Abstract

Major bioactive compounds, crocin compounds, the major bio-actives of saffron, exhibit significant antioxidant, anti-inflammatory, and anticancer properties. Their high commercial value is attributed to the difficulty of obtaining large quantities in a highly pure form. In the current study, antisolvent precipitation, optimized through response surface methods (RSM), was applied to the selective enhance the concentration of both total crocins and crocin-I from the extract of saffron. The best extraction conditions were 59.94 mg/mL of saffron concentration, 3.09 of antisolvent-to-solvent ratio, 782.42 µL/min of addition rate, and 28.3 °C of temperature. In the case of using ethyl acetate as an antisolvent under the said conditions, the total content of crocin increased by 81%, with crocin-I accounting for 55% of the total crocins. Compared to this, the use of ethyl acetoacetate as the antisolvent increased the crocin-I content from 26 to 47%. This process also reduced undesired components such as picrocrocin. By utilizing antisolvent precipitation, the method offers a cost-effective, straightforward approach for enriching crocins, especially thermally sensitive crocin-I, without the need for complex heating or cooling systems. This method was a straightforward and efficient means of boosting the yield of very pure crocins, offering a scalable and practicable answer to the challenges of saffron extraction and purification.

Similar content being viewed by others

Introduction

Saffron (Crocus Sativus L.), is a highly valued medicinal and herbal spice known throughout the world. It finds wide applications as a food colorant1,2 flavoring agent, and taste enhancer in the food processing and nutraceutical industries3. Other medicinal properties of saffron include anti-inflammatory, antimicrobial4 antioxidant5,6 anticancer7 and anti-depression8,9. The pharmacological effects of saffron are primarily attributed to its bioactive compounds, including crocins, crocetin, safranal, picrocrocin, essential oils, and several mineral compounds10. Crocins and picrocrocin are the two major constituents in the stigmas of saffron, ranging from 8 to 50% and 0.8–26.6% of dry saffron mass, respectively11,12,13. In general, the chemical structure of the crocin molecule consists of a long chain of polyunsaturated diterpene called 8,8’-diapo-8,8’-carotenoic acid, with two terminal carboxyl groups14. The diversity of the crocin derivatives is derived from the various quantities and types of sugar moieties linked to the carboxylic group, as well as from the presence of cis- and trans-isomers produced under the overall photoisomerization process15. To date, 47 crocin derivatives have been reported and grouped into eight structural classes, with 32 identified as novel compounds11,12,13.

All the crocin derivatives, with the exception of crocin-I, demonstrate pairs of cis-trans isomers, and the trans-crocins are typically converted to cis-crocins by photoisomerization mechanisms11,16. Due to its high water solubility, crocin has a higher coloration ability than other carotenoids present in saffron. This makes it favorable in food and cosmetic industries where water solubility is required7. The aforementioned chemicals have been of immense interest to scholars in most recent research studies. Figure 1 A: has shown the distribution of publications on crocins (blue) and picrocrocin (red). Figure 1B has shown the distribution of data in respect to the time of publication, which is shown with different colors. Figures 1 C and 1D have shown the relationship between the date of publication of crocins and picrocrocin and the separation techniques used, respectively. The Figures are drawn with larger circles and words to show the higher importance of the subject matter. The connecting lines depict the connection among article keywords.

Analysis of information sources based on the CVS-SCOPUS algorithm using VOSviewer software for research keywords of natural product extraction, medicinal plants, and Crocus Sativus L., in 117,904 related information sources (A) from 2014 to 2024 (B). Research subject relationship of extraction method, picrocrocin, and crocin (C and D).

Analysis of sources with keywords related to the isolation, purification, and applications of crocins shows that research has mainly focused on four areas: pharmacological applications, phytochemical methodology, metabolic and biosynthetic pathways, and molecular docking studies (Fig. 1 A). In the last few decades, research interest has shifted from the pharmaceutical and food industries to metabolic studies and the purification of bioactive chemicals (Fig. 1B). Most studies have focused on improving the crocin extraction process by using advanced techniques like solvent extraction, supercritical fluid extraction, microwave-assisted extraction, and pulsed electric field extraction17. Various types of crocins were purified using butanol, methanol, and methylene chloride solvents18,19. The various methods used in this process include medium-pressure preparative liquid chromatography, preparative thin-layer chromatography, centrifugal partition chromatography, and high-speed counter-current chromatography20,21. Even the pursuit of synthetic alternatives has not supplanted plant-derived isolation as the primary method for large-scale crocin production. The use of response surface methodology (RSM) optimized the methods of extraction and purification by the scientists22,23,24.

However, long separation times, great quantities of solvent required, and labor-intensive procedures are economic viability and efficiency barriers to these methods. Besides, the structural similarity of crocins and the complex matrix in plants under the given conditions may reduce further the effectiveness of such techniques. Therefore, extraction and purification methodology needs to be developed that yields final products which are economically viable, environmentally friendly, and free of contaminants2,25,26. Various enrichment strategies have been devised to tackle these issues in purifying. All of these are devised to optimize the process of purification by eliminating interference from other compounds, increasing the concentration of the component of interest within the starting material, and improving the loading capacity in chromatographic systems. Antisolvent precipitation is a useful technique of enriching a sample solution by adding a nonsolvent or antisolvent, which gives rise to the precipitation of the target molecule accordingly. The precipitation can be optimized in terms of selectivity and yield by adjusting the appropriate parameters, which include the solvent-to-antisolvent ratio, temperature, and others27.

Simultaneously, this technique offers several advantages, including simplicity, ease of scaling up, and the ability to purify the molecule of interest while simultaneously removing impurities. It is especially flexible in the processing of heat-liable chemicals with complicated matrices28. Whereas antisolvent precipitation has been variously employed and optimized for a variety of natural products, such as ellagic acid from pomegranate peel, flavonoid enrichment in Ginkgo biloba extract and Eucommia ulmoides leaves, and Taxanes from crude Taxus cuspidata extract, its application to the enrichment of crocins and crocin-I has not been investigated up to now (28, 30). The present work is devoted to the elaboration of an efficient purification procedure for the isolation of crocins from saffron stigma. An ultra-sonication-assisted extraction procedure was applied to obtain a crude extract of saffron, which was further subjected to antisolvent precipitation in order to increase its concentration27,29.

Response surface methodology was used to optimize the enrichment process by altering sequentially the nature of antisolvent, temperature, ratio of antisolvent to solvent, and oxygen exposure. The new optimization allowed selective and efficient enrichment of crocins and crocin-I with much higher purity. Notably, ethyl acetate was the most effective in enriching total crocins, while ethyl acetoacetate carried out selective enrichment of crocin-I. Overall, this approach describes a very efficient and scalable technique for the synthesis of high-purity crocins and crocin-I in bulk quantities.

Materials and experimental methods

Samples and chemicals

The saffron stigmas from Iranian producers in the Khorasan Razavi Province, Iran, were acquired in 2021. HPLC grade acetonitrile, methanol, ethanol, acetone, methyl acetate, ethyl acetate, methyl acetoacetate, ethyl acetoacetate, and trifluoroacetic acid (TFA) were acquired from Merck Co., (Darmstadt, Germany). Picrocrocin, with a purity of 91.13%, and total crocins, 97.20%, were obtained and utilized as reference standards, as described in previous publications30. The crocin-I standards solution was acquired from Sigma-Aldrich Co., (Darmstadt, Germany). All the compounds were of analytical quality and utilized without additional purification. The Millipore ultrapure water system (18 Msimplicity185, Millipore Co., France) produced the distilled water.

Extraction procedure of saffron extract

The saffron stigmas were first dried using a traditional method in which fresh stigmas were spread evenly over a silk sieve and left to dry in room temperature under shaded conditions to preserve their bioactive compounds.

Following complete drying, the stigmas were crushed in an agate mortar and pestle to fine powder for use in extraction. The powdered saffron used for the extraction amounted to 10 g. 2.5 L of 80% ethanol was employed in soaking the powdered saffron initially and then kept in darkness to prevent light-induced degradation of labile compounds. A single initial extraction was followed by three successive re-extractions to maximize crocin compound yield. The initial and second re-extractions were performed with 1 L of 80% ethanol, but the third one used 0.5 L. After each extraction step, the mixture was centrifuged to get solid residue and liquid extract both separately. The supernatants of each step were combined and concentrated under low pressure using a rotary evaporator to drive off ethanol up to 530 ± 0.1 mL. The resulting concentrated extract was subsequently freeze-dried to obtain a stable dry saffron extract in the form of 6.31 ± 0.05 g powder. The powder was stored in airtight, light-opaque vessels in an attempt to isolate it from light and moisture. Offline high-performance liquid chromatography (HPLC) was used to determine the constituents of the extract, identifying 26% crocin-I, 44% total crocins, and 23% picrocrocin.

High-performance liquid chromatography

Analytical high-performance liquid chromatography (HPLC) was performed using a KNAUER 2800Q (Berline, Germany) system. The system included a binary wellchrome K1001, a multiple wavelength UV-Vis (DAD) 2800 model, and a KNAUER Eurospher RP C18 column (4.6 mm × 250 mm × 5 μm × 10 Å), Kenauer Co., (Berline, Germany). The separation method relies on prior publications30. The mobile phase consisted of A: Acetonitrile (ACN) and B: Water. 55 min linear gradient solution system based on the percentage of A was applied as follows: 90%T0, 90% T 0−5, 20% T 5−25, 20% T 25−35, 0% T 35−37, 0% T 37−39, 90% T 39−40, 90% T 40−46. The flow rate was set at 1 mLmin−1. The detector was calibrated at several maximum wavelengths, specifically 250 nm for the analysis of picrocrocin and 440 nm for the analysis of crocins.

Liquid Chromatography–Mass Spectrometry (LC-MS) analysis

To isolate the Saffron bioactive compounds, filtered extract was directly piped into LC-MS vials and stored at 4 °C until analysis. The liquid chromatography of LCMS analysis was performed by employing a reversed-phase C18 column (150 mm × 2.1 mm × 1.7 μm × 10 Å) at 35 °C. The mobile phase consisted of solvent A (0.1% formic acid in water) and solvent B (0.1% formic acid in acetonitrile), pumped at a flow rate of 0.3 mL/min. Gradient elution was employed: starting from 5% B, increasing linearly to 30% B in 10 min, then to 70% B in 25 min, held for 10 min, followed by re-equilibration to starting conditions. The injection volume was 10 µL. Mass spectrometric detection was performed on a Waters QTOF mass spectrometer (Waters Co., USA) equipped with an electrospray ionization (ESI) source in a positive ion mode. The key source parameters were a capillary voltage of 3.5 kV, source temperature at 120 °C, desolvation temperature at 350 °C, and desolvation gas at 600 L/h with nitrogen.

Experimental conditions for antisolvent precipitation

For preparation of raw saffron extract for optimization of antisolvent precipitation, 5 mL of the extract was mixed with 20 mL of ethanol-80% and transferred to a 30 mL glass flask. The above solution was subjected to ultrasonic treatment at room temperature for approximately 15 min to enhance solubilization as well as uniform dispersion of the extract. After sonication, the sample was centrifuged at 1000 rpm for 5 min to decant off any residual undissolved solid particles. The supernatant containing the solubilized extract was transferred to the antisolvent precipitation process. A known quantity of this extract solution was slowly added into a known quantity of antisolvent under controlled conditions. The injection was performed under constant temperature and injection rate and the mixture was stirred at 1000 rpm continuously under a magnetic stirrer for homogeneity. The system temperature was very carefully regulated by a thermostatic water bath to introduce uniform thermal conditions during the process. Fast precipitation of crocin-rich compounds was seen under optimized conditions following mixing. After sufficient time for complete precipitation, the obtained suspension was centrifuged at 1000 rpm for approximately 10 min to collect the solid precipitate. The obtained residue was then dried through a dry bath process in order to obtain the final enriched crocin product.

Statistical analysis

In order to evaluate and optimize antisolvent precipitation process for the enrichment of crocin-I and total crocins, a two-stage experimental design was used. Initially, a one-factor at a time strategy was employed to identify the separate influence of key parameters on precipitation efficiency (explained in Sects. "Materials and experimental methods", "Results and discussion",“Conclusion”). Based on the initial screening, the variables for the subsequent multivariate analysis were selected. A central composite design (CCD) was then implemented to design the final process conditions and identify optimal combinations of parameters. This design was constructed from trial version 7 software of Design Expert (State-Ease Inc., USA). Four independent variables were selected on the basis of the likely impact on the precipitation of crocin: (A) concentration of saffron extract (mg/mL), (B) antisolvent-to-solvent volume ratio (v/v), (C) antisolvent addition rate (µL/min), and (D) temperature of solvent (°C). Every variable was investigated at five levels (−α, − 1, 0, + 1, +α), as shown in Table 1.

That is, the concentration of saffron ranged from 30 to 70 mg/mL, the antisolvent-to-solvent ratio from 1:1 to 9:1 (v/v), the addition rate from 200 to 1000 µL/min, and the temperature from 24 to 40 °C. The design matrix had 16 factorial points, 6 experimental error estimate center points, and 8 axial points for curvature estimation, with an alpha of ± 2 in order to afford rotatability. In order to keep the uncontrolled factors to a minimum, the trials were conducted in random fashion (Table 2).

Optimization was based on composite response, i.e., desirability function (Df), which is a simultaneous effect of total crocin yield (Y%), content of crocin-I (C%), and reduction in picrocrocin content (P%) as per the following equation (Eq-1).

Y, C, and P represent the extraction yield percentages, crocin content, and picrocrocin content percentages. A linear design domain assessed 30 runs using a randomly selected sample of total crocins. The least significant differences were computed, with differences deemed significant at a p-value of 0.05. This function prioritizes crocin yield while accounting for crocin-I selectivity and impurity reduction, providing a balanced measure for process optimization.

Structural characterizations of the precipitant

The scanning electron microscopy (SEM) technique, explicitly using the SEM MIRA3 (TESCAN Co, Brno, Czech Republic) was employed to determine the structure and morphology of crocin-I.

Results and discussion

Enrichment of total Crocins and Crocin-I

Enrichment was performed using ethyl acetate and ethyl acetoacetate as antisolvents on the ethanolic extract. Ethyl acetate achieved a precipitation yield of 49.1% mg/g crude Extract, while ethyl acetoacetate resulted in a slightly lower yield of 41.6% mg/g crude Extract. The results presented in Table 3 (chromatograms can see in supplementary file; figure S1) indicate that using ethyl acetate as an antisolvent led to a substantial 81% mg/g crude Extract rise in the crocin compounds concentration, resulting in a 1.84-fold increase. Crocin-I accounted for 55% mg/g crude Extract of the overall content of crocin compounds, whereas the remaining 26% mg/g crude Extract comprised several additional crocin derivatives, along with a small amount of picrocrocin and other saffron chemicals. The remaining unwanted compounds in this study could be flavonoids, carbohydrates, carotenoids, etc.

However, when ethyl acetoacetate was used as an antisolvent, the amount of picrocrocin, a significant contaminant that hinders crocin purification, decreased to below 0.5%. In addition, the antisolvent’s selective characteristics resulted in an increase in the concentration of crocin-I from 26 to 47% mg/g crude Extract. As a result, ethyl acetoacetate showed a selective increase (+ 26.8% mg/g crude Extract) in the concentration of crocin-I, while ethyl acetate was much more effective and increased (+ 44.5% mg/g crude Extract) the overall concentration of crocin at a higher magnitude. Figure 2 A-C: RP-HPLC chromatograms represent the metabolite composition of the extract of saffron before and after its enrichment with the application of ethyl acetate and ethyl acetoacetate as antisolvents. The chromatograms obtained at a wavelength of 440 nm represent the absorption spectrum of crocins. In contrast, the region at 250 nm corresponds to the absorption of picrocrocin and flavonoid chemicals found in saffron. The chromatogram obtained following precipitation exhibits a substantial decrease in chemicals apart from crocins. Therefore, in the following investigations, ethyl acetoacetate and ethyl acetate were used as appropriate antisolvents to concentrate crocin-I and total crocins selectively.

The chromatograms of (a) total crocins at antisolvent of ethyl acetate and (b) crocin-I at antisolvent of ethyl acetoacetate; green curve: before enrichment and black curve: after enrichment. The solvent is 80% ethanol. The quantitative variation pattern of the %crocin-I yield in (a) different saffron extract concentrations, (b) volume ratio of antisolvent to solvent, (c) rate addition, (d) solvent temperature on the crocin-I enrichment (a) at 0 °C, (e) solvent temperature on the crocin-I enrichment (a) at 25 °C.

Screening of parameters

The study initially screened and subsequently optimized the four primary influencing variables in the approach utilizing the response surface methodology. The factors investigated encompassed the concentration of the extract employed, the rate of antisolvent addition, the antisolvent-to-solvent ratio, and the impact of temperature. In these optimizations, changing the antisolvent hardly affected the value of these four parameters. Thus, its optimum value was directly applied on ethyl acetate and ethyl acetoacetate without any further adjustment. This infers that the intrinsic property mainly governs the behavior of each antisolvent in concentrating total crocin or crocin-I. It was revealed from the results that ethyl acetoacetate can preferentially collect crocin-I, while ethyl acetate can precipitate all the crocins no discriminatingly. For this, it is certainly important to choose a proper antisolvent in order to concentrate the desired components of crocin from saffron extracts selectively.

Type of solvent and antisolvent

The first step in carrying out the antisolvent precipitation of crocins is assessing the available solvent and antisolvent alternatives. The selected solvent must be fully miscible with the antisolvent to avoid the formation of an emulsion. Further, optimization in regard to the solubility of bioactive chemicals in the solvent is required. Among common solvents such as methanol, ethanol, and acetone, 80% ethanol is an appropriate choice for the solvent. This aligns well with the information found in the literature reference31. To examine the impact of the antisolvent parameter, different antisolvents, including methyl acetate, ethyl acetate, methyl acetoacetate, and ethyl acetoacetate, were evaluated while utilizing 80% ethanol as the solvent. Both crocin-I and total crocins were assessed for all antisolvents. However, ethyl acetoacetate resulted in the highest enrichment of crocin-I, while ethyl acetate had the highest total crocin concentration.

Effect of saffron extract concentration

The concentration of the saffron extract could be considered as the most influencing variable in the antisolvent precipitation process. In this regard, different volumes of saffron extract (20, 30, 50, and 70 mg/mL) were added into ethyl acetoacetate as an antisolvent. Amounts of crocin-I and picrocrocin were measured. No precipitation was generated when the extract concentrations were low. Nevertheless, when the extract concentration reached 30 mg/mL, crocin-I production reached its highest point and declined when the extract concentration was further increased (Fig. 2 C). To elucidate the findings, it is crucial to consider the correlation between supersaturation and nucleation rate. Increasing the amount will increase the level of supersaturation upon addition to the antisolvent. This will increase the nucleation rate, creating a large number of small crystals that then aggregate. This aggregation can reduce the quality of the final product. Previous studies have shown a correlation between more significant concentrations of colloidal particles and enhanced accumulation [36]. Hence, the interplay between the excessive saturation that triggers the formation of nuclei and the aggregation effects establishes the ideal concentration for extraction.

Effect of addition rate

The rate at which the extract is added to the antisolvent is critical to the antisolvent precipitation process. The high supersaturation is achieved by injecting the bioactive component solution into the antisolvent, which has a high percentage. By testing injection rates of 100, 200, 500, 1000, and 2000 µL/min, it was observed that the yield of crocin-I reached its highest point at an injection rate of 1000 µL/min, with a peak yield of 94%. A greater injection rate of 2000 µL/min decreased the efficiency of crocin-I precipitation (Fig. 2 F). The very high degree of supersaturation resulted in a too rapid generation of a lot of small and unstable nuclei. These indeed tend to agglomerate rather than growing into the desired crocin-I crystals. In contrast, the use of smaller amounts led to a decrease in the production of crocin-I. This probably resulted from the precipitation of other components of saffron, which produced a lesser preference for this compound29.

Effect of volume ratio of antisolvent to solvent

The crocin content in the enriched saffron extract is greatly influenced by the volume ratio of antisolvent to solvent. The crocin-I yield was examined at the volume ratios of antisolvent to solvent 3, 5, and 7 (Fig. 2D). The crocin-I content was maximized at 96% by raising the ratio from 3 to 5. However, increasing the ratio to 7 resulted in a little decrease in the crocin-I yield to 92%. The phenomenon can be elucidated by the alteration in the equilibrium solubility of the constituents of saffron as the volume ratio is augmented.

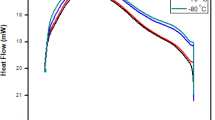

Effect of temperature

Increasing the extract solution temperature during antisolvent precipitation increases the solubility of chemicals. The dispersion and particle growth on preexisting nuclei were favored by the high temperature, causing their dimensions to increase27. In order to analyze this, the temperature of the solvent to be added, extract, was varied at 25, 30, and 40 °C along with the antisolvent’s temperature fixed at 0 and 25 °C. Figure 2 F depicts the results presented in Fig. 2G. The yield of crocin-I at an antisolvent temperature of 0 °C was higher than at an antisolvent temperature of 25 °C, regardless of the solvent temperature. The drop in temperature of the antisolvent reduces the solubility of crocin-I, resulting in a more pronounced selective precipitation. Nevertheless, elevating the temperature of the solvent from 25 to 40 °C resulted in a decrease in the production of crocin-I, irrespective of the temperature of the antisolvent.

Optimization of parameter with Response Surface Methodology (RSM)

Experimental design and model fitting

Through the multiple regression analysis of the experimental data, the predictive second-order polynomial equations were obtained to express the enrichment of crocins in terms of the coded factors A, B, C, and D:

(Desirable function)2.83 = + 1.739E + 005 + 26387.54 × A + 2580.45 × B −7786.18 × C −14803.01 × D −1486.22 ×AB + 6158.17 × AC −45781.83 ×AD −23659.05 ×BC + 17353.15 × BD −3265.08 × CD + 15876.01 × A2 + 8386.49 × B2 + 3680.33 × C2 −35332.98 × D2.

The response corresponds to the yield. A, B, C, and D represent the code values for extract concentration, volume ratio of antisolvent to solvent, rate of addition, and solvent temperature, respectively. Table 3 displays the ANOVA findings for the model (Table 4).

All model terms were statistically significant, with a p-value less than 0.05. The absence of significance of the lack of fit (p-value > 0.05) indicated that the linear model was appropriate for the current study. Furthermore, the values of R2 and Adj-R2 were determined to be 0.8225 and 0.6313, respectively, indicating a strong correlation. These values align well with the high accuracy rate of 99.5%. An evident strong association between the predicted and actual values was obtained. The residual analysis depicted in Figure S2a reveals no deviations from the assumptions of the linear model. Simultaneously, the lambda value 1.00 (Figure S2b) indicated that the data did not require a particular adjustment.

Response analysis and optimization

The response surface contour plots for determining the factor levels are given in Fig. 3 A F. Two variables were kept at the center level while the interaction of the other two factors was examined. An increase in concentration at the medium temperature (Fig. 3 A and B) corresponds to the rise in the reaction. Similarly, a decrease in temperature at lower antisolvent-to-solvent ratios also increases the response (Fig. 2D and E). Higher levels of the concentration parameter in the two-factor interactions result in increased responses, as seen in Fig. 3 C and E. The desirability function was maximized to 84.95, thus optimizing the process. Therefore, the optimal parameters presented earlier were determined for the enrichment of both crocin-I and total crocins: concentration of the saffron extract, 59.94 mg/mL; antisolvent to solvent ratio, 3.09; addition rate, 782.42; temperature of the solvent, 28.3 °C. These experimental results were in excellent agreement with the predicted values, which had less than 0.2% deviation (Fig. 3D, F).

Scale-up procedure

The scale-up procedure to study the application of this method on an industrial scale to the highest extent, purity, and yield of crocin-I from the precipitate was performed by scaling up the optimum conditions 20-fold. Therefore, 600 mg of saffron extract containing 26% crocin-I (15.6 mg) was mixed with 10 mL of 80% ethanol at 28.3 °C. This solution was half-poured into 30 mL of ethyl acetoacetate at a temperature of 0 °C with a flow rate of 1 mL/min. This process is quite effortless, time-consuming, inexpensive, and environmentally harmless. A total of 12.9 milligrams of crocin-I precipitate was produced under these circumstances. Based on the quantitative analysis, the yield of crocin-I was 82%. These results indicate that crocin-I may be efficiently obtained in large quantities utilizing the antisolvent precipitation approach. This process is straightforward, fast, cost-effective, and ecologically benign.

Scanning electron microscope analysis

The morphology and structure of the purified crocin-I were studied using SEM (Fig. 4 A F). They all were obtained at a 15,000× magnification, which show surface morphology and particle structure of saffron-derived crocin extracts under different processing conditions. Images A and B are irregularly shaped, aggregated particles with relatively rough surfaces and heterogeneous sizes, suggesting incomplete precipitation and partial agglomeration. Image C is slightly less aggregated material with sharper edges and more broken structure, reflecting greater surface area and, perhaps, better access to solvents. Micrographs D and E are more even, compact particle distribution with smaller particles, reflecting that conditions of optimized antisolvent favored more controlled and effective precipitation. Finally, image F possesses the most advanced particle morphology with well-separated homogeneously distributed fine particles and minimal clumps and smoother surfaces, suggesting successful operation with optimal process parameters for selective crocin enrichment. Complementary to the above, the findings confirm the efficacy of antisolvent precipitation optimization as suggested by the improvement in particle homogeneity and control of morphology that contribute towards improved purity and yield of crocin-I and total crocins with the direct measure of study objective being the achievement of high-quality saffron bioactives.

LCMS analysis

The quantity of crocin purified from the stigmas of saffron was determined by LCMS (Fig. 4G H). It showed that among the other bioactive constituents present in the antisolvent-derived saffron, crocin-I contains the highest percentage. Chromatographic resolution was achieved under optimal reverse-phase conditions on a C18 column with gradient elution profile to yield high-resolution separation of the crocin-I, which led to a sharp peak at 31.99 min corresponding to the sodium-adducted molecular ion [M + Na⁺] at m/z 999.2652 (C₄₄H₆₄O₂₄)32. Retention time was set by extraction of the ion chromatogram (EIC) of the precursor crocin-I and by confirmation of peak purity through comparison of UV/Vis spectra across the elution profile and identification of a single, dominant species in the MS signal. High-resolution mass spectrometry (HRMS) in positive electrospray ionization (ESI)-mode was referenced to lower than 2 ppm mass error, and data-dependent MS/MS was acquired with normalized collision energies for generating a diagnostic fragmentation pattern. Software deconvolution and graphical visualization by manual spectral analysis revealed a prominent product ion at m/z 675.2455 corresponding to loss of an entire glucose unit ([M + Na–Glu]⁺), a secondary fragment at m/z 329.1367 resulting from further glucose loss, and an ion at m/z 195.0893 corresponding to intra-glycosidic cleavage; all such diagnostic ions are highly analogous to literature-reported crocin-I fragmentation patterns33. Structural confirmation was aided by automated library correlation and eye inspection of neutral losses compatible with glycosidic bond cleavages. Together, retention behavior, accurate mass measurement, high-resolution MS/MS data, and diagnostic neutral losses unequivocally identify crocin-I as the principal crocin analog in the extract and determine the specificity and effectiveness of the antisolvent extraction, purification, and analytical procedure.

This research confirmed that antisolvent precipitation with ethyl acetate and ethyl acetoacetate is a potent and selective method in improving crocin compounds from saffron extract. For the compound extraction improvement, the absolute improvement calculated as the result of subtracting initial value from final value, and the relative improvement calculated as obtained by calculating the percentage by dividing absolute improvement by initial value.

Crocin compounds were improved by ethyl acetate from 44 to 81%, an absolute + 37% and a relative + 84% rise, while crocin-I was enhanced from 26 to 55%. These results outpace previous less complex crystallization methods by Hadizadeh et al.31, containing just 40–60% crocin with compromised impurity control and are comparable to more complex multicolumn countercurrent chromatography by Ardakani et al.15, with similar crocin-I purity but taking longer and being less scalable. Our method also effectively removed picrocrocin, reducing it from 23 to 0.1%, a level of impurity removal rarely achievable with preparative HPLC or TLC procedures used by earlier studies12,18. The mild conditions and simplicity of our method make it a potential substitute for biosynthetic procedures, which, despite their promise, remain far from commercial-scale viability4. On the other hand, ethyl acetoacetate was shown to be more selective for crocin-I, increasing its content from 26 to 47%, while still raising total crocins to 57%. Compared to solid-phase extraction approaches, which required tailored polymers and showed moderate selectivity, our method achieved similar or better crocin-I enrichment with a simpler and greener process34. Furthermore, picrocrocin was reduced to 0.4% (− 98.3%), that indicating strong selectivity and purification potential compared to latest research30,35. These findings position our method as a flexible strategy depending on the desired outcome: ethyl acetate for maximum crocin recovery and ethyl acetoacetate for selective crocin-I concentration. By integrating efficiency, scalability, and selectivity, this work provides a practical advancement over both conventional and advanced extraction methods, strengthening its relevance for future crocin-based pharmaceutical and food applications.

Conclusion

This study uses an anti-solvent precipitation method to introduce a sustainable and scalable technique for enhancing the concentration of crocins and crocin-I in the saffron extract. The response surface methodology was employed to optimize the critical process parameters, such as extract concentration, solvent-antisolvent ratio, addition rate, and temperature. The comparative analysis of the two antisolvents—ethyl acetate and ethyl acetoacetate—demonstrated significant differences in their effectiveness and selectivity for enriching crocin compounds from saffron extract. Under optimal conditions, the concentration of saffron extract is 59.94 mg/mL, antisolvent-to-solvent ratio is 3.09, addition rate is 782.42 µL/min, and temperature of the solvent is 28.3 °C. The findings can conclude with:

-

(a)

Ethyl acetate was most effective in overall enrichment of crocin, raising the crocin compounds from 44 to 81%; +37% absolute, + 84% relative improvement.

-

(b)

Level of Crocin-I with ethyl acetate was raised from 26 to 55%; +29% absolute, + 111.5% relative improvement.

-

(c)

Ethyl acetoacetate was more discriminatory towards crocin-I, raising its level from 26 to 47%; +21% absolute, + 80.7% relative improvement.

-

(d)

The total of crocins with ethyl acetoacetate increased to 57%; +13% absolute, + 29.5% relative gain.

-

(e)

Unwanted impurity picrocrocin was reduced significantly by antisolvents; From 23 to 0.1% by ethyl acetate (− 99.6%) and from 23 to 0.4% by ethyl acetoacetate (− 98.3%).

-

(f)

Ethyl acetate will maximize crocin compounds recovery, while ethyl acetoacetate resulted in selective crocin-I enrichment.

Besides, some bio-solvents used in the present study are of biological origin and thus environmentally friendly, including ethanol, ethyl acetate, and ethyl acetoacetate, further contributing to the greenness of the whole process34,36,37. Also anti-solvent precipitation has several advantages: it is simple to operate, inexpensive to perform, fast, and suitable for large-scale industrial work. It hence represents one of the most effective and low-cost methodologies for the purification of natural products from complex plant matrices.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Choi, H. J. et al. Isolation and characterization of the major colorant in gardenia fruit. Dyes Pigm. 49, 15–20 (2001).

Lee, I. A., Lee, J. H., Baek, N. I. & Kim, D. H. Antihyperlipidemic effect of Crocin isolated from the fructus of gardenia jasminoides and its metabolite Crocetin. Biol. Pharm. Bull. 28, 2106–2110 (2005).

Spence, C. & Saffron The colourful spice. Int. J. Gastron Food Sci. 34, 100821 (2023).

Pu, X. et al. In vivo production of five Crocins in the engineered Escherichia coli. ACS Synth. Biol. 9, 1160–1168 (2020).

Cerdá-Bernad, D., Valero-Cases, E., Pastor, J. J. & Frutos, M. J. Saffron bioactives crocin, Crocetin and safranal: effect on oxidative stress and mechanisms of action. Crit. Rev. Food Sci. Nutr. 62, 3232–3249 (2022).

Zeka, K. et al. Petals of crocus sativus L. as a potential source of the antioxidants Crocin and Kaempferol. Fitoterapia 107, 128–134 (2015).

Alavizadeh, S. H. & Hosseinzadeh, H. Bioactivity assessment and toxicity of crocin: a comprehensive review. Food Chem. Toxicol. 64, 65–80 (2014).

Mohtashami, L., Amiri, M. S., Ramezani, M., Emami, S. A. & Simal-Gandara, J. The genus crocus L.: A review of ethnobotanical uses, phytochemistry and Pharmacology. Ind. Crops Prod. 171, 113923 (2021).

Siddiqui, S. A. et al. Anti-Depressant properties of Crocin molecules in saffron. Molecules 27 2076 (2022).

Mohammadi, Y., Rezaei Farimani, A., Beydokhti, H. & Riahi, S. M. Comparison of the effect of saffron, crocin, and Safranal on serum levels of oxidants and antioxidants in diabetic rats: A systematic review and meta-analysis of animal studies. Food Sci. Nutr. 11, 2429–2439 (2023).

Younis, I. Y. et al. Non-targeted metabolomics and chemometrics for saffron (Crocus sativus L.) authentication and adulteration detection in relation to its anticholinesterase activity. Food Chem. Adv. 2, 100217 (2023).

Moras, B., Loffredo, L. & Rey, S. Quality assessment of saffron (Crocus sativus L.) extracts via UHPLC-DAD-MS analysis and detection of adulteration using gardenia fruit extract (Gardenia jasminoides Ellis). Food Chem. 257, 325–332 (2018).

Si, W. et al. Comprehensive characterization of ingredients in crocus sativus L. from different origins based on the combination of targeted and nontargeted strategies. Food Chem. 397, 133777 (2022).

Ali, A. et al. Functional characteristics, extraction, food applications and efficacy against brain related disorders. Front. Nutr. 9, 1009807 (2022). Crocin.

Hooshyari Ardakani, M. et al. Enhancing the purification of crocin-I from saffron through the combination of multicolumn countercurrent chromatography and green solvents. Anal. Bioanal Chem. 416, 2553–2564 (2024).

Ni, Y. et al. Discovery and LC-MS characterization of new Crocins in gardeniae fructus and their neuroprotective potential. J. Agric. Food Chem. 65, 2936–2946 (2017).

Rahaman, A. et al. Novel extraction techniques: an effective way to retrieve the bioactive compounds from saffron (Crocus Sativus). Food Reviews Int. 39, 2655–2683 (2023).

Castellar, M. R., Montijano, H., Manjón, A. & Iborra, J. L. Preparative high-performance liquid chromatographic purification of saffron secondary metabolites. J. Chromatogr. A. 648, 187–190 (1993).

IBORRA, J. O. L., MANJÓN & CASTELLAR, M. R., CÁNOVAS, M. A. & A. R. TLC preparative purification of picrocrocin, HTCC and Crocin from saffron. J. Food Sci. 57, 714–716 (1992).

Balasopoulou, A. et al. Symposium Recent advances and challenges in the management of retinoblastoma Globe saving Treatments. BMC Ophthalmol 17, 1 (2017).

Liu, F., Ding, F., Shao, W., He, B. & Wang, G. Regulated Preparation of Crocin-1 or Crocin-2′ triggered by the cosolvent DMSO using Bs-GT/At-SuSy One-Pot reaction. J. Agric. Food Chem. 67, 12496–12501 (2019).

Taheri, M., Fotovati, M., Hosseini, S. K. & Ghassempour, A. Optimization of throughput in semipreparative chiral liquid chromatography using stacked injection. Chirality 29, 579–588 (2017).

Ardakani, M. H., Rezadoost, H. & Norouzi, H. R. Sequential purification of Cannabidiol by two-dimensional liquid chromatography combined with modeling and simulation of elution profiles. J. Chromatogr. A. 1717, 464702 (2024).

Liu, S. et al. Statistical design of experiments for production and purification of Vanillin and aminophenols from commercial lignin. Green Chem. 22, 3917–3926 (2020).

Suchareau, M., Bordes, A. & Lemée, L. Improved quantification method of Crocins in saffron extract using HPLC-DAD after qualification by HPLC-DAD-MS. Food Chem. 362, 130199 (2021).

Tahri, K. et al. Characterization and discrimination of saffron by multisensory systems, SPME-GC-MS and UV-Vis spectrophotometry. Anal. Methods. 7, 10328–10338 (2015).

Kumar, R. et al. Liquid antisolvent crystallization of pharmaceutical compounds: current status and future perspectives. Drug Delivery Translational Res. 2022. 13:2 13, 400–418 (2022).

Shahid, M., Sanxaridou, G., Ottoboni, S., Lue, L. & Price, C. Exploring the role of Anti-solvent effects during washing on active pharmaceutical ingredient purity. Org. Process. Res. Dev. 25, 969–981 (2021).

Park, M. W., Yeo, S. & Do Antisolvent crystallization of carbamazepine from organic solutions. Chem. Eng. Res. Des. 90, 2202–2208 (2012).

Kabiri, M., Rezadoost, H. & Ghassempour, A. A comparative quality study of saffron constituents through HPLC and HPTLC methods followed by isolation of Crocins and Picrocrocin. LWT 84, 1–9 (2017).

Hadizadeh, F., Mohajeri, S. A. & Seifi, M. Extraction and purification of Crocin from saffron stigmas employing a simple and efficient crystallization method. Pak J. Biol. Sci. 13, 691–698 (2010).

Rocchi, R. et al. Crocins pattern in saffron detected by UHPLC-MS/MS as marker of quality, process and traceability. Food Chem. 264, 241–249 (2018).

Srivastava, R., Ahmed, H., Dixit, R., Saraf, S. & Dharamveer & Crocus sativus L.: A comprehensive review. Pharmacogn Rev. 4, 200–208 (2010).

Mohajeri, S. A., Hosseinzadeh, H., Keyhanfar, F. & Aghamohammadian, J. Extraction of Crocin from saffron (Crocus sativus) using molecularly imprinted polymer solid-phase extraction. J. Sep. Sci. 33, 2302–2309 (2010).

Revelou, P. K. et al. Optimization of a Solid-Phase extraction procedure for the separation of Picrocrocin and Crocins from saffron extract. Compounds 3, 233–243 (2023).

Almodóvar, P., Briskey, D., Rao, A., Prodanov, M. & Inarejos-García, A. M. Bioaccessibility and Pharmacokinetics of a Commercial Saffron (Crocus sativus L.) Extract. Evidence-based Complementary and Alternative Medicine (2020). (2020).

Singletary, K. & Saffron Potential health benefits. Nutr. Today. 55, 294–303 (2020).

Acknowledgements

The authors thank the Research Council of Shahid Beheshti University for their help and support.

Author information

Authors and Affiliations

Contributions

HR: Conceptualization, Supervision, Methodology. EF: Data curation, Writing an original draft. MH: Data curation, formal analysis, and FM: Statistical design, Writing and editing the original draft.

Corresponding author

Ethics declarations

Competing interests

The authors certify that there is no conflict of interest with any organization, financial, or other regarding the material discussed in the manuscript. The graphical abstract generated base on the study findings using Open AI: ChatGPT 4.5, 2024. Also, the text was English editing using QuillBot AI and Grammarly Online software and reviewed by the authors.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Fotouhi, E., Mirzajani, F., Rezadoost, H. et al. Efficient purification of CrocinI from saffron stigmas using antisolvent precipitation to implications for food technology. Sci Rep 15, 30050 (2025). https://doi.org/10.1038/s41598-025-15176-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-15176-5