Abstract

Building energy consumption accounts for nearly one-third of the total energy consumption of the whole society, and this proportion is higher in China. We rehabilitate a large number of buildings every year, and the reuse of existing building materials can significantly reduce energy consumption and building pollution, as well as save time and money spent on rehabilitation. The insulation and decorative integrated board is widely used in cold regions of China, once damage occurs, the old one is often dismantled and replaced with a new one, which takes a long time to repair and also causes pollution and waste. The objectives of authenticity restoration method is to reduce building pollution, save construction time, and restore the original appearance of the building. It is divided into two main steps: the first is the reinforcement of the thermal insulation and decorative integrated board, and the second is the repair of the decorative layer. Compared with the traditional restoration method, it does not require the removal of the old one-piece board, which can shorten the restoration time by 50% and produce zero pollution. It adds construction materials to the building facade, which can improve the thermal insulation performance of the building. The external wall reinforcement technology and facade optimisation design are key to authenticity restoration, ensuring the building’s sturdiness while also reducing the amount of building materials. For buildings with large areas of damage to the insulation and decorative integrated boards, the authenticity restoration method has been proven to be effective through practice and time.

Similar content being viewed by others

Introduction

Energy consumption has become a key concern for economic development. Governments have vigorously advocated the concept of energy conservation, emission reduction and green environmental protection1. The energy consumption of the construction industry cannot be ignored. China is in a period of rapid economic development, with a large number of new buildings every year2. At the same time, a large number of existing buildings have been renovated in recent years, especially those with damaged facades. Their air conditioning, heating, ventilation, water supply and drainage systems have aged, and energy consumption is huge. Therefore, the repair and transformation process must pay attention to energy conservation and emission reduction in order to achieve stable development. In cold regions, due to the large temperature difference in one year, once the building facade is damaged, it not only affects the building image, but also affects the building insulation and safety3.

The Insulation and Decoration Integrated Board (IDIB) is a new type of insulation board for external walls. In recent years, it has been widely used as a prefabricated building component. It is composed of an adhesive layer, thermal insulation decorative finished board, anchorage, sealing materials, and so on4. It integrates many functions, such as fire prevention, waterproofing, thermal insulation, and decoration. As it can be produced in a factory-integrated manner, saving a lot of manpower, material resources, and time costs, its construction cycle is relatively short. It has received unanimous praise in cold areas and is widely used. However, as it is bonded as one unit, if one material is not up to standard, the materials will affect each other under low-temperature conditions, causing damage to other materials and resulting in the loss of thermal insulation and decorative properties. This leads to a long repair time and poor maintenance. According to the materials, the IDIB studied in this paper can be divided into: stone paint IDIB, metallic paint IDIB, multicoloured paint IDIB, and waterborne sand IDIB (Fig. 1)5.

There are also some problems in the application process (Fig. 2), such as fading, breakage, shedding, mould, thermal bridging, etc. These problems are often caused by freeze-thaw damage of materials, which cannot be avoided in cold regions. They mainly arise during the production, installation, and usage phases. Once a problem occurs6, the safety and insulation of the building will be compromised7. The traditional restoration method involves the demolition of the old and the installation of the new integrated board. In this case, the old IDIB will be discarded, resulting in building pollution and material wastage. At the same time, removing the old ones and installing the new ones are two separate construction processes, which takes longer and affects both the use of the building and its thermal insulation performance. In cases of extensive damage, major restoration is required, which consumes a significant amount of time, labour and materials, and results in a waste of resources and money, making it unsustainable. This study proposes the concept of “authenticity restoration”. The main approach is not to remove the original broken one-piece board but to install mesh fabric and back-screwed bolts on it. The facade is then painted, and the building’s lines are designed to restore the original appearance. This method aims to save building materials during the restoration process, saving both time and money while also improving the building’s thermal insulation to better suit the characteristics of cold urban buildings8.

External wall thermal insulation technology research has a long history. European countries have academic theoretical system and project application experience in the 1940s9. After the thermal insulation wall is put into use for a certain period of time, many walls have cracking problems10. The earliest repair method is to paste the thermal insulation board on the outer wall, which can effectively play a thermal insulation effect on the internal space, reduce the occurrence of wall cracks, and ensure the indoor temperature. The thermal insulation materials used in the structure are mainly EPS boards, followed by XPS boards and other materials. According to the temperature change and climatic conditions in Germany11, the thickness of economic thermal insulation board suitable for domestic use is studied. New technologies are also used in the external enclosure structures such as doors, windows and glass. For example, a certain thickness of thermal insulation material is added to the structural nodes such as external walls, external windows and roofs. Three layers of glass material and closed window frame with inert gas barrier are also used in doors and windows to achieve thermal insulation effect and decorative effect. At the same time, the United States has also begun to improve the insulation technology12. For example13, the cold areas in the north and the hot areas in the south of the United States have widely used the external wall insulation technology, and the building energy saving effect has been significantly improved14.

Rodrigues et al. evaluated the theoretical test performance of the new external thermal insulation system15. The purpose of the study was to improve the energy efficiency of residential buildings. A comprehensive investigation and test was conducted to test the applicability and effectiveness of the new external thermal insulation system in buildings, including: The theoretical thermal performance of the new thermal insulation system was tested by steady-state simulation. Based on laboratory test data, the demand for air conditioning heating was reduced by 42%16, and the demand for heating energy added to the system was reduced by 49%. The research also shows that the new thermal insulation system can not only meet the thermal insulation performance of the external wall, but also is easy to install and does not depend on the change of weather conditions17. It can be seen that the external wall insulation technology has been widely used around the world, and has achieved results in building energy conservation and environmental protection18.

Sha et al. conducted a study on the impact resistance of IDIB in cold regions. The experimental results revealed that impact-induced pits easily occurred on the IDIB, but without leading to fracture. This fully demonstrates that the IDIB is suitable for use in cold regions. The research results show that the larger the bonding area, the more stable the material, with maximum stability achieved when the bonding area exceeds 77%19. Kan et al. conducted research on the innovation and development of vacuum insulation panels, a new type of high-efficiency thermal insulation material. Due to its excellent properties, it has been widely promoted in China20. Chu et al. studied the fire resistance of IDIB. The experimental results showed that it has better fire resistance21, which is not affected by outdoor ambient temperature. The structure also exhibits certain stability, and suitable protection layer materials can prevent cracking and loss of cohesiveness. This demonstrates that improving the material can enhance the service life of the one-piece board, preventing damage. In summary, most of the research on IDIB focuses on various properties of the material, mainly including fire resistance, thermal insulation, and stability. While it has been shown to be usable in cold regions, there is little research on its damage, especially regarding how to ensure safety and aesthetics during its use. This study aims to fill this gap.

In recent years, China has paid more attention to IDIB work. In 2019, Liu conducted a survey and analysis of the external thermal insulation shedding accidents of existing buildings, investigated the structural composition and material classification of common external thermal insulation systems22, and carried out tensile tests on the stress and performance. The structural and construction technical requirements of the anchor bolt in the block base were proposed, and the ABAQUS finite element software was used to simulate and analyze the mechanical properties of the external wall system to determine the reasonable number and arrangement of the anchor bolts. Li Ming et al. have studied, analyzed and optimized the thermal insulation capacity, stability and durability of the system through on-the-spot investigation, test detection and software simulation, so as to ensure the safety of IDIB use23. However, most of the problems are removed and repaired, which wastes both time and money. It can be seen that although the external thermal insulation technology has gradually matured, there are also quality problems that need to be further studied and solved24.

Current situation investigation and problem analysis

Present situation investigation

The structural composition of the IDIB can be basically divided into a thermal insulation layer, a base plate, and a decorative layer (Fig. 3), which simultaneously addresses the thermal insulation and decoration of the building’s exterior wall. However, some IDIBs have experienced fading, damage, detachment, thermal bridge effects, and other issues after a period of use. Due to the difficulty of maintenance and repair in the later stages, along with high construction costs, the facade image of many buildings has been damaged, and the thermal insulation performance has significantly decreased, impacting its overall functionality.

In China, the climate varies greatly between regions. The cold region referred to in this study is mainly the region shown in (Fig. 4). The coldest temperature in this area ranges from − 5 °C to -20 °C over the course of a year, with the daily average temperature falling below 5 °C for more than 120 days. This region is one of the five major climate zones in China, with representative areas including Beijing, Hebei, and other regions25. In winter, indoor buildings should meet the needs of heat preservation and antifreeze protection, while in summer, attention should be paid to heat protection and the reduction of air conditioning energy consumption. At the same time, relevant norms and requirements have also been issued to improve the use and subsequent restoration of IDIB (Table 1)26.

Climate zones in China. The map was generated using QGIS (version 3.28.0; https://www.qgis.org) and Adobe Photoshop (version 2020; https://ps.adobe-cn.com/). Boundaries were obtained from Building Climate Zoning Standards (https://ebook.chinabuilding.com.cn/zbooklib/bookpdf/probation?SiteID=1&bookID=57793).

Problem analysis

-

1.

Production Phase

The IDIB is primarily composed of thermal insulation core material and decorative board Material. The physical properties, compactness, and structural characteristics of the thermal insulation core material will have different effects on thermal conductivity27. The material of the thermal insulation layer may be a complex capillary porous body, and there may be air, liquid water, and other substances in the pores of the wallboard. The choiceof veneering material will also affect the thermal performance of the composite integrated board.

From the perspective of the material’s properties, the thermal conductivity of metals is larger, followed by non-metallic materials, liquids, and finally gases, which have the smallest thermal conductivity.

The quality per unit area is not up to standard. According to the requirements of the “Insulation and Decoration Integrated Board Insulation System Materials”, the weight of the integrated board should be less than 30 kg/m². Exceeding this value will increase the burden on the wall, leading to the risk of falling off. At the same time, the weight of the panel in the integrated board constitutes the majority of the weight. Generally speaking, the lighter the panel weight, the higher the cost28. To save costs, some enterprises fail to meet the panel standards, leading to the eventual detachment of the integrated board over time.

The water absorption and water vapour permeability are not up to standard. Generally, the water vapour permeability of the polyurethane core material is higher than that of the panel. In winter, as the outdoor temperature drops, there is a large temperature difference between the interior and exterior of the building’s external wall insulation system. The side with a higher temperature exerts a larger water vapour pressure, causing the water vapour to migrate from high to low pressure. If the water vapour permeability of the panel is poor, the water vapour between the panel and the insulation core material cannot escape, leading to condensation, which generates frost heaving forces and exacerbates the damage to the integrated panel. This is especially problematic in cold cities, where the temperature difference between the indoors and outdoors in winter is significant29. The frost heaving force persists for a long time, and the force increases over time. To ensure better air permeability and water absorption performance, a wider strip position should be reserved to ensure structural stability.

Insulation core material is not up to standard. The thermal insulation core material is an important component of the thermal insulat on decoration integrated board, as it determines the thermal insulation performance30. Common core materials used in integrated boards include rigid polyurethane boards (PU), rock wool, expanded polystyrene (EPS), phenolic resin, and others. In different building climate zones, different materials should be selected during construction. The thermal conductivity, apparent density, and combustion grade performance of these core materials are summarised as follows (see Table 2).

Table 2 Main properties of different insulation core materials. It can be seen from the table that organic thermal insulation materials (EPS, XPS, PU, phenolic) have low thermal conductivity and good thermal insulation properties, but they are poor in fire resistance and can easily catch fire. Although the thermal conductivity of rock wool is larger, it is classified as a Class A non-combustible material and is relatively safe. In cold areas, thermal conductivity is particularly important; generally, as the thermal conductivity decreases, so does the mechanical strength, and therefore, careful selection is required.

-

2.

Installation Phase

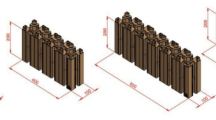

The installation methods for IDIB mainly include bonding type, dry-hanging type, anchoring type (Fig. 5).

Bonding type: This method involves connecting the integrated board to the foundation wall solely through bonding. According to the design needs of the external wall, it can be either point-sticky or full-sticky, with the plate joints sealed with mortar seaming material. This method is easier to install but tends to have the most issues in the long term31.

Dry-hanging type: This method fixes the keel to the base wall first, then connects the integrated board to the keel using a metal connector or special anchor. The external insulation system’s seams can be sealed with sealant.

Anchoring type: This method combines both bonding and anchoring. The integrated board is securely fixed to the foundation wall, ensuring stability. This method is more costly but the safest option.

Additionally, materials have different curing times. If the materials have not fully cured before installation32, there may still be interactions between them. In cold areas, temperature fluctuations cause thermal expansion and contraction, which can lead to internal stress and damage from mutual extrusion. Workers must evenly distribute the mortar on the back of the integrated board during installation, then paste it onto the wall surface, adjusting the flatness and joint width. The bonding mortar should be stirred regularly and must be used up within 4 h. Furthermore, the construction follows a point bonding process, with the bonding area measuring 130–150 mm straight, and covering about 40% of the integrated board’s area. If the bonding area is less than specified, the firmness of the integrated board is greatly reduced, leading to cracking and detachment.

-

3.

Using phase

The thermal bridge effect is a part of the building envelope’s thermal performance. The existence of thermal bridges increases energy loss throughout the building, and this is inevitable. It is primarily manifested in thicker structures or materials with larger thermal conductivity in the building envelope, such as thermal bridge columns or larger thermal bridges. It can also be seen in areas where the internal and external surfaces of the enclosure structure are uneven, such as ceilings, walls, and floors. The integrated boards in these areas are prone to fading and shedding (Eq. 1)33.

$$\:{K}_{m}\:=\:\frac{{K}_{P}\cdot\:{F}_{P}+{K}_{B}\cdot\:{F}_{B}}{{F}_{P}+{F}_{B}}$$(1)Where KP represents the heat transfer coefficient of the main part of the external wall, kB represents the heat transfer coefficient of the thermal bridge of the external wall, fP represents the area of the wall, fB represents the area of the thermal bridge composed of beam, plate and column.

It can be seen from the equation that since the heat transfer coefficient KB of the thermal bridge is much larger than the heat transfer coefficient KP of the main part, the existence of the thermal bridge will increase the average heat transfer coefficient of the entire wall. The structural area at the thermal bridge is large, and this increase in the average heat transfer coefficient will lead to greater energy loss from the building (Table 3).

Level of deterioration of IDIBS

Repair methods

Traditional repair methods

In the event of damage, shedding, and other problems with the IDIB, the traditional repair method typically involves removing the original board entirely and reinstalling a new integrated board34. If there are multiple integrated boards with problems, additional new boards need to be installed. This results in multiple “big patches” on the building, which causes the facade to have varying colors. This not only affects the aesthetic appearance of the building but also compromises its safety. It is a temporary repair method that does not address the underlying issues and may even cause further shedding problems, leading to potential safety hazards. While removing and reinstalling the problematic integrated boards may solve safety and aesthetic issues, it is costly in terms of manpower, materials, and financial resources. Moreover, the construction period will be lengthy, and the repair costs will be significantly high.

Authenticity restoration method

The authenticity restoration method follows the principle of “repairs the old to a state akin to new,” using a comprehensive repair approach that preserves the original style of the building facade while achieving safety and thermal insulation objectives. As a technical expert, the author participated in a practical project focused on repairing the insulation and decoration integrated boards in cold regions. This maintenance project has been in use for five years and has yielded positive results. Without damaging the original insulation and decorative integrated boards35, the authenticity restoration process involves applying three layers of cement mortar and two layers of grid cloth, anchored by re-twisting bolts in the outer layer of the decorative panel (after calculations, the load area of a single bolt is no more than 0.18 m². The veneer adopts an imitation stone paint maintenance scheme, and the facade is optimized36. The repair process primarily consists of two stages: the repair process and the stone-like paint finishing process (Fig. 6).

-

1.

Integrated board repair process

Although the integrated board has faded and suffered damage37, the thermal insulation function of the polyurethane core remains intact (Fig. 7). Therefore, the primary goal of the repair is to prevent further damage and detachment while maintaining its thermal insulation function.

-

2.

Stone-like lacquer finishing process

After the integrated board system has been restored (Fig. 8), an imitation stone paint process is used to restore the original facade effect and achieve the goal of “repairing as good as new.”

In this process, each step involves multiple construction stages (Fig. 9), and the two main processes should be integrated. This scheme represents a comprehensive maintenance approach, with the building’s details, such as doors, windows, openings, and parapets, being treated in paralle (Fig. 10). Due to the large number of construction steps and technical requirements, detailed calculations and planning are necessary to ensure the integrity and scientific accuracy of the authenticity restoration.

Comparison of the two restoration methods

Compared with the traditional restoration method, authenticity restoration does not produce a large amount of construction waste or pollute the environment. For example, for a building with a length of 50 m, a width of 12 m, and a height of 30 m, the total area of the building facade is 3720 m² according to Eq. 2. When the building’s IDIB is extensively damaged, the traditional method can only involve removal and reinstallation. The IDIB will occupy about 80% of the total area due to the number and location of windows and doors, resulting in more than 3000 m² of construction waste and environmental pollution. Authentic restoration does not involve the removal of the old decorative integrated board, thus preventing the generation of construction waste and environmental pollution. Authentic restoration can be applied to the existing decorative integrated board without its removal, thus reducing construction time by 50%. Authentic restoration can improve the building’s thermal insulation. It involves reapplying mesh fabric, mortar, and other materials to the exterior surface of the existing building38, increasing its thickness, which is especially important in cold regions. Authentic restoration also saves money, as the author’s total labour costs are lower due to the shorter duration of the work involved in the project. In terms of building material costs, there is no longer a need to purchase decorative integrated boards. However, materials such as mortar, mesh, and bolts are required, with material costs remaining stable and an overall cost reduction of about 10%. In summary, the advantages of authenticity restoration are clear39.

Where S represents the total area of the building facade, l represents the length of the building, w represents the width of the building, and h represents the height of the building.

Key points in authenticity restoration

Construction process

The construction process is divided into two main steps40. The first step involves the repair construction of the integrated board. According to the characteristics of the fiber grid cloth, the weight of the two-layer grid cloth should follow the principle of “heavier inside, lighter outside” to ensure better attachment to the wall. The thickness of the three layers of anti-cracking mortar should follow the principle of “thinner inside, thicker outside” to ensure the flatness of the wall surface. At the same time, the re-twisting bolts should be securely fastened to the building41.

During construction, the following points should be ensured: The anti-crack mortar must be mixed well on-site and allowed to cure for more than five minutes to ensure its viscosity and air-tightness; The glass fiber mesh cloth must be properly overlapped, especially around doors, windows, and parapets, to ensure the integrity, standardization, and safety of the construction.

The second step involves the imitation stone paint process, which is key to the restoration of authenticity. The objective is to “repair as good as new” and restore the original appearance of the building. The process begins with flattening the two putty layers to ensure the facade’s smoothness, followed by the application of imitation stone paint to restore the building’s original color. The color must closely match the original, and line divisions should be done using high-quality grain paper. To ensure the overall aesthetic, the facade can be optimized during this process. The original integrated plates are often limited by size, resulting in a dense and less aesthetically pleasing appearance. Re-optimization can involve creating larger segments, which improve the visual effect (Figs. 11 and 12). Finally, a stone-like topcoat is sprayed. During construction, it’s crucial that each layer of spray coating has adequate drying time and is applied at an appropriate temperature to ensure the coating’s stability and prevent chemical reactions that may interfere with each other.

Construction materials

Several building materials are used in the authenticity restoration process, including glass fiber mesh, anti-crack mortar, back-screw bolts, putty, paint, and textured paper, as well as auxiliary tools like spray guns, hammers, and brushes. Some of these materials are particularly critical39. Glass Fiber Mesh: The weight of the glass fiber mesh is essential. From inside to outside, the mesh should weigh 300 g/m² for the inner layer and 160 g/m² for the outer layer. Experimental studies have shown that the weight of mesh should be accurate. Back-screw Bolts: The thickness of the insulation and decoration integrated board is approximately 110 mm, so the length of the bolt should be around 150 mm to embed into the main structure of the building, ensuring sufficient pullback force. Textured Paper: The width of the textured paper should align with the gap width between the original integrated boards, typically around 12 mm, to maintain a unified and coordinated facade style.

Calculation of the umber of screw-back bolts

Reinforcement technology is crucial in the repair of integrated boards. The re-twisted bolt is a primary component, and its number directly affects the building’s safety. If the number of bolts is too high, it may create “nail bags” that negatively impact the building’s appearance. If too few bolts are used, the reinforcing effect is inadequate, leading to potential damage and shedding, which defeats the purpose of the repair.

To determine the optimal number of bolts, a scientific mathematical model is used, considering factors such as building height, wind load, and the compression resistance of the integrated boards21. The process involves the following steps:

-

1.

Numerical calculation of wind load (Eq. 3)

$${W_k} = {\beta _{gz}}{\mu _{s1}}{\mu _z}{w_o}$$(3)Where Wk is the standard value of wind load (kn/m2), βgz is the gust coefficient at height Z, µs1 is the local shape coefficient of wind load, µz is the height variation coefficient of wind pressure, wo is the basic wind pressure (kn/m2).

Among them, for flat or slightly undulating terrain, the wind pressure coefficient (βgz) and the wind pressure height variation coefficient (µz) of the maintenance component should be determined according to the surface roughness (Tables 4 and 5 ). The ground roughness is divided into four categories: A, B, C and D: A refers to the near sea surface and island area; B refers to the field villages and towns with sparse houses; C refers to the urban area with dense buildings; D refers to the urban area with only dense buildings and high building height.

Most buildings with a height of less than 30 m are in Environment C. In this study, Environment C is selected as the standard. From the Table 3, we can see that the wind pressure coefficient for maintenance components at a height of 30 m is twice that at 5 m. This indicates that as the height increases, the wind pressure increases, although this is not an absolute relationship. The coefficient of variation of wind pressure for the maintenance component at a height of 30 m is lower than that at 5 m, indicating that as height increases, the coefficient of variation of wind pressure decreases. The coefficient of variation of wind pressure is related to wind speed fluctuations. At higher heights, wind speed is more stable, which leads to a smaller coefficient of variation of wind pressure. Specific data can be found in the (Tables 4 and 5) according to GB 50,009 − 2012.

Table 4 The gust coefficient at height z (βgz). Table 5 Wind pressure height variation coefficient (µz). -

2.

Local shape coefficient of wind load (µs1)

The local wind pressure shape coefficient µs1 (suction, tension) of the enclosure member is calculated. According to GB 50,009 − 2012, the local wind pressure shape coefficient is determined, the wall surface value is 1.0, and the wall angle value is 1.40. Basic wind pressure: Refer to the snow pressure wind pressure and basic temperature of cities across the country (select Harbin) .Here, the basic wind (wo = 0.55 kN/m2) pressure value of 50 years is selected. In summary, the standard value of wind load is calculated as follows (Tables 6 and 7).

Table 6 Wind load value at wall surface. Table 7 Wind load value at wall corner. -

3.

Bolt calculation

The design value of the wind load is 1.5 times the standard value. Considering issues such as.

Anchoring bolt types, oversized boreholes, improper insertion methods, and material aging, a safety factor of 2 is applied. According to the standard JGT366-2022 for “Anchor Bolts for Exterior Wall Insulation,” the tensile bearing capacity of a single anchor bolt must not be less than 0.6 kN. Based on this, the number of bolts for wall surfaces and corners is calculated (Tables 8 and 9).

Table 8 Calculation results of screw-back bolts at the wall surface. Table 9 Calculation results of screw-back bolts at corners. For buildings less than 30 m high, the results indicate that the number of screw-back bolts should be greater than 5.15 per square metre. This study recommends 6 to 7 per square metre.

Facade optimization design

The construction of the imitation stone lacquer should adopt the concept of “repairing the old as the new.” The goal is to reshape and refresh the building’s facade, improving its visual appeal.

-

1.

Color selection

The architectural color should blend harmoniously with the surrounding environment and reflect the local history and culture42. It should also incorporate modern elements while coordinating with the building’s original color. For cold regions, the facade color should take into account the solar radiation heat absorption rate and the local cultural context. Different types of buildings, such as residential, office, industrial, and agricultural buildings, may require different colors depending on their functional roles in the city. For example: Dormitory buildings at a university may use a classic red, white43, and gray color scheme, with natural textures such as stone or marble, aligning with the academic environment’s solemn and elegant image (Fig. 13); A childcare building in a maternity and child hospital may use pink and light yellow to create a warm, inviting atmosphere, matching the hospital’s function and gentle, caring environment (Fig. 14).

-

2.

Design of lines

In the construction of imitation stone paint, the “bullet line division” method can be used to design the facade’s composition. Different styles include (Fig. 15). Horizontal Composition: Using design lines and the horizontal lines of windows to form a horizontal grid. Vertical Composition: Creating a vertical grid using concave or convex wall features. Grid Composition: Incorporating window concave designs and line patterns to form a grid. Irregular Composition: Using different shapes and arrangements to create graphics and patterns.

-

3.

Details of the transformation

The structural joints of the building facade—such as the feet, corners, doors and windows, balconies, awnings, parapets, and air conditioning partitions—are vulnerable to cracking and falling off due to material heat, anchoring methods, and external forces. This study suggests optimization designs for the feet, windows, and parapets to ensure practicality and structural integrity.

Leg structure design

The foot of the building helps protect the exterior wall from rainwater and surface water. The design must ensure a moisture-proof layer to prevent water leakage, with an appropriately thick, strong, and impact-resistant decorative layer (Fig. 16).

Window structure design

The focus is on thermal insulation and air-tightness. The window design must prevent rain and snow accumulation, which could cause water leakage into the window frame. The window frame materials must be integrated to prevent thermal bridge effects (Fig. 17).

Parapet wall structure design

The parapet wall is designed to prevent cracking and water seepage while ensuring the building’s thermal performance. The structural design should address external weather impacts, settlement, and ensure proper anchoring of the thermal insulation system (Fig. 18).

Precautions in authenticity restoration

-

1.

The number of screw-back bolts is crucial for authenticity restoration, as it affects both the safety and aesthetics of the building. There are several influencing factors, primarily including building height and surroundings. Wind load values should be calculated separately for the corners and walls. For buildings with significant damage to the facade, the maximum value at the highest point of the wall corner should be used (see Table 8). For buildings with limited damage to the facade, the wind load value should be determined based on the specific height and location. Then, according to the Technical Specification for the Application of External Thermal Insulation Systems for Thermal Insulation and Decorative Panels (GB5229/2022), we determine the number of bolts per square metre based on the standard tensile load capacity of individual anchor bolts, which, in principle, should be calculated for the highest point at the building’s corner. In this study, the height of the building’s highest point was chosen to be 30 m, which aligns with the design standards for older Chinese buildings. If the building height exceeds 30 m, the number of screw-back bolts should not be excessive. If the number exceeds the calculated value, it can cause an uneven facade appearance due to the excessive number of bolts, which negatively impacts the aesthetics and fails to achieve the desired effect of authenticity restoration.

-

2.

After restoration, the building must undergo regular inspection and maintenance. The cover coat is the final step in the authenticity restoration process. It ensures the style of the restored building facade, with a general service life of 10–15 years. However, in cold regions, its service life may be reduced by 3 to 5 years. Cleaning should be done using a mild detergent or a low-pressure water jet, with regular maintenance performed on the overcoat. These maintenance products can form a protective film on the surface of the overcoat, enhancing its resistance to staining and weathering and prolonging its service life.

-

3.

The repair scheme does not fundamentally solve the problem of poor water vapor permeability of the decorative panel. At the same time, the plastering layer may also increase the wet resistance of the original surface after maintenance. Although the force is relatively small, and the re-twisting bolt has fixed it, strengthening the wet permeability adjustment measures should enhance the structure’s stability.

-

4.

Nodes such as parapets and exterior wall doors and windows in the building are easy to ignore in architectural design and construction. The standard specification of the IDIB is 600 mm×1200 mm, but at the location of doors, windows, and parapets, the dimensions may vary, leading to integration issues with the wall. During the repair process, these areas often need to be addressed separately. In the grid cloth lap, the integrity should be paid attention to. The density of the screw-back bolt should be greater than that of the ordinary repair surface. Additionally, the construction techniques used when spraying the imitation stone paint should be carefully managed to ensure the unity and integrity of the facade style.

-

5.

Screw-back bolts exhibit a certain brittleness, and after prolonged exposure to low-temperature environments, their strength may be significantly affected. At this point, regular pull-out tests should be performed at different points. It is essential to ensure that the load-bearing capacity of a single screw-back bolt is not less than 0.6 kn. If the experimental data decreases, the number of bolts at the same position should be increased to ensure the safety of the building facade.

-

6.

To assess the feasibility of using or rehabilitating IDIBs in cold regions, it is necessary to establish an evaluation methodology that integrates thermal performance and environmental impact. The method should take into account the energy consumption of the building (heating/cooling load) and the “embodied energy” required for redecoration (Table 10).

The methodological recommendations for evaluating the viability of IDIB in cold regions are as follows:

Thermal simulation: both steady-state and dynamic thermal simulations are employed to evaluate the heat transfer performance of three distinct wall configurations: (1) the original unmodified assembly, (2) full replacement with new IDIB panels, and (3) a restoration approach employing an authenticity-preserving retrofit strategy. These simulations allow for a comparative assessment of heating and cooling loads under each scenario.

Energy demand comparison: based on simulation outcomes, calculate the annual energy savings per square meter. Additionally, assess the impact of increased insulation thickness—particularly from added layers in the retrofit process—on the overall thermal resistance and energy efficiency.

Life Cycle Assessment (LCA): apply standardized LCA tools and databases (e.g., Ecoinvent) to evaluate and quantify the embodied energy of materials used in both the full replacement and authenticity-preserving repair strategies. This enables a comparative analysis of the environmental burden introduced by each method, including material production, transportation, and installation.

Structural stability assessment: ensure mechanical safety by modeling wind loads and calculating the required number of screw-in anchor bolts, based on national wind load standards and material pull-out strength. This ensures the structural integrity of the retrofit while minimizing material use and maintaining safety margins.

These components form a comprehensive and science-based methodology for assessing the technical and environmental feasibility of IDIB retrofitting strategies in severe climate zones.

Conclusion

-

1.

From the above discussion, it can be concluded that the authenticity restoration method is an innovative approach. When the building facade’s IDIB is extensively damaged, it can still provide thermal insulation and decorative functions, ensuring the building’s safety. Compared to previous research, this method is applicable to various building materials, and both the construction process and concept are innovative.

-

2.

Reinforcement technology is a critical step in authenticity restoration, ensuring the building’s safety. After calculations for cold regions, when the building height is less than 30 m, 6–7 screw-back bolts per square metre are appropriate and safe (see Table 8). When the building height exceeds 30 m, the wind load on the wall increases. To ensure safety, more screw-back bolts are required. However, if the number exceeds 10 per square metre, this may cause an uneven facade, affecting aesthetics and compromising the authenticity of the restoration.

-

3.

The authenticity restoration method is not applicable when the heat preservation decorative integrated board suffers small-scale damage, as it requires additional building materials, which will increase the thickness of the restoration, making the building appear uneven and affecting its aesthetics. In this case, the old IDIB should be removed and replaced with new panels. Although this construction process is more involved, it remains a feasible solution.

-

4.

To ensure the longevity of the restoration, spray coating is the final step. In cold regions, coatings with cold and alkali resistance should be selected, and the warranty period should exceed 15 years. Additionally, wall cleaning should be performed every 5 years to maintain the building’s safety and aesthetics.

-

5.

In cold regions, IDIB may be damaged after more than 20 years of use. If the area of damage exceeds 1/3 of the building facade, overall restoration becomes feasible. The concept of authenticity restoration is innovative, as it saves building materials, reduces construction waste, conserves energy, and protects the environment. With the increasing number of old buildings and the general deterioration of facades, the authenticity restoration method holds significant promotion value and practical relevance.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Kilicaslan, A. E. & Kus, H. Evaluation of the hygrothermal performance of external thermal insulation applications on the outer walls of existing buildings. J. Fac. Eng. Archit. GAZI Univ. 36, 89–103 (2021).

Kayfeci, M., Kecebas, A. & Gedik, E. Determination of optimum insulation thickness of external walls with twodifferent methods in cooling applications. Appl. Therm. Eng. 50, 217–224 (2013).

Rodrigues, L. et al. Theoretical and experimental thermal performance assessment of aninnovative external wall insulation system for social housing retrofit. Energy Build. 162, 77–90 (2018).

Park, S. et al. Evaluation of mechanically and adhesively fixed external insulation systems using vacuum insulation panels for High-Rise apartment buildings. Energies 7, 9 (2014).

Zhao, X. Coastal building energy conservation based on rigid polyurethane foam external wallinsulation technology. J. Coastal Res. 110, 247–250 (2020).

Tettey, U. Y. A., Dodoo, A. & Gustavsson, L. Primary energy implications of different wall insulation materialsfor buildings in a cold climate. In International Conference on Applied Energy, 61, 1204–1207 (2014).

Parracha, J. L., Borsoi, G. & Flores-Colen, I. Impact of natural and artificial ageing on the properties of multilayer external wall thermal insulation systems. Constr. Build. Mater. 317(2021).

Goncalves, M. et al. A review of the challenges posed by the use of vacuum panels in external insulation finishing systems. Appl. Energy. 257 (2021).

Zhu, J. & Li, D. Current situation of energy consumption and energy saving analysis of large public building. Procedia Eng. 121, 1208–1214 (2015).

Oral, G. K., Yener, A. K. & Bayazit, N. T. Building envelope design with the objective to ensure thermal, visual and acoustic comfort conditions. Build. Environ. 39, 281–287 (2004).

Sadineni, S. B., Madala, S. & Boehm, R. F. Passive building energy savings: a review of building envelope components. Renew. Sustain. Energy Rev. 15(8), 3617–3631 (2011).

Ke, W., Gang, W. & Wan, Y. Application of composite sandwich panels in construction engineering. Appl. Mech. Mater. 291-294, 1172–1176 (2013).

Shu, R. The application and developmental trend of exterior wall external insulation. Appl. Mech. Mater. 18, 1367–1371 (2012).

Guiding Opinions of the General Office of the State Council on Comprehensively. Promoting the Transformation of Old Urban Communities, Bulletin of the State.

Council of the People’s Republic of China,11–15. (2020).

Barreira, E. & Freitas, V. P. D. External thermal insulation composite systems: critical parameters for surface hygrothermal behaviour. Adv. Mater. Sci. Eng. 1-16, 2014 (2014).

Zhou, B., Yoshioka, H., Noguchi, T. & Ando, T. Experimental study of expanded polystyrene (EPS) external thermal insulation composite systems (ETICS) masonery façade reaction-to-fire performance. Therm. Sci. Eng. Prog. 8, 83–92 (2018).

Hou, Y., Cheng, X., Liu, S., Liu, C. & Zhang, H. Experimental study on upward flame spread of exterior wall thermal insulation materials. Energy Proc. 66, 161–164 (2015).

Sha, B. & Yuan, K. Experimental study on the impact resistance of insulation and decoration integrated board. Case Stud. Therm. Eng. 103–121. https://doi.org/10.1016/j.csite.2023.103339 (2023).

Ankang Kan, N., Zheng, W., Zhu, D., Cao, W. & Wang Innovation and development of vacuum insulation panels in china: A state-of-the-art review. J. Building Eng. 113–133. https://doi.org/10.1016/j.jobe.2021.103937 (2022).

Chengyi Chu, X., Ye, B., Fu, L., Zhang, W. & Gao, D. Fan, Fire resistance of steel beams with integrated fire-resistant and decorative constructions. J. Constr. Steel Res. 2024, 68–92 https://doi.org/10.1016/j.jcsr.2024.109096

Sun, C., Shu, S., Ding, G., Zhang, X. & Hu, X. Investigation of time lags and decrement factors for different building outside temperatures. Energy Build. 61, 1–7 (2013).

Yoo, J. et al. Performance of the hygrothermal behavior of the CLT wall using different types of insulation; XPS, PF board and glass wool, case stud. Therm. Eng. 24, 100846 (2021).

Jiang, D. et al. Effect of thermal insulation components on physical and mechanical properties of plant fibre composite thermal insulation mortar. J. Mater. Res. Technol. 9(6), 12996–13013 (2020).

Skubic, B., Lakner, M. & Plazl, I. Microwave drying of expanded perlite insulation board. Ind. Eng. Chem. Res. 8(51), 3314–3321 (2012).

Li, X. et al. Simulating study on mechanical properties of rock wool board for thermal insulation on external walls. Adv. Mater. Sci. Eng. 1-11, 2020 (2020).

Jeon, C. K., Lee, J. S., Chung, H., Kim, J. H. & Park, J. P. A study on insulation characteristics of glass wool and mineral wool coated with a polysiloxane agent. Adv. Mater. Sci. Eng. 1-7, 2017 (2017).

Ma, M., Cai, W. & Wu, Y. China act on the energy efficiency of civil buildings (2008): a decade review, sci. Total Environ. 651, 42–60 (2019).

M´ear, F., Yot, P., Viennois, R. & Ribes, M. Mechanical behaviour and thermal and electrical properties of foam glass. Ceram. Int. 33(4), 543–550 (2005).

Ji, R. et al. Utilization of mineral wool waste and waste glass for synthesis of foam glass at low temperature. Construct Build. Mater. 215, 623–632 (2019).

V, E. M. & K, Y. S. Foam glass and problems of energy conservation. Glass Ceram. 63, 105–108 (2008).

Rodrigues, L., White, J., Gillott, M., Braham, E. & Ishaque, A. Theoretical and experimental thermal performance assessment of an innovative external wall insulation system for social housing retrofit. Energy Build. 162, 77–90 (2018).

Byrne, A., Byrne, G., Donnell, G. O. & Robinson, A. Case studies of cavity and external wall insulation retrofitted under the Irish home energy saving scheme: technical analysis and occupant perspectives. Energy Build. 130, 420–433 (2016).

Choi, H. J., Kang, J. S. & Huh, J. H. A study on variation of thermal characteristics of insulation materials for buildings according to actual long-term annual aging variation. Int. J. Thermophys. 39(1), 1–11 (2018).

Stazi, F., Tittarelli, F., Politi, G., Perna, C. D. & Munafo, P. ` assessment of the actual hygrothermal performance of glass mineral wool insulation applied 25 years ago in masonry cavity walls. Energy Build. 68, 292–304 (2014).

Masi, R. F. D., Ruggiero, S. & Vanoli, G. P. Multi-layered wall with vacuum insulation panels: results of 5-years in-field monitoring and numerical analysis of aging effect on Building consumptions. Appl. Energy. 278, 115605 (2020).

Paolini, R., Zani, A., Poli, T., Antretter, F. & Zinzi, M. Natural aging of cool walls: impact on solar reflectance, sensitivity to thermal shocks and Building energy needs. Energy Build. 153, 287–296 (2017).

Griciutė, G., Bliūdžius, R. & Norvaišienė, R. The durability test method for external thermal insulation composite system used in cold and wet climate countries. J. Sustain. Architect Civ. Eng. 1 (2013).

Liisma, E., Lohmus, G. & Raado, L. M. The effect of temperature and humidity on the permanence of external thermal insulation composite systems. Procedia Eng. 108, 340–348 (2015).

Kuang, F. et al. Unique microstructure and thermal insulation property of a novel waste-utilized foam ceramic. J. Mater. Sci. Technol. 40, 175–179 (2020).

Wu, X. et al. Experimental study on hygrothermal deformation of foamed ceramic insulation decorative board under accelerated aging conditions. Case Stud. Constr. Mater. 17, e01314. (2022).

Approvals, E. O. T. Ead 040083-00-0404: External Thermal Insulation Composite Systems (ETICS) with Rendering, (2020).

Institute, A. N. S. NSI/EIMA 99-A-2001: American National Standard for Exterior Insulation and Finish Systems (EIFS), American National Standards Institute (EIMA-EIFS Industry Members Association, 2001).

Acknowledgements

We sincerely appreciate the editors and reviewers for their valuable comments. We also wish to thank all the authors who provided source codes and datasets. This research is based on the project of Heilongjiang Provincial Department of Communications, funding number: 2024Z0016. This research is based on the project of Heilongjiang East University, funding number: HDFHX2025016.

Funding

This research is based on the project of Heilongjiang Provincial Department of Communications, funding number: 2024Z0016. This research is based on the project of Heilongjiang East University, funding number: HDFHX2025016.

Author information

Authors and Affiliations

Contributions

Y.Z. provided methods and ideas, X.S completed the experimental design, and X.S wrote the original draft. Y.Z. reviewed and edited the manuscript. Y.J. conducted the investigation. X.S. provided the supervision. Y.Z. performed the data formal analysis.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zu, Y., Sun, X. & Jiang, Y. Restoration of authenticity in building insulation-and-decoration integrated board in cold regions. Sci Rep 15, 20880 (2025). https://doi.org/10.1038/s41598-025-05215-6

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-05215-6