Abstract

Condensers with helical tubes have received much attention in diverse industries. The optimal design of the mentioned equipment necessitates predictive tools for calculating the condensation heat transfer coefficient (HTC). However, literature models are applicable only to specific operational and geometrical conditions. The current study aims at developing reliable models for the condensation HTC within smooth helical tubes at all flow directions. Two machine learning (ML) techniques, namely Support Vector Machine (SVM) and Gaussian Process Method (GPM) were implemented to accomplish this target. To design and validate the models, 563 HTC data, encompassing a wide spectrum of conditions, were gathered from 10 experimental studies. While both SVM and GPM tools provided excellent predictions, the latter achieved the highest accuracy with mean absolute percentage error (MAPE) and R2 value of 3.36% and 99%, respectively, for the testing dataset. Also, more than 96% of the HTC values calculated by the GPM model were situated within a ± 5% error margin. The accuracy of the literature correlations was also analyzed based on the collected data, and it was found that all of them showed MAPE values exceeding 25% from the experimental data. Moreover, unlike the previous models, the novel ML tools allowed the prediction of HTC for all flow directions with adequate precision. Also, they were capable of describing the physical variations of the condensation HTC versus operational factors. Finally, the dominant dimensionless parameters governing the two-phase Nusselt number in helical tubes were identified based on a sensitivity analysis.

Similar content being viewed by others

Introduction

Condensers are integral equipment in diverse industries, including chemical, nuclear, air conditioning, refrigeration, etc.1,2,3. During the recent years, researchers have focused on optimizing the thermal performance of condensers. One strategy is the utilization of mini-channels as replacement for conventional channels4,5. Numerous studies have demonstrated the superiority of mini/micro channels over the conventional ones in terms of heat transfer performance6,7,8,9. An alternative enhancement technique is the utilization of helical tubes, in which the centrifugal forces, arisen from their curvature, leads to a secondary flow that improve the rate of heat transfer10,11,12,13. Moreover, the geometry of helical tubes offer a higher surface area-to-volume ratio, resulting in more compact heat exchanger designs14,15,16. Consequently, the efficient design of condensers necessitates the evaluation of condensation heat transfer inside helical tubes17.

Various experimental studies have examined the heat transfer coefficient (HTC) during two-phase flow condensation in helical tubes. Al-Hajeri et al.18 determined the influence of mass flux and saturation temperature on R134a condensation within a 6.5 mm inner diameter helical tube. They observed that condensation HTC has a direct correlation with mass flux, and an inverse relationship with saturation temperature. Shao et al.19 presented a comparative study on HTC inside straight and helical tubes. The results indicated a 4–13% enhancement in HTC for the helical geometry. Han et al.20 studied the HTC during R134a condensation inside a vertical helical tube. They demonstrated the fundamental impact of saturation temperature and mass velocity on condensation HTC. In another work, Salimpour et al.21 showed that the coil pitch has neglectable impact on the condensation HTC of R404A inside helical tubes. However, they observed around 45% increase in HTC inside 87 mm tube compared to 153 mm tube. The effect of tube orientation on HTC in helical tubes was explored by Lin and Ebadian22. The diameters of coil and tube tested in this study were 177.8 and 9.4 mm, respectively. This study revealed that the condensation HTC for inclination angles between 0° and 45° is remarkably higher than that for angles between 45° and 90°. In another related work, Mozafari et al.23 observed a peak HTC for R600a condensation in a helical tube at the inclination angle of 30° with upward flow. Zakeralhoseini et al.24 examined the condensation HTC of R1234yf inside a helical tube with 8.2 mm inner diameter. It was found that the use of helical tube instead of straight tube leads to 60–120% increase in HTC under various conditions.

Several empirical correlations, derived from experimental data, have been proposed for calculating the condensation HTC within helical tubes. Nevertheless, all of these correlations have been constructed based on data obtained under limited operating conditions and employing specific working fluids. Hence, employing such correlations outside their applicability domain results in considerable errors. For instance, a comparative analysis of the Wongwises and Polsongkram25 correlation against the experimental data obtained by Gupta et al.26 and Solanki and Kumar27 revealed large deviation, which can be explained by the differences in operating conditions. Gupta et al.26 suggested an updated HTC model for R134a condensation inside helical channels, achieving relative errors less than 15% for their own data. Mosaad et al.28 derived an HTC correlation for R134a condensation within helical tubes. They emphasized that the correlation is valid in \(1200\le {\text{Re}}^{*}\le 95000\) and \(0.3\le \frac{\Delta {T}_{s}}{{T}_{s}}\le 0.6\) domain, where \(\Delta {T}_{s}\) stands for the difference between coolant and saturation temperatures. Additionally the modified Reynolds number, \({\text{Re}}^{*}\), can be expressed as follow28,

It should be noted that the predictions of the Mosaad et al.28 correlation did not show satisfactory agreements with the HTC values reported by Gupta et al.26. These deviations be attributed to the considerable differences between the coil geometry of these studies. Yu et al.29 suggested an empirical correlation based on HTC data obtained from the condensation of R50/R290 zeotropic blends. Their model considered two different regimes, i.e., annular and non-annular, to model the condensation. The boundary between the foregoing regimes was defined as29,

where \({X}_{tt}\) and \(\text{We}^{*}\) are Lockhart–Martinelli parameter and modified Weber number, respectively, calculated as30,

The MAPE values obtained by this model for annular and non-annular flows were 12.1% and 15.3%, respectively.

Another correlation was presented by Zakeralhoseini et al.24 based on their data for R1234yf condensation in helical tubes,

where \(\text{Nu}_{l}\) is the liquid-phase Nusselt number defined by Mori and Nakayama31,

The mentioned correlation predicted the corresponding HTC values with a MAPE of 5%.

The above literature survey reflects the point that the existing models cannot be considered as reliable tools to estimate the condensation HTC in helical tubes. Hence, designing robust predictive tools applicable for diverse conditions and flow directions is crucial. On the other hand, the application of ML approaches in the field remains unevaluated. Moreover, there is no insight into the order of significance of factors affecting the condensation HTC in helical tubes. Therefore, the main objective of this study is to develop new accurate ML models for predicting the condensation HTC in helical tubes across diverse conditions and flow directions, and to identify the key parameters influencing HTC. To achieve this, comprehensive databank, including 563 measured samples, has been assembled from the literature. The foregoing data comprise the condensation HTCs pertinent to diverse working fluids across an extensive range of conditions in smooth helical tubes at diverse orientations. Two heuristic ML tools, i.e., GPM and SVM are employed to link the two-phase Nusselt number with the influential dimensionless groups. The accuracy level of the newly proposed models is compared to that of the literature correlations through a wide spectrum of statistical and graphical tools. Also, the variation of the condensation HTC versus operational parameters is studied based on the models’ outcomes, and the most influential factors are introduced through a sensitivity analysis.

Materials and methods

Intelligent methods

In this study, the intelligent soft-computing methods of SVM and GPM have been utilized to model the condensation HTC within helical tubes. Several factors have been considered in the selection of the foregoing approaches. The dataset size is manageable for both GPM and SVM methods, so that can discover fundamental patterns without the complexity of other modeling tools, such as artificial neural networks and deep learning, which require larger datasets. Additionally, the ability of GPM for probabilistic predictions with uncertainty estimations, along with the robustness of SVM to overfitting, makes them computationally efficient, requiring less training time and resources compared to artificial neural network and deep learning approaches. As a result, the employed methods provide a balance of performance, interpretability, and practicality, making them well-suited for the scope of this study. A detailed description of the SVM and GPM methods is presented below.

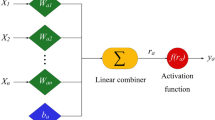

SVM

Support vector machine (SVM), is a well-known regression approach developed based on the statistical learning theory32,33. This method transforms input data (initially residing in a low-dimensional space) into a higher-dimensional feature space34,35,36. A kernel function then allows the construction of a linear regression model over the high-dimensional space. The input dataset includes N points, each defined by an n-dimensional vector37. So the input matrix can be expressed as: \(\left\{\left({x}_{i}^{\left(m\right)},{y}_{i}\right), i=\text{1,2},\dots ,N;m=\text{1,2},\dots ,n\right\}\), in which \({x}_{i}^{\left(m\right)}\) signifies the i-th element of the m-th input feature, and \({y}_{i}\) is the corresponding scaler output. Hence, a support vector regression can be expressed as38,

Here, \(W\) is the symbol of the weight vector, \(\theta (x)\) is the transform function, and \(b\) represents the regression function’s bias (or the deviation term). An optimal modeling is carried out through the minimization of the regularized risk function39,40,41,

where \({L}_{\varepsilon }\) is an \(\varepsilon\)-intensive cost function developed by Vapnik42,

Accordingly, the optimization problem can be defined as43,

where \(\xi\) and \({\xi }^{*}\) are non-negative slack variables that adjust the deviation during the training step44. Also, \(C\) denotes the penalty factor, which balances the complexity of the models and the training error45,46,47. Utilization of the Lagrange multipliers results in the following solution for the support vector regression48,

where \(a_{i}\) and \(a_{i}^{*}\) are Lagrange multipliers. Also, the kernel function \(K\left( {x_{i} ,x_{j} } \right)\) calculates the inner product of the mapped feature vectors49,

For non-linear systems, a Gaussian radial basis function (RBF) kernel is usually employed as the kernel function50,

where \(\sigma\) is the variance of the gaussian function, which is adjusted in the training stage.

GPM

Regression methods developed based on probabilistic concepts are commonly used decrease the errors occurred in the learning process49,51. GPM is a non-parametric and non-linear technique that operates in a probabilistic framework52,53,54. This method approximates the target variable, y, by defining an uncertain function, f, corrupted by a Gaussian noise, \(\varepsilon\),

It should be noted that the variance of \(\varepsilon\) is assumed to be \({\sigma }^{2}\)55.

Indeed, GPM utilizes a Gaussian process to define a prior probability distribution over the function, instead of directly estimating the uncertain function56,57,58. The data-generating process in this method is performed based on a mean function \(m\left(x\right)\) and a covariance function \(cov(x,{x}{\prime})\)59,60,61. Given prior and observed data points, the prediction for a new input vector (\({x}_{*}\)) is determined based on the Gaussian distribution62,

Here, \(K\) represents the covariance matrix with elements \({\left[K\right]}_{ij}=cov\left({x}_{i},{x}_{j}\right)\). Also, the vector \({k}_{*}\) is defined as63,64,

The constant parameters included in the mean and covariance functions significantly control the performance of the predictive distribution65,66. Accordingly, in order to design a robust model, the values of these factors, which are known as hyperparameters, should be optimized in the testing stage. To achieve this purpose, log-likelihood of the training data (\(logp\left(y|X\right)\)) should be maximized67,

Experimental data collection

The availability of sufficient experimental data is crucial for designing reliable and robust data-driven models. Hence, in the current research, attempts have been made to collect all relevant data reported in the literature. Nevertheless, some studies have not reported enough information regarding the operating and geometrical conditions, making it impossible to analyze their data. Overall, 563 experimental measurements pertinent to the condensation HTC within smooth helical tubes have been assembled from 10 published studies. As shown in Table 1, the collected dataset envelops a wide range of working fluids, saturation pressures, mass velocities, flow directions, inclination angles and tube diameters. It is important to note that the experimental data pertinent to enhanced helical tubes, such as dimpled tubes, wire-inserted tubes, etc., have not been analyzed in this study due to their different heat transfer characteristics compared to smooth tubes. The thermophysical features pertinent to the analyzed working fluids have been calculated at the saturation condition using REFPROP 9.0 software from NIST68.

Input variables of the novel models

According to experimental evaluations, diverse factors, including operating conditions (i.e., as working fluid, mass flux, saturation pressure and vapor quality) and helical tube details (i.e., coil diameter, flow direction, inclination angle and tube diameter) can affect the condensation HTC within helical tubes. In order to derive trustworthy and robust models, the aforementioned factors were lumped into well-known dimensionless groups, and used as the input features of the models. Thereupon, the relationship between the two-phase Nusselt number and input features can be expressed as follows,

These parameters have been chosen to represent the dominant physical phenomena governing the condensation HTC in helical tubes. In fact, \(\text{Re}_{tp}\) captures hydrodynamic effects71,72, \(\text{Pr}_{tp}\) is used to model the thermal boundary layer development, \({P}_{red}\) represents thermodynamic state of working fluid, \(CR\) quantifies geometric effects, \(\text{We}_{v}\) reflects surface tension influence, and \(Y\) accounts for gravitational effects. To clarify the valid range of applicability of the models, the maximum and minimum values of the above dimensionless groups for the analyzed databank have been presented in Table 2. It is seen that the collected data cover a broad range of conditions for the condensation HTC in helical tubes.

Error analysis

In order to examine the truthfulness of diverse models for estimating the condensation HTC within helical tubes, the statistical error indices presented below have been utilized,

Results and discussions

Development of the novel HTC models

Based on the collected experimental data and the form presented in Eq. (21), the ML tools of SVM and GPM were utilized to find the correlation between the two-phase Nusselt number and independent variables. It should be noted that two subsets, including training and testing with 4:1 training-to-testing split ratio, were created by the analyzed data. The larger dataset was utilized to design the intelligent models and tune their hyperparameters, and the smaller one was used for testing the predictive capability of the models. To properly tune the hyperparameters, the Bayesian Regularization method was employed. Table 3 shows the ultimate tuned hyperparameter values/types for the SVM and GPM models.

Table 4 represents the statistical error metrics achieved by the novel intelligent models during training and testing phases. As observed, both models present adequate accuracy in estimating the condensation HTC within helical tubes. The GPM model predict the HTC samples included in the training and testing datasets with MAPE values of 0.22% and 3.36%, RRMSE values of 0.27% and 4.45%, and R2 values of 100% and 99%, respectively. Hence, it can be considered as the superior model for the scope of this study. The SVM model also presents reliable estimations, since its MAPE, RRMSE and R2 values for the testing data are 5.86%, 6.93% and 97.58%, respectively. The high accuracy level of the proposed models reflects the fact that the dimensionless factors introduced in Eq. (21) are adequate to describe the HTC of condensing flow in helical tubes. The HTC measurements reported in the literature typically have uncertainties in the range of 9 to 16.52%, as reported in Table 1. However, it is important to note that the data used for model training and testing consist of averaged HTC values extracted from these studies, rather than raw, individual measurements. Because the models have been constructed based on averaged HTC values, the impact of random experimental errors, and therefore the effective uncertainty is reduced, leading to a more stable input for the models. It can be estimated that the prediction errors of the established models are close to this reduced effective uncertainty, suggesting that the accuracy of the models is approaching the limits of what the current data can support. This highlights the importance of improving the accuracy of the individual experimental measurements. Reducing the uncertainty at the source can have a greater impact than simply refining the model.

Evaluation of literature models

For determining the accuracy level of literature models, the collected HTC data were also compared with the outcomes of the correlations suggested by Gupta et al.26, Solanki and Kumar27, Yu et al.29 and Zakeralhoseini et al.24. The statistical error indices pertinent to the mentioned models for estimating the HTC data have been summarized in Table 5. As it is evident, all the literature models exhibit fairly large uncertainties from the experimental HTC samples with MAPE values higher than 25%. The best accuracy among these correlations can be attributed to that presented by Solanki and Kumar27, with MAPE, RRMSE and R2 values being 25.86%, 33.62% and 45.50%, respectively. The correlations suggested by Gupta et al.26, Zakeralhoseini et al.24, Yu et al.29 exhibit the MAPE values of 31.21%, 32.43% and 38.51%, respectively. Also, their R2 values are negative, and this is another testimony regarding their low precision in describing the HTC. Overall, it can be found that the literature models are not capable of estimating the condensation HTC within helical tubes with adequate accuracy.

Investigation of the models’ performance

In this section, diverse graphical tools, including cross-plot, cumulative frequency analysis and bar chart have been employed to investigate the performances of the novel and literature models.

The cross-plots of Fig. 1 illustrates the Nusselt numbers estimated by the novel and literature models against the relevant actual values. It is clear that the novel models represent excellent agreement with the experimental Nusselt numbers, representing their high accuracy level. However, it can be found that the GPM model benefits from higher precision compared to the SVM approach, and its outcomes are slightly closer to the best-fit line. The results also indicate the high deviations of the literature correlations, since the majority of their predicted values lie outside the ± 10% error margins. This observation implies the fact that these correlations generally cannot be utilized for estimating the condensation HTC over various operational and geometrical conditions. In contrast, the ML models presented in this study are reliable tools that allow the prediction of the condensation HTC in helical tubes across a broad range of conditions with adequate precision. All experimental data analyzed in this study as well as the Nusselt number values predicted by the novel models have been provided as Supplementary Data S1.

Figure 2 represents the cumulative frequency curves of the novel and earlier models for predicting the condensation HTC within helical tubes in various ranges of error. This analysis demonstrates the fraction of data that fall within pre-defined error margins for various models. Indeed, predicting a high percentage of data with low relative errors indicates the high reliability of the HTC models. It is seen that the curves corresponding to the new models lie above the curves of the literature correlations, representing the higher reliability of the ML models. The GPM model estimates 74.42%, 86.32%, 89.88%, 96.09%, and 98.40% of the analyzed HTC data with relative deviations less than 0.5%, 1%, 2%, 5%, and 10%, respectively. So, this model ranks first from the perspective of accuracy in describing the HTC. The next accurate predictive model is that designed based on the SVM method, as the percentages of data predicted within ± 5% and ± 10% error bounds for this model are 81.17% and 90.94%, respectively. The literature correlations do not give much larger deviations, and noticeable fractions of their predictions are located beyond the ± 20% error margins. As a result, this investigation testifies the superiority of the novel models for estimating the condensation HTC within helical tubes. It should be noted that a more comprehensive evaluation of the presented models’ robustness and broader applicability will be possible when additional experimental data for the condensation HTC inside smooth helical tubes become available.

Figure 3 compares the MAPEs of the models for estimating the condensation HTC within helical tubes at various flow directions. As illustrated, the models designed based on the GPM and SVM approaches present much better performance than the literature correlations at all flow directions. The best predictions can be attributed to the GPM models, which shows the MAPEs of 0.83%, 0.65% and 1.27% for horizontal, upward and downward flows, respectively. The corresponding values for the novel SVM model are 3.55%, 1.53%, 3.60%, respectively, and this model ranks second in terms of accuracy. The literature correlations demonstrate significantly larger uncertainties, and none are applicable to precisely estimate the HTC at all flow directions. However, the results of Gupta et al.26 for horizontal and upward flows, Solanki and Kumar27 for upward and downward flows, and Zakeralhoseini et al.24 for upward flow are reasonable with MAPE values less than 20%. Consequently, the new ML models thus offer considerable improvements in predicting the condensation HTC within helical tubes at all flow directions. This can be explained by the fact that the impact of flow direction on HTC has been taken into account in the input variables of the novel models.

A fivefold cross validation on the established models

In order to assess the robustness and reliability of the generated models, a fivefold cross-validation technique was employed, using the GPM model, determined to be the optimal predictive tool in this study. Consequently, the heat transfer data set under examination was randomly divided into five separate subsets, referred to as folds. The modeling process entailed selecting a single fold to act as the testing set, with the remaining subsets serving as training set. This process was repeated a total of five times, guaranteeing that each subset was utilized as the testing group on a single occasion. The MAPE values attained by the GPM model, with each subset performing as the testing data, are summarized in Table 6. The training MAPE values for the GPM approach remains consistently below 0.3% across all iterations, signifying excellent learning capability. Moreover, the testing MAPE values obtained are highly favorable, fluctuating between 3.31 and 4.31% across the varied folds designated as testing data. Therefore, the proposed model provides dependable predictions for the condensation heat transfer inside smooth helical tubes, independent of the specific subset utilized for testing. These results underscore the robust prediction ability of the models constructed through these intelligent techniques.

Detection of outlying samples

The integrity of models built using data-driven methods can be negatively impacted by outlying samples, which are the data points with extreme deviations from the dataset’s bulk. Such observations can arise from the uncertainties of experimental works, the complexities of the studied processes, and human error during data collection, etc. To ensure the reliability of the models, an assessment of the data for the probable presence of outliers is required. Although numerous techniques are available for outlier detection, the William’s plot is considered a powerful method in this regard. This approach employs two key statistical indicators, i.e., the hat value (\({HV}_{ii}\)) and the standardized residual (\(\xi\)). Considering a dataset with “b” observations and “a” variables, the input matrix, X, can be represented as an b-by-a matrix. Subsequently, the elements along the primary diagonal, represented as \({HV}_{ii}\), are key values derived from the following matrix73,

The William’s plot divides the analyzed data into three categories based on the following criteria:

-

(i)

Valid data: \(-3<\xi <3\) and \({HV}_{ii}<H{V}^{*}\)

-

(ii)

High-leverage data: \(-3<\xi <3\) and \({HV}_{ii}>H{V}^{*}\)

-

(iii)

Outlying data: \(\xi \ge 3\) or \(\xi \le -3\)

It should be noted that \(H{V}^{*}\), the critical hat value, is calculated as 3(1 + a)/b.

Figure 4 depicts the results of applying the above method to the HTC data calculated by the GPM model. The figure reveals that the majority of the data points lie within the valid data region. According to calculations, 532 out of a total of 563 HTC data points are identified as valid, which confirms the high quality and integrity of the dataset. Furthermore, the GPM model has favorably predicted the HTC values for 14 high-leverage data, corresponding to operating conditions significantly different from the bulk of dataset. On the other hand, around 3% of the total dataset are detected as outlying, which are too insignificant to affect the overall integrity of data. Therefore, the models constructed based on this reliable dataset, can be utilized with confidence for the prediction of condensation HTC within helical tubes.

Trend analysis

To evaluate whether the proposed models are capable of describing the physical variations of the condensation HTC versus operating factors, a trend analysis is conducted below. Thus, the explicit impacts of operational factors (i.e., mass velocity, vapor quality and saturation temperature) and helical tube information (i.e., inclination angle and curvature ratio) are studied through the outputs of the GPM model. To ascertain the exact contribution of a given parameter in the HTC variations, for each scenario, all other relevant variables were maintained at fixed levels. Also, the selected ranges of operating conditions were subject to the availability of experimental data to validate the predictions of the models.

Figure 5 illustrates the impact of vapor quality and mass flow rate on the condensation HTC of R134a in a vertical helical tube. It is observed that the HTC is enhanced by increasing mass flow rate and vapor quality. This can be explained by the amplification of phases’ velocity difference, which leads to thinner liquid film and higher HTC. As seen, the GPM model correctly describes the HTC variations versus mass velocity and vapor quality, and its outcomes excellently agree with measured data.

Figure 6 compares the HTCs of R1234yf during condensation inside a horizontal helical tube at different saturation temperatures. The results reveal that the condensation HTC is declined by increasing the saturation temperature. In fact, a higher saturation temperature means an enhanced vapor density and a reduced liquid density. Consequently, the phases’ velocity difference and interfacial shear stress are dramatically decreased, which contributes to the decrease of the HTC. The proposed GPM model properly follows the overall trend, and predicts the corresponding data points with high accuracy.

Figure 7 demonstrates the effect of curvature ratio on the condensation HTC of R404A during flow inside a horizontal helical tube under constant conditions. It is obvious that increasing the curvature ratio results in higher HTC values, which can be justified by the growth of centrifugal force and secondary flow. On the other hand, the condensation HTC is enhanced by increasing the vapor quality. Indeed, the increase of vapor quality leads to a higher vapor velocity and lower liquid velocity. Hence, the velocity difference at the vapor–liquid interface is enhanced, and higher HTC values are obtained. As observed, the HTC values estimated by the GPM model have excellent consistency with the experimental samples, confirming the high accuracy of the model.

The influence of inclination angle on the condensation HTC of R600a in a helical tube has been illustrated in Fig. 8. Analysis of both experimental and predicted data reveals a non-monotonic relationship between the condensation HTC and the angle of inclination, showing a maximum value at 30 degrees. This peak efficiency at 30° aligns with those observed by Wang et al.74 for straight tubes. Their research indicated that the magnitude of interfacial turbulence and the development of waves are significantly amplified at this particular inclination angle. Furthermore, the influence of interfacial shear stress seems to outweigh that of gravitational forces in determining the HTC. The predictions of the new model appropriately describe the variations of the HTC versus inclination angle, and have good consistency with experimental results.

Sensitivity analysis

Knowledge regarding the sensitivity of the established models to each input feature can be useful for developing further predictive tools. Accordingly, the Pearson’s correlation factors (PCF) between input factors introduced in Eq. (21) and the outputs of the GPM model were calculated and the corresponding values have been depicted in Fig. 9. As observed, all selected dimensionless groups have great relationships with the Nusselt number. The factors that directly affect the Nusselt number are CR, Wev, Retp, and Y, while those with inverse correlation are Pred and Prtp. On the other hand, Retp, Wev, and Y are, respectively, the dominant factors governing the two-phase Nusselt number during condensation within helical tubes with absolute PCF values exceeding 0.4. The remaining dimensionless parameters, including Pred, CR and Prtp show slightly lower relevancies with the Nusselt number, and ranks fourth to sixth, respectively, in terms of importance. The observed order of importance of factors stems from the fact that the variables that directly govern the two-phase flow regime inside tubes, including Retp, Wev, and Y have a more pronounced effect on the HTC compared to the factors primarily relevant to the bulk fluid characteristics (e.g. Pred and Prtp) or tube size (e.g., CR). This occurs because the flow regime directly dictates the mechanisms of heat transfer. For instance, high Retp promotes turbulence, which disrupts the condensate film and enhances mixing, leading to a higher heat transfer coefficient. Higher Wev indicates greater inertial forces in the vapor phase which can promotes turbulence and mixing within the vapor phase near the liquid–vapor interface, thus enhancing mass and heat transfer to the condensate film. Additionally, an optimized inclination angle can remove the condensate film efficiently, promoting heat transfer. In contrast, changes in fluid properties (linked to Pred and Prtp) or tube geometry (CR) might influence the overall process, but their effects are often less direct and can be mediated by the flow regime itself.

Conclusions

In this study, two powerful ML tools, i.e., GPM and SVM were utilized to model the condensation HTC within smooth helical tubes of various flow directions. An extensive set of 563 experimental points, encompassing a wide spectrum of operating conditions, was compiled from literature. Both GPM and SVM models achieved excellent results with MAPEs of 3.36% and 5.86%, RRMSEs of 4.45% and 6.93%, and R2 values of 99% and 97.58%, respectively, for the testing data. In contrast, the literature correlations failed to accurately predict the condensation HTC in helical tubes, yielding MAPE values greater than 25%. The novel models also exhibited high accuracy for predicting the HTC at all flow directions. Additionally, they properly captured the physical variations of the condensation HTC with respect to operational parameters. Finally, according to the sensitivity analysis performed based on the ML models, Retp, Wev, and Y were the factors of greatest importance in controlling the two-phase Nusselt number.

Overall, the current study offered considerable improvements in predicting the condensation HTC inside smooth helical tubes through the development of robust models based on ML-based methods. The models presented in this study contribute to the efficient design of helical tubes heat exchangers. Further experimental investigations of condensation HTC inside helical tubes, using new working fluids and under broader operating conditions, are vital to confirm the generality and broad applicability of the presented models, and to modify them as needed. Also, the ML-based approaches can be utilized as robust tools for modeling the HTC inside other configurations of heat exchangers, including those with dimpled tubes, wire-inserted tubes, etc.

Data availability

The datasets used and/or analyzed during the current study have been provided as Supplementary Data S1.

Abbreviations

- CR:

-

Curvature ratio \(={D}_{t}/{D}_{c}\)

- \(D\) :

-

Diameter, m

- G :

-

Total mass flux, \(\text{kg}\,\text{m}^{-2}\,\text{s}^{-1}\)

- g:

-

Acceleration due to gravity, m \({\text{s}}^{-2}\)

- \(h\) :

-

Heat transfer coefficient, \(\text{W}\,\text{m}^{-2}\,\text{K}^{-1}\)

- \({J}_{g}\) :

-

Dimensionless vapor velocity, (–)

- k:

-

Thermal conductivity, \(\text{W}\,\text{m}^{-1}\,\text{K}^{-1}\)

- \(\text{Nu}\) :

-

Nusselt number = \({h}_{tp}{D}_{t} {k}_{l}^{-1}\), (–)

- \(P\) :

-

Pressure, Pa

- \(\text{Pr}\) :

-

Prandtl number, (–)

- \(\text{Re}\) :

-

Reynolds number, (–)

- \(\text{Su}\) :

-

Suratman number \(={\uprho \upsigma }{\text{D}}_{t}{\mu }^{-2}\), (–)

- \(T\) :

-

Temperature, \(^\circ{\text{C}}\)

- \(\text{We}\) :

-

Vapor Weber number = \({G}^{2} {D}_{t} {\rho }^{-1}{\sigma }^{-1}\), (–)

- \({X}_{tt}\) :

-

Martinelli parameter, (–)

- x:

-

Vapor quality, (–)

- Y:

-

Orientation factor \(=2+\text{sin}( \gamma )\), (–)

- \(\mu\) :

-

Dynamic viscosity, Pa s

- \(\rho\) :

-

Density, kg \(\text{m}^{-3}\)

- \(\sum\) :

-

Mathematical symbol for summation

- \(\sigma\) :

-

Surface tension, N \(\text{m}^{-1}\)

- \(\gamma\) :

-

Inclination angle of coil axis to horizontal, Degree (0 is horizontal and + 90 is vertical up flow)

- c:

-

Coil

- cr:

-

Critical

- Pre:

-

Predicted

- exp:

-

Experimental

- l :

-

Liquid

- red:

-

Reduced

- s:

-

Saturation condition

- t:

-

Tube

- \(tp\) :

-

Two-phase flow

- \(v\) :

-

Vapor

- GPM:

-

Gaussian process method

- HTC:

-

Heat transfer coefficient

- MAPE:

-

Mean absolute percentage error

- RRMSE:

-

Relative root mean squared error

- SVM:

-

Support vector machine

References

Sacasas, D., Vega, J., Cuevas, C., Menéndez, A. & Borrajo, R. An improved approach to model compressors, condenser/gas cooler and their control system in refrigeration systems with R404A and R744 based on physical principles. Int. J. Refrig. 153, 127–139 (2023).

Subba Rao, T. & Bera, S. Protective layer dissolution by chlorine and corrosion of aluminum brass condenser tubes of a nuclear power plant. Eng. Fail. Anal. 123, 105307 (2021).

Gao, X., Li, Y., Xia, Y. & Li, H. A review on thermo-fluidic study of droplets impact in spray cooling. Heat Transf. Res. https://doi.org/10.1615/heattransres.2024053386 (2024).

Qiu, G., Xue, Y., Yue, X., Liu, K. & Cai, W. Experimental study on condensing flow and heat transfer characteristics in minichannels under mechanical vibration conditions. Int. J. Heat Mass Transf. 236, 126274 (2025).

Patel, T., Parekh, A. D. & Tailor, P. R. Experimental analysis of condensation heat transfer and frictional pressure drop in a horizontal circular mini channel. Heat Mass Transf. und Stoffuebertragung 56, 1579–1600 (2020).

Türkakar, G., Okutucu-Özyurt, T. & Kandlikar, S. G. Entropy generation analysis of a microchannel-condenser for use in a vapor compression refrigeration cycle. Int. J. Refrig. 70, 71–83 (2016).

Qi, C., Chen, X., Wang, W., Miao, J. & Zhang, H. Experimental investigation on flow condensation heat transfer and pressure drop of nitrogen in horizontal tubes. Int. J. Heat Mass Transf. 132, 985–996 (2019).

Chen, J., Zhou, L., Ding, S. & Li, F. Numerical simulation of moored ships in level ice considering dynamic behavior of mooring cable. Mar. Struct. 99, 103716 (2025).

Wu, J. et al. Grooved-porous composite wick structures for highly efficient capillary-fed boiling heat transfer. Appl. Therm. Eng. 256, 124029 (2024).

Su, Y., Li, X. & Wu, X. Experimental investigation of subcooled flow boiling characteristics of water in vertical helically coiled tubes. Nucl. Eng. Des. 430, 113716 (2024).

Abdelmagied, M. Thermo-fluid characteristics and exergy analysis of a twisted tube helical coil. Sci. Rep. 14, 27873 (2024).

Sun, X. et al. Heat transfer augmentation, endothermic pyrolysis and surface coking of hydrocarbon fuel in manifold microchannels at a supercritical pressure. Int. Commun. Heat Mass Transf. 161, 108564 (2025).

Li, Y. et al. Nucleate boiling heat transfer and critical heat flux in controllable droplet trains cooling. Appl. Therm. Eng. 267, 125824 (2025).

Aroonrat, K. & Wongwises, S. Condensation heat transfer and pressure drop characteristics of R-134a flowing through dimpled tubes with different helical and dimpled pitches. Int. J. Heat Mass. Transf. 121, 620–631 (2018).

Mohammadzadeh, A. M., Jafari, B., Hosseinzadeh, K. & Paikar, E. Numerical investigation of segmental baffle design in shell and tube heat exchangers with varying inclination angles and spacing. Sci. Rep. 15, 4683 (2025).

Han, Y. et al. Coupled hydrodynamic lubrication and unbalanced magnetic force analysis in water-lubricated bearings for rim-driven thrusters. Phys. Fluids 37, 057103 (2025).

Cai, Y., Wei, J., Hou, Q., Fan, H. & Tijsseling, A. S. A Lagrangian particle model for one-dimensional transient pipe flow with moving boundary. Eng. Appl. Comput. Fluid Mech. 19, 2452360 (2025).

Al-Hajeri, M. H., Koluib, A. M., Mosaad, M. & Al-Kulaib, S. Heat transfer performance during condensation of R-134a inside helicoidal tubes. Energy Convers. Manag. 48, 2309–2315 (2007).

Shao, L., Han, J., Su, G. & Pan, J. Condensation heat transfer of R-134A in horizontal straight and helically coiled tube-in-tube heat exchangers. J. Hydrodyn. 19, 677–682 (2007).

Han, J. T., Lin, C. X. & Ebadian, M. A. Condensation heat transfer and pressure drop characteristics of R-134a in an annular helical pipe. Int. Commun. Heat Mass. Transf. 32, 1307–1316 (2005).

Salimpour, M. R., Shahmoradi, A. & Khoeini, D. Experimental study of condensation heat transfer of R-404A in helically coiled tubes. Int. J. Refrig. 74, 582–589 (2017).

Lin, C. X. & Ebadian, M. A. Condensation heat transfer and pressure drop of R134a in annular helicoidal pipe at different orientations. Int. J. Heat Mass. Transf. 50, 4256–4264 (2007).

Mozafari, M., Akhavan-Behabadi, M. A., Qobadi-Arfaee, H. & Fakoor-Pakdaman, M. Condensation and pressure drop characteristics of R600a in a helical tube-in-tube heat exchanger at different inclination angles. Appl. Therm. Eng. 90, 571–578 (2015).

Zakeralhoseini, S., Sajadi, B., Akhavan Behabadi, M. A., Azarhazin, S. & Fazelnia, H. Experimental investigation of the heat transfer coefficient and pressure drop of R1234yf during flow condensation in helically coiled tubes. Int. J. Therm. Sci. 157, 106516 (2020).

Wongwises, S. & Polsongkram, M. Condensation heat transfer and pressure drop of HFC-134a in a helically coiled concentric tube-in-tube heat exchanger. Int. J. Heat Mass Transf. 49, 4386–4398 (2006).

Gupta, A., Kumar, R. & Gupta, A. Condensation of R-134a inside a helically coiled tube-in-shell heat exchanger. Exp. Therm. Fluid Sci. 54, 279–289 (2014).

Solanki, A. K. & Kumar, R. Two-phase flow condensation heat transfer characteristic of R-600a inside the horizontal smooth and dimpled helical coiled tube in shell type heat exchanger. Int. J. Refrig. 107, 155–164 (2019).

El-Sayed Mosaad, M., Al-Hajeri, M., Al-Ajmi, R. & Koliub, A. M. Heat transfer and pressure drop of R-134a condensation in a coiled, double tube. Heat Mass Transf. und Stoffuebertragung 45, 1107–1115 (2009).

Yu, J., Jiang, Y., Cai, W., Li, X. & Zhu, Z. Condensation flow patterns and heat transfer correction for zeotropic hydrocarbon mixtures in a helically coiled tube. Int. J. Heat Mass. Transf. 143, 118500 (2019).

Neeraas, B. O. Condensation of Hydrocarbon mixtures in coil-wound LNG heat exchangers. Tube-side heat transfer and pressure drop. Nor. Inst. Technol. Trondheim 1993 (1993).

Mori, Y. & Nakayama, W. Study of forced convective heat transfer in curved pipes (2nd report, turbulent region). Int. J. Heat Mass Transf. 10, 37–59 (1967).

Cai, J., Wang, W., Guo, D., Yang, Q. & Yan, Q. Adaptive backstepping control for a class of nonlinear systems with output modeling error and external disturbance. Trans. Inst. Meas. Control https://doi.org/10.1177/01423312251318793 (2025).

Zhou, L., Sun, Q., Ding, S., Han, S. & Wang, A. A machine-learning-based method for ship propulsion power prediction in ice. J. Mar. Sci. Eng. 11, 1381 (2023).

Xiao, R., Chen, L., Hou, Y., Du, C. & Cai, Y. Experimental study on heat transfer behavior and prediction of heat transfer deterioration of supercritical nitrogen in vertical tubes. Int. Commun. Heat Mass Transf. 155, 107467 (2024).

Wang, L. et al. Study on mixed thermal-visco-hyerelastic hydrodynamic lubrication performance of water-lubricated rubber bearings in deep-sea environment. Tribol. Int. 209, 110713 (2025).

Wang, Z. et al. Analytical springback modelling for thermal-mechanical bending of TA18 tube under non-isothermal loading. Appl. Math. Model. 143, 115964 (2025).

Wang, K., Liu, X. & Wang, G. Self-scheduled direct thrust control for gas turbine engine based on EME approach with bounded parameter variation. Chin. J. Aeronaut. https://doi.org/10.1016/j.cja.2024.103392 (2025).

Zhai, C., Sui, Y. & Wu, W. Machine learning-assisted correlations of heat/mass transfer and pressure drop of microchannel membrane-based desorber/absorber for compact absorption cycles. Int. J. Heat Mass Transf. 214, 9136 (2023).

Wang, J. Optimizing support vector machine (SVM) by social spider optimization (SSO) for edge detection in colored images. Sci. Rep. 14, 9136 (2024).

Liu, M., Xu, N., Niu, B. & Alotaibi, N. D. Sliding-mode surface-based fixed-time adaptive critic tracking control for zero-sum game of switched nonlinear systems. Math. Comput. Simul. 229, 78–95 (2025).

Sun, H., Wang, Y., Jia, L., Lin, Z. & Yu, H. Theoretical and numerical methods for predicting the structural stiffness of unbonded flexible riser for deep-sea mining under axial tension and internal pressure. Ocean Eng. 310, 118672 (2024).

Vapnik, V. Statistical Learning Theory 97–106 (Wiley, New York, 1998). https://doi.org/10.1017/9781108938051.008.

Baghban, A., Bahadori, A., Mohammadi, A. H. & Behbahaninia, A. Prediction of CO2 loading capacities of aqueous solutions of absorbents using different computational schemes. Int. J. Greenh. Gas Control 57, 143–161 (2017).

Xu, N. et al. Prediction of higher heating value of coal based on gradient boosting regression tree model. Int. J. Coal Geol. 274, 104293 (2023).

Rafieezade, M. R. & Fazeli, A. Predicting the amino group pKa of amino acids using machine learning-QSPR methods. J. Mol. Liq. 408, 125355 (2024).

Zhang, C. et al. Mechanisms of bedding fracturing in the Junggar Basin, northwest China: Constraints from in situ U-Pb dating and C-O-Nd isotopic analysis of calcite cements. GSA Bull. https://doi.org/10.1130/B37973.1 (2025).

Jiang, X. et al. Advancing industrial data augmentation in AIGC Era: from foundations to frontier applications. IEEE Trans. Instrum. Meas. https://doi.org/10.1109/TIM.2025.3572162 (2025).

Yusuf, F., Olayiwola, T. & Afagwu, C. Application of Artificial Intelligence-based predictive methods in Ionic liquid studies: A review. Fluid Phase Equilib. 531, 112898 (2021).

Wang, T. & Su, C. H. Medium Gaussian SVM, Wide Neural Network and stepwise linear method in estimation of Lornoxicam pharmaceutical solubility in supercritical solvent. J. Mol. Liq. 349, 118120 (2022).

Parveen, N., Zaidi, S. & Danish, M. Development and analyses of data-driven models for predicting the bed depth profile of solids flowing in a rotary kiln. Adv. Powder Technol. 31, 678–694 (2020).

Wu, W., Zhao, N., Zhang, L. & Wu, Y. Approximation-based adaptive two-bit-triggered bipartite tracking control for nonlinear networked MASs subject to periodic disturbances. Robot. Intell. Autom. https://doi.org/10.1108/RIA-01-2024-0026 (2024).

Liu, S., Zhao, N., Zhang, L. & Xu, N. Adaptive neural hierarchical sliding mode control for uncertain switched underactuated nonlinear systems against unmodeled dynamics and input delay. Asian J. Control https://doi.org/10.1002/asjc.3528 (2024).

Wang, T., Niu, B., Xu, N. & Zhang, L. ADP-based online compensation hierarchical sliding-mode control for partially unknown switched nonlinear systems with actuator failures. ISA Trans. https://doi.org/10.1016/j.isatra.2024.09.011 (2024).

Li, Y. F., Zhao, W., Zhang, C., Ye, J. & He, H. A study on the prediction of service reliability of wireless telecommunication system via distribution regression. Reliab. Eng. Syst. Saf. 250, 110291 (2024).

Leco, M. & Kadirkamanathan, V. A perturbation signal based data-driven Gaussian process regression model for in-process part quality prediction in robotic countersinking operations. Robot. Comput. Integr. Manuf. 71, 102105 (2021).

Wei, F., Xu, N., Zhao, X., Li, L. & Al-Barakati, A. A. Dynamic memory event-triggered adaptive neural prescribed-time bipartite consensus control for high-order MASs with privacy preservation. Commun. Nonlinear Sci. Numer. Simul. 145, 108693 (2025).

Wang, Y. et al. Identification of human microRNA-disease association via low-rank approximation-based link propagation and multiple kernel learning. Front. Comput. Sci. 18, 182903 (2024).

Wang, H., Li, Y. F., Men, T. & Li, L. Physically interpretable wavelet-guided networks with dynamic frequency decomposition for machine intelligence fault prediction. IEEE Trans. Syst. Man Cybern. Syst. 54, 4863–4875 (2024).

Kumar, P. S., Kumaraswamidhas, L. A. & Laha, S. K. Selection of efficient degradation features for rolling element bearing prognosis using Gaussian Process Regression method. ISA Trans. 112, 386–401 (2021).

Wu, Y., Liang, H., Zhao, N. & Niu, B. Low-computation-based adaptive self-triggered bipartite consensus control for nonlinear multi-agent systems subject to sensor faults. IEEE Trans. Control Netw. Syst. https://doi.org/10.1109/TCNS.2024.3373132 (2024).

Wu, X., Zong, G., Wang, H., Niu, B. & Zhao, X. Collision-free distributed adaptive resilient formation control for underactuated USVs subject to intermittent actuator faults and denial-of-service attacks. IEEE Trans. Veh. Technol. https://doi.org/10.1109/TVT.2025.3565820 (2025).

Mahdaviara, M., Rostami, A., Keivanimehr, F. & Shahbazi, K. Accurate determination of permeability in carbonate reservoirs using Gaussian Process Regression. J. Pet. Sci. Eng. 196, 107807 (2021).

Safaei-Farouji, M. et al. Application of robust intelligent schemes for accurate modelling interfacial tension of CO2 brine systems: Implications for structural CO2 trapping. Fuel 319, 123821 (2022).

Lu, Y. et al. Reliability estimation method based on nonlinear Tweedie exponential dispersion process and evidential reasoning rule. Comput. Ind. Eng. 206, 111205 (2025).

Li, Z., Hong, X., Hao, K., Chen, L. & Huang, B. Gaussian process regression with heteroscedastic noises—A machine-learning predictive variance approach. Chem. Eng. Res. Des. 157, 162–173 (2020).

Wu, X. et al. Dual-channel event-triggered prescribed performance adaptive fuzzy time-varying formation tracking control for nonlinear multi-agent systems. Fuzzy Sets Syst. 498, 109140 (2025).

Abrantes, R. J. E., Mao, Y. W. & Ren, D. D. W. Rate coefficient function estimation using Gaussian process regression. J. Quant. Spectrosc. Radiat. Transf. 283, 108134 (2022).

Lemmon, E. W., Huber, M. L. & McLinden, M. O. Reference fluid thermodynamic and transport properties – REFPROP. NIST. at (2013).

Yu, J. et al. Experimental investigation of forced convective condensation heat transfer of hydrocarbon refrigerant in a helical tube. Appl. Therm. Eng. 129, 1634–1644 (2018).

Solanki, A. K. & Kumar, R. Condensation of R-134a inside dimpled helically coiled tube-in-shell type heat exchanger. Appl. Therm. Eng. 129, 535–548 (2018).

Chen, J. et al. Closed-loop plasma flow control of a turbulent cylinder wake flow using machine learning at Reynolds number of 28 000. Phys. Fluids 36, 015123 (2024).

Sun, W. et al. Study on interaction mechanism between natural convection and forced convection during storage and temperature rise of waxy crude oil tank. Eng. Appl. Comput. Fluid Mech. 19, 2498354 (2025).

Baghban, A., Sasanipour, J. & Zhang, Z. A new chemical structure-based model to estimate solid compound solubility in supercritical CO2. J. CO2 Util. 26, 262–270 (2018).

Wang, W. C., Ma, X. H., Wei, Z. D. & Yu, P. Two-phase flow patterns and transition characteristics for in-tube condensation with different surface inclinations. Int. J. Heat Mass Transf. 41, 4341–4349 (1998).

Author information

Authors and Affiliations

Contributions

Chou-Yi Hsu: Project administration, Data curation, Software, Investigation, Writing—review & editing. Nikunj Rachchh: Conceptualization, Methodology, Writing—original draft. Ramachandran T: Formal analysis, Methodology, Writing—original draft. Aman Shankhyan: Investigation, Data curation, Validation. KARTHIKEYAN A: Methodology, Validation, Writing—review & editing. Ahmad Alkhayyat: Data curation, Supervision, Validation. Prabhat Kumar Sahu: Methodology, Supervision, Writing—review & editing. Abhinav Kumar: Conceptualization, Writing—original draft, Validation. Satvik Vats: Software, Validation, Visualization. Fereydoon Ranjbar: Data curation, Methodology, Writing—review & editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Using AI-based tools in the writing process

During the preparation of the current study, the authors have used AI-based tools for enhancing the fluency, and solving the grammatical/typographical issues of the context. After using these tools/services, the authors have reviewed and edited the content, as needed, and take full responsibility for the content of the publication.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Hsu, CY., Rachchh, N., Ramachandran, T. et al. Reliable models for calculating the condensation heat transfer inside smooth helical tubes of different flow directions utilizing smart computational techniques. Sci Rep 15, 30454 (2025). https://doi.org/10.1038/s41598-025-15240-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-15240-0