Abstract

The effect of inducing circular holes into aluminum wrapped with glass/epoxy (Al/GFRP) pipes was investigated. Intact and holed specimens were evaluated in quasi-static axial compression after being constructed using the wet wrapping procedure. The effect of the induced holes' parameters i.e., hole diameter (d), number of holes (n), the hole position to specimen height ratio (L/H), on the crashworthiness of Al/GFRP structures was investigated. Results indicated that the existence of the cutouts visibly affects the values of crushing parameters. Increasing (d) remarkably reduces the total absorbed energy (U) and enhances the crushing force efficiency (CFE) of Al/GFRP pipes. Introducing two holes in two opposite faces with keeping their location constant reduces initial peak crush force \({(\mathrm{F}}_{\mathrm{ip}})\), mean crush force \({(\mathrm{F}}_{\mathrm{m}})\), and U of Al/GFRP pipes but increases CFE. As the hole location goes to the lower edge of the pipe i.e., L/H increases, U obviously increases. The specimens with 4 mm holes in one side at medium height and specimens with 12 mm holes on one side at L/H = 0.8 had the best crushing parameters, respectively. The adequate design of the induced cutouts in thin-walled constructions is valuable to enhance the crashworthy performance of engineering structures.

Similar content being viewed by others

Introduction

In recent decades, thin-walled structures are extensively used as energy dissipating devices in automobiles and aircrafts to improve crashworthiness1,2,3. The term “crashworthiness” can be defined as the ability of a material to protect its occupant from injuries during crush incidences4,5. In a number of technical fields, including as aviation, transportation, the nuclear industry, and civil engineering, lightweight structures with high energy absorption capacity are becoming more and more common6,7,8. Making a vehicle design as light as possible without sacrificing functional criteria like vehicle durability and safety is in high demand9,10.

The type of the material used in the manufacture of energy dissipating devices is a key factor that determines how efficient energy will be absorbed11. Traditionally, metals such as steel or aluminum have been utilized in crashworthy constructions as they display controllable plastic deformation, while polymeric composites (PCs) are fragile and cannot sustain this type of deformation12. PC structure has a substantially higher cost than standard metals due to the intricate design and fabrication process. On the other hand, PCs fail progressively which improves the energy absorption and they have lower density than metals, which enhances the specific properties and reduces the overall weight of the vehicle and consequently reduces the vehicle’s fuel consumption13. Also, if PCs are appropriately designed, they could gradually crash and delaminate to dissipate the impact energy14,15,16,17. PCs are characterized by their excellent specific stiffness and strength, outstanding energy absorbing capacity, non-conductivity, good corrosion resistance, and high thermal insulation18,19,20,21.

The advantages of increased specific strength and stiffness of FRP as well as the toughness of the metals can be combined to create hybrid structures out of metals and fiber reinforced polymers (FRP)22. Therefore, it is possible to create very desirable energy-absorbing structures by using the right amount of metallic components in combination with FRP composites23. Metal/FRP hybrid tubes' crushing reactions frequently result in plastic deformation for the metal component and a type of progressive crushing for the FRP component24. Metal/FRP hybrid structures have been extensively studied for their crashworthiness in the literature25,26,27,28.

For engineering specifications like internal connection and access or reducing the weight, introducing cutouts in energy dissipating devices walls is suggested29. Introducing cutouts offers two advantages. First, the initial peak force can be decreased and may be controlled. Second, such structures exhibit much less force oscillation during crushing30. The contributions of well-known researchers who studied the crashworthiness performance of metallic constructions included cutouts are displayed in Table 1.

FRP composites included cutouts have not been the subject of many investigations. Taheri-Behrooz et al.45 determined the axial force that E-glass/epoxy (GFRP) tubes with piercing can withstand. It was revealed that the unholed and holed tubes show the same instability mode profiles when subjected to axial force. But, the critical load and overall stiffness of the holed tubes were significantly reduced. The rigidity and load-carrying capability of composite tubes are negatively impacted by the presence of numerous tiny perforations. However, a moderate increase in the perforation's diameter and spacing has no appreciable impact on the outcome. For instance, as the perforation diameter increased from 2.5 to 15 mm, the tubes' axial rigidity reduced by 17 and 25%, respectively. Later on, an experimental research was done to determine how the hole diameter, vertical hole space, pipe diameter, hole pattern, transverse hole space, and the hole reinforcement affected the axial compressive behavior of perforated GFRP tubes, Wang et al.46. Perforated tubes' axial stiffness, critical load, and deformation capacity have all been shown to significantly decrease. The perforation pattern, transverse hole spacing, hole diameter, and tube diameter all had a big impact on how the tubes behaved when compressed axially. The impacts of vertical hole spacing and hole reinforcement, however, were barely noticeable.

Through the use of quasi-static axial compression, Kathiresan et al.47 investigated how the addition of circular, square, and elliptical cuts altered the U and deformation features of conical frusta made of GFRP. Additionally, conical frusta crush behavior was simulated using finite element software, and the resulting results were compared to the experimental ones. According to Zbek et al.'s48 investigation into the impact of adding a circular cut-out trigger mechanism on GFRP tubes made using the filament wrapping technology under quasi-static axial load, the performance of circular cut-outs can be improved in terms of crashworthiness.

Liu et al.49 investigated the impact of holes’ size, figure and spreading on both the bearing performance and the failure signs of tubes made of carbon fiber-reinforced plastic (CFRP). Compared with the intact CFRP specimens, the holed tubes’ \({\mathrm{F}}_{\mathrm{ip}}\) and SEA were decreased by, respectively, 3–22% and 26–57%. The holes’ size effect on the tube failure strength is less profound than that of the laminates but compared to the distribution and shape of the holes, it is considerably stronger. Alhyari and Newaz50 calculated the U of CFRP tubes that were subjected to quasi-static stresses and had single or double induced holes in specific locations with varying diameters. With single or double perforations that are 15 mm in diameter and 100 mm from the top of the tube, SEA has been seen to be reduced by 50%. When the hole is 20 mm in diameter and 100 mm from the top of the tube, the SEA drop is about 60% less than it would be for an undamaged tube. When the holes are 75 mm from the top of the tube, the reduction is the greatest. The hole’s location (from 100 to 75 mm) can generate more pronounced influence than the size of the hole (15 vs. 20 mm) for the studied specimens.

Numerous studies have been done metal/polymer structures to merge the high specific strength and stiffness of composites with the plastic deformation of metals51,52,53. But few works investigate the effect of introduced cut-outs on hybrid structure, Shun et al.1 explored how the induced holes affect the crushing behavior of aluminum (Al)/CFRP members studied under quasi-static axial loads. The dimension and number of holes have a significant impact on the crushing behaviour, according to the results. The parameters of the induced holes were optimized using multi-objective optimization. Compared with the intact Al/CFRP tube, \({\mathrm{F}}_{\mathrm{ip}}\) of the optimum specimen reduced by 24.32% and SEA is slightly enriched by 0.68%. According to the research done by Alshahrani et al.18, the criteria that can effectively regulate the performance of crashworthiness and alter the failure mechanism of Al/polymer composite cylinders include the diameter, the number of induced holes, and the number of fiber/epoxy layers.

Recently, it was observed that metal-PC hybrid architectures are adapted in the automotive industry because of their excellent versatility and crashworthiness. However, very few studies have concentrated on illuminating the mechanisms through which metal-PC hybrids absorb energy. Moreover, it is clear from the review above that few experiments were done to look at how cutouts affect the performance of metal/PC hybrid pipes and it is clear that more research efforts should be intensified towards the windowed hybrid metal-PC pipes. Therefore, the primary goal of the current study is to experimentally investigate how well Al/GFRP thin-walled tubular constructions with circular cutouts perform in terms of crashworthiness. Wet wrapping was used to create the specimens, which were then put through testing with nearly static axial loads. The hole diameter (d = 0, 4, 8, 12 mm), hole position to height ratio (L/H = 0.5, 0.6, 0.7, 0.8), and number of holes (n = 1, 2) are the research factors. To comprehend the impacts of circular cuts on the energy absorption and fracture characteristics of GFRP over wrapped Al pipe samples, the crush characteristics of these three groups were investigated.

Methodology

According to numerous authors14,29, uniaxial quasi-static crush tests do not currently have a standard. Crosshead speed of 10 mm/min was adapted in uniaxial quasi-static crush tests based on many studies in the literature18,54,55,56. Since circular samples absorb more energy and reduce stress concentrations than square or rectangular samples, they were employed to facilitate crushing testing57. The studied variables are the hole diameter (d = 4, 8, 12 mm), the hole position to height ratio (L/H = 0.5, 0.6, 0.7, 0.8), the number of holes (n = 0, 1, 2).

Materials

As a reinforcement, a woven E-glass fabric (200 g/m2) supplied by Hebei Yuniu Fiber Glass Manufacturing Co. Ltd. China was used. Chemicals for Modern Buildings Co. Ltd. Egypt supplied Kemapoxy 150RGL matrix. The mechanical characteristics of E-glass and Kemapoxy 150 RGL are shown in Table 2. Al6063 aluminum alloy pipe with 50 mm outer diameter and 2 mm thickness was given by Military Production Co. Ltd. Egypt. Table 3 lists the chemical make-up of Al6063 in weight percentages.

Surface treatment of Al-pipes

Al-alloy pipes were subjected to mechanical and chemical treatments to ensure a strong connection with GFRP, see Fig. 1. Al-pipes underwent mechanical treatment by being rinsed with acetone, Fig. 1a. Then pipes were smoothly abraded with #400-grit sandpaper Fig. 1b, after that the pipes were rinsed with distilled water, Fig. 1c. Finally, the pipes were dried in an oven, Fig. 1d. To increase the surface roughness of the mechanically treated Al-pipes, a chemical treatment utilizing acid washing with HCl having an 11% volumetric concentration was applied, Fig. 1e. For 30 min, acid etching was done at room temperature. Al-pipes were dried after being rinsed with distilled water. Al-pipes were then submerged in a 5 weight percent NaOH solution at 70 °C for 5 min, see Fig. 1f. The oxidized Al-pipes were rinsed with tap water to remove the oxide residue after being baked in an oven to stabilize the oxide layer, as shown in Fig. 1g 58,59,60.

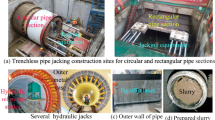

Fabrication of Al/GFRP specimens

In this study, Al/GFRP hybrid pipes were constructed using a wet-wrapping procedure done by hand. The steps of the fabrication process are as follows:

-

For 5 min, epoxy and its hardener were manually combined and swirled, Fig. 2a. Using a brush, the liquid was then evenly applied to the glass cloth, Fig. 2b. Additionally, glass fabric layers were impregnated with the matrix using a metallic roller, Fig. 2c.

-

50 mm-diameter and 2 mm-thick Al pipes were wrapped with the impregnated cloth, Fig. 2d. Each Al-pipes was wrapped by 8 glass/epoxy plies.

-

The constructed Al/GFRP hybrid pipes were shielded by caulk paper and let in room temperature for seven days to be cured, Fig. 2e. According to the data given by the supplier, curing conditions of Kemapoxy 150 RGL are 8 h initial setting time, 24 h final setting time, and 7 days’ full hardness time. Attia et al.61 and Awd Allah et al.62 adapted the above-mentioned curing conditions.

-

The manufactured hybrid pipes were visually examined for material flaws and geometrical abnormalities after curing. The samples were separated into 100 mm-long pieces. The chosen holes were made using a tungsten carbide twist drill, Fig. 2f. A schematic of test specimens is shown in Fig. 3. Table 4 provides a list of the test specimens' geometrical dimensions.

Testing

Quasi-static axial compression is a recognized test to study the energy absorption capacity of polymer composites6. It was performed on Al/GFRP specimens with induced holes using a universal testing machine with 100 kN capacity. Load–displacement data was directly recorded using an automatic data acquisition system. Additionally, the histories of deformation for test specimens were tracked and documented. For each case, three samples were examined, and the average was then given. The generated load versus displacement plots can be used to objectively assess the performance of crashworthy Al/GFRP specimens. Figure 4 schematically demonstrates the typical load–displacement plot attained from axial crushing test. The crushing key parameters were determined as follows: -

-

Initial peak force (\({\mathrm{F}}_{\mathrm{ip}})\) can be directly recorded from the crushing load versus displacement plot. It is recommended to be small enough to avoid the transformation of the crushing force from the energy absorber to the main vehicle body.

-

Total absorbed energy (U) can be calculated as follows:

$$\mathrm{U}= {\int }_{0}^{{\updelta }_{\mathrm{max}}}\mathrm{ F}\left(\updelta \right)\mathrm{ d\delta },$$(1)where, \(\mathrm{F}\left(\updelta \right)\mathrm{ and }{\delta }_{\mathrm{max}}\) are the instant load and overall displacement, respectively.

-

Mean crush force (\({\mathrm{F}}_{\mathrm{m}})\) can be obtained from the following equation:

$${\mathrm{F}}_{\mathrm{m}}= \frac{{\int }_{0}^{{\updelta }_{\mathrm{max}}}\mathrm{ F}\left(\updelta \right)\mathrm{ d\delta }}{{\delta }_{\mathrm{max}}}.$$(2) -

Crushing force efficiency (CFE) can be calculated as follows:

$$\mathrm{CFE}= \frac{{\mathrm{F}}_{\mathrm{m}}}{{\mathrm{F}}_{\mathrm{ip}}} \times 100.$$(3) -

Specific absorbed energy (SEA) is (U) divided by the mass of the component (\(\mathrm{M}\)):

$$\mathrm{SEA}=\frac{\mathrm{U}}{\mathrm{M}}.$$(4)

Results and discussions

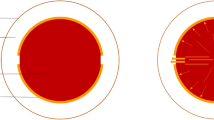

Hole diameter (d) effect

Figure 5 displays the force versus displacement plots and the damage history for Al/GFRP samples with induced holes. Holes with diameters of 0, 4, 8, and 12 mm were employed at the specimens’ mid length to study the influence of the hole diameter on crashworthiness performance of E-glass/epoxy over-wrapped Al-pipes. As illustrated in Fig. 5a, A0, d4-n1-r0.5, d8-n1-r0.5, and d12-n1-r0.5 specimens behave linear till they reach \({\mathrm{F}}_{\mathrm{ip}}\) of 77.91 kN, 76.09 kN, 80.80 kN and 68.51 kN, respectively. A sharp load drop was noticed after \({\mathrm{F}}_{\mathrm{ip}}\) due to crack initiation and propagation. Intact and perforated pipes have the same instability mode shapes in the post crushing zone. Global buckling accompanied with matrix cracking, delamination, and fiber breakage in the intact specimen wall can be observed, Fig. 5b. For perforated pipes, cracks start close to the hole and propagate in the peripheral direction with noticeable wrinkling. Holed tubes prone to collapse in the mid-height. This outcome aligns with that attained by Liu et al.63 for CFRP tubes.

It is clear from Table 5 that a slight decrease in \({\mathrm{F}}_{\mathrm{ip}}\) of Al/GFRP composite pipes was noticed by inducing a center hole with 4 mm diameter. 12.07% decrease in \({\mathrm{F}}_{\mathrm{ip}}\) of Al/GFRP composite pipes was noticed by inducing a enter hole with 12 mm diameter. As reported by Awd Allah et al.29, it is advised to include cutouts to the walls of crashworthy components for technical purposes such as connecting and weight reduction. A key design objective is to reduce the overall vehicle weight. Fuel consumption will decrease when vehicle weight decreases. The high strength to weight ratio, which is directly associated to fuel consumption and reduction of CO2 emissions, is an important characteristic in designing of transportation systems64. The introduction of any discontinuities along the walls of crashworthy components allows for a decrease in the peak load65. As reports by Guler et al.66, initial peak load should be low enough to avoid the transformation of the forces from the crush element to the main body of vehicle. It can be seen that perforating the tubes with holes of d = 4 mm decreases the peak loads a little. A fluctuation in peak load values for holed specimens was recorded. Rouzegar et al.67 and liu et al.63 recorded similar results for the hesitation in peak load values of Al over wrapped E-glass/vinyl ester tubes. Song et al.68 recorded the same trend in peak load values. The reason is mainly due to the initial overall stiffness of the tubes after the introduction of cutouts.

A0 specimen exhibits the maximum U with a value of 3441.14 J followed by d4-n1-r0.5 with a value of 3058.63 J. Presence of small holes in Al/GFRP pipes adversely affects their U and SEA. Increasing the diameter of the hole from 4 to 12 mm decreases SEA of the pipe by 11.11 and 22.14%. The existence of cutouts has a negative effect on U of square CFRP tubes according to the research conducted by Liu et al.63. As reported by Fan et al.69, when choosing cylinders as energy absorbing elements, it is significant that cylinders of high SEA are chosen, to maximize the energy absorption while keeping the structure light. d12-n1-r0.5 specimen exhibits the higher CFE with a value of 0.66. The obtained results is consistent with that obtained by Alhyari and Newaz50 for CFRP tubes.

Number of holes (n) effect

After the examination of hole diameter (d) effect, the next step is to analyze of the effect of the number of holes (n) on the crashworthiness. Al/GFRP samples with three numbers of holes (0, 1, and 2) at the specimen mid-length were used to investigate the impact of cutout number on crush performance. Figure 6 shows the load versus displacement plots and damage history for different samples with the selected hole numbers. All specimens have linear trends till they approach \({\mathrm{F}}_{\mathrm{ip}}\) values at 71.4 kN, 73.07 kN and 62.39 kN for d4-n2-r0.5, d8-n2-r0.5 and d12-n2-r0.5 specimens, respectively. Then a sharp decrease in the load after \({\mathrm{F}}_{\mathrm{ip}}\) was detected due to crack propagation and folds that appear in the vicinity of the hole. Obvious fluctuations were recorded in the post crushing zones for all specimens.

It is clear from Table 5 that \({\mathrm{F}}_{\mathrm{ip}}\) values of d4-n2-r0.5, d8-n2-r0.5 and d12-n2-r0.5 specimens decrease, respectively, by 8.36, 6.25, and 19.92% compared with A0 specimen. \({\mathrm{F}}_{\mathrm{ip}}\) values of d4-n2-r0.5, d8-n2-r0.5 and d12-n2-r0.5 specimens decrease, respectively, by 6.16, 9.59, and 8.93% compared, respectively, with d4-n1-r0.5, d8-n1-r0.5 and d12-n1-r0.5 specimens. U values of double hole specimens are lower than those of single hole specimens. The reduction in \({\mathrm{F}}_{\mathrm{ip}}\) value is owing to cracks generated around the cut-outs and propagated due to the high-stress concentrations. These cracks weaken the specimens causing a decrease in \({\mathrm{F}}_{\mathrm{ip}}\) value. This result agrees with that obtained by Özbek et al.48.

\(U\) values of d4-n2-r0.5, d8-n2-r0.5 and d12-n2-r0.5 specimens decrease, respectively, by 12.54, 16.28, and 25.93% compared with A0 specimen. \(\mathrm{U}\) values of d4-n2-r0.5, d8-n2-r0.5 and d12-n2-r0.5 specimens decrease, respectively, by 1.61, 2.9, and 4.81% % compared, respectively, with d4-n1-r0.5, d8-n1-r0.5 and d12-n1-r0.5 specimens. Results are in line with what was discovered by Shun et al.1 for Al/CFRP thin-walled structures. Max CFE with a value of 0.67 was observed for d12-n2-r0.5 specimen against a value of 0.66 for d12-n1-r0.5 specimen. This means that presenting two holes instead of one hole in a known place has approximately no effect on CFE.

Hole position to specimen height ratio (L/H) effect

In this section of the study, the effect of the hole location on crashworthiness performance of Al/GFRP pipes was examined. Figure 7 displays the load versus displacement plots and damage history for Al/GFRP samples with 12 mm hole size where the hole position to height ratio (L/H) is 0.5, 0.6, 0.7, and 0.8. d12-n1-r0.6, d12-n1-r0.7 and d12-n1-r0.8 specimens perform linear till they reach \({\mathrm{F}}_{\mathrm{ip}}\) at 70.08, 75.00, and 70.03 kN, respectively. The reason is that the extra increase in “the hole position to height ratio” can decrease the remaining material at the bottom edge of the holed specimens and consequently decreases the specimen stiffness68. Later \({\mathrm{F}}_{\mathrm{ip}}\) sharply dropped accompanied with oscillations which reflects the unstable behavior of the pipes (Fig. 7a). Cracks around the holes accompanied with buckling and wrinkling of the specimens’ wall were recorded (Fig. 7b).

Compared with A0 specimen, \({\mathrm{F}}_{\mathrm{ip}}\) of d12-n1-r0.6, d12-n1-r0.7 and d12-n1-r0.8 specimens decreases by 10.05, 3.74, and 10.11%, respectively. Max CFE with a value of 0.67 was detected for d12-n1-r0.6 specimen against a value of 0.66 for d12-n1-r0.5 specimen. It can be concluded that (L/H) of the cut-out has no weighty effect on CFE. Improving in U was observed by increasing (L/H). Against d12-n1-r0.5 specimen, an improvement of 5.78, 6.38, and 6.87% in U was recorded for d12-n1-r0.6, d12-n1-r0.7 and d12-n1-r0.8 specimens, respectively.

Scatter in the obtained results

The manufacturing, preparation, handling, storage, test rig design, and experimental technique of the specimens are just a few of the many variables that can influence the test findings. The experimental test findings' statistical scatter, or coefficient of variation (CV), has been determined and is shown in Table 5. The maximum CV for \({\mathrm{F}}_{\mathrm{ip}}\), U, SEA, \({\mathrm{F}}_{\mathrm{m}}\), and CFE was noted to be 11.64% for d12-n2-r0.5, 13.02% for d8-n2-r0.5, 14.33% for d12-n1-r0.6, 9.47% for A0, and 14.76% for d4-n2-r0.5, respectively. It is clear that the coefficient of variation (CV) values of all results are less than 15%, which confirm the repeatability of the results and reflect noticeable accuracy. Rouzegar et al.67 attributed the deviations observed between the results to the fabrication imperfections.

Mechanisms of failure

An important factor to be considered when examining the energy-absorbing capability of Al/GFRP pipes with cuts is the failure mechanism. The same failure mode was observed for intact and perforated pipes. Pipes first buckle, and then macro cracks in the matrix start to form around the holes. The cracks then spread outward in the direction of the pipes' periphery. As the cracks spread further, the lamina bends and forms internal and exterior folds. Delamination, fiber breakage and fiber pull-out can be noticed around the holes accompanied with global buckling and wrinkling. These signs of failure were recorded by Mache et al.70 for jute/polyester and glass/polyester tubes. Figure 8 demonstrates top view of the representative sample of crushed specimens.

Applications

The suggested metal-PC hybrid composites can be employed in high-performance applications and safety equipment in the transportation sectors including the maritime, aerospace, and automobile industries. The proposed pipes can be used as energy-absorbing parts in forward-facing vehicle structures i.e., impact-resistant rods or crush boxes, see Fig. 9. In addition, they can be adapted to be used in the fuselage of aircrafts.

Future trend

Future research will examine patterns with various window shapes and arrangements. The proposed window method can be expanded to pipes with varied cross-sectional forms and different loading situations due to its simplicity compared to other pattern design methods, which will be investigated in later studies.

Conclusions

In this paper, it was suggested to use circular tubes made of aluminum (Al) and glass fiber-reinforced polymer (GFRP) with cuts in the shape of circular holes as crush boxes for automobiles. To investigate the impact of the induced holes on the crashworthiness performances, the effect of hole diameter (d), hole number (n), and hole position to specimen height ratio (L/H) were explored. The inferences that can be made are as follows:

-

The crashworthiness performance and failure mechanism of Al/GFRP circular pipes exposed to quasi-static axial crushing were found to be greatly influenced by the hole variables, namely hole diameter (d), hole number (n), and the hole position to specimen height ratio (L/H).

-

Increasing “d” decreases the initial peak crush force \({(\mathrm{F}}_{\mathrm{ip}})\), overall absorbed energy (U), and specific absorbed energy (SAE) but enhances the crushing force efficiency (CFE) of Al/GFRP pipes.

-

When n = 2 instead of 1, this reduces \({(\mathrm{F}}_{\mathrm{ip}})\) and (U), but slightly enhances (CFE) of Al/GFRP pipes.

-

Increasing (L/H) from 0.5 to 0.8, increases \({(\mathrm{F}}_{\mathrm{ip}})\) and (U) with approximately no effect on CFE of Al/GFRP pipes.

-

Adequate design of induced holes in thin-walled structure is important to enhance the crashworthy performance of engineering structures.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Shun, W., Qi-hua, M., Xue-hui, G. & Tian-jun, Z. Crashworthiness analysis and multi-objective optimization of Al/CFRPtubes with induced holes. Polym. Compos. 42, 5280–5299 (2021).

Tang, Z., Liu, S. & Zhang, Z. Energy absorption properties of non-convex multi-corner thin-walled columns. Thin-Walled Struct. 51, 112–120 (2012).

Yin, H. et al. Multi-objective robust optimization of foam-filled bionic thin-walled structures. Thin-Walled Struct. 109, 332–343 (2016).

Abd El-baky, M. A., Hegazy, D. A. & Hassan, M. A. Advanced Thin-walled composite structures for energy absorption applications. Appl. Compos. Mater. 29, 1195–1233 (2022).

Alshahrani, H., Sebaey, T. A., Hegazy, D. A. & El-baky, M. A. A. Development of efficient energy absorption components for crashworthiness applications: An experimental study. Polym. Adv. Technol. 33, 2921–2942 (2022).

Islam, M. K., Hazell, P. J., Escobedo, J. P. & Wang, H. Biomimetic armour design strategies for additive manufacturing: A review. Mater. Des. 205, 109730 (2021).

Ahamed, M. K., Wang, H. & Hazell, P. J. From biology to biomimicry: Using nature to build better structures—A review. Constr. Build. Mater. 320, 126195 (2022).

Siddique, S. H., Hazell, P. J., Wang, H., Escobedo, J. P. & Ameri, A. A. H. Lessons from nature: 3D printed bio-inspired porous structures for impact energy absorption—A review. Add. Manuf. 58, 103051 (2022).

Liu, W., Lin, Z., Wang, N. & Deng, X. Dynamic performances of thin-walled tubes with star-shaped cross section under axial impact. Thin-Walled Struct. 100, 25–37 (2016).

Srinivas, G. R., Deb, A., Sanketh, R. & Gupta, N. K. An enhanced methodology for lightweighting a vehicle design considering front crashworthiness and pedestrian impact safety requirements. Proc. Eng. 173, 623–630 (2017).

Baroutaji, A., Sajjia, M. & Olabi, A.-G. On the crashworthiness performance of thin-walled energy absorbers: Recent advances and future developments. Thin-Walled Struct. 118, 137–163 (2017).

Gupta, N. K. & Velmurugan, R. Analysis of polyester and epoxy composite shells subjected to axial crushing. Int. J. Crashworthiness 5, 333–344 (2000).

Paul, D., Ramachandran, V. & Gupta, N. K. Improvements in the crushing behaviour of glass fibre-epoxy composite tubes by the addition of hollow glass particles. Thin-Walled Struct. 141, 111–118 (2019).

Abd El-baky, M. A., Hegazy, D. A., Hassan, M. A. & Kamel, M. Potentiality of halloysite nanoclay on crashworthiness performance of polymer composite tubular elements. J. Compos. Mater. 56, 1901–1919 (2022).

Abd El-baky, M. A., Hegazy, D. A. & Hassan, M. A. Novel energy absorbent composites for crashworthiness applications. J. Ind. Text. 51, 64035–64425 (2022).

Abd El-Aziz, K., Hegazy, D. A. & Abd El-baky, M. A. Impact of montmorillonite clay on energy absorption capability of glass/epoxy composite tubes: An experimental study. Fiber. Polym. 23, 2284–2298 (2022).

Alshahrani, H., Sebaey, T. A., Hegazy, D. A. & Abd El-baky, M. A. Effects of halloysite clay nanotubes on the energy absorption and failure mechanisms of glass/epoxy composite tubes subjected to quasi-static axial crushing. Polym. Compos. 43, 7099–7117 (2022).

Alshahrani, H., Sebaey, T. A., Awd Allah, M. M. & Abd El-baky, M. A. Metal/polymer composite cylinders for crash energy absorption applications. Polym. Compos. https://doi.org/10.1002/pc.27060 (2022).

Alshahrani, H., Sebaey, T. A., Awd Allah, M. M. & Abd El-baky, M. A. Quasi-static axial crushing performance of thin-walled tubes with circular hole discontinuities. J. Compos. Mater. 56, 4195–4218 (2022).

Kara, M., Ak, S., Uyaner, M., Gunoz, A. & Kepir, Y. The effect of hydrothermal aging on the low-velocity impact behavior of multi-walled carbon nanotubes reinforced carbon fiber/epoxy composite pipes. Appl. Compos. Mater. 28, 1567–1587 (2021).

Kepir, Y., Gunoz, A. & Kara, M. Nonpenetrating repeated impact effect to the damage behavior of prestressed glass/epoxy composite pipes. Polym. Compos. 43, 5047–5058 (2022).

Sun, G., Huo, X., Wang, H., Hazell, P. J. & Li, Q. On the structural parameters of honeycomb-core sandwich panels against low-velocity impact. Compos. Pt. B Eng. 216, 108881 (2021).

Isaac, C. W. & Ezekwem, C. A review of the crashworthiness performance of energy absorbing composite structure within the context of materials, manufacturing and maintenance for sustainability. Compos. Struct. 257, 113081 (2021).

Zhu, G., Sun, G., Yu, H., Li, S. & Li, Q. Energy absorption of metal, composite and metal/composite hybrid structures under oblique crushing loading. Int. J. Mech. Sci. 135, 458–483 (2018).

Kim, H. C., Shin, D. K., Lee, J. J. & Kwon, J. B. Crashworthiness of aluminum/CFRP square hollow section beam under axial impact loading for crash box application. Compos. Struct. 112, 1–10 (2014).

Li, S., Guo, X., Li, Q. & Sun, G. On lateral crashworthiness of aluminum/composite hybrid structures. Compos. Struct. 245, 112334 (2020).

Sun, G., Yu, H., Wang, Z., Xiao, Z. & Li, Q. Energy absorption mechanics and design optimization of CFRP/aluminium hybrid structures for transverse loading. Int. J. Mech. Sci. 150, 767–783 (2019).

Huang, Z., Zhang, X. & Yang, C. Static and dynamic axial crushing of Al/CRFP hybrid tubes with single-cell and multi-cell sections. Compos. Struct. 226, 111023 (2019).

Awd Allah, M. M., Shaker, A., Hassan, M. A. & Abd El-baky, M. A. The influence of induced holes on crashworthy ability of glass reinforced epoxy square tubes. Polym. Compos. https://doi.org/10.1002/pc.27004 (2022).

Song, Z. et al. Improving the energy absorption capacity of square CFRP tubes with cutout by introducing chamfer. Int. J. Mech. Sci. 189, 105994 (2021).

Han, H., Cheng, J., Taheri, F. & Pegg, N. Numerical and experimental investigations of the response of aluminum cylinders with a cutout subject to axial compression. Thin-Walled Struct. 44, 254–270 (2006).

Han, H., Taheri, F. & Pegg, N. Quasi-static and dynamic crushing behaviors of aluminum and steel tubes with a cutout. Thin-Walled Struct. 45, 283–300 (2007).

Shariati, M. & Rokhi, M. M. Numerical and experimental investigations on buckling of steel cylindrical shells with elliptical cutout subject to axial compression. Thin-Walled Struct. 46, 1251–1261 (2008).

Mamalis, A. G. et al. The effect of the implementation of circular holes as crush initiators to the crushing characteristics of mild steel square tubes: Experimental and numerical simulation. Int. J. Crashworthiness 14, 489–501 (2009).

Bodlani, S. B., Chung Kim Yuen, S. & Nurick, G. N. The energy absorption characteristics of square mild steel tubes with multiple induced circular hole discontinuities—Part II: Numerical simulations. J. Appl. Mech. 76, (2009).

Bodlani, S. B., Yuen, S. C. K. & Nurick, G. N. The energy absorption characteristics of square mild steel tubes with multiple induced circular hole discontinuities—Part I: Experiments. J. Appl. Mech. 76, (2009).

Huang, M. Y., Tai, Y. S. & Hu, H. T. Dynamic crushing characteristics of high strength steel cylinders with elliptical geometric discontinuities. Theor. Appl. Fract. Mech. 54, 44–53 (2010).

Taştan, A., Acar, E., Güler, M. A. & Kılınçkaya, Ü. Optimum crashworthiness design of tapered thin-walled tubes with lateral circular cutouts. Thin-Walled Struct. 107, 543–553 (2016).

Ravi Sankar, H. & Parameswaran, V. Effect of circular perforations on the progressive collapse of circular cylinders under axial impact. Int. J. Impact Eng. 122, 346–362 (2018).

Baaskaran, N., Ponappa, K. & Shankar, S. Quasi-static crushing and energy absorption characteristics of thin-walled cylinders with geometric discontinuities of various aspect ratios. Lat. Am. J. Solids Struct. 14, 1767–1787 (2017).

Nikkhah, H. et al. The effect of different shapes of holes on the crushing characteristics of aluminum square windowed tubes under dynamic axial loading. Thin-Walled Struct. 119, 412–420 (2017).

Pirmohammad, S. & Esmaeili-Marzdashti, S. Multi-objective crashworthiness optimization of square and octagonal bitubal structures including different hole shapes. Thin-Walled Struct. 139, 126–138 (2019).

Patel, V., Tiwari, G. & Dumpala, R. Effect of cut-outs on the axial crushing response of cap and open-end hybrid frusta tube. Mater. Tod. Proc. 28, 2539–2546 (2020).

Kathiresan, M. Influence of shape, size and location of cutouts on crashworthiness performance of aluminium conical frusta under quasi-static axial compression. Thin-Walled Struct. 154, 106793 (2020).

Taheri-Behrooz, F., Esmaeel, R. A. & Taheri, F. Response of perforated composite tubes subjected to axial compressive loading. Thin-Walled Struct. 50, 174–181 (2012).

Wang, W., Sheikh, M. N. & Hadi, M. N. S. Behaviour of perforated GFRP tubes under axial compression. Thin-Walled Struct. 95, 88–100 (2015).

Kathiresan, M., Manisekar, K., Rajamohan, V. & Güler, M. A. Investigations on crush behavior and energy absorption characteristics of GFRP composite conical frusta with a cutout under axial compression loading. Mech. Adv. Mater. Struct. 1–18, (2021).

Özbek, Ö., Bozkurt, Ö. Y. & Erkliğ, A. Development of a trigger mechanism with circular cut-outs to improve crashworthiness characteristics of glass fiber-reinforced composite pipes. J. Braz. Soc. Mech. Sci. Eng. 44, 1–14 (2021).

Liu, Q. et al. Multiobjective optimization of perforated square CFRP tubes for crashworthiness. Thin-Walled Struct. 149, 106628 (2020).

Alhyari, O. & Newaz, G. Energy absorption in carbon fiber composites with holes under quasi-static loading. Carbon 7, 16 (2021).

Zhu, G., Liao, J., Sun, G. & Li, Q. Comparative study on metal/CFRP hybrid structures under static and dynamic loading. Int. J. Impact Eng. 141, 103509 (2020).

Wang, Z., Jin, X., Li, Q. & Sun, G. On crashworthiness design of hybrid metal-composite structures. Int. J. Mech. Sci. 171, 105380 (2020).

Huang, Z., Zhang, X. & Yang, C. Static and dynamic axial crushing of Al/CRFP hybrid tubes with single-cell and multi-cell sections. Compos. Struct. 226, 111023 (2019).

Ma, J. & Yan, Y. Quasi-static and dynamic experiment investigations on the crashworthiness response of composite tubes. Polym. Compos. 34, 1099–1109 (2013).

Attia, M. A., Abd El-Baky, M. A., Hassan, M. A., Sebaey, T. A. & Mahdi, E. Crashworthiness characteristics of carbon-jute-glass reinforced epoxy composite circular tubes. Polym. Compos. 39, E2245–E2261 (2018).

Luo, H., Yan, Y., Meng, X. & Jin, C. Progressive failure analysis and energy-absorbing experiment of composite tubes under axial dynamic impact. Compos. Pt. B Eng. 87, 1–11 (2016).

Huang, J. & Wang, X. On a new crush trigger for energy absorption of composite tubes. Int. J. Crashworthiness 15, 625–634 (2010).

Zamani Zakaria, A. & Shelesh-nezhad, K. Introduction of nanoclay-modified fiber metal laminates. Eng. Fract. Mech. 186, 436–448 (2017).

Saber, D., Abd El-baky, M. A. & Attia, M. A. Advanced fiber metal laminates filled with silicon dioxide nanoparticles with enhanced mechanical properties. Fiber. Polym. 22, 2447–2463 (2021).

Melaibari, A. A., Attia, M. A. & Abd El-baky, M. A. Understanding the effect of halloysite nanotubes addition upon the mechanical properties of glass fiber aluminum laminate. Fiber. Polym. 22, 1416–1433 (2021).

Attia, M. A., El-baky, M. A. A., Abdelhaleem, M. M. & Hassan, M. A. Hybrid composite laminates reinforced with flax-basalt-glass woven fabrics for lightweight load bearing structures. J. Ind. Text. 51, 4622S-4664S (2020).

Awd Allah, M. M., Abd El-baky, M. A., Hassan, M. A. & Shaker, A. Crashworthiness performance of thin-walled glass/epoxy square tubes with circular cutouts: An experimental study. Fiber. Polym. 23, 3268–3281 (2022).

Liu, Q., Ma, J., Xu, X., Wu, Y. & Li, Q. Load bearing and failure characteristics of perforated square CFRP tubes under axial crushing. Compos. Struct. 160, 23–35 (2017).

Estrada, Q. et al. Effect of radial clearance and holes as crush initiators on the crashworthiness performance of bi-tubular profiles. Thin-Walled Struct. 140, 43–59 (2019).

Estrada, Q. et al. Crashworthiness behavior of aluminum profiles with holes considering damage criteria and damage evolution. Int. J. Mech. Sci. 131–132, 776–791 (2017).

Guler, M. A., Cerit, M. E., Bayram, B., Gerçeker, B. & Karakaya, E. The effect of geometrical parameters on the energy absorption characteristics of thin-walled structures under axial impact loading. Int. J. Crashworthiness 15, 377–390 (2010).

Rouzegar, J., Assaee, H., Elahi, S. M. & Asiaei, H. Axial crushing of perforated metal and composite-metal tubes. J. Braz. Soc. Mech. Sci. Eng. 40, 1–6 (2018).

Song, Z. et al. Improving the energy absorption capacity of square CFRP tubes with cutout by introducing chamfer. Int. J. Mech. Sci. 189, 105994 (2021).

Fan, Z., Lu, G. & Liu, K. Quasi-static axial compression of thin-walled tubes with different cross-sectional shapes. Eng. Struct. 55, 80–89 (2013).

Mache, A., Deb, A. & Gupta, N. An experimental study on performance of jute-polyester composite tubes under axial and transverse impact loading. Polym. Compos. 41, 1796–1812 (2019).

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

M.A.A.E.: Idea, writing-conceptualization and methodology, original draft preparation, investigation, writing-reviewing and editing, supervision. M.M.A.A.: Experimental work, writing-conceptualization and methodology, original draft preparation, investigation, writing-reviewing and editing. W.A.-E.: Writing-original draft preparation, preparation of figures. M.K.: Writing-original draft preparation, preparation of figures. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

El-baky, M.A.A., Allah, M.M.A., kamel, M. et al. Energy absorption characteristics of E-glass/epoxy over-wrapped aluminum pipes with induced holes: an experimental research. Sci Rep 12, 21097 (2022). https://doi.org/10.1038/s41598-022-25679-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-022-25679-0

This article is cited by

-

Discovering the Impact of Printing Parameters on the Crashworthiness Performance of 3D-Printed Cellular Structures

Fibers and Polymers (2025)

-

Comparative Analysis of Metal–Thermoplastic Hybrid Circular Structures Under Quasi-static Lateral Loading: Implications for Crashworthiness

Fibers and Polymers (2025)

-

Impact energy absorption and failure analysis of basalt-/glass-fiber-reinforced cylindrical hybrid composites

Sādhanā (2025)

-

The Influence of Trigger Angle Structure on the Energy Absorption Capabilities of Aluminum Alloy/Thermoplastic Reinforced Polypropylene Hybrid Tubes

Applied Composite Materials (2025)

-

Energy Absorption Performance of 3D-Printed Windowed Structures Under Quasi-Static Axial Loading Condition

Fibers and Polymers (2025)