Abstract

Injection molding is a common plastic processing technique that allows melted plastic to be injected into a mold through pressure to form differently shaped plastic parts. In injection molding, in-mold electronics (IME) can include various circuit components, such as sensors, amplifiers, and filters. These components can be injected into the mold to form a whole within the melted plastic and can therefore be very easily integrated into the molded part. The brain–computer interface (BCI) is a direct connection pathway between a human or animal brain and an external device. Through BCIs, individuals can use their own brain signals to control these components, enabling more natural and intuitive interactions. In addition, brain–computer interfaces can also be used to assist in medical treatments, such as controlling prosthetic limbs or helping paralyzed patients regain mobility. Brain–computer interfaces can be realized in two ways: invasively and noninvasively, and in this paper, we adopt a noninvasive approach. First, a helmet model is designed according to head shape, and second, a printed circuit film is made to receive EEG signals and an IME injection mold for the helmet plastic parts. In the electronic film, conductive ink is printed to connect each component. However, improper parameterization during the injection molding process can lead to node displacements and residual stress changes in the molded part, which can damage the circuits in the electronic film and affect its performance. Therefore, in this paper, the use of the BCI molding process to ensure that the node displacement reaches the optimal value is studied. Second, the multistrategy differential evolutionary algorithm is used to optimize the injection molding parameters in the process of brain–computer interface formation. The relationship between the injection molding parameters and the actual target value is investigated through Latin hypercubic sampling, and the optimized parameters are compared with the target parameters to obtain the optimal parameter combination. Under the optimal parameters, the node displacement can be optimized from 0.585 to 0.027 mm, and the optimization rate can reach 95.38%. Ultimately, by detecting whether the voltage difference between the output inputs is within the permissible range, the reliability of the brain–computer interface after node displacement optimization can be evaluated.

Similar content being viewed by others

Introduction

The brain–computer interface (BCI) is a technology that directly connects the brain to external devices, allowing people to control computers, machinery, or other devices via electroencephalographic signals1. The field of brain–computer interfaces (BCIs) has undergone significant development over the past few decades, moving from speculative concepts to practical applications with far-reaching implications for health care, neuroscience, and human-computer interaction. The origins of BCI research can be traced back to the mid-twentieth century, when the first attempts were made to understand and utilize the electrical activity of the brain. These early attempts were largely experimental, focusing on basic neuroscience research and the development of rudimentary neurophysiological recording techniques.

In the 1990s and early 2000s, significant advances were made in computational power, signal processing algorithms, and machine learning techniques that allowed for more sophisticated analysis and interpretation of brain signals. The development of both invasive and noninvasive biometric identification (BCI) systems accelerated during this period, driven by growing interest in a variety of potential applications, including complementary therapies, neural network therapy, electroencephalography, and neural network analysis2.

In recent years, there has been a surge in interdisciplinary research and collaboration, blending insights from neuroscience, engineering, computer science, and clinical practice. This convergence has led to significant breakthroughs in understanding brain dynamics and improving the performance and usability of biometric (BCI) systems. Notable achievements include the development of more accurate and reliable signal acquisition methods3, enhanced real-time processing capabilities4, and innovative applications in neurorehabilitation, communications, and entertainment5.

The primary purpose of a BCI is to detect and quantify the brain signal characteristics of a user’s intentions and to translate these characteristics in real time into commands that control a device to execute the user’s intentions. To accomplish this, BCI systems typically consist of four sequential components: signal acquisition, feature extraction, feature conversion, and device output. These components are controlled by an operating protocol that defines details regarding the start and end times of operations, details of signal processing, nature of device commands, and supervision of performance. Effective operating protocols give BCI systems the flexibility to meet the specific needs of each user. Figure 1 illustrates the principles of BCI and the related application areas.

Although current technologies make neuromodulation and neurostimulation possible, the complexity of the brain and the high degree of individual variation make complete control of the brain a great challenge6. Neuromodulation and neurostimulation techniques are primarily used to modulate brain activity, treat certain neurological disorders or improve certain cognitive functions, but these techniques do not allow for full control of all brain functions. The uncontrollable nature of the brain further emphasizes the importance of optimizing EEG signal acquisition devices to ensure the best possible signal quality and device reliability with the current state of the art7.

As BCI technology continues to advance, the development of dry electrodes and wireless integrated acquisition systems is driving a new generation of wearable, mobile electroencephalography (EEG) devices. In recent years, researchers have made significant progress in dry electrode thin-film technology8. First, dry electrodes do not require conductive adhesive, which greatly simplifies the process of using the device and enhances the user’s wearing experience. Second, the flexibility and thinness of the dry electrode film enables it to closely fit a scalp, improving signal stability and quality. Moreover, the sensors are integrated into the electronic film, and these sensors are distributed around the electrode array or at the gap to avoid affecting electrode signal acquisition9. This feature not only enhances the accuracy of signal acquisition but also reduces the discomfort and wearing pressure that may be associated with traditional electrodes.

When a dry electrode film is integrated into the injection molding process, it is critical to ensure the reliability of the wiring connections in the electronic film and the accuracy of the signal transmission10,11. The wiring within the electronic film is responsible for transmitting EEG signals, so any small displacement of nodes or change in volume shrinkage can result in signal distortion or interruption of transmission, which in turn can affect the overall performance of the device. During the injection molding process, nodes within the electronic film may be displaced due to material flow and mold pressure. Ensuring precise alignment of node locations is critical to maintaining the integrity and stability of the signal path. Research needs to develop rigorous process control programs to minimize node displacement and ensure the functional integrity of the circuitry. Volumetric shrinkage of materials during injection molding is an unavoidable phenomenon. Changes in volumetric shrinkage may lead to deformation of an electronic film or breakage of a circuit, affecting the reliability of signal transmission. By selecting suitable materials and optimizing injection parameters, volume shrinkage can be effectively controlled to ensure the dimensional accuracy and shape stability of electronic films.

In the manufacturing process of BCI, the node displacement refers to the node displacement caused by the uneven surface of the plastic parts due to improper parameter setting during the injection molding process of the IME electronic film. This displacement will directly affect the final performance and signal quality of BCI equipment. It is important to note that node displacement usually occurs during helmet manufacturing. After the BCI is made, there is no displacement between the electrode, coil and helmet. Therefore, any displacement caused by manufacturing errors will be fixed during the helmet manufacturing process.

The nodal displacement of IME films needs to be refined, as it affects the overall device performance and signal quality. Optimizing these shifts reduces manufacturing errors, improves device consistency and reliability, and ensures the accuracy and stability of the EEG signals received from the electrodes.

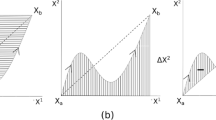

As shown in Fig. 2, for all IME injection molded products, the displacement of the IME film may be caused by improper parameter setting or uneven surface of the plastic parts during injection molding. The graph represents the direction and shape of the node displacement through curves. The node displacement that occurs may be greater or less than the original value, affecting the overall performance. Node displacement refers to the displacement of the IME film relative to its initial position during injection molding, which can occur in multiple directions.

To achieve the above objectives, in this paper, the LHS and MSDE algorithms are used for multiobjective optimization. LHS is an efficient sample generation method that can uniformly distribute sample points in multidimensional space to ensure comprehensive coverage of the parameter space and to improve the efficiency and accuracy of the optimization process. MSDE is a global optimization method based on evolutionary computation. The differential evolutionary (DE) algorithm searches for the optimal solution in the solution space by means of population evolution and a differential variation strategy. MSDE shows high optimization efficiency and robustness when dealing with complex multiobjective optimization problems and can efficiently find the optimal parameter combinations to satisfy multiple performance metrics. In this paper, we discuss the design principle and fabrication process of this technology in detail and its practical application in EEG signal acquisition, providing theoretical and technical support for the development of a new generation of wearable and mobile BCIs.

After injection molding is complete, the electronic film covers the surface of the line, providing an additional layer of protection. Due to the electronic film, friction between the scalp and the device, as well as the user’s head movements (e.g., head bobbing), will not cause displacement or damage to the line. The flexibility and durability of the electronic film not only enhances the comfort and longevity of the device but also ensures the stability and accuracy of signal transmission.

In summary, this study aims to ensure the high quality and reliability of electronic thin-film EEG signal acquisition devices by multiobjective optimization of parameters in the injection molding process through LHS and MSDE. In this paper, we discuss in detail the design principle, manufacturing process of this technology and its practical application in EEG signal acquisition. This provides theoretical and technical support for the development of a new generation of wearable and mobile EEG devices.

Literature review

Research progress in brain–computer interface technology

With the continuous advancement of technology, brain–computer interfaces have gradually become a field of great interest, especially with the emergence of computer graphics and artificial intelligence. Brain–computer interface (BCI) and neurostimulation technologies have made remarkable progress in neuroscience and clinical applications.

In 2012, Nicolas-Alonso et al.12 discussed the different electrophysiological control signals that determine user intent and can be detected in brain activity. First, some techniques for dealing with artifacts in control signals and improving performance are presented in the signal enhancement step. Second, a number of mathematical algorithms used in the feature extraction and classification steps, which convert information from control signals into commands to operate a computer or other device, are examined. Finally, an overview of the various BCI applications that control a range of devices is given.

In 2012, Hanson et al.13 described the design of a high-side digital current-controlled bipolar microstimulator and the in vivo validation of the device. Electrical stimulation of nerve tissue is widely used as a tool in experimental neuroscience research and as a method for restoring neurological function in patients with sensory and motor disorders. In the central nervous system, intracortical microstimulation (ICMS) has been shown to be an effective way of inducing or modulating sensory perception, including vision and touch. ICMS also holds promise for brain–computer–brain interfaces (bmbi) by writing information directly into the brain.

In 2017, Jun et al.14 designed, built and tested a new type of silicon probe, called a neural pixel, to meet this demand. The voltage signal is filtered, amplified, multiplexed and digitized, allowing noiseless digital data to be transmitted directly from the probe. The fully integrated functionality and small size of the neural pixel probes allow the recording of a large number of neurons from multiple brain structures in freely moving animals. This combination of high-performance electrode technology and scalable chip fabrication methods facilitates recording neural activity throughout the brain during a specific behavior.

In 2017, Yeon et al.15 presented a feasibility study of wireless power and data transmission via inductive links to a 1 sq mm implant used as a free-floating neural probe distributed over areas of interest in the brain. The proposed structure uses a four-coil induction link for backward telemetry, which is shared with a three-coil link for wireless power transmission. A geometric optimization design method for an induction link based on the power transfer efficiency (PTE) is proposed, accounting for the specific absorption rate and the data rate. An active data transmission circuit based on low-power pulses is designed, and the performance of the proposed induction link is characterized in terms of the data rate and bit error rate.

In 2021, Zhou et al.16 reviewed flexible thin-film devices, which can be divided into the following four categories: plane layout, open network layout, probe layout and microwire layout. The preparation methods are also introduced. Traditional lithography and the most advanced processing methods are discussed for the key problem of high resolution. For special substrates and interconnects, different materials and manufacturing processes are also emphasized. Finally, obstacles and directions for future research are discussed.

In 2021, Sun et al.17 proposed an improved eddy current sensor drive circuit. To generate a stable oscillator source with high stability and good frequency accuracy, a quartz oscillator circuit with a power boost is used instead of the traditional Kolpitz oscillator circuit. The experimental results show that the designed eddy current sensor has good linearity (1.12%) and sensitivity (2.14 V/mm), which can ensure stable operation of the magnetic levitation turbomolecular pump at the rated speed.

In 2021, Hramov et al.18 discussed the main results of the development and application of BCIs based on invasive and noninvasive EEG recordings. The new technological trend in the development of brain interfaces, namely, the use of neural interfaces to enhance human interaction, known as brain-to-brain interfaces (BBIs), is also discussed.

In 2022, Song et al.19 presented an implantable pulsed UWB wireless telemetry system for neural sensing interfaces in the cortex. Three-dimensional hybrid pulse modulation is proposed, which consists of phase shift keying (PSK), pulse position modulation (PPM), and pulse amplitude modulation (PAM).

In 2022, Pei et al.20 developed a Pregel electrode with a short installation time and good comfort for EEG acquisition. A hydrogel probe is preplaced on the Ag/AgCl electrodes prior to wearing the EEG headband rather than undergoing a time-consuming gel injection after wearing the headband.

In 2022, Yao et al.21 developed a Pregel electrode with a short application time and good comfort for EEG recording. A hydrogel probe is pre-applied to the Ag/AgCl electrodes before the EEG headband is put on instead of a time-consuming gel injection after the headband is put on.

In 2023, Liu et al.22 reviewed the preparation of nanomaterial-based MEAs for bidirectional in vitro BCIs from a multidisciplinary perspective. These researchers also considered the decoding and encoding of neural activity through the interface and highlighted the various uses of MEAs in combination with isolated neural cultures to benefit the future development of BCIs.

In summary, brain–computer interfaces and neurostimulation technologies have made significant progress in detection, signal processing, neural recording and wireless transmission. These studies have not only enriched our understanding of brain function but also provided strong technical support for neuroscience research and clinical applications. From enhancing electrophysiological signals to high-performance neural recording to wireless transmission and the application of flexible devices, a series of innovative technologies are driving the field of brain–computer interfaces forward. The collection of brain signals can be divided into invasive and noninvasive methods. In this paper, we use noninvasive methods to realize brain–computer interactions through IME in-mold electronic decoration technology, in which electrode films were combined to realize interface fabrication. The collected signals are feature extracted and classified and recognized using MEAs to increase the accuracy of signal collection and extraction from the brain–computer interface.

Research progress of electronic thin films

In recent years, there has been significant progress in electronic thin-film technology in a number of high-tech applications. Electronic thin films, especially those with integrated microelectrodes and sensors, have become an important means of realizing highly sensitive and accurate signal acquisition. Their ability to provide excellent mechanical strength and chemical stability, as well as good adhesion and waterproofing properties, makes them promising for a wide range of applications in medical, industrial and consumer electronics.

In 2014, Fukuda et al.23 reported fully printed organic thin-film transistor devices and circuits fabricated on 1-mm-thick polystyrene-c films with high field-effect mobility and fast operation (~1 ms) at low operating voltages. These devices are also very lightweight and exhibit excellent mechanical stability. Even at 50% compressive strain, the devices remain operational with no significant change in performance.

In 2016, Petti et al.24 presented the implementation of large-area digital circuits such as flexible near-field communication tags and analog integrated circuits such as bendable operational amplifiers. These include foldable displays, power transmission elements and integrated systems for large-area sensing and data storage and transmission.

In 2017, Mohammed et al.25 demonstrated a fully automated printing process for flexible and stretchable electronics based on liquid metals. The printing process allows for the production of liquid metal-based sensors, and in addition, this printing process can produce complex conductive patterns that were not possible with previous nonautomated manufacturing methods.

In 2018, Wen26 prepared a transparent and stretchable wrinkled poly(3,4-ethylenedioxythiophene):poly(4-styrenesulfonate) (PEDOT:PSS) electrode-based TENG (WP-TENG) for use in human motion monitoring sensors.

In 2023, Zheng et al.27 fabricated flexible transient circuits for human-computer interactions by printing liquid metal conductors on water-soluble electrospun silk films. Due to the inherent liquid conductor within the porous substrate, the circuits offer high resolution, custom pattern feasibility, attractive magnetic permeability, excellent conductivity, and superior mechanical stability.

Although these studies show that electronic thin films have great potential in terms of mechanical stability, flexibility, and conductive properties, optimizing the displacement of the nodes of electronic thin films remains a key issue in practical applications. The micrometer-scale lines of electrodes and sensors in thin films are susceptible to stress and deformation during fabrication and use, which in turn affects the accuracy of signal transmission and the overall performance of the device. Therefore, it is necessary to further study and optimize the displacement of these nodes to improve the reliability and stability of electronic thin films in complex application environments.

Research progress on optimization methods

Multiobjective optimization techniques are widely used for the optimal design and performance improvement of various complex systems. This paper reviews the multiobjective optimization methods applied in the fields of injection molding and BCI in recent years, especially the application of LHS and MSDE in these fields.

In 2013, Roshanian et al.28 adopted the Latin hypercube sampling (LHS) method and assumed that the uncertain variables were normally distributed; this method was used to select the sample values of the simulation run and finally to compute the probability density function and reliability of the constraint at each design point. Sequential quadratic programming (SQP) was used to determine the optimal solution.

In 2016, Maschio et al.29 described a new probabilistic history-matching iterative process hypercube (DLHC) sampling method with nonparametric density estimation using discrete Latin. The iterative process selects a set of models based on the quality of the historical fit (normalized disfit) to generate the histogram. The histogram is smoothed and used to estimate the marginal probability density of reservoir attributes.

In 2023, Chang et al.30 proposed applying the Latin hypercube sampling method and combining the response surface model with the constraint generation inverse design network (CGIDN) to achieve multiobjective optimization of the injection process, shorten the time needed to find the optimal process parameters, and improve the production efficiency of plastic parts.

In 2015, Raza et al.31 proposed a covariate offset detection and adaptation method and applied it to a BCI based on moving images. Covariate offset detection tests based on exponentially weighted moving average models are used to detect covariate offsets in features extracted from brain responses based on moving images. After the covariate offset detection test, the method initiates adaptivity by updating the classifier during the test/operation phase. The effectiveness of the proposed approach was evaluated using real BCI datasets, namely, the BCI Competition IV datasets 2A and 2B.

In 2018, Navid et al.32 studied the Nelder‒Mead algorithm for diesel engine optimization, and the Sobol sequence and Latin hypercube sampling method for initial point distribution. The Nelder‒Mead algorithm is a non-evolutionary algorithm that requires some initial points to start the optimization process to understand the relationship between the input parameters and the output objective functions. In this study, these points were generated from Sobol sequences and Latin Hypercube sequences to compare the two types of sequences and to study the effect of the sequences on the results.

In 2020, Zhao et al.33 proposed a new optimization strategy for the injection molding process, which transforms the problem of parameter optimization into a weight classification problem. Injection-molded parts are produced under different parameters and marked as positive or negative compared to the standard weight, and weight errors are calculated for each sample. A classification hyperplane with zero weight error is constructed using a support vector classifier (SVC). Particle swarm optimization (PSO) was used to adjust the hyperparameters of the SVC model to reduce the error between the SVC prediction results and the experimental results.

In 2020, Hao et al.34 proposed a linear population size reduction adaptive differential evolution optimization algorithm (MSDE) based on a multistrategy success history. The proposed MSDE is superior to the existing algorithms in terms of accuracy, reliability and time consumption. The experimental results and analysis show that the MLSHADE algorithm is highly competitive in terms of accuracy and reliability.

In 2021, Niu et al.35 proposed a new hybrid gravity search algorithm. The method uses the gravity search algorithm as a unified framework. The neighborhood search strategy is used to consider social information and individual experience to improve the convergence speed. An adaptive mutation strategy was adopted to improve population diversity through elite preservation and mutation operators. The improved elastic sphere strategy and constraint processing technique are used to improve the feasibility of solving the problem. The simulation results of the numerical functions demonstrate the proposed method.

In 2021, Peng et al.36 proposed a new differential evolution algorithm, namely, multistrategy coevolutionary differential evolution (MSDE). In MVOPs, a mixed-variable coevolution scheme is adopted, which considers both continuous and discrete variables. Based on this, a multistrategy coevolution method is proposed that considers a dynamic adaptive selection mechanism and combines different feature mutation strategies and crossover operators to adapt to all-inclusive MVOPs. In addition, to improve the efficiency and flexibility of MSDE, a statistics-based local search (SBA) is proposed for discrete-variable optimization in MVOPs.

In 2022, Chang et al.37 adopted the Pareto method to optimize the frame and injection molding process parameters to carry out multiobjective optimization of unmanned aerial vehicle (UAV) shell parts. The kriging function predicts the mathematical relationship among the die index and warp value and process parameters. Using LHD sampling and NSGA-II, a convergence curve of warp values is found near the Pareto optimal bound.

By reviewing the multiobjective optimization techniques in the field of injection molding and brain–computer interfaces in recent years, it can be seen that Latin hypercube sampling and multistrategy differential evolution algorithms have significant advantages in improving system performance and optimizing design. These studies not only provide effective methods and tools for multiobjective optimization of complex systems but also lay a solid foundation for future research and application.

Therefore, this paper proposes to investigate the node displacement of BCIs, which mainly focuses on optimizing the injection parameters to achieve the minimum change in node displacement to increase the accuracy of EEG signal transmission. Table 1 summarizes the reviewed literature by listing the individual articles on the study of node displacement in the brain–computer interface. In this paper, the importance of coil displacement is mainly studied. Previous studies1,4,14 have mentioned that the overall framework structure of the brain–computer interface and node displacement affect the accuracy of the signal1. The optimization method is mentioned in14 but is insufficient; therefore, this paper builds upon the above to further optimize using the LHS and MSDE methods.

In BCI-printed circuits, the thickness of the lines in the electronic film is usually at the micrometer level. This is because micron-level lines provide higher sensitivity and better spatial resolution for capturing and detecting EEG signals. In general, the width of the coils in a brain–computer interface is usually between a few microns and a few tens of microns. Optimizing nodal displacement and volume shrinkage is therefore particularly important for ensuring the quality of the electronic film. Since the line connections in electronic films experience thermal and mechanical stresses during the injection molding process, any undue node displacement or volume shrinkage can affect the accuracy of signal transmission. By optimizing these parameters, signal distortion and data errors due to inaccuracies in the manufacturing process can be reduced, thereby improving the overall performance and reliability of the BCI system.

Voltage detection is a key aspect in regard to the quality of BCI electronic films. According to a review of the literature, the multistrategy differential evolutionary algorithm has advantages over the NSGA-II in terms of efficiency and robustness. Furthermore, when dealing with complex problems in the injection molding process of the brain–computer interface, it can avoid local optimal solutions due to the irrationality of the parameters. According to the multistrategy approach of many researchers, to solve the problems of the traditional differential evolution algorithm, in this paper, mainly the multistrategy differential evolution algorithm is mainly utilized to find the optimal parameter combinations for the BCI.

In summary, many scholars have carried out many studies on the preparation of BCIs. According to the realization process of brain–computer interfaces, these interfaces are proposed by using in-mold electronic decoration technology, which sandwiches printed circuits between films to form an integrated organizational structure, avoiding problems such as shifting and instability of the electronic film nodes.

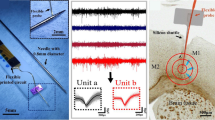

As shown in Fig. 3, for the realization of BCIs, an innovative scheme is proposed to fabricate BCIs using in-mold electron decoration technology. Molecular sensor technology is introduced to monitor the minute displacements of nodes. The relationships between the injection molding parameters (melting temperature, holding pressure, and holding time) and the target parameters (node displacement and volume shrinkage) are thoroughly explored using LHS technology. By finding the optimal combination of parameters, the performance and reliability of the BCI are successfully improved. An improved multistrategy differential evolutionary algorithm is used to optimize the injection parameters, and the effectiveness of the optimized parameter combinations is verified via simulation.

Materials and methods

The selection of materials is carried out first. In 2015, Deng et al.38 grew large-area graphene films on copper foil by using an R2R chemical vapor deposition process. These films were thermally laminated onto nanowire precoated ethylene vinyl acetate copolymer (EVA)/ethylene terephthalate (PET) films. The copper foil was preserved for reuse by R2R electrochemical layering. The packaging structure minimizes the wire-to-wire resistance and graphene grain boundary resistance and enhances the adhesion of nanowires and graphene to the plastic substrate, resulting in excellent photoelectric performance, corrosion resistance and mechanical flexibility. In 2010, Junxia et al. introduced a new process for the recycling of EVA and PET composite plastic films by improving the traditional floatation and sinking process to realize the continuous production of plastic separation and recycling.

To ensure that the BCI is comfortable and reliable, electrodes can be fabricated using PET plus surface EVA polymers. The PET film provides good mechanical strength and chemical stability, while the EVA polymers provide good adhesion and water resistance.

Therefore, PET and EVA were finally selected as the materials for the electronic film. The PET film was chosen for its good mechanical strength and chemical stability, which can effectively protect the internal circuits from external shocks and chemical corrosion. The EVA polymer material, on the other hand, provides excellent adhesion and water resistance to ensure the stability and reliability of the electronic film under different environmental conditions.

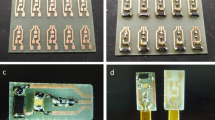

First, lines are printed on the PET film to create electrode connections. Minute electrode patterns are precisely formed on the surface of the PET film to ensure that the electrodes are aligned and connected as designed. In addition, the mechanical strength and chemical stability of the PET film make it an ideal substrate material for holding and protecting microelectrode arrays. Next, the PET film is coated with a layer of EVA polymer, which has excellent adhesion properties, adheres firmly to the PET film, and provides good water resistance to protect the electrodes from moisture and liquids. The flexibility of EVA also improves the overall flexibility of the electronic film, making it more suitable for use in head-worn devices. The prepared electronic film is then processed using injection molding electronics (IME) technology, which combines the electronic film with the injection molding material to form an integrated structure.

Liquid silicone rubber (LSR) was chosen as the injection molding material to ensure a comfortable wearing experience. LSR is a soft and flexible material that provides a good wearing experience, and its biocompatibility and durability make it an ideal material for head-worn devices39.

It can be seen that the EVA and PET polymer materials have good adhesion. In this paper, an EVA film layer is applied to the surface of a PET shell using in-mold electronic decoration technology to improve the safety and stability of a BCI. The IME membrane has good electrical properties and high transparency and can achieve efficient stimulation and monitoring of nerve tissue. Figure 3 shows the PVT diagram of the PET and EVA materials used in this work.

A pressure‒volume‒temperature (PVT) diagram is a diagram that describes the behavior of a material under different pressure, volume and temperature conditions. Specifically, the PVT diagram contains the following information: pressure (P), volume (V), and temperature (T).

As shown in Fig. 4, the PET material has good chemical stability and mechanical strength to protect the electrode array and prevent signal loss. At the same time, the EVA polymer material can fill the gap between the electrodes, improving the efficiency of signal transmission.

Second, the use of PET and EVA materials can effectively prevent the electrode array from being disturbed and damaged by the external environment and reduce artifacts caused by mechanical motion, thus improving the reliability of the BCI.

Finally, the use of IME technology to produce electrode arrays can realize high-precision and efficient manufacturing. Moreover, PET and EVA materials are also easy to process and manufacture, making the entire production process simpler and more controllable.

Latin hypercube sampling (LHS)

LHS is a statistical method for generating quasi-random parameter values from multidimensional distributions in programming that is designed to create a fair distribution between input variables to reduce the number of iterations during computational fluid dynamics (CFD) simulations. The key to the Latin hypercube method is the proper stratification of the probability distribution of the input parameters. This stratification divides the cumulative curve into equal partitions from 0 to 1.0, which is the range of the probability scale. A sample is then taken from each stratum or interval of the input distribution. The Latin hypercube sampling technique involves sampling without substitution. In a sense, the number of layers performed by the sequence is equal to the number of iterations performed on the selected sample. For example, for an input distribution with five levels, there would be five iterations. In this sampling method, another important key is to maintain independence between variables. This independence is achieved by randomly selecting input parameters in the distribution and as variables from an interval that will never be used in the future. This method avoids unnecessary correlations between parameters.

They are random sampling points on the interval [0,1]. It is obvious that for each dimension k = 1…N, only one point falls in the interval (i − 1)/N and i/N, i = 1…N. Of course, this stratification is established by superimposing layered samples on one dimension and is not expected to provide good uniformity in dimension.

The parameters in the injection molding process were considered to be coordinates in multidimensional space by the Latin hypercube sampling method. Several sampling points were selected as parameter combinations by using this sampling method, and then a mold flow simulation was performed to obtain corresponding product quality indicators, such as size, shape, and surface finish. By analyzing the experimental data, the optimal injection molding parameter combination was determined to achieve the best product quality and production efficiency. In addition, the Latin hypercube sampling method can also be used to analyze and optimize the uncertain factors in the injection molding process, such as batch differences in the raw materials, ambient temperature and other factors, thereby improving the stability and reliability of the manufacturing process. When using this method for parameter optimization, it is necessary to select the appropriate number of sampling points and distribution mode to ensure the representativeness and reliability of the obtained parameter combination. At the same time, different sampling point settings and experimental designs may be required for different injection products and requirements.

Multistrategy differential evolution algorithm (MSDE)

When the differential evolution algorithm solves complex optimization problems, it needs to consider how to ensure the global search ability and convergence of the algorithm, but the variational strategy of the classical differential evolution algorithm has obvious characteristics and shortcomings. Therefore, in this section, to improve the convergence of the algorithm and maintain the diversity of the population, three adjustment strategies are adopted, and a multistrategy differential evolution algorithm is designed by combining the elite sharing strategy, the perturbation back-solving strategy and the adaptive adjustment strategy.

Elite sharing strategy

The existing differential evolution algorithm uses the information of the current optimal individual and the possible direction of descent to design the differential mutation operator. However, this mutation operator weakens individual diversity by producing all offspring with the genetic fragments of the optimal individual. Therefore, to maintain the diversity of the population, the population is divided into several subgroups by the clustering algorithm so that the optimal individuals of the subgroups can participate in the variation process of other subgroups, thus realizing the genetic interaction among the subgroups and slowing the crisis of rapid reduction in individual genetic diversity. The specific process is as follows:

First, the k-means clustering method is used to divide the population into s subgroups, denoted as \({X}_{k}^{G}=\left\{{X}_{k1}^{G},{X}_{k2}^{G},\cdots {X}_{km}^{G}\right\}\), where \({k}_{m}\) represents the size of the Kth subgroup k = 1,2,5. Then, the optimal individuals in each subgroup are selected to form the candidate solution set \(\left\{{X}_{b1}^{G},{X}_{b2}^{G},\cdots {X}_{bm}^{G}\right\}\). Finally, \({X}_{bi}^{G}\) is used to generate the offspring individuals of subgroup \({X}_{j}^{G}\), i.e.,

where \(i\ne j\) and \({X}_{kr}^{G},{X}_{ks}^{G}\in {X}_{j}^{G}\). Notably, too small a scale to generate subpopulations using clustering may cause the above mutation operation to fail. Therefore, when the size of the subgroup is less than 3, this type of subgroup is randomly merged into other subgroups.

The K-means algorithm is a clustering analysis algorithm based on the principle of distance and proximity and is solved by multiple iterations. The main steps are as follows: First, K objects are randomly generated as the initial clustering center; second, the distance between each object and K objects is calculated, and each object is assigned to the nearest clustering center according to the distance value. Finally, the group is formed.

Perturbation reverse solution strategy

When differential evolution (DE) is used to solve complex multimodal optimization problems, it is difficult for the population to be uniformly distributed in the high-dimensional decision space, so the algorithm often stagnates due to the rapid decline in population diversity during the process of evolution. To avoid such problems, DE searches the decision space as widely as possible in the early stages of evolution to maintain population diversity. The algorithm in this section uses the reverse solution technique for poorly performing individuals rather than population initialization and therefore has a better effect on maintaining individual diversity throughout the evolutionary process. However, it should be noted that this method may have a symmetry problem due to the reverse solution, resulting in a higher gene repetition rate or similarity rate of individual offspring. To avoid the above problems, the random perturbation technique is combined with the inverse solution to perform a random perturbation on the inverse solution.

Let \(x=\left({x}_{1},{x}_{2},\cdots {x}_{D}\right)\), where D is the dimension of the decision variable, and the reverse solution is defined as follows:

where \({x}_{j}^{U}\) and \({x}_{j}^{L}\) represent the upper and lower limits of component \({x}_{j}\), respectively.

Notably, \({\widehat{x}}_{j}\) and \({x}_{j}\) are symmetric with respect to the center of the interval \(\left[{x}_{j}^{L},{x}_{j}^{U}\right]\). If x is near the center point, then there may be too many redundant points in the process, which reduces the ability of the algorithm to explore new regions. To overcome this shortcoming, the following perturbation reverse solution is established as follows:

Clearly, the above equation can produce different solutions even if there are the same individuals in the population.

Adaptive adjustment strategy

The appropriate setting of parameters in the differential evolution algorithm can improve the performance of the algorithm. To obtain satisfactory algorithm performance, one of the factors to be considered is whether there is a significant difference between the fitness values of the parent individual and the offspring individual. In addition, the probability of the parent being selected as the next generation individual and the a priori success parameter values contain potentially useful information and are therefore considered in the parameter setting process of the algorithm. Based on the above considerations, a simple and effective nonparametric hypothesis test is used to propose an adaptive parameter adjustment strategy. The specific procedure is described as follows:

First,, assume we have hypothesis \({H}_{0}\): there is no significant difference between the fitness values of the parent individual and the offspring individual. Then, we have the opposite hypothesis \({H}_{1}\): there is a significant difference between the fitness values of the parent individual and the offspring individual.

Second, for a given significance level, the Wilcoxon signed rank test was used to test whether the original hypothesis \({H}_{0}\) was valid.

Then, the probability of the parent individual being selected as the next generation individual is calculated, denoted as p;

Finally, the Wilcoxon signed rank test results and probability value p were used to design the relevant parameter values F and CR, i.e.,

In the above equation, \(\delta \) represents the increase or decrease step size of the related parameters. Clearly, \(\delta \) should increase with decreasing evolutionary algebra, that is,

\(\delta =\frac{0.1}{{e}^{\tau \left(\frac{G}{{G}_{max}}\right)-\beta }}\)

-

1.

If the original hypothesis H is rejected, then there is a significant difference between the goal value of the generation individual and the goal value of the offspring individual, and the probability value meets \(p<0.5\). This indicates that there is a high possibility of producing high-quality offspring individuals, which means that the current parameter is valid. Therefore, the values of the variation factor F and crossover probability value CR should increase in the next generation of evolution.

-

2.

If the probability value of the original hypothesis \({H}_{0}\) meets \(p>0.5\), then there is a significant difference between the goal value of the parent individual and the goal value of the offspring individual; however, the offspring individuals produced are poor. Therefore, the values of related parameters should be reduced in the evolution process of the next generation.

-

3.

If the original hypothesis \({H}_{0}\) is accepted, then the algorithm search tends to be stable, and the original parameters remain unchanged. Finally, considering the range of empirical values of parameters, if they exceed this range, then the parameter values are modified by the following rules:

$$ \left\{ {\begin{array}{*{20}c} {F^{{G + 1}} = 1.2,} & {if\,F^{{G + 1}} \ge 1.2} \\ {F^{{G + 1}} = 0.2,} & {if\,F^{{G + 1}} \le 0.2} \\ \end{array} } \right. $$$$ \left\{ {\begin{array}{*{20}c} {CR^{{G + 1}} = 1} & {if\,CR^{{G + 1}} \ge 1} \\ {CR^{{G + 1}} = 0,} & {if\,CR^{{G + 1}} \le 0} \\ \end{array} } \right. $$

In the proposed algorithm, several subpopulations are generated by the K-means clustering method. Elite individuals are selected from the subpopulation to participate in the mutation process of other subpopulations, and the elite sharing strategy is applied to produce offspring. It is expected that better individuals will be found through gene recombination so that high-quality gene fragments can be transferred to individuals in another subpopulation and interactions between genes can be realized. At the same time, the value of the variation factor F and the crossover probability CR are important factors affecting the performance of the differential evolution algorithm, and whether there is a significant difference between the individual target value of the parent and the offspring has a certain influence on the parameter setting. The Wilcoxon signed rank test with the nonparametric hypothesis can be used to assess whether there is a significant difference between the parent and offspring targets. Therefore, it is effective to use the results of the Wilcoxon signed rank test to design adaptive fitting parameters. Furthermore, the reverse perturbation strategy is applied to individuals with poor fitness in the early stage of evolution to improve the search ability of the algorithm. The differential evolution algorithm based on the reverse perturbation strategy, elite sharing strategy and adaptive adjustment strategy is referred to as SOSESDE.

The MSDE algorithm is a common optimization algorithm that searches for the best solution through a variety of different strategies. In this application, the algorithm must first define the objective function and the parameter space of the optimization problem. Then, an initial set of individuals is generated based on different strategies, and these individuals are evaluated and selected according to the objective function. Next, the individuals are updated and evolved according to the strategies using differential evolution algorithms. In each generation of evolution, the best individuals are selected, and new individuals are generated according to different strategies. This process is repeated until the stopping condition is met or the maximum evolutionary algebra is reached.

The MSDE algorithm can play an important role in the optimization of injection molding BCIs by means of the elite sharing strategy, the perturbation reverse solution strategy and the adaptive adaptation strategy. It improves the search ability and optimization effect by increasing the diversity of the search space, preserving excellent solutions, and flexibly adjusting the strategy weight.

Among them, the elite sharing strategy is a core multistrategy differential evolution algorithm. It maintains excellent individuals in the population by preserving the best solution in each generation and using it as a reference object for cross-variation by other individuals in the population. The purpose of this method is to prevent the algorithm from falling into the local optimum prematurely and to speed up the convergence to the global optimum.

In addition, the perturbation backtracking strategy is also an important part of the multistrategy differential evolution algorithm. In this strategy, the solution vector is randomly perturbed and updated toward smaller objective function values. This approach can effectively increase the exploration capacity of the search space and further improve the effect of optimization. The adaptive adjustment strategy is a key element of the multistrategy differential evolution algorithm. By adaptively adjusting the weight or probability distribution of different strategies, the algorithm can automatically adapt to different problem characteristics and optimization requirements during the search process. By dynamically adjusting the probability of using strategies, the algorithm can balance global search and local search to better cope with the complexity and diversity of problems.

Case study

Figure 5 shows a detailed map of human brain functions. The brain can be roughly divided into five functional areas, namely, the frontal lobe, parietal lobe, occipital lobe, temporal lobe and cerebellum. In this paper, the proposed BCI is mainly used to control behavior and speech. There are many nerves in the brain. When external information is transmitted, sensory neurons first receive this information and transmit it to appropriate regions in the cerebral cortex. When the information is processed and interpreted, it activates motor neurons, which trigger motor behavior. The brain controls behavior and language through coordination and communication between neurons. This control involves coordination and communication between several regions of the brain, including sensory, motor and language centers. Therefore, when designing a 3D model, we should try our best to cover each brain area with a coil circuit to improve the accuracy and reliability of information transmission.

The advantage of functional area electrode arrays is that more accurate signal separation and decoding can be achieved. By accurately recording activity in the target brain region, the accuracy and stability of the brain–computer interface (BCI) can be improved. This is important for enabling precise control and feedback of brain signals, such as motor control, speech production or external device operation. Thus, by placing electrodes according to functional areas of the brain, BCI systems can achieve greater reliability. Related studies have shown that placing electrodes in specific functional areas can improve signal specificity and selectivity, reduce interfering signals, and achieve more accurate decoding of brain signals. Based on the literature, the electrode distribution of a BCI is shown in Fig. 6. According to the distribution of brain functional areas, corresponding electrodes are placed within each functional area. Each electrode covers the control of the whole functional area, and the control of brain activity can be analyzed and judged through the corresponding electrode output signal. It is also possible to control the corresponding brain area through external signal transmission to realize the expected commands.

In this paper, a noninvasive head-mounted brain–computer interface is designed to cover all functional regions of the brain. First, the top of the helmet is covered with a layer of 0.300 mm of electronic film using PET as the substrate, and the electrode, which is usually made of conductive metal, is designed as a microelectrode array, which is placed in accordance with the electrode positions in Fig. 6e. This ensures that each electrode accurately captures the electrical signals of the corresponding brain region. Three-dimensional modeling is then performed to establish the structural features that conform to the human head, with the head circumference of 58 cm and the cranial top height of 10 cm, as shown in Fig. 6a–d. The injection molding process of the BCI is simulated using Moldex3D software.

As shown in Fig. 6e, which shows the distribution of brain electrodes according to the international standard 10–20 system, an all-inclusive brain–computer interface can provide a more comprehensive acquisition and analysis of EEG signals. The international standard 10–20 system is a commonly used electrode placement system for locating specific brain regions on the scalp. The system is based on a number of standard locations on the scalp, such as the prefrontal area (Fz), the superior area (Cz), and the occipital area (Pz), and the equidistant points between these locations40. With this system, using the top view shown in Fig. 5c, the electrodes are placed at locations that correspond to specific functional areas of the brain.

Noninvasive brain–computer interfaces are technologies that enable interactions between the human brain and a computer or other devices by detecting electrical signals on the surface of the scalp. Compared with traditional invasive brain–computer interfaces, noninvasive brain–computer interfaces do not require intracranial surgery, are easy to use, are low risk, and thus have great potential for application. In this paper, PET/EVA material is used as the electronic film, LSR material is used as the injection molding material, and molten plastic is injected into the mold through high pressure to form the desired product.

In the injection molding process of the brain–computer interface, it is necessary to ensure the accuracy of the collected signals, so the quality of the film surface must be high to prevent the node displacement of the lines in the film. Therefore, in this paper, the change in node displacement on the surface of the BCI as a function of volume shrinkage is investigated, as defects due to this phenomenon can greatly affect the quality and performance of the plastic parts. In the process of injection molding, many important injection parameters are usually involved, which have a great influence on the molding quality and efficiency of the product. The melting temperature has a great influence on the fluidity and physical properties of the material, and an appropriate melting temperature can ensure the fluidity of the material to improve its ability to fill the molds and improve the dimensional accuracy of the surface of the plastic parts as well as the finish of the surface. The holding pressure will directly affect the size of the plastic parts, mainly by controlling the two aspects of molding shrinkage and deformation, so in the injection molding of the brain machine interface, reasonable holding pressure control is needed. The injection pressure determines the speed of the material entering the mold and has an effect on the filling, cooling and shrinkage of the molded parts. If the injection pressure is too high and the speed is too fast, then insufficient filling may occur. If the injection pressure is too low and the speed is too slow, then the injection cycle, as well as the molding cycle, may be prolonged.

Latin hypercube sampling (LHS)

Latin hypercube sampling is a method of designing experiments suitable for multivariate variables to better explore the relationships between variables by sampling them uniformly. In BCI manufacturing, the parameter setting of the injection material has a great influence on the performance and stability of the BCI. Therefore, the optimization of injection parameters is an important research direction, and the best combination of injection parameters can be found by exploring the relationship between injection parameters and BCI performance. The Latin hypercube sampling method can help researchers to efficiently design experiments and collect data in the case of multiple variables.

In this paper, the Latin hypercube sampling method was used to determine the sample injection molding parameters, such as the melting temperature, holding pressure, and injection pressure, while the corresponding BCI performance indicators, such as surface node displacement and volume shrinkage, were recorded. By analyzing the sampled data, the relationship between injection molding parameters and BCI performance can be obtained, and the best combination of injection molding parameters can be found.

In this experiment, Latin hypercube sampling was used to sample 20 points on the surface of the BCI, as shown in Fig. 7. Twenty samples were randomly selected. The injection molding parameters, namely, the melting temperature (°C), pressure holding pressure (MPa) and injection pressure (MPa), were taken as experimental factors. The nodal displacement (mm) and volume shrinkage (%) of the BCI were selected as the optimization objectives. As shown in Table 2, 20 groups of sample data were obtained via Latin hypercube sampling. Compared with the DOE experimental design method, LHS allows parameters of different dimensions to interact with each other so that the interaction relationship between parameters can be fully explored.

Among the 20 groups of sample data obtained by Latin hypercube sampling, the displacement and volume shrinkage of the 14th node reach a maximum of 0.792 mm and 9.566%, respectively. At this time, the node displacement will greatly affect the stability of signal transmission and reception. The displacement and volume shrinkage of the fifth node both reach a minimum of 0.470 mm and 9.533%, respectively, which is more conducive to ensuring the reliability of signal transmission and reception.

For the 23 electrode positions, considering that there are linear connections between electrodes in the membrane, in this experiment, we randomly sampled 20 points on the surface of the BCI, as shown in Figs. 8 and 9, representing the node displacement distribution of the BCI. The bar chart shows the node displacement distribution of the entire BCI, thus more directly reflecting the performance of the system under different parameter Settings.

As shown in Figs. 8 and 9, the top figure represents the result value of 20 data samples obtained from Latin hypercube sampling, while the bar figure represents the distribution of node displacement and volume shrinkage respectively. We divided the change range of node displacement and volume shrinkage in the whole BCI in the process of injection molding into 10 parts and calculated their distribution proportions. The results show that the maximum distribution of node displacement is 13.67% in the range of 0.553–0.593 mm. The volume shrinkage rate is most distributed in the range of 10.149–10.580 MPa, reaching 47.10%. The experimental data show that the average coil displacement is 0.585 mm when the initial parameter holding pressure is 300 MPa, the holding time is 20 s and the melting temperature is 250 °C. The volume shrinkage was 9.992%.

BCIs often require precise electrical signal control to achieve stimulation and response of the human nervous system. Therefore, compared to the volume shrinkage rate, optimizing the node displacement can more precisely control the transmission of electrical signals and excite the target neural tissue, thus improving the functional performance of the BCI. Therefore, in this study, we optimized the coil node displacement.

Multistrategy differential evolution algorithm

BCIs have attracted much attention as direct communication channels between the human brain and external devices. These interfaces have great potential to improve the quality of life for people with movement disorders or disabilities. However, the success of BCIs depends on the precise manufacture of the interface components, in particular, the injection molding process. Injection parameters such as injection speed, temperature, pressure and mold design play a crucial role in determining the quality and function of BCIs. Therefore, the optimization of these parameters is critical. In this section, an MSDE algorithm is introduced to optimize the injection parameters of BCIs.

During each iteration, the MSDE algorithm adjusts the injection speed, temperature, pressure and mold design parameters based on the fitness evaluation of the candidate solutions. The fitness function is designed to improve the overall performance and reliability of BCIs by considering important factors such as fill quality, defect reduction and uniformity of material distribution. Figure 10 shows the flowchart of the multistrategy difference algorithm.

The algorithm flow of MSDE

-

1.

Define the problem Set the optimization objective of the node displacement, and consider the holding time, holding pressure and melting temperature as the optimized parameters. Additionally, set the minimization direction of the node displacement.

-

2.

Initialize the population Generate the initial parameter combinations as the population, and calculate the node displacements corresponding to each parameter combination.

-

3.

Elite distribution strategy Select a subset of individuals with high fitness as the elite, and share their information with the whole population. A competitive selection strategy can be used to select individuals with higher fitness as elites and crossbreed and mutate their parameter combinations with other individuals.

-

4.

Perturbation reverse splicing strategy Perturbation factors are introduced to increase the search range and diversity of the algorithm. Random perturbations are introduced into the variational operation of individuals by, for example, adding random perturbations to the holding time, holding pressure and melting temperature to change the parameter values.

-

5.

Adaptive adjustment strategy Adaptively adjust the parameters of the algorithm according to the current search state of the population. For example, the crossover rate and variation rate can be dynamically adjusted according to the change in population fitness to balance exploration and exploitation capabilities.

-

6.

Iterative repetition The population is iteratively updated by crossover, variation and selection operations until a stopping condition is reached. The stopping condition can be when a predefined maximum number of iterations is reached or when the average or optimal fitness of the population reaches a predefined threshold. At each iteration, a selection operation is performed based on fitness, and new individuals are generated via crossover and mutation operations.

-

7.

Output results The parameter combinations of the optimal individuals, i.e., the optimal holding time, holding pressure and melting temperature settings, are recorded during the iteration. These parameters are used for the injection molding process of the BCI to optimize the node displacement.

As shown in Fig. 11, using the above multi-strategy differential evolution algorithm, the above 20 nodes can be compared with the results under the initial value, and the optimization is greater. The average node displacement of the specific BCI surface can reach 0.027 mm, which is compared with the initial node displacement of 0.585 mm, and the optimization rate is 95.38%.

As shown in Table 3, the optimal parameters for BCI injection molding were obtained by the multistrategy differential evolution algorithm; namely, the injection pressure was 400 MPa, the pressure holding pressure was 400 MPa, the pressure holding time was 250 s, the melting temperature was 160 °C, the mold temperature was 30 °C, and the cooling time was 30 s. The average nodal displacement of the surface reached 0.027 mm. The volume shrinkage reached 0.853%. Compared with the results before optimization, the node displacement is 0.585 mm, the volume shrinkage is 9.992%, and the optimization rates are 95.38% and 91.46%, respectively.

It can be seen from the data in the table that the optimization rate of node 14 is the highest, reaching 97.94%, and that of node 18 is the lowest, reaching 93.87%.

Results and discussion

A BCI is a technology that establishes a direct connection between the human brain and a computer or other external device to enable human‒machine interaction by interpreting EEG or other neural signals. In this study, the MSDE algorithm is used to optimize the injection parameters of the BCI. BCI technology allows neural signals to be acquired directly from the human brain and applied to control parameters in the injection molding process to improve product quality and production efficiency.

MSDE is an evolutionary algorithm-based optimization method that searches for optimal solutions in the injection molding parameter space by simulating the natural evolutionary process of variation, crossover and selection operations. The multistrategy concept allows the MSDE algorithm to use multiple evolutionary strategies simultaneously and to dynamically select the best strategy based on the characteristics of the problem. This allows the algorithm to have a better global search capability and convergence speed.

In our study, first, EVA/PET composites are selected for injection molding based on previous studies, and the geometric range of the injection parameters based on the material properties are determined. The nodal displacement of the finished product and the magnitude of volume shrinkage are obtained via mold flow simulation. Next, we use the Latin hypercube sampling method to extract 20 data points to obtain the combination of injection molding parameters corresponding to the maximum and minimum nodal displacements. Subsequently, we introduce a multistrategy differential evolution algorithm to search for the best combination of injection parameters. The algorithm evolves by generating a set of candidate solutions and using variation and crossover operations. By flexibly combining multiple strategies, the MSDE algorithm can balance exploration and exploitation in the search process, effectively finding the global optimal solution or the set of solutions close to the optimal solution. Finally, we evaluate the impact of MSDE-optimized BMI injection molding parameters on product quality and productivity through analysis and experimental validation of the optimization results. Compared with traditional manual parameter adjustment or other optimization methods, we expect to achieve better control of the injection molding process and performance improvement by combining the BCI and MSDE algorithms.

In the process of injection molding a BCI, the change in voltage difference is used to determine the amount of coil displacement, which in turn assesses the reliability of the finished BCI. BCI is a technology used to connect the human brain to external devices, allowing people to control robotic arms, prostheses or other external devices through thought control.

In an injection-molded BCI, the key components are electroencephalography (EEG) electrodes and coils. EEG electrodes are placed on the scalp to record electrical signals from the brain. These electrical signals are transmitted to an external device through the coil. While the electrical signals generated by neurons in the brain are not affected by electrode or coil displacement, the recorded signals, including neuroelectric signals, artifacts due to displacement of the electrode/tissue interface, and environmental disturbances can be affected by coil displacement. Therefore, the magnitude of coil displacement can be reflected by changes in voltage difference.

Sun et al.17 proposed an improved eddy current sensor driving circuit. The experimental results show that the designed eddy current sensor has good linearity (1.12%) and sensitivity (2.14 V/mm), which can ensure the stable operation of the magnetic levitation turbomolecular pump at the rated speed. The relationship between the voltage change and node displacement reported in the literature is shown in Fig. 12.

As shown in Fig. 12, the greater the output voltage is (i.e., the measurement voltage we will eventually use), the greater the node displacement. For a 0.05 mm change in the coil displacement, the output voltage also changes by approximately 0.1 V. In this paper, we suggest that it is important to determine the magnitude of the node displacement by the magnitude of the output voltage difference to determine its compliance. By measuring the voltage difference of the coil, the node displacement can be indirectly inferred, and thus, the conformity of the product can be assessed.

According to previous research, the node displacement x and the output voltage Y is fit by the linear relationship equation Y = 1.66x + 17.54. The node displacement obtained in this paper is substituted, and the relationship graph shown in Fig. 13 is obtained. The node displacement of the optimal solution is 0.027 mm; at this time, the output voltage is 17.585 V, and the magnitude of the output voltage difference is positively correlated with the node displacement. When the node is displaced, the inductive circuit in the BCI is affected, resulting in a change in the inductance of the coil. This in turn leads to a change in the output voltage, i.e., the generation of the output voltage difference. By measuring and analyzing the output voltage difference, the magnitude of the node displacement can be determined, and the conformity of the product can be further determined.

Based on the relationship between the voltage difference and the node displacement, it can be concluded that the voltage difference of the previous injection parameters differed by approximately 11.7 V. The voltage difference of the previous injection parameters was approximately 1.5 V, which is the same as that of the node displacement. Such a large voltage difference also indicates that the node displacement of the BCI is too large. The distance between the coil and the head increases, affecting the strength and quality of the signal. As a result, the BCI may not be able to accurately detect and interpret the EEG signals, which will reduce the performance of the system. Therefore, by optimizing the injection parameters, the node displacement can reach 0.027 mm, and the voltage difference can vary by 0.054 V. The optimization rate can reach 95.38%, as shown in Fig. 14. Smaller node displacements can improve the signal quality, positioning accuracy, stability and reliability of BCI data interpretation. Ensuring that the lines are stably fixed to the target location will help obtain high-quality and reliable EEG signals and improve the performance and functionality of the BCI.

This method of determining displacement based on the output voltage difference has the advantages of accuracy and real-time performance. With proper circuit design and signal processing algorithms, the output voltage difference can be accurately measured to provide an accurate estimate of the coil displacement. Moreover, since the output voltage difference is a real-time indicator of coil displacement, the conformity of the product can be detected and determined in a timely manner to ensure the quality and reliability of the product.

Conclusion

In the BCI injection molding process, node displacement on the surface of the injected BMI can be significantly reduced by optimizing the dwell time, dwell pressure and melt temperature. A proper dwell time ensures that the injection plastic is fully melted and fills the mold cavity channel, avoiding defects and incomplete filling problems. Optimizing the holding pressure ensures that the injection plastic is evenly distributed and fills the mold, resulting in a flatter surface for the BCI. Optimizing the melt temperature can ensure that the injection plastic has proper flowability and plasticity, which improves the surface quality of the BMI. Therefore, the optimization of the holding time, holding pressure and melting temperature in the manufacturing process of injection-molded BCI products is crucial, and they work together to improve the product quality and ensure the reliability, accuracy and durability of the products, providing better experience and results for users.

This paper introduces the development status and trends of BCIs worldwide based on a summary of previous research and analyses and explores the injection molding process of BCIs. The main purpose of this study was to optimize the injection molding process of BCIs. First, we use the LHS method to obtain 20 sets of sample data to create a combination of injection parameters with the smallest surface node displacement and volume shrinkage rate. Second, we use the MSDE algorithm to obtain the best combination of injection molding parameters for the BCI. Finally, the node displacement can be verified by the voltage difference based on previous studies to finally determine whether the product is qualified. The main conclusions drawn from the results of the study are as follows:

-

1.

There are several advantages to using IME technology to detect node displacements in BCIs. IME technology is a voltage-based measurement that evaluates the quality of a plastic part by monitoring voltage changes in the line to determine the magnitude of node displacements.

-

2.

Using the LHS method, 20 sets of sample data were selected on the surface of the BCI, resulting in an average displacement of 0.585 mm and a volume shrinkage of 9.9922% for the coil under the original injection molding conditions.

-

3.

The MSDE algorithm, which combines the elite sharing strategy, the perturbation inverse solution strategy and the adaptive adjustment strategy, is used to derive the parameter combination that minimizes the node displacement. When the injection pressure is 400 MPa, the holding pressure is 400 MPa, the holding time is 250 s, the melting temperature is 160 °C, the mold temperature is 30 °C and the cooling time is 30 s, the average nodal displacement of the surface can reach 0.027 mm, and the volume shrinkage can reach 0.853%. The optimization rates reached 97.94% and 93.87%, respectively.

-

4.

The application of MSDE in the optimization of injection molding parameters for BCIs has the advantages of global search capability, flexibility, adaptability and low computational complexity. This makes this algorithm a powerful tool for optimizing injection molding parameters for BCIs, which effectively supports improvements in product quality, performance and productivity.

Data availability

The authors declare that the data supporting the results of this study are available in the paper. If any raw data files in other formats are required, they can be obtained from the corresponding author upon reasonable request.

References

Ramadan, R. A. & Vasilakos, A. V. Brain computer interface: Control signals review. Neurocomputing 223, 26–44. https://doi.org/10.1016/j.neucom.2016.10.024 (2017).

Gao, X., Wang, Y., Chen, X. & Gao, S. Interface, interaction, and intelligence in generalized brain–computer interfaces. Trends Cogn. Sci. 25, 671–684. https://doi.org/10.1016/j.tics.2021.04.003 (2021).

Naseer, N. & Hong, K. S. fNIRS-based brain–computer interfaces: A review. Front. Hum. Neurosci. 9, 3. https://doi.org/10.3389/fnhum.2015.00003 (2015).

Gao, S., Wang, Y., Gao, X. & Hong, B. Visual and auditory brain–computer interfaces. IEEE Trans. Biomed. Eng. 61, 1436–1447. https://doi.org/10.1109/TBME.2014.2300164 (2014).

Yuan, H. & He, B. Brain–computer interfaces using sensorimotor rhythms: Current state and future perspectives. IEEE Trans. Biomed. Eng. 61, 1425–1435. https://doi.org/10.1109/TBME.2014.2312397 (2014).

Lun-De, L. et al. Biosensor technologies for augmented brain–computer interfaces in the next decades. Proc. IEEE 100, 1553–1566. https://doi.org/10.1109/jproc.2012.2184829 (2012).

Mullen, T. R. et al. Real-time neuroimaging and cognitive monitoring using wearable dry EEG. IEEE Trans. Biomed. Eng. 62, 2553–2567. https://doi.org/10.1109/TBME.2015.2481482 (2015).

Ha, S. et al. Integrated circuits and electrode interfaces for noninvasive physiological monitoring. IEEE Trans. Biomed. Eng. 61, 1522–1537. https://doi.org/10.1109/TBME.2014.2308552 (2014).

Lou, Z., Chen, S., Wang, L., Jiang, K. & Shen, G. An ultra-sensitive and rapid response speed graphene pressure sensors for electronic skin and health monitoring. Nano Energy 23, 7–14. https://doi.org/10.1016/j.nanoen.2016.02.053 (2016).

Tang, X., Shen, H., Zhao, S., Li, N. & Liu, J. Flexible brain–computer interfaces. Nat. Electron. 6, 109–118. https://doi.org/10.1038/s41928-022-00913-9 (2023).

Song, E., Li, J., Won, S. M., Bai, W. & Rogers, J. A. Materials for flexible bioelectronic systems as chronic neural interfaces. Nat. Mater. 19, 590–603. https://doi.org/10.1038/s41563-020-0679-7 (2020).

Nicolas-Alonso, L. F. & Gomez-Gil, J. Brain computer interfaces, a review. Sensors (Basel) 12, 1211–1279. https://doi.org/10.3390/s120201211 (2012).

Hanson, T. L. et al. High-side digitally current controlled biphasic bipolar microstimulator. IEEE Trans. Neural Syst. Rehabil. Eng. 20, 331–340. https://doi.org/10.1109/TNSRE.2012.2187219 (2012).

Jun, J. J. et al. Fully integrated silicon probes for high-density recording of neural activity. Nature 551, 232–236. https://doi.org/10.1038/nature24636 (2017).

Yeon, P., Mirbozorgi, S. A., Lim, J. & Ghovanloo, M. Feasibility study on active back telemetry and power transmission through an inductive link for millimeter-sized biomedical implants. IEEE Trans. Biomed. Circuits Syst. 11, 1366–1376. https://doi.org/10.1109/TBCAS.2017.2775638 (2017).

Zhou, Y. et al. Implantable thin film devices as brain–computer interfaces: Recent advances in design and fabrication approaches. Coatings 11, 204. https://doi.org/10.3390/coatings11020204 (2021).