Abstract

Nitrogenous (N) fertilizers are widely applied in agriculture for improving crop yield. However, significant quantity of chemically-applied N is lost leading to low nitrogen use efficiency (NUE). Therefore, two laboratory incubation studies were designed to evaluate the effects of different coating agents [no coating, neem (Azadrichta indica) oil coating and potassium ammonium phosphate (PAP) coating) on urea hydrolysis and nitrification under varying temperatures (25, 35 and 40 °C) and moisture regimes (30, 60 and 90% of field capacity). Results revealed that the NH4+ and NO3− concentrations increased both with temperature and moisture levels. Using the organic-coated neem oil coated urea (NOCU) significantly reduced the release of NH4+ and NO3−. Thereafter, a field experiment was conducted to explore the best coating agent [N0, 100% conventional urea, 75, 50 and 25% of recommended neem oil coated urea (NOCU)] using irrigated (Akbar-2019) and rainfed (Barani-2017) wheat cultivars. Even the reduced rates (50%) of the recommended NOCU performed at par to 100% recommended uncoated urea fertilizers. Application of 1% NOCU @ 75% of the recommended urea resulted in maximum grain yield (3.65 Mg ha− 1), N in roots (0.87%), N in straw (0.85%) and N in grains (1.07%) in irrigated wheat variety (Akbar-2019). Thus, using 1% neem oil coated urea @ 75% of the recommended uncoated urea has the potential to enhance the growth, yield, N uptake and NUE in wheat effectively under both rain fed and irrigated conditions.

Similar content being viewed by others

Introduction

According to Food and Agriculture Organization (FAO) projections, global grain production must be increased by 140% or more by the year 2050 to meet the food demands of the growing population1,2. A considerable improvement in crop yield in developing nations would alleviate the pressure of the global grain demand and ensure food security3,4. However, the crop yield in developing countries is far below the potential because of the lack of knowledge, meagre resources, degraded soils and improper management practices. Among the nutrients, N is the most critical macronutrient for ensuring high-quality crop production5. Nitrogen (N) deficiency is a significant concern in many agricultural regions worldwide. That’s why, N fertilizers are important foundation for sustainable crop production6. Nitrogen application improve the yield and quality of almost all crops because it affect the growth and development of plants under diverse agro-climatic environments7,8,9,10.

Nitrate (NO3−) and ammonium (NH4+) are two bio-available forms of N for plant use. Fertilizers like urea (46% N) are commonly used to replenish soil N, and N assimilation and biomass of plants because of its high N content11. However, utilization of large quantities of urea fertilizer in agriculture leads to the environmental problems (eutrophication of waterways, greenhouse gas emission and soil degradation). Excessive application of N fertilizer has adverse impacts on groundwater and atmosphere by runoff, denitrification, leaching and volatilization of N12 thus decreasing N recovery efficiency (NRE), which in turn can reduce crop yield13,14. Ozone depletion is another problem associated with nitric (NO2) and nitrous oxide (N2O) or production15,16. Using excessive fertilizer that is high in N content is not only wasteful, but also has the potential to contaminate groundwater17 and leads to environmental and health issues. Thus, present study aimed to explore more sustainable N management solutions, such as natural and polymer-coated fertilizers.

The use of 4R strategy (right rate, source, placement and timing) to ensure N availability as per crop need to enhance its yield is an important part of effective N management18,19. Indiscriminate and excessive use of conventional fertilizers is discouraged due to negative effects on the environment19,20 animal and human health21 and agricultural products21 whereas the goal of agriculture is to produce more from less while restoring the environment. Thus, researchers are exploring several options. Effective management of fertilizers by using innovative formulations can reduce N losses via volatilization, denitrification and leaching22. Therefore, using plant-based and other natural materials that contain urease, volatilization or nitrification inhibitors may reduce N losses, and improve crop yield in eco-friendly manner23,24,25,26. Sulfur-coated urea (SCU) was the first coated slow-release fertilizer (SRF), but its high N content makes it challenging to synchronise with the time at which plant needs N27,28. Scientist have refined the coating material and developed polymer-coated fertilizers to enhance the efficacy of SRF. Crop yield and nitrogen use efficacy (NUE) can be improved by introducing polymer-coated fertilizers because the rate of N release well matches with the nutritional demands of crops29. However, the manufacturing of polymer-coated SRF is complex and costly30,31,32,33. Similarly, natural zeolites are a suitable option to reduce nutrient leaching. However, there exists a strong need for conducting batch and column tests for site-specific soil while also simultaneously validating the data under field conditions34,35,36,37,38. On other hand, in potassium ammonium phosphate coated fertilizers, the phosphate reduces the loss of nitrogen by volatilization39. Therefore, in order to prevent denitrification-related losses, N should remain in the ammonium form for an extended period of time40. Nitrogen use efficiency (NUE) can also be improved by coating urea granules natural oil extracted from neem because neem oil coated urea (NOCU) can delay nitrification thereby, lower the N release making it suitable to fulfil plants’ needs41.

The performance of coating-based products (polymer coated, sulphur coated and urea formaldehyde) depends upon soil and climatic conditions42,43,44. Furthermore, these formulations are costly and labour-intensive. Therefore, the present study was designed to compare the performance of natural and chemical coating agents on urea hydrolysis and nitrification under different temperature and moisture regimes under laboratory conditions and to further validate the performance of best treatments under field conditions while using different wheat cultivars as a test crop. Specific objectives of the study were (a) Selection of suitable coating agents to slow N concentration from urea. (b) Determination of effect of different coating agents on NUE of urea and yield of wheat and (c) Dose optimization of NOCU for two different wheat varieties grown at two different locations. Following hypotheses were tested (a) Different coating agents (natural and chemical) significantly decreased the N concentration from urea as compared to uncoated urea and (b) Use of coated urea improved the NUE and yield of wheat under irrigated and rainfed conditions.

Results

Effect of coating agents and temperature level on urea hydrolysis and nitrification

The analysis of data revealed that the NH4+ concentration decreased over time in uncoated urea but the it was still much higher than that drawn from all types of coated urea under all temperature regimes (Table 1). While, in coated urea, NH4+ concentration was the lowest at 10 days of incubation at 25 and 35 °C temperature that was slightly increased at later intervals but it was yet much lower than that from the uncoated urea. At 40 °C temperatures NH4+ concentration was the highest at 20 days of incubation (1485.0 mg kg− 1) under coated urea that decreased at later intervals. However, the uncoated urea caused the highest NH4+ concentration at the first interval and that was 1385.0 mg kg− 1. Among coating materials, both NOCU (neem oil coated urea) and PAPCU (potassium ammonium phosphate coated urea) had a strong impact on NH4+ concentration in comparison to uncoated urea. Use of NOCU resulted in 64.53%, 61.39% and 61.66% decrease in NH4+ concentration at 25, 35 and 40 °C in comparison to uncoated urea, respectively. PAPCU performed more effectively than NOCU in decreasing NH4+ concentration with 64.77%, 64.69% and 65.85% decrease in NH4+ concentration after first interval at 25, 35 and 40 °C, respectively. Though all materials performed effectively, but the results were statistically non-significant for NH4+ concentration among all coated urea treatments.

The ANOVA indicated a decreasing trend in NO3− concentration over time for uncoated urea but the concentration was still much higher than that drawn from all types of coated urea and under all temperature regimes. While in coated urea, NO3− concentration was the lowest at 10 days of incubation at 25 and 35 °C temperature that was slightly increased at later time intervals but it was yet much lower than that under the uncoated urea. At 40 °C temperature, NH4+ concentration was the highest at 20 days of incubation from coated urea which decreased at later intervals, but uncoated urea caused the highest NO3− concentration at the first interval (971 mg kg− 1, 1007 mg kg− 1, 1121 mg kg− 1) under all temperature regimes. Among coating materials, neem oil was the most effective (971 mg kg− 1, 1007 mg kg− 1, 1121 mg kg− 1) in reducing NO3− concentration showing 72.09%, 68.52% and 70.65% decrease in NO3− concentration in comparison with the uncoated urea and 71.27%, 71.1% and 73.68% decrease in NO3− concentration with 1.5% PAPCU at 25, 35 and 40 °C temperature respectively, as compared to uncoated urea. However, all materials were effective in reducing NO3− concentration and the results were non-significant for NO3− concentration among all types of coated urea.

Effect of coating agents on urea hydrolysis and nitrification in soil at different moisture levels

The results regarding NH4+ and NO3− concentration as affected by different coating agents under varying moisture regimes are presented in Table 2. The maximum NH4+ concentration was observed for uncoated urea (1217.0 mg kg− 1) at 90% of field capacity that was relatively decreased with decreasing moisture levels but was yet the highest than those under all other treatments at respective moisture levels at 10 days of incubation period. Similarly, NH4+ concentration from coated treatments were also lowered with a decrease in moisture content. But the time of incubation indicated different trend, as NH4+ concentration from uncoated urea was lowered with the time. However, from coated treatments it was relatively increased. Among coating materials, PAPCU (1.5%) induced lowest NH4+ concentration with least observed value (295.0 mg kg− 1) at 30% of field capacity at first interval. PAPCU was most effective in reducing NH4+ concentration after 10 days intervals with values of 72.25%, 71.07% and 70.95% decrease in NH4+ concentration at 30, 60 and 90% of the field capacity. NOCU was more effective with 71.03%, 70.32% and 68.99% decrease in NH4+ concentration as compared to uncoated urea at 30, 60 and 90% of field capacity after 10 days of incubation. NOCU resulted in the highest N concentration (1407.0 mg kg− 1) after 20 days of incubation at moisture levels of 90% of the field capacity (Table 2).

The highest reduction in NO3− concentration from all types of coated urea over uncoated urea was at 10 days of incubation at all moisture levels which was significantly higher than later incubation intervals (Table 2). Similarly, NO3− concentration from coated treatments was also increased by rising soil moisture content. An opposite trend was observed regarding time of incubation, as the NO3− concentration from uncoated urea was lowered with the passage of time compared to coated treatments where it was relatively increased. At first interval, PAPCU (1.5%) proved more effective in decreasing NO3− concentration with 74.47%, 65.97% and 65.05% decrease in NO3− concentration over uncoated urea at 30, 60 and 90% of field capacity respectively, after 10 days of incubation. The reduction in NO3− concentration over uncoated urea from NOCU was 72.95% (267 mg kg− 1), 64.53% (371 mg kg− 1) and 64.58% (452 mg kg− 1) as compared to uncoated urea at 30, 60 and 90% of field capacity after 10 days of incubation respectively.

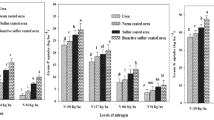

Plant height, grain and biological yield of wheat as affected by NOCU

Plant height, grain and biological yield were significantly affected by NOCU (Fig. 1a–c). The maximum plant height (94.2 cm) was observed where 75% NOCU was used as compared to recommended rate of commercial urea followed by uncoated recommended urea (88.2 cm) in irrigated wheat variety “Akbar-2019” (Fig. 1a). A reduced rate of all types of coated urea was also effective in increasing plant growth. Use of 25% of the recommended rate NOCU resulted in 76.1 cm plant height. Furthermore, in rainfed wheat variety “Barani-2017” the 75% NOCU produced more plant height (86.8 cm) in comparison to all other treatments. Regarding the rate of urea, 50% of the recommended coated treatments resulted in slightly lower plant height (81.6 cm) than recommended rate of uncoated urea (83.6 cm). However, 25% of the recommended rate was the least effective, as it produced much smaller plant height than the recommended rate of uncoated urea (76.1 and 72.4 cm) in both varieties, respectively.

The data in Fig. 1b show a significant increase in grain yield when compared to control receiving zero N in both tested wheat varieties. Minimum grain yields (2521 and 2393 kg ha− 1) were observed in control where no N fertilizer was applied in irrigated and rainfed wheat varieties. A significant improvement in grain yield was noticed with the application of 25% of the recommended rate of NOCU showing numerical values of 2761 and 2661 kg ha− 1, respectively. Grain yield was further improved with 3292 and 3054 kg ha− 1 of grain yield recorded when 50% of recommended rate of NOCU was applied in both tested varieties. However, recommended rate of uncoated urea produced higher grain yield in both varieties (3440 and 3305 kg ha− 1). Maximum grain yield (3648 and 3419 kg ha− 1) was recorded when 75% of the recommended rate of NOCU was applied compared to all other treatments.

The biological yield was significantly improved with N application as compared to control in both tested wheat varieties (Fig. 1c). Maximum biological yield (9162 kg ha− 1) was obtained where 75% of the recommended NOCU was applied followed by the 100% recommended uncoated urea (8799 kg ha− 1) in irrigated wheat variety “Akbar-2019”. Application of 50% of recommended NOCU produced significantly lower biological yield (8527 kg ha− 1) than uncoated urea but it was yet higher than 25% of recommended NOCU (8074 kg ha− 1). Same trend was observed in rainfed wheat variety where maximum biological yield (8618 kg ha− 1) was obtained with 75% of the NOCU followed by the recommended rate of uncoated urea (8255 kg ha− 1).

Chlorophyll contents (µmol m− 2)

The chlorophyll content showed a significant improvement in response to the application of coated or uncoated urea as compared to control (N0) regardless of varieties used (Fig. 2). Regarding rates of NOCU, 75% of recommended NOCU produced the highest chlorophyll content of 49 and 47 SPAD compared to 100% recommended urea in wheat varieties Akbar-2019 and Barani 2017, respectively. The lowest chlorophyll content of 33 and 30 SPAD were observed in control (N0) in wheat varieties Akbar-2019 and Barani 2017, respectively. Addition of coated urea fertilizer efficiently improved the chlorophyll content in wheat leaf as compared to the control. Thus, chlorophyll content in wheat leaf was significantly increased by enhanced level of N showing the positive effect of N on wheat plant development.

Agronomic N use efficiency (NUE)

The agronomic NUE was significantly improved in treated plants compared to control in both tested wheat varieties (Fig. 3). The highest NUE (12.85) was observed under plots treated with 50% of recommended coated urea followed by treatment with 75% coated urea (12.52%) in case of irrigated wheat variety (Akbar- 2019). Both of these treatments were proved non significant when tested statistically. The NUE at at 25% of the recommended NOCU was significantly lower (8) than 75% and 50% of the recommended NOCU but was significantly higher than 100% recommended uncoated urea (7.68). Similar results were also observed in rainfed wheat variety. The highest NUE was found when under 75% recommended NOCU (11.4) followed by 50% of recommended NOCU (11). The lowest NUE (7.58) was recorded under 100% uncoated urea. Thus, coating of urea with neem oil maximally improved the NUE of applied fertilizer.

Nitrogen concentration (%) in root, straw and grain

The N concentration in different plant parts of both varieties were significantly improved with the application of N as conventional urea or NOCU compared to control (Fig. 4a). The 75% of recommended NOCU produced highest N concentration in roots (0.87%) than 100% of the recommended uncoated urea (0.76%) as presented in Fig. 4a. The NOCU applied at the rate of 25% of the recommended rate resulted in 0.61% N in roots that was much higher (0.48%) than that under the control treatment (N0) in irrigated wheat variety “Akbar-2019”. Similarly, in the rainfed variety, maximum N concentration (0.79%) was achieved with 75% of recommended NOCU.

Nitrogen concentration in straw was significantly increased in treated plants compared to control in both tested wheat varieties (Fig. 4b). The maximum N concentration (0.85%) in wheat straw was observed under 75% of NOCU followed by 100 recommended uncoated urea (0.73%). However, N concentration in wheat straw (0.39%) of plants grown under 25% of recommended NOCU was slightly higher than that under the control treatment (0.27%) in irrigated wheat variety (Akbar-2019). Similar results were also observed for straw N content of rainfed wheat variety. The lowest N concentration in straw (0.21%) was observed in control while the maximum of 0.74% N was observed with 75% of recommended NOCU treatment which was significantly higher than 100% of uncoated urea.

The N concentration in wheat grain was also significantly increased with application of N in any form compared to control regardless of cultivars (Fig. 4c). The lowest N concentration (0.44 and 0.29%) in wheat grains of both tested varieties was observed under control (N0). An increase in N concentration was recorded when coated or uncoated urea was applied. However, the maximum concentration of N in wheat grains (1.07 and 0.95%) was observed where 75% of the recommended NOCU was applied that was followed by the 100% of the recommended uncoated urea (0.93 and 0.88%).

Total N concentration in soil (%)

The total N concentration in soil was significantly increased when urea was applied regardless of form and rates. The lowest total N content was observed in control treatment (N0) as shown in Fig. 5 which was improved the the application of urea. The effect of NOCU was more pronounced at all three applied levels. A gradual improvement in total N content of soil was observed with numerical values of 0.19, 0.20 and 0.22% when NOCU was applied @ 25, 50 and 75% respectively in irrigated wheat variety. Similar trend was reflected in rainfed wheat variety where maximum N concentration in soil was (0.20%) obtained where 75% of NOCU was applied followed by the 100% of recommended uncoated urea (0.18%).

Discussion

The application of chemical fertilizers, particularly those containing N, has become a cornerstone in modern agriculture due to its significant role in boosting crop yields28. However, the introduction of chemical N fertilizers into the soil is accompanied by numerous challenges, primarily related to substantial N losses through various processes such as nitrification and denitrification45,46. Research has shown that applied N undergoes a series of complex mechanisms, involving chemical interactions with soil bacteria and plant roots, which often lead to its loss in the form of N2O or NO247,48,49. Due to high solubility and negative charges the significant portion of nitrate form of N is subjected to losses by the process of leaching and runoff. When nitrates from fertilizers are washed away by rain or irrigation, they can seep into groundwater, leading to contamination of drinking water sources. This can cause health issues such as methemoglobinemia, or “blue baby syndrome,” in infants. Nitrate runoff into surface waters, such as rivers and lakes, can lead to eutrophication, where excessive nutrients cause algae blooms that deplete oxygen levels, harming aquatic life and disrupting ecosystems50,51. Hence, it is critical to closely monitor the N dynamics in the soil to mitigate these impacts.

Therefore, this study was designed to enhance NUE of wheat by utilizing coated urea fertilizers. In the laboratory experiments, the performance of standard urea granules was compared with 1.0% neem oil and 1.5% potassium ammonium phosphate coated urea. These specific coatings were selected based on their proven efficacy in ensuring a more consistent release of N, as observed in previous studies by Noor and colleagues52. Our lab findings indicated that the coated urea treatments exhibited significantly lower nitrification rates compared to uncoated urea. This reduction in nitrification can be attributed to the presence of nitrification inhibitory compounds in the coatings, particularly melacin and azadirachtin found in neem oil53,54. These results are in accord with the Kumar and colleagues’, who also demonstrated that lower concentrations of neem oil effectively improved NUE in irrigated rice55.

In the present study, the coated urea treatments notably reduced N release efficiency (NRE) by decreasing the release of NH4, NO3−, and cumulative N in soil at earlier intervals. However, over time and with increasing temperature, the NRE of the coated urea improved. This phenomenon can be explained by the coating material acting as a physical barrier, which regulates the release of nutrients from the fertilizer granules. The coating materials has ability to slow the release of N was further validated by a model characterizing the kinetics of N release from coated urea56. The environmental implications of heavily subsidized N fertilizers are also of significant concern. These fertilizers contribute to pollution by emitting gases such as NH3 into the atmosphere. Ammonia is a toxic gas that poses health risks, causing cardiovascular problems in humans and animals, and negatively impacting crop growth57. Although various techniques have been employed in the past to mitigate these losses, many were either prohibitively expensive for common farmers or difficult to implement58. In the laboratory experiments, coated urea fertilizers were evaluated for their potential to reduce volatilization losses and ensure the effective use of these materials under different moisture and temperature conditions.

The data presented herein showed that both NH3 and NO3 releases were significantly increased from uncoated and coated urea with higher moisture and temperature levels. This increase can be attributed to the urea reacting with water in the presence of urease, with the coated materials’ antimicrobial properties playing a role in reducing losses59,60,61. The results are in accord with those of Ali and colleagues, who reported a decline in N losses from neem oil-coated fertilizers62. The significant reduction in NH3 and NO3 release from coated fertilizers, compared to uncoated urea, highlighted the efficacy of the coating materials (NOCU and PAPCU), with reductions of up to 90% at 10-day intervals. Although this reduction decreased at later intervals, the effect was still prominent, particularly with neem oil, which contains compounds that reduce urease activity in the soil63,64,65.

Laboratory results showed that both coating agents decreased nitrification rates however, the performance of neem oil coating was better than PAPCU. Similar findings were mirrored in field trials, where the 75% of recommended NOCU yielded comparable or improved crop performance than 100% recommended un-coated urea. The filed results showed that wheat yield, chlorophyll, and N content in plants were higher with all levels of coated urea compared to the control. Even at a reduced application rate (75% of the recommended dose), coated urea outperformed (100%) uncoated urea, providing a consistent N supply that supported vegetative and physiological plant functions66,67.

The field trials, conducted in both irrigated and rainfed conditions, confirmed that neem oil-coated urea at 75% of the recommended rate resulted in the highest growth attributes, including shoot weight, grain yield, and biological yield. This improvement is likely due to the prolonged availability of N in the plant root zone, which is essential for vegetative growth and various metabolic processes68,69,70. Higher chlorophyll content observed in wheat leaves treated with neem oil-coated urea further supports this, as N is a key component of chlorophyll71,72.

The benefits of neem oil-coated urea are not limited to wheat. Similar positive outcomes have been reported for other crops, such as rice, where NOCU improved grain yield and NUE compared to conventional urea73,74,75,76,77,78. The enhanced NUEs can be attributed to the coating materials acting as cation exchange sites, which facilitate better nutrient uptake by plants79. Furthermore, it is important to highlight the broader implications of these findings. The ability of coated urea fertilizers to slow down the release of N has significant ramifications for sustainable agriculture. By reducing the frequency of fertilizer applications and minimizing N losses, farmers can achieve higher efficiency and lower costs, ultimately leading to more sustainable agricultural practices. Additionally, the reduction in N runoff and leaching into water bodies can help protect aquatic ecosystems and reduce the occurrence of algal blooms and other forms of water pollution. This aspect is crucial for maintaining the health of both natural ecosystems and human populations that rely on these water resources.

Overall, the neem oil-coated urea demonstrated superior performance over uncoated urea in enhancing wheat growth, yield, N concentration and NUE. The protective coating layer slows the release of N, allowing for more efficient use by crops80. This study underscores the potential of coated urea fertilizers in improving NUE and reducing environmental impacts in agricultural practices. Future researcher should focus on optimizing coating formulations and testing in diverse agro-climatic conditions, as well as exploring the potential of integrating neem oil-coated urea with other sustainable agricultural practices such as precision farming, to enhance overall crop productivity and environmental sustainability. Furthermore, exploring the synergistic effects of combining coated urea with other sustainable agricultural practices, such as integrated nutrient management and precision farming, could provide a holistic approach to enhancing crop productivity and sustainability in agriculture.

Conclusions

The use of different coating agents, both natural and synthetic, improved nitrogen (N) release from urea compared to uncoated urea. Among the coating agents, NOCU (1.0%) performed better than PAPCU (1.5%) in decelerating ammonium (NH4) and nitrate (NO3) release. However, their release were increased with increasing temperature and moisture. The NOCU applied at 75% of the recommended conventional urea provided the best yield response and increased NUE, straw and grain N concentration, and total soil N under both irrigated and rainfed conditions. Therefore, coating urea with neem oil and its subsequent application at the rate of 75% of recommended urea can effectively improve urea utilization efficiency and improve crop yield in economical and eco-friendly manner under both irrigated and rain fed conditions.

Materials and methods

Preparation of coated urea in the laboratory

Coating of neem oil and potassium ammonium phosphate compound was carried out in the laboratory of department of soil and environmental sciences, UOS-Sargodha. Controlled conditions were maintained to avoid any contamination during these activities. The urea was coated using a rotary pan made of stainless steel. Granules of urea were weighed and added to the rotary pan. The coating ingredients (neem oil and potassium ammonium phosphate) were weighed out individually before being combined. Figure 6 indicates the water mist being supplied to the bed surface after the coating material and urea granules were mixed in rotary pan. This process was repeated until all the coating material and urea had been consumed. Finally, the urea granules were collected after being dried with a tiny fan and placed on a vibration tray. The ideal temperature for storing coated urea was 25 °C.

Soil sampling and analysis

Soil samples were collected from the research area of COA, UOS by using the soil auger (0–15 cm depth). Random sampling was followed to collect 30 sub samples to make composite samples. These samples were prepared (dried, ground and sieved). Table 3 presents the analytical features of soils. Soil textural class was determined with the help of a hydrometer method81. The saturated soil paste was prepared and percentage of saturation was determined82. The pH of soil saturated paste was determined with the help of a pH meter (JENWAY 3510)83. Pure extract of previously mentioned paste was taken using a vacuum pump extractor. By using the conductivity meter (JENWAY 4510), the electrical conductivity of extract was noted. Meter was calibrated by using the solution of 0.01 N KCl 8345. For estimation of total N, protocol suggested by Jackson84 was followed. Available phosphorus (P) was recorded on a spectrometer (T80 UV / VIS Spectrometer) using a wavelength of 880 nm85. Similarly, a flame photometer (Jenway PFP-7) was used to analyze the K86.

Laboratory incubation studies

The laboratory incubation studies were conducted at departmental laboratory of soil science using to check the effect of soil moisture content (30, 60 and 90% of field moisture capacity) and temperature regimes (25, 35 and 40 °C) on the performance of coatings material [NOCU (1.0% release), and PAPCU (1.5% release)] in optimizing urea hydrolysis and nitrification. Experiment was designed according to a completely randomized design (CRD) factorial design with three repeats. Three sets of treatments were run for the determination of NH4 + 1 and NO3− release at 10, 20 and 30 days intervals.

Field moisture capacity was established using retention curve method and soil moisture content was determined by the gravimetric method87. Urea fertilizer were added in cups manually. Distilled water is used to maintain the weight of cups that have been filled with soil, fertilizer, and water. During the incubation, soil moisture content was maintained at field capacity after 24 h, NH4+ and NO3− release was measured after 10, 20 and 30 days of incubation through indophenol blue method and phenol disulphonic acid method88.

Field experiment

Field experiments were performed using two factorial randomized complete block design (RCBD) with three replicates to further explore the performance of best coating agent (N0, 100% conventional urea, 75, 50 and 25% of the recommended NOCU) under irrigated and rainfed conditions using Akbar-2019 and Barani-2017 wheat cultivars respectively. The purpose of the field experiments was dose optimization of newly generated coated urea for wheat variety sown at particular location. The field experiment was performed at two locations. Location one was situated at experimental farm of the College of Agriculture, University of Sargodha, Sargodha (32.0740° N, 72.6861° E) where an irrigated wheat variety (Akbar-2019) was used as a test crop. Soil of the location one was taxonomically aridisol, haplargid, ustic, and hyper thermic. Maximum summer temperature is recorded as 50 °C (122 o F) and the lowest temperature at about freezing point in winter with an average temperature of about 24 °C, and annual average rainfall is about 410 mm89. Similar experiment was established at location two situated at Naeem Zari farm Pind Dadan Khan, Chakwal (32.8322° N, 72.6151° E) where rainfed wheat cultivar (Barani-2017) was grown as test crop. The maximum summer temperature of location two was 40 °C and the lowest winter temperature of 4 °C. The average annual rainfall is ranging between 558 and 635 mm. Soil of location two was taxonomically alfisols, ustalfs, haplustalfs, aridic, and hyperthermic90.

Urea was used as N source while single super phosphate (SSP) and potassium sulphate (SOP) were used as P and potassium (K) sources at the rate of 120: 90: 60 kg ha− 1 (N: P: K). P and K fertilizers were added as basal, while urea was applied in split doses. The method of application of coating materials in soil is manually broadcast. Flood irrigation method used in the experiment. Weeds were removed by manual hoeing. Plants were harvested and data regarding plant fresh, grain and biological yield were recorded. After the wet digestion, N content in different plant parts was measured using a Kjeldahl apparatus88. NUE was calculated using following formula91.

\({\text{NUE }}=\frac{{({\text{Yield in fertilizer plot kg h}}{{\text{a}}^{ - \,}}^{{\text{1}}})--({\text{Yield in control plot kg h}}{{\text{a}}^{ - \,}}^{{\text{1}}})}}{{{\text{Quantity of applied N }}({\text{kg h}}{{\text{a}}^{ - \,}}^{{\text{1}}})}}\)

Chlorophyll content was recorded using soil plant analysis development (SPAD) meter (Spad-502 chlorophyll meter, Konica Minolta Optics, Japan)92.

Statistical analysis

The data was analysed statistically following the Fisher’s analysis of variance for CRD and the LSD test for comparison of treatment means93.

Data availability

All data collected/used during this study are included in this published article.

References

Tilman, D. et al. Agricultural sustainability and intensive production practices. Nature 418 (6898), 671–677. https://doi.org/10.1038/nature01014 (2002).

Bruinsma, J. The resource outlook to 2050. In Expert meeting on how to feed the world. 2050 1–33. https://www.scirp.org/reference/referencespapers?referenceid=1642737 (2009).

Godfray, H. C. J. et al. Food security: the challenge of feeding 9 billion people. Science 327 (5967), 812–818. https://doi.org/10.1126/science.1185383 (2010). https://www.science.org/doi/

Chen, X. P. et al. Integrated soil–crop system management for food security. Proc. Natil. Acad. Sci. 108 (16), 6399–6404. https://europepmc.org/article/med/21444818 (2011).

Zhao, J., Ni, T., Li, J., Lu, Q., Fang, Z., Huang, Q. & Shen, Q. Effects of organic–inorganic compound fertilizer with reduced chemical fertilizer application on crop yields, soil biological activity and bacterial community structure in a rice–wheat cropping system. Appl. Soil Ecol. 99, 1–12. https://ui.adsabs.harvard.edu/abs/2016AppSE.99… Z/abstract (2016).

Akelah, A. Novel utilizations of conventional agrochemicals by controlled release formulations. Mater. Sci. Eng. 4 (2), 83–98. https://doi.org/10.1016/0928-4931(96)00133-6 (1996).

Grant, O. M., Davies, M. J., Johnson, A. W. & Simpson, D. W. Physiological and growth responses to water deficits in cultivated strawberry (Fragaria× ananassa) and in one of its progenitors, Fragaria Chiloensis. Environ. Exp. Bot. 83, 23–32. https://doi.org/10.1016/j.envexpbot.2012.04.004 (2012).

Abbasi, M. K., Tahir, M. M. & Rahim, N. Effect of N fertilizer source and timing on yield and N use efficiency of rainfed maize (Zea Mays L.) in Kashmir–Pakistan. Geoderma 195, 87–93 (2013). https://www.sciencedirect.com/science/article/abs/pii/S0016706112004090

Cao, W. & Tibbitts, T. W. Study of various NH4+/NO3– mixtures for enhancing growth of potatoes. J. Plant. Nutr. 16 (9), 1691–1704 (1993). https://www.tandfonline.com/doi/abs/10.1080/01904169309364643

Rahimizadeh, M., Kashani, A., Zare-Feizabadi, A., Koocheki, A. R. & Nassiri-Mahallati, M. Nitrogen use efficiency of wheat as affected by preceding crop, application rate of nitrogen and crop residues. Aust J. Crop Sci. 4 (5), 363–368. https://doi.org/10.1007/s12230-010-9134-7 (2010).

Silva, J. G., França, M. G. C., Gomide, F. T. F. & Magalhaes, J. R. Different nitrogen sources affect biomass partitioning and quality of potato production in a hydroponic system. Am. J. Potato Res. 90, 179–185. https://doi.org/10.1007/s12230-012-9297-5 (2013).

Fowler, D. et al. The global nitrogen cycle in the twenty-first century. Philosophical Trans. Royal Soc. B: Biol. Sci. 368 (1621), 20130164. https://doi.org/10.1098/rstb.2013.0164 (2013).

Cassman, K. G., Dobermann, A., Walters, D. T. & Agroecosystems nitrogen-use efficiency, and nitrogen management. AMBIO: J. Hum. Environ. 31 (2), 132–140. https://doi.org/10.1579/0044-7447-31.2.132 (2012).

Singh, J., Kunhikrishnan, A., Bolan, N. S. & Saggar, S. Impact of Urease inhibitor on ammonia and nitrous oxide emissions from temperate pasture soil cores receiving Urea fertilizer and cattle urine. Sci. Total Environ. 465, 56–63. https://doi.org/10.1016/j.scitotenv.2013.02.018 (2013).

Smith, L. E. & Siciliano, G. A comprehensive review of constraints to improved management of fertilizers in China and mitigation of diffuse water pollution from agriculture. Agric. Ecosyst. Environ. 209, 15–25. https://doi.org/10.1016/j.agee.2015.02.016 (2015).

Power, J. F., Wiese, R. & Flowerday, D. Managing farming systems for nitrate control: A research review from management systems evaluation areas. J. Environ. Qual. 30 (6), 1866–1880. https://doi.org/10.2134/jeq2001.1866 (2001).

Kim, Y. et al. Estimation and mitigation of N2O emission and nitrate leaching from intensive crop cultivation in the Haean catchment, South Korea. Sci. Total Environ. 529, 40–53. https://doi.org/10.1016/j.scitotenv.2015.04.098 (2015).

Dinnes, D. L. et al. Nitrogen management strategies to reduce nitrate leaching in tile-drained Midwestern soils. Agron. J. 94 (1), 153–171. https://doi.org/10.2134/agronj2002.1530 (2002).

Motavalli, P. P., Goyne, K. W. & Udawatta, R. P. Environmental impacts of enhanced-efficiency nitrogen fertilizers. Crop Manage. 7 (1), 1–15. https://doi.org/10.1094/CM-2008-0730-02-RV (2008).

Serpil, S. An agricultural pollutant: chemical fertilizer. Intl J. Environ. Sci. Develop. 3 (1), 77–80. https://doi.org/10.7763/IJESD.2012.V3.191 (2012).

Wimalawansa, S. A. & Wimalawansa, S. J. Impact of changing agricultural practices on human health: chronic kidney disease of multi-factorial origin in Sri Lanka. Wudpecker J. Agricult Res. 3, 110124 (2014). https://www.researchgate.net/publication/264978995

Malhi, S. S., Grant, C. A., Johnston, A. M. & Gill, K. S. Nitrogen fertilization management for no-till cereal production in the Canadian great plains: a review. Soil. Tillage Res. 60 (3–4), 101–122 (2001). https://www.researchgate.net/publication/248301041

Otteson, B. N., Mergoum, M. & Ransom, J. K. Seeding rate and nitrogen management effects on spring wheat yield and yield components. Agron. J. 99 (6), 1615–1621. https://doi.org/10.2134/agronj2007.0002 (2007).

Guertal, E. A. Preplant slow-release nitrogen fertilizers produce similar bell pepper yields as split applications of soluble fertilizer. Agron. J. 92 (2), 388–393 (2000). https://www.researchgate.net/publication/237757662

Nelson, K. A., Motavalli, P. P. & Smoot, R. L. Utility of dried distillers grain as a fertilizer source for corn. J. Agric. Sci. 1 (1), 3. https://doi.org/10.5539/jas.v1n1p3 (2009).

Xiang, Y. A. N., Jin, J. Y., Ping, H. E. & Liang, M. Z. Recent advances on the technologies to increase fertilizer use efficiency. Agricultural Sci. China. 7 (4), 469–479 (2018). https://www.researchgate.net/profile/Xiang-Yan-17/publication/222780428

Ni, K. et al. Nitrous oxide emissions from a rainfed-cultivated black soil in Northeast china: effect of fertilization and maize crop. Biol. Fertil. Soils. 48, 973–979. https://doi.org/10.1007/s00374-012-0709-y (2012).

Yan, X. et al. Fertilizer nitrogen recovery efficiencies in crop production systems of China with and without consideration of the residual effect of nitrogen. Environ. Res. Lett. 9 (9), 095002. (2014).

Yen, A. S., Kim, S. S., Hecht, M. H., Frant, M. S. & Murray, B. Evidence that the reactivity of the Martian soil is due to superoxide ions. Science 289 (5486), 1909–1912 (2000). https://ntrs.nasa.gov/citations/20210002565

Liu, T., Su, Y., Niu, Z. & An, F. Attapulgite application improves maize yield, water, and fertilizer utilization efficiency in newly cultivated sandy farmland in Northwestern China. Arid Land. Res. Manag. 37 (3), 408–426 (2023). https://www.ncbi.nlm.nih.gov/pmc/articles/PMC3896526/

Cui, Y., Parker, G., Braudrick, C., Dietrich, W. E. & Cluer, B. Dam removal express assessment models (DREAM). Part 1: model development and validation. J. Hydraul Res. 44 (3), 291–307 (2006). https://www.researchgate.net/publication/240611804

Abbasi, N. A., Madramootoo, C. A., Zhang, T. & Tan, C. S. Nitrous oxide emissions as affected by fertilizer and water table management under a corn-soybean rotation. Geoderma 375, 114473 (2020). https://www.researchgate.net/publication/341952528

Zareabyaneh, H. & Bayatvarkeshi, M. Effects of slow-release fertilizers on nitrate leaching, its distribution in soil profile, N-use efficiency, and yield in potato crop. Environ. Earth Sci. 74, 3385–3393. https://doi.org/10.1007/s12665-015-4374-y (2015).

Gholamhoseini, M., Ghalavand, A., Dolatabadian, A., Jamshidi, E. & Khodaei-Joghan, A. Effects of arbuscular mycorrhizal inoculation on growth, yield, nutrient uptake and irrigation water productivity of sunflowers grown under drought stress. Agric. Water Manag. 117, 106–114 (2013). https://research-repository.uwa.edu.au/en/publications/effects-of-arbuscular-mycorrhizal-inoculation-on-growth-yield-nut

Colombani, N., Mastrocicco, M., Di Giuseppe, D., Faccini, B. & Coltorti, M. Variation of the hydraulic properties and solute transport mechanisms in a silty-clay soil amended with natural zeolites. Catena 123, 195–204 (2014). https://www.researchgate.net/publication/265210043

Latifah, S. Y. et al. Germinated brown rice (GBR) reduces the incidence of aberrant crypt foci with the involvement of β-catenin and COX-2 in azoxymethane-induced colon cancer in rats. Nutr. J. 9 (1), 1–8 (2010). https://pubmed.ncbi.nlm.nih.gov/20346115/

Colombani, J. et al. Drosophila Lgr3 couples organ growth with maturation and ensures developmental stability. Curr. Biol. 25 (20), 2723–2729 (2015). https://pubmed.ncbi.nlm.nih.gov/26441350/

Monreal, C. M., Sultan, Y. & Schnitzer, M. Soil organic matter in nano-scale structures of a cultivated black Chernozem. Geoderma 159 (1–2), 237–242 (2010). https://www.researchgate.net/publication/248166961

Jadon, P. et al. Volatilization and leaching losses of nitrogen from different coated Urea fertilizers. J. Soil. Sci. Plant. Nutr. 18 (4), 1036–1047 (2018). http://www.scielo.cl/scielo.php?script=sci_arttext&pid=S071895162018000401036.

Murthy, K. M., Rao, A. U., Vijay, D. & Sridhar, T. V. Effect of levels of nitrogen, phosphorus and potassium on performance of rice. Indian J. Agricultural Res. 49 (1), 83–87 (2015). https://arccarticles.s3.amazonaws.com/webArticle/articles/A4037.pdf

Singh, A., Jaswal, A. & Singh, M. Impact of Neem coated Urea on rice yield and nutrient use efficiency (NUE). Agricultural Reviews. 40 (1), 70–74 (2019). https://www.researchgate.net/publication/334130411

Wilson, M. L., Rosen, C. J. & Moncrief, J. F. Effects of polymer-coated Urea on nitrate leaching and nitrogen uptake by potato. J. Environ. Qual. 39 (2), 492–499 (2010). https://pubmed.ncbi.nlm.nih.gov/20176822/

Zheng, W. et al. Long-term effects of controlled‐release Urea on crop yields and soil fertility under wheat–corn double cropping systems. Agron. J. 108 (4), 1703–1716. https://doi.org/10.2134/agronj2015.0581 (2016). https://acsess.onlinelibrary.wiley.com/doi/

Moodie, R. B., Connor, T. M. & Stewart, R. The nuclear magnetic resonance spectra of triaryl carbonium ions. Can. J. Chem. 37 (9), 1402–1408. https://eurekamag.com/research/080/992/080992087.php?srsltid=AfmBOoq7ObwU77OWKNnrATy2ohON5UAFlrbOFNiIoa7IRGmy3SGJJC_z (1959).

Li, H. F. et al. Urea fertilizer with precisely regulable slow-release performance by complexing with random copolyester. J. Environ. Chem. Eng. 9 (2), 105–120 (2021). https://www.researchgate.net/publication/348702801

Belete, F., Dechassa, N., Molla, A. & Tana, T. Effect of nitrogen fertilizer rates on grain yield and nitrogen uptake and use efficiency of bread wheat (Triticum aestivum L.) varieties on the vertisols of central highlands of Ethiopia. Agric. Food Secur. 7 (1), 1–12. https://doi.org/10.1186/s40066-018-0231-z (2018). https://agricultureandfoodsecurity.biomedcentral.com/articles/

Van Eerd, L. L. et al. Comparing soluble to controlled-release nitrogen fertilizers: storage cabbage yield, profit margins, and N use efficiency. Can. J. Plant. Sci. 98 (4), 815–829 (2017). https://www.researchgate.net/publication/321147365

Castellano-Hinojosa, A., González-López, J., Vallejo, A. & Bedmar, E. J. Linking ammonia volatilization with moisture content and abundance of nitrification and denitrification genes in N-fertilized soils. Microb. Probiot. Agric. Syst. Adv. Agron. Use 2019 29–43. https://www.researchgate.net/publication/334500837 (2019).

Abbas, Q. et al. Transformation pathways and fate of engineered nanoparticles (ENPs) in distinct interactive environmental compartments: A review. Environ. Int. 2020 138 105646. https://www.sciencedirect.com/science/article/pii/S016041201933925X (2020).

Sun, H. et al. Effect of biofertilizer and wheat straw Biochar application on nitrous oxide emission and ammonia volatilization from paddy soil. Environ. Pollut. 275, 116640 (2021). https://pubmed.ncbi.nlm.nih.gov/33556733/

Wang, Y., Ying, H., Yin, Y., Zheng, H. & Cui, Z. Estimating soil nitrate leaching of nitrogen fertilizer from global meta-analysis. Sci. Total Environ. 657, 96–102 (2019). https://pubmed.ncbi.nlm.nih.gov/30537582/

Noor, S., Yaseen, M., Naveed, M. & Ahmad, R. Use of controlled release phosphatic fertilizer to improve growth, yield and phosphorus use efficiency of wheat crop. Pak J. Agri Sci. 54 (4), 541–547 (2017). https://www.researchgate.net/publication/325877138

Plaimart, J. et al. Coconut husk Biochar amendment enhances nutrient retention by suppressing nitrification in agricultural soil following anaerobic digestate application. Environ. Pollut. 268, 115684 (2021). https://pubmed.ncbi.nlm.nih.gov/33010549/

Savich, V. & Novik, G. Waste biodegradation and utilization by Pseudomonas species. J. Microbiol. Biotechnol. Food Sci. 6 (2), 851 (2021). https://www.researchgate.net/publication/364751241

Kumar, D. et al. Relative efficiency of prilled Urea coated with major Neem (Azadirachta indica A. Juss) oil components in lowland irrigated rice of the Indo-Gangetic plains. Arch. Agron. Soil. Sci. 57 (1), 61–74 (2011). https://www.researchgate.net/profile/Dinesh-Kumar-132/publication/262868177

Trinh, T. H., Kushaari, K., Shuib, A. S., Ismail, L. & Azeem, B. Modelling the release of nitrogen from controlled release fertilizer: constant and decay release. Biosyst Eng. 130, 34–42 (2015). https://www.researchgate.net/publication/270572793

Adegbeye, M. J. et al. Sustainable agriculture options for production, greenhouse gasses and pollution alleviation, and nutrient recycling in emerging and transitional nations-An overview. J. Clean. Prod. 242, 118319 (2020). https://www.academia.edu/82295736/

Zhu, D. et al. Nitrous oxide emissions from the surface of the three Gorges reservoir. Ecol. Eng. 60, 150–154 (2013). https://hero.epa.gov/hero/index.cfm/reference/details/reference_id/2461539

Frame, W. Ammonia volatilization from Urea treated with NBPT and two nitrification inhibitors. Agron. J. 109 (1), 378–387 (2017). https://www.researchgate.net/publication/310389091

Akhtar, M. & Naeem, A. Reduction in ammonia loss by applying Urea in combination with phosphate sources. Commun. Soil. Sci. Plant. Anal. 43 (15), 2043–2049 (2012). https://www.researchgate.net/publication/264839644

Ashraf, M. N. et al. Evaluating organic materials coating on Urea as potential nitrification inhibitors for enhanced nitrogen recovery and growth of maize (Zea mays). Int. J. Agric. Biol. 22, 1102–1108. https://doi.org/10.5555/20203409314 (2019). https://www.cabidigitallibrary.org/doi/pdf/

Ali, M., Maqsood, M. A., Azizl, T. & Awan, M. I. Neem (Azadirachta indica) oil coated Urea improves nitrogen use efficiency and maize growth in an alkaline calcareous soil. Pak J. Agric. Sci. 57 (3). https://research-repository.uwa.edu.au/en/publications/neem-azadirachta-indica-oil-coated-urea-improves-nitrogen-use-eff (2020).

Kaur, M., Aggarwal, N. K., Kumar, V. & Dhiman, R. Effects and management of Parthenium hysterophorus: A weed of global significance. Int. Sch. Res. Notices 2014 368647.https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4897546/ (2014).

Opoku, A., Chaves, B. & De Neve, S. Neem seed oil: a potent nitrification inhibitor to control nitrate leaching after incorporation of crop residues. Biol. Agric. Hortic. 30 (3), 145–152 (2014). https://www.researchgate.net/publication/271944220

Rajeswari, S., Poongothai, E. & Hemalatha, N. 7 Antimicrobial activities of cow dung extracts against human pathogens. Int. J. Curr. Pharm. Res. 8 (4), 9–12. https://journals.innovareacademics.in/index.php/ijcpr/article/view/15268/8175 (2016).

Ghafoor, I. et al. Slow-release nitrogen fertilizers enhance growth, yield, NUE in wheat crop and reduce nitrogen losses under an arid environment. Environ. Sci. Pollut Res. 28 (32), 43528–43543. https://doi.org/10.1007/s11356-021-13700-4 (2021). https://link.springer.com/article/

Shivay, Y. S., Pooniya, V., Prasad, R., Pal, M. & Bansal, R. J. C. R. C. Sulphur-coated Urea as a source of sulphur and an enhanced efficiency of nitrogen fertilizer for spring wheat. Cereal Res. Commun. 44 (3), 513–523 (2016). https://www.researchgate.net/publication/304455211

Zhang, L. et al. Tiller development affected by nitrogen fertilization in a high-yielding wheat production system. Crop Sci. 60 (2), 1034–1047. https://doi.org/10.1002/csc2.20140 (2020). https://acsess.onlinelibrary.wiley.com/doi/abs/

Wu, D. et al. 7 bol, R. Nitrification inhibitors mitigate N2O emissions more effectively under straw-induced conditions favoring denitrification. Soil. Biol. Biochem. 104, 197–207 (2017). https://publications.goettingen-research-online.de/ID-43673

Rychel, K. et al. Deep N fertilizer placement mitigated N2O emissions in a Swedish field trial with cereals. Nutr. Cycl. Agroecosyst. 118, 133–148 (2020). https://www.researchgate.net/publication/343876162

Oad, F. C., Buriro, U. A. & 7 Agha, S. K. Effect of organic and inorganic fertilizer application on maize fodder production. Asian J. Plant. Sci. 3 (3), 375–377. (2004).

Khalofah, A. et al. Deep placement of nitrogen fertilizer improves yield, nitrogen use efficiency and economic returns of transplanted fine rice. Plos One. 16 (2), e0247529 (2021). https://journals.plos.org/plosone/article?id=10.1371/journal.pone.0247529

Yaseen, M. et al. Subsurface-applied coated nitrogen fertilizer enhanced wheat production by improving nutrient-use efficiency with less ammonia volatilization. Agronomy 11 (12), 2396 (2021). https://www.mdpi.com/2073-4395/11/12/2396

Kashiri, H., Kumar, D., Shivay, Y. S., Kumar, R. & Anand, A. Growth, productivity and profitability of aromatic hybrid rice (Oryza saliva) as affected by essential oil coated Urea under aerobic condition. Indian J. Agron. 58 (3), 316–321 (2013). https://www.researchgate.net/profile/Yashbir-Shivay/publication/257812236

Kumar, N. et al. Soil biological indicators associated with nitrogen mineralization patterns in rice soils under long-term integrated nutrient management. Soil Use Manag. 40 (1), e12963. https://doi.org/10.1111/sum.12963 (2024).

Upadhyay, S. K. & Tripathi, R. S. Response of prilled and Neem extract coated Urea application timings to rice (Oryza sativa). Agric. Sci. Dig. 20 (2), 84–86 (2000). https://arccarticles.s3.amazonaws.com/webArticle/articles/asd202005.pdf

Singh, A., Jaswal, A. & Singh, M. Impact of Neem coated Urea on rice yield and nutrient use efficiency (NUE). Agric. Rev. 40 (1), 70–74 (2019). https://arccjournals.com/journal/agricultural-reviews/R-1817

Imran, M., Irfan, M., Yaseen, M. & Rasheed, N. Application of Glycerin and polymer coated diammonium phosphate in alkaline calcareous soil for improving wheat growth, grain yield and phosphorus use efficiency. J. Crop Sci. Biotechnol. 21, 425–434 (2018). https://www.researchgate.net/publication/329882231

Perveen, S. et al. Assessing the potential of polymer coated Urea and sulphur fertilization on growth, physiology, yield, oil contents and nitrogen use efficiency of sunflower crop under arid environment. Agronomy 11 (2), 269 (2021). https://www.mdpi.com/2073-4395/11/2/269

Hegab, R. H. Evaluation of nitrogen sources and polymer coated fertilizers on wheat yield in sandy soil. Asian J. Soil. Sci. Plant. Nutr. 3 (3), 1–12 (2018). https://journalajsspn.com/index.php/AJSSPN/article/view/20

Folina, A. et al. Evaluation of various nitrogen indices in N-Fertilizers with inhibitors in field crops: A review. Agronomy 11 (3), 418 (2021). https://www.mdpi.com/2073-4395/11/3/418

U. S. Salinity Laboratory staff. Diagnosis and improvement of saline and alkali soils. USDA Handbood No. 60. Washington D. C. USA. https://www.ars.usda.gov/ARSUserFiles/20360500/hb60_pdf/hb60complete.pdf (1954).

Jackson, M. L. Soil Chemical Analysis: Advanced Course. 1–854. https://nepis.epa.gov/Exe/ZyPURL.cgi?Dockey=91024B2E.TXT (UW-Madison Libraries Parallel Press, 1962).

Olsen, S. R., Cole, C. V., Watanabe, F. S. & Dean, L. A. Estimation of available phosphrous in soil by extraction with sodium bicarbonate. Circular No. 939, USDA. US Government Printing Office, Washington, DC, USA. https://archive.org/download/estimationofavai939olse/estimationofavai939olse.pdf (1954).

Chapman, H. D. & Pratt, P. F. Method of Analysis for Soil, Plant and Water. Division of Agriculture Science https://doi.org/10.1097/00010694-196201000-00015 (University of California Riverside, 1962).

Reynold, S. G. The gravimetric method of soil moisture determination part I A study of equipment, and methodological problems. J. Hydrol. 11 (3), 258–273 (1970). http://quebec.hwr.arizona.edu/classes/hwr432/2014/reynolds70-1-soil-moisture-by-gravity.pdf

Keeney, D. R. & Nelson, D. W. Nitrogen inorganic forms. In Page, AL, editor. Methods of soil analysis, part 2. Chemical and microbiological properties. Madison (WI): Soil Sci. Soc. Am. Am. Soc. Agron. 643–698. https://www.cabidigitallibrary.org/doi/full/https://doi.org/10.5555/19841981415 (1989).

Ashraf, E. et al. An assessment of in-service training needs for agricultural extension field staff in the scenario of climate change using Borich needs assessment model. Sarhad J. Agric. 36 (2), 427–446 (2020). https://www.researchgate.net/publication/341446021

Nizami, M. I., Shafiq, M., Rashid, A. & Aslam, M. The soils and their agricultural development potential in Pothwar. https://www.tandfonline.com/doi/full/10.1080/09064710902960259 (WRRI-LRRP, National Agricultural Research Centre, 2004).

Ahmad, H., Khan, S. M., Ghafoor, S. & Ali, N. Ethnobotanical study of upper Siran. J. Herbs Spices Med. Plants. 15 (1), 86–97 (2009). https://www.researchgate.net/publication/227349756

Wolf, B. A comprehensive system of leaf analyses and its use for diagnosing crop nutrient status. Commun. Soil. Sci. Plant. Anal. 13 (12), 1035–1059. https://doi.org/10.1080/00103628209367332 (1982).

Kariya, K., Matsuzaki, A. & Machida, H. Distribution of chlorophyll content in leaf blade of rice plant. Nihon Sakumotsu Gakkai Kiji. 51, 134–135 (1982). https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6752913/

Steel, R. G. D., Torrie, J. H. & Dickey, D. A. Principles and procedures of statistics, 2nd edition. https://www.scirp.org/reference/ReferencesPapers?ReferenceID=1855584 (McGraw Hill Inc., 1997).

Acknowledgements

The authors extend their appreciation to the ongoing Research Funding Program Research Chairs (ORF-RC-2025-2600), King Saud University, Riyadh, Saudi Arabia.

Funding

The authors extend their appreciation to the ongoing Research Funding Program Research Chairs (ORF-RC-2025-2600), King Saud University, Riyadh, Saudi Arabia.

Author information

Authors and Affiliations

Contributions

Conceptualization, A.A. and M.A.T.; supervision and proof reading, N.U.S; co-supervision, review and editing, M.A.; validation, M.Ah., M.A.A-M, W.H.Al-Q, A.M.Z and M.R; formal analysis, M.A.; investigation, A.A.; resources, A.A.; data collection, A.A, M.A.T; writing-original draft preparation, A.A.; writing, S.F; visualization, R.L. M.Ah, A.M.Z; review, editing and revision of the article, All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Aziz, A., Tahir, M.A., Sabah, N.U. et al. Effects of coating agents on nitrogen dynamics and yield of wheat (Triticum aestivum L.) under irrigated and rainfed conditions. Sci Rep 15, 35258 (2025). https://doi.org/10.1038/s41598-025-14121-w

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-14121-w