Abstract

This research delves into the transfer and loss of energy in a discrete mass when subjected to forced vibration. Using discrete element method (DEM), we analyzed the dynamic behavior of regular spherical granular assemblies and the energy distribution characteristics under different excitation frequencies and reduced accelerations. Moreover, the energy transfer and dissipation process of granular assemblies under different vibration states are studied using an experimental method. The results show that the granular assemblies will produce collision energy dissipation, thermal energy dissipation, acoustic energy dissipation and other forms of energy dissipation in the forced vibration state and the proportion of different energy dissipation under different excitation is given. The collision and friction of granular assemblies are the key to affecting other forms of energy dissipation. When the excitation increases, the energy dissipation forms are generated inside the granular assemblies, and the proportion of collision energy dissipation of the granular assemblies increases. The acoustic energy above 20 kHz occupies the main part of the acoustic energy dissipation. Thermal energy consumption always exists, which takes a long time to play a role. The granular also have other forms of energy loss, which is hard to be measured, including Rayleigh waves generated by granular collision. In this study, the relationship between the forced vibration state of the granular assemblies and the energy loss distribution is established. Various types of energy transfer and conversion distribution which further enriches the energy dissipation of discrete element calculation of the granular assemblies is discussed and provides a reference for the energy loss analysis of the granular assemblies.

Similar content being viewed by others

Introduction

The energy transfer and loss in the discrete mass system contain complex physical laws. The energy transfer and loss behavior are related to many factors such as the vibration state inside the discrete body and the material shape of the discrete body. The conversion of kinetic energy and potential energy caused by the internal micro-vibration of the discrete mass and the energy loss and conversion of the discrete mass as a whole, make the study of its energy change behavior widely concerned.

The DEM has been gradually applied to the study of granular assemblies in recent years. This method can better simulate the internal motion state of the discrete mass, focusing on the conversion process of the energy of the microscopic particles inside it, and analyzing the internal discrete mass. The conversion and loss law between kinetic energy and potential energy at a certain time scale1,2. The energy transfer and dissipation in the discrete mass is not only the solid dynamic vibration problem of the granular assemblies, but also the fluidization state caused by the change of the internal vibration state of the discrete mass during the vibration process. The change of the gap between the discrete mass leads to the change of its thermal conductivity, electrical conductivity and other properties3,4. The contact network dynamics formed by the contact between discrete mass bodies is an important factor in energy loss and energy transfer. Collision energy dissipation, friction energy dissipation, thermal energy dissipation, acoustic energy dissipation and other energy dissipation forms all need to be generated and further realized by contact force. The research on the collision energy of discrete mass is extensive. This is because the discrete mass body shows the mutual collision between the discrete mass bodies after being excited and vibrated. This collision energy dissipation process has good engineering significance. Vasileios et al. given the method of generating different discrete mass shape, which obtained the possibility of simulation5,6,7,8.Yang et al. obtained the collision energy loss method of particle aggregates by steady-state energy flow method9. Wong et al. further applied this method to obtain the calculation and experimental analysis method of the loss factor of granular assemblies10. Combining the DEM to calculate the kinetic energy loss of the granular assemblies in the process of forced vibration has become a reliable form of analyzing the energy loss of the particle11. The development of DEM enables researchers to better study the internal vibration process of particles. This method has been used to find more complex and diverse vibration states inside particles12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30. Zhang et al. discussed the vibration morphology of granular assemblies under different excitation conditions. The DEM was used to study various motion states and corresponding energy dissipation effects of particles in different containers such as two-dimensional closed containers under low frequency and large amplitude31,32,33,34.Francesco Zarattini et al. used the DEM to discuss the collapse of a submerged granular column35. Fan et al. used the DEM to discuss the internal vibration state and energy dissipation process of the granular assemblies36. The combination of forced vibration state and energy loss behavior of particles has become an important research method for its engineering design and application. In the process of forced vibration of particles, there are many forms of energy conversion. The problems of thermal energy consumption and acoustic energy consumption caused by collision and friction energy consumption have not been studied and analyzed enough. These energy dissipation forms are accompanied by the vibration collision of particles, which is also an important process of energy conversion and loss of particles37,38,39,40,41,42. These processes are also closely related to the vibration state inside the particles.

Regarding thermal losses generated by particle aggregates, Hunt studied the heat exchange behavior of small particles. Fischer proposed a particle–particle heat transfer model to optimize the heat transfer process in the discrete element method43,44. Haydar and Chaudhuri also studied the thermal transport of particles in rotating drums using the discrete element method45,46. It is understood that thermal losses constitute a vital energy dissipation method in particle aggregate vibration. However, there needs to be a clear explanation of the process of thermal losses or their corresponding proportion47,48,49,50,51,52. The acoustic radiation characteristics of the particle in different motion states will show nonlinear characteristics34.The internal propagation of acoustic energy in dense particle aggregates has received extensive attention. The propagation of acoustic waves and the transfer of energy inside particles have been widely studied and applied in phenomena such as earthquakes14,15,16,17.

For the energy dissipation process of discrete mass, some achievable measurement methods for the overall energy distribution of discrete mass have not been fully applied. The energy dissipation characteristics and energy distribution of discrete mass under forced vibration conditions have not been fully studied. In this paper, the regular discrete mass (or granular assemblies) is taken as the research object. Based on the study of the forced vibration law of the particle body, the energy dissipation state of the particle body under the typical forced vibration state is tested and analyzed. The discrete element method is used to analyze the micro kinetic energy change inside the particle body. The macroscopic energy conversion and loss frequency-dependent characteristics of granular assemblies were obtained by experimental methods, and the distribution of collision energy dissipation, acoustic energy dissipation and thermal energy dissipation under forced vibration are explored. The proportion of different energy dissipation forms and their energy dissipation process are discussed. The relationship between the forced vibration state of the particle and the energy loss distribution is established, further enrich the discrete element calculation of the discrete mass system, and provide a reference for the energy loss analysis of the discrete mass system.

The arrangement of this paper is as follows : In "Energy loss mechanism of forced vibration of granular assemblies", the discrete element model of granular assemblies is established, the kinetic energy distribution of granular assemblies under forced state is analyzed, and the energy dissipation model of granular assemblies forced vibration is established. "Forced vibration energy loss test device for granular assembly" describes the experimental device and experimental process of granular assemblies. “Analysis of forced vibration behavior and energy dissipation distribution law of granular assembly” analyzes the forced vibration and energy dissipation distribution law of granular assemblies. “Analysis of vibration intensity and energy dissipation distribution law of granular assembly” and “Analysis of size and energy dissipation distribution of granular assembly” discuss the influence of external factors such as excitation intensity and internal factors such as particle size on energy dissipation distribution.

Energy loss mechanism of forced vibration of granular assemblies

Granular collision and friction model

When the adhesion of the granular surface is not considered, the normal force between the granular is generally used: normal contact force \({\mathbf{F}}_{c}\) is the soft ball contact model is a soft ball dry contact model based on the improved discrete element method39. Deformation will occur and the normal contact force will be obtained \(F_{n}\):

where \(R^{*}\) is the equivalent radius, \(E^{*}\) is the equivalent elastic modulus, given by the following formula, \(\delta_{n}\) is the normal overlap.

The energy loss in this process is mainly based on the research of Tsuji et al.42. The normal damping force is \(F_{n}^{d}\):

where \(\zeta\) is the damping ratio, \(v_{n}^{{\overrightarrow {rel} }}\) is the normal component of the relative velocity of the two particles, \(m^{*}\) is the equivalent mass, \(k_{n}\) is the normal stiffness, its expression is as follows :

where \(m_{i} ,m_{j}\) is the mass of the two collision particles, the particles selected in this experiment are particles of the same material and volume. Therefore, the mass of the particles that collide is the same.

-

(1)

(1) Tangential contact force

The tangential contact force model of the particle is based on the Mindlin-Deresiewicz contact theory. The calculation of the tangential contact force is as follows:

$$ F_{t} = - k_{t} \delta_{t} $$(8)where \(\delta_{t}\) is the tangential overlap,\(k_{t}\) is tangential stiffness, derived from formula (9):

$$ k_{t} = 8G^{*} \sqrt {R^{*} \delta_{n} } $$(9)

In Eq. (9), \(G^{*}\) is the equivalent shear modulus:

where \(G_{1}\) and \(G_{2}\) is the shear modulus of the two particles, which is determined by the elastic modulus and Poisson 's ratio of the material.

Based on the study of Tsuji et al.42, the tangential damping force can be defined as :

where \(v_{t}^{{\overrightarrow {rel} }}\) is the tangential component of the relative velocity of the two particles.

In the forced vibration friction model, the particle is in contact with other particles or container walls, and is subjected to vertical positive pressure \(F_{n}\) and horizontal thrust \(F_{t}\). In the discrete element method, the shareholder friction of the particle body is considered as applying a moment on the surface of the particle:

where \(\mu_{r}\) is the rolling friction coefficient, \(R_{i}\) is the distance from the particle contact point to the center of mass, \(\omega_{i}\) is the unit angular velocity vector of the object at the contact point.

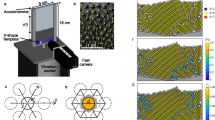

The particle collision and friction energy dissipation model was established, and the discrete element simulation software EDEM was used to analyze the vibration process of particle aggregates under different excitation conditions. The particle mass is 557 g, the particle size is 2 mm, the filling rate is 80%, and the particle container is a \(\Phi 72 \times 37.5{\text{mm}}\) cylindrical container. The main parameters are given in Table 1. A series of sinusoidal excitations acting on the container along the Z axis. The distance between the bottom of the container and the initial position is represented by \(A\sin (2\pi f)\) where A it is the vibration amplitude, f is the vibration frequency. The two control parameters in the simulation are A and f.The forced vibration model of the granular assemblies adopts the Hertz contact theory model, and the normal contact force adopts the soft ball contact model as the soft ball dry contact model of the improved discrete element method. The established granular assemblies discrete element simulation model is shown in Fig. 1 below.

When analyzing the vertical forced vibration of the granular assemblies, the reduced acceleration is usually used to characterize the excitation intensity of the granular assembly. The reduced acceleration \(\Gamma\) is a dimensionless parameter.

where \(A\) it is the vibration amplitude, \(\omega\) the vibration angular frequency, and the \(g\) gravity acceleration.

The excitation intensity and frequency of granular assemblies are different, which will lead to the difference of the internal motion state of granular assemblies. The change of the internal vibration state of granular assemblies will cause the change of different energy transfer and dissipation forms. Changing the amplitude and frequency of the excitation will lead to the change of the vibration state inside granular assemblies, and reduced acceleration is affected by the amplitude and frequency of the excitation. Through the discrete element simulation method, the researchers found that at a large reduced acceleration (greater than 10), the granular assemblies will produce violent vibration states such as the Undulation bed, Density inversion, Leidenfrost effect, Buoyancy convection and Bidirectional Leidenfrost effect, which means a larger amplitude and input frequency.

In this paper, a small reduced acceleration (less than 10) is used for excitation, so the internal vibration state cannot produce the above vibration state. According to the vibration and velocity vector changes of granular assemblies, the granular assemblies are divided into five typical vibration states : solid-like, micro-vibrational, intermediate vibrational, strong vibrational, and gas-like.

The discrete element method can effectively extract the kinetic energy information of each particle at the calculation time. Figure 2 shows the distribution of the kinetic energy of the every internal granular assemblies with the Z-axis height of the container under different excitation conditions at 0.5 T, T is a vibration period.

Kinetic energy distribution of particles along the z direction of the container. (a) Solid-like state, excitation frequency is 50 Hz and reduced acceleration is 0.8. (b) Micro-vibration state, excitation frequency is 250 Hz and reduced acceleration is 1.2. (c) Intermediate vibration state, excitation frequency is 150 Hz and reduced acceleration is 6. (d) Strong vibration state, excitation frequency is 25 Hz and reduced acceleration is 2.5. (e) Gas-like state, excitation frequency is 100 Hz and reduced acceleration is 6.

-

(1)

When the granular assemblies is in solid-like vibration, the granular inside the particle move with the whole body, so its kinetic energy is in a small range and the range of variation is small. In the direction of excitation vibration, the kinetic energy distribution of the particles is more uniform.

-

(2)

When the micro-vibration state and intermediate vibration state are generated inside the granular assemblies, the kinetic energy increases and the distribution range increases. In the direction of excitation vibration, some particles at different positions have greater kinetic energy, which also makes the kinetic energy distribution inside the particles larger than the velocity distribution range of solid-like vibration kinetic energy.

-

(3)

When the granular assemblies enters the strong vibration state, the overall performance is the impact on the container, and the kinetic energy of the internal particle increases significantly after the internal particle is forced to vibrate. When the particle aggregate exhibits an impact on the container, the internal particle interaction leads to an increase in the kinetic energy of a large number of particles. The particles in the upper layer are less affected by other particles during the vibration process, so the kinetic energy is greater.

-

(4)

When the granular assemblies enters the gas-like vibration, the movement of the internal particle is more intense and the kinetic energy is significantly improved. In the gas-like state, the particles inside the particle assembly show a violent movement process, and the velocity distribution of the particles is larger along the excitation direction.

The discrete element method can effectively simulate the interaction inside the granular assemblies. Through the discrete element method analysis of the kinetic energy distribution under different vibration states, it means that the energy obtained by the particles under different vibration states is different, and the corresponding energy dissipated outward will also be different. The increase of kinetic energy means that the collision and friction inside the granular assemblies are frequent. Under the violent action inside the particles, the granular assemblies will produce more complex energy dissipation processes, including various energy dissipation behaviors such as acoustic energy dissipation and thermal energy dissipation caused by collision and friction. The transformation of the granular assembly from a stationary state to a vibrating state requires continuous input of external energy. When the excitation stops, the granular cannot continue to maintain its forced vibration state, which means that the energy input each time will be stored in the particle body or a variety of different forms of energy are consumed. These energy dissipation processes cannot be obtained by the discrete element method at present, so the experimental method is used to study the dissipation process of this part of energy.

Energy dissipation model of granular assemblies

Collision energy dissipation model

When the granular assembly is forced to vibrate, similar motion behaviors will generally occur under each constant sinusoidal excitation. The collision effect will first occur inside the granular, and its energy dissipation behavior can be obtained by the steady-state energy flow method. The input power of the forced vibration of the particle assembly is :

In the formula, \(f(t)\) and \(v(t)\) are the time histories of the force and velocity signals respectively ; \(F\) and \(V\) are the Fourier transform of \(f(t)\) and \(v(t)\), respectively. \(V*\) is the conjugate complex number of \(V\); \(\left| F \right|,\left| V \right|\) is the amplitude of force and velocity, and \(\cos (\phi_{F} - \phi_{V} )\) is the cosine value of the phase difference between force and velocity.

In steady-state vibration, the loss power is equal to the system \(P_{in}\)

Therefore, the loss caused by the collision of particle aggregates is obtained by the following formula.

where \(\omega\) is the angular frequency,\(E\) is the structural vibration maximum kinetic energy(\(E = \frac{1}{2}mVV* = \frac{1}{2}m\left| V \right|^{2}\)), and \(m\) is the system dynamic mass.

The simultaneous Eqs. (15)–(18) can be obtained.

Acoustic energy dissipation model

Since the granular size is much smaller than the wavelength of the sound wave, the sound pressure of a single granular satisfies :

where the point source strength is \(Q_{0} = 4\pi r_{0}^{2} v_{a}\), \(v_{a}\) is the vibration velocity amplitude.

In the granular assembly, there are collisions between granular and granular, granular and containers. The collisions of different granular are different in amplitude and phase. It is assumed that the point at any position of the granular assembly can be expressed as a small surface source \({\text{d}}s\) on the surface of the sound source. At this time, the point source strength of the granular assembly is expressed as :

In the formula, \(v_{a} (x,y,z)\) is the vibration velocity amplitude of the point.

The sound pressure of the granular assembly satisfies :

The distance from the point bin to the observation point \(r(x,y,z)\) is the initial phase of the point. The superposition of all the contributions of the granular assembly to the spatial sound field \(\varphi (x,y,z)\) is the total sound pressure :

To simplify the calculation, it is considered that the granular assembly is composed of N uniform point bins, that is, it is composed of point sources with the same strength and irregular phase changes. Then the above equation can be simplified as :

where \(l_{i}\) is the distance between the i-th point source and the observation point. \(\varphi_{i}\) is the initial phase of the ith point source.

The acoustic energy dissipation caused by the collision of granular assembly is obtained by the experiment of the particle body. The sound power level can be obtained by measuring the sound pressure. The sound power level of the sound source is tested by the following formula :

where the reference sound power is \(W_{ref} = 10^{ - 12} {\text{W}}\).

When the frequency of the sound wave is greater than 20 kHz, this corresponding ultrasonic range. At this time, the sound power is affected by the frequency of the ultrasonic wave, the radiation area and other factors. The sound power is calculated by the following formula :

W is the sound power, r is the propagation distance, c is the sound velocity, P is the sound pressure, A is the radiation area, f is the frequency. The integral of the sound power \(W\) over a certain duration \(T\)(beginning \(t_{1}\), ending \(t_{2}\)) represents the sound energy \(Q_{a}\) generated during that time :

In the process of forced vibration of particles, the energy input in each period is determined. Therefore, the energy consumption of the particles \(\alpha_{a}\) can be obtained as follows, where Q is the total input energy :

Thermal energy consumption model

The heat loss of the forced vibration of the granular is caused by the long-term collision and friction in the granular. For any granular A, the temperature \(T^{A}\) satisfies the heat conduction control equation41 :

The boundary conditions are :

Set each granular has only one temperature. For granular A, it is set that there is no heat source inside, that is \(\dot{q} = 0\). All the factors that change the granular temperature come from the external conditions, that is, the \(q^{A}\) is the sum of friction heat and heat exchange. The relationship between particle temperature change and boundary heat exchange is expressed as :

The frictional heat \(q^{BA}\) transfer between the granular adds the heat exchange of each granular to the granular A, and the total heat exchange with the other N granular can be obtained, namely \(q^{A} = \sum {q^{BA} }\). At the same time, is related to the properties and temperature difference of the contact to the granular, which can be expressed as :

The change of granular temperature can be calculated by the sum of contact heat exchange, namely :

According to Newton 's law of cooling, in a closed granular container, the natural convection of air is a heat transfer mode without forced air flow. The convective heat transfer of air \({\text{Q}}_{air}\) is as follows :

where the convective heat transfer coefficient is \({\text{h}}\).\(A\) is the surface area of the object exposed to the moving fluid. According to Stefan-Boltzmann's law, the thermal radiation of a granular is determined by the following formula :

where \(\sigma\) is the Stefan-Boltzmann constant, the value is \(\sigma = 5.67 \times 10^{ - 8} {\text{W}} /m^{2} \cdot K^{4}\). During the experiment, the heat insulation layer is added to reduce the consumption of thermal radiation, \(Q_{i} < < Q_{p}\),so the thermal radiation of the granular can be ignored. By testing the temperature T change of the granular assemblies, the thermal energy consumption can be calculated.

Therefore, the proportion of thermal energy consumption generated by the granular in the forced vibration process to the total energy is :

The energy loss and conversion distribution of granular assembly should be composed of various forms of energy, which \(Q_{o}\) are other forms of energy.

The total energy \({\text{Q}}\) during the forced vibration of a particle is the sum of the energy of forced vibration in each period, among them, the experiment can record the variation curve of the reduced acceleration of the particle body with time under different forced vibration states. Because the reduced acceleration curve of each cycle is similar, the reduced acceleration in multiple cycles is integrally averaged. The average speed of the particle damper in a cycle under different vibration states is calculated. The total energy of each cycle in the forced vibration time is as follows, where n is the total number of all periods in the forced vibration time. :

Forced vibration energy loss test device for granular assembly

In this experiment, 2 mm 304 stainless steel particles were used as the research object, and the granular of this material did not have magnetism. 304 stainless steel particles without magnetism are selected, which can show obvious characteristics of the whole particles under excitation conditions32,33. The granular assembly container is \(\Phi 72 \times 80{\text{mm}}\) and adopts high-permeability organic glass material with inner diameter as shown in Fig. 3.

In order to ensure the consistency of the experimental environment, the experiment is carried out in a constant temperature closed anechoic chamber. The collision energy dissipation, thermal energy dissipation and acoustic energy dissipation in the process of forced vibration are analyzed experimentally. The schematic diagram and physical diagram of the test device are shown in Fig. 4.

The excitation frequency of the exciter is 5–300 Hz. According to the range of excitation frequency, the shooting speed of the high-speed camera is set to 10,000 fps, the shutter speed is 1/10,163 s, and the image resolution is \(1024 \times 1024\). In the granular collision energy dissipation experiment, the high-speed camera is used to record the internal vibration state of the granular, and the B&K vibration test system is used for signal acquisition, analysis and closed-loop control of the exciter. The signal generator outputs a sinusoidal signal with a specific frequency and amplitude, which is output to the exciter through the power amplifier, and the force sensor and the acceleration sensor collect the signal. The time domain signals of force and acceleration of particles under forced vibration can be obtained by impedance head. The analysis of “Collision energy dissipation model” shows that the proportion of collision energy consumption can be obtained by analyzing the acceleration signal and force signal of particle assembly in vibration state.

The thermal energy consumption test of granular was carried out by infrared thermal imaging thermometer and high precision thermometer. The infrared thermal imaging thermometer can test and record the surface temperature of granular assembly, and the high-precision thermometer can penetrate into granular assembly through two temperature probes to test and record the temperature inside granular assembly. When measuring the temperature, it is necessary to stop the excitation and open the upper cover of the container. Firstly, the infrared temperature sensor is used to measure the surface temperature of the particles. Two contact high-precision thermometers are used to measure the particles deeply inside and at the bottom of the particles at the same time. The measurement time is 1 min. After the end of the measurement, the upper cover plate is quickly closed and the particle body is continuously excited.

In the acoustic energy dissipation experiment, the sound pressure test was carried. The B&K 2671 1/2 inch free field microphone is used in the granular acoustic energy dissipation test, and the measurement frequency is 6.3 Hz to 20 kHz. According to ISO3744, combined with the size of the granular damper container, 1 m is selected as the measurement spherical radius for 20 Hz to 20 kHz sound power test. The MPA401 1/4 free field microphone is used. The measurement frequency is 20 kHz to 50 kHz. The sound attenuation in the measurement frequency range is fast. Therefore, the measurement microphone is set at 10 mm away from the container.

Analysis of forced vibration behavior and energy dissipation distribution law of granular assembly

Combined with the discrete element method, the excitation frequencies of 20 Hz, 50 Hz, 100 Hz, 150 Hz, 200 Hz, 250 Hz and 300 Hz are selected, and the reduced accelerations are 0.8,1.2,2.5 and 6. Under the above excitation intensity and frequency, the granular will exhibit diverse and complex vibration states.

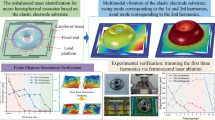

According to the discrete element simulation analysis and experimental research, Fig. 5a shows the corresponding vibration states of the granular under different typical vibration conditions. When the excitation frequency is 50 Hz and the reduced acceleration is 0.8, the granular assembly is at a solid-like vibrational state. When the excitation frequency is 250 Hz and the reduced acceleration is 1.2, the granular assembly presents micro-vibration state.When the excitation frequency is 150 Hz and the reduced acceleration is 6, the granular assembly is at a intermediate vibrational state. When the excitation frequency is 25 Hz and the reduced acceleration is 2.5, the granular assembly shows strong vibrational state. When the excitation frequency is 100 Hz and the reduced acceleration is 6, the granular assembly presents a gas-like state. The corresponding granular assembly vibration states under the above experimental conditions correspond to points a, b, c, d and e, respectively. The sound pressure distribution law under the corresponding state of granular assembly and the temperature distribution map of the infrared thermometer on the surface of the granular assembly for two hours of forced vibration are given. And the energy dissipation distribution of the granular assembly under the corresponding vibration state.

Under the forced vibration of granular assembly, the main energy dissipation processes include collision energy dissipation, thermal energy dissipation, acoustic energy dissipation and other energy dissipation forms. These energy dissipation forms are closely related to the vibration state of granular assembly. With the increase of the input excitation energy the loss energy of different energy dissipation processes shows an increasing trend. Collision energy consumption increases with the change of granular assembly vibration state. When the particle is at solid-like state, the collision behavior of granular assembly is not obvious, and the corresponding energy consumption is relatively small.

When the vibration state changes to micro-vibration state and intermediate vibrational state, the internal granular assembly begin to appear obvious collision behavior, and the corresponding energy consumption increases. Figure 5b shows the sound pressure distribution of granular assembly under different vibration states and Fig. 5c shows the surface temperature distribution of granular assembly under forced vibration for 2 h. The acoustic energy dissipation process of granular assembly occupies a significant proportion in the energy dissipation process of the forced vibration of the particles. The granular assembly is excited to produce the internal granular to produce the collision friction effect, which will produce the acoustic radiation phenomenon, and the generated acoustic wave frequency is more. Figure 5d shows the energy dissipation distribution under different vibration states.

As the interior and vibration state becomes more intense, the acoustic waves of different frequency bands radiate energy outward. In the range of 20 Hz to 20 kHz, the acoustic energy consumption of the granular assembly is not obvious, generally accounting for only 0.1% of the energy consumption. At the same time, the granular assembly radiate sound waves greater than 20 kHz, that is, the ultrasonic frequency band. This part of the acoustic energy consumption has a large amount of energy, but it is limited by the propagation medium, and it attenuates rapidly during the outward radiation process and is not easy to be detected. The ultrasonic loss part bears the main part of the acoustic energy consumption of the particles. The thermal energy dissipation of granular assembly is considered to be an important form of long-term forced vibration energy conversion and loss of granular, which requires long-term collision accumulation of granular. The violent vibration inside the granular assembly will lead to a significant increase in the temperature of the granular, but the corresponding heat loss of the granular will not increase significantly. Severe vibration will also lead to an increase in other energy consumption. In addition, in the process of forced vibration, the granular also have other forms of energy loss, which is not easy to be measured, including Rayleigh waves generated by granular collision. The vibration state inside the granular assembly brings about changes in the collision process and eventually dissipates through different energy forms.

Analysis of vibration intensity and energy dissipation distribution law of granular assembly

The energy dissipation behavior of granular assembly is limited by the internal vibration state, and the internal vibration state is affected by the excitation characteristics. The frequency and reduced acceleration of excitation are the key factors affecting the vibration state of granular. Figure 6 shows the proportion of granular assembly energy consumption under different reduced acceleration and frequency. There are many forms of energy dissipation in the process of forced vibration of granular assembly.

When the reduced acceleration is 0.8, the increase of frequency does not lead to the change of the internal vibration of granular, and granular assembly is at the solid-like state. When the frequency increases, the internal granular will have a certain heating effect under the frequent excitation of the internal granular. Due to the small input energy, the energy loss caused by the heating effect is more obvious. At the same time, there is also a certain ultrasonic energy loss process inside the solid-like state.

When the reduced acceleration increases to 1.2, the granular are generally in the micro-vibration state. With the increase of frequency, a large number of granular will appear micro-vibration, micro-rotation, which will bring a variety of loss energy increase. When the frequency increases, more granular will vibrate at their positions, and the collision loss will increase significantly.

When the reduced acceleration is 2.5 and 6, at a lower frequency, the granular assembly is prone to produce a strong vibrational state or a gas-like state, the frequency increases, and the intermediate vibrational state gradually appears. In these states, the collision energy consumption of granular assembly is obvious, and the proportion of other energy consumption forms is reduced. At lower frequencies, the granular assemblies vibrate violently, and the proportion of acoustic energy consumption increases. The energy of the ultrasonic part above 20 kHz accounts for a large proportion, and the radiated acoustic energy within 20–20 kHz is very small. As the frequency continues to increase, the internal collision and friction of the granular will be more frequent. Under the action of long time and multiple cycles, the proportion of thermal energy consumption will gradually increase. The more severe the collision is, the greater the proportion of collision energy consumption is, and the proportion of other energy consumption forms will decrease accordingly. Therefore, the collision and friction of particles are the key to affecting other energy consumption forms.

Analysis of size and energy dissipation distribution of granular assembly

Figure 7 shows the size of the granular assembly leads to the difference in the collision under the same excitation. Therefore, the 304 stainless steel granular, i.e., 1 mm, 2 mm, 3 mm, 4 mm and 5 mm are taken as the research object. The mass of the granular is always 557 g, and the energy consumption ratio under different reduced accelerations and frequencies is experimentally studied. Granular with different sizes show similar energy dissipation processes under the same mechanism conditions.

When the granular assembly is at a solid-like state, the internal collision energy consumption behavior is not obvious, and the acoustic energy consumption, thermal energy consumption and other energy consumption forms account for a large proportion. With the increase of excitation frequency and reduced acceleration, the vibration state of the internal granular assembly changes. At this time, the collision energy consumption of the granular assembly increases, and the thermal energy consumption decreases. The proportion of acoustic energy consumption always exists in the process of forced vibration, and the proportion of energy consumption above 20 kHz is still an important part of the acoustic energy consumption of forced vibration of granular assembly. In contrast, the acoustic energy consumption of 20 Hz to 20 kHz is not obvious. When the size of granular becomes smaller, the granular assembly will show a state of bias towards the powder particles under forced vibration, and the interaction between the granular assembly is closer. Under the same excitation conditions, the collision friction effect inside the granular assembly is not obvious, so the proportion of energy consumption such as collision energy consumption is not high. When the size of the granular increases, the collision between the granular is more likely to occur, so that the collision energy consumption and the proportion of other energy consumption forms due to collision friction also increase accordingly.

Conclusion

In this paper, the energy dissipation law of forced vibration of discrete mass is analyzed and experimentally studied. The discrete element method is used to analyze the internal kinetic energy distribution of the granular assembly under different vibration conditions by using the regular spherical granular assembly. The macroscopic distribution law and dissipation behavior of the granular under forced vibration conditions are explored by experimental methods. The conclusions are as follows:

-

(1)

The transformation of the granular assembly from a static state to a vibration state requires continuous input of external energy. When the excitation stops, the granular assembly cannot continue to maintain its forced vibration state, which means that each input energy will be stored inside the granular assembly or consumed in various forms of energy.

-

(2)

Under the forced vibration of granular assembly, the main energy dissipation processes include collision energy dissipation, thermal energy dissipation, acoustic energy dissipation and other energy dissipation forms. These energy dissipation forms are closely related to the vibration state of the granular assembly. In the range of 20 Hz to 20 kHz, the acoustic energy consumption of granular assembly is not obvious, which generally accounts for only 0.1% of the total energy consumption. The granular assembly will radiate sound waves greater than 20 kHz. This part of the acoustic energy consumption has a large amount of energy, but it is limited by the propagation medium. The ultrasonic loss part bears the main part of the acoustic energy consumption of the particles. The thermal energy dissipation of particles is considered to be an important form of long-term forced vibration energy conversion and loss of particles, which requires long-term collision accumulation of particles.

-

(3)

The excitation intensity of granular assembly is changed by changing the frequency and the reduced acceleration. Under the action of long-term multi-cycle, the proportion of heat energy consumption gradually increases. The more severe the collision degree is, the greater the proportion of collision energy consumption is, and the proportion of other energy consumption forms will decrease correspondingly. Therefore, the collision and friction of granular assembly is the key to affect other energy consumption forms.

-

(4)

The change of granular size will lead to the change of the proportion of energy consumption under the same excitation condition. When the size of the granular assembly increases, the collision between the granular assembly is more likely to occur, so that the collision energy consumption and the proportion of other energy consumption forms due to collision friction also increase accordingly.

The study of energy consumption under forced vibration of particles can effectively explain the energy change caused by collision and friction between particles. The experimental analysis of various energy consumption forms such as thermal energy consumption and acoustic energy consumption of particles will provide more references for the future application of particle-related technologies, such as better application of particle damping technology in the field of vibration and noise reduction.

Data availability

Data cannot be shared openly but are available on request from authors.

References

Zhao, J., Zhao, S. & Luding, S. The role of particle shape in computational modelling of granular matter. Nat. Rev. Phys. 5(9), 505–525 (2023).

Senetakis, K. Energy transport and dissipation in granular systems. Granular Matter 25(4), 64 (2023).

Zhang, K. et al. Granular wave-solid state: An accident of density inversion?. Granular Matter 24(4), 108 (2022).

He, H. et al. Influence of particle size and packing on the thermal conductivity of carbonate sand. Granular Matter 24(4), 117 (2022).

Essayah, A., Shire, T. & Gao, Z. The relationship between contact network and energy dissipation in granular materials. Granular Matter 24(4), 100 (2022).

Sassel, T. S. et al. Linking the macro-scale response of granular materials during drained cyclic loading to the evolution of micro-structure, contact network and energy components. Granular Matter 25(2), 23 (2023).

Choi, C. E. & Yu, J. Mesoscopic dimensional analysis of submarine debris flows: Implications for physical modelling. Granular Matter 25(1), 14 (2023).

Angelidakis, V. et al. CLUMP: A code library to generate universal multi-sphere particles. SoftwareX 15, 100735 (2021).

Yang, M. Y. et al. Development of a design curve for particle impact dampers. Noise Control Eng. J. 53(1), 5–13 (2005).

Wong, C. X., Daniel, M. C. & Rongong, J. A. Energy dissipation prediction of particle dampers. J. Sound Vib. 319(1–2), 91–118 (2009).

Romdhane, M. B. et al. The loss factor experimental characterisation of the non-obstructive particles damping approach. Mech. Syst. Signal Process. 38(2), 585–600 (2013).

Clément, E., Duran, J. & Rajchenbach, J. Experimental study of heaping in a two-dimensional ‘“sand pile”’. Phys. Rev. Lett. 69(8), 1189 (1992).

Evesque, P. & Rajchenbach, J. Instability in a sand heap. Phys. Rev. Lett. 62(1), 44 (1989).

Keiko, M. & Aoki, A. T. Spontaneous wave pattern formation in vibrated granular materials. Phys. Rev. Lett. 77(20), 4166 (1996).

Douady, S., Fauve, S. & Laroche, C. Subharmonic instabilities and defects in a granular layer under vertical vibrations. EPL (Europhys. Lett.) 8(7), 621 (1989).

Sano, O. Dilatancy, buckling, and undulations on a vertically vibrating granular layer. Phys. Rev. E 72(5), 051302 (2005).

Hsiau, S. S., Wu, M. H. & Chen, C. H. Arching phenomena in a vibrated granular bed. Powder Technol. 99(2), 185–193 (1998).

Ehrichs, E. E. et al. Granular convection observed by magnetic resonance imaging. Science 267(5204), 1632–1634 (1995).

Risso, D. et al. Friction and convection in a vertically vibrated granular system. Phys. Rev. E 72(1), 011305 (2005).

Kudrolli, A., Wolpert, M. & Gollub Jerry, P. Cluster formation due to collisions in granular material. Phys. Rev. Lett. 78(7), 1383 (1997).

Meerson, B., Pöschel, T. & Bromberg, Y. Close-packed floating clusters: Granular hydrodynamics beyond the freezing point?. Phys. Rev. Lett. 91(2), 024301 (2003).

Eshuis, P.G. Leidenfrost Effect and Coarsening in a Granular Gap, Un. Twente, 2003 Dissertation Master Thesis (2003).

Eshuis, P. et al. Granular Leidenfrost effect: Experiment and theory of floating particle clusters. Phys. Rev. Lett. 95(25), 258001 (2005).

Lim, E. W. C. Granular Leidenfrost effect in vibrated beds with bumpy surfaces. Eur. Phys. J. E 32(4), 365–375 (2010).

Rivas, N. et al. From the granular Leidenfrost state to buoyancy-driven convection. Phys . Rev. E 91(4), 042202 (2015).

Guo, Y. & Curtis, J. S. Discrete element method simulations for complex granular flows. Annu. Rev. Fluid Mech. 47, 21–46 (2015).

Ze-Hui, J., Yun-Ying, W. & Jing, W. Subharmonic motion of granular particles under vertical vibrations. Europhys. Lett. 74(3), 417 (2006).

Tsuji, Y., Tanaka, T. & Ishida, T. Lagrangian numerical simulation of plug flow of cohesionless particles in a horizontal pipe. Powder Technol. 71(3), 239–250 (1992).

Jaeger, H. M., Nagel, S. R. & Behringer, R. P. Granular solids, liquids, and gases. Rev. Mod. Phys. 68, 1259–1273 (1996).

Pöschel, T. & Brilliantov, N.V. (eds.) Granular Gas Dynamics. Vol. 624 (Springer, 2003).

Zhang, K., Chen, T. & He, L. Damping behaviors of granular particles in a vertically vibrated closed container. Powder Technol. 321, 173–179 (2017).

Zhang, K. et al. Dissipation behaviors of granular balls in a shaken closed container. Mech. Syst. Signal Process. 172, 108986 (2022).

Zhang, K. et al. Dissipation behaviors of suspended granular balls in a vibrated closed container. Powder Technol. 399, 117158 (2022).

Zhang, K. et al. Rheology behavior and optimal damping effect of granular particles in a non-obstructive particle damper. J. Sound Vib. 364, 30–43 (2016).

Zarattini, F. et al. Micromechanical simulations of the collapse of a submerged granular column[C]//E3S web of conferences. EDP Sci. 415, 02025 (2023).

Yin, Z., Su, F. & Zhang, H. Investigation of the energy dissipation of different rheology behaviors in a non-obstructive particle damper. Powder Technol. 321, 270–275 (2017).

Liao, C. C., Chung, Y. C. & Weng, C. H. A study on the energy dissipation mechanism of dynamic mechanical systems with particle dampers by using the novel energy method. Nonlinear Dyn. 111(17), 15955–15980 (2023).

Ren, J. et al. Influence of Methocel cellulose ether additive on micro-scale friction, abrasion and energy dissipation of rough-heterogeneous particles. Granular Matter 24(4), 113 (2022).

Chlebnikovas, A. & Jasevičius, R. Investigation of the interaction of particulate matter and its separation from the gas flow in a multi-channel cyclone with recirculation. Granular Matter 24(4), 98 (2022).

Oda, M., Iwashita, K. & Kakiuchi, T. Importance of particle rotation in the mechanics of granular materials. Powders Grains 97, 207–210 (1997).

Theofanous, T. G. et al. The physics of aerobreakup. II. Viscous liquids. Phys. Fluids 24(2), 1 (2012).

Tsuji, Y. et al. Lagrangian numerical simulation of plug flow of cohesionless particles in a horizontal pipe. Powder Technol. 71(3), 239–250 (1992).

Bergman, T. L. et al. Fundamentals of Heat and Mass Transfer (Wiley, 2007).

Fischer, J. et al. Particle-particle contact heat transfer models in thermal DEM: A model comparison and experimental validation. Powder Technol. 4, 118909 (2023).

Haydar, C., Martin, S. & Bonnefoy, O. Long time extrapolation of DEM with heat conduction in a moving granular medium. Chem. Eng. Sci. 277, 118815 (2023).

Chaudhuri, B., Muzzio, F. J. & Tomassone, M. S. Experimentally validated computations of heat transfer in granular materials in rotary calciners. Powder Technol. 198(1), 6–15 (2010).

Thomas, B. et al. Heat transfer in shallow vibrated beds. Powder Technol. 99(3), 293–301 (1998).

Tada, É. F. R. et al. Investigation of heat transfer in partially filled horizontal drums. Chem. Eng. J. 316, 988–1003 (2017).

Cheng, G. J., Yu, A. B. & Zulli, P. Evaluation of effective thermal conductivity from the structure of a packed bed. Chem. Eng. Sci. 54(19), 4199–4209 (1999).

Sullivan, W. N. & Sabersky, R. H. Heat transfer to flowing granular media. Int. J. Heat Mass Transf. 18(1), 97–107 (1975).

Holman, J. P. Heat Transfer (McGraw Hill, 1986).

Razgaitis, R. & Holman, J. P. A survey of heat transfer in confined swirl flows. Future Energy Prod. Syst. Heat Mass Transf. Process. 2, 831–866 (1976).

Acknowledgements

The authors are grateful for the financial support provided by National Major Special Basic Research (J2019-II-0013-0033), Basic Strengthening Plan Key Basic Research (2020-JCJQ-ZD-204), and Discrete Mass Damping Nonlinear Energy Dissipation Mechanism and Application Research (No. 1227020353).

Author information

Authors and Affiliations

Contributions

Zhang Shengwu, Wang Chiming, and Zhang Yuanchao proposed the idea. Zhang Shengwu, Xuwei, and Li Yanan completed the experiments. Wang Chiming, Zhang Shengwu, Zhu shunzhi, and Chengjianwei wrote the paper. All of the authors analyzed the data, discussed the results, and reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Shengwu, Z., Chiming, W., Yuanchao, Z. et al. Exploring the collision, acoustic and thermal energy dissipation distribution of discrete mass. Sci Rep 14, 16726 (2024). https://doi.org/10.1038/s41598-024-67619-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-67619-0