Abstract

Underground cavities have complex spatial structures and geological settings, their arrangement is dense and crisscrossed. The construction system involves multiple work surfaces, levels, and processes. The close integration of construction simulation with actual production conditions is crucial for enhancing the guidance that simulation results provide for practical engineering. Therefore, from the perspective of optimizing construction organization and management, this article comprehensively considers various factors in the construction process, innovatively introduces the principle of production line balance and the concept of rule cycle, and combines technology and management, an underground cavities construction simulation system (UCCSS) is developed. In UCCSS, a hierarchical model is built and calculation are performed on models with different construction methods by modifying the parameters as per the actual engineering characteristics. The simulation results are comprehensively analysed to determine the optimal construction programme. An application case is proposed based on the construction organisation design of the long and parallel diversion tunnels at the CB Hydropower Station. The results show that the system has good practicality and credibility and can provide guidance for the construction organisation design of underground cavities with various features.

Similar content being viewed by others

Introduction

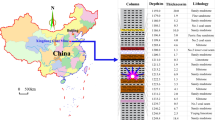

The construction of underground cavities in hydraulic and hydropower projects is extremely complex because the arrangement of underground cavities in such projects is dense and crisscrossed (Fig. 1). Accordingly, the construction system involves multiple work surfaces, levels, and processes. Further, the construction procedure is affected by many factors, such as the geological settings of the project, construction technology level, corresponding mechanical equipment configuration, traffic conditions, spatial structure of the cavities, support forms, and construction quality, these factors are often random and changeable. Therefore, accurately estimating and evaluating the construction organisation design by using only traditional methods is difficult. However, the construction of underground cavities is both repetitive and linear 1. Therefore, on a theoretical level, conducting simulations is expected to be an effective tool for planning projects2.

Owing to recent developments in computer technology, many international researchers have conducted numerous studies on construction simulation technology. The cycle operation network was first proposed by Halpin 3, who combined queuing theory with grid technology to simulate the construction process with cyclic characteristics. Accordingly, many influential software programmes were developed, such as INSIGHT4, RESQUE5, UM-CYCLONE6, Micro-CYCLONE7, COOPS8 DISCO9, STROBOSCOPE 10, Simphony 11, Vitascope 12, S3 13, COSYE 14, and hybrid SD-DES 15. However, these programmes are mostly used for high-rise buildings, road construction, and pipeline engineering, whose engineering characteristics are significantly different from those of hydropower station underground cavities. Therefore, a more suitable construction simulation software or systems must be developed by considering the construction characteristics of hydropower station underground cavities.

Zhong et al. 16 first used simulation technology to analyze the construction process of underground cavities, and used the cycle operation network simulation model to describe the construction process, which laid a theoretical foundation for tunnel construction simulation. Some scholars have proposed a simulation method for underground cavity construction that is more in line with engineering practive by considering different construction effects and detailed simulation of construction procedures. Liu et al. 17 considered the uncertain geologic conditions and risks and presented an adaptive cyclic operation network simulation (CYCLONE) simulation technique to predict the schedule of TBM. A.Shahim et al. 18 considered the uncertainty of tunnel construction caused by cold weather. The unit activities sensitive to climate in tunnel construction were identified and quantified, and then the simulation model tunnel construction in cold weather was established. Zhong et al. 19 proposed a robustness analysis method that involves underground powerhouse construction simulation based on the Markov Chain Monte Carlo (MCMC) method. The robustness of underground powerhouse construction was quantified, and the time buffer was introduced. The application of this methodology not only considered duration but also robustness, which effectively reduced the interference of construction uncertainty. Yu et al.2 defined optimal probability distribution for construction activities with BestFit technology, so as to realize fine and effective analysis of ordinary risk factors at the operation level of tunnel construction. And Bayesian network is embedded into simulation program to quantitatively analyze the occurrence probalitity of potential risk events. Finally, a tunnel construction simulation model considering the impact of risks was established. Sharafat et al. 20 presented a novel risk analysis methodology based on a generic bow-tie method for systematic assessment and management of risks associated with tunnel boring machine in difficult ground conditions.

On the basis of improving the accuracy of underground cavities simulation, some studied have combined visualization technology to realize the intuitive expression and visual analysis of simulation results. Zhong et al. 21 developed a two-dimensional progress display system, combining a visualisation technology with a construction simulation technology for the first time, and then developed a three-dimensional visualisation underground cavities construction simulation system based on OpenGL, which displayed the results more vividly. Wang et al. 22 carried out parametric modelling of diversion tunnel through CATIA, which provided a visual simulation of the rapid establishment and modification of the tunnel model. Sharafat et al.23 proposed a BIM-based multi-model tunnel information modeling (TIM) framework to visualize, manage, and simulate the drill-and-blast tunnel construction process. Moreover, new technologies such as 3D visualization modeling and artificial intelligence (AI) technology have been introduced into construction simulation. These new technologies can not only achieve visualization but also optimize construction project scheduling by considering various factors, analyze historical project data and real-time information to identify potential risks on construction and provide real-time progress tracking by analyzing data from various sources24,25.

At present, the reaserch theory and implementation of construction simulation for underground cavities have been very perfect, and visualization expression has also been achieved. Most of the above studies are devoted to obtaining more accurate simulation results by considering the influence of construction unfavorable factors on simulation and studying the optimization of simulation parameters. It fails in the perspective of innovating the concept of underground cavern construction organization and management to realize the organic combination of technology and management. It needs to be closely combined with the actual production situation, so as to improve the guiding significance of the simulation results to the actual project. Therefore, this study innovatively introduces the principle of production line balance and the concept of rule cycle, and develops a simulation system that is more suitable for the actual construction organization mode. In the system, a hierarchical model is established to meet the characteristics of complex spatial structure and crisscross of underground cavities. The system includes a variety of excavation and lining method models. Through the modification of construction equipment parameters, construction traffic parameters and engineering parameters, the simulation of different projects is completed. Finally, based on the analysis of the calculation data of construction progress, equipment resources, construction strength and traffic flow, the optimal construction scheme is established. The system was successfully applied in the construction programme design of the CB diversion tunnels.

Method

Principle

In order to make the construction simulation of underground cavities more closely combined with the engineering practice, the simulation model can accurately and objectively reflect the actul. The principle of production line balance and rule cycle concept is proposed.

An average distribution of operations is called production line balance. The construction of underground cavities is regarded as a complex production line, and the cavities are divided into multiple unit operations through construction task allocation, such as a diversion tunnel being divided into several sections and an underground powerhouse being divided into several floors. These unit tasks can be appropriately combined into task groups, and each task group is assigned different equipment and construction procedures due to the use of different construction methods. Furthermore, when assigning tasks, efforts should be made to evenly distribute the workload among various equipment or processes. If the allocation of work is uneven, it will result in idle time for equipment or operations.

The rule cycle concept is to consider the objective fact that the natural conditions such as engineering geology and hydrogeology with a certain range of the underground cavities changed little, and the excavation or lining section is also unchanged. The same construction cycle is used to constructed, which not only conforms to the actual construction, but also improves the efficiency of simulation.

Solving process

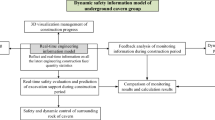

Simulation systems are generally classified as continuous or discrete systems. The state of a continuous system changes with time, whereas that of a discrete system changes with jumps in finite time. A discrete system is more suitable for simulating underground cavities compared to a contiuous system26. The basic concept of discrete system is to use simulation clocks to reflect the running trajectory of simulation time, so the underground cavities construction simulation system (UCCSS) is equipped with both a global and local simulation clock, and its dynamic simulation process is shown in Fig. 2.

The global simulation clock is used to record the simulation trajectory of the overall simulation system, throughout which the time-step method is adopted. The time-step method is called the fixed-time incremental propulsion method, which uses \(\Delta \text{T}\) as an increment to check whether any construction events occurred. If so, the event is considered to occur at the termination of the time increment, and the system state is changed accordingly. Otherwise, the system state is not changed. When a construction event is detected, the global simulation clock retained its current state and the control power is transferred to the local simulation clock. The time-step method is also adopted throughout the local simulation clock, and the local simulation clock is used to record the simulation trajectory of the construction process. Starting time from 0 clock, the local simulation clock is advanced for \(\Delta \text{t}\) to detect whether a construction process occurred and the usage of various resources is tracked. These steps are repeated until the event is completed, then, the control power is returned to the global simulation clock, which advanced the global simulation clock until the project is completed. Subsequently, the simulation results are analysed to obtain the final results. And the construction schedule, construction intensity and resource sets etc. are output.

When the time step method is used to simulate the system, the selection of time step is a very important issue. The smaller the selected time step is, the more refined simulation results will be. However, it will increase the number of state checking and judgment in the simulation process, thereby increasing the simulation running time. On the contrary, when the time step is too large, although it can reduce the running time, it is easy to lose some information of the system behavior and lead to the distortion of the simulation state. The global simulation clock is mainly used to determine the occurrence of construction events. In actual engineering, the working time of workers is usually measured in days. Therefore, the global simulation clock selects days as the step, which not only meets the working rules of humans, but also meets the accuracy of simulation. And the use of local simulation clock is mainly oriented to all aspects of specific construction, such as cavities excavation, slag discharge, lining and other activities. Usually, similar activities are measured in hours. Therefore, taking hours as a step can not only meet the requirements of simulation accuracy, but also meet the requirements of simulation running time.

Model

The simulation is ensured to be in line with the actual construction organisation mode regarding the entire process of underground cavities construction. There are four hierarchical structure models, namely, unit project, units project, division project, and sub-project. The hierarchical structure model construction process for the simulation system is illustrated in Fig. 3. First, we set the system processing time and build a new project or open an existing project. Next, the unit hierarchical structure is built, and the construction parameters, equipment parameters, traffic parameters, etc. are set. After the appropriate settings were determined, a simulation calculation is performed, and then, the simulation results are viewed. If the simulation results are unsatisfactory, the corresponding parameters are reset.

Drilling-blasting excavation model

The drilling-blasting excavation model is adopted for full-section excavation, guide hole method excavation, and guide hole sidewall expansion excavation. The primary construction procedures include drilling, charging, blasting, ventilation, slag transportation, and support. The main parameters of the drill-blasting simulation model are cyclic footage, drilling time, slag transportation time, shotcrete time, daily cycle number, construction period, and cycle volume. These parameters are described as follows.

(1) Cyclic footage

Owing to the role of the rock support, the cyclic footage is generally less than the drilling depth. Because of the different blasting efficiencies, the cyclic footage is not the same as the same drilling depth.

Equation (1) defines the objective function of cyclic footage, where \({L}_{xh}(n)\) is the footage of the nth cycle, \(h\) is the drilling depth, and \({K}_{bs}(n)\) is the blasting efficiency of the nth cycle.

(2) Drilling time

There is no perfect formula for the theoretical calculation of drilling time, accordingly, it is determined mainly based on previous engineering experience.

Here, \({t}_{zk}\) is the drilling time, \(N\) is the number of designed blast holes, \({V}_{zj}\) is the speed of the drilling, \({n}_{1}\), \({n}_{2}\), and \(h\) are the number of drilling rigs configured for a single working face, number of drilling arms of the configured drilling rigs, and drilling depth,respectively, and \(\gamma\) is the average value of the working coefficients for multiple drilling rigs.

(3) Slag transportation time

Owing to the high concentration of dust in the cavity during slag transportation, no other operations are performed during slag removal. During the excavation of cavities, the slag output per cycle is calculated as follows:

Here, \(Z\) is the amount of slag transported in a single cycle, \(\alpha\) is the expansion coefficient of the excavation, \(\beta\) is the over- and under-excavation coefficient, \(S\) is the cavity design excavation area, and, \(d\) is the blasting cyclic footage.

The loading time of the loader is \({t}_{z}\).

Here, \({V}_{z}\) is the productivity of the loader and \(a\) is the number of loaders.

The slag transportation time, \({t}_{y}\), for a single dump truck is calculated using the following formula:

Here, \({L}_{1}\) and \({L}_{2}\) are the transport distances inside and outside the cavities, respectively, and \({V}_{1}\) and \({V}_{2}\) are the vehicle speeds inside and outside the cavities, respectively.

The slag transportation time, \({t}_{c}\), for a single dump truck is calculated using the following formula:

(4) Anchoring and safe handling time.

As this process part can be constructed in parallel with other operations, the temporary support time, \({t}_{zh}\), to ensure construction safety can be considered as the occupied linear time.

(5) Shotcrete time.

Because no other operations can be carried out during the shotcrete, it is considered an occupied linear time.

Here, \(H\) is the thickness of the shotcrete, \(L\) is the contour line after cavities excavation, \({d}_{s}\) is the upper blasting cyclic footage, \(N\) is the number of sets of shotcrete machines, \({V}_{ph}\) is the effective spraying quantity per hour of a single set of shotcrete machines, and \(\zeta\) is the average value of the working coefficient of the shotcrete machine, for \(N\) =1, \(\zeta\) =1; for \(N\) >1, \(\zeta\) <1.

(6) The single-cycle operating time, \({t}_{xh},\) is calculated using the following formula:

where \({t}_{a}\) is the time of safety inspection and treatment, \({t}_{tf}\) is the ventilation and smoke dispersion time, and \({t}_{fx}\) is the time required to measure the unreeling and hole siting.

(7) Daily cycles

When \({t}_{xh}\le {t}_{r}\), the rule cycle criterion is used, and the single-day multiple cycles are denoted as n.

When \({t}_{xh}\)>\({t}_{r}\), a multi-day cycle is used, and the multi-day cycles are denoted as n.

where \({t}_{r}\) is the effective daily working hours.

(8) Circulation engineering quantity.

When \({H}_{cqs}\)≥0,

When \({H}_{cqs}\)<0,

In Eqs. (11), (12) and (13) \({H}_{cqs}\) is the over- and under-excavation depth, \({V}_{cw}\) is the over-excavation quantity, \({V}_{qw}\) is the under-excavation quantity, and \(V\) is the unit project excavation quantity.

(9) Unit project construction time

In Eqs. (14) and (15), \({d}_{zx}\) is the construction period of the unit project, \({d}_{w}\left(n\right)\) is the last cycle completion time, \({d}_{s}(1)\) is the first cycle start time, \({d}_{y}\) is the entire duration of the unit project, \({d}_{q}\) is the unit project pre-processing time, and \({d}_{h}\) is the unit project post-processing time.

Layered excavation model

The layered excavation model is adopted for the second and lower layers of the layered excavation of a large section. Its construction workflow differs from that of the drilling-blasting excavation method, where, the operation of upper circulation slagging and lower circulation drilling, as well as that of anchoring and lower circulation drilling and slagging are parallel.

(1) Workflow of the layered excavation cycle.

The main processes of the construction procedures are drilling, charging, upper cycle slag transportation, upper cycle anchoring, safety evacuation, blasting, ventilation, safety inspection, slag transportation in this cycle, and lower cycle drilling and loading.

(2) Layered excavation cyclic footage.

The layered excavation method is adopted for the cavern with upper air faces, which is performed by vertical drilling with a down-hole drill, where the cyclic footage is the same as the drilling range.

(3) Layered excavation method cycle operation time.

It includes measuring the unreeling and hole-siting times, drilling time, safety inspection and processing time, slag transportation time, and smoke dispersion time. Its calculation method and shotcrete time are the same as those of the drilling-blasting excavation model. Because the upper circulation of the slag-out procedure is performed simultaneously with the lower circulation drilling, the cycle of operation time, \({t}_{xh}(n)\), is calculated as follows.

When \(n=1\),

When 2 ≤ \(n\)≤\(N\),

If \({t}_{a}\left(n\right)+{t}_{zk}\left(n\right)\)<\({t}_{c}\left(n-1\right)\), the upper circulation of the slag-out cannot be completed in the next drilling cycle.

(4) Quantity of layered excavation cycles

Because of the pre-split in the layered excavation, it is not necessary to consider the amount of over- and under-excavations.

Here, \(d\) denotes the cyclic footage, \(H\) is the step height, and \(B\) is the excavation width.

Steel trolley lining model

The steel trolley lining method is widely used in cavern engineering considering the lining sequence and different lining parts, which are divided into full section, top arch, side top arch linings, and other forms. The characteristics of this method are as follows: The lining process adopts a sequential operation, and the lining length of each cycle is the same, except for the last cycle. Its cycle operation processes include wall cleaning, keyways, measurement and placement, steel reinforcement installation, formwork placement, inspection, concrete injection, concrete maintenance, and demolding.

(1) Number of cycles per project unit

Here, L is the length of the unit project lining and Lt is the length of the template.

(2) Cycle operation time

The steel trolley cycle operation time mainly includes the unreeling time, steel reinforcement installation time, formwork placement time, inspection time, concrete warehousing time, concrete maintenance time, and demolding time.

The measuring unreeling time, \({t}_{fx}\), is generally based on an empirical input.

Steel reinforcement installation time is expressed as follows:

Here, \(G\) is the amount of reinforcing steel installed, calculated from the reinforcement ratio, \(p\) is the efficiency of the single-group steel placement, and \({N}_{gj}\) is the number of steel placement groups.

The formwork placement and inspection time, \({t}_{mb}\), is determined based on experience.

According to construction experience, the concrete warehousing time is generally greater than the concrete loading time. Therefore, the optimal number of vehicle configurations for concrete transportation primarily depends on the transport path length, pump truck speed, and concrete warehousing time. When the last concrete pump truck arrives to the warehouse, the round trip is completed by the first concrete pump truck. The optimal number of pump truck configurations, \({N}_{bc}\), is determined as follows:

In Eqs. (21), (22), and (23), \({t}_{x}\) is the transport time for a pump truck to complete a round trip, \({t}_{rc}\) is the concrete warehousing time, \({t}_{z}\) is the pump truck concrete loading time, \(L\) is the length of the transport path travelled by the pump truck, \({v}_{b}\) is the transport speed of the pump truck, \(V\) is the amount of concrete loaded into the pump truck, and \(\eta\) is the efficiency of the pump truck in the bin.

Concrete warehousing is considered continuous, accordingly, the total concrete warehousing time, tzr, is expressed as follows:

In Eqs. (24) and (25) , \({V}_{z}\) is the amount of concrete required for concrete entry and \(n\) is the number of times the pump truck is loaded.

In the same unit project, the concrete maintenance and demolding time, \({t}_{yh}\), is kept constant based on engineering experience.

The cycle operation time is.

(3) The cycle time, cycle quantity, and construction period calculation methods are similar to those of the drilling-blasting excavation model, thus, these are not further described.

Sliding block lining model

The sliding block lining model is suitable for lining the bottom board of the cavern and another continuous lining. The sliding distance per hour is often used to describe the lining speed, therefore, a discrete simulation is conducted with a cycle of one hour. In the actual construction process, the lining speed is limited by the concrete supply, and the effective daily working time is set according to the overall rule cycle concept.

(1) Number of cycles per project unit

Here, \({S}_{z}\) is the total lining length of the unit project and \(L\) is the length of one lining cycle.

(2) Daily lining footage and concrete supply strength assessment

In Eqs. (28) and (29), \({S}_{c}\) denotes the lined concrete sectional area, \({L}_{d}\) denotes the daily lining footage, \({t}_{r}\) denotes the daily effective working time, and \({V}_{c}\) denotes the daily lining squared volume.

Concrete pump trucks and belt conveyors are used for the transportation of the sliding block lining to the workbench. When a concrete pump truck is used, the transport time is limited by the concrete condensation time and supply strength. A belt conveyor is used to satisfy the concrete supply strength requirements.

Construction transportation model

Construction traffic characteristics

The construction traffic at underground cavities has the following characteristics:

-

(1) Paths are specific. Compared with urban and highway transportation, underground cavities construction transportation has unique characteristics. For a specific construction section, regardless of the number of transportation paths available, only one optimal path is selected for the material transportation path layout, which is generally composed of an open-line road outside the cavern, construction adit, and cross passage. Its road characteristics, such as slope and length, are obvious, which is conducive to a reasonable designation of vehicle speed.

-

(2) The vehicle type and load capacity are explicit. In general, the construction transportation at underground cavities can be carried out using various ways, such as belt conveyors, track transportation, and trackless transportation. Trackless transportation slag dump tracks are categorised into different models, such as 10t, 15t, 20t, and 25t, concrete pump trucks are categorised into different models, such as 3 m3 and 6 m3, and rail transportation is classified into different models of mine trucks or railroad pump trucks. Underground cavities involve the construction of multiple work surfaces. However, for a specific construction section, to facilitate construction organisation management and maintenance, the same type of vehicle transportation is usually chosen, such that the load capacity is explicit.

-

(3) The starting points and destinations of transport are explicit. During the excavation of underground cavities, slag materials can be transported to sand-processing factories, waste slag storage sites, slag transfer sites, dam fillings, and other destinations. The lining concrete is typically supplied by the nearest concrete production system. For a specific section, slag utilisation is usually planned, therefore, the slag destination and concrete supply station are explicit.

-

(4) The concrete warehousing time is stipulated during transportation to prevent the concrete from condensing before it is placed. Regardless of whether rail or trackless transportation is used, the concrete delivery time cannot exceed the condensation time provisions.

Construction traffic flow

(1) Optimal number of vehicles on a working surface.

The number of vehicles configured requires that when the last car in the convoy leaves, the cycle in the conveyor is completed exactly by the first car. When the car is out of slag and actual number of configured vehicles is greater than the optimal, cars need to wait in line to load slag. Conversely, when the actual number of configured vehicles is less than the optimal, the loading system need to wait for cars to load slag.

In Eqs. (30) and (31), \({N}_{zj}\) is the optimal number of vehicles in a single working surface, \({t}_{d}\) is the time required for a vehicle round trip, \({t}_{x}\) is the time required for vehicle slag unloading, \({t}_{z}\) is the time required to fill a vehicle, \({t}_{o}\) is the time required for a vehicle to make an adjustment, turn, etc., \({L}_{1}\) is the length of the slag transport route through the construction adit, \({L}_{2}\) is the length of the slag transport route through the cross passage, \({L}_{3}\) is the length of the slag transport route through the open road, \({v}_{d1}\) is the construction adit vehicle speed which is on-load, \({v}_{d2}\) is the construction adit empty vehicle speed, \({v}_{h1}\) is the cross passage vehicle speed which is on-load, \({v}_{h2}\) is the cross passage empty vehicle speed, \({v}_{m1}\) is the open road vehicle speed which is on-load, and \({v}_{m2}\) is the open road empty vehicle speed.

(2) Vehicle transportation time

In Eqs. (32) and (33), \({N}_{z}\) is the loading time of a single working face slag discharge, and \({t}_{yz}\) is the slag transport time.

When the first slag transport vehicle drives out of the working face, the one-way hourly vehicle flow is counted, forming a vehicle statistical function \({q}_{t}\) with respect to time. The time node of the vehicle flow is related to the starting time of the working day, vehicle speed, loading time, and construction time before the slag transport.

Here, \({Q}_{t}\left(i,m\right)\) is the \(m\)-hour traffic flow of the \(i\) th construction support hole, and \({q}_{t}(i,j,m)\) is the \(m\)-hour traffic flow of the \(j\) th unit project carried by the \(i\) th construction adit. Similarly, we can determine the real-time traffic flow of the cross-passage and open-line road.

Case study

This section discusses the application of the proposed underground cavities construction simulation system. The construction of the diversion tunnel at the CB Hydropower Station is long with deep burial, large cross-section, and complex geological conditions.

Project overview

Engineering conditions

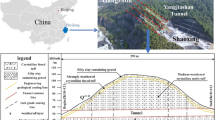

The CB Hydropower Station is located in the upper gorge section of the Jinsha River, and is the 11th stage among the planned 13 cascade hydropower stations in the Chuanzang section in the upper reaches of the Jinsha River. The two tunnels and four engines are arranged according to the diversion system of the hydropower station, most are buried at more than 400 m deep, and the maximum buried depth is approximately 1160 m. The single tunnel length of the diversion tunnels is approximately 11.17 km (from the starting point of the 1st diversion tunnel to the surge chamber) (Fig. 4), distance between the axes is 51 m, and longitudinal slope of the tunnel ranges between 1.39%–1.41%. The tunnel has a circular cross-section with an inner diameter of 13 m.

Based on the rock type, rock integrity, and rock structure type of the diversion tunnel area, the surrounding rock of the 1st diversion tunnel is preliminarily classified (Fig. 5). The Type III surrounding rock is mainly composed of medium-thick layered schist, marble and massive granite. The rock is hard, but the joints are developed and the rock mass is more complete. It accounts for approximately 40.4% of the total length of the tunnel. The Type IV surrounding rock is mainly thin layer, phyllite schist, slate, and weathering, fracture development, fault influence tunnel section. The rock is relatively weak and the structure is developed. It accounts for approximately 49.9% of the total length of the tunnel. The Type V surrounding rock is mainly a fault fracture zone, and the rock mass is in a fragmented and clastic structure. The surrounding rock is extremely unstable and the deformation and failure are serious. It accounts for approximately 9.7% of the total length of the tunnel. The specific surrounding rock types and mechanical parameters of the diversion tunnel are shown in Table. 1.

Main construction characteristics

-

(1) The construction section is large and cavity is long, accordingly, the project scale is extremely large.

-

(2) Construction safety issues are prominent. The ground stress is high. The maximum buried depth of the tunnel will reach 1100 m, the vertical stress can reach 30 MPa, and the horizontal stress can reach more than 20 MPa. It can be obtained from the strength stress ratio of surrounding rock Rb/σm = (50 ~ 60)/(30 ~ 40MPa) = 1 ~ 2 that there is the possibility of weak rock burst. The rock mass near regional faults such as Wangdalong fault is relatively broken and has strong water permeability, which may connect river water and gully surface water and produce water inrush.

-

(3) The construction period is relatively short. The scale of the diversion tunnel project is large, and construction traffic, ventilation, drainage, and other related issues are relatively difficult to solve.

-

(4) The two diversion tunnels are parallel. There are cross-passages between the two diversion tunnels that can be used for workers to enter the 1st diversion tunnel from the 2nd diversion tunnel. To ensure the adequate construction of the 1st diversion tunnel and shorten the corresponding construction period, the construction work surface at the 1st diversion tunnel is increased. Then, simultaneous excavation and lining construction of multiple work surfaces can be realised.

-

(5) Excavation and lining procedures: The excavation of the diversion tunnel is performed by the drilling-blasting excavation method. Considering that the construction section of the diversion tunnel is large, the excavation is conducted in layers. Accordingly, the excavation of the upper layer is completed before the excavation of the lower layer. The lining is performed one month after the tunnel excavation is completed, so that the lining and excavation would not interfere with each other. Both diversion tunnels are first lined with a steel trolley for the arch lining and then for the floor lining.

-

(6) The single diversion tunnel of the hydropower station is approximately 11 km long with four construction adits (8 m × 7 m), which are of the city gate type. The control section is between the 2nd construction adit and 3rd construction adit, which is 3.79 km long.

Construction simulation parameters and programme settings

Parameters

The main parameters selected are the excavation model, lining model, construction machinery equipment, and related construction engineering parameters. The parameters are described as follows:

-

(1) Excavation model

-

The upper and lower halves of the diversion tunnel are excavated in layers. The drilling-blasting excavation model is adopted for the excavation of the upper half of the tunnel, whereas the layered excavation model is adopted for the lower part.

-

(2) Lining model.

-

The concrete lining of the diversion tunnel should be first applied to the upper 3/4 part of the cavern, the bottom 1/4 part of the cavern should be lined later. The arch ring of the lining should be implemented based on a steel trolley lining model, and the bottom board of the lining should be implemented based on a sliding block lining model.

-

(3) Selection of the machinery equipment.

-

The excavation of the upper half of the tunnel should be performed with a three-arm hydraulic drilling rig, whereas that of the lower part should be performed with a down-hole drill. The 20t dump truck should be selected as the slag truck, 6m3 pump truck should be used as the concrete pump truck, 4.2 M loader should be configured as the loader, and steel trolley should be configured for the arch ring lining.

-

(4) Construction footage.

-

Because of the unique engineering, geological, and hydrogeological settings of the project diversion tunnel, the processes on key lines that affect the construction period of the tunnel excavation are listed in Table. 2. According to the total time spent on the critical processes of different types of surrounding rock, the Type III surrounding rock can complete one cycle every day, and the Type IV and V surrounding rock can complete two cycles every day. The cyclic footage of surrounding rock of Type III, Type IV and Type V is 4m, 1.4m and 0.8m respectively. Considering 25 effective working days per month, the monthly excavation footage of Type III surrounding rock is 100 m/month, that of Type IV surrounding rock is 70 m/month, and that of Type V surrounding rock is 40 m/month.

-

Due to the inability to concretely consider the risks in construction simulation, this paper chooses to consider the construction risks handling time of 4 months, and allocate the delayed progress to each day.

Based on the actual project characteristics, it is proposed to use a steel trolley for the concrete lining of the arch ring, which is 12 m long. Accordingly, because of the large lining section, the average monthly lining footage is considered to be 120 m.

The bottom board lining of this project is behind the arch lining, and there is less interference in the bottom clearing construction. The speed of the concrete lining of the bottom board is considered to be 300 m/month.

Programme settings

The line of the CB diversion tunnel is long, construction scale is large, and construction term is highly uncertain. To ensure progress, the working surface area is increased by arranging construction adits and cross passages. In general, construction adits are arranged according to the terrain and geological settings along the tunnel. Therefore, the adjustment room is not large. The cross passage is relatively flexible and can be arranged accordingly. Currently, it is often set every few hundred meters, according to the experience of engineering personnel. In actual construction, there will be too much or too little investment, resulting in insufficient optimisation of the construction progress and excessive waste of resources.

Based on these characteristics, the upper and lower halves of the CB diversion tunnel are excavated in layers. To optimise the construction process, the lower half of the tunnel is excavated in advance by arranging a cross passage in the control section. As shown in Fig. 6, the excavations of the upper half of the two diversion tunnels are conducted simultaneously, and a cross passage is arranged at an appropriate position. When the cross-passage is used, slag-out of the upper half of the 1st diversion tunnel can be carried out through the 1st cross passage—2nd diversion tunnel—construction adit. When the excavation of the lower half of the 1st diversion tunnel is completed, it can be used as a slag-out construction channel. The lower half of the 2nd diversion tunnel is excavated in advance, and slag-out of the upper half of the 2nd diversion tunnel is carried out through the 1st cross passage—1st diversion tunnel—construction adit. Thus, the cross passage can be used to optimise the construction progress of the two diversion tunnels. Setting different numbers of cross passages affects the input of equipment resources and construction process. Hence, five comparison programmes are set up to perform a more comprehensive analysis, as listed in Table 3.

Analysis of results

The simulation results from the aspects of construction schedule, construction intensity, construction machinery, and construction traffic are analysed in this chapter.

Construction progress

The simulation results for Programmes 1–5 are listed in Table 4. The diversion tunnel in Programme 5 is able to fulfil the conditions of power generation and water supply the earliest, whereas the diversion tunnel in Programme 1 is able to fulfil the conditions of water supply and power generation the latest. The annual construction progress of Programme 5 is shown in Fig. 7.

Construction traffic

The construction traffic is analysed mainly regarding the control section after the cross-passage became operational. The traffic flow and slag transportation of 2nd and 3rd construction adits are described as follows.

In the construction simulation of the diversion tunnel, 20t dump trucks are all used for slag-out. The peak period of slag-out vehicles is mainly concentrated after the cross-passage became operational, accordignly, an increase in the construction section leads to an increase in the number of slag-out vehicles. The number of slag-out vehicles during the peak construction period of the 2nd construction adit is shown in Fig. 8a. The maximum vehicle flow for Programme 1 is 20 vehicles/h, and that for Programmes 2–5 is 25 vehicles/h. No sustained traffic flow in excess of the control is present.

Construction traffic simulation results for the peak section of 2nd and 3rd construction adit: (a) the number of slag-out vehicles with 2nd construction adit; (b) the amount of slag-out with 2nd construction adit; (c) the number of slag-out vehicles with 3rd construction adit; (d) the amount of slag-out with 3rd construction adit.

The monthly amount of slag-out in the peak section of the 2nd construction adit is shown in Fig. 8b. The maximum strength of the monthly slag-out in each construction programme is 38,300 m3, 52,700 m3, 52,700 m3, 52,700 m3, and 67,200 m3, respectively, for Programmes 1–5.

The number of slag-out vehicles in the peak construction period of the 3rd construction adit is shown in Fig. 8c, the maximum vehicle flows are 16, 21, 23, 24, and 24 vehicles/h for Programmes 1–5, respectively. All vehicle flows are less than 25 vehicles/h.

The monthly amount of slag-out in the peak section of the 3rd construction adit is shown in Fig. 8d. The maximum strength of the monthly slag-out in each construction programme is 40,800 m3, 55,300 m3, 63,800 m3, 69,700 m3, and 69,800 m3, respectively, for Programmes 1–5.

Construction intensity

The construction intensity of the downstream excavation surface of the 2nd construction adit is shown in Fig. 9. The maximum construction intensity for Programmes 1–4 is 29,000 m3, and that for Programme 5 is 38,200 m3.

The construction intensity of the upstream excavation surface of the 3rd construction adit is shown in Fig. 9. The maximum construction intensity for Programmes 1–5 is 29,000 m3, 29,000 m3, 38,100 m3, 40,700 m3, and 40,800 m3, respectively.

Construction machinery equipment

In the construction of the diversion tunnel, a three-arm hydraulic drilling rig and down-hole drill are mainly used for the excavation. The loading equipment adopts a 4.2 M loader, 20t dump truck for slag-out, 6 m3 pump truck to transport concrete, and steel trolley for lining, the maximum uses of mechanical equipment are reported in Table 5.

This section focuses on the analysis of the monthly maximum demand plan for down-hole drills and 20t dump trucks.

A down-hole drill is primarily used in the lower-layer excavation. As shown in Fig. 10a, the maximum monthly demand for Programme 1 is 16 sets for 7 months, that for Programme 2 is 20 sets for 4 months, that for Programme 3 is 22 sets for 3 months, that for Programme 4 is 22 sets for 6 months, and that for Programme 5 is 22 sets for 7 months. Programmes 1 and 5 are more reasonable in terms of resource investment and last up to 7 months, however, the duration of Programme 1 is deemed too long.

The 20t dump truck is mainly used for slag transportation during tunnel excavation. As shown in Fig. 10b, the maximum monthly demand for Programme 1 is 84 vehicles for 3 months, that for Programme 2 is 90 vehicles for 2 months, that for Programme 3 is 90 vehicles for 6 months, that for Programme 4 is 90 vehicles for 9 months, and that for Programme 5 is 90 vehicles for 10 months. Programme 5 is more reasonable in terms of resource investment and lasts up to 10 months.

Comprehensive analysis

The construction programme design of the CB diversion tunnel group is discussed in this section, mainly based on the layout of cross-passages between the tunnels, effectively increasing the construction surface, and carrying out the excavation of the lower layer of the diversion tunnel in advance to speed up the construction progress.

In this section, a programme for laying 2–5 cross passages in the control section is proposed. Construction simulation is conducted using the UCCSS developed in this study, and comprehensive analysis of each programme is conducted by considering the aspects of construction intensity, construction traffic, machinery and equipment, construction progress, etc.. In terms of construction intensity, the maximum excavation intensity of the control sections for Programmes 1–5 is 58,000 m3, 58,000 m3, 67,100 m3, 69,700 m3, and 69,900 m3. According to the construction traffic simulation results of Programmes 1–5, the 20t dump truck fully meets the slag-out requirements, resulting in no traffic congestion. From the perspective of the construction period, the beginning of the diversion tunnel excavation is the April of the first year. The construction period of the 1st diversion tunnel for Programmes 1–5 is 74.5 months, 67, 65, 64.5, and 63 months, respectively, and that of the 2nd diversion tunnel is 76, 72, 69, 66.5, and 66 months, respectively.

The construction period of Programme 5 is the shortest, and the equipment resource input is similar to that of the other four programmes, making it more economical. Based on the comprehensive analysis, Programme 5 can be used as the recommended construction programme.

Discussions

Numerous engineering applications show that the UCCSS is practical and reliable and has advantages in terms of parametric design, whole-process system simulation, easy operation, and strong expansion. First, a fully parametric design is adopted for different construction methods and working procedures so that programme adjustments can be easily made by modifying the parameters. Second, a dynamic simulation of construction transportation, resource allocation, period, and intensity during the entire process of excavation and lining construction of different underground cavities space types can be carried out. The traffic flow and transport intensity of each process time under different paths, as well as the excavation and lining intensities at any moment of construction, can be queried using this system. Third, the system model is relatively simple, owing to the functions of technical parameters that prompt, copy, modify, help, automatic update of the entire system, dynamic information queries, and error identification. Finally, owing to the developments in large-scale construction machinery and equipment and progress of tunnelling construction technology, innovations in underground engineering construction technology and updates of organisational management concepts will be effectively promoted by new methods, technologies, and equipment. New models and simulation programmes based on new mathematical models can be added to this system to adapt it for development.

However, in view of the current rapid developments in computer technology and engineering practice and demand for more comprehensive simulation functions, many shortcomings still remain in the UCCSS. First, visualisation technology is not implemented well in the system and the process of real-time simulation is not entirely fulfilled. Therefore, the follow-up needs to be improved based on these two aspects. Implementing 3D animation demonstration technology is suggested to demonstrate the complex construction process with moving images in a realistic manner and provide a visual analysis means for construction management. Second, developing a real-time construction simulation system is recommended for actual construction processes so that the actual situation can be fed back to the system in a timely manner to better guide the actual construction schedule.

Conclusions

The construction of underground cavities in hydraulic and hydropower projects involves many factors and it is an extremely complex process. It is of great significance to closely integrate construction simulation with actual production situations to improve the guidance of simulation results for practical engineering. This article innovatively introduces the principles of production line balance and rule cycle concept, combining technology with management, and a practical, expandable, full-featured, and easy-to-operate UCCSS is developed. The time-step method of the discrete system is adopted to perform hierarchical modelling, which divides the entire project into four levels, namely, unit project, units project, division project, and sub-project. Different excavation, lining, machinery equipment models and construction plans are implemented in the system based on the actual construction characteristics. Accoroding to the analysis of the construction transportation, construction intensity, and construction progress to obtain the optimal construction scheme of underground cavities construction. The proposed method is an efficient calculation and analysis tool for complex underground cavities construction, improves the modernisation level of construction organisation design to a certain extent, and has broad application prospects. The system is successfully applied to the construction organisation design of the diversion tunnels of the CB Hydropower Station, providing important technical support for the optimisation of the construction programme and decision-making management.

Data availability

All data generated or analysed during this study are included in this article.

References

Hajjar, D., & AbouRizk, S. Development of an object oriented framework for the simulation of earth moving operations. Proc., Intelligent Information Systems Conf., IEEE, New York, 326-330. https://doi.org/10.1109/iis.1997.645279. (1997).

Yu, J., Zhong, D., Ren, B., Tong, D. & Hong, K. Probabilistic risk analysis of diversion tunnel construction simulation. Comput.-aided Civil Infrastruct. Eng. 32(9), 748–771. https://doi.org/10.1111/mice.12276 (2017).

Halpin, D. W. Cyclone-Method for modeling job site processes. J. Constr. Div. 103(3), 489–499. https://doi.org/10.1061/jcceaz.0000712 (1977).

Paulson, B. C. Interactive graphics for simulating construction operations. J. Constr. Div. 104(1), 69–76. https://doi.org/10.1061/jcceaz.0000758 (1978).

Chang, D. Resque [D] (University of Michigan, 1987).

Ioannou, P. G. UM-CYCLONE user’s guide[D] (University of Michigan, 1989).

Halpin, D. W. Micro-CYCLONE User’s Manual (Purdue University, West Lafayette, 1990).

Liu, L. COOPS: Construction object-oriented process simulation system. https://deepblue.lib.umich.edu/handle/2027.42/128820. (1991).

Huang, R., Grigoriadis, A. M. & Halpin, D. W. Simulation of cable-stayed bridges using disco. Winter Simul. Conf. , 1130-1136. https://doi.org/10.5555/193201.194680 (1994).

Martinez, J. C. & Ioannou, P. G. General purpose simulation with stroboscope. Winter Simul.Conf. , 1159-1166. https://doi.org/10.5555/193201.194688 (1994).

AbouRizk, S. & Mohamed, Y. Simphony: An integrated environment for construction simulation. Winter Simul.Conf. 2, 1907–1914. https://doi.org/10.5555/510378.510656 (2000).

Kamat, V. R. & Martinez, J. C. Validating complex construction simulation models using 3D visualization. Syst. Anal. Model. Simul. 43(4), 455–467. https://doi.org/10.1080/02329290290028507 (2003).

Lu, M., Lam, H. & Dai, F. Resource-constrained critical path analysis based on discrete event simulation and particle swarm optimization. Autom. Constr. 17(6), 670–681. https://doi.org/10.1016/j.autcon.2007.11.004s (2008).

AbouRizk, S. M., & Hague, S. An overview of the COSYE environment for construction simulation. Proc. 2009 Winter Simulation Conference (WSC). https://doi.org/10.1109/wsc.2009.5429307. (2009).

Alvanchi, A., Lee, S. & AbouRizk, S. Modeling framework and architecture of hybrid system dynamics and discrete event simulation for construction. Comput.-Aided Civil Infrastruct. Eng. 26(2), 77–91. https://doi.org/10.1111/j.1467-8667.2010.00650.x (2011).

Denghua, Z. Simulation study of tunnel cycle construction process (in Chinese)[D] (University of Tianjin, 1987).

Liu, D., Xuan, P., Li, S. & Huang, P. Schedule risk analysis for TBM tunneling based on adaptive CYCLONE simulation in a geologic Uncertainty-Aware context. J. Comput. Civil Eng. 29(6), https://doi.org/10.1061/(asce)cp.1943-5487.0000441 (2015).

Shahin, A., AbouRizk, S., Mohamed, Y. & Fernando, S. Simulation modeling of weather-sensitive tunnelling construction activities subject to cold weather. Can. J. Civ. Eng. 41(1), 48–55. https://doi.org/10.1139/cjce-2013-0087 (2014).

Zhong, D., Bi, L., Yu, J. & Zhao, M. Robustness analysis of underground powerhouse construction simulation based on markov Chain monte carlo method. Sci. China. Technol. Sci. 59(2), 252–264. https://doi.org/10.1007/s11431-015-5859-3 (2015).

Sharafat, A., Latif, K. & Seo, J. Risk analysis of TBM tunneling projects based on generic bow-tie risk analysis approach in difficult ground conditions. Tunn. Undergr. Space Technol. 111, 103860. https://doi.org/10.1016/j.tust.2021.103860 (2021).

Denghua, Z., Weibo, Z. & Jiaxiang, Z. Study on Dynamic Visual Simulation System for Complex Construction Processes (in Chinese). Hydroelectricity 12, 28–30 (2000).

Wang Xiaoling, Qu., Liwen, R. B., Mengqi, Z., Yao, X. & Zhen, L. Dynamic visual simulation of diversion tunnel construction based on CATIA (in Chinese). J. Hydraulic Eng. 49(03), 369–378. https://doi.org/10.13243/j.cnki.slxb.20170646 (2018).

Sharafat, A., Khan, M. S., Latif, K. & Seo, J. BIM-Based Tunnel Information Modeling framework for visualization, management, and simulation of Drill-and-Blast tunneling projects. J. Comput. Civil Eng. 35(2). https://doi.org/10.1061/(asce)cp.1943-5487.0000955 (2021).

Rafsanjani, H. N. & Nabizadeh, A. H. Towards human-centered artificial intelligence (AI) in architecture, engineering, and construction (AEC) industry. Comput. Hum. Behav. Rep. 11, 100319. https://doi.org/10.1016/j.chbr.2023.100319 (2023).

Wang, M., Zhou, J., Chen, J., Jiang, N., Zhang, P., Li, H. Automatic identification of rock discontinuity and stability analysis of tunnel rock blocks using terrestrial laser scanning. J. Rock Mech. Geotech. Eng. 15(7), 1810–1825. https://doi.org/10.1016/j.jrmge.2022.12.015 (2023).

Fengju, K. Modern simulation technology and applications (in Chinese) [M] (National Defense Industry Press, 2001).

Acknowledgements

We gratefully acknowledge the support of the Sichuan Youth Science and Technology Innovation Research Team Project (2020JDTD0006) and the Open Research Fund of Key Laboratory of Reservoir and Dam Safety Ministry of Water Resources (YK323002).

Author information

Authors and Affiliations

Contributions

Yu-han Ran and Hai-bo Li wrote the main manuscript text . Hai-bo Li, Yu-han ran and and Xingguo Yang jointly developed the simulation system. Zhi-chao Yu prepared Figs. 4 and Table 1. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ran, Yh., Li, Hb., Xu, St. et al. Construction simulation and scheme optimisation of complex underground cavities. Sci Rep 14, 20879 (2024). https://doi.org/10.1038/s41598-024-71515-y

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-71515-y