Abstract

The mechanical behavior of prosthetic liners significantly influences stress distribution, soft tissue protection, and the overall efficiency of the prosthetic. While extensive research has been conducted on liner materials, the impact of liner thickness (2 mm, 4 mm, and 6 mm) on biomechanical response remains underexplored. This study utilizes finite element analysis in Abaqus to investigate how liner material (Gel vs. Silicone) and thickness affect contact pressure (CPRESS), maximum principal strain (Le. Max), shear stress (CSHEAR1), and vertical displacement (U3) at the residual limb-liner interface. A three-dimensional numerical model was developed to simulate stress transmission and displacement behavior under physiological loading conditions. The results demonstrate that liner thickness plays a critical role in modulating pressure distribution and mechanical stability, with Gel providing superior flexibility and shock absorption, whereas Silicone offers enhanced structural integrity. At a thickness of 2 mm, the highest pressure of 0.4656 MPa is recorded. When the thickness is increased to 4 mm, the pressure decreases to 0.4153 MPa, reflecting a reduction of approximately 10.8%. Further increasing the thickness to 6 mm results in a pressure drop of 0.3825 MPa, corresponding to a total reduction of 17.9%. These findings provide quantitative insights into stress attenuation mechanisms, contributing to the optimization of prosthetic liner design for improved clinical outcomes in lower-limb amputees.

Similar content being viewed by others

Introduction

Prosthetic liners serve as a critical interface between the residual limb and the socket, playing a fundamental role in load distribution, pressure mitigation, and user comfort1. Their mechanical properties, particularly material composition and thickness, directly influence stress transmission, protection of soft tissue, and overall prosthetic functionality2. While gel liners are recognized for their superior shock absorption and flexibility, silicone liners offer enhanced durability and compressive resistance, making material selection a key factor in optimizing prosthetic performance3. Despite extensive research on prosthetic liners, the influence of liner thickness on stress distribution remains inadequately explored, particularly in terms of mechanical stability and load transmission efficiency4. Previous studies have primarily focused on material characterization, leaving a research gap concerning how different liner thicknesses (2 mm, 4 mm, and 6 mm) affect contact pressure, stress distribution, and limb displacement5. Understanding these biomechanical interactions is crucial for enhancing prosthetic liner design and improving clinical outcomes for individuals with lower-limb amputations. To address this gap, the present study employs finite element analysis (FEA) in Abaqus to evaluate the effects of liner thickness and material composition (Gel vs. Silicone) on contact pressure (CPRESS), maximum principal strain (Le. Max), shear stress (CSHEAR1), and vertical displacement (U3)7. By quantifying these parameters, the study provides valuable insights into the mechanical behavior of different liner configurations, contributing to the optimization of liner selection in lower-limb prosthetic applications. Before presenting the methodology and results, it is essential to review the current state of the art to contextualize the study within existing literature. The interface between the residual limb and the prosthetic socket has been the subject of extensive biomechanical analysis, with particular attention to the role of liner materials and thickness in stress distribution and user comfort. Sahli et al.8 investigated the effect of personalized liner thickness and confirmed that increasing thickness helps reduce both pressure and shear stress at the limb/socket interface. However, their study did not include very thin liners such as 2 mm, leaving room for further exploration in this range. Rodrigues and Da Gama9 focused on material influence, demonstrating that softer liners, such as silicone, are more effective at reducing maximum principal stress than firmer ones, due to their superior capacity to conform to the residual limb geometry. Similarly, Narimen et al.10 demonstrated that a 6 mm liner improves stress distribution, although stress concentration points may persist. Boudjemaa et al.11 introduced a multi-layer prosthetic foam liner design, finding it capable of distributing pressure more uniformly across the interface, thereby emphasizing the advantages of material layering strategies. In a dynamic context, Henao et al.12 analyzed stress behavior under gait cycle loading, revealing that shear stress can increase by up to 23% during walking compared to standing. This highlights the importance of materials that can adapt to varying load conditions. Finally, Messaad et al.13 conducted a finite element analysis on different liner materials under dynamic loads. They concluded that both the material type and structural design critically influence biomechanical performance and comfort. In summary, the literature underscores the importance of optimizing both the material properties and the thickness of prosthetic liners to improve stress attenuation, user comfort, and interface performance under both static and dynamic conditions. Safari14 concluded that future prosthetic sockets integrating sensing, monitoring, and actuator technologies will likely be fabricated through a fully automated, patient-specific, and data-driven process. This approach will leverage advanced computer modeling, accurate quantification of residual limb geometry and mechanical properties, artificial intelligence, and simulation techniques to optimize performance and user comfort. Abbood15 studied the highlights of the critical impact of thermal conditions on prosthetic comfort and function. Excessive heat and perspiration inside the socket often lead to discomfort, reducing the user’s quality of life and potentially affecting physical, mental, and emotional well-being.

In addition to the above-mentioned studies, numerous investigations have utilized the finite element method to address biomedical problems and presented their findings in the literature. Examining these researches will provide readers with a more comprehensive perspective on the content of this study16,17,18,19,20,21,22. Tanriverdi et al.23 focused on prosthetic limbs as the first application of Roliner. Roliner is made of silicone elastomers with embedded millifluidic channels that can be pneumatically pressurized. Osama et al.24 presented a method of stereolithography that made a significant difference in prosthetic limbs, due to the flexibility within the provided parameters. The designed leg weighs 4 kg approx. The whole weight acts on the sole of the leg. The sole once more experienced a SolidWorks simulation with the application of a 1200N stack. The preferred fabric, TPU, was selected after considering all the components. Gailey et al.25 reported that over 42% of transfemoral amputees wearing liners of ≤ 4 mm thickness experienced issues such as skin breakdown, pressure ulcers, and localized discomfort, particularly in pressure-tolerant zones, including the posterior aspect of the residual limb. Clinical evidence highlights that transfemoral amputees using prosthetic liners thinner than 6 mm face a significantly increased risk of pressure-related complications.

These limitations highlight the need for more sophisticated, realistic, and comprehensive FE models, such as the one proposed in this study, which considers different liner materials and thicknesses, advanced contact mechanics, and loading conditions to simulate real-world prosthetic behavior more accurately.

A three-dimensional finite element model (FEM) was developed to simulate stress transmission and displacement behavior under physiological loading conditions.

This study aims to analyze the influence of the coating material (gel or silicone) and its thickness on the contact pressure (CPRESS), maximum principal strain (Le. Max), shear stress (CSHEAR1), and vertical displacement (U3) at the residual member-coating interface.

Methodology

This study employed the finite element method using Abaqus software to compare the mechanical behaviors of different liners in a transfemoral amputated lower limb. The finite element method has proven itself in many areas and has become a method that can yield results as accurate as those obtained from experimental studies. It is a handy tool for researchers, especially in engineering26,27,28,29, medical sciences30,31,32,33, material sciences34,35, and nanoscale studies36,37.

Geometrical model design

The three-dimensional models were developed based on computed tomography (CT) scan data and magnetic resonance imaging (MRI) of the residual limb to ensure anatomical accuracy. The CT scan employed a slice increment of approximately 1 mm with a [512 × 512] pixel matrix, and the scanning was conducted while the patient was not wearing a prosthesis. The CT scanner operated at a power level of 80 kW. The medical images were processed using 3D Slicer, allowing the extraction of the geometric structure of muscles and bones. Subsequently, the external shape of the limb was reconstructed in Autodesk Meshmixer, where the liner and socket were adapted to the residual limb’s geometry. This step ensures that the liner conforms precisely to the anatomical shape of the limb.

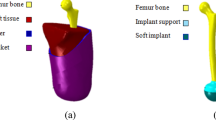

To enhance geometric precision and ensure compatibility with numerical analysis, the models were converted into NURBS surfaces using Geomagic Design X, enabling smooth surface representation and export in IGES format for further simulations. The final model, illustrated in Fig. 1, consists of three main components: bone, muscle, and the liner enclosed within the external socket. This study focuses on evaluating the effect of liner thickness variation on mechanical performance while maintaining all other components unchanged to ensure accurate comparison.

Design of models with different liner thicknesses

To analyze the mechanical response of prosthetic liners, three geometrical models were developed, each featuring a different liner thickness (2 mm, 4 mm, and 6 mm). Since the liner is positioned between the residual limb and the socket, any change in liner thickness directly affects the socket’s internal geometry, requiring a corresponding adjustment in socket dimensions to maintain proper fit and alignment.

As illustrated in Fig. 2, the three models highlight the variations in liner thickness and the associated modifications in socket geometry. This ensures that each model accurately represents the realistic interaction between the liner, socket, and residual limb, allowing for a precise evaluation of stress distribution and mechanical performance.

Mechanical properties

The mechanical properties of materials used in prosthetic limbs play a fundamental role in enhancing liner compatibility with the residual limb and mitigating undesirable mechanical stresses. In this study, four primary components were analyzed: Bone, Muscle, Liner, and Socket. Each component was assigned a mechanical model tailored to its specific response under varying loading conditions.

Bone was modelled as a linear elastic material due to its inherent stiffness and its critical role as a load-bearing structure, which allows for effective load distribution. Similarly, muscle was modeled as a linear elastic material38,39, following a widely accepted assumption in previous finite element studies concerning the residual limb. The socket, typically composed of carbon fiber or acrylic resin, was also considered linear elastic, as its rigidity is essential for ensuring the prosthetic limb’s structural integrity.

The liner, which serves as the primary interface between the residual limb and the socket, was analyzed using two distinct materials, selected based on their mechanical properties and their influence on the interaction between the liner and the residual limb. The gel liner is modeled as a linear elastic material, with its properties derived from established literature. In contrast, the silicone liner is characterized using a first-order Ogden model, with its material parameters obtained from experimentally validated sources.

The parameters given in Table 1 included the initial shear modulus (μ₁), the Ogden exponent (α₁), and the compressibility parameter (D1), which collectively define the material’s Hyperelastic response.

Mesh generation

The numerical mesh for the model was generated using tetrahedral elements (C3D4), which are well-suited for three-dimensional finite element analysis (FEA). A uniform element size of 5 mm was adopted for all model components to achieve an optimal balance between numerical accuracy and computational efficiency. The model consists of four main components: muscle, bone, liner, and socket. The meshing strategy is designed to ensure a homogeneous distribution of elements, particularly in contact regions between different components, to maintain computational stability.

The effect of liner thickness on the residual limb was studied by analyzing three different models with thicknesses of 2 mm, 4 mm, and 6 mm, while keeping all other parameters constant to ensure an objective comparison. The specific mesh details for each model component, including the number of elements, element type, and element size, are summarized in Table 2.

To provide a visual representation of the generated mesh, Fig. 3 illustrates the finite element mesh for each component, highlighting the structured distribution of elements across the bone, muscle, liner, and socket. This structured mesh ensures stability in contact interactions and enhances the accuracy of stress and displacement calculations.

Mesh convergence analysis

The mesh convergence curve in Fig. 4 provides a comprehensive evaluation of the relationship between element size and CPRESS values, offering a critical assessment of numerical accuracy.

As observed, CPRESS values exhibit significant variations at larger element sizes, indicating computational instability. However, as the mesh is refined, these variations decrease, and numerical stability is achieved around 300,000 elements.

At an element size of 5 mm, CPRESS reaches 435,772 elements. Marking a convergence threshold where further refinement does not introduce significant changes. This finding confirms that 5 mm is the optimal element size, striking a balance between computational cost and numerical precision.

To ensure reliability and reproducibility, this mesh configuration was consistently applied across all simulations involving the liner model with a thickness of 6 mm for both Gel and Silicone materials.

Boundary and loading conditions

A static vertical load of 400 N, representing half of the patient’s body weight, was applied to the proximal end of the femur to simulate weight-bearing during the stance phase of gait11,44. The distal end of the prosthetic socket was fully constrained to prevent any displacement or rotation40,45.

The interaction between the residual limb and the liner was modeled using a surface-to-surface contact formulation with a friction coefficient of 0.5, as reported in previous studies41. Full contact between the liner and the residual limb was assumed to simulate realistic conditions46.

As shown in Fig. 5, the model incorporates boundary and loading conditions, including the applied vertical load, fixed constraints, and interaction between the prosthetic components.

Results and discussion

Effect of liner thickness on contact pressure (CPRES)

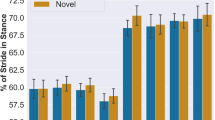

The results indicate that as the thickness of the Gel liner increases, the contact pressure (CPRESS) at the residual limb/socket interface decreases. At a thickness of 2 mm, the pressure reaches 0.4656 MPa, the highest recorded value. Increasing the thickness to 4 mm results in a decrease to 0.4153 MPa, representing a 10.8% reduction. At 6 mm, the pressure further drops to 0.3825 MPa, totaling a 17.9% decrease compared to the 2 mm liner.

As observed in Fig. 6, the contour plot highlights that thinner Gel liners (2 mm) exhibit higher stress concentrations, particularly in localized regions. When the thickness increases to 4 mm, the stress intensity reduces slightly, but some high-pressure areas remain visible. At 6 mm, stress becomes more evenly distributed. However Gel still exhibits higher pressure levels compared to Silicone, confirming its tendency to retain more pressure. The Silicone liner exhibits a more substantial reduction in CPRESS with increasing thickness, as also seen in Fig. 6. At a thickness of 2 mm, the contact pressure is 0.1936 MPa, significantly lower than that of the Gel.

When the thickness increases to 4 mm, the pressure drops to 0.1128 MPa, a 41.7% reduction. At 6 mm, the pressure further decreases to 0.0850 MPa, representing a 56.1% reduction in total pressure compared to the 2 mm thickness. These findings confirm that CPRESS levels are influenced by liner material and thickness. Silicone consistently exhibits lower CPRESS values than Gel, demonstrating a superior ability to distribute stress effectively. To illustrate these differences, Fig. 7 presents Histograms comparing CPRESS values for each material and liner thickness. The Histograms reinforce the trends observed in Fig. 6, showing that Gel retains higher contact pressure than Silicone at all thicknesses. At the same time, Silicone achieves a greater reduction in CPRESS values.

Effect of liner thickness on maximum principal strain (Le. Max)

The results indicate that the Le. Max values for Gel remain consistently higher across all thicknesses, suggesting a tendency for greater stress accumulation compared to Silicone. At lower thickness levels, Gel exhibits high stress concentrations, which decrease slightly as the thickness increases.

As observed in Fig. 8, the contour plot highlights intense strain regions in the 2 mm Gel liner. When the thickness increases to 4 mm, the high-strain areas become less concentrated, but localized stress peaks are still visible. At 6 mm, the stress distribution improves further, yet Gel retains higher strain levels than Silicone, confirming its tendency for stress accumulation.

The Silicone liner exhibits significantly lower Le. Max values at every thickness level, demonstrating better load distribution properties. At a thickness of 2 mm, the strain values are already significantly lower than those of the Gel.

As shown in Fig. 8, the contour plot for Silicone illustrates a more uniform strain distribution even at lower thicknesses. Increasing the thickness to 4 mm and 6 mm results in further reductions in peak stress, with the 6 mm Silicone liner achieving the most uniform distribution and the lowest stress concentrations. This confirms that Silicone provides superior stress management compared to Gel.

These findings confirm that the maximum principal strain (Le. Max) is highly dependent on both the liner material and its thickness. The contour plot (Fig. 8) visually represents stress distribution, showing that Gel liners exhibit more concentrated stress regions, while Silicone provides a more uniform load distribution.

To emphasize these trends, Fig. 9 presents a Histograms comparing Le. Max values for each material and liner thickness. The Histograms reinforce the contour plot findings, demonstrating that Gel maintains higher stress levels than Silicone across all thicknesses. This analysis underlines the superior performance of Silicone in strain distribution and its advantage in minimizing strain accumulation.

Effect of liner thickness on shear stress (CSHEAR1)

The results indicate that the CSHEAR1 values for Gel remain consistently higher across all thicknesses, suggesting a tendency for greater stress accumulation compared to Silicone. At a thickness of 2 mm, the Gel exhibits the highest shear stress concentrations, indicating localized areas of high stress. Increasing the thickness to 4 mm results in a reduction of peak stress, while at 6 mm, the stress distribution improves further.

As observed in Fig. 10, the contour plot highlights intense shear stress regions in the 2 mm Gel liner, particularly in localized high-stress zones. As the thickness increases to 4 mm, the stress distribution becomes slightly more uniform; however some areas of elevated stress remain. At 6 mm, while the stress further decreases, Gel still exhibits higher shear stress levels compared to Silicone. The Silicone liner demonstrates a more effective reduction in CSHEAR1 compared to Gel, as also seen in Fig. 10. At a thickness of 2 mm, the stress values are already significantly lower than in Gel. When the thickness is increased to 4 mm, the stress levels drop further, and at 6 mm, the stress distribution becomes highly uniform with minimal high-stress areas. This confirms that Silicone provides superior shear stress management, ensuring a more even load distribution across all thickness levels. These findings confirm that shear stress (CSHEAR1) levels are highly dependent on both liner material and thickness. The contour plot (Fig. 10) visually represents shear stress distribution, clearly showing that Gel liners exhibit more concentrated stress regions. In contrast, Silicone ensures a more uniform stress spread.

To further emphasize these differences, Fig. 11 presents a bar chart comparing CSHEAR1 values for each material and liner thickness. The bar chart reinforces the trends observed in Fig. 10, demonstrating that Gel maintains higher shear stress levels than Silicone across all thicknesses. This analysis further highlights the advantage of Silicone in reducing shear stress accumulation.

Effect of liner thickness on vertical displacement (U3)

The results indicate that the U3 values for the Gel liner increase consistently as thickness increases. At 2 mm, the displacement is minimal; however, as the thickness reaches 6 mm, there is a significant increase in U3. This trend suggests that a thicker Gel liner allows for greater vertical movement, which may contribute to improved shock absorption but could also lead to reduced control of the limb inside the prosthetic socket.

As observed in Fig. 12, the contour plot highlights that thinner Gel liners (2 mm) exhibit lower displacement, indicating more stability. However, as thickness increases to 4 mm and 6 mm, the U3 values rise, showing increased vertical movement. This confirms that Gel liners provide controlled deformation, but with higher thicknesses, the displacement becomes more pronounced.

The Silicone liner exhibits significantly higher U3 values at every thickness level compared to the Gel liner, indicating that it undergoes greater deformation under load. The difference between the two materials becomes more pronounced as the thickness increases, reinforcing the role of material compliance in determining displacement behavior.

As shown in Fig. 12, the Silicone liner experiences higher U3 values than Gel at all thickness levels. The 2 mm Silicone liner already shows more displacement, while at 6 mm, the increase is much more significant. This confirms that Silicone provides superior flexibility and shock absorption, but may lead to reduced prosthetic stability compared to Gel.

The results confirm that U3 displacement is significantly influenced by both liner thickness and material properties. Silicone consistently exhibits higher U3 values than Gel, indicating that it deforms more underload, which enhances shock absorption but may lead to prosthetic instability. Conversely, Gel exhibits lower U3 values, indicating that it provides better stability and less deformation for shock absorption.

To illustrate these differences, Fig. 13 presents Histograms comparing U3 values for each material and liner thickness. The Histograms reinforce the trends observed in Fig. 12, demonstrating that thicker liners allow greater vertical displacement, but the effect is more significant in softer materials such as Silicone.

Comparison with experimental studies

The results of this study align with previous research, particularly the experimental study by Boutwell et al.1, which demonstrated that increasing the thickness of the gel liner reduces contact pressure (CPRESS) at the residual limb interface. Both studies confirm that increased liner thickness leads to a decrease in CPRESS, enhancing pressure distribution and reducing localized stress. This study extends previous research by providing a comprehensive analysis of gel liner thicknesses that have not been previously examined, thereby offering a deeper understanding of their impact on stress distribution. These findings complement existing literature and contribute valuable insights for optimizing prosthetic liner design. A comparison of the results of this study with existing literature data is presented in Table 3.

Comparison with finite element (FE) studies

The mechanical response of different liner thicknesses is quantitatively assessed in Table 4, which presents a comparative analysis of CPRESS, CSHEAR1, and U3 between the current study and the findings of Sahli et al.8

The findings confirm that increasing liner thickness reduces pressure and shear stress while increasing vertical displacement, aligning with the results from Sahli et al.8. However, the numerical values in the current study are significantly higher, which may be attributed to differences in material properties, friction coefficients, or load modeling.

The absence of data at 2 mm in Sahli et al.8 allows the current results to provide additional insight into the effects of this thickness, enhancing the scientific framework for comparison and supporting the development of improved liner designs that offer greater comfort for users.

Limitations

Despite the relevance of the findings, several limitations must be acknowledged. The bone tissue was modeled as a single linear-elastic isotropic material, disregarding the distinct mechanical behavior of trabecular and cortical bone, as well as their inherent non-linear and orthotropic characteristics. This simplification, though common in some studies, may affect the accuracy of stress and strain predictions. Additionally, boundary conditions were limited to a static weight-bearing stance phase, although dynamic and parafunctional loading scenarios were discussed in the introduction, leaving out critical loading variations. The liner design was not based on a commercial catalog nor validated experimentally, which raises concerns about reproducibility. Furthermore, the lack of comparison with experimental or previously published numerical results, particularly regarding the mechanical response of gel and silicone materials, restricts the validation and generalizability of the model. These limitations suggest that while the study offers valuable insights, further refinement is necessary to enhance its clinical and biomechanical applicability.

Conclusion

This study investigated the mechanical response of different liner thicknesses (2 mm, 4 mm, and 6 mm) and material types (Gel vs. Silicone) in transfemoral prosthetic applications using finite element analysis (FEA) in Abaqus. A three-dimensional numerical model was developed to analyze the effects of liner thickness and material on key mechanical parameters, including contact pressure (CPRESS), maximum principal strain (Le. Max), shear stress (CSHEAR1), and vertical displacement (U3).

-

The results demonstrated that increasing liner thickness significantly reduces contact pressure and stress concentrations, leading to improved load distribution at the residual limb-liner interface.

-

However, this reduction is accompanied by an increase in vertical displacement (U3), indicating a potential trade-off between stress attenuation and prosthetic stability.

-

Furthermore, material selection plays a critical role in mechanical performance. Silicone liners consistently exhibited lower stress values and superior load distribution compared to Gel liners, confirming their greater efficiency in reducing peak pressures and enhancing mechanical stability. In contrast, Gel liners, while offering greater flexibility, showed higher stress concentrations and increased displacement, which may affect long-term comfort and control.

-

These insights emphasize the necessity of optimizing liner selection based on both mechanical performance and clinical considerations, ensuring an optimal balance between load distribution, comfort, and prosthetic functionality.

Future research should explore nonlinear material properties, dynamic loading conditions, and subject-specific geometries to enhance model accuracy and applicability. Additionally, experimental validation remains crucial for further refining the numerical predictions and improving prosthetic liner design for transfemoral amputees.

Data availability

No datasets were generated or analysed during the current study.

References

Boutwell, E., Stine, R., Hansen, A., Tucker, K. & Gard, S. Effect of prosthetic gel liner thickness on gait biomechanics and pressure distribution within the transtibial socket. J. Rehabil. Res. Dev. 49(2), 227–240 (2012).

Bertolini, M., Moreschini, C., Siffredi, P., Colombo, G. & Rossoni, M. Finite element analysis of the donning phase of a prosthetic socket for transfemoral amputees. In Advances in Digital Human Modeling DHM 2023 Lecture Notes in Networks and Systems Vol. 744 (eds Scataglini, S. et al.) (Springer, 2023). https://doi.org/10.1007/978-3-031-37848-5_1.

Ragolta, C.I. & Morford, M. Novel materials for prosthetic liners. NASA Kennedy Space Center. https://ntrs.nasa.gov/api/citations/20110016246/downloads/20110016246.pdf (2011).

Lagan, S. & Liber-Kneć, A. The determination of mechanical properties of prosthetic liners through experimental and constitutive modelling approaches. Tech. Trans. 3, 197–209 (2018).

Ali, I., Kumar, R. & Singh, Y. Finite element modelling and analysis of trans-tibial prosthetic socket. Glob. J. Res. Eng. 14, 42–50 (2014).

Yang, X. et al. Material, design, and fabrication of custom prosthetic liners for lower-extremity amputees: A review. Med. Nov. Technol. Devices. 17, 100197 (2023).

Konada, N. K. & Sai, S. K. N. Finite element analysis on prosthetic leg under different loads and flexion angles for medical applications. J. Mech. Energy Eng. 6(2), 295–310 (2022).

Sahli, A. et al. Effect of personalized liner thickness on the stresses at the stump-prosthesis interface. Mech. Adv. Mater. Struct. 31(12), 2703–2711 (2023).

Rodrigues, P. & Da Gama, A. Material influence on stress distribution in prosthetic liners: A finite element study. Biomech. Biomed. Eng. 29(4), 321–335 (2022).

Narimen, B., El Sallah, Z. M., Abdelmadjid, M., Abdelghani, B. & Ismail, B. Comparative study of a femoral amputated limb with and without implant. Mech. Adv. Mater. Struct. https://doi.org/10.1080/15376494.2024.2414205 (2024).

Boudjemaa, I., Sahli, A., Benkhettou, A. & Benbarek, S. Effect of multi-layer prosthetic foam liner on the stresses at the stump–prosthetic interface. Frat Integrita Strut. 15(56), 187–194 (2021).

Henao, S. C., Orozco, C. & Ramírez, J. Influence of gait cycle loads on stress distribution at the residual limb/socket interface of transfemoral amputees: A finite element analysis. Sci. Rep. 10(1), 1–11 (2020).

Messaad, T. Finite element analysis of prosthetic liner materials for transfemoral amputees: Biomechanical behavior under dynamic loads. Preprint at https://doi.org/10.21203/rs.3.rs-4804207/v1 (2024).

Safari, R. Lower limb prosthetic interfaces: Clinical and technological advancement and potential future direction. Prosthet. Orthot. Int. 44(6), 384–401 (2020).

Abbood, S. A., Wu, Z. & Sundén, B. Thermal assessment for prostheses: State-of-the-art review. Int. J. Comput. Methods Exp. Meas. 5(1), 1–12 (2017).

Güvercin, Y., Abdioğlu, A. A., Dizdar, A., Uzun Yaylacı, E. & Yaylacı, M. Suture button fixation method used in the treatment of syndesmosis injury: A biomechanical analysis of the effect of the placement of the button on the distal tibiofibular joint in the mid-stance phase with finite elements method. Injury 53(7), 2437–2445 (2022).

Güvercin, Y. et al. Biomechanical analysis and solution suggestions of screw replacement scenarios in femoral neck fracture surgeries: Finite element method. Orthop. Surg. 17(2), 614–623 (2025).

Yemenoglu, H. et al. Evaluation of prostheses retained zygomatic and dental implants in large defects in the maxilla due to tumors or major trauma by biomechanical 3-dimensional finite element analysis. BMC Oral Health 25, 99 (2025).

Benouis, A. et al. Finite element analysis of the behavior of elliptical cracks emanating from the orthopedic cement interface in total hip prostheses. Struct. Eng. Mech. 89(5), 539–547 (2024).

Javali, M. A. et al. Comparative analysis of occlusal stresses on bone around natural teeth, platform matched and switched implants abutments: A finite element study. Sci. Rep. 15, 19541 (2025).

Sun, Y. et al. Finite-element analysis of different fixation types after Enneking II + III pelvic tumor resection. Sci. Rep. 14, 20878 (2024).

Pei, X. et al. Biomechanical performance evaluation of S2AI combine with LC-2 screw for day II pelvic crescent fracture dislocation via finite element analysis. Sci. Rep. 15, 16765 (2025).

Tanriverdi, U. et al. Dynamically adaptive soft metamaterial for wearable human–machine interfaces. Nat. Commun. 16(1), 2621 (2025).

Osama, M., & Allauddin, U. Design and modelling of lower prosthetic limb for additive manufacturing. In IMEC-2022: 11th International Mechanical Engineering Conference 27 (2022).

Gailey, J. A. Attribution of responsibility for organizational wrongdoing: A partial test of an integrated model. J. Criminol. 2013(1), 920484 (2013).

Yaylacı, M. et al. Examining the contact problem of a functionally graded layer supported by an elastic half-plane with the analytical and numerical methods. Math. Methods Appl. Sci. 47(12), 10400–10420 (2024).

Ye, X. et al. Finite element analysis for pullout resistance and progressive failure of strip anchors in strain softening marine soils. Sci. Rep. 15, 5543 (2025).

Chen, X. et al. Finite element analysis of flexural performance of reinforced truss hollow composite concrete slabs. Sci. Rep. 15, 7057 (2025).

Ouchen, L. et al. A finite element with statistical analysis study to investigate the electrical performance of composite insulators under water droplet impact. Sci. Rep. 15, 7364 (2025).

Güvercin, Y. et al. Biomechanical analysis of odontoid and transverse atlantal ligament in humans with ponticulus posticus variation under different loading conditions: Finite element study. Injury 53(12), 3879–3886 (2022).

Zhang, L. et al. Finite element analysis of pedicle screw fixation biomechanics and adjacent segment degeneration in varied bone conditions. Sci. Rep. 15, 19047 (2025).

Mehta, A. et al. Finite element study of the efficacy of three different loops for bodily protraction of the mandibular molar. Sci. Rep. 15, 13938 (2025).

Ng, B. et al. Finite element analysis and clinical evaluation of cross locking external fixator configuration for distal third tibia fracture. Sci. Rep. 15, 13310 (2025).

Sekban, D. M. et al. Formability behavior of AH-32 shipbuilding steel strengthened by friction stir process. Theor. Appl. Fract. Mech. 132, 104485 (2024).

Sekban, D. M., Uzun Yaylacı, E. U., Özdemir, M. E. & Yaylacı, M. Determination of formability behavior of steel used in ships by various methods. Struct. Eng. Mech. 92(2), 189–196 (2024).

Uzun Yaylacı, E., Yaylacı, M., Özdemir, M. E., Terzi, M. & Öztürk, Ş. Analyzing the mechano-bactericidal effect of nano-patterned surfaces by finite element method and verification with artificial neural networks. Adv. Nano Res. 15(2), 165–174 (2023).

Uzun Yaylacı, E., Özdemir, M. E., Güvercin, Y., Öztürk, S. & Yaylacı, M. Analysis of the mechano-bactericidal effects of nanopatterned surfaces on implant-derived bacteria using the FEM. Adv. Nano Res. 15(6), 567–577 (2023).

Ramírez, J. F. & Vélez, J. A. Incidence of the boundary condition between bone and soft tissue in a finite element model of a transfemoral amputee. Prosthet. Orthot. Int. 36, 405–414 (2012).

Vélez Zea, J. A., Bustamante Góez, L. M. & Villarraga Ossa, J. A. Relation between residual limb length and stress distribution over stump for transfemoral amputees. Revista EIA 12(23), 107–115 (2015).

Jia, X., Zhang, M. & Lee, W. C. Load transfer mechanics between trans-tibial prosthetic socket and residual limb dynamic effects. J. Biomech. 37(9), 1371–1377 (2004).

Lee, W. C., Zhang, M., Jia, X. & Cheung, J. T. Finite element modeling of the contact interface between trans-tibial residual limb and prosthetic socket. Med. Eng. Phys. 26(8), 655–662 (2004).

Kistenberg, R. S., Kondor, S., Tawfik, S. A. & Terk, M. R. Medical imaging generated dynamic prosthetic sockets. hdl.handle.net/1853/43824 (2011).

Lagan, S. & Liber-Knec, A. The determination of mechanical properties of prosthetic liners through experimental and constitutive modelling approaches. Tech. Trans. 3(115), 197–209 (2018).

Wu, C. et al. A proposal for the pre-evaluation protocol of below-knee socket design—Integration pain tolerance with finite element analysis. J. Chin. Inst. Eng. 26(6), 853–860 (2003).

Cagle, J. C. et al. A finite element model to assess transtibial prosthetic sockets with elastomeric liners. Med. Biol. Eng. Comput. 56, 1227–1240 (2018).

Meng, Z., Wong, D. W. C., Zhang, M. & Leung, A. K. L. Analysis of compression/release stabilized transfemoral prosthetic socket by finite element modelling method. Med. Eng. Phys. 83, 123–129 (2020).

Acknowledgements

This work was supported by Recep Tayyip Erdoğan University Scientific Research Projects Unit under Grant FBI-2024-1589. This study has been supported by the Recep Tayyip Erdoğan University Development Foundation (Grant number: 02025007001575)

Funding

This work was supported by Recep Tayyip Erdoğan University Scientific Research Projects Unit under Grant FBI-2024-1589.

Author information

Authors and Affiliations

Contributions

Aichouba Adda Cherif: Methodology, Investigation, Visualization. Moulgada Abdelmadjid: Methodology, Formal analysis, Visualization. Zagane Mohammed El Sallah: Data Curation, Investigation, Visualization. Benouis Ali: Data Curation, Formal analysis, Visualization. Murat Yaylacı: Conceptualization, Validation, Writing—review & editing, Project administration, Supervision Sahli Abderahmane: Data Curation, Formal analysis, Conceptualization. Mehmet Emin Özdemir: Conceptualization, Writing—Review & Editing, Resources Ayberk Dizdar: Validation, Visualization, Resources Ecren Uzun Yaylacı: Conceptualization, Writing—Review & Editing, Investigation Yılmaz Güvercin: Validation, Investigation, Data curation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Cherif, A.A., Abdelmadjid, M., El Sallah, Z.M. et al. Comparative study by FEM of different liners of a transfemoral amputated lower limb. Sci Rep 15, 31878 (2025). https://doi.org/10.1038/s41598-025-15974-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-15974-x

Keywords

This article is cited by

-

Intra-osseous and coverage fixation for inferior pole fracture of the patella: a comparative finite element analysis and retrospective cohort study

Journal of Orthopaedic Surgery and Research (2025)

-

Biomechanical evaluation of a lower-limb implant model under gait and stumbling conditions using finite element analysis

Scientific Reports (2025)