Abstract

This study aims to analyze the aesthetic, mechanical, and antibacterial properties of clear retainer materials with an antibacterial coating. Specifically, it evaluates whether the coating can retain its effectiveness after repeated toothbrushing by assessing material integrity, surface roughness, and bacterial adhesion in vitro. Four types of 1.0-mm thermoplastic sheets widely used in orthodontic clear retainers were tested: PUL (Magicfoil R, Osstem, Korea), PUC (Magicfoil R with a hydrophilic antibacterial coating), PUZ (Zendura, Bay Materials, USA), and PET (CA Retention Foil, Scheu-Dental, Germany). The PUL, PUC, and PUZ sheets were composed of polyurethane (PU), whereas the PET sheets were made of polyethylene terephthalate glycol (PETG). Flexural strength, tensile strength, and cyclic load tests were conducted to compare the mechanical properties of these four materials, and transparency was compared to evaluate aesthetic properties. The surface roughness of the specimens and the antibacterial ability against Streptococcus mutans were measured before and after toothbrushing. The antibacterial coating did not change the mechanical or aesthetic properties of the retainer material. After brushing, all types’ materials had similar surface roughness values as before brushing. Additionally, the antibacterial coating group (PUC) exhibited lower bacterial adhesion than the uncoated group (PUL), with reductions of 36% before and 40% after toothbrushing. The difference was statistically significant before toothbrushing (p < 0.05), but not after simulated toothbrushing. These results confirm that the hydrophilic coating has an antibacterial effect and that this effect can be maintained even after repeated toothbrushing.

Similar content being viewed by others

Introduction

Clear retainers are highly favored for active orthodontic treatment and long-term retention in clinics due to their convenience, aesthetic appeal, and semi-transparent characteristics. However, these appliances have inherent shortcomings, such as low wear resistance in the oral environment and frequent fractures of the thermoplastic resin material. Moreover, their continuous intraoral use—up to 24 h a day for over a year1—inevitably leads to microbial and plaque accumulation2,3. This microbial colonization not only compromises oral hygiene but also poses a strong risk factor for bacteria-related diseases, including dental caries, gingivitis, and periodontitis. In particular, clear retainers can act as reservoirs for cariogenic bacteria such as Streptococcus mutans4, highlighting the need for effective antibacterial strategies to ensure hygienic and safe long-term use.

To address these challenges, various materials and surface modification techniques have been developed to alter surface properties and reduce bacterial adhesion. Among them, hydrophilic surface modification has gained attention for its ability to inhibit initial bacterial attachment and maintain cleanliness on medical device surfaces5,6,7. Hydrophilic coatings on medical devices create a thin film that disrupts interactions between the medical device surface and biofilms, inhibiting biofilm formation8,9,10,11,12. In an experimental study, polyethylene terephthalate glycol (PETG) sheets coated with polysilsesquioxane (PSQ) demonstrated a reduction in bacterial density for three different types of oral bacteria, leading to a reduction in bacterial growth of over 60% compared with the control group13.

In this study, materials were selected based on their physical and mechanical properties, as well as their clinical relevance. Commercially used products from both polyurethane (PU)-based (PUZ) and polyethylene terephthalate glycol-modified (PETG)-based (PET) groups were included to reflect materials widely adopted in clinical practice. In addition, a general PU material (PUL) and a PU material with a hydrophilic antibacterial coating (PUC) were incorporated for comparison. By evaluating PU and PETG materials with and without surface modifications, the study aimed to assess the effects of antibacterial coating on aesthetic, mechanical, and microbiological performance.

PEI (polyethylenimine) is a widely used germicidal ingredient in various formulations, ranging from detergents to packaging materials14. It contains primary, secondary, and tertiary amino groups, making it polycationic. This compound is formed through the cationic polymerization of aziridine15. The polycationic nature of PEI is crucial, because polycations have antibacterial properties owing to their ability to destroy bacterial cell membranes with a negative charge16. In particular, previous research has demonstrated that PEI nanoparticles exhibit potent antibacterial effects against Streptococcus mutans17, maintaining antibacterial properties for more than one month. Given its proven long-term antibacterial efficacy, hydrophilicity, and biocompatibility, PEI was recently applied as the coating material to develop a durable antibacterial surface for orthodontic retainers.

Because clear retainers are placed in the oral cavity for extended periods (ranging from 3 months to 1 year), the durability of coatings with antibacterial properties must be validated and research is needed to enhance the stability of antibacterial coatings. Changes in surface roughness caused by toothbrushing can impact bacterial colonization, and the removal of the coating may undermine its antibacterial capacity18,19,20. Therefore, maintaining antibacterial capacity even after repeated toothbrushing is necessary. However, previous studies on durability have primarily focused on chemical stability under various oral conditions such as pH level and enzymatic conditions, without replicating the mechanical conditions of toothbrushing. Therefore, this study aims to assess the aesthetic and mechanical properties of an antibacterial clear retainer in vitro and bacterial adhesion after repeated toothbrushing.

The null hypothesis assumes that antibacterial coating would not significantly affect the aesthetic, mechanical, or antibacterial properties of polyurethane-based clear retainers, and that toothbrushing does not result in a significant difference in the antibacterial performance of the coating.

Results

Comparison of transparency

The PET, PUL, and PUC groups had significantly higher transparencies than the PUZ group (p < 0.01) (Table 1).

Analysis of mechanical properties

Flexural strength

There were significant differences in the maximum flexural strengths among the four groups (p < 0.01). The mean maximum flexural strengths of the PUL, PUC, PUZ, and PET groups were 70.50, 64.38, 69.09, and 59.57 MPa, respectively. The PUL and PUZ groups had significantly higher mean maximum flexural strengths than the PET group (p < 0.01) (Table 2; Fig. 1A).

Tensile strength

There were significant differences in tensile strengths among the four groups (p < 0.01). The mean tensile strengths of the PUL, PUC, PUZ, and PET groups were 45.67, 44.97, 41.90, and 34.28 MPa, respectively. The PUL and PUC groups had significantly higher tensile strengths than the PET group (p < 0.01) (Table 2; Fig. 1B).

Cyclic load

The force was the lowest for the PET group after cyclic loading; however, there were no significant differences in the forces for each cycle among the four groups (p > 0.05) (Fig. 1C). After 400 cycles of cyclic loading (approximately 67 days of clinical use, assuming six insertions and removals per day), all groups showed an average force reduction of 18–22%. Although the PET group exhibited the lowest absolute force after loading, it had the smallest rate of force reduction compared to the other groups.

Examination of surfaces before and after toothbrushing

Examination of surface roughness using FE-SEM

After thermoforming, no marked changes were observed in the surface morphology of the four groups before and after toothbrushing under SEM examination. Figure 2 shows the SEM images of the surfaces before and after toothbrushing for each group. Before toothbrushing, indentation marks caused by the thermoforming process can be seen despite the differences in surface characteristics among the groups. The surface of the PUZ group showed increased roughness before toothbrushing because of greater fitting and consequent negative pressure. After repeated toothbrushing, all groups showed increased irregular pitting and indentation on the surfaces.

Examination of surface roughness using a non-contact microscope

Significant differences were observed in the Ra of the groups before and after toothbrushing (p < 0.001). The Ra values for the PUL, PUC, and PUZ groups were significantly higher than those for the PET group both before and after toothbrushing (p < 0.001) (Table 3; Fig. 3A). The Ra values increased slightly after repeated toothbrushing for the PUL, PUC, and PET groups; however, the changes were not significant (p > 0.05).

Antibacterial testing

After toothbrushing, a significant difference in bacterial adhesion was observed among the groups (p < 0.05), with bacterial adhesion being lower for the PUC group than for the PUL group. The PUL, PUC, and PUZ groups exhibited slightly lower bacterial adhesion after toothbrushing than before toothbrushing, whereas the PET group demonstrated a slight increase in bacterial adhesion. However, none of the groups had significant changes in bacterial adhesion after toothbrushing compared to that before toothbrushing (p > 0.05) (Table 4).

Figure 3B shows the bacterial adhesion of each group before toothbrushing as a percentage of that for the PUL group. Compared to the other three groups, the PUC group exhibited reduced bacterial adhesion. Specifically, its coated surface showed a 36% reduction in bacterial adhesion compared to the uncoated control (PUL) before toothbrushing (p < 0.05), and a 40% reduction after toothbrushing, although the latter was not statistically significant.

Discussion

This study aimed to evaluate whether an antibacterial coating could reduce bacterial adhesion without causing significant changes in the aesthetic and mechanical properties of clear retainers, even after repeated toothbrushing. The null hypothesis assumes that the antibacterial coating would not significantly affect the aesthetic, mechanical, or antibacterial properties of polyurethane-based clear retainers, and that toothbrushing does not result in a significant difference in the antibacterial performance of the coating. Based on the results, the null hypothesis was not rejected. Hydrophilic surface coatings limit hydrophobic interactions and protein adsorption, thereby hindering bacterial colonization and subsequent biofilm formation21,22,23. This mechanism helps explain the consistently lower bacterial adhesion observed in the coated group compared with the uncoated control.

Transparency plays a crucial role in the clinical acceptability of clear retainers, as patients undergoing orthodontic treatment often prioritize aesthetic features such as material clarity and color stability24,25. Since even minor alterations in optical properties may impact patient compliance, preserving transparency is essential when developing functional surface modifications, including antibacterial coatings.

In this study, there was no significant difference in transparency between the PUL and PUC groups, indicating that the application of the antibacterial coating did not adversely affect the optical clarity of the material. Among all groups, PET showed the highest transparency, while PUZ exhibited the lowest, consistent with previous findings26. These differences may be attributed to variations in polymer composition and structural characteristics. PETG is an amorphous polymer known for its high light transmittance and minimal crystallinity, which contributes to its superior transparency27. In addition, previous studies have shown that thermoforming conditions and surface roughness can influence optical properties, with rougher surfaces reducing transparency through increased light scattering and haze. In line with these reports, our study demonstrated that PUZ had the highest surface roughness among the tested materials. We interpret this to mean that, beyond the intrinsic properties of polyurethane, the relatively rougher surface of PUZ likely intensified light scattering, thereby amplifying its lower transparency compared with other groups. On the other hand, the PUC group, despite also being polyurethane-based, showed relatively high transparency, which we attribute to its reduced surface irregularities that mitigated light scattering.

There were no changes in surface roughness due to toothbrushing in any of the groups. Regardless of whether toothbrushing was performed, all three groups in the PU series had higher roughness than the PET group. Since a difference in surface roughness already existed between the two materials before toothbrush abrasion, the difference in roughness can be considered to have occurred during specimen fabrication rather than due to the effect of toothbrushing. This study utilized a 3D printing model used in the actual production of transparent orthodontic devices during specimen preparation, and the changes in surface roughness at the part of the specimen in contact with the printed model were evaluated. In the thermal deformation process of the surface of the model printed in layers, the surface roughness can increase due to contact. In addition, the condition of the specimen’s surface can be affected by the heating temperature and pressure conditions of the thermoforming process for each material28. During the thermoforming process for specimen preparation, all groups were subjected to the same temperature (220 °C) and pressure (58 kPa). However, the polyurethane-based materials required a longer heating time (either 40–55 s) compared to the PET group (30 s), which may have contributed to the increased surface roughness observed in the PU specimens due to the extended thermal exposure.

In this experiment, no changes in surface roughness were observed following toothbrushing in any of the groups. A previous study reported a significant increase in the surface roughness of various PETG-based materials after a 30-day cumulative toothbrushing simulation, except for Erkodur A1, a commercially available PETG-based thermoplastic retainer material (Erkodent Erich Kopp GmbH, Pfalzgrafenweiler, Germany)29. These findings highlight variations in surface roughness changes among different materials. Even within the same material type (i.e., PETG), surface roughness following toothbrushing can vary depending on factors such as differences in the manufacturing process (molding), the material’s structure, and the duration of toothbrushing. Thus, further comparative studies with extended toothbrushing durations are needed to confirm these findings.

Although surface roughness varied among the groups, this study did not observe a corresponding difference in bacterial adhesion. This interpretation is based on the descriptive comparison of quantitative results (Tables 3, 4), as no formal statistical correlation analysis was conducted. In contrast, previous studies on the surface roughness of clear orthodontic materials have reported that high surface roughness is associated with bacterial adhesion18,19,20. Differing results may be attributed to factors such as the type of bacteria, surface free energy, exposure time of bacteria, type of mold, and type of test surface. In this study, Streptococcus mutans cultured overnight was used for bacterial adhesion testing, whereas the culture conditions in previous studies may have varied. The specimens were fabricated using 3D-printed molds, which can introduce surface irregularities and layer patterns that affect surface free energy. Furthermore, bacterial adhesion was evaluated on the inner surface of the specimens—the area in direct contact with teeth—unlike many previous studies that assessed the outer or flat polished surfaces. These methodological differences may have contributed to the discrepancies in results. In this study, the surface roughness of the PET group was lower than that of the PU groups by more than 1.5 times, which is a significant difference. However, no significant reduction in the number of bacterial colonies was observed for the PET group in comparison with the PU groups.

After the production process, all groups exhibited a high surface roughness exceeding 0.9 μm. Bollen, Lambrechts, and Quirynen investigated the correlation between surface roughness and bacterial adhesion in the dental field and reported that bacterial adhesion increased when the Ra value exceeded 0.2 µm30. However, various factors, such as surface free energy, types of bacteria, surface roughness patterns, and external environmental conditions, may also interact with each other and affect bacterial colonization; hence, it is difficult to definitively conclude that the relationship between surface roughness and bacterial adhesion is linear beyond the critical point. Therefore, if the surface roughness exceeds a certain level, the Ra value may not be the critical reason for the increase in bacterial colonization. Furthermore, the initial and final Ra values in this study indicate that the environment is clinically conducive to bacterial colonization in terms of bacterial adhesion, as evidenced by previous studies. The final surface roughness values of the PETG material after exposure to thermocycling and brushing were all above 0.2 μm, which is clinically relevant in terms of bacterial adhesion. Therefore, an antibacterial effect on the surface is necessary, and this study aimed to evaluate the durability of the coating to determine if the antibacterial effect is retained. While the coating demonstrated significantly reduced bacterial adhesion compared to uncoated group, the consistently lower—but not statistically significant—adhesion compared to PET suggests a potential benefit that merits further investigation with a larger sample size.

To meet the rapidly increasing demand for clear retainers in the field of orthodontics, it is essential to improve the material itself, particularly in terms of enhancing its antibacterial activity and mechanical strength. This study successfully demonstrated the possibility of maintaining antibacterial effects over time without compromising transparency or physical properties of the material using the antibacterial coating. However, this study also has several limitations. First, the flat shape of the sample does not fully reflect the actual shape of a retainer. For the purpose of this study, a flat standard specimen with a uniform cross-section was necessary, providing standardized results that can be used in future research. Second, the experiment did not perfectly replicate the oral environment, including salivary secretion, temperature, and humidity conditions. Finally, the model conditions considered only a single tooth, without fully reproducing clinical situations. Therefore, further research is required to replicate the oral environment and clinical situations more accurately.

An antibacterial effect is necessary for retainers because the possibility of bacterial proliferation increases with surface roughness. This study confirmed the durability of the antibacterial coating. Such a durable coating is expected to reduce the growth of bacterial colonies to some extent in clear orthodontic devices. However, further studies focusing on long-term use are necessary since clear retainers can be worn for as long as 6 months.

Methods

Sample preparation

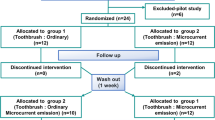

In this study, four 1.0-mm single-layer thermoplastic sheet for clear retainers, namely, uncoated Magicfoil R, hydrophilic antibacterial-coated Magicfoil R, Zendura, and CA Retention Foil, which are currently available in the market, were used. The specimens were divided into 4 groups based on the type of material used: PUL (uncoated Magicfoil R, Osstem, Seoul, Korea), PUC (antibacterial-coated Magicfoil R, Osstem, Seoul, Korea), PUZ (Zendura, Bay Materials, Fremont, CA, USA), and PET (CA Retention Foil, Scheu-Dental, Iserlohn, Germany). For PUC, the surface of polyurethane (PU) sheets was modified and coated with a polymer, polyethylenimine (PEI), which contains secondary amine groups, to form a hydrophilic and antibacterial layer by applying heat at 70–80 °C. PEI is a weakly basic, aliphatic, and non-toxic synthetic polymer. The PUL, PUC, and PUZ groups used PU sheets, whereas the PET group used a PETG sheet. Each experiment was conducted after thermoforming, and five specimens were prepared for each group.

The reference model, 3D printed with MED610 photopolymer resin (Stratasys, Eden Prairie, MN, USA), was placed in the center of a Biostar thermoforming machine (Scheu-Dental, Iserlohn, Germany). The machine settings (including pressure, temperature, and duration) were configured according to the manufacturer specifications (Supplementary Table 1). Subsequently, the thermoformable material was shaped to fit the model. The model was fabricated based on the existing model of maxillary occlusal morphology in Korean adults31, albeit with different dimensions. A rectangular specimen measuring 17 mm in width and 65 mm in length was created by cutting the side (Surface X) of the thermoformable material, which had been shaped to fit the model, using scissors (Fig. 4A). Inner surfaces that were in contact with the model were tested in all experiments.

Experimental procedures for evaluating mechanical properties and toothbrush abrasion. A Schematic illustration of specimen preparation for mechanical testing; surface X was sectioned from the fabricated dental model for analysis. B Flexural strength test. C Tensile strength test. D Cyclic loading test, with snapshots of the procedure conducted using a universal testing machine (Model 3365, Instron, Norwood, MA, USA). E Standardized toothbrush abrasion test performed using a toothbrushing machine (Hangil Technics, Korea).

Comparison of transparency

Transparency refers to the color difference in substances with a uniform thickness when placed against a black-and-white background32. Five specimens, each measuring 12 mm in width and 60 mm in length, were prepared for each group. To calculate the transparency index, the specimens were placed on black-and-white backgrounds, and their colors were measured using a spectrophotometer (CM-3700 A, Konica Minolta, Tokyo, Japan) in the transmittance mode in the visible light range (400–700 nm). Transmittance (T) was expressed as transparency, calculated as the relative transmittance according to the following formula33:

where Is is the energy reflected by the white calibration plate on the light source, and Io is the energy transmittance through the specimen from the light source reflected on the white calibration plate. The transparency index ranges from 0 (complete opacity) to 100 (complete transparency)34.

Testing of mechanical properties

The mechanical properties before and after coating were examined by assessing the flexural strength, tensile strength, and cyclic load. Only the PUC group received the hydrophilic antibacterial coating, while the PUL, PUZ, and PET groups were used as uncoated controls.

Flexural strength

A three-point bending test was performed using a universal testing machine (Model 3365, Instron, Norwood, MA, USA) (Fig. 4B). The crosshead speed was set at 5 mm/min, and the distance between the two ends of the jig was set to 24 mm, which reflected the distance between two upper central incisors and one lateral incisor. The prepared specimens (width: 12 mm; length: 60 mm) were placed at the center of the three-point bending test apparatus, and the maximum flexural strength was measured. The mechanical test data were analyzed using the Bluehill software (Instron, USA).

Tensile strength

Tensile strength measurements were performed using a universal testing machine (Model 3365, Instron, Norwood, MA, USA) (Fig. 4C) by connecting the ends of clear retainer specimens to the testing machine and applying a load by pulling at both ends. Dumbbell-shaped specimens were prepared (width: 10 mm; length: 60 mm), with the gauge length set at 20 mm and the remaining portions fixed in the jig. The specimens fixed to the jig were tested at a crosshead speed of 12 mm/min. The ultimate tensile strength (MPa), which is described as the maximum strength that could be withstood by the specimen before fracturing, was measured. The mechanical test data were analyzed using the Bluehill software (Instron, USA).

Cyclic load

Cyclic load measurements were obtained using a universal testing machine (Model 3365, Instron, Norwood, MA, USA) (Fig. 4D). The prepared specimens (width: 12 mm; length: 60 mm) were fixed with jigs, with the distance between the two jigs (one at either end) set to 24 mm. Cyclic load was ensured by compressing the specimens at a crosshead speed of 5 mm/min, with 3-mm increments, for a total of 400 cycles. The changes in load after 400 cycles were compared with the initial value. Load measurements were obtained after 1, 100, 200, 300, and 400 cycles.

Examination of surfaces before and after toothbrushing

Examination of surface roughness using FE-SEM

The thermoformed thermoplastic material was cut into rectangular specimens (width: 17 mm; length: 65 mm) and punched using a Ø 12-mm mold. Subsequently, the surface of each specimen was brushed using a toothbrushing machine (Hangil Technics, Korea) (Fig. 4E). The toothbrushing machine was operated at a speed of 1.25 strokes per second to simulate brushing of clear retainers 10 times per day. FE-SEM images were obtained before brushing and after 3 months of simulated brushing (corresponding to 900 strokes). The same type of toothbrush was used across all groups. The soaking solution was prepared with distilled water, without specific control of temperature or humidity.

After the brush test, the specimens were coated with platinum and then observed through FE-SEM (JSM-7610 F Plus Jeol, USA) at 100× magnification to examine the surface microstructures before and after toothbrushing.

Examination of surface roughness using a non-contact microscope

The brush test specimens were observed using a non-contact 3D laser microscope (LEXT OLS 5000, Olympus Europa SE & Co. KG, Germany). The average Ra value, which is the most commonly used parameter for surface roughness measurement, was calculated35.

Antibacterial testing

Streptococcus mutans was incubated overnight in a brain–heart infusion broth (Merck) at 37 °C under anaerobic conditions. Next, the bacterial culture was diluted to 1/400, a standardized optimal concentration determined through preliminary experiments for effectively assessing antibacterial effects, with reference to previous studies reporting effective dilution ranges between 1/100 and 1/200036,37. Both pre- and post-brushing specimens were sterilized under UV light for 30 min before being placed in 24-well plates for bacterial adhesion testing. Next, 1 ml of the diluted bacterial culture was added to each well and incubated at 37 °C under anaerobic conditions for 16 h. The samples were placed in 2% formalin, washed with PBS, and stained with a 0.1% crystal violet solution (Junsei Chemical, Tokyo, Japan) for 10 min. Subsequently, the samples were rinsed twice with PBS to remove any residual dye and dried before immersing them in 500 µL of a 10% acetic acid solution for 20 min to dissolve the stained crystal violet dye. The optical density of the dissolved crystal violet dye was quantified at 595 nm using a spectrophotometer (SpectraMax iD3 Multi-Mode Microplate Reader, Molecular Devices). The relative bacterial adhesion was evaluated based on optical density (OD) measurements, rather than by performing absolute colony counts.

Statistical analysis

Statistical analyses were performed using SPSS software version 22.0 (IBM Corp., Armonk, New York, USA). To determine the general characteristics of the samples, all data were presented as means and standard deviations. Normality and equal variance tests were conducted for comparisons of results among groups. Data that met both normality and equal variance assumptions were analyzed using a one-way analysis of variance (ANOVA) followed by Tukey’s test. If the assumptions were not met, non-parametric tests such as the Kruskal–Wallis and Mann–Whitney U tests were used with Bonferroni’s correction. The Ra values and bacterial adhesion densities before toothbrushing and after repeated toothbrushing were compared using Student’s t test. Changes in load after 400 repeated-load cycles were analyzed using repeated ANOVA measurements. A p value of < 0.05 was deemed to be statistically significant.

Data availability

Data supporting the findings of this study are available from the corresponding author upon request.

References

Johnston, C. D. & Littlewood, S. J. Retention in orthodontics. Br. Dent. J. 218, 119–122 (2015).

Schuster, S., Eliades, G., Zinelis, S., Eliades, T. & Bradley, T. G. Structural conformation and leaching from in vitro aged and retrieved invisalign appliances. Am. J. Orthod. Dentofac. Orthop. 126, 725–728 (2004).

Levrini, L. et al. ATP bioluminometers analysis on the surfaces of removable orthodontic aligners after the use of different cleaning methods. Int. J. Dent. 2016, 5926941 (2016).

Da Jason, C. S., Seneviratne, C. J., Wong, H. C. & Yow, M. Effects of Hawley, Essix, and Vivera retainers on salivary properties, oral hygiene, and Streptococcus mutans levels: a prospective clinical pilot study. APOS Trends Orthod. 11, 198–208 (2021).

Cho, W. K., Kang, S. M. & Lee, J. K. Non-biofouling polymeric thin films on solid substrates. J. Nanosci. Nanotechnol. 14, 1231–1252 (2014).

Lee, J. K., Kang, S. M., Yang, S. H. & Cho, W. K. Micro/Nanostructured films and adhesives for biomedical applications. J. Biomed. Nanotechnol. 11, 2081–2110 (2015).

Lichter, J. A., Van Vliet, K. J. & Rubner, M. F. Design of antibacterial surfaces and interfaces: polyelectrolyte multilayers as a multifunctional platform. Macromolecules 42, 8573–8586 (2009).

Patel, P., Choi, C. K. & Meng, D. D. Superhydrophilic surfaces for antifogging and antifouling microfluidic devices. JALA J. Assoc. Lab. Autom. 15, 114–119 (2010).

Yoon, S. H., Rungraeng, N., Song, W. & Jun, S. Superhydrophobic and superhydrophilic nanocomposite coatings for preventing Escherichia coli K-12 adhesion on food contact surface. J. Food Eng. 131, 135–141 (2014).

Hwangbo, S., Heo, J., Lin, X., Choi, M. & Hong, J. Transparent superwetting nanofilms with enhanced durability at model physiological condition. Sci. Rep. 6, 1–12 (2016).

Hwangbo, S. et al. Antibacterial nanofilm coatings based on organosilicate and nanoparticles. React. Funct. Polym. 102, 27–32 (2016).

Choi, M. et al. Superhydrophilic coatings with intricate nanostructure based on biotic materials for antifogging and antibiofouling applications. Chem. Eng. J. 309, 463–470 (2017).

Park, S. et al. Ladder-like polysilsesquioxanes with antibacterial chains and durable siloxane networks. Chem. Eng. J. 393, 124686 (2020).

Helander, I. M., Alakomi, H. L., Latva-Kala, K. & Koski, P. Polyethyleneimine is an effective permeabilizer of gram-negative bacteria. Microbiology (Reading) 143 (Pt 10), 3193–3199 (1997).

Yudovin-Farber, I., Golenser, J., Beyth, N., Weiss, E. I. & Domb, A. J. Quaternary ammonium polyethyleneimine: antibacterial activity. J. Nanomater. 1–11 (2010).

Kawabata, N. & Nishiguchi, M. Antibacterial activity of soluble pyridinium-type polymers. Appl. Environ. Microbiol. 54, 2532–2535 (1988).

Beyth, N., Yudovin-Farber, I., Bahir, R., Domb, A. J. & Weiss, E. I. Antibacterial activity of dental composites containing quaternary ammonium polyethylenimine nanoparticles against Streptococcus mutans. Biomaterials 27, 3995–4002 (2006).

Al Groosh, D. H., Bozec, L., Pratten, J. & Hunt, N. P. The influence of surface roughness and surface dynamics on the attachment of methicillin-resistant Staphylococcus aureus onto orthodontic retainer materials. Dent. Mater. J. 34, 585–594 (2015).

Quirynen, M. & Bollen, C. M. The influence of surface roughness and surface-free energy on supra- and subgingival plaque formation in man. A review of the literature. J. Clin. Periodontol. 22, 1–14 (1995).

Suter, F. et al. Roughness and wettability of aligner materials. J. Orthod. 47, 223–231 (2020).

Zhao, Q., Liu, Y., Wang, C., Wang, S. & Peng, N. Zwitterionic materials for antifouling membrane surface construction. Acta Biomater. 40, 1–16 (2016).

Ishihara, K., Ueda, T. & Nakabayashi, N. Preparation of phospholipid polymers and their properties as polymer hydrogel membranes. Polym. J. 22, 355–360 (1990).

Leng, C., Buss, H. G., Segalman, R. A. & Chen, Z. Surface structure and hydration of zwitterionic polymers: origin of nonfouling properties at interfaces. Langmuir 32, 2159–2167 (2016).

Bichu, Y. M. et al. Advances in orthodontic clear aligner materials. Bioact Mater. 22, 384–403 (2023).

Macrì, M., Murmura, G., Varvara, G., Traini, T. & Festa, F. Clinical performances and biological features of clear aligners materials in orthodontics. Front. Mater. 9, 819121 (2022).

Daniele, V. et al. Color stability, chemico-physical and optical features of the most common PETG and PU based orthodontic aligners for clear aligner therapy. Polymers (Basel) 14, 14 (2021).

Dupaix, R. B. & Boyce, M. C. Finite strain behavior of Poly (ethylene terephthalate)(PET) and Poly (ethylene terephthalate)-glycol (PETG). Polymers (Guildf) 46, 4827–4838 (2005).

Park, C., Kim, M., Hong, S., Go, J. & Shin, B. A study on the comparison mechanical properties of 3D printing prototypes with laminating direction. J. Korean Soc. Manuf. Technol. Eng. 24, 334–341 (2015).

Šimunović, L., Blagec, T. & Meštrović, S. Resistance of PETG materials on thermocycling and brushing. Dent. J. (Basel) 11, 135 (2023).

Bollen, C. M., Lambrechts, P. & Quirynen, M. Comparison of surface roughness of oral hard materials to the threshold surface roughness for bacterial plaque retention: a review of the literature. Dent. Mater. 13, 258–269 (1997).

Min, S., Hwang, C. J., Yu, H. S., Lee, S. B. & Cha, J. Y. The effect of thickness and deflection of orthodontic thermoplastic materials on its mechanical properties. Korean J. Orthod. 40, 16–26 (2010).

O’Brien, W. J., Boenke, K. M. & Groh, C. L. Coverage errors of two shade guides. Int. J. Prosthodont. 4, 45–50 (1991).

Ryu, J. H., Kwon, J. S., Jiang, H. B., Cha, J. Y. & Kim, K. M. Effects of thermoforming on the physical and mechanical properties of thermoplastic materials for transparent orthodontic aligners. Korean J. Orthod. 48, 316–325 (2018).

Abdelbary, O., Wahsh, M., Sherif, A. & Salah, T. Effect of accelerated aging on translucency of monolithic zirconia. Future Dent. J. 2, 65–69 (2016).

Ko, S., Lee, J. Y. & Park, D. Recent progress of antibacterial coatings on solid substrates through antifouling polymers. Appl. Chem. Eng. 32, 371–378 (2021).

Kozmos, M. et al. Bacterial adhesion of Streptococcus mutans to dental material surfaces. Molecules 26, 1152 (2021).

Nima, G. et al. Antibacterial efficacy of non-thermal atmospheric plasma against Streptococcus mutans biofilm grown on the surfaces of restorative resin composites. Sci. Rep. 11, 23800 (2021).

Funding

This work was supported by the Korea Medical Device Development Fund grant funded by the Korea government (the Ministry of Science and ICT, the Ministry of Trade, Industry and Energy, the Ministry of Health & Welfare, the Ministry of Food and Drug Safety) (Project Number: 1475013501, RS-2023-00208725).

Author information

Authors and Affiliations

Contributions

H.S.Y and J.Y.C conceived and designed the experiments; Y.E.O, J.S.K, T.H.C performed all experiments. Y.E.O conceived the study and wrote the manuscript. J.Y.C and S.H.C provided writing assistance and critically revised the manuscript for important intellectual content. All authors have reviewed and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethics declarations

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Oh, YE., Yu, HS., Choi, SH. et al. Impact of toothbrushing on aesthetic and mechanical properties of hydrophilic antibacterial coating materials for orthodontic clear retainers. Sci Rep 15, 41541 (2025). https://doi.org/10.1038/s41598-025-25437-y

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-25437-y