Abstract

The rapid growth of logistics demand has made improving operational efficiency and service level an important development goal for logistics enterprises. Radio frequency identification technology has great potential in logistics processes such as cargo tracking and path optimization due to its real-time and efficient nature. However, existing research mostly focuses on the theoretical application of technology, lacking support for investment feasibility analysis and system optimization strategies based on practical scenarios. Therefore, this study proposes a logistics optimization solution that combines RFID technology with two core modules: cargo tracking and path optimization. The results demonstrated that the cargo tracking scheme enhanced the tracking accuracy to 98.7%, reduced the cargo circulation time by 22.1%, and significantly reduced the cargo circulation error rate. The path optimization scheme improved delivery efficiency by 23.5% and reduced transportation costs by 18.2% by reducing ineffective travel distance. Further analysis showed that after the deployment of the plan, the overall logistics operation efficiency has increased by 21.8%, and the warehousing turnover rate has increased by 19.4%. In addition, this study further explored the key challenges in the implementation of radio frequency identification technology and proposed targeted optimization strategies. This study provides important reference for logistics enterprises in investment decision-making and application promotion of radio frequency identification technology, which helps to improve the intelligence level of logistics systems and reduce operating costs.

Similar content being viewed by others

Introduction

The acceleration of global economic integration and the booming development of e-commerce have brought unprecedented opportunities and challenges to the logistics industry1,2. The rapid growth of logistics demand has made improving operational efficiency and service level an important development goal for logistics enterprises. In this context, Radio Frequency Identification Technology (RFID) has gradually become an emerging technology that has attracted much attention in the logistics field due to its advantages in real-time and efficiency3,4. However, despite the broad application prospects of RFID technology in the logistics field, existing research mostly focuses on theoretical technical applications, lacking investment feasibility analysis and system optimization strategy support based on practical scenarios. Many logistics companies still have many doubts about their investment decisions in RFID technology, such as technology costs, implementation difficulties, data security, and other issues. In addition, how to deeply integrate RFID technology with existing logistics processes to achieve efficient operation of key links such as cargo tracking and path optimization is also an urgent problem that needs to be solved. Therefore, this study proposes a logistics optimization solution that combines RFID technology, focusing on two core modules: cargo tracking and path optimization, and incorporating artificial intelligence algorithms. The paper targets to analyze the application effect of RFID in logistics, explore its investment feasibility, and propose targeted optimization strategies. The innovation is reflected in the introduction of Kalman Filtering (KF) to dynamically correct the motion trajectory of RFID tags, improving tracking accuracy. It combines Particle Swarm Optimization (PSO) and Genetic Algorithm (GA) to solve the task allocation problem of multiple robots.

Related works

RFID technology, as an efficient information recognition technology, has been widely utilized in logistics, retail, healthcare, and enterprise asset management. Many scholars have researched the application of RFID technology in the logistics field. Guo J et al. designed a logistics scheduling model based on RFID technology to optimize vehicle routing and constructed a vehicle scheduling model to meet the dynamic delivery needs of logistics companies. Meanwhile, the study also employed an adaptive taboo search algorithm. This model reduced the total transportation cost by over 25%5. Novitasari N et al. designed a new RFID tag technology to improve the service quality of logistics companies. This study considered the expectations of logistics service users, namely reliability, convenience, service, and cost, which could improve the process time efficiency of express delivery service goods transportation6. Hussein O D et al. combined RFID technology and IoT technology to address the limitations of traditional barcode systems to achieve intelligent logistics. This study explored the combination of RFID and the IoT, and demonstrated it through case analysis. This study could enhance the responsiveness, accuracy, and efficiency of logistics, and meet the constantly changing demands of the global logistics industry7. Alashjaee et al. designed a secure symmetric key authentication protocol that supports RFID/IoT for tracking objects in an intelligent logistics-based ecosystem, to achieve intelligent logistics. This study designed the underlying protocol for supply chain intermediates from the perspectives of security and computational efficiency. This method had sufficient security and greatly reduced computational overhead8.

Zhang Q et al. designed an industrial product Logistics Information Traceability (LIT) method based on RFID middleware to enhance the effectiveness of LIT. This method constructed an RFID module and utilized global positioning system technology to monitor the logistics transportation process in real-time. The average traceability success rate was 93.54%, the location information acquisition time was less than 1.50 min, and the logistics location information matching accuracy could reach 95.1%9. Bottani et al. surveyed over 40,000 companies to understand the level of interest and adoption of RFID among logistics service providers and retailers, and obtained 58 useful responses. This study used social science statistical software packages for statistical analysis. 31% of respondents have implemented RFID solutions, while 21% have tested RFID solutions10. Abdullahi M O et al. comprehensively outlined the application of RFID in port logistics, including container tracking and real-time inventory monitoring, to cope with the continuously increasing freight volume and achieve sustainable development of Somali ports. This study emphasized the advantages, obstacles, and future potential of RFID in port logistics, providing direction for the sustainable development of Somali ports11. Alzahrani B A et al. designed a new intelligent logistics security RFID authentication scheme supported by fifth generation mobile communication technology to address the limitations of authentication key protocols based on logistics and supply chain, and adopted a formal security analysis based on a random Oracle model. The security features supported by this scheme have increased by 19%12.

In summary, current research on RFID in the logistics field mainly focuses on optimizing logistics scheduling, improving service quality, combining IoT technology to achieve intelligent logistics, and LIT. However, there are still some problems in current research, such as the lack of investment feasibility analysis and system optimization strategy support based on actual scenarios, and the deep integration of RFID technology with existing logistics processes. Therefore, this study designs an optimization scheme that combines RFID technology with two core modules: cargo tracking and path optimization, and analyzes the feasibility of the corresponding scheme.

The novelty of the research lies in the following aspects: firstly, the introduction of Kalman filtering to dynamically correct the motion trajectory of RFID tags. Compared with traditional cargo tracking algorithms, the cargo tracking scheme in the study considers the changes in tag phase with time and angle, thereby significantly improving tracking accuracy. Secondly, in the path optimization scheme, PSO and GA are combined to form the PSO-GA algorithm. Compared with standard PSO and GA, PSO-GA performs well in time consumption and shortest picking distance, and can quickly and effectively complete task allocation at different task scales, providing a better solution for multi robot collaborative picking path planning. Thirdly, three improvements have been made to the A* algorithm, including the introduction of weighted average distance, improvement of heuristic function, and optimization of paths, enabling it to generate shorter and smoother paths on different grid maps, further improving the efficiency and quality of path planning. These novel features give this study significant advantages in logistics cargo tracking and path optimization, providing more innovative and practical methods for the application of RFID technology in the logistics field.

Methods and materials

This study conducts a feasibility analysis of investing in RFID technology in logistics, focusing on two aspects: cargo tracking and path optimization. A Cargo Tracking Scheme (CTS) and a Path Optimization Scheme (POS) based on RFID are designed, forming the final logistics optimization scheme.

A logistics operations cargo tracking solution based on RFID technology

To analyze the application of RFID technology in cargo tracking and path optimization, and evaluate its technical and economic feasibility, a logistics optimization scheme combining RFID with cargo tracking and path optimization Is constructed. This scheme consists of two sub-schemes, namely the logistics CTS built on RFID and the logistics POS built on RFID. The CTS adopts the active sensing method in RFID technology, and uses phase to estimate the initial position of RFID tags. The least squares method (Levenberg Marquard, LM) is introduced to estimate the movement speed and position of RFID tags, achieving cargo tracking (Scheme 1). To dynamically correct the motion trajectory of RFID tags, KF is introduced to further improve the accuracy of cargo tracking (Scheme 2). The structure of the RFID system is shown in Fig. 113.

In Fig. 1, the RFID includes application programming interfaces, air interfaces, application systems, readers, and electronic tags. In RFID systems, phase refers to the phase difference between the signal emitted by the reader and the signal reflected or backscattered back from the tag. By measuring the change in phase, the position change of the label can be calculated, thereby achieving high-precision positioning and tracking. To obtain the initial position of RFID tags, it is necessary to use measured phase and theoretical phase. The expression of phase a is shown in Eq. (1)14.

In Eq. (1), c is the antenna number and b is the measurement number. \(d\left( \cdot \right)\) is the theoretical phase, as shown in Eq. (2).

In Eq. (2), \(AE\) is the distance between the tag and the reader antenna, and \(\bmod\) is the modulo operation. \({E_c}\) is the position of the c-th antenna, and g is the wavelength of the RF signal. \({A_{c,b}}\) and \(d\left( {{A_{c,b}},{E_c}} \right)\) are the positions of the RFID tag at the c-th antenna and the theoretical phase obtained from the RFID tag during the b-th measurement. To determine the true location of RFID tags in the initial area, this study introduces weights and assigns them to interference points (containing the true location of RFID tags). Meanwhile, the smaller the absolute value h of the difference between the measured phase and the theoretical phase, the greater the weight assigned. An exponential function is introduced to reflect the differences in weights, and phase errors and device heterogeneity are eliminated. It also amplifies points where h is close to zero to improve the weights. Finally, based on the highlighted weights, the initial position of the RFID tag can be clearly determined. LM is an optimization algorithm used to solve nonlinear least squares problems, which has high efficiency and stability, and has an extensive interval of applications in motion trajectory prediction and curve fitting15,16. Therefore, the paper uses the LM algorithm to estimate the speed and position of goods. To obtain the motion trajectory of RFID tags, it is necessary to continuously solve the position of RFID tags. The main process of tag trajectory tracking is shown in Fig. 2.

In Fig. 2, step 1 in label trajectory tracking is to construct a velocity function model. Step 2 is initialization, including speed, angle, step size factor, and initial iteration. Step 3 is to solve the iterative equation, and step 4 is to determine the testing conditions. If the conditions are met, the next step will be taken, otherwise the initial iteration = initial iteration*step size factor, and then return to the first step. Step 5 is to determine whether the iteration step size meets the accuracy requirements. If it does, the true velocity vector is clarified. Otherwise, the rate of change is r = r + 1, and then return to step 1. Step 6 is to obtain the label position using the distance formula. Due to the rotation of goods during delivery, it can affect the phase of RFID tags, thereby affecting tracking accuracy. Therefore, the paper analyzes the relationship between phase change and RFID tags, and introduces KF to dynamically correct the motion trajectory of RFID tags (Scheme 2). The fixed point rotation of the label is shown in Fig. 3.

In Fig. 3, the N axis is perpendicular to the antenna plane, while the M-N plane is parallel to the ground, and the Q axis is perpendicular to the M-N plane. When the RFID tag rotates along the Q axis, it will cause a change in the measurement phase. The temporal and angular variations of phase will be discussed in the results section. Based on the experimental results, this study uses a consistent RFID reader and two circularly polarized antennas to obtain continuous phase readings. Meanwhile, this study also makes modifications to the phase formula and clarifies the geometric tracking process of RFID tags. The new position expression of the label is shown in Eq. (3).

.

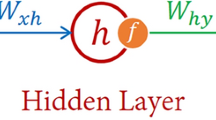

In Eq. (3), C and H are different antennas. \({L_i}\) is the current location of the RFID tag. i is the sequence number of the time. \(\Delta {p_{1,i}}\) and \(\Delta {p_{2,i}}\) are the moving distances for i and \(i+1\). \({\mathop {CD}\limits^{ \to } _i}\) and \({\mathop {HD}\limits^{ \to } _i}\) are projections of RFID tags in different directions. By using \(\Delta {p_{1,i}}\) and \(\Delta {p_{2,i}}\), the rotation angle can be calculated. By combining the rotation angle, \(\Delta {p_{1,i}}\), and \(\Delta {p_{2,i}}\), the new coordinates of the RFID tag can be obtained. To remove the cumulative error during the tracking process, this study uses a KF processor for processing. KF algorithm is an algorithm that utilizes linear system state equations to estimate the optimal state of a system through input-output observation data. It has significant advantages in removing cumulative errors17,18. When removing cumulative errors, it is necessary to initialize the mean square error of the state and solve for the observation vector. Subsequently, it is necessary to perform error covariance prediction and solve the Kalman gain. The tracking trajectory of the processed goods will be more accurate and smooth.

Optimization scheme for logistics operations path based on RFID technology

Based on the analysis of the RFID in cargo tracking and path optimization, a logistics cargo tracking sub-scheme based on RFID has been constructed. To complete the application analysis of RFID technology in path optimization, a logistics POS based on RFID is designed. This POS uses the LANDMARC positioning system, which includes RFID, to obtain the specific location of the goods19. A multi-robot picking task allocation model based on PSO solution is designed, and then multi-robot collaborative picking path planning is implemented through an improved A* algorithm. LANDMARC mainly includes tags, readers, and positioning algorithms. Its advantages are high positioning accuracy, wide coverage, strong scalability, long tag lifespan, and easy portability20. When using LANDMARC, it is necessary to compare the Received Signal Strength Indication (RSSI) values of the reference tag and the unknown tag. The process of the LANDMARC positioning algorithm is displayed in Fig. 4.

In Fig. 4, step 1 of LANDMARC is to obtain the position of the reference tag, and step 2 is to obtain the RSSI values of the reference tag and the tag to be located. Step 3 is to select k neighboring reference tags with the smallest difference in RSSI values from the tag to be located. Step 4 is to determine the weight parameters of k adjacent reference labels based on their similarity. Step 5 is to solve the coordinates of the position of the label to be located based on weight parameters and the positions of k adjacent reference labels. Step 6 is to determine whether to proceed to the next round. If necessary, it will return to the second step, otherwise it will proceed to the next step. Step 7 is to obtain the location of the tag to be located and end the process. At the same time, the system uses a logarithmic distance path loss model to estimate the position of labels. However, in practical applications, there are various factors that affect RSSI values, leading to unstable and inaccurate RSSI values, such as environmental noise. To solve this problem, this study also uses the KF algorithm to process RSSI values. KF consists of two parts: prediction and correction. The RSSI value optimization process based on this algorithm is shown in Fig. 5.

In Fig. 5, step 1 in optimizing RSSI values is to initialize parameters, such as the covariance matrix of process errors and the covariance matrix of measurement noise. Step 2 is to estimate the prior estimate of the RSSI value at time t. Step 3 is to estimate the prior error covariance matrix at t. Step 4 is to calculate the Kalman gain at t. Step 5 is to obtain a posterior estimate of the RSSI value at t. Step 6 is to refresh the posterior error covariance matrix at t. Step 7 is to determine if the termination condition is met: if it is met, output the processed RSSI value; otherwise, return to the second step until the final termination condition is met. Before conducting path planning for multiple robots in logistics warehouses, task allocation needs to be done first. When assigning tasks, it is needed to consider conditions including the location of goods and the maximum load capacity of the machine. Therefore, this study constructs the objective function for task allocation, as shown in Eq. (4).

In Eq. (4), U and V are the number of task groups and sub-tasks. u is the u-th task group (robot), and \({U_u}\) is the number of sub-tasks of u. v and w are different sub-tasks and both belong to V. \(S_{{01}}^{u}\) is the length between u and the first picking point. \({y_{vw}}\) and \({z_{vwu}}\) are both decision variables. \(S_{{{U_u}0}}^{u}\) is the length of u from position \({U_u}\) to the packing table. The objective function contains three constraint conditions, namely the maximum cargo weight, the uniqueness of the task corresponding robot, and the task point robot.

To solve the objective function, an improved PSO algorithm is designed in this study. PSO is a stochastic optimization algorithm based on swarm intelligence, which has the advantages of fast convergence speed, strong global search ability, and low requirements for the objective function. It has huge of advantages in solving the objective function21,22,23. To better solve the objective function, GA is introduced and combined with PSO algorithm to form the final solution algorithm PSO-GA. GA is a random search algorithm inspired by the process of biological evolution, which has strong global search ability, robustness, and is easy to combine with other algorithms24,25. Therefore, this study initializes the population using PSO and further optimizes the individuals in the population using GA. The main process of PSO-GA is shown in Fig. 6.

In Fig. 6, the main process of PSO-GA consists of seven steps. The most important steps are the first, fifth, and sixth steps. Step 1 is to initialize parameters such as particle position, velocity, size, global optimum, and local optimum, and solve the total cost of each particle path. Step 5 is to separately calculate the path costs after cross mutation. Step 6 is to determine whether the current position is better than the local optima. If so, the global optima and local optima will be updated, otherwise it will proceed to the next step.

After clarifying the assigned tasks for each robot, path planning for the robots can be carried out. To construct an environmental map of the warehouse, this study adopts the grid method, and the robot can only move in four directions: up, down, left, and right. Grid method is a commonly used method for constructing map models. It divides spatial regions into regular grid units, which have the advantages of simplicity, intuitiveness, convenient data processing, strong spatial analysis ability, and suitability for integrating multi-source data26,27. For the path planning of a single robot, this study adopts the A* algorithm and improves it. The A* algorithm is a heuristic search algorithm commonly used for pathfinding. Its advantages in path planning are high search efficiency, the ability to find the path with the lowest cost, and strong flexibility28,29. However, this algorithm also faces shortcomings such as insufficiently smooth generation paths and strong dependence on heuristic functions. Therefore, this study proposes three improvements to A*, focusing on distance formula, heuristic function, and path optimization. The first improvement is to introduce a weighted average distance G, which is expressed as Eq. (5).

In Eq. (5), \({G_{Euclidean}}\) is the Euclidean distance. \(\partial\) is the equilibrium factor, with [0,1]. \({G_{Manhattan}}\) denotes the distance from Manhattan. The larger the \(\partial\), the shorter the search time, so its specific settings need to be set according to experimental requirements. The second improvement is to introduce an exponential function \({e^R}\) into the heuristic function, where R is the obstacle rate. Therefore, the improved heuristic function is shown in Eq. (6).

In Eq. (6), T is the node, and \(\alpha \left( T \right)\) represents the actual cost from the starting point to the current node T. Improvement three involves optimizing the path three times, with a focus on avoiding obstacle boundaries, removing redundant nodes, and reducing turning angles. In multi-robot path planning, there are three common conflicts: facing conflict, node conflict, and catching up conflict. Due to the fact that most robots in the warehouse travel at a constant speed, overtaking conflicts are avoided. Therefore, this study mainly focuses on avoiding head-on conflicts and node conflicts. Subsequently, multi-robot path planning adopts time window algorithm to solve conflicts between multiple robots. The time window algorithm is an algorithm that plans paths by assigning specific time intervals (i.e. time windows) to the actions of each robot and analyzing and managing these time windows30. Through this algorithm, this study is able to predict potential conflicts in order to adopt corresponding strategies to avoid them in the future. The strategy selection mainly considers the path re-planning scheme, that is, the priority of the robot is the main consideration. Therefore, the path planning process for multiple robots is shown in Fig. 7.

In Fig. 7, step 1 in multi-robot path planning is to establish a grid map and initialize various parameters. Step 2 is to plan paths for all robots built on the improved A* algorithm. Step 3 is to determine the time window for all robot paths. Step 4 is to determine whether there is an overlap in the time window. If so, it means there is a conflict, and the conflict needs to be handled according to the path replanning scheme before returning to step 3. If the judgment is negative, it will continue to check whether each robot has completed path planning. If the judgment is yes, the process ends; otherwise, it returns to step 3.

Results

To validate the feasibility of the research plan, the configurations and parameters were set, and the comparative schemes and algorithms were explained. This study also explained the problems encountered during the implementation of the plan and proposed corresponding solutions.

Feasibility verification of logistics operations and cargo tracking plan

To verify the feasibility of the designed logistics CTS (Scheme 2), ThingMagic Mercury6e Nano reader was used, which operates in the global frequency range of 840-960 MHz. This study also used two FEIG ELECTRIC LPR-6210 circularly polarized antennas and NXP UCODE 8 ultra-high frequency passive RFID tags. The operating frequency of this tag was between 840 and 960 MHz. The study selected a typical logistics distribution warehouse as the physical environment for technical validation. The warehouse has an area of approximately 1000 square meters, a height of 8 m, a reasonable internal layout, and a complete shelving system and cargo storage area. And there are multiple cargo channels with a width of 3 m in the warehouse to ensure smooth transportation of goods and robot operation. In order to achieve effective tracking of goods, multiple RFID readers were installed in the warehouse, and these readers were evenly placed at key positions on the shelves and passages. At the same time, RFID tags were affixed to the goods in the study. In addition, the experiment also used the Windows 10 system, with an Intel Core i5-11400 F central processor, a processor clock speed of 2.6 GHz, and a maximum turbo frequency of 4.4 GHz. The experiment used a small car (with RFID tags attached) to simulate the movement of goods, and selected two classic motion trajectories, namely circular track and linear track. The comparison schemes selected include Scheme 1, Scheme A combining video assistance and RFID tags, Scheme B combining RFID tags and trajectory similarity measurement, and Scheme C combining laser sensing information and RFID tags. To verify the significance of the experimental results, t-test statistical method was used in the study. By conducting t-tests on the performance indicators of different schemes/algorithms, the corresponding p-values are calculated to determine whether the performance differences between schemes/algorithms are statistically significant. The designed Scheme 2 considered the variation law of label phase with time and angle, and the specific content of this law is shown in Fig. 8.

In Fig. 8 (a), in the temporal variation pattern of the label, as time increases, the phase corresponding to the label rotation shows a trend of first rising, then sharply falling, and then repeating this process. The time required for each change will gradually decrease. In Fig. 8 (b), as the angle between the tag and the antenna increases, the trend of phase change gradually increases and then vertically decreases, and this process is repeated continuously. This indicates that there is a linear relationship between phase and time as well as the phase and angle corresponding to label rotation. The comparison of tracking accuracy of different schemes on different trajectories is shown in Fig. 9.

In Fig. 9 (a), on a straight track, the maximum tracking accuracy of Scheme 2 is 98.70%, and the minimum is 94.17%. The maximum tracking accuracy of Schemes 1, A, B, and C is 93.24%, 90.17%, 92.76%, and 93.98%, which is 5.46%, 8.53%, 8.53%, and 4.72% lower than 98.70%. In Fig. 9 (b), Scheme 2 has better tracking performance on a circular orbit, followed by Scheme 1, Scheme C, and Scheme B. Scheme A has the lowest tracking performance. In addition, the maximum tracking accuracy of the five schemes is 97.43%, 93.16%, 88.94%, 90.79%, and 91.32%. Overall, the Scheme 2 has better tracking performance and higher precision on both straight and circular orbits. The comparison of maximum tracking errors for different schemes on different orbits is listed in Table 1.

In Table 1, the average maximum error of Scheme 2 on a straight trajectory is 0.182 cm. The maximum average errors of Scheme 1, Scheme A, Scheme B, and Scheme C are 0.365 cm, 0.476 cm, 0.671 cm, and 0.809 cm, which are 0.183 cm, 0.294 cm, 0.489 cm, and 0.627 cm higher than 0.182 cm. Meanwhile, on the circular track, the maximum average errors of the five schemes are 0.263 cm, 0.353 cm, 0.535 cm, 0.766 cm, and 0.806 cm. On a circular orbit, the maximum error of the Scheme 2 is obviously smaller than that of the comparative scheme. Overall, the tracking performance of the research plan is better and the tracking error is smaller. To further analyze the practical application effect of the research plan and analyze its potential problems, this study selects a certain e-commerce logistics center as an example and analyzes the cargo flow time and cargo flow error rate before and after the implementation of the plan. The actual application effect of the logistics CTS is shown in Fig. 10.

In Fig. 10 (a), the Maximum Value (MaxV) of the logistics transfer time in the warehouse before the implementation of the plan is 24 h, the Minimum Value (MinV) is 6 h, and the mean is 14 h. After experimenting with the research plan, the maximum, minimum, and average transit times of goods in the warehouse are 18.696 h, 5.173 h, and 11.56 h, with a decrease rate of 22.1%, 13.78%, and 17.43%. In Fig. 10 (b), the MaxVs of the error rate in goods circulation before and after the implementation of the plan are 0.98% and 0.34%, with a difference of 0.64% between the two. Overall, the CTS reduces the logistics transfer time by 22.1% and significantly lowers the error rate of cargo flow. However, during the experiment of this scheme, some issues are also encountered, including the reliability of RFID tags and multi-tag interference. To address these issues, waterproof, moisture-proof, and high-temperature resistant RFID tags can be used, or a dual tag backup mechanism can be employed. In addition, multi-antenna readers and advanced signal processing algorithms can be used to reduce signal interference between tags.

Feasibility verification of logistics operations path optimization plan

To verify the feasibility of the optimized logistics path design, Windows 10 and Intel Core i5-11400F were also used. The iteration count of KF was 20 times. This study designed a 23*23 unmanned warehouse area, equipped with 7 robots, and each robot had a load capacity of 12kg. There were four types of task quantities set: 20, 60, 100, and 140 tasks. The ‘task size’ is quantitatively measured by the number of goods picking tasks that need to be completed, specifically referring to the total number of goods picking tasks that robots need to handle in the logistics warehouse scenario. The task size reflects the workload and complexity that robots need to face in path planning and task allocation processes. In PSO-GA, the population size was 100, the crossover and mutation probabilities were 0.9 and 0.5, the number of particles was 100, and the inertia factor was 1. Three types of grid maps were designed, corresponding to scales of 30*30, 50*50, and 120*120, with medium obstacles set in each map. In multi-robot path planning, this study set priorities for different robots to verify the feasibility of path optimization solutions in resolving robot conflicts. The comparative algorithm of PSO-GA selected GA, PSO, and the Algorithm D that combines power-law distribution function and PSO, as well as the Algorithm E combining heuristic crossover operator based on greedy strategy, nearest neighbor search operator, and GA. The comparison algorithms for improved A* include A* algorithm, Artificial Potential Field (APF) method, Algorithm F combining APF with fast exploration of random trees, and Algorithm G combining visual inspection, corner cost function, and A*. The comparison effect before and after RSSI value optimization is shown in Fig. 11.

In Fig. 11 (a), as the number of iterations increases, the trend of KF estimation error changes rapidly, first decreasing and then increasing rapidly, and then gradually decreasing and increasing again. After reaching a certain value, it begins to gradually stabilize. In addition, the maximum and MinVs of KF estimation error are 1.79dbm and 1.17dbm, with corresponding iteration times of 0 and 20. Therefore, this study sets the number of KF iterations to 20. In Fig. 11 (b), the maximum RSSI value before optimization is −42.57dBm, and the MinV is −60.67dBm, with a difference of 18.10dBm between the two. This indicates that the fluctuation range of RSSI values before optimization is relatively large. After KF optimization, the maximum and minimum RSSI values are − 46.98 dBm and − 56.13 dBm, with a difference of 9.15 dBm, significantly less than 18.10 dBm. The optimized RSSI value has a smaller fluctuation range and better quality. The performance verification results of PSO-GA are shown in Fig. 12.

In Fig. 12 (a), in terms of time consumption comparison, the MaxV of PSO-GA is 58ms and the MinV is 29ms. The maximum time consumption of GA, PSO, Algorithm D, and Algorithm E is 158ms, 137ms, 117ms, and 121ms, which are 100ms, 79ms, 59ms, and 63ms higher than 58ms. In Fig. 12 (b), in the comparison of shortest picking distances, PSO-GA performs better in all four task scales, followed by Algorithm E and Algorithm D, and finally PSO and GA. When the task size is 140, the shortest picking distance of PSO-GA is 975.23. The shortest picking distances of the four comparison algorithms are 1546.48, 1387.56, 1198.76, and 1087.65, which are 571.25, 412.33, 223.53, and 112.42 more than 975.23. Overall, PSO-GA has good performance and can better allocate tasks. The comparison results of the improved A* algorithm are shown in Fig. 13.

In Fig. 13 (a), on a 30*30 map, the Average Search Time (AST) of the improved A* is 8.72ms. The AST for A*, APF, Algorithm F, and Algorithm G is 80.54ms, 74.83ms, 43.17ms, and 33.65ms. The shortest path lengths of the five algorithms are 25.21, 79.33, 68.54, 43.98, and 38.34, with 3, 7, 6, 5, and 4 turning points. In Fig. 13 (b), on the 50*50 map, the improved A* performs better, with corresponding AST, shortest path length, and 6 turning points of 46.51ms, 29.76, and 6, which are significantly better than the compared algorithms. In Fig. 13 (c), on the 120*120 map, the AST of the improved A* is 7369ms, which is lower than the comparison algorithms of 18765ms, 16754ms, 12873ms, and 10873ms. The improved A* also has significantly better shortest path length and number of turning points than the compared algorithm. Overall, the improved A* performs well. The comparison of planned paths before and after conflict resolution is shown in Fig. 14.

In Fig. 14 (a), there is a conflict between the planned paths of Robot 1 and Robot 2 in the original path. At this point, there is also an overlap in the original time windows of robots 1 and 2. Based on the consideration of robot priority, this study retains the planned path of robot 1 and adjusted the path of robot 2 with lower priority. In Fig. 14 (b), after path adjustment, although the planned paths of robots 1 and 2 also have overlapping points, their adjusted time windows do not have overlapping parts, so there is no conflict between the two. This study also implements and deploys the path planning scheme, taking a certain e-commerce logistics center as an example. The optimization effect is shown in Table 2.

In Table 2, after implementing the research plan, the delivery efficiency of e-commerce logistics centers increased by 23.5%, and transportation costs decreased by 18.2%. The reduction of transportation costs is closely related to the improvement of delivery efficiency. By optimizing transportation routes, not only have transportation costs such as fuel consumption and vehicle wear and tear been directly reduced, but more transportation tasks can also be completed per unit time, significantly improving delivery efficiency. At the same time, due to the optimization of transportation routes and the acceleration of cargo turnover, the full load rate of vehicles has increased, the resource utilization rate has been improved, and the unit transportation cost has been further reduced. Therefore, the reduction of transportation costs and the improvement of delivery efficiency are complementary, jointly reflecting the significant improvement of logistics operation efficiency. At the same time, the overall logistics operation efficiency increased by 21.8%, and the warehousing turnover rate increased by 19.4%. This scheme has good application effects. However, in practical applications, there may be risks of illegal reading, tampering, or leakage of cargo information, transportation routes, and other data stored in RFID tags, which involves customer privacy and trade secrets. Therefore, relevant enterprises need to establish strict data access control mechanisms and regularly conduct security assessments and vulnerability scans of RFID systems to promptly fix security vulnerabilities and prevent data leakage. Meanwhile, the logistics delivery scenarios in reality are complex and ever-changing, such as traffic congestion, weather changes, and temporary order insertion. Relevant enterprises can establish real-time feedback mechanisms, adjust path optimization plans promptly based on the actual logistics process, and continuously improve and perfect path optimization algorithms in combination with actual logistics scenarios.

Discussion and conclusion

Based on the application effect of RFID in logistics, this study started from two perspectives: cargo tracking and path optimization, and constructed a logistics optimization plan that includes both and RFID technology. In the experiment, on a straight track, the maximum tracking accuracy of Scheme 2 was 98.70%, which was 5.46%, 8.53%, 8.53%, and 4.72% higher than the MaxV of the comparative scheme. The tracking accuracy of this scheme on a circular orbit was also significantly superior to the comparison algorithm, with a MaxV of 97.43%. The maximum time consumption of PSO-GA was 58ms, which was 100ms, 79ms, 59ms, and 63ms lower than the MaxVs of the compared algorithms. When the task size was 140, the corresponding shortest picking distance was 975.23. The improved A* algorithm performed better on different grid maps. On the 120*120 map, the AST of the improved A* was 7369ms, which was lower than the comparison algorithms’ 18765ms, 16754ms, 12873ms, and 10873ms. Its shortest path length and number of turning points were also significantly better. After implementing the designed path planning scheme, the delivery efficiency within the same province and city increased by 18.25% and 20%. However, there is still room for improvement in the use of filters in this study. Future research can be combined with practical applications to improve its tracking performance and accuracy. The specific improvement methods include optimizing the filter parameters to dynamically adjust them according to different logistics environments and cargo characteristics, thereby improving the accuracy of state estimation. Introducing adaptive filtering technology to enhance the response capability of filters to environmental changes and interference, and improve tracking stability. Integrating multiple filtering algorithms and combining the advantages of different algorithms to cope with complex cargo movement trajectories. In addition, filter defects that affect tracking performance include assumptions that do not match reality, computational complexity and real-time issues, and initial state estimation errors. Therefore, future research can also focus on filter studies for nonlinear motion models and develop filtering algorithms suitable for complex trajectories. Reduce the computational complexity of the filter and improve real-time response capability. Improve the initial state estimation method of the filter to reduce the impact of initial errors and enhance system stability.

Data availability

All data generated or analysed during this study are included in this published article.

References

Liu, Z. & Li, X. Optimization model of cold chain logistics delivery path based on genetic algorithm. Int. J. Industrial Eng. 31 (1), 152–169 (2024).

Chen, Y. Real-Time load monitoring of logistics delivery vehicles using deep Learning-Based image analysis. Traitement Du Signal. 41 (4), 1741–1748 (2024).

Cao, F. M. & He, X. P. Lightweight RFID bidirectional authentication protocol based on improved hash function. Int. J. Netw. Secur. 26 (1), 98–105 (2024).

Liu, W. R., Ji, Z. Y. & Chu, C. C. An improved secure RFID authentication protocol using elliptic curve cryptography. Int. J. Netw. Secur. 26 (1), 106–115 (2024).

Guo, J. et al. Exploring logistics transport route optimization: an algorithmic study based on RFID technology. Int. J. RF Technol. 14 (2), 107–124 (2024).

Novitasari, N. & Anwar, N. Enhanced technology for logistics courier delivery using RFID label to minimize processing time. JOIV: Int. J. Inf. Visualization. 6 (3), 610–617 (2022).

Hussein, O. D. & Muhudin, A. Smart logistics: leveraging RFID and IoT for seamless operations. SSRG Int. J. Electron. Communication Eng. 11 (11), 146–152 (2024).

Alashjaee, A. M. et al. Resots: rfid/iot-enabled secure object tracking key exchange for trustworthy smart logistics. Wireless Pers. Commun. 139 (2), 777–799 (2024).

Zhang, Q. Traceability method of industrial product logistics information based on RFID middleware. Int. J. Manuf. Technol. Manage. 37 (3), 257–271 (2023).

Bottani, E., Correale, S., Rizzi, A., Stefanini, R. & Vezzani, L. How RFID technology enables the supply chain and retail 4.0: A survey with Italian stakeholders. Int. J. RF Technol. 14 (2), 125–150 (2024).

Abdullahi, M. O., Nageye, A. Y., Ahmed, A. D. & Ahmed, M. M. Optimizing Port logistics: empowering Mogadishu Port with RFID technology in Somalia. Int. J. Electron. Commun. Eng. 11 (4), 115–120 (2024).

Alzahrani, B. A. & Irshad, A. An improved IoT/RFID-enabled object tracking and authentication scheme for smart logistics. Wireless Pers. Commun. 129 (1), 399–422 (2023).

Wang, B., Yuan, Y., Wang, K. & Cao, S. Toward chipless RFID sensor for metal surface cracks detection. Sens. Rev. 44 (6), 696–703 (2024).

Le Breton, M., Larose, É., Baillet, L., Lejeune, Y. & van Herwijnen, A. Monitoring snow water equivalent using the phase of RFID signals. Cryosphere 17 (8), 3137–3156 (2023).

Raja, M. A. Z. et al. A predictive neuro-computing approach for micro-polar nanofluid flow along rotating disk in the presence of magnetic field and partial slip. AIMS Math. 8 (5), 12062–12092 (2023).

Kumar, M., Kaswan, P. & Kumari, M. Entropy generation analysis of Microrotating casson’s nanofluid with Darcy-Forchheimer porous media using a neural computing based on Levenberg-Marquardt algorithm. Int. J. Numer. Methods Heat. Fluid Flow. 34 (6), 2285–2320 (2024).

Bai, Y., Yu, Q. & Ma, Y. An embedded differential evolution approach to adaptive covariance inflation with the ensemble Kalman filter. Int. J. Remote Sens. 45 (22), 8425–8440 (2024).

Gümüş, M. G. Forecasting future scenarios of coastline changes in türkiye’s Seyhan basin: a comparative analysis of statistical methods and Kalman filtering (2033–2043). Earth Sci. Inf. 17 (6), 5207–5232 (2024).

Song, S. & Li, C. Complex environmental localization of scenic spots by integrating LANDMARC localization system and traditional location fingerprint localization. Int. J. Adv. Comput. Sci. Appl. 15 (8), 860–870 (2024).

Tang, M. & Chen, R. Study and implementation of a tunnel personnel and materials management system based on RFID technology. Scientific bulletin, university POLITEHNICA bucharest, series. Electr. Eng. 85 (1), 227–244 (2023).

Su, H., Song, S. & Wang, X. Probabilistic calculation of tidal currents for wind powered systems using PSO improved LHS. Energy Eng. 121 (11), 3289–3303 (2024).

Bendine, K., Wei, Y. J., Wang, X., Chen, M. & Zhang, S. Q. An improved active damping of fan blade using piezoelectric MFC actuators and PSO optimization. Mech. Adv. Mater. Struct. 31 (28), 10614–10623 (2024).

Sreekantha Kumar, V. P. & Kumaratharan, N. Achieving optimal data collection efficiency with dynamic levy flight-enabled PSO in mobile sink-based WSNs. Telecommunication Syst. 87 (4), 939–957 (2024).

Liu, H., Liu, Q., He, R., Li, F. & Luo, K. Research on the capacity cost allocation and the electricity capacity price optimization method for a power system based on the BARY-GA algorithm. Energy Sci. Eng. 12 (1), 168–180 (2024).

Kanth, S. Dynamic adaptive resource allocation for edge computing in big data analytics using GBDT, DQN, and GA algorithms. J. Electr. Syst. 20 (5), 2158–2165 (2024).

Liu, N., Chen, Y. & Huang, Y. Two-grid methods for maxwell’s equations in a Cole-Cole dispersive medium. East. Asian J. Appl. Math. 14 (2), 371–396 (2024).

Tianhang, X., Haolin, Z. H. I., Shuanghou, D., Zhaolin, C. & Xinying, L. Enhancement on parallel unstructured overset grid method for complex aerospace engineering applications. Chin. J. Aeronaut. 36 (1), 115–138 (2023).

Daniel, K. L. & Poonia, R. C. An In-Depth analysis of collision avoidance path planning algorithms in autonomous vehicles. Recent. Adv. Comput. Sci. Commun. 17 (8), 62–72 (2024).

Yali, Z., Zhenjie, M. O., Haoxin, T., Yubin, L. & Linlin, W. Path planning algorithm of agricultural robot based on improved APF-FMT. J. South. China Agricultural Univ. 45 (3), 408–415 (2024).

Xie, G. & Time Window, N. S. G. A. I. I. Route planning algorithm for home care appointment scheduling in the elderly industry. Int. J. Adv. Comput. Sci. Appl. 15 (6), 1327–1338 (2024).

Funding

Project ID: 2024KTSCX226. Project Title: Research on an AI-assisted Diagnostic Algorithm for Dry Eye Disease Based on Multi-source Prior Knowledge.

Author information

Authors and Affiliations

Contributions

All authors wrote the main manuscript text. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Han, J., Ai, H., Li, R. et al. Investment feasibility and optimization strategies of RFID technology in logistics field. Sci Rep 15, 27500 (2025). https://doi.org/10.1038/s41598-025-11483-z

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-11483-z