Abstract

Bubble nucleation plays a significant role in applications ranging from food and beverages to cosmetics, polymer foams, and advanced porous materials. While extensively studied in homogeneous solutions and particle suspensions, bubble nucleation mechanisms in heterophasic liquid dispersion, such as emulsions, are less understood. This study hypothesizes that tuning physicochemical and mixing hydrodynamics allows design over the bubble nucleation and growth under mild gas supersaturations. Supersaturated oils were emulsified under mild stirring, followed by rapid decompression to trigger nucleation. The process was analyzed by monitoring changes in emulsion volume and optical microscope observations. Key parameters such as gas saturation pressure, viscosities of the continuous and dispersed phases, gas solubility and dissolution kinetics, and mixing intensity were systematically varied. Bubble nucleation occurs mainly via a heterogeneous mechanism, accelerated by shear and gas migration kinetics. Increased oil phase viscosity enhanced bubble formation and retention in droplets, while higher aqueous phase viscosity suppressed nucleation in the continuous phase. The number and size of the obtained bubbles varied significantly, depending on the phase of nucleation origin and the physicochemical conditions. This study reveals pathways to optimize bubble nucleation and initial growth dynamics, which can be used for optimization of pore size distribution of emulsion-based materials.

Similar content being viewed by others

Introduction

The nucleation of bubbles in supersaturated fluids has a practical application in carbonated beverages and foamed foods1,2. It has the potential to replace propellants (such as nitrous oxide or carbon dioxide) in aerosol whipped creams3,4, and could also be used for optimization of processing of ice-creams, and other dairy products. Nucleation is useful for significant shortening of the processing time (the bubble generation), whereas the gas type plays an important role in subsequent foam coarsening. Bubble nucleation also has tremendous potential in cosmetics for the delivery of foamed emulsions5 and oily foams6. Gas supersaturated cosmetics could not only reduce the use of volatile organic compounds in aerosol formulations, such as shaving creams7, but could also be used to alter the consumer perception by allowing a vast range of sensory effects, including less oily texture of emulsions and increased aroma in foamed surfactant solutions with essential oils. Bubble nucleation, however, has attracted the broadest and most systematic interest in polymer science8,9,10,11,12,13,14,15,16,17,18. It is often exploited to make cheaper, lighter, and more effective polymers for thermoplastics8,9,10,11,12,13,14,15,16, polyurethanes/polyisocyanurate foams12,13,14,15,16, and in the synthesis of porous microparticles17,18 that have broad applications in pharmaceuticals18.

Experimental and theoretical studies explore gas solubility and bubble nucleation in solutions, polymer melts, and complex dispersions19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39. They show that the supersaturation needed to achieve homogeneous nucleation varies tremendously across different studies. Jones, Evans, and Galvin33,34 deemed that homogeneous nucleation requires supersaturation, ζ > 100 times, as theoretically estimated and experimentally observed in their reviews. The used definition of the supersaturation is ζ = Cg/C0-1, where the amount of dissolved gas, Cg, is divided by the ambient solubility, C0. For instance, Hemmingsen 1970 showed that supersaturations in the order of 150–270 times were needed for He nucleation in water via “massive cavitation”35, while nucleation in superheated toluene-polystyrene solutions was already increasing exponentially at 15–16 times supersaturation36. Meanwhile, heterogeneous nucleation was active at much lower supersaturations in the presence of shear37, e.g., at ζ < 10. Some studies claimed ζ < 0.3 for the lower boundary of heterogeneous nucleation2, while others claimed that undersaturated fluids nucleate upon shear38. These significant variations in the conditions needed to start nucleation, and its feasibility and efficiency in mild industrial conditions need to be explored in detail. Such industrial conditions include short saturation times, low pressures, and saturation of single components in binary, ternary, or more complex mixtures.

The experimental conditions for efficient nucleation seem to be explored most systematically to produce foamed polymers. Bulk materials and thin films showed dependence on gas solubility, gas supersaturation, rate of pressure drop, temperature variations, and presence of blowing agents and surfactants, exploiting versatile and wetting behavior for the case of heterogeneous nucleates. The effect of gas solubility has been widely explored: nitrogen, oxygen, carbon dioxide, propane, iso-butane, argon, and other gases have been explored for fundamental scientific or industrial applications19,20,21,22,23,24,25,26,27,28,29. At pressures below 100 bars, the gas solubility increased linearly with pressure following Henry’s law, and gases with higher solubility at ambient conditions showed larger solubility at elevated pressure21– 22. Interestingly, larger gas molecules showed higher solubility in polymer melts, C4H10 > CO2 > O2 > N223, as well as in aqueous solutions of surfactants24. In general, gases with lower or intermediate solubility (such as N2 and CO2) showed a larger potential to expand (nucleate and grow) with an increase in pressure compared to gases with high solubility (such as iso-butane) due to intensive bubble-bubble and bubble-air coalescence. For example, thermoplastic polyethylene showed CO2 to be more effective than N2 and iso-C4H10 in having the largest expansion of the polymer matrix and the smallest size of the bubbles at the highest pressure drops23,25,26. N2 performed better than CO2 in extruded cellulose palmitate, providing similar expansions but smaller bubbles, while iso-butene suffered rapid disproportionation and coalescence with the atmosphere26. Therefore, we should balance gas solubility, bubble generation, bubble growth, and stability to improve material characteristics.

Many industrial foams are made from binary or more complex fluid mixtures with different physicochemical properties: gas solubility, viscosity of each component or phase, surface and interfacial tensions, etc. For example, polyurethane and polyisocyanurate (PIR) foams are commonly made in the presence of blowing agents, such as iso- or cyclopentane, fluorocarbons, water, or others11,12,13,14,15. As pentane is not fully soluble in the surrounding matrix, the dispersions should be considered emulsions14, whose properties depend on the compound’s mixing sequence and hydrodynamics. The nucleation and growth of bubbles in such emulsions have been of increasing interest in the last years11,12,13,14,15,30,31,32, but the mechanisms of bubble nucleation in such emulsions have remained unclear. Recent studies by Hamann et al. 2023–202415,30,31 showed that fluorinated blowing agents “assist the entrapment” of bubbles during the initial mixing process and claimed “type IV non-classical nucleation”. Reigner et al. 201914 showed a lack of nucleation from the presence of emulsion drops, and Brondi et al.13 claimed suppressed nucleation in PIR foams if mechanical aeration is performed first (as the generated gas led to foam coarsening).

Apart from the unclear nucleation mechanisms, these studies pay negligible attention to the specific physicochemical properties of the individual components in the formulations. Moreover, the kinetics of gas transfer between phases and nucleation mechanisms in these emulsions, particularly the role of drops, remain unclear beyond their physical blowing during heating from the chemical reaction.

Therefore, in this work, we design simple model emulsions to clarify nucleation mechanisms in emulsions, where one phase is pre-saturated with dissolved gas. This approach aims to better understand bubble nucleation in emulsions by considering thermodynamic factors like gas solubility and supersaturation while accounting for the kinetics of gas transfer between phases.

To achieve these objectives, we simulate mild, industrial-like conditions, examining the role of gas supersaturation and the kinetics of gas transfer. Additionally, we analyze the effects of emulsification parameters, including the viscosity of both the continuous and dispersed phases and the mixing rate. For consistency, we use polydimethylsiloxanes (PDMS) with viscosities ranging from 10 to 30 000 mPa.s, as these materials demonstrate similar gas dissolution rates due to Knudsen diffusion within the fractional free volume surrounding the fluid molecules28.

Materials and methods

We used deionized water purified via the Elix 3 module (Millipore) and glycerol with analytical purity (Teokom, Bulgaria) for the solutions. We used sodium dodecyl sulfate (SDS) to stabilize bubbles during nucleation, a product of Sigma Reagent Plus > 99%.

We used linear polydimethyl siloxanes with various viscosities (Wacker), denoted as AK10, AK100, AK1000 and AK30000. The silicone polymers had different macroscopic viscosity but practically the same gas solubility and diffusivity as determined experimentally in28. Alkanes, including pentane, hexane, cyclohexane, and hexadecane, were purchased from Sigma Aldrich.

The relevant physicochemical properties of the chemicals used are summarized in Table 1 below. For the gas saturation, we used compressed N2 (Sol Bulgaria) at 25 ± 3 °C.

Gas supersaturation, emulsification, and bubble nucleation

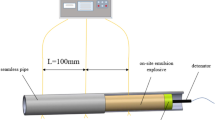

We recently published details on the experimental cell28. The 50 mL fluid cell comprises a sapphire tube (26 mm inner diameter, 100 mm height from Saint Gobain Crystals) and Teflon-coated alumina plates pressed against it. The upper plate has a removable gas valve that enables air pressurization via a nitrogen cylinder. The following procedure was used for the studies, as illustrated in Fig. 1 below:

-

(1)

We measured 20 g of the continuous phase and put it together with a 2 cm Teflon stirrer bar.

-

(2)

Next, we added a 2.2 g oil phase on top via a pipette to form a ≈ 4.14 mm thick layer. The oil was saturated for 15 min at different pressures of up to 30 bars upon compression with a nitrogen cylinder without stirring. The saturation time allowed us to achieve average supersaturation in the oil, equal to ζoil ≈ 0.36 ± 0.03 × ΔP for each pressure. Section S1 presents the averaged estimation from one-dimensional diffusion using the Henry solubility from Table 1.

-

(3)

The magnetic stirrer was set on for 60 s to emulsify the oils at different nominal speeds.

-

(4)

The cell was decompressed via electromagnetic valves and stirred for another 30 s to trigger the nucleation. Stirring was stopped, and changes in volume were recorded with an accuracy of ≈ 0.3 mL and a typical reproducibility of ± 0.50 mL.

-

(5)

In independent repetitions of the experiments, we took samples during the final stages of stirring for microscope observation between 3 glass slides via ×5 LD objective (Nikon E Plan).

These equilibrium procedures were meant to allow emulsification and bubble nucleation without achieving equilibrium conditions, thus mimicking the initial process of mixing reactive dispersions that settle rapidly through polymerization.

Schematic presentation of the procedure for studying bubble nucleation in emulsions: (1) Water phase is added, (2) Oil phase is put on top, (3) Oil phase is supersaturated under pressure, (4) Oil is emulsified under pressure via stirring, (5) Emulsion is decompressed to observe nucleation start via changes in turbidity and to register the increase in the foamed emulsion volume, and (6) Sample is taken for microscope observations after nucleation. Figure drawn via Chemix - free online editor for drawing science lab diagrams, https://chemix.org/.

Experimental results

Mechanism of bubble formation in supersaturated emulsions

We started the study by investigating the origin of bubble nucleation whenever the upper fluid was supersaturated. We poured 20 g deionized water as a high-density fluid in the pressure cell and added 7.5 g AK1000 as an oil phase on top of the water phase to enable a large volume of oil that suppresses diffusion to the lower phase and allows high visibility for possible nucleation in bulk after supersaturation. Then, we applied 20 bars of pressure via a nitrogen cylinder to saturate the oil phase. We saturated the oil for 1.5 h, corresponding to an average saturation of ζoil ≈ 5. We used a side camera with ×3 optical magnification to visualize the nucleation of bubbles. After supersaturation, the overpressure was released via rapid decompression, leaving both phases without significant changes, as illustrated in Fig. 2, whereas a video is available online as Movie S1. The oil phase remained supersaturated with the nucleation of some bubbles near the upper interface, which was most probably triggered by the higher local supersaturation and the gas convection.

Stirring caused a significant portion of the gas to migrate to the aqueous phase, where it started to nucleate from the Teflon stirrer and Teflon sealing at the bottom of the cylinder, see Movie S2. The newly formed bubbles grew rapidly and detached from the heterogeneous interface to migrate to the water-PDMS interface, where they slowed down their creaming velocity due to the oil viscosity. Oil started to emulsify into large drops, where some larger millimetric ones contained bubbles within themselves. The overall turbidity of the solution increased fast, making process observation hard to interpret. We should mention that similar behavior was observed in bulk oils and emulsions, even when the container walls were polycarbonate and when the mixing device was pure metal.

Observation of the mechanism of bubble nucleation in supersaturated PDMS on top of water. 7.5 g AK1000 is put on top of 20 g water to increase the visibility of the bubbles forming at the interface and supersaturated for 1.5 h at 20 bars (ζoil ≈ 5). (a) Single bubbles nucleate below the oil-air interface and coalesce with air above. (b) Stirring causes the gas to migrate from the oil to the aqueous phase, nucleating heterogeneously at the container walls and the Teflon sealing and stirrer bar. Nucleation in the drops occurs simultaneously at the bottom of the container during emulsification.

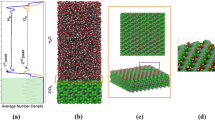

To better visualize the appearance of bubbles on a microscopic level, we prepared emulsions via Ultra Turrax. We emulsified AK1000 in 20 mM SDS via rotor-stator homogenizer Ultra Turrax, equipped with S10N − 10G Dispersing tool, for 5 min at 7000 and 14,000 rpm and supersaturated the emulsions at 20 bars for 1 h during continuous stirring. Next, we stopped the stirring and decompressed the emulsions. Without stirring, the emulsions remained supersaturated without the appearance of bubbles. We took samples with a pipette and recorded the emulsion injection between three glass plates with a high-speed camera to visualize the appearance of bubbles in flow. As illustrated in Fig. 3, we observed a combination of heterogeneous nucleation in the dispersed and continuous phases (see Movies S3 and S4).

Bubbles that nucleated in the continuous phase were more numerous and grew more slowly than the bubbles that nucleated in the emulsion drops. The Epstein-Plesset diffusion-limited model predicts slower bubble growth in the aqueous phase as RB ~(D0.C0.t)0.540. Therefore, the bubble growth rate within the oil should be ≈ 3.6 times faster than in the water for the same supersaturation. Notably, the bubble growth rate is even quicker during injection as convective motion increases the bubble growth rate following Gross et al.29,37. They show RB ~ tn when mixing, and that n increases to values that easily exceed a power index ≥ 1. Thus, we should expect that the bubble growth should be limited by the size of the droplets and the amount of gas they contain, whilst the gas migration from the drops in the continuous phase limits the bubble growth in the continuous phase. Therefore, we focused the next part of the study on the characterization of the physicochemical factors that affect the bubble’s nucleation and growth.

Observation of the mechanism of bubble nucleation in supersaturated emulsions: (a) Schematic presentation of the observation. (b) Nucleation observation in emulsion drops -UT at 7000 rpm, SI Movie S3. (c) Bubbles nucleation in the continuous phase - UT at 14,000 rpm, SI Movie S4. Optical observations in transmitted light at ×5 optical magnification. Image sequences represent ≈ 100 ms period. Images are 1680 μm wide.

Factors affecting the nucleation and bubble growth in supersaturated emulsions

Before we proceed with the experimental results further, we clarify the selection of surfactant and its concentration as recommended by one of the reviewers. As clarified by the mechanism of nucleation, the most relevant characteristics of the surfactants are their ability to store and transport gas under pressure, along with their ability to stabilize the drops and bubbles:

-

Gas solubility in surfactant solutions is affected by the surfactant concentration and the length of its hydrophobic tail, as reviewed and discussed in Ref28. Gas is solubilized in the micelles’ hydrophobic interior, and the micelles serve as reservoirs that release bubbles rapidly upon shear. The presence of micelles also seems to increase the gas migration rate from the drops to the aqueous phase or in aqueous solutions without oil. To suppress the effects from the micelles, we selected 5 mM SDS, which is a concentration of the surfactant that is below the critical micellization point (as CMC for SDS is ≈ 8 mM).

-

Gas migration rate from the oil drops interior to the continuous phase. The gas migration rate depends on the interface permeability, where the surfactant acts as a molecular barrier that resists the gas transfer based on its adsorption density. Condensed surfactant layers lead to slower migration kinetics, which was illustrated for dissolving bubbles in our recent study, Ref28. Whenever we use a surfactant that decreases the surface permeability of the drops, such as 1 wt% escin, we obtain a significant increase in the number of bubbles that remain within the drops due to the enhanced gas retention.

-

Bubble stability after their rapid generation is affected by the surfactant, too. Most nonionic surfactants showed significant coalescence and loss of bubbles even above CMC due to their slow adsorption and the requirement for the formation of dense adsorption layers to stabilize the bubbles. Anionic surfactants, such as SDS, showed much higher foam stability due to the electrostatic repulsion between the bubbles that stabilizes the foam films. As illustrated in Ref41, around 2.5 mM SDS is sufficient to start stabilizing bubbles in a rapid foam generation process. As some of the surfactant adsorbs at the droplet interfaces and suppresses the drop-drop coalescence during the emulsification42, we increased the surfactant concentration slightly to 5 mM.

Selection of an oil phase

First, we compared the nucleation in several oil phases with different gas solubilities. We chose pentane and cyclopentane (typical blowing agents used in industry) and compared them to more viscous alkanes and silicone oils. Figure 4 shows illustrative results for the foam generated after supersaturating 1 mL oil phase for 15 min at 20 bars, mixing it for 1 min under pressure at 1100 rpm, then decompressing and stirring for another 30 s. The bubbles that nucleated were slightly more than estimated from gas dissolution in the oil phase only (see SI section S1 for estimates). The higher amount was mainly related to the saturation of the aqueous phase during the 1 min stirring under pressure, as shown in Fig. 5. Pentane alone showed a more pronounced effect as a small portion (less than 0.04 g, as measured in bulk samples) underwent a liquid-to-gas transition: a phenomenon observed at low-temperature flash jetting of pentane drops as in Ref43. As there was no other difference in the other oils but their solubility, we decided to continue our work with a series of silicon oils that allowed us to vary the viscosity without altering the gas diffusion and the solubility within the drop phases.

Role of the oil viscosity

Figure 5 shows the results from bulk experiments with oils with varying viscosities from 10 to 30 000 mPa.s. As we recently showed with dissolving bubbles in PDMS, these oils allow practically constant solubility while allowing the same rate of gas transport within themselves. We prepared 20 g 5 mM SDS solution, put 2.2 g silicon oil on top, and saturated it for 15 min at 20 bar (ζoil ≈ 6.6). Then, we emulsified the oil via a magnetic stirrer at 1200 rpm (Fig. 5A) or via Ultra Turrax at 7000 rpm (Fig. 6A).

We observed an increase in the amount of generated gas with an increase in the drop viscosity in the range studied. The increase was related to two competing mechanisms:

-

(1)

the low-viscosity oils emulsify more readily, causing a larger portion of the gas to migrate from the drops’ interior in the continuous phase compared to more viscous oils, where it serves for slow bubble growth during mixing (see SI section S2 for illustrative kinetics of foam formation, based on the emulsion drop size in equilibrium supersaturations).

-

(2)

The nucleation of bubbles within the drops leads to their rapid growth during mixing, which in turn causes the drops to expand and the surrounding oil film to thin down. Along the thinning, the less viscous films rupture and cause the bubble to migrate to the continuous phase.

(a) Amount of gas obtained from nucleation and bubble growth after supersaturation of 2.2 mL silicon oil for 15 min and emulsification in 5 mM SDS solution at 1200 rpm (red symbols). The dashed line presents the gas entrapment from stirring under pressure without oil (without 15 min supersaturation), while non-saturated oil compression to 20 bars and stirring gives 0.8 mL foam as illustrated in Figure S2. (b) Optical observation from emulsion with 100 mPa.s oil, illustrating the bimodal distribution of bubbles. The scale bar is 200 μm. (c) Schematic illustration of drop breakage and gas release in the continuous phase for low-viscosity oils. (d) Schematic illustration of the mechanism of bubble nucleation in large oil droplets, their growth, and eventual separation from the oil droplets in viscous oils.

As a result of these two mechanisms, the more viscous oils lead to larger drops that promote bubble growth after nucleation and their retention within the oil phase. On the contrary, the less viscous oils promote drop breakage and allow faster bubble-drop separation. As the less viscous oils keep the gas “compartmentalized” into smaller drops, the subsequent growth of the bubbles relies on the kinetic properties of the continuous phase.

As the drops from the magnetic stirrer are millimetric for the more viscous oils and hard to visualize via an optical microscope (see SI section S3), we repeated the experiments with more intensive homogenization via Ultra Turrax at 7000 rpm. We present visually the distribution of bubbles and drops in Fig. 6. Bubbles in AK10 are comparable in size to the droplets, and almost no bubbles seem confined in the droplets. AK100 shows a bimodal distribution of the bubbles, implying that a part of the bubbles grew within drops, whereas others “originated” in the continuous phase. AK1000 and AK30000 showed a general increase in the size of the larger bubbles, with many of them confined within larger oil drops.

The more viscous oils demonstrated significant post-mixing growth in the foam volume. Some of the gas remained dissolved and compartmentalized within oil drops without bubbles due to the short mixing period. As a result, the drops from the more viscous oils creamed faster (due to their large drops) and got in close contact with the bubbles in the foam, thus causing accelerated coarsening. The low-viscosity oils experienced similar growth but with a lower magnitude, indicating more intensive gas migration from the oil to the aqueous phase during the mixing stage.

Role of the continuous phase

Next, we studied how the viscosity of the continuous phase affects the nucleation and growth process. We used the same procedure for AK1000 and dissolved 5 mM SDS in different glycerol concentrations up to 90 wt%, see Fig. 7A for volumetric data and Fig. 7B for microscope images. As lower viscosity allows faster saturation during stirring, we compared the emulsions against the pure solutions. Solutions with higher viscosity show much lower bubble nucleation and growth due to decreased gas solubility and transport. Mixing the solutions themselves has a mild effect in the pure water and is less pronounced than the saturation during mixing (see Fig S1.2). The emulsions seem to go through a well-pronounced maximum. At low glycerol concentrations, the gas migration from the oil to the aqueous phase is much faster and nucleation occurs mainly in the continuous phase. As the gas concentration in the aqueous phase rises faster, the bubble growth accelerates. The resulting foam contains some enormous bubbles that coalesce with the atmosphere. The latter is best evident post-mixing in static conditions. By decreasing the gas solubility and the gas transfer rate in the continuous phase, we start observing more bubbles within the dispersed phase. For brevity, we illustrate it in Fig. 6B for AK1000 but have similar observations in AK100 (not shown here). For 5 mM SDS in water, the bubbles are mainly in the continuous phase; in 70 wt% glycerol, however, we observe a mixture of both with larger bubbles in the drops and smaller bubbles in the aqueous phase; and in 90 vol% glycerol, we observe a much smaller number of bubbles in the continuous phase and many bubbles in the oil drops. The last observation should be taken with a pinch of salt, as SDS loses part of its stabilization properties at high glycerol concentrations, and thus, some coalescence might skew the gas distribution assessment in the aqueous phase. Also, emulsification efficiency worsens, and we observe larger drops above 70 wt% glycerol.

(a) Amount of gas obtained from nucleation and bubble growth after supersaturation of 2.2 mL AK100 for 15 min and emulsification in 5 mM SDS solutions in water-glycerol solutions at 1200 rpm (red symbols). The blue symbols represent the pure solutions. (b) Illustrative images from microscope observations with AK1000 samples at 0, 20, 70, 80 and 90 wt% glycerol (left-to-right). Images are 1680 μm wide.

Role of mixing rate

Next, we wanted to investigate if the mixing rate and the oil phase’s supersaturation affect the bubbles’ nucleation and growth. We illustrate the effect of the mixing rate, immediately after mixing (Fig. 8a) and post-mixing growth (Fig. 8b), together with a schematic illustration of the process in Fig. 8c. At low mixing rates, such as 600 rpm, we observed much lower foam generation with a well-pronounced post-mixing growth from supersaturated oil drops. At the higher mixing rate (1200 rpm), we observed a larger bubble volume immediately after mixing and delayed post-mixing growth due to the slower drop creaming and the lower gas concentration within the drops. At 1500 rpm, we observed some foam entrapment from the mixing under pressure that resulted in the expansion of the foam after decompression, for which reason we restrained from further interpretation of these results.

(a) Amount of gas obtained from nucleation and bubble growth after supersaturation of 2.2 mL AK100 for 15 min and emulsification in 5 mM SDS solutions in water-glycerol solutions at 1200 rpm (red symbols). (b) Illustrative images from the foam growth after mixing is stopped for 600 rpm and 1200 rpm, as illustrated. (c) Schematic presentation of the post-mixing foam growth with time.

Role of gas supersaturation

Finally, we decided to study the effect of saturation pressure on nucleation and bubble growth during the initial mixing. We present results with AK100 with 5 mM SDS in 70 wt% glycerol and different pressures in Fig. 9. The foam generation in the absence of oil increased slightly with the pressure increase due to saturation. We estimate that nearly 10% of the total gas solubility in the 70 wt% glycerol solutions is achieved within 1 min of mixing before decompression. At 10 bars, the amount of bubbles acting as a reservoir for gas during the saturation step. Increasing the pressure above 10 bars does not significantly improve the initial gas generation but leads to nearly constant volume immediately after mixing is stopped. The foams at 20 bars increase their volume more intensively post-mixing, thus implying a significant fraction of the gas remained dissolved and compartmentalized within the oil drops. In the meantime, the foams at 30 bars show lower growth with time, implying that some of the gas might have been lost to coalescence. The latter is possibly related to the intensive growth and coalescence of the largest bubbles in dynamic conditions, as observations did not show larger bubbles anticipated from growth and mixing.

Amount of gas obtained from nucleation and bubble growth after supersaturation of 2.2 mL AK100 for 15 min and emulsification in 5 mM SDS solutions in 70 wt% glycerol solutions at 900 (green symbols) and 1200 rpm (red symbols). Pure solutions mixed at 1200 rpm show that some gas dissolves during mixing without oil, which corresponds to around 10% of the theoretically soluble amount at equilibrium.

Results discussion

We studied the nucleation and the initial growth of bubbles in supersaturated emulsion drops. We investigated the mechanism of bubble nucleation and physicochemical factors that affect the kinetics of the process. From the model experiments, we established that the primary active mechanism of nucleation is heterogeneous nucleation near the container walls that can occur in both the supersaturated oil phase and the continuous phase during the gas migration.

The shearing promotes the gas transfer from the oil to the aqueous phase, enabling more numerous and smaller bubbles to be formed in the latter and promoting slower growth of the bubbles due to lower supersaturation and solubility, as suggested by the theory of Gross et al.29,37. The gas transfer from the oil phase can be suppressed kinetically by reducing the solubility and the dissolution rate (via the addition of glycerol) or by increasing the oil phase’s viscosity, allowing better longevity of the bubbles within the oil drops before their growth and rupture. The latter is related to the larger size of the viscous drops during their emulsification and the slower “evacuation” of the bubbles from the drops’ interior. Higher pressures did not improve the nucleation significantly, as it was related mainly to the heterogeneous collisions of the gas with defects near the walls, but a large portion of the gas remained confined within the oil drops and served as a reservoir for growth at a later stage. This summary paves the way for building novel materials with more efficient gas distribution during nucleation and offers an approach to handle the bubble growth more efficiently based on the physical chemistry of the constituents. For example, we show that lower viscosity oils and fast transfer of gas lead to an out-of-drop regime for the formation of bubbles that leads to more numerous and smaller bubbles (see Fig. 10). The opposite way around – more viscous oil and kinetically hindered gas transfer promote nucleation-in-drops regime that promoted drop-confined bubble growth.

As we selected silicon oils with high gas solubility and transport characteristics, the drop growth accelerated, but selecting appropriate materials could reverse the trend. As a proof-of-concept experiment, we selected a commercial polyester polyol (similar to the ones used for polyurethane foams32) with lower gas solubility than the silicone oils but a much lower gas diffusivity within itself. We characterized the polyol, following the procedures in Ref27. , and measured has gas solubility C0 = 60 g/m3 and D0 = 20 µm2/s and the macroscopic viscosity of 3840 mPa.s. We supersaturated the polyol to achieve low supersaturation, ζoil ≈ 5, and poured 70 wt% glycerol on top of it (as polyol is the higher-density fluid). Then, we homogenized it with Ultra Turrax at 15,000 rpm for 2 minutes and took samples for microscope observations. Figure 11 illustrates the result, where the viscous polyol retains all the bubbles within the drops due to hindered growth and enhanced bubble-polyol-glycerol films.

Therefore, by balancing the physicochemical parameters and the hydrodynamics in emulsions, one can achieve various porosities and sizes of the materials whenever appropriate cross-linking agents and procedures are selected. This way, one should be able to synthesize porous microparticles with different tailored porosity and sizes for various applications.

Conclusions

This study comprehensively examines the mechanisms and factors influencing bubble nucleation in supersaturated emulsion drops, focusing on controlled physicochemical and hydrodynamic conditions. The study of the nucleation mechanisms in emulsions elucidates the role of the individual phases during mixing relevant to industrial polymeric foams13,14,15,30,31,32. We observe heterogeneous bubble nucleation in both phases, similar to mildly saturated homogeneous fluids, where bubbles nucleate from cavities and grow rapidly upon mixing29,37 at a rate higher than anticipated by the Epstein-Plesset model40.

We highlight the interplay between gas solubility, the viscosity of the involved phases, and the emulsification dynamics, identifying key parameters for optimizing nucleation processes in industrial and scientific applications.

The viscosity of the supersaturated oil phase plays a crucial role, as higher viscosities enhance bubble retention within droplets but may lead to the formation of larger bubbles, as the droplets act as a gas reservoir after nucleation. Larger “reservoirs” lead to better gas retention within, but also to more pronounced growth of the bubbles.

Similarly, increasing the viscosity of the continuous phase via glycerol addition slows the gas transfer and promotes in-drop nucleation while suppressing out-of-drop nucleation. The approach built within this manuscript offers practical means to tailor nucleation dynamics for specific applications, such as producing porous microcapsules17,18.

Hydrodynamic effects further influence nucleation, with moderate shear rates optimizing droplet size and controlled gas transfer, while excessive shear can cause bubble coalescence and efficiency losses similar to polymeric materials with highly soluble gases23,26. Lower supersaturation pressures, though achieving similar nucleation efficiencies, result in reduced bubble growth during later stages.

The study proposes strategies for the optimization design of tailored foams and porous materials by manipulating system properties. For example, viscosities of each phase of emulsion-based materials could be altered via an increase in the molecular weights of oligomers (similar to PDMS oils, where gas solubility remains similar despite the increase in viscosity) or via the introduction of solvents that alter the gas solubility and diffusion rates within each phase. Many such solvents are often used as additives, including fire retardants or blowing agents, and their careful selection and optimization have the potential to significantly improve the properties of the final materials based on the physicochemical understanding of their role.

Additional proof-of-concept experiments demonstrate the feasibility of confining bubbles within viscous oil phases with intermediate solubilities, paving the way for the development of porous microparticles or capsules, as well as functional materials with applications in various industries.

Data availability

Data is provided within the manuscript or supplementary information files.

References

Bamforth, C. W. The physics and chemistry of beer foam: a review. Eur. Food Res. Technol. 249, 3–11. https://doi.org/10.1007/s00217-022-04134-4 (2023).

Deotale, S., Dutta, S., Moses, J. A., Balasubramaniam, V. M. & Anandharamakrishnan, C. Foaming characteristics of beverages and its relevance to food processing. Food Eng. Rev. 12, 229–250. https://doi.org/10.1007/s12393-020-09213-4 (2020).

Blankart, M., Weiss, J. & Hinrichs, J. Understanding the effect of homogenisation pressure on emulsion and foam properties of aerosol whipping cream. Int. Dairy. J. 129, 105332. https://doi.org/10.1016/j.idairyj.2022.105332 (2022).

Blankart, M., Neugebauer, K. & Hinrichs, J. Expansion of the concept of critical micelle concentration for the application of a saturated monoacylglyceride emulsifier in aerosol whipping cream. Food Res. Int. 161, 111791. https://doi.org/10.1016/j.foodres.2022.111791 (2022).

Salonen, A. Mixing bubbles and drops to make foamed emulsions. Curr. Opin. Colloid Interface Sci. 50, 101381. https://doi.org/10.1016/j.cocis.2020.08.006 (2020).

Ribourg-Birault, L. et al. Oleofoams: the impact of formulating air-in-oil systems from a lipid oxidation perspective. Curr. Res. Food Sci. 8 https://doi.org/10.1016/j.crfs.2024.100690 (2024).

K Othmer. Chemical Technology of Cosmetics. Wiley (2012).

Ray, S. S. & Banerjee, R. The science behind foaming, in: Foam. Thermoplast. Polym. Mater. 37–78. https://doi.org/10.1016/B978-0-323-90767-5.00002-9 (2022).

Azdast, T. & Hasanzadeh, R. Increasing cell density/decreasing cell size to produce microcellular and nanocellular thermoplastic foams: A review. J. Cell. Plast. https://doi.org/10.1177/0021955X20959301 (2020).

Banerjee, R. & Ray, S. S. Foamability and special applications of microcellular thermoplastic polymers: A review on recent advances and future direction. Macromol. Mater. Eng. 305, 1–49. https://doi.org/10.1002/mame.202000366 (2020).

Ashida, K. Polyurethane and Related Foams: Chemistry and Technology Taylor & Francis Group, LLC (2007).

Han, M. S. et al. Effects of silicone surfactant on the cell size and thermal conductivity of rigid polyurethane foams by environmentally friendly blowing agents. Macromol. Res. 17, 44–50. https://doi.org/10.1007/BF03218600 (2009).

Brondi, C., Di Maio, E., Bertucelli, L., Parenti, V. & Mosciatti, T. Competing bubble formation mechanisms in rigid polyurethane foaming. Polym. (Guildf). 228, 123877. https://doi.org/10.1016/j.polymer.2021.123877 (2021).

Reignier, J., Alcouffe, P., Méchin, F. & Fenouillot, F. The morphology of rigid polyurethane foam matrix and its evolution with time during foaming – New insight by cryogenic scanning electron microscopy. J. Colloid Interface Sci. 552, 153–165. https://doi.org/10.1016/j.jcis.2019.05.032 (2019).

Hamann, M. et al. Directing the pore size of rigid polyurethane foam via controlled air entrainment. J. Cell. Plast. 59, 201–214. https://doi.org/10.1177/0021955X231152680 (2023).

Sauceau, M., Fages, J., Common, A., Nikitine, C. & Rodier, E. New challenges in polymer foaming: A review of extrusion processes assisted by supercritical carbon dioxide. Prog. Polym. Sci. 36, 749–766. https://doi.org/10.1016/j.progpolymsci.2010.12.004 (2011).

Lu, T., Fan, R., Delgadillo, L. F. & Wan, J. Stabilization of carbon dioxide (CO2) bubbles in micrometer-diameter aqueous droplets and the formation of Hollow microparticles. Lab. Chip. 16, 1587–1592. https://doi.org/10.1039/C6LC00242K (2016).

Ghosh Dastidar, D., Saha, S. & Chowdhury, M. Porous microspheres: synthesis, characterisation and applications in pharmaceutical & medical fields. Int. J. Pharm. 548, 34–48. https://doi.org/10.1016/j.ijpharm.2018.06.015 (2018).

Kennan, R. P. & Pollack, G. L. Pressure dependence of the solubility of nitrogen, argon, krypton, and Xenon in water. J. Chem. Phys. 93, 2724–2735. https://doi.org/10.1063/1.458911 (1990).

Petzold, M., Paul, N., Hohl, L., Böhm, L. & Kraume, M. Gas/liquid mass transfer phenomena in micellar multiphase systems. Chem. Eng. Process. Process. Intensif. 171, 108547. https://doi.org/10.1016/j.cep.2021.108547 (2022).

Battino, R., Rettich, T. R. & Tominaga, T. The solubility of nitrogen and air in liquids. J. Phys. Chem. Ref. Data. 13, 563–600. https://doi.org/10.1063/1.555713 (1984).

Sander, R. Compilation of henry’s law constants (version 4.0) for water as solvent. Atmos. Chem. Phys. 15, 4399–4981. https://doi.org/10.5194/acp-15-4399-2015 (2015).

Zhang, H. et al. Foaming and dimensional stability of LDPE foams with N2, CO2, i-C4H10 and CO2 - N2 mixtures as blowing agents. J. Supercrit. Fluids. 164, 104930. https://doi.org/10.1016/j.supflu.2020.104930 (2020).

Roy, S., Mehra, A. & Bhowmick, D. Prediction of solubility of nonpolar gases in micellar solutions of ionic surfactants. J. Colloid Interface Sci. 196, 53–61. https://doi.org/10.1006/jcis.1997.5181 (1997).

Kim, S. G., Park, C. B. & Sain, M. Foamability of thermoplastic vulcanizates blown with various physical blowing agents. J. Cell. Plast. 44, 53–67. https://doi.org/10.1177/0021955X07079224 (2008).

Rokkonen, T., Willberg-Keyriläinen, P., Ropponen, J. & Malm, T. Foamability of cellulose palmitate using various physical blowing agents in the extrusion process. Polym. (Basel). 13, 2416. https://doi.org/10.3390/polym13152416 (2021).

Di Maio, E. et al. Structure optimization of Polycaprolactone foams by using mixtures of CO2 and N2 as blowing agents. Polym. Eng. Sci. 45, 432–441. https://doi.org/10.1002/pen.20289 (2005).

Lesov, I., Alexandrov, H., Ivanov, B., Delavoipiere, J. & Tcholakova, S. Role of dispersion nanostructure for bubble dissolution under pressure. Colloids Surf. A. 712, 136443. https://doi.org/10.1016/j.colsurfa.2025.136443 (2025).

Groß, T. F., Bauer, J., Ludwig, G., Fernandez Rivas, D. & Pelz, P. F. Bubble nucleation from micro-crevices in a shear flow: experimental determination of nucleation rates and surface nuclei growth. Exp. Fluids. 59, 0. https://doi.org/10.1007/s00348-017-2459-y (2018).

Hamann, M. et al. Quantitative investigation of the pore size–reducing effect of perfluorocarbons in polyurethane foaming. Colloid Polym. Sci. 301, 763–773. https://doi.org/10.1007/s00396-023-05107-z (2023).

Hamann, M. et al. Fluorocarbon-driven pore size reduction in polyurethane foams: an effect of improved bubble entrainment. Colloid Polym. Sci. 302, 585–596. https://doi.org/10.1007/s00396-023-05208-9 (2024).

Di Caprio, M. R. et al. Polyether polyol/CO2 solutions: solubility, mutual diffusivity, specific volume and interfacial tension by coupled gravimetry-Axisymmetric drop shape analysis. Fluid Phase Equilib. 425, 342–350 (2016).

Jones, S. F., Evans, G. M. & Galvin, K. P. The cycle of bubble production from a gas cavity in a supersaturated solution. Adv. Colloid Interface Sci. 80, 51–84. https://doi.org/10.1016/S0001-8686(98)00075-X (1999).

Jones, S. F., Evans, G. M. & Galvin, K. P. Bubble nucleation from gas cavities - A review. Adv. Colloid Interface Sci. 80, 27–50. https://doi.org/10.1016/S0001-8686(98)00074-8 (1999).

HemmingsenE.A. Supersaturation of gases in water: absence of cavitation on decompression from high pressures. Science. 167, 1493–1494. https://doi.org/10.1126/science.167.3924.1493 (1970).

Han, J. H. & Han, C. D. Bubble nucleation in polymeric liquids. I. Bubble nucleation in concentrated polymer solutions. J. Polym. Sci. Part B Polym. Phys. 28, 711–741. https://doi.org/10.1002/polb.1990.090280509 (1990).

Groß, T. F. & Pelz, P. F. Diffusion-driven nucleation from surface nuclei in hydrodynamic cavitation. J. Fluid Mech. 830, 138–164. https://doi.org/10.1017/jfm.2017.587 (2017).

Han, J. H. & Han, C. D. A study of bubble nucleation in a mixture of molten polymer and volatile liquid in a shear flow field. Polym. Eng. Sci. 28, 1616–1627. https://doi.org/10.1002/pen.760282408 (1988).

von Hammel, A. Gaslöslichkeit in Wässerigen lösungen von Glycerin und chloralhydrat. Z. Für Phys. Chem. 90U, 121–125. https://doi.org/10.1515/zpch-1915-9007 (1915).

Epstein, P. S. & Plesset, M. S. On the stability of gas bubbles in Liquid-Gas solutions. J. Chem. Phys. 18, 1505–1509. https://doi.org/10.1063/1.1747520 (1950).

Petkova, B. et al. Foamability of aqueous solutions: role of surfactant type and concentration. Adv. Colloid Interface Sci. 276, 102084. https://doi.org/10.1016/j.cis.2019.102084 (2020).

Tcholakova, S., Denkov, N. D. & Lips, A. Comparison of solid particles, globular proteins and surfactants as emulsifiers. Phys. Chem. Chem. Phys. 10, 1608. https://doi.org/10.1039/b715933c (2008).

Senda, J., Yamaguchi, M., Tsukamoto, T. & Fujimoto, H. Characteristics of spray injected from gasoline injector. JSME Int. J. Ser. B. 37, 931–936. https://doi.org/10.1299/jsmeb.37.931 (1994).

Acknowledgements

The authors are grateful to Bozhidar Ivanov from the Bulgarian Academy of Science for his contributions to the pressurization cell design and assembly.

Funding

This study is financed by Saint Gobain Research and by the European Union-Next Generation EU, through the National Recovery and Resilience Plan of the Republic of Bulgaria, project № BG-RRP-2.004-0008-C01.

Author information

Authors and Affiliations

Contributions

Ivan Lesov: Conceptualization, Methodology, Investigation, Formal analysis, Visualization, Supervision, Writing – Original draft, Writing – Review&Editing; George. I. Georgiev: Investigation, Visualization Jessica Delavoipiere: Conceptualization, Funding acquisition; Slavka Tcholakova: Conceptualization, Writing – Review&Editing, Project administration, Funding acquisition.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary Material 1

Supplementary Material 2

Supplementary Material 3

Supplementary Material 4

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Lesov, I., Georgiev, G.I., Delavoipiere, J. et al. Bubbles nucleation in supersaturated emulsion drops. Sci Rep 15, 22542 (2025). https://doi.org/10.1038/s41598-025-06117-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-06117-3