Abstract

The movement of overburden strata under valley geomorphological conditions presents significant challenges for ground pressure control and the protection of surface ecosystems and aquifers. In this study, geological and boundary mechanical conditions were obtained through field investigation and monitoring, and were subsequently applied in both physical similarity simulation and numerical modeling. The research focuses on two mining sequences—steep gully to deep gully (SG→DG) and deep gully to steep gully (DG→SG)—to analyze the evolution of stress and displacement in overburden strata at different mining stages. A novel approach integrating deep learning techniques was employed to identify and analyze stress-displacement image patterns. Results indicate that when vertical stress is considered, the proportion of high-risk stress zones under the DG→SG method reaches 5.57%, compared to only 3.28% under the SG→DG method. This implies that the probability of stress-related hazards in the SG→DG sequence is approximately 58% of that in the DG→SG sequence. These findings suggest that the SG→DG method offers significant advantages in mitigating ground pressure risks. It is therefore recommended as the preferred mining approach, especially when combined with ground grouting and underground hydraulic fracturing techniques. Furthermore, the study reveals that mining direction is a critical human-controllable factor affecting overburden behavior. By investigating stress redistribution under different mining sequences, this research provides new insights into stress transfer mechanisms in overburden strata, offering theoretical guidance for the safe and efficient extraction of coal resources in complex valley terrain environments.

Similar content being viewed by others

Introduction

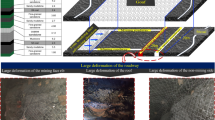

According to the “13th Five-Year” Plan for the Development of the Coal Industry issued by the National Development and Reform Commission and the National Energy Administration, it is clearly stated that the overall layout of China’s coal development is to “compress the eastern region, restrict the central and northeastern regions, and optimize the western region.” In 2020, the National Mine Safety Administration reported that coal production in northwest China accounted for more than 60% of the country’s total output. This is sufficient to indicate that the western region will continue to play a central role in China’s independent supply of basic energy for a long time to come. Within the Shenfu coalfield, there are more than 300 coal mines under the jurisdiction of Yulin City alone, with an annual output of about 250 million tons, making it an important coal production base in the western region. The hilly and gully landforms are widespread in the Shenfu mining area, and the shallow burial of coal seams leads to the interaction between overburden rock movement caused by coal mining and the stability of valley and gullies as well as fracture development, which are important factors affecting the safe and efficient mining of mines in this area. Due to the special geological conditions of SG (shallower gully) and DG (deeper gully) on the surface, during the mining process of the working face, when the pushing degree reaches below the valley shaped landform, the working face enters the stage of strong mining pressure manifestation, with a large period of nearly 100 lengths to press the step distance, causing strong mining pressure events such as coal wall caving, roof collapse, and damage to the hydraulic support of the working face, posing a threat to safety production.

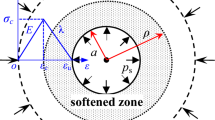

“The impact of gully landforms on underground coal mining has long been a research focus for experts and scholars in the fields of mining and geology, both domestically and internationally. Studies have found that when the working face of an underground coal mine traverses hills and gullies, the manifestation of mine pressure is influenced by the landforms. Specifically, it is commonly observed that as the mining passes through gully areas, the working resistance of the stope supports exceeds the rated value or reaches several times the peak stress1. Additionally, due to mining disturbances, the development of the overlying caving zone, fracture zone, and bending subsidence zone exerts a coupled impact on the surface landforms of the overburden strata. The development of these “three zones” can cause the aquifer water conduction zone in the gully soil layer to connect with the excavation space, triggering water hazards2,3,4,5,6,7,8. Furthermore, the stress and displacement reconstruction of the gully soil layer due to mining disturbances can further lead to abnormal manifestation patterns of mine pressure in the stope9. Therefore, research on the manifestation mechanism and control technology of mine pressure in underground coal mining under gully landforms is of great significance for safe mining and the green protection of surface water, soil, and vegetation environments.“10,11.

Due to the complexity of coal seam geological conditions, foreign scholars have studied the influence of topography on the self-weight stress field of isotropic rock masses beneath through analytical methods, deriving the stress values within anisotropic rock masses beneath mountainous and valley terrains12,13. They considered that the stress near the surface is affected by the terrain to a certain extent, leading to stress concentration at the bottom of valleys and the toes of valley slopes, and studied the stress distribution patterns under different topographic conditions14,15. However, they did not investigate the mining influence under special topographic conditions. Chengxuan Tana & Ruijiang Wang16 considered that tectonic stress under different topographic conditions is an important factor inducing geological disasters, and studied the stress distribution pattern under semi-U-shaped valley terrain through numerical simulation methods. Many domestic experts and scholars have conducted extensive research on the mining of shallow coal seams, such as the engineering problems encountered during the nearly two decades of production in the Shendong Mining Area, including roof falls, abnormal pressure on supports, and water and sand inrushes in the working face. However, there has been very little research on the influence of topography on the strata pressure in shallow coal seam working faces.

In 2002, Ma Maosheng mentioned in his thesis “Shallow Coal Seam Mining and Strata Pressure Research in Shendong Mining Area”17 that “the large variation in relative elevation along the advancing direction of the working face directly affects the roof pressure and weighting interval of the working face,” but did not conduct corresponding research on the influence of surface topography on strata pressure in the working face.

In 2004, Wang Qingcang and Zhao Yongfei from the Shagou Coal Mine of Shenhua Group Shenfu Dongsheng Company conducted strata pressure observations on the first mining face 12,205 of the 2–2 coal seam in Huojitu Coal Mine18. Preliminary research was conducted on the change in strata pressure when the working face passed through the valley terrain of Gaobulamiao Temple Gully. The observation results showed that during uphill periods with coal seam burial depths of 100–120 m and ground gullies crisscrossing, the roof pressure in the working face increased, with more safety valve fluid discharge, significant strata pressure manifestation, severe rib spalling and roof falls, and ground cracks reaching 500–1000 mm, with the largest step reaching 1000 mm.

In 2009, Dr. Wang Xufeng studied the generation mechanism of different activity modes of gullied mining slopes, taking bedrock and sandy soil mining slopes as research objects. It’s considered that the larger the slope angle and the smaller the bedrock thickness, the easier it is for the “multi-block” hinged structure of the mining slope to slide and fail19. It can be seen that research on the manifestation of strata pressure in working faces affected by valley terrain has made certain progress in field observations, theoretical research, and laboratory experiments20,21. However, further supplementary research is needed to explain and verify the combination of theory, experiments, and field observations.

Introduction to natural geology and mining technology of valley-gully condition mines

The Qianshuta Coal Mine is located in the border area between the Maowusu Desert and the Loess Plateau in northern Shaanxi, with most of the surface being newly formed Covered by loose sediments, the terrain is mainly composed of loess ridges and hills, with some areas being desert beaches. Overall terrain The northwest is higher and the southeast is lower, with an elevation of generally 1250–1310 m. The highest point is located in the north of the mining area, with an elevation of 1409.0 m, and the lowest point is located in the southeast valley of the mining area, with an elevation of 1225 m. The maximum relative height difference is 184 m.

The 12,305 working face is located in the 12th panel of the first level, and the main mining coal seam is the No.3 coal seam with a thickness ranging from 10.10 m to 11.06 m, averaging approximately 10.58 m. The coal seam structure is simple, featuring a nearly horizontal orientation and a low coefficient of variation. The immediate roof overlying the coal seam consists of siltstone with an average thickness of 3.4 m, while the basic roof of the stope is composed of coarse sandstone with an average thickness of 22.66 m. The immediate floor is a combination of mudstone and silty mudstone, with a total thickness of 1.68 m. The basic floor of the 12,305 working face comprises siltstone and feldspar sandstone, with a thickness of approximately 3.05 m. The lithological characteristics of the roof and floor are shown in the Fig. 1.

In order to enhance the characteristics of the research object, several terms and research logic in the research process should be standardized before adopting mechanical calculations and simulation experiments. For a galley with a depth of 60 m, it is called a deeper gully (DG), for a galley with a depth of 35 m, it is called a shallower gully (SG), and the process of selecting to cut from the deeper gully to the shallower gully for coal seam mining is called “start with deeper gully” method (SD methods). The mining stage before the working face enters the deeper gully and covers the rock layer is called Stage I. When the working face is mined below the projection area of the deeper gully, it is called Stage II. When the working face is mined below the projection area of the mountain valley, it is called Stage III. When the working face is mined beyond the projection area of the mountain valley and enters below the projection area of the shallower gully, it is called Stage IV. When the working face is mined beyond the projection area of the shallower gully, it is called Stage V. The method of mining from SG as the cutting direction towards DG is called “start with shallower gully” method (SS methods).

Spatiotemporal inversion of stress state of overlying strata disturbed by mining under gully conditions

Research on mining-related topics generally adopts methods such as theoretical analysis22, actual measurement, and simulation experiments. Compared with plain areas, the special geological conditions of hills and gullies make both mine pressure changes and mining-induced fracture development more complex and variable. It is difficult to comprehensively analyze the overburden rock movement, mining-induced development, and other issues caused by mining in hills and gullies through either theoretical analysis or field monitoring. Long-term research has shown that physical similarity simulation experiments can directly reflect the spatial structural characteristics, displacement changes, and fracture development of overburden rocks during the mining process, with an intuitive process and convenient observation. Therefore, this project intends to conduct research by contrasting physical similarity simulation experiments with numerical simulations, highlighting the advantages of material representation superiority in physical similarity simulations and the controllability of single-factor variables in simulations. The press used for rock mechanics parameter calibration testing and the sample collection process are shown in Fig. 2.

Calibration process and parameter introduction of rock mechanics parameters

This physical similarity simulation experiment relies on the Mine Pressure and Rock Control Laboratory, using a three-dimensional stress model device22. Based on the measured drilling rock information and coal rock physical and mechanical parameters at the coal mine site, a suitable similarity ratio is selected, and sand, gypsum, and calcium carbonate are used as proportioning materials to lay the similarity model. The rock mechanics experimental parameters were calibrated for rock drilling samples, as shown in Fig. 2. The relevant information of coal rock layers is shown in Table 1.

Through the calibration experiment of rock mechanics parameters, as shown in Table 1, it can be preliminarily seen that the characteristics of the overlying rock strata on the coal mine working face are that the coal seam mining thickness is relatively large, the roof lithology is not hard, and the distance from the surface is not far. The backfilling of the working face is greatly affected by the self weight of the surface rock strata. Therefore, it is necessary to further simulate the movement and subsidence of the working face roof during the mining process, hoping to obtain effective control methods for surface subsidence and roof rock pressure [24].

Experimental design and process of similar material simulation experiment

Physical similarity simulation experiments are a common and reliable experimental method in rock mechanics and mining engineering to simulate the disturbance effect of mining on surrounding rocks. They can approximately simulate the mine pressure, relative displacement of roof and floor, overburden caving and fracture status, as well as the coupling relationship between support and surrounding rocks. To accurately evolve the mining process, strict settings need to be made for the geometric similarity, dynamic similarity, and material similarity of the experimental simulation.

Geometric similarity requires that the experimental model be similar in geometric shape to the prototype, with length, width, and height proportionally reduced. Here, αL represents the length ratio; LH and LM represent the length of the prototype and the model, respectively.

Dynamic similarity requires that all forces acting on the model and the prototype be similar in terms of volume and stress. Let t and tm represent the time required for corresponding points in the prototype and model to complete geometrically similar trajectory motions, respectively. PH, rH, VH, and PM, rM, VM represent the body force, apparent density, and volume of the corresponding parts of the prototype and model, respectively. Then, obtained:

Based on the regulations in the principle of similarity, a simulation test bench model as shown in the figure is established through curing. According to the geometric similarity ratio and time similarity ratio, excavating 3 cm per hour is equivalent to the daily footage of the actual working face.The construction of a similar simulation experimental platform and the arrangement of observation equipment are shown in Fig. 3.

Utilizing the cutting speed of the coal shearer and the reciprocating feed cycles organized according to the labor cycle in the field-SD methods, the model coal seam was excavated from the deep gully (DG) to the shallow gully (SG). Since the model was established up to the surface soil layer, no stress loading was applied to the upper boundary, while the lateral and bottom boundaries were subject to fixed constraints. As mining progressed through different stages, the overburden rocks underwent continuous collapse and fracture development, with the disturbance process depicted in the figure. After advancing 83.47 m, a through-going fracture emerged in the main roof strata. Upon reaching 139.2 m, between Stage II and Stage III, the fractured zone in the overburden strata above the working face communicated with the surface at the depth of DG, achieving a maximum actual displacement of 6.8 m in the strata. When advancing to 245.92 m, the working face entered the transition between Stage IV and Stage V, where notable fractures appeared deep within SG and connected with the advanced fracture line in the overburden strata above the working face. As mining progressed further, SG exhibited a lag effect due to the disturbance from the working face, with the location of vertical displacement visibly lagging behind the working face position by approximately 30 to 50 m.

The physical similarity simulation of rock strata materials in Fig. 4 (The DIC countor image processing in Fig. 4 is implemented using Matlab 2022), spanning from excavation at 15 m (Stage 1) to 300 m (Stage 5), showcases the envelope contours of crack propagation and the DIC imaging of vertical displacements on the strata surface. During the mining process of Stage 1, it is evident that the immediate roof strata collapse immediately after coal seam excavation. By analyzing and summarizing the characteristics of overburden migration at each stage, it can be discerned that the impact of Stage I’s advancement on the overburden is not significantly different from that of conventional geological features. However, as the working face progresses to Stage II and enters the DG (Dengu) geomorphology, prior to reaching the lowest point of the valley, the maximum displacement and vertical stress on the roof are both somewhat lower than those in horizontal terrain due to the absence of a portion of the soil layer weight compared to level terrain. Through inductive analysis of over 200 photographs and 3,210 DIC images obtained from the experiment, a series of characteristics regarding the interaction between excavation disturbance and overburden in valley geomorphology can be summarized:

-

1.

When excavating from the DG-SG direction and entering Stage III, part of the weight of the valley strata is transferred to the roof of the working face, which is borne by the support structure. Consequently, the mine pressure in this area becomes intense, leading to a sharp increase in the working resistance of the support.

-

2.

Due to the lack of horizontal displacement constraints from the DG strata, the horizontal displacement of overlying strata towards the rear becomes pronounced during Stage III excavation, resulting in significant horizontal shear stress above the support. This can easily lead to support crushing, collapse, or instability.

-

3.

Upon entering Stage IV, the vertical displacement range in the valley section increases sharply, accompanied by an increase in the peak advanced stress at the working face. This is because as the excavation moves from the valley into the SG section, the thickness of the overlying soil layer becomes significantly greater than that in the DG section, leading to a more intense manifestation of mine pressure compared to Stages I and II.

To further explore the evolution pattern of stress contours during excavation and to compare the stress-displacement states of overburden rocks and the manifestation of mine pressure at the working face under different mining sequences, it is necessary to conduct modeling and analytical research on numerical simulation experiments based on the physical-mechanical condition parameters from similar simulation experiments and on-site geological condition parameters.

Design and evolution of numerical simulation experimental scheme

The numerical simulation experimental model is modeled and excavated based on the actual geometric dimensions and excavation sequence of the site, and the physical and mechanical parameters of the rock strata obtained through on-site sampling and calibration are used for parameter assignment. The impact of mining disturbance on the mechanical state of the strata under valley landform conditions is compared between the two different mining methods of SD and SG. The degree and causes of mine pressure at different stages are explored. Based on the aforementioned similar simulation experiment analysis, it is expected to obtain a more comprehensive risk identification mechanism for the strong mine pressure-large deformation area of the overburden rock under valley landform conditions, as shown in Fig. 5.(The numerical simulation experiment was implemented using Flac3D 7.01 software,).

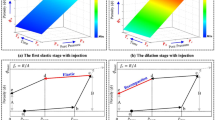

An overview of Figs. 6,7 and 8 reveals that during the excavation process of retreat mining from left to right, as the disturbance range of the overburden strata above the mining field continues to expand, the area of vertical stress concentration in the overburden profile increases monotonously from Stage I to Stage V, and the area of stress increase zone higher than the in-situ vertical stress decreases within the limited and identical geometric dimensions. However, considering the Saint-Venant’s Principle, it is evident that the stress increase zone in the overburden strata of the mining field, which is in a semi-infinite state under actual working conditions, should also increase. Similarly, the area proportion of the ini-state rock stress zone continues to decrease under the influence of disturbance. Unlike vertical stress, vertical and horizontal displacements are vector units, making it difficult to determine the area of high deformation disaster risk solely based on numerical values. Therefore, further analysis is required by integrating the evolution pattern of stress nephograms and the distribution of measuring lines arranged in different rock strata as shown in Fig. 8.

As can be seen from Fig. 9, there is a general pattern that during the process of Stages I-V, the vertical stress measured in the immediate roof is generally greater than that in the main roof, which is in turn greater than that in the key strata. Furthermore, as the mining process progresses, the vertical stress in the immediate roof first decreases and then increases, with a peak value reaching approximately 6.0 MPa, and the advanced peak stress concentration factor reaching approximately 2.3. The stress variation range in the main roof and key strata remains relatively stable.

Numerical simulation experiments were conducted to simulate the evolution process of the SD method, verifying the accuracy of similar simulation experiments. It was found that during the process of advancing the working face of the SD method, the stress of the overlying rock layer was redistributed and transferred, and the protruding valley parts on the surface formed stress concentration on the working face, with a large displacement. This is an important source of large period mining pressure faced during the advancing process of the working face, which makes it difficult to control surface subsidence.

Furthermore, it is necessary to conduct a comparative analysis of the stress transfer process in the overlying rock under the SS method.

Furthermore, the excavation method is changed while keeping the model parameters unchanged, adopting the SG mining technology (excavation from SG to DG), and comparing and analyzing the evolution rule of stress and displacement field nephogram at different propulsion stages, as shown in Figs. 10 and 11-12.

A preliminary visual comparative analysis of Figs. 13 reveals that it is challenging to determine the proportion of stress concentration areas, in-situ stress areas, and stress-elevated zones solely based on the comparison of the areas covered by different color bands in the cloud images. Furthermore, it is difficult to compare the intensity of strong mining pressure manifestations and the risk of disaster caused by large deformations at the same stage under different mining methods. Analysis of the measuring lines indicates that the peak stress in the immediate roof during SG methods is higher than that during SD methods, reaching approximately 8.0 MPa. However, it is also challenging to distinguish the floating ranges of the basic roof stress and key stratum stress measuring lines between SG methodsand SD methodss. Therefore, a cloud image binarization image processing technique is required to process the stress-displacement cloud images of the mining section, enabling the identification of risk areas for mining pressure and surrounding rock deformation under different mining methods and stages. By regressing the data, a quantitative relationship between key influencing factors and the area of risk regions can be obtained. The logical process of identification is shown in Fig. 14.

First, the image file to be recognized is loaded into Matlab 2022b software. The gaussianfilter function is initially employed to reduce noise in the image. To facilitate uniform recognition of different colorimetric patterns, the image is further normalized to within the interval [0,1]. The Sobel edge detection operator is then utilized to detect edge information in the image, and contour edge boundaries are extracted. After completing these preparatory steps, the k-means clustering neural network is utilized to classify the color levels of the processed image. Finally, the area and proportion information of different color regions can be obtained. Following analysis, the color level regions are categorized into hazardous region, stable region, and original areas.After the extraction and processing, the proportion of Hazardous area, stable area and original area is arranged in stages according to the mining method to obtain the bar chart as Fig. 15.

After fitting, the cubic function fitting forms of three hazardous area curves σzz, Disp-x and Disp-z are obtained.

Through a comprehensive analysis of the bar chart in Fig. 14 and the mathematical implications of the fitted function expressions, it can be observed that the peak values of the risk areas in both displacement curves occur during the final mining stages of SG methodsand SD methodss (Stage V). Within the same mining method, as the mining progresses, the proportion of the risk area also gradually increases. In contrast, the vertical stress σzz curve exhibits a different evolutionary pattern from the two displacement curves. The two locations with the highest proportion of risk areas appear in the stage IV of both mining methods, and the proportion of risk areas does not monotonically increase with the deepening of mining stages. Therefore, a comprehensive analysis of the evolutionary patterns necessitates an integration with the mathematical expressions of the functions.

It is evident that when considering the peak in the final mining stage IV, the proportion of the risk area for vertical displacement Disp-z during SG methods (41.2%) is greater than that of the SD methods (39.42%). Additionally, the average proportion of the stable area for vertical displacement in SD methods reaches 73.62%, while it is 69.3% for SG methods. Meanwhile, the proportion of the risk area for horizontal displacement Disp-x during SD methods (35.41%) is higher than that of SG methods (32.41%). The average proportion of the stable area for horizontal displacement in SD methods is 42.83%, compared to 30.48% for SG methods regarding vertical displacement (which might be a typographical error, assuming it should be about horizontal displacement).

When considering the factor of vertical stress, the proportion of the stress risk area for SD methods (5.57%) is greater than that of SG methods (3.28%). The average proportion of the stable area for vertical stress in SD methods reaches 27.11%, while it is 22.38% for SG methods regarding vertical displacement (again, assuming a possible typographical error for consistency).

Upon comprehensive analysis, certain patterns emerge. When both mining methods advance to the same stage with the same footage, the probability of a significant vertical displacement risk area in SG methods is slightly higher than that in SD methods. However, the probability of a significant horizontal displacement risk area in SG methods is slightly lower than that in SD methods. Yet, when considering vertical stress (During the peak pressure stage of nearly 100 m in the valley shaped landform), the probability of a stress risk area in SG methods is 58% of that in SD methods, significantly smaller than the area of the vertical stress disaster risk area in SD methods.

Conclusions

Based on the comprehensive analysis of data results from field observation, physical similarity simulation material experiments, and numerical simulation experiments, although the mechanistic influencing factors for strong ground pressure manifestation in shallow coal seams with valley geomorphology are complex, from the perspective of effective control measures, regulation can be carried out through the following aspects:

-

1.

By analyzing the overburden disturbance process in the physical similarity simulation experiments, it can be observed that during the retreat mining process, to effectively control the effect of high-level overburden migration on the working face, grouting reinforcement can be applied to SG before entering Stage III of mining, aiming to form an integral bearing structure for the overburden strata above the working face under SG, thereby weakening its load effect on the roof of the working face;

-

2.

By comparing the SG methodsand SD methodss, it can be found that to effectively control the manifestation of ground pressure and roof pressure, under the geomorphic form of adjacent SG-DG combination, the SS methods should be selected to avoid the non-uniform manifestation characteristics of overburden due to geomorphic conditions.

Further research should be conducted on the long-term control technology of mining subsidence related to soil mechanics, and the evolution laws of micro plastic zones should be compared and analyzed in numerical simulation experiments to control the factors related to the manifestation of mining pressure in the working face during the mining process.

Data availability

All data generated or analysed during this study are included in this published article.

References

Shen Binxue, Z. et al. Research on the breaking characteristics of overlying strata in fully mechanized caving mining under gully landforms [J]. Coal Eng. 53 (07), 1–6 (2021).

Zhang Yujun, L. F. Monitoring and analysis of the destruction height and fracture development evolution of mining overburden rock in High-Intensity fully mechanized caving mining [J]. Chin. J. Rock Mechan. Eng. 30 (S1), 2994–3001 (2011).

Yang Shengqiang, Z. et al. Distribution law of three zones of spontaneous combustion in Goaf of fully mechanized mining face [J]. J. China Univ. Min. Technol. (01), 93–96 (2000).

Wang Zhiqiang, L. Further discussion on the division method and engineering application of three zones in mining area [J]. J. China Coal Soc. 38 (S2), 287–293. https://doi.org/10.13225/j.cnki.jccs.2013.s2.027 (2013).

Wang Zhiqiang, Z. & Jingli, L. Determination method of three zones height in staggered Stopes with internal staggered layout [J]. J. Min. Saf. Eng. 30 (02), 231–236 (2013).

Xu Jialin, Q. Study on the influence of key strata movement on overlying strata and surface movement [J]. J. China Coal Soc. (02), 122–126. https://doi.org/10.13225/j.cnki.jccs.2000.02.003 (2000).

Fan Gangwei, Z. & Dongsheng, M. L. Overlying strata movement and fracture distribution characteristics of shallow coal seam mining in Shendong mining area [J]. J. China Univ. Min. Technol. 40 (02), 196–201 (2011).

Zuo Jianping, S., Yunjiang, Q. & Minggao Movement mechanism of overlying strata with Thick loose layer and its Hyperbola-like model [J]. J. China Coal Soc. 42 (06), 1372–1379. https://doi.org/10.13225/j.cnki.jccs.2016.1164 (2017).

Luo, L. H., Ma, J. & Li, F. Y. Simulation of loess gully evolution based on geographic cellular automata[J]. Earth. Surf. Proc. Land. https://doi.org/10.1002/esp.5283 (2021).

Ma, S. & Kang, Y. Characteristics of Mining-Induced slope movement and ground behavior under gully landforms. Sustainability 14, 13941. https://doi.org/10.3390/su142113941 (2022).

Zgłobicki, W., Kołodyńska-Gawrysiak, R. & Gawrysiak, L. Gully erosion as a natural hazard: the educational role of geotourism. Nat. Hazards. 79 (Suppl 1), 159–181. https://doi.org/10.1007/s11069-014-1505-9 (2015).

Akhpatelov, D. M. & Ter-Martirosyan, Z. G. The stressed state of ponderable semi-infinite domains. Armen. Acad[J] Sci. Mech. Bull. 24, 33–40 (1971).

Yanpeng He,Qingxiang Huang,Li Ma. Study on the mechanism and control of strong ground pressure in the mining of shallow buried close–distance coal seam passing through the loess hilly region[J]. Geomech. Geophys. Geo-energ. Geo-resour. 11:14. (2025). https://doi.org/10.1007/s40948-024-00929-9

Luo, J. et al. Research on the quantitative relationship between stress shadow effect of multiple Thick and hard key layers and surface subsidence[J]. Sci. Rep., 15(1):1–152025 https://doi.org/10.1038/s41598-024-84179-5

Ewy, R. T. & Hood, M. Surface Strain Over Longwall Coal Mines:its Relation To the Subsidence Trough Curvature and To Surface Topography[J]21155–160 (International Journal of Rock Mechanics, Mining Science & Geomechanics, 1984). 3.

Savage, W. Z., Swolfs, H. S. & Powers, P. S. Gravitational stress in long symmetric ridges and valleys[J]. Internation J. Rock. Mech. Min. Sci. Geomech. 22, 291–302 (1985).

Swolfs, H. S. & Savage, W. Z. Topographic modification of in-situ stress in extensional and compressional tectonic environments[J]. Int. Symp. Rock. Stress Rock. Stress Meas. 22, 291–302 (1985).

Chengxuan Tana, R., Wang, Y. & Sun etc. Numerical modelling estimation of the ‘tectonic stress plane’ (TSP) beneath topography with quasi-U-shaped valleys. International Journal of Rock Mechanics & Mining sciences. 41(5): 303–310. (2004).

Pan, E.& B. Amadei, W. Z Savage. Gravitational and tectonic stresses in anisotropic rock with irregular topography[J]. Int. J. Rock. Mech. Min. Sci. Geomech. 32 (3), 201–214 (1995).

Pan, E., Amadei, B. & Savage, W. Z. Gravitational stresses in long symmetric ridges and valleys in anisotropic rock[J]. International Journal of Rock Mechanics Mining Science & Geomechanics. 31: 293–312. L. HOLLAT. Ground movement due to longwall mining in high relief areas in NewSouth Wales, Australia[J]. International Journal of Rock Mechanics & Mining sciences, 1997, 34(5): 775–787. (1994).

Bai, X. et al. The focal mechanism and field investigations of mining-induced earthquake by super-thick and weak cementation overburden strata fracturing[J].Geomechanics and geophysics for Geo-Energy and Geo-Resources, 11(1):1–29. (2025). https://doi.org/10.1007/s40948-024-00922-2

Liang, C. et al. Experimental investigation on gush disaster in shield tunnel driven through upper-silt and lower-sand strata[J].Tunnelling and underground space technology incorporating trenchless technology research, 158. https://doi.org/10.1016/j.tust.2025.106393 (2025).https://doi.org/10.1016/j.tust.2025.106393

Funding

This research received funding from the National Natural Science Foundation of China project “Research on the Time Effect Mechanism and Dynamic Response of Overburden goaf Coal Pillar Synergistic Action and Residual Coal Re mining”, 52074291, the National Natural Science Foundation of Surface Project of China, 51774289 and the National Natural Science Foundation of the Youth Science Foundation of China, 51404270.

Author information

Authors and Affiliations

Contributions

Peng, Fu. Jianqiao, Luo. And Shaohong, Yan. wrote the main manuscript text and dealt with all figures, Junqing, Mu. conducted a preliminary translation of the manuscript. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Fu, P., Luo, J., Yan, S. et al. The evolution law of mining stress concentration effect and mining pressure manifestation mechanism under different pushing methods in valley landforms. Sci Rep 15, 21113 (2025). https://doi.org/10.1038/s41598-025-06907-9

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-06907-9

This article is cited by

-

Overburden movement laws in thin bedrock workfaces under thick backfilled loose bodies

Scientific Reports (2025)