Abstract

Semiconductor laser diode machining has emerged as a disruptive solution improving precision and efficiency in leather cutting making it an indispensable technology in industries such as automotive and aerospace. This study investigates the improvement of Normalized Performance Index (NPI) through the application of Extremum Seeking Control (ESC) to optimize the laser diode cutting process focusing on minimizing carbonization and kerf width while maximizing material removal rate (MRR) to improve the overall process efficiency. As this technology requires less power compared to conventional cutting methods and also reduce the overall carbon footprint promotes sustainability and supports ecofriendly manufacturing practices. The classic control techniques such as Linear-Quadratic Regulator (LQR) controllers and Proportional-Integral-Derivative (PID) controllers find it difficult to adjust to real-time process fluctuations. With adaptive real-time capabilities of ESC this approach offers a possible substitute by dynamically modifying parameters such as Pulse Width Modulation (PWM) and Stand-off Distance (SOD) to preserve the ideal cutting conditions. The impact of ESC on the Material Removal Rate (MRR), kerfwidth and carbonization of leather analysed in the proposed study. The results indicate that ESC considerably enhances the adaptability and consistency of the cutting process reducing carbonization and maintaining constant quality cut across varying conditions. These findings contribute to the advancement of semiconductor laser diode assisted leather cutting and proposes a unique technique for incorporating ESC into manufacturing processes for improved performance contributing to more sustainable and efficient leather cutting practices.

Similar content being viewed by others

Introduction

The leather industry contributes significantly to world trade with an annual value reaching $80 billion USD1. Leather machining involves processes such as cutting and engraving which used to be energy intensive and results in material waste2. The application of laser in cutting and engraving provide improved accuracy and control to create complicate designs by reducing material waste3. Laser cutting uses a focused light source to achieve extreme precision and control. The laser cutting has emerged as a leading method for intricate designs because of its non-contact nature, capability to produce fine kerfs and compatibility with organic materials like leather. Among the available laser types CO₂ lasers are widely used but their high thermal load can cause significant carbonization at cut edges, degrade material properties and release hazardous emissions4. The laser cutting cause carbonization on the surface of the leather material demanding careful parameter alterations to limit potential harm5. When the laser beam makes contact with the leather causing smokes and surface debris leads to carbonization in the leather contour cut edge. This results damage in the leather material leads to diminished durability and lower structural integrity6. During laser cutting of leather the thermal degradation of the collagen not only causes edge carbonization but also generates smoke containing carbonaceous particulates and volatile compounds. The formation of carbon-related functional groups at the cut edges, indicating the presence of char and oxidized organic products. These findings highlight the need for both parameter optimization such as moderating laser power and increasing feed rates to reduce the thermal damage7 . The factors such as wavelength,intrinsic qualities and surface features of the material heavily rely on the material capacity to absorb the laser radiation in the laser beam processing8.

Laser diodes work better in scenarios that need more precision and minimal post processing.This offers lower carbonization and better cut quality when measured and analysed using microscopic techniques9. According to10 this study assists in the optimization of cutting parameters and also to reduce carbonization which helps in the quality of the leather contour edges after cutting11. New era in laser material processing with increased power and accuracy leads to the latest advances in solid state lasers12. Compared to other laser systems laser diodes provide accurate machining of complicated patterns with minimal carbonization and also this technology produces less amount of leather waste with no tool wear.This offers exceptional precision and accuracy while cutting leather13. Control strategies are crucial in advanced manufacturing technologies. These control approaches are necessary to manage the dynamic conditions of manufacturing processes to prevent defects and implement a closed-loop control approach. These strategies enhance the reliability and effectiveness of manufacturing processes in these industries14. The control strategy optimization is critical for addressing key challenges in laser assisted leather cutting, including inconsistent emission levels, carbonization, and variable material thickness. Recent work has applied machine learning models such as Random Forest (RF) to optimize laser process parameters for emission reduction, demonstrating significant gains in environmental compliance and cutting performance. While emission mitigation and process stability have been studied in contexts such as CO₂ laser machining, there is limited research on real-time adaptive control of semiconductor laser diodes for sustainable leather cutting15.

According to16 the challenge of continuously optimizing a dynamic system performance by determining the maximum or minimum of its output function is known as Extremum Seeking (ES). The ESC offers a real time optimization used to adjust parameters dynamically to maintain optimal cutting performances despite disturbances or material variability. The advantages include robustness to uncertainties, continuous adaptation without pre trained models and compatibility with multi parameter optimization. Using mathematical techiques and perturbation theory of convergence analysis ES entails creating an estimate of the gradient of the target function by utilizing perturbations to estimate the gradient of the unknown function17. Due to the nature of adjusts cutting parameter in real time by Integrating ESC into the laser cutting process improve performance by lowering waste and energy consumption in wider industrial applications18. Conventional controllers provide significant improvements, they have limitations in handling real-time process variations and dynamic conditions19.

Laser cutting machines with advanced process parameters and real-time control systems enable precise optimization of cut quality and efficiency. The machine learning algorithms integrated with the machines significantly improving overall cutting performance and accuracy20. The importance of parameter optimization in laser based cutting of flexible materials has been explored through multi-criteria approaches. A recent comprehensive study conducted an in-depth analysis of cutting polypropylene, polyethylene, and PVC using CO₂ lasers to manufacture flexible two-phase passive thermal management systems (FTP-TMS)21. The effectiveness of composite polymer structures in thermal management by employing pulsating heat stripes fabricated using selective transmission laser welding, which significantly enhanced heat distribution in flexible substrates. The potential of laser based fabrication methods not only in electronics and aerospace but also in sustainable applications requiring thermal precision and passive heat dissipation22.

The adaptive control methods rely on state-dependent rule selection or parameter tuning.This results in only limited adaptability to changes in system parameters within fixed rule sets. The heuristic techniques and mathematical optimization are static, model-dependent production control strategies that require significant modifications when system conditions change23. ESC algorithm developed to identify the system cost function in real time. The major advantage is its ability to operate without prior knowledge of the objective function24. ESC is a effective solution for ensuring excellent leather cutting performance under a variety of settings and requirements. The integration of ESC with laser diode used to minimizing carbonization, improving MRR and also it reduces emission during leather cutting. ESC actively determing the ideal settings for critical parameters25. ESC dynamically responds to system fluctuations and helps to increase the process flexibility and adaptability to tackle the difficulties where conventional systems failed to appropriately react to the quickly changing parameters26. The other applications such as tracking optimal slip-ratio for Anti-lock braking system for different road conditions27 , and tracking maximum power for solar panel in an electric vehicle28 have implemented using ESC control. Parameters like SOD and PWM assists in the optimization of these control approaches29. Pulsed mode laser cutting enhances laser cutting precision and reliability in real time data processing30. The key focus of this study is to maximiza MRR using ESC by continuously modifying the control settings to maintain the maximum efficiency of the machining process31. The analysis of kerfwidth in addition to MRR also gives a complete evaluation of material parameters during laser cutting32. The cutting speed was found to be the dominant factor influencing kerf width, while power and material thickness showed non-linear effects33. Implementing ESC with the adaptive control approach guaranteed that the SOD is continuously optimized to reduce carbonization and to improve process efficiency34.

From a detailed review of existing literature it was inferred that only a minimal focus on sustainable leather cutting on utilizing advanced control approaches for unconventional machining processes. It was also found that a notable absence of research on the application of ESC to optimize the critical performance parameters such as carbonization, Kerf width and MRR in real-time adjustment under dynamic conditions. The lack of focus on advanced control techniques in laser assisted cutting processes has motivated the proposed study which seeks to implement ESC based control to improve the Normalized Performance Index in semiconductor laser diode machining contributing to more sustainable and efficient leather cutting practices.

Experimental methodology

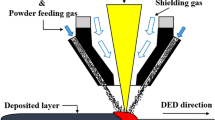

The power supply unit (PSU) converts the input voltage from an external source into a stable output voltage suitable for powering various components, such as the controller and the semiconductor laser diode as shown in Fig. 1. The PSU ensures that the system operates reliably by maintaining consistent voltage and current levels. PWM control is used to adjust the laser diode average output power resulting in desired cutting.

This PWM mode changes the width of pulses in a fixed frequency signal which is used to adjust the laser output power. The laser diode emitting at a wavelength of 445 nm produces the laser beam used in the machining process due to its higher absorption efficiency in leather materials compared to other wavelengths enabling precise cutting with minimal thermal damage and improved processing speed. The blue laser offers superior energy coupling into organic materials like leather thus improving the quality and efficiency of the machining process.The controller is the core component used to maintain and coordinate parameters to optimize the machining process. Figure 2 illustrates the block diagram with ESC in the feedback path as proposed.

Normalized Performance Index (NPI) is used to asses and optimize the leather cutting process which employs an ESC in the feedback path. NPI combines three essential performance metrics such as carbonization,Kerfwidth and Material Removal Rate to offer a comprehensive assessment of machining efficiency and quality.NPI is used to assess and optimize the leather cutting process using ESC in the ffedback path. Carbonization is the important parameter that influences the quality of the leather cut.The presence of carbonization produces charred edges and also this leads to the emission of hazardous fumes in the environment. Reducing carbonization ensures a safer working environment for operators. Kerfwidth is also a significant factor in measuring laser cuts and evaluating the precision and quality. For measuring the system productivity MRR is a critical indicator directly impacting the overall throughput.

The proposed system uses an ESC in the feedback path to dynamically alter the cutting parameters inorder to optimize the NPI.ESC always searching for the best operating conditions to maximize MRR while minimizing kerfwidth and carbonization. The overall efficiency of the leather cutting process is represented by a single normalised value calculated by NPI. This is derived by adding the normalized values of MRR,kerfwidth and carbonization which are weighted based on their relevance in individual application.This performance index enables real time monitoring and optimization resulting in increased productivity,accuracy and environmental sustainability in leather cutting processes.

Modelling and design for ESC in LBM process

Inorder to maximize MRR,Minimize kerfwidth and carbonization a framework must be developed for the modelling and design of an ESC system for optimal leather cutting. The firsdt step in this method is to create a dynamic model that accurately depicts the laser cutting procedure.Equations describing the connections between input parameters and output performance measures are included in this model.To make sure the model accurately represents behaviour in the real world these model parameters have been identified and validated using experimental data.The ESC design attempts towards improving NPI by combining MRR,Kerfwidth and carbonization into a single normalized value.Each performance parameter is normalized and weighted to get this NPI. To determine the ideal operating conditions the ESC algorithm iteratively modifies the control inputs. This requires an integrator, a demodulator to extract gradient information from the system response and a perturbation signal applied to the control parameters to explore the performance terrain. Under a variety of circumstances, the control systems feedback path maintains optimal function thanks to the integration of ESC. Both simulation and experimental validation are used in the implementation process. Through the use of dynamic model simulations the capacity of the ESC to optimize the NPI under different scenarios is examined.This assures that the NPI converges to the ideal point between MRR, Kerfwidth and carbonization.

The optimal combination of productivity, accuracy and quality is ensured by adjusting the ESC parameters and weights assigned to the performance indicators in accordance with the results of the experiment. The inclusion of ESC in the feedback path monitoring and adjusting the system leading to the quality of the leather cutting process contributing to higher production,accuracy and environmental sustainability.

The impact of laser input process parameters on NPI

The input process parameters settings such as SOD,feed rate, duty cycle and frequency have a substantial impact on laser beam machining.These settings directly influence the output metrics that makeup the NPI. The NPI is critical for optimizing the cutting process and to achieve an optimal combination of efficiency, accuracy and quality. The SOD guarantees adequate laser focus leading to efficient material ablation. The laser beam may defocus if the SOD is too great, which would decrease the MRR and increase the kerf width because of distributed energy. A very small SOD might result in an excessive concentration of heat, which raises carbonisation. In order to maximise MRR while minimising kerf width and carbonisation which favourably influences the NPI it is imperative to maintain an appropriate SOD. The cutting quality and efficiency of the leather are greatly influenced by the feed rate at which the laser hits across the surface. Since more material is digested faster with a greater feed rate, the MRR usually rises. Too high of a feed rate, however, might result in inadequate laser engagement time, which would increase kerf width and cause incomplete cutting. Conversely, an extremely low feed rate may lead to an excessive accumulation of heat, which would increase carbonisation. Consequently, in order to maximise the NPI and balance high MRR with low kerf width and carbonisation, an ideal feed rate is needed.

The presence of high duty cycle always indicate that more energy is imparted to the leather material which might maximize MRR but also increases the danger of overheating which leads to carbonization.The Lower values of duty cycle decreasing the laser input energy and potentially minimize MRR and kerfwidth but improving the cutting precision by reducing the thermal damage during leather cutting.The optimization of duty cycle is critical for producing high MRR with acceptable amount of kerfwidth and carbonization and therefore enhancing the NPI. The control of laser diodes with high frequencies result in more material removal and finer kerfwidth due to the increased number of pulses present during the cutting process.The excessive high frequency may result in overlapping of pulses and this leads to more carbonization in the cut edges of the leather samples.Due to the presence of fewer pulses in the lower frequencies mode may result in minimize MRR and precision of the leather cut. Therefore the selection of proper frequency is critical for maximizing MRR while minimizing kerfwidth and carbonization eventually improving the NPI.

The proper tuning of laser input settings necessary for enhancing the NPI in leather cutting.Inorder to perform the proper leather cut each parameters must be tuned properly to balance MRR,Kerfwidth and carbonization.This will improve the performance of the leather cutting process with high efficiency,precision and quality in long run by optimizing the NPI.

Development of non-linear model for combined performance index

Formulation of performance index that integrates NPI to derive a non-linear equation

The closed loop structure of Extremum Seeking Controller is as shown in Fig. 3 and the proposed ESC control for the LBM as shown in Fig. 4. The system is represented by the equation \(\dot{{z}}\) = \({f}\left({z},\upbeta \left({z},\uptheta \right)\right)\) and v \(=f(z,\theta\)), where z represents the state variables, \(\upbeta\) the control input and θ the system parameters. The output v is fed back into the ESC loop for optimization. The integrator with transfer function \(\frac{\mathbf{K}}{\mathbf{s}}\) accumulates the input signal over time, which helps in adjusting the control input \(\widehat{{\varvec{\uptheta}}}\) towards the optimal value. This adjustment is based on the feedback from the system output. The LPF with transfer function \(\frac{{\upomega }_{{l}}}{{s}+{\upomega }_{{l}}}\) used to smooth the signal τ from the integrator, eliminating high-frequency noise and retaining the low-frequency components that represent the trend of the system’s response. This ensures that the ESC focuses on the underlying behavior rather than transient fluctuations.

A sinusoidal signal is injected into the system to perturb the input. This signal helps the controller explore the input space and detect how changes in the input affect the system output.The output from the HPF is multiplied by the perturbation signal. This product is used to estimate the gradient of the performance index, which informs how the input should be adjusted to improve the system’s performance. From Eq. 1 y represents the performance index.x represents the input variables to the system.θ is the parameter or control variable being adjusted by the ESC to optimize the performance index J(θ).f(x,θ) is the system’s function that defines how the output y depends on the inputs x and the parameter θ.

The input error value is \(\overline{{\uptheta }}\) where \(\overline{{\uptheta }} = {{ \theta }}^{ * } - \widehat{{\uptheta }}\).

Equation 2 is derived from the Taylor series expansion and describes the behavior of a non-linear system under an Extremum Seeking Controller (ESC). Here, y = J(θ) represents the system output as a function of the input θ where J(θ*) is the cost function value at the optimal point θ* indicating the desired performance. The term \(\frac{{{{J}}{\prime }(\theta )}}{2}\) is the second derivative of the cost function, providing curvature information around the θ*. The expression \({(\widehat{\uptheta }+{a}.{sin}\left({\omega t}\right)-{\uptheta }^{*})}^{2}\) captures the squared difference between the perturbed input \(\widehat{\uptheta }+a\). \({sin}\left({\omega t}\right)\) and the optimal input θ* where \(\widehat{\uptheta }\) is the estimated input, a is the perturbation amplitude, and ω is its frequency. By applying this perturbation, the ESC explores the system’s response, estimates the gradient of J(θ), and iteratively adjusts \(\widehat{\uptheta }\) to converge towards \({\uptheta }^{*}\) thus optimizing the laser beam machining process by continuously seeking the optimal discharge time that maximizes the Normalized Performance Index (NPI).

The term \(\zeta\) in Eq. (3) elaborates on the dynamic behaviour of the cost function under the influence of the Extremum Seeking Controller (ESC). The term \(\frac{{{J}}^{{\prime }}({\uptheta }^{*}){\widehat{\uptheta }}^{2}}{2}\) represents the static influence of the estimated input \(\widehat{\uptheta }\) on the cost function’s curvature near the optimal point \({\uptheta }^{*}\). The term \(a*J^{{\prime }} \left( {\theta ^{*} } \right)*\bar{\theta }*{{sin}}\left( {\omega t} \right)\) introduces a sinusoidal variation due to the interaction between the perturbation and the deviation from the optimal input \(\overline{\uptheta }= {\uptheta }^{*}-\widehat{\uptheta }\) facilitating the ESC’s exploration and gradient estimation. The term \(J^{{\prime }} \left( {\theta ^{*} } \right)*\frac{{a^{2} }}{4}*{{cos}}(2\omega t)\) accounts for the higher-order effects of the perturbation, creating a cosinusoidal component at twice the perturbation frequency, which can cause fluctuations around the optimal point. Overall \(\zeta\) encapsulates the combined static and dynamic effects of the system’s non-linear response, the perturbation, and the deviation from the optimal input, illustrating how the ESC dynamically optimizes the cost function to achieve the optimal performance index.

Equation 4 elucidates the effect of the perturbation and the system response. This term represents an additional component arising from the interaction between the perturbation’s amplitude a, the deviation from the optimal input \(\overline{\uptheta }= {\uptheta }^{*}-\widehat{\uptheta }\) and the curvature of the cost function \({{J}}^{{\prime }} \left( {\theta ^{*} } \right)\). It highlights how the squared amplitude of the perturbation \({{a}}^{2}\) influences system performance by modulating the impact of the deviation from the optimal input. The negative sign indicates that this term acts to counterbalance the deviation, effectively damping the perturbations caused by the sinusoidal signal.

By incorporating T the ESC algorithm can better manage the trade-off between exploration and stability, ensuring that the system converges towards the optimal input \({\uptheta }^{*}\) while minimizing oscillations and errors around the optimal point. This correction term emphasizes the role of the perturbation amplitude in optimizing the cost function and enhancing the overall performance of the laser beam machining process.

Equation 5 establishes the relationship between the deviation from the optimal input, the estimated input and the controller gain K. Here \(\overline{\uptheta }\) and \(\widehat{\uptheta }\) represent the same quantity, which is the deviation of the input parameter from the optimal value. The term \({{K}}{\rm T}\) shows that the ESC adjusts the estimated input based on the gradient information encapsulated in T, with K being the controller gain that dictates the adjustment rate. This relationship underscores how the ESC leverages the perturbation amplitude a, the deviation \(\overline{\uptheta }\) and the curvature of the cost function \({{J}}^{{\prime }} \left( {\theta ^{*} } \right)\) to refine the input parameter \(\widehat{\uptheta }\). By incorporating the term \({{Ka}}^{2} .\frac{{\theta {{J}}^{{\prime }} (\theta ^{*} )}}{2}\) the ESC algorithm dynamically updates the input to minimize the cost function, aiming for the optimal performance index. This adjustment mechanism ensures that the input converges towards the optimal value \({\uptheta }^{*}\) by continuously correcting for deviations, enhancing the stability and precision of the laser beam machining process.

Equation 6 elaborates on the evolution of the deviation \(\overline{{\uptheta }}\) over time. Here \({{e}}^{{{{ka}}^{2} }}\) represents an exponential factor that amplifies the influence of the perturbation amplitude a and the controller gain K on the system’s response. The term \(\frac{{\overline{\theta } {{J}}^{{\prime }} (\theta ^{*} )({{t}} - {{t}}_{0} )}}{2}\) captures the time-dependent contribution of the deviation \(\overline{\theta }\) the curvature of the cost function \({{J}}^{{\prime }} \left( {\theta ^{*} } \right)\) and the elapsed time t-t0 since the start of the adjustment process. This relationship emphasizes how the deviation from the optimal input \(\overline{\theta }\) evolves exponentially over time, influenced by the perturbation and the system’s intrinsic properties. The addition of \(ln\overline{\theta }_{0}\) indicates the logarithmic influence of the initial deviation \(\overline{{\uptheta }_{0}}\) reflecting the starting condition of the system. By incorporating this exponential and logarithmic adjustment, the ESC algorithm dynamically refines the input parameter \(\hat{\theta }\)ensuring convergence towards the optimal input. This continuous adjustment mechanism enhances the stability and precision of the laser beam machining process, optimizing the cost function to achieve the desired performance index.

Equation 7 indicates that, as time progresses indefinitely, the deviation \(\overline{\theta }\) from the optimal input \({\uptheta }^{*}\) approaches zero. This outcome reflects the effectiveness of the Extremum Seeking Controller (ESC) in driving the system towards the optimal performance index. As the perturbation and adjustments are continuously applied, the ESC algorithm refines the input parameter \(\widehat{\uptheta }\) based on the feedback and gradient information. The exponential and logarithmic terms in the previous equations illustrate how the system dynamically adjusts over time, with the perturbations and corrections becoming increasingly precise. Ultimately, \(\underset{{t}\to \infty }{{lim}}\overline{\uptheta }\)=0 signifies that the system converges to the optimal input \({\uptheta }^{*}\) achieving minimal deviation and optimizing the cost function effectively. This convergence ensures that the laser beam machining process operates at its best performance level, minimizing errors and maximizing the desired outcomes (Figs. 5 and 6).

Results and discussion

Experimental setup

The ESC optimal control model for the real LBM process depicted in Fig. 5 was developed in MATLAB 2024a and the process parameters outlined in Table 1. The LBM process outputs such as carbonization, Kerfwidth, and MRR are measured using respective sensors, and calibrated readings are sent to the computational system. One such output set is listed in Table 2. The SEM image of the resulting leather cutting is shown in Fig. 7. As per the LBM process performance, mainly three output parameters as mentioned above have been considered into account to validate the performance of the LBM by varying the input parameter called pulse width modulated waveform as other parameters are fixed as constants. The laser intensity controlled by PWM has more impact on the performance of the output as compared with other input parameters. The pulse width modulated waveform signal is generated by the controller as shown in Fig. 6 and it is supplied to the Laser diode directly. It was observed that all three performance parameters are being increased as the duty cycle of the PWM waveform increases. The repeatability and reproducibility of the output results were verified by conducting three trials at each duty cycle setting shown in Table 2. The reported values represent the average of these three trials ensuring consistency and reliability of the experimental data. Even though the increment in MRR is desired, the increment in the other two parameters such as carbonization and Kerfwidth is not desired. Hence, the compromise in percentage of duty cycle is required to get a better MRR with minimal carbonization and Kerfwidth. Furthermore, a normalized performance index (NPI) is derived from the normalized performance values as listed in Table 3. The regression model is created by fixing the NPI as the output and duty cycle as the input as given in the following equation Fig. 7.

Where NPI is the normalized performance index and D is the duty cycle of PWM in percentage. As the above equation is in non-linear form, the non-linear optimal control ESC is employed for controlling as discussed in Chapter 3. The plot of NPI with duty cycle variation is given in Fig. 8. At an optimal point of the duty cycle, the NPI is maximum as illustrated in Figure.

As shown in the Fig. 7 shows the digital microscope images were also captured to provide a clearer visual comparison of carbonization effects in chrome vegetable tanned cow leather of thickness 1 mm between the open-loop and extremum seeking control (ESC) approaches. As shown in the figure the open loop cut exhibits a wider and darker carbonized zone, whereas the ESC approach results in a visibly reduced and more uniform carbonized layer.

The grooves in the Fig. 8 appear less defined with varying depths and widths. This could indicate a non-optimal duty cycle where the laser energy is either insufficient or inconsistent. The manual searching for the optimal duty cycle the variability in groove formation suggests that more careful tuning is needed to achieve consistent and well-defined grooves. There are noticeable protrusions scattered across the surface. The presence of protrusions points to the need for a lower duty cycle or better control of the laser parameters to reduce excessive melting .This SEM image shows regions of rough texture, likely due to dross formation. The dross appears uneven and could affect the surface quality negatively. Minimizing dross is crucial and this image suggests that the current duty cycle may be too high leading to incomplete vaporization of the material. Striations are visible lines suggest that the laser movement was relatively stable but some improvement might be necessary to achieve smoother results. Fine-tuning the duty cycle could reduce these striations, leading to a more uniform surface finish.

The grooves in the Fig. 9 are more uniform and better defined compared to the first image. This suggests that the duty cycle is closer to optimal for consistent material removal. ESC can effectively fine-tune the duty cycle by continuously adjusting to maintain this level of consistency in groove formation suggesting that this image reflects a more optimized process. There are still some protrusions in this image, but they are less prominent than in the first image. This shows a better control over the laser power.The presence of ESC modify the duty cycle to further reduce the protrusions resulting in a more uniform surface.The more evenly distributed dross show the laser energy is better controlled this is reason for the formation of less residue. The ESC further optimize the duty cycles by monitoring the dross levels and adjustas needed to obtain a dross free surface.The formation of striations are more uniform indicating the the movement of the laser and the laser output are more stable resulting in a smoother surface.The uniform striations shows the ESC is efficiently maintaining between optimal duty cycle which is used to maintain the balance between the material removal and surface integrity.

The unwanted striations and dross along with grooves and protrusions formed using such open loop approach still require some optimization to attain the best results. It is evident from the observed variability in the striations,grooves and dross and striations indicates that the process paramaters are not properly optimized. The use of ESC for duty cycle optimization demonstrates marked improvements with surface features that are more uniform and controlled. ESC proves to be highly effective in fine-tuning the duty cycle, achieving a more balanced approach between material removal and surface quality. This dynamic adjustment capability of ESC allows for continuous real-time optimization leading to enhanced precision and quality in laser diode-assisted leather machining. While manual optimization has its merits it is less efficient and may fall short of achieving the same level of optimization as ESC.

The Normalized Performance Index versus duty cycle analysis provides valuable insights into the relationship between the laser diode duty cycles and the overall machining performance in leather processing. The NPI is a comprehensive metric that integrates key process parameters which are normalized to allow for a direct comparison.From Fig. 10 NPI initially increases with the duty cycle indicating improved process efficiency. The NPI reaches its peak at a duty cycle of 75% where the balance between minimal carbonization, optimal kerf width and maximum MRR is achieved. This suggests that the process is most effective at this specific duty cycle delivering the best overall performance.Beyond the 75% duty cycle the NPI begins to decline. This decrease indicates that while higher duty cycles may still improve certain individual parameters such as MRR they do so at the expense of increased carbonization and widening of the kerf. As a result, the overall machining quality diminishes reflected in the decreasing NPI values.The highest NPI normalized to a value of 1.000 is observed at 75% duty cycle confirming it as the optimal point for balancing all critical machining parameters. Lower or higher duty cycles, while offering certain advantages, do not achieve the same level of comprehensive performance, making 75% the most effective setting for laser diode-assisted leather machining in this study.

Extremum Seeking for optimal duty cycle

The setup as discussed in Chapter 3 is made for conducting experiments. The setting of parameters for ESC has been done as per the nature of the LBM process. Since the performance parameters of the LBM process are lagging, the low frequency is set as a perturbation frequency for the ESC controller. The frequency is set as 1 to 3 rad/sec as dither frequency should be lower than overall system’s dynamics. As we track the optimal duty cycle percentage, the amplitude increment is fixed as 0.2 to 0.5 by fixing the initial amplitude as 50. Then, K value is set as 10 for the proper tracking of the optimal duty cycle by the tuning method. The optimal point using manual search of duty cycle in the optimal point region is shown in Fig. 11 a with the increment of 5% in the duty cycle. The maximum NPI is obtained at 70% of the duty cycle as illustrated in the graph. However, the actual value of the optimal point at which attainment of maximum NPI happened at 70.55% of the duty cycle as illustrated in Fig. 11 b. Hence, the detection of optimal value and tracking of changes of optimal point are performed automatically without any intervention in ESC control. The automatic adjustments on the duty cycle are performed during the process to make the response favorable. Initially, 20 manual trials without ESC control are conducted by manually adjusting the duty cycle in and around 70% of the duty cycle. The mean value of NPI for the different trials is listed in Table 4.

The standard deviation of the mean value is also plotted in Fig. 12a–c for the different standoff distances of 18 mm, 20 mm, and 22 mm respectively. Even the highest value of the manual trial is not the same as optimal searching of ESC as illustrated. ESC optimal searching provides accuracy of 10 to 15% more than a manual searching. At the highest value of optimal searching, ESC outperforms with an accuracy of 1 to 2%.

Conclusions

In the present study an endevor was made to implement Extremum Seeking Control (ESC) with optimal point tracking of the duty cycle in semiconductor laser diode assisted machining for sustainable leather cutting. The integration of ESC also supports tracking the change of optimal points due to changes in processes and environmental conditions. The Normalized performance index (NPI) has been formulated with the help of non-linear regression for improving the MRR and reduce the carbonization and Kerfwidth. Based on the experimental analysis the following conclusions were made.

-

The semiconductor laser diode machining process for cutting leather specimens has been implemented using ESC and its related formulation have been developed for efficiency and greener environment.

-

Modeling of ESC is done and the same is simulated for the computations of duty cycle percentage.

-

Normalized Performance Index (NPI) is formulated using non-linear regression by including the performance parameters such as MRR, carbonization, and Kerfwidth for the variation of the duty cycle of PWM.

-

ESC consistently outperforms manual optimization achieving higher NPI values. It can be identified that the SOD of 20 mm and a frequency of 18 kHz the ESC delivers best performance with NPI indicating its effectiveness in optimizing the process dynamically.

-

ESC enables automatic tracking and adjustment of the optimal duty cycle outperforming manual methods in accuracy and efficiency. ESC provides 10 to 15% more accuracy than manual searching with an error margin reduced to 1 to 2% for optimal duty cycle identification.

Data availability

The datasets generated and analyzed during the current study are not publicly available owing to ongoing analyses investigating multiple control approaches but are available from the corresponding author upon reasonable request.

References

Omoloso, O., Mortimer, K., Wise, W. R. & Jraisat, L. Sustainability research in the leather industry: A critical review of progress and opportunities for future research. J. Clean Prod. 285, 125441. https://doi.org/10.1016/j.jclepro.2020.125441 (2021).

Senthil, R. Regenerated products from leather industrial solid waste: Future perspective and current advances. J. Hazard Mater. Lett. 5, 100112. https://doi.org/10.1016/j.hazl.2024.100112 (2024).

You, K., Yan, G., Luo, X., Gilchrist, M. D. & Fang, F. Advances in laser assisted machining of hard and brittle materials. J. Manuf. Process. 58, 677–692. https://doi.org/10.1016/j.jmapro.2020.08.034 (2020).

Mekid, S., Vasanth, S. & Chekalil, I. Comparative study of ultrasonic and laser assisted machining for sustainable leather cutting in greener industry practices. Sci. Rep. 15, 22791. https://doi.org/10.1038/s41598-025-05181-z (2025).

Gulbiniene, A., Urboniene, E. F., Juciene, M., Dobilaite, V. & Valeika, V. Effect of CO2 laser treatment on the leather surface morphology and wettability. J. Ind. Text. 51(2), 2483S-2498S. https://doi.org/10.1177/15280837211022612 (2022).

Devi, M., Wang, H., Moon, S., Sharma, S. & Strauss, V. Laser-carbonization—a powerful tool for micro- fabrication of patterned electronic carbons. Adv. Mater. 35, 202211054. https://doi.org/10.1002/adma.202211054 (2023).

Swaminathan, V. et al. Analysis of carbon formation on machined leather specimen using FTIR technique in laser diode assisted cutting process. Materials 16, 148. https://doi.org/10.3390/ma16010148 (2023).

Karamimoghadam, M., Moradi, M. & Azami, M. A comparative investigation of different overlaps of the diode laser hardening in low-carbon steel and stainless steel. Optik 251, 168093. https://doi.org/10.1016/j.ijleo.2021.168093 (2022).

Wu, X. et al. Research on carbon emission measurement and low-carbon path regional industry. Environ. Sci. Pollut. Res. 29, 90301–90317. https://doi.org/10.1007/s11356-022-22006-y (2022).

Vasanth, S., Muthuramalingam, T., Prakash, S. S., Raghav, S. S. & Logeshwaran, G. Experimental of PWM laser standoff distance control for power diode based LBM. Opt. Laser. Technol. 158, 108916. https://doi.org/10.1016/j.optlastec.2022.108916 (2023).

Tang, J. et al. Carbon emission prediction in a region of Hainan Province based on improved STIRPAT model. Environ. Sci. Pollut. Res. 31, 58795–58817. https://doi.org/10.1007/s11356-024-35027-6 (2024).

Levichev, N., Herwig, P., Wetzig, A. & Duflou, J. R. Towards robust dynamic beam shaping for laser cutting applications. Proc. CIRP. 111, 746–749. https://doi.org/10.1016/j.procir.2022.08.116 (2022).

Vasanth, S. et al. Review of semiconductor laser diode technologies for sustainable energy in leather machining. Clean Technol. Environ. Policy 26, 7. https://doi.org/10.1007/s10098-024-02976-y (2024).

Herzog, T. et al. Process monitoring and machine learning for defect detection in laser- based metal additive manufacturing. J. Intell. Manuf. 35, 1407–1437. https://doi.org/10.1007/s10845-023-02119-y (2024).

Swaminathan, V. & Prakash, S. Machine learning hyperparameters optimization of control strategies for emission reduction in sustainable leather cutting using semiconductor laser diode. J. Clean. Prod. 522, 146350. https://doi.org/10.1016/j.jclepro.2025.146350 (2025).

Scheinker, A. 100 years of extremum seeking: A survey. Automatica 161, 111481. https://doi.org/10.1016/j.automatica.2023.111481 (2024).

Oliveira, T. R. & Krstic, M. Extremum seeking for infinite-dimensional systems. Annu. Rev. Control. 56, 100908. https://doi.org/10.1016/j.arcontrol.2023.100908 (2023).

Vasanth, S. & Muthuramalingam, T. Application of laser power diode on leather cutting and optimization for better environmental quality measures. Archiv. Civ. Mech. Eng 21, 54. https://doi.org/10.1007/s43452-021-00208-4 (2021).

Mohamed Rabik, M., Vasanth, S. & Muthuramalingam, T. Implementation of LQR based SOD control in diode laser machining on leather specimens. Opt. Laser Technol. 170, 110328. https://doi.org/10.1016/j.optlastec.2023.110328 (2024).

Levichev, N. et al. Experimental validation of a machine learning algorithm for roughness quantification in laser cutting. Proc. CIRP 113, 564–569. https://doi.org/10.1016/j.procir.2022.09.175 (2022).

Der, O., Ordu, M. & Basar, G. Optimization of cutting parameters in manufacturing of polymeric materials for flexible two-phase thermal management systems. Mater. Test. 66(10), 1700–1719. https://doi.org/10.1515/mt-2024-0127 (2024).

Der, O., Alqahtani, A. A., Marengo, M. & Bertola, V. Characterization of polypropylene pulsating heat stripes: Effects of orientation, heat transfer fluid, and loop geometry. Appl. Therm. Eng. 184, 116304. https://doi.org/10.1016/j.applthermaleng.2020.116304 (2021).

Chakrabarthy, A. et al. Extremum seeking controller tuning for heat pump optimization using failure-robust Bayesian optimization. J. Process Control 120, 86–96. https://doi.org/10.1016/j.jprocont.2022.11.006 (2022).

Su, Z. & Chen, P. Extremum seeking control-based control framework for electric vehicle platooning. IFAC 55–24, 1123–1128. https://doi.org/10.1016/j.ifacol.2022.10.272 (2022).

Liu, H., Tan, Y. & Oetomo, D. A novel extremum seeking control to enhance convergence and robustness in the presence of nonlinear dynamic sensors. J. Syst. Sci. Complex 37, 3–21. https://doi.org/10.1007/s11424-024-3447-y (2024).

Kuhnle, A. et al. Designing an adaptive production control system using reinforcement learning. J. Intell. Manuf. 32, 855–876. https://doi.org/10.1007/s10845-020-01612-y (2021).

Nandhini, M. Mohamed Rabik. A new spacing policy in a platoon using extremum seeking controller on an Anti-lock braking system. Transactions of the Institute of control and measurements. https://doi.org/10.1177/01423312241266680 (2024)

Ragul, G. & Mohamed Rabik, M. ESC based efficient power point tracking for a solar panel in an electric vehicle. AIP Conf. Proc. https://doi.org/10.1063/12.0017616 (2023).

Vasanth, S. et al. Implementation and performance analysis of combined SOD and PWM control in diode based laser beam machining process on leather specimen. Opt. Laser Technol 169, 110093. https://doi.org/10.1016/j.optlastec.2023.110093 (2024).

Indira Kusuma, A. & Huang, Y. M. Product quality prediction in pulsed laser cutting of silicon steel sheet using vibration signals and deep neural network. J. Intell. Manuf. 34, 1683–1699. https://doi.org/10.1007/s10845-021-01881-1 (2023).

Mohamed Ismail, M. R. et al. Design of real-time extremum-seeking controller-based modelling for optimizing MRR in low power EDM. Materials 16(1), 434. https://doi.org/10.3390/ma16010434 (2023).

Yilbas, B. S., Shaukat, M. M. & Ashraf, F. Laser cutting of various materials: Kerf Width size analysis and life cycle assessment of cutting process. Opt. Laser. Technol. 93, 67–73. https://doi.org/10.1016/j.optlastec.2017.02.014 (2017).

Basar, G., Der, O. & Guvenc, M. A. AI-powered hybrid metaheuristic optimization for predicting surface roughness and kerf width in CO₂ laser cutting of 3D-printed PLA-CF composites. J. Intell. Mater. Syst. Struct. https://doi.org/10.1177/08927057251344183 (2025).

Krstic, M. Extremum Seeking Control. In Encyclopedia of Systems and Control (eds Baillieul, J. & Samad, T.) (Springer, London, 2014). https://doi.org/10.1007/978-1-4471-5102-9_114-1.

Author information

Authors and Affiliations

Contributions

V.S.: Conceptualization, Writing—Original draft, Writing—review and editing. M.M.R.: Writing—original draft, Writing—review and editing, resources, Methodology. R.M.: Writing—original draft, Writing—review and editing. I.C.: Writing—original draft, supervision, validation. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical approval

We confirmed that the current work is original to the authors and has not published or reviewed in any journal.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Swaminathan, V., Rabik, M.M., Meligy, R. et al. Implementation of real-time optimization control to reduce environmental impact in laser diode assisted sustainable leather cutting. Sci Rep 15, 40904 (2025). https://doi.org/10.1038/s41598-025-19032-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-19032-4