Abstract

This study introduces a novel application of composite materials as Lost Circulation Materials (LCM), leveraging their high specific strength, non-abrasiveness, and environmentally friendly profile. A new formulation of Carbon Fiber Reinforced Polymer (CFRP) composites was developed using an advanced twin-screw extrusion process followed by compression molding. Their efficacy in sealing fractures was quantitatively assessed in accordance with American Petroleum Institute (API) standards using a Bridging Material Tester (BMT). Comparative analysis with previous studies on Bagasse Fiber Reinforced Polymer (BFRP) composites was conducted. Interfacial interactions and fracture morphology were examined through Scanning Electron Microscopy (SEM), revealing the CFRP composites’ superior resistance to water absorption. The moisture absorption tests indicated that the CFRP absorbed 0.7% moisture after 24 h, compared to 15% for BFRP, suggesting enhanced durability in wet conditions. However, despite their robust mechanical properties, they exhibited lower fracture-sealing efficiency compared to BFRP composites. These findings not only underscore the potential of composite-based LCMs in enhancing drilling safety but also guide future research toward optimizing composite formulations for more effective field applications.

Similar content being viewed by others

Introduction

In subsurface engineering, lost circulation—where drilling fluids fail to return to the surface— presents a critical challenge, impacting not only hydrocarbon extraction but also geothermal energy development1 carbon sequestration2, and subsurface energy storage3. Natural or induced fractures4 in the subsurface formation often precipitate this costly issue, which accounts for significant operational inefficiencies, with an estimated 1.8 million barrels of drilling fluids lost annually5.

Lost Circulation Materials (LCM) have emerged as the principal method for combating this issue. These materials, including fibrous, granular, and flaked forms, have been extensively studied for their effectiveness. Pioneering work by Loeppke et al.6 in the 1990s leveraged thermoset rubber and expanded aggregates to mitigate fluid loss, while Aadnoy et al.7 explored the potential of carbon fibers to enhance circulation control.

Recent research has focused on the strategic combination of LCMs, leveraging their synergistic effects to improve fracture sealing. Kumar et al.8 and Pilehravi and Nyshadam9 demonstrated the effectiveness of combining fibers with granular materials for optimized fracture plugging. Additionally, Arshad et al.10 developed a fiber-based pill tailored to specific particle size distributions, providing a customized solution to mud loss. Building on these foundations, Nasiri et al.‘s11 comparative analysis of LCM performance based on concentration highlights the ongoing refinement of subsurface sealing technologies.

Composite materials, distinguished by their adjustable properties and manufacturability into various forms, have attracted increasing interest across multiple disciplines. Their application within drilling fluids has been particularly transformative, offering customized solutions for intricate subsurface challenges. Studies have explored a range of composite formulations. For example, Wagle et al.12 pioneered a nanocomposite activated by inorganic agents for addressing severe fluid losses, while Alanqari et al.13 and Wang et al.14 advanced the capabilities of composite materials using epoxy resins and gel composites, respectively, for fracture sealing and circulation control. Studies by Kefi et al.15 and Savari et al.16 have further demonstrated the adaptability of composite materials to specific loss zones and downhole conditions.

Subsequent advancements have introduced smart materials that respond dynamically to drilling environments, as evidenced by the research of Zhong et al.17, who formulated deformable, oil-absorbent polymer particles, and Ahmed Mansour et al.‘s18 smart LCM that exhibited enhanced performance when combined with fibers. The experimental investigations by Ma et al.19 into polymer/Graphene Oxide Composites and by Mohammadian et al.20 into hybrid nanocomposites have emphasized the role of novel materials in improving fluid loss control and rheological properties. The exploration of shape memory polymers by Tabatabaei et al.21 and the Nano-laponite/polymer composite by Dong et al. and Liu et al.22,23 have contributed to the repertoire of LCMs capable of forming robust seals in demanding conditions.

While these studies contribute valuable insights into the development of advanced LCMs, our research offers a new formulation of CFRP specifically designed for enhanced sealing performance in drilling applications. Unlike previous materials, our CFRP formulation incorporates unique additives and processing techniques to improve its mechanical strength and sealing capabilities. This formulation aims to maximize both mechanical strength and sealing capabilities, thereby addressing specific challenges associated with fluid loss in drilling environments. Our study goes beyond surface-level comparisons by offering a detailed analysis of the interactions between carbon fibers and the polypropylene matrix. This mechanistic understanding aids in elucidating how the unique properties of our CFRP formulation contribute to its performance advantages. Additionally, the particle size distribution of CFRP, which is optimized using the Al-Saba model, is a novel approach in this field. This study conducts a comparative analysis with the previously24 formulated BFRP composites, with the objective of not only enhancing the safety and efficiency of subsurface engineering operations but also guiding future innovations towards sustainable and adaptable sealing solutions.

Materials and methods

Materials

The study employed commercial-grade polypropylene as the matrix material, sourced from Arak Petrochemical Corporation, with its physico-mechanical properties detailed in Table 1. Carbon fibers (Fig. 1), calcium carbonate, and maleic polypropylene (MAPP) as a coupling agent were the additional raw materials, essential to the composite formulation.

Preparation of composites

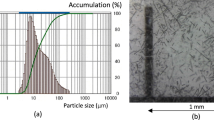

The CFRP composites were synthesized using a counter-rotating Twin-Screw Extruder, based on findings by Ghanai and Ahmad that this process yields enhanced fiber-polymer interaction25 The preparation process was designed as follows: a dry mix of propylene and MAPP was first prepared, to which carbon fibers were then added. This blend was subsequently melt-compounded in the extruder and extruded. The extrudate was quenched in cold water and granulated using a semi-industrial mill (WG-LS 200/200 model). Sieving through a series of meshes followed, to achieve the desired Particle Size Distribution (PSD), which was analyzed according to the Al-Saba model26 (Fig. 2).

Extrusion was carried out under controlled conditions, with temperature profiles and screw speeds optimized to improve composite properties. The extrusion parameters are summarized in Table 2, including the type of extruder, temperature settings (T1–T3 at 463–483 K, T4 at 493 K), screw dimensions, rotational speed, and cooling method.

Physical and mechanical properties

To evaluate the mechanical characteristics of CFRP composites, specimens measuring 250 × 125 mm with a thickness of 2 mm were prepared using a conventional compression molding press, set at a temperature of 443 K and a pressure of approximately 5076 psi (Fig. 3).

The resulting samples were subjected to tensile, flexural, and impact testing to evaluate their performance parameters. The dimensions of the fabricated composite samples are showed in Table 3. The tests included flexural, tensile, and impact assessments, conducted according to ASTM D790, ASTM D638, and ASTM D256, respectively. Additionally, water absorption, a critical physical property, was evaluated following ASTM D570 guidelines. All tests were conducted at ambient temperature and humidity to simulate standard testing conditions.

Water-based mud (WBM) preparation

The drilling fluid utilized in testing the LCM efficacy of CFRP composites was a standard water-based mud (WBM), replicating a 10bbl oil field volume. The mud was composed of a 7% bentonite mixture, with its density and rheological properties benchmarked against API standards and outlined in Table 4.

Fractures sealing performance test

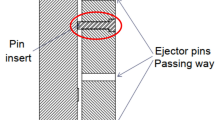

The Bridging Material Tester (BMT), a recognized standard in LCM efficacy testing, was used to simulate subsurface fractures. Using 3-D slots replicating two sizes (0.08-in and 0.16-in), the BMT apparatus (Fig. 4) provided a controlled environment for assessing the sealing performance of the CFRP composite.

The testing protocol involved the following steps, sieving CFRP particles and designing the particle size distribution in alignment with the Al-Saba model, introducing a 20-ppb concentration of the CFRP composite into the WBM, positioning the simulated fracture slot within the BMT cell, subjecting the system to atmospheric pressure and initiating mud flow through the slot, gradually increasing the applied pressure from 100 psi up to 1000 psi, while monitoring the sealing efficiency and fluid loss volume.

The test was designed to continue until a stable seal was maintained under a pressure of 1000 psi for a duration of 10 min. The performance of the CFRP composites was then critically compared with the outcomes from the study by Abdollahi et al.24.

Results and discussion

Physical and mechanical properties

The influence of carbon fibers on the physical and mechanical properties of the composites was evaluated through a series of standardized tests. To ensure accuracy and reliability, each test was conducted using five specimens, and the average values were reported. All mechanical tests were performed under controlled room temperature conditions to maintain consistency in the results. The results provide a comprehensive understanding of how carbon fibers influence the physical and mechanical properties of the composites.

Tensile properties

The tensile properties of the CFRP composites are presented in Fig. 5. Additionally, Fig. 5 compares the tensile properties of BFRP composites from reference21. The CFRP composite exhibited a tensile strength of 2422 psi, significantly higher than that of BFRP composites. This difference can be attributed to the inherently higher tensile strength of carbon fibers. Furthermore, the hydrophilic interaction between carbon fibers and polypropylene (PP) enhances the adhesive bonding, further improving the tensile properties of the CFRP composites. The enhanced tensile and flexural strengths of CFRP compared to BFRP can be attributed to the advantageous fiber orientation and strong interface properties, which together lead to superior load transfer and structural performance. Several studies emphasize the importance of fiber orientation in determining the mechanical properties of hybrid composites. For instance, research indicates that aligned fibers significantly enhance load-bearing capacity, allowing for effective stress transfer along the fiber axis. This aligns with our observations regarding the superior mechanical performance of CFRP composites27,28,29.

Flexural properties

Figure 6 illustrates the flexural properties of the CFRP composite, along with a comparison of the BFRP composites from reference21. The CFRP composite demonstrated a flexural strength of 3858 psi, notably higher than the BFRP composite. This enhanced flexural strength is due to the exceptional stiffness of carbon fibers and the strong interface between the fiber and the matrix, resulting in superior resilience and flexural performance in CFRP composites.

Compressive strength

A servo testing machine with a force capacity of 100 kilonewtons (KN) is utilized for the purpose of evaluating the compressive strength of CFRP composites. These composites are extensively used in various industries due to their exceptional mechanical properties. In order to gain a comprehensive understanding of the performance of CFRP composites, the obtained results are compared with those of BFRP composites as well as pure Polypropylene. The comparative analysis is visually represented in Fig. 7, where the compressive strength values are graphically depicted. It is noteworthy that the maximum pressure applied by the servo testing machine is surpassed by all the tested composites, indicating that their compressive strength exceeds the threshold value of 24,100 pounds per square inch (psi).

The resistance of composite materials to pressure is of utmost importance, particularly in applications such as downhole drilling and bit pressure environments, where the composites are subjected to immense forces. Therefore, measuring the compressive strength of these materials becomes a crucial aspect in assessing their suitability for such demanding conditions. As illustrated in Fig. 7, the CFRP composite exhibits a compression modulus of 2509 ksi and a strain amount of 23%. These values provide valuable insights into the behavior of the CFRP composites under compressive loading, aiding in the design and optimization of structures that require high strength and durability.

Impact strength test

The measurement of impact strength, which is a crucial property in the context of composites, is conducted for the purpose of assessing the performance of CFRP composite. The impact strength of CFRP composites was measured to evaluate its ability to absorb energy during fracture. The impact tests were carried out using a pendulum-type Charpy impact tester at room temperature. During the test, each sample was clamped at both ends and subjected to a pendulum strike in the center. The energy absorbed by the material during fracture was measured and expressed in terms of impact strength (KJ/m²). The results for CFRP, BFRP, and PP composites were compared to assess the relative performance of each material in terms of impact resistance. To facilitate a comprehensive evaluation, the obtained results are then compared to those of BFRP composite, considering two different fiber percentages, namely 30% and 40%, as well as Polypropylene (PP). In order to visualize the obtained findings, Fig. 8 is utilized, which demonstrates that the CFRP composite exhibits the lowest impact strength value, specifically measuring at 2.14 Kj/m2. One plausible explanation for this observed outcome could be attributed to the fact that the Carbon fibers within the composite possess a uniform orientation.

The morphological study using scanning electron microscope images (SEM)

To investigate the microstructure of the CFRP composite, a specimen obtained from the tensile test was meticulously examined using a Scanning Electron Microscope (SEM). The SEM images, presented in Fig. 9 (a-d), revealed that no chemical reaction occurred between the carbon fibers and the polymer matrix within the composite. Notably, the carbon fibers displayed a smooth and tubular morphology with a circular cross-section, promoting a strong bond with the surrounding polymer matrix.

The carbon fibers were found to have an average diameter of approximately 5 microns, with lengths ranging between 80 and 100 microns. The dispersion of fibers within the composite plays a crucial role in determining the overall mechanical properties of the material. The SEM images also revealed a uniform fiber orientation within the polymer matrix. The dispersion of the fibers within the composite plays a critical role in determining its mechanical properties29. As observed, the carbon fibers within the polymer exhibit a uniform orientation, which results in significantly reduced impact and bending resistance when the force is applied perpendicular to the fiber direction.

Water absorption

Water absorption is a crucial physical property that is often measured for various composites. Several studies have explored the impact of moisture on polymer composite properties30,31. For example, Norman et al. reviewed the importance of understanding how moisture uptake affects the mechanical performance of Fiber-reinforced plastics, emphasizing the need for further research in this area30. In the present study, the focus is on the measurement of this property specifically for a CFRP composite. To determine the extent of water absorption, the CFRP composite is subjected to immersion in distilled water for two distinct time durations, namely 2 h and 24 h. After each immersion period, the samples were carefully re-weighed, and the results are presented in Fig. 10, illustrating the water absorption percentages.

From Fig. 10, the CFRP composite exhibits water absorption rates of 0.1% and 0.7% during the 2-hour and 24-hour immersion periods, respectively. This relatively low water absorption can be attributed to several factors that significantly influence the water absorption behavior of CFRP composites. Firstly, the non-polarity of the carbon fiber structure plays a pivotal role in limiting the water absorption capacity of the CFRP composite. Additionally, the high polymer content within the CFRP composite further contributes to its relatively low water absorption characteristics.

Additionally, while the bagasse fiber used in the composite contains a high level of hydroxyl (–OH) groups, which are polar and can enhance water absorption, the overall water absorption of the CFRP composite remains lower than that of BFRP composites. This can be attributed to the dominant non-polar characteristics of the carbon fiber and the overall composite structure.

In summary, the water absorption behavior of CFRP composites is an important aspect to consider in composite material research. The results obtained from the immersion of CFRP composites in distilled water for different time durations shed light on the influence of various factors, such as the non-polarity of carbon fiber structure, the high polymer content, and the presence of hydroxyl OH groups in the constituent materials. These findings contribute significantly to the understanding and optimization of composite materials for numerous applications, ranging from construction to aerospace engineering.

The sealing ability of CFRP composite

The measurement of the ability of CFRP particles to seal fractures of sizes 0.08 inches and 0.16 inches is conducted using the BMT apparatus, and the corresponding results are visually represented in Fig. 11. Due to the significantly high mechanical strength possessed by CFRP particles, they cannot be milled to achieve a wide particle size distribution, thereby rendering them unable to effectively seal fractures of size 0.08 inches. Conversely, in accordance with the findings presented in reference 24, it has been demonstrated that BFRP composites, as well as the combination of bagasse fiber and BFRP particles (MBFRP), have exhibited successful plugging of a 0.08-inch slot. Furthermore, the limited efficiency of CFRP particles is also observed in the case of 0.16-inch slot fractures.

Comparing the sealing ability of CFRP composite with the presented composite in the previous study24. (a) 0.08-inch (b) 0.16-inch slot.

Conclusion

In this research endeavor, the primary objective is to develop a specialized material that would effectively regulate and mitigate lost circulation issues in fractures of small to medium size. To achieve this goal, a specific type of composite material known as CFRP composites have been meticulously created through the utilization of the extrusion process. Following the development of these composites, an in-depth analysis of their sealing performance in water-based mud systems was conducted using the advanced BMT apparatus, which featured various slot depths ranging from 0.08 to 0.16 inches. The particle size distribution of the different LCMs was accurately determined based on the Al-Saba method. Subsequently, the study thoroughly examined the quantities of spurt loss, total fluid loss, and sealing pressure associated with each material in the bentonite mud. These metrics were compared to gain a comprehensive understanding of the materials’ relative effectiveness in addressing lost circulation.

The key findings from the experimental work in this study are summarized as follows:

-

The properties of the composite material, in contrast to conventional materials, have the distinctive characteristic of being able to undergo alteration through the modification of their formulation.

-

Microscopic analysis revealed that the carbon fibers have a smooth and polished surface, devoid of any discernible irregularities. Importantly, there was no evidence of a chemical reaction between the carbon fibers and the polypropylene matrix, indicating strong compatibility and inertness between the two materials.

-

The mechanical properties exhibited by the CFRP composites surpassed those of the BFRP composites, thus emphasizing the superiority of the former over the latter. It is worth noting that the CFRP composites showcased a remarkable enhancement in tensile strength and flexural strength, with an approximate increase of 35% and 25% respectively, when compared to the BFRP counterparts. The incorporation of carbon fiber within the composite material played a pivotal role in augmenting its mechanical properties to a significant extent. However, it is crucial to acknowledge that this improvement in mechanical properties was overshadowed by the inability of carbon fiber to effectively seal fractures, leading to a failure in this particular aspect.

Data availability

The authors declare that the data supporting the findings of this study are available within the paper, its supplementary information files.

Abbreviations

- CFRP:

-

Carbon Fiber-reinforced polypropylene

- BFRP:

-

Bagasse Fiber-reinforced polypropylene

- BFRP-30%:

-

Bagasse Fiber-reinforced polypropylene with 30% bagasse fiber

- BFRP-40%:

-

Bagasse Fiber-reinforced polypropylene with 40% bagasse fiber

- MBFRP:

-

Mixture of BFRP-30% and Bagasse fiber (70/30 ratio)

- WBM:

-

Water-based mud

- LCM:

-

Lost Circulation Materials

- BMT:

-

Bridging Material Tester

- SEM:

-

Scanning Electron Microscopy

- PSD:

-

Particle Size Distribution

- MMA:

-

Methyl methacrylate

- BA:

-

Butyl acrylate

- HMA:

-

Hexadecyl methacrylate

- EFBLC:

-

Engineered fiber-based loss circulation

- MAPP:

-

Maleic Anhydride Grafted Polypropylene

- PV:

-

Plastic Viscosity (cp)

- YP:

-

Yield Point (lb./100\(\:{ft}^{2}\))

- GS:

-

Gels Strength (lb./100\(\:{ft}^{2}\))

- Ksi:

-

kilopound per square inch

- L/D:

-

The ratio of length of the screw to its outside diameter

- T1-T5:

-

Temperature

- ppb:

-

pound per barrel

- ppg:

-

pound per gallon

References

Barbier, E. Geothermal energy technology and current status: an overview. Renew. Sustain. Energy Rev. 6(1–2), 3–65 (2002).

Hassanpouryouzband, A. et al. Geological CO2 capture and storage with flue gas hydrate formation in frozen and unfrozen sediments: method development, real time-scale kinetic characteristics, efficiency, and clathrate structural transition. ACS Sustain. Chem. Eng. 7.5, 5338–5345 (2019).

Hassanpouryouzband, A. et al. Offshore geological storage of hydrogen: is this our best option to achieve net-zero? ACS Energy Lett. 6.6, 2181–2186 (2021).

Howard, G. C. & Scott, P. P. An analysis and the control of lost circulation. J. Pet. Technol. 3 (06), 171–182. https://doi.org/10.2118/951171-g (1951).

Alsaba, M. T., Nygaard, R., Hareland, G. & Contreras, O. M. Review of Lost Circulation Materials and Treatments with an Updated Classification; (2014).

Loeppke, G. E., Glowka, D. A. & Wright, E. K. Design and evaluation of lost-circulation materials for severe environments. J. Pet. Technol. 42 (03), 328–337. https://doi.org/10.2118/18022-PA (1990).

Aadnoy, B. S., Belayneh, M., Arriado, M. & Flateboe, R. Design of well barriers to combat circulation losses. SPE Drill. Complet. 23 (03), 295–300. https://doi.org/10.2118/105449-PA (2008).

Kumar, A., Savari, S., Whitfill, D. L. & Jamison, D. E. Wellbore Strengthening: The Less-Studied Properties of Lost-Circulation Materials. In All Days; SPE, (2010). https://doi.org/10.2118/133484-MS

Pilehvari, A. A. & Nyshadham, V. R. Effect of Material Type and Size Distribution on Performance of Loss/Seepage Control Material. In All Days; SPE, (2002). https://doi.org/10.2118/73791-MS

Arshad, U., Jain, B., Pardawalla, H., Gupta, N. & Meyer, A. Engineered Fiber-Based Loss Circulation Control Pills To Successfully Combat Severe Loss Circulation Challenges During Drilling and Casing Cementing in Northern Pakistan. In Day 2 Thu, May 22, SPE, (2014). https://doi.org/10.2118/169343-MS

Nasiri, A., Ghaffarkhah, A., Keshavarz Moraveji, M., Gharbanian, A. & Valizadeh, M. Experimental and Field Test Analysis of different loss control materials for combating lost circulation in Bentonite Mud. J. Nat. Gas Sci. Eng. 44, 1–8. https://doi.org/10.1016/j.jngse.2017.04.004 (2017).

Wagle, V., Kalgaonkar, R., AlYami, A. & Alanqari, K. Novel loss circulation composition to treat moderate to severe losses. In Day 1 Tue, April 09, 2019; SPE, https://doi.org/10.2118/194653-MS. (2019).

Alanqari, K., Wagle, V., Al-Yami, A. & Mohammed, A. A. Novel epoxy Resin Composition as a lost circulation material: Formulation, Lab Testing and Field execution. In Day 1 Mon, December 06, 2021; SPE, https://doi.org/10.2118/204301-MS (2021).

Wang, H. S. M. Y., ., T. B. F. &. and Z. S. Strengthening a Wellbore With Multiple Fractures: Further Investigation of Factors For Strengthening a Wellbore. In the 43rd U.S. Rock Mechanics Symposium & 4th U.S. - Canada Rock Mechanics Symposium; North Carolina, (2009).

Kefi, S., Lee, J. C., Shindgikar, N. D., Brunet-Cambus, C. & Vidick, B. Diaz, N. I. Optimizing in Four Steps Composite Lost-Circulation Pills Without Knowing Loss Zone Width. In All Days; SPE, (2010). https://doi.org/10.2118/133735-MS

Savari, S., Whitfill, D. L., Scorsone, J. T. & Next-Generation Right-Angle-Setting Composition for Eliminating Total Lost Circulation. In All Days; SPE, (2013). https://doi.org/10.2118/166697-MS

Zhong, H. et al. Mitigation of lost circulation in oil-based drilling fluids using oil Absorbent polymers. Mater. (Basel). 11 (10), 2020. https://doi.org/10.3390/ma11102020 (2018).

Mansour, A., Dahi Taleghani, A., Salehi, S., Li, G. & Ezeakacha, C. Smart lost circulation materials for productive zones. J. Pet. Explor. Prod. Technol. 9 (1), 281–296. https://doi.org/10.1007/s13202-018-0458-z (2019).

Ma, J., Pang, S., Zhang, Z., Xia, B. & An, Y. Experimental study on the Polymer/Graphene Oxide Composite as a fluid loss Agent for Water-Based Drilling fluids. ACS Omega. 6 (14), 9750–9763. https://doi.org/10.1021/acsomega.1c00374 (2021).

Mohamadian, N., Ghorbani, H., Wood, D. A. & Khoshmardan, M. A. A hybrid nanocomposite of poly(styrene-Methyl methacrylate- acrylic acid) /Clay as a Novel Rheology-Improvement Additive for Drilling fluids. J. Polym. Res. 26 (2), 33. https://doi.org/10.1007/s10965-019-1696-6 (2019).

Tabatabaei, M., Taleghani, A. D., Li, G. & Zhang, T. Shape memory polymers as lost circulation materials for sealing wide-opened natural fractures. SPE Drill. Complet. 36 (04), 931–942. https://doi.org/10.2118/205514-PA (2021).

Dong, X. et al. Nano-Laponite/Polymer Composite as Filtration Reducer on Water-based drilling fluid and mechanism study. R Soc. Open. Sci. 9 (10). https://doi.org/10.1098/rsos.220385 (2022).

Liu, F. et al. Novel Modified Nano-Silica/Polymer composite in Water-Based Drilling fluids to Plug Shale pores. Energy Sources Part. Recover Util. Environ. Eff. 44 (4), 8662–8678. https://doi.org/10.1080/15567036.2021.1943071 (2022).

Abdollahi Khoshmardan, M., Jafari Behbahani, T., Ghotbi, C. & Nasiri, A. Experimental investigation of mechanical behavior and Microstructural Analysis of Bagasse Fiber-Reinforced Polypropylene (BFRP) composites to control lost circulation in Water-Based Drilling Mud. J. Nat. Gas Sci. Eng. 100, 104490. https://doi.org/10.1016/j.jngse.2022.104490 (2022).

Ab Ghani, M. H. & Ahmad, S. The Comparison of Water Absorption Analysis between Counterrotating and Corotating Twin-Screw Extruders with Different Antioxidants Content in Wood Plastic Composites. Adv. Mater. Sci. Eng. 1–4. (2011). https://doi.org/10.1155/2011/406284 (2011).

Alsaba, M., Al Dushaishi, M. F., Nygaard, R., Nes, O. M. & Saasen, A. Updated Criterion to select particle size distribution of lost circulation materials for an effective fracture sealing. J. Pet. Sci. Eng. 149, 641–648. https://doi.org/10.1016/j.petrol.2016.10.027 (2017).

Alagumalai, V. et al. Impact response and damage tolerance of Hybrid Glass/Kevlar-Fibre Epoxy Structural composites. Polymers. 13, 2591. https://doi.org/10.3390/polym13162591 (2021).

Razavi, S. M. J. et al. Efficient improvement in fracture toughness of laminated composite by Interleaving Functionalized nanofibers. Polymers. 13, 2509. https://doi.org/10.3390/polym13152509 (2021).

Samson, P. E., Kumaran, S. S., Shanmugam, V. & Das, O. The effect of fiber orientation and stacking sequence on carbon/Kevlar/epoxy intraply hybrid composites under dynamic loading conditions. Polym. Adv. Technol. 34 (5), 1585–1598. https://doi.org/10.1002/pat.5993 (2023).

Osa-uwagboe, N., Silberschmidt, V. V. & Demirci, E. Review on mechanical performance of Fibre-Reinforced Plastics in Marine environments. Appl. Compos. Mater. https://doi.org/10.1007/s10443-024-10247-8 (2024).

Norman, O., Silberschmidt, V. V., Konstantinos, P., Baxevanakis, E. & Demirci Effects of moisture absorption on penetration performance of FRP sandwich structures. Compos. Struct. 344, 0263–8223. https://doi.org/10.1016/j.compstruct.2024.118319 (2024).

Author information

Authors and Affiliations

Contributions

Maryam. Abdollahi Khoshmardana prepared the experimental data and wrote the main manuscript text. Taraneh. Jafari Behbahani designed the experimental set up , validated experimental data and edited manuscript as supervisor.Cyrus. Ghotbi validated manuscript as supervisor. Aliakbar Hassanpouryouzband edited the manuscript. Alireza. Nasiri prepared the used material in experimental tests.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Khoshmardan, M.A., Behbahani, T.J., Ghotbi, C. et al. Experimental study of polymeric composite reinforced with carbon fiber for mud lost control application. Sci Rep 14, 25225 (2024). https://doi.org/10.1038/s41598-024-76756-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-76756-5