT-Food Sci. Technol. 141, 110885 (2021).

Raigar, R. K. & Mishra, H. N. Effect of moisture content and particle sizes on physical and thermal properties of roasted Bengal gram flour. J. Food Process. Preserv. 39(6), 1839–1844 (2015).

Seth, D., Mishra, H. N. & Deka, S. C. Functional and reconstitution properties of spray-dried sweetened yogurt powder as influenced by processing conditions. Int. J. Food Prop. 20(7), 1603–1611 (2017).

Pracham, S. & Thaiudom, S. The effect of protein content in jasmine rice flour on textural and rheological properties of jasmine rice pudding. Int. Food Res. J. 23(4), 1379 (2016).

AACC. American Association of Cereal Chemists: “Approved Methods of the AACC”. Method, 76–11, St. Paul, MN, USA (1976).

Goñi, I., García-Alonso, A. & Saura-Calixto, F. A starch hydrolysis procedure to estimate glycemic index. Nutr. Res. 17(3), 427–437 (1997).

Bolarinwa, I. F. & Muhammad, K. K, Functional properties, antioxidant activities and storage stability of cookies from germinated brown rice and rice-potato starch composite flour. Pertanika J. Trop. Agric. Sci. 42(2), 503–518 (2019).

Scheuer, P. M. et al. Response surface methodology assessment of the effect of whole wheat flour and fat replacer levels on bread quality. Int. Food Res. J. 23, 2079–2087 (2016).

AOAC. Official Methods of Analysis. 18th edn. Association of Official Analytical Chemists; Arlington, VA, USA (2005).

FSSAI. Manual of Methods of Analysis of Foods-Milk and Milk products, Lab Manual I. Food Safety and Standards Authority of India (Ministry of Health and Family Welfare). New Delhi (2015).

Thaiudom, S. & Pracham, S. The influence of rice protein content and mixed stabilizers on textural and rheological properties of jasmine rice pudding. Food Hydrocolloids 76, 204–215 (2016).

Liu, J., Wang, J., Leung, C. & Gao, F. A multi-parameter optimization model for the evaluation of shale gas recovery enhancement. Energies 11(3), 654 (2018).

Hussain, S. Z., Beigh, M. A., Naseer, B., Amin, T. & Naik, H. R. Characteristics of resistant starch in water chestnut flour as improved by preconditioning process. Int. J. Food Prop. 22(1), 449–461 (2019).

Barbosa-Cánovas, G. V. & Juliano, P. Compression and compaction characteristics of selected food powders. Adv. Food Nutr. Res. 49(1), 233–300 (2005).

Gaucher, I., Piot, M., Beaucher, E. & Gaucheron, F. Physico-chemical characterization of phosphate-added skim milk. Int. Dairy J. 17, 1375–1383 (2007).

McSweeney, D. J., Maidannyk, V., Montgomery, S., O’Mahony, J. A. & McCarthy, N. A. The influence of composition and manufacturing approach on the physical and rehydration properties of milk protein concentrate powders. Foods 9(2), 236 (2020).

Fan, F. et al. Protein cross-linking and the Maillard reaction decrease the solubility of milk protein concentrates. Food Sci. Nutr. 6(5), 1196–1203 (2018).

Sadat, A., Ezzatpanah, H. & Bakhoda, H. Solubility and structure of milk powders manufactured with the addition of disodium phosphate and tetrasodium pyrophosphate mixtures. Int. J. Food Prop. 20(11), 2645–2657 (2017).

Harper, M., Holsinger, V., Fox, K. & Pallansch, M. Factors influencing the instant solubility of milk powders. J. Dairy Sci. 46(11), 1192–1195 (1963).

Noisuwan, A., Hemar, Y., Wilkinson, B. & Bronlund, J. Dynamic rheological and microstructural properties of normal and waxy rice starch gels containing milk protein ingredients. Starch-Stärke 61, 214–227 (2009).

Lobato-Calleros, C., Ramírez-Santiago, C., Vernon-Carter, E. J. & Alvarez-Ramirez, J. Impact of native and chemically modified starches addition as fat replacers in the viscoelasticity of reduced-fat stirred yogurt. J. Food Eng. 131, 110–115 (2014).

Rahma, M. et al. Recent developments of carboxymethyl cellulose. Polymers 13(8), 1345 (2021).

Hussain, S. Z. et al. Effect of radiofrequency induced accelerated ageing on physico-chemical, cooking, pasting and textural properties of rice. LWT 139, 110595 (2020).

Chandra, M. V. & Shamasundar, B. A. Texture profile analysis and functional properties of gelatin from the skin of three species of fresh water fish. Int. J. Food Prop. 18(3), 572–584 (2013).

Nunes, M. C., Raymundo, A. & Sousa, I. Rheological behaviour and microstructure of pea protein/κ-carrageenan/starch gels with different setting conditions. Food Hydrocolloids 20(1), 106–113 (2006).

Adhikari, B., Howes, T., Bhandari, B. & Truong, V. Stickiness in foods: A review of mechanisms and test methods. Int. J. Food Prop. 4, 1–33 (2001).

Guimarães, F. I., Caliari, M. & Junior, M. S. Instrumental analysis of texture, color and acceptance of instant dessert formulated with broken-rice grains. Food Sci. Technol. Res. 20(4), 785–792 (2014).

Coronato, R., Biasutti, E. A., Carvalho, C. W. & Grossmann, M. V. Gellan gum/cassava starch mixtures in water systems and in milk systems. Starch-Stärke 64(5), 359–366 (2012).

Lobato, L. P., Grossmann, M. V. E. & Benassi, M. T. Inulin addition in starch-based dairy desserts: Instrumental texture and sensory aspects. Food Sci. Technol. Int. 15(4), 317–323 (2009).

Kumar, P. & Mishra, H. N. Mango soy fortified set yoghurt: effect of stabilizer addition on physicochemical, sensory and textural properties. Food Chem. 87(4), 501–507 (2004).

Zhang, T. et al. Effects of stabilizers and exopolysaccharides on physiochemical properties of fermented skim milk by Streptococcus thermophilus ST1. Afr. J. Biotech. 11(22), 6123–6128 (2012).

Åkerberg, A., Liljeberg, H. & Björck, I. Effects of amylose/amylopectin ratio and baking conditions on resistant starch formation and glycaemic indices. J. Cereal Sci. 28(1), 71–80 (1998).

Noisuwan, A., Hemar, Y., Wilkinson, B. & Bronlund, J. E. Adsorption of milk proteins onto rice starch granules. Carbohydr. Polym. 84, 247–254 (2011).

Loveday, S. M., Ye, A., Anema, S. G. & Singh, H. Tuning heat-induced colloidal aggregation of whey proteins, sodium caseinate and gum arabic: Effect of protein composition, preheating and gum arabic level. Food Res. Int. 62, 128–136 (2014).

Weinbreck, F., De Vries, R., Schrooyen, P. & De Kruif, C. G. Complex coacervation of whey proteins and gum arabic. Biomacromol 4(2), 293–303 (2003).

Elmståhl, H. L. Resistant starch content in a selection of starchy foods on the Swedish market. Eur. J. Clin. Nutr. 56(6), 500–505 (2002).

Thomas, D. E. & Elliott, E. J. The use of low-glycaemic index diets in diabetes control. Br. J. Nutr. 104(6), 797–802 (2010).

Sun, L., Tan, K. W. J., Han, C. M. S., Leow, M. K. S. & Henry, C. J. Impact of preloading either dairy or soy milk on postprandial glycemia, insulinemia and gastric emptying in healthy adults. Eur. J. Nutr. 56(1), 77–87 (2017).

Manokaran, S. et al. Determination of glycaemic responses of low fat milk incorporated with whey proteins and oats powder. J. Clin. Nutr. 4, 8 (2018).

Sugiyama, M., Tang, A. C., Wakaki, Y. & Koyama, W. Glycemic index of single and mixed meal foods among common Japanese foods with white rice as a reference food. Eur. J. Clin. Nutr. 57(6), 743–752 (2003).

Kraithong, S. & Rawdkuen, S. The effects of chemical composition of rice flour on physico-chemical and functional properties. Prawarun Agric. J 16(1), 49–70 (2019).

Jung, D. S., Bae, I. Y., Han, S. I., Lee, S. J. & Lee, H. G. Classification of hydrocolloids based on in vitro starch digestibility and rheological properties of Segoami gel. Int. J. Biol. Macromol. 104, 442–448 (2017).

Vashistha, S., Argade, A., Kapoor, C. M. & Ahlawat, S. S. Studies on development of milk powder based instant kheer-mix. Pharma Innov. J. 8(12), 61–64 (2019).

Foster-Powell, K., Holt, S. H. & Brand-Miller, J. C. International table of glycemic index and glycemic load values: 2002. Am. J. Clin. Nutr. 76(1), 5–56 (2002).

Wang, S. et al. Starch–lipid and starch–lipid–protein complexes: A comprehensive review. Compr. Rev. Food Sci. Food Saf. 19(3), 1056–1079 (2020).

Aguirre-Cruz, A., Méndez-Montealvo, G., Solorza-Feria, J. & Bello-Pérez, L. A. Effect of carboxymethylcellulose and xanthan gum on the thermal, functional and rheological properties of dried nixtamalised maize masa. Carbohydr. Polym. 62(3), 222–231 (2005).

Pongsawatmanit, R., Thanasukarn, P. & Ikeda, S. Effect of sucrose on RVA viscosity parameters, water activity and freezable water fraction of cassava starch suspensions. Sci. Asia 28(2), 129–134 (2002).

Lim, H. S. & Narsimhan, G. Pasting and rheological behavior of soy protein-based pudding. LWT-Food Sci. Technol. 39(4), 344–350 (2006).

Du, B. et al. Influence of molecular weight and degree of substitution of carboxymethylcellulose on the stability of acidified milk drinks. Food Hydrocolloids 23, 1420–1426 (2009).

Ye, L., Wang, C., Wang, S., Zhou, S. & Liu, X. Thermal and rheological properties of brown 519 flour from Indica rice. J. Cereal Sci. 70, 270–274 (2016).

Naseer, B., Naik, H. R., Hussain, S. Z., Qadri, T. & Beigh, M. A. Visco-thermal behaviour and structural characterization of temperate highland himalayan rice cultivars. Starch-Stärke 73, 2000170 (2020).

Uthumporn, U., Nadiah, I., Izzuddin, I., Cheng, L. & Aida, H. Physicochemical characteristics of non-starch polysaccharides extracted from cassava tubers. SainsMalaysiana 46(2), 223–229 (2017).

Saif, S. M. H., Lan, Y. & Sweat, V. E. Gelatinization properties of rice flour. Int. J. Food Prop. 6(3), 531–542 (2003).

Chisenga, S. M., Workneh, T. S., Bultosa, G. & Laing, M. Characterization of physicochemical properties of starches from improved cassava varieties grown in Zambia. AIMS Agric. Food 4(4), 939–966 (2019).

Tamime, A. Y., Barrantes, E. & Sword, A. M. The effect of starch based fat substitutes on the microstructure of set-style yogurt made from reconstituted skimmed milk powder. Int. J. Dairy Technol. 49(1), 1–10 (1996).

Dundar, A. N. & Gocmen, D. Effects of autoclaving temperature and storing time on resistant starch formation and its functional and physicochemical properties. Carbohydr. Polym. 97, 764–771 (2013).

Borad, S. G., Patel, A. A., Singh, A. K., Tomar, S. K. & Singh, R. R. B. Effect of storage and reheating on textural properties of rice in dairy dessert as related to its pasting properties and microstructure. LWT 80, 485–491 (2017).

Xiong, J., Li, Q., Shi, Z. & Ye, J. Interactions between wheat starch and cellulose derivatives in short-term retrogradation: Rheology and FTIR study. Food Res. Int. 100, 858–863 (2017).

El-Garawany, G. A. & Abd El Salam, M. H. Preparation and rheological properties of a dairy dessert based on whey protein/potato starch. Food Chem. 91(2), 261–267 (2005).

Carvalho, C. W., Onwulata, C. I. & Tomasula, P. M. Rheological properties of starch and whey protein isolate gels. Food Sci. Technol. Int. 13(3), 207–216 (2007).

He, F. et al. Effect of sugar molecules on the viscosity of high concentration monoclonal antibody solutions. Pharm. Res. 28(7), 1552–1560 (2011).

Acknowledgements

Authors acknowledge the support from Council of Scientific and Industrial Research, New Delhi, India. Rheometer facility and the assistance of Dr. Hilal Ahmad Makhroo, extended for the research work by the Department of Food Technology, IUST, Awantipora is highly acknowledged.

Author information

Authors and Affiliations

Contributions

Dr. B.N.: Investigation and writing of manuscript. Dr. H.R.N.: Supervision. Dr. S.Z.H.: Conceptualization and validation. T.Q.: Manuscript editing. Dr. B.N.D.: Resources. Dr. T.A.: Software. Dr. M.R.: Data curation. Dr. F.S.: Formal Analysis. Dr. T.F.: Resources.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Naseer, B., Naik, H.R., Hussain, S.Z. et al. Development of low glycemic index instant Phirni (pudding) mix-its visco-thermal, morphological and rheological characterization. Sci Rep 12, 10710 (2022). https://doi.org/10.1038/s41598-022-15060-6

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-022-15060-6