Abstract

Cranes are widely used in the construction industry for the installation, maintenance and repair of large, specialized equipment. With the increased use of cranes, there has been more frequent occurrence of crane accidents, which makes it difficult to identify key causative factors and create the crane accident chain due to large amounts of accident data. In this study, an intelligent method was established to determine the key factors and crane accident chain by combining text mining, complex network and integrated interpretive structure modeling (ISM) in this study. Causative factors of crane accidents were firstly identified using text mining based on 203 accidents that occurred from 2011 to 2022 in China. Meanwhile, an indicator system for crane operation causative factors was established by calculating the term frequency-inverse document frequency value. Subsequently, a complex network was constructed to determine the key causative factors. Furthermore, the crane accident chain was established using ISM. Finally, a practical tower crane accident was used to verify the rationality of the accident chain. The results showed that factors such as “cross parallel operation” and “insufficient safety management” were found to play a key role of crane operation. This study can provide a reference for the targeted safety management of crane operation and improve crane operation safety in the construction.

Similar content being viewed by others

Introduction

With the rapid development of construction, the use of cranes as a central component for construction operations can improve significantly production efficiency1. For example, tower cranes have been used as critical lifting equipment in prefabricated construction2 and particularly valued and widely adopted in China3– 4. However, more and more crane accidents occurred following the increased use of cranes due to complex operating procedures, poor conditional workplaces, and insufficient safety management5. Although a crane accident rarely causes an extremely serious accident (more than 30 fatalities), the accumulated number of crane accidents often leads to substantial casualties and economic losses. For example, among the 110 accidents with 99 death involving special equipment in China in 2021, 29 accidents and 30 deaths were related to cranes (almost 30%)6. This highlights the great significance to acquire the key factors affecting the accident process for preventing crane accidents.

The causative factors of crane accidents are complex, which can be broadly divided into four aspects: human, equipment, environment and management, and have attracted much attention in recent years. He et al.7 proposed a safety assessment method of crane accidents based on scenario analysis to determine the key factors, and found that emergency response was key factors. Sadeghi and Zhang8 developed a system that could assess the risk of tower cranes automatically based on expert experience and analytic hierarchy process, which could help managers make decisions. Chen et al.9 established a tripartite evolutionary game model of tower crane user, maintenance responsibility and supervision responsibility, and they pointed that the responsible party for repair has a greater impact on the evolution and the strategy stability of the three stakeholders. Kargar et al.10 utilized the fuzzy fault tree analysis to assess the risk of overturning of mobile cranes. They revealed that “failure in the supply of modern equipment and technologies”, “failure in load/equipment information provided by the manufacturer” and “failure in instructions and administration” were the main reasons. Wu et al.11 combined Bayesian networks and the N-K model to analyze the crane accident risk, and found that “workers’ illegal operations”, “inadequate safety supervision”, and “bad weather conditions” were high-risk factors for crane accidents. In the above studies, the causative factors were proposed largely based on crane accident investigation reports and some form of mathematical statistics or safety evaluation methods were then used to carry out quantitative assessment and clarify the key factors. However, one of the limitations of these studies is that these factors were often summarized subjectively with large omissions and were also rarely classified systematically. Meanwhile, the accident process was seldom studied to construct the crane accident chain and analyze the relationships among these factors. Furthermore, many studies have focused only on tower crane accidents, and all types of crane accidents were studied rarely.

Text mining refers to extracting the important knowledge or information from unstructured texts to reveal the key information. Currently, text mining has been utilized widely in coal and chemical industries, which can acquire contributors to accidents by providing data analysis of accident investigation reports12. Li et al.13 combined text mining, association rule mining and a Bayesian network to identify risk factors of coal mine safety production. The results showed that lack of management, education, and supervision was the root cause of coal mine accidents. Liu et al.14 extracted intelligent information from government on-site inspection reports of construction projects using KeyBERT, text mining and association rule mining and highlighted that this method can give inspectors valuable knowledge for better management. Liu and Yang15 constructed the knowledge graph of signal failure events for electromagnetic interference railway accidents based on text mining and convolutional neural networks to realize the visual presentation of research results. The above studies showed the efficiency of text mining in risk factors identification. However, the key risk factors and the accident chain of crane accidents have rarely explored by text mining.

In the relationship analysis among causative factors, some scholars have paid more attention. Guo et al.16 utilized the complex network to explore the risk chain of building construction accidents and found that unsafe acts related to construction tasks at height and operation of machines and equipment should be collaboratively controlled. Yang et al.17 combined complex network with cascading failure model to analyze the causative factors and path of construction collapse accident, and pointed out “construction scheme and organization” was the key factor for the accident. The above studies show that complex network theory provides a method to identify the key factors by analyzing the relationship among these factors. However, the hierarchy of these causative factors and how to describe the accident chain using the complex network were considered rarely. ISM has been used widely to acquire the hierarchy of risk factors and construct the accident chain in various industries. Sakar et al.18 combined ISM with a fuzzy Bayesian network to construct the hierarchy of risk factors for cargo liquefaction. Guo et al.19 proposed a Decision-making Trial and Evaluation Laboratory (DEMATEL)-ISM approach to unveil the supply chain and study the impact pathways of decreasing this chain vulnerability. The results showed that the government policy emerges was the influential factor, which was located at the bottom of the supply chain. While the complex network was used to identify key factors and ISM to divide the factors hierarchically, they were rarely combined to determine both the key factors and the hierarchical relationships among these factors.

In this study, the causative factors of crane accidents were extracted automatically using the text mining based on 203 crane accident investigation reports from 2011 to 2022 in China, from which an indicator system of the causative factors was constructed in four aspects: human, equipment, environment, and management. Based on the inter-relationship of these indicators, a complex network was established to determine the key factors by calculating the complex relationships among these factors including degree analysis, betweenness centrality, and clustering coefficient. Subsequently, integrated interpretive structure modeling (ISM)was used to classify the hierarchy of these factors automatically and acquire the complete development process of the crane operation accident. Subsequently, a practical tower crane accident was used to verify the accuracy of the ISM. Finally, several countermeasures were proposed for the safe operation of cranes.

Methodology

Data collection

The 203 crane accident investigation reports were collected from websites such as safehoo.com and the official website of the government. To clearly identify the causative factors, the 203 accident investigation reports all include the specific causes of accidents. And the crane types in the accidents were chosen for common crane operation, including mobile crane, tower crane and fixed crane. The accident causes were extracted according to the text structure of reports, as shown in Fig. 1.

The determination of causative factors

The accident causes of crane accidents are multiple, which the descriptions of same cause are different in each accident. Therefore, it is important to summarize the accident causes and determine the causative factors of crane accidents based on large historical data. Text mining technology is a data mining method to acquire the text feature information and discover the valuable potential information to implement classification and clustering of these texts, which has been widely used in the determination of causative factors15,20,21. Therefore, the causative factors of crane accidents were acquired by text mining, and the process was shown in Fig. 2. First, the causes with the same meaning were summarized briefly. Then, the term frequency-inverse document frequency (TF-IDF) of each factor was calculated, which showed the word frequency and inverse document frequency. Finally, the cloud map of causative factors was made automatically to determine the commonly occurred causative factors.

The key factors analysis

The key factors of crane accidents are important to prevent the accidents and propose the targeted control suggestions. The complex network can be used to analyze the key factors in complex systems by calculating the complex relationships among these factors, including degree analysis, betweenness centrality and clustering coefficient22. Therefore, the key factors of crane accidents were determined by complex network, and the process was shown in Fig. 3. First, the structure of complex network was established based on the relationships among causative factors, which was determined by expert experience and investigation reports. Then, some evaluation indicators were calculated in the crane accidents complex network, including degree analysis, betweenness centrality and clustering coefficient. Subsequently, the key factors were determined to propose further measures of preventing crane accidents.

The degree of a node in the complex network is the number of edges that connects with this node, including the input degree, output degree and total degree. The input degree of the node is the number of edges that other nodes point to the node, and the output degree of the node is the number of edges that this node points to other nodes. The total degree of a node is the sum of the input and output degrees.

The clustering coefficient represents the association strength between this node and an adjacent node and can be calculated as:

\(Ni=\frac{{2Ei}}{{di(di-1)}}\)

where \(di\) is the degree of the node i and\(Ei\)the number of the edges of this node.

The betweenness centrality is a measure of the shortest path length of a node in relation to the shortest path length of the entire network, reflecting the mediating role played by this node and can be calculated as:

where \(\varphi ab(i)\)is the number of the shortest path length through a→b of the node i and \(\varphi \text{a}\text{b}\)is the number of the shortest path length through a→b.

The construction of crane accident chain

The process of crane accidents is complex, in which the relationships among factors are intricate with vary combination. Therefore, it is important to clarify the hierarchical relationships among causative factors to interrupt the accident chain at the source. Integrated interpretive structure modeling (ISM) is a method to describe complex relationships between factors and analyze the crucial factors23. ISM can be used to express the correlation and logical hierarchy among these factors24. Therefore, the crane accident chain and the hierarchy of causative factors were determined by ISM. The process of this method was shown in Fig. 4. First, the adjacency matrix A was established based on the relationships among causative factors shown in the complex network. In this adjacency matrix A, the element “1” represented a directed edge connection from node i to node j, while the element “0” meant that node i had no influence over node j. Then, the reachable matrix was obtained. And, the reachability set (R), antecedent set (S) and intersection set (U) were combined to determine the hierarchy of each factor, where R included the factor itself and other factors it holed influences over, S encompassed the factor itself and other factors which it exerted influence on and U signified the superposition between R and S. Subsequently, the hierarchy of each factor was divided based on the reachable matrix. Finally, the crane accident chain was constructed according to the hierarchy, which clearly showed the relationships of causative factors for crane accidents.

The reachable matrix M is obtained as:

where I is the identity matrix, and r represents the order that satisfies the equation.

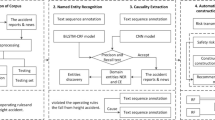

The framework

This study is aimed to improve the objectivity of the causative factors of crane accidents and the accuracy of the accident cause chain, a method based on text mining, complex network and ISM model is established and the specific framework is shown in Fig. 5. Firstly, based on 203 crane accident investigation reports from 2011 to 2022 in China, the causes of crane accidents were determined automatically by text mining. The TF-IDF value of each cause was calculated and the causative factors were sorted out to construct an indicator system for the causative factors of crane accidents from four aspects: human, equipment, environment and management. Subsequently, the complex network was established to determine the key causative factors by calculating average path length, degree, clustering coefficient and betweenness centrality. Furthermore, ISM was utilized to acquire the factors hierarchy automatically and construct the complete crane accident chain. Finally, countermeasures were proposed for safe operation of cranes and prevention of crane accidents.

Results and discussion

The text mining of the causative factors

The causative factor extraction

The 203 crane accident investigation reports were collected and sorted in terms of the causes of the accident. The causes in the accident investigation report are detailed, which is difficult to extract. Therefore, causes with the same meaning were summarized. For example, the specific descriptions of violations against the procedures were unified into “operation against the procedures”. With the application of Python and Jieba25 the sentences describing the causes were subjected to text segmentation automatically. To decrease the disruption of irrelevant words, some keywords like “accident” and “crane” were deleted, whereas the stopword lexicon and specific word lexicon were added to improve the accuracy of the data. The causes of crane accidents were extracted to further calculate their TF-IDF value.

Due to the large number of feature items, only the top 100 were selected, and irrelevant items that are not related to the expression of the causative factor such as “equipment”, “combustibles” and “safety management” were manually deleted. The TF-IDF values of the top ten causes are shown in Table 1, where it can be seen that the TF-IDF value of “operation against the procedures” is highest. It is mainly because crane operation is complex, which involves signalers, machinery drivers, machinery installers, and workers in other necessary specialties26. It was noted in the reports that some workers with inadequate safety training have low safety awareness, which often resulted in operation against the procedures. The TF-IDF value of insufficient safety management is also high, which could be due to the fact that, as crane operation rarely leads to serious casualties (more than 30), supervisors have relatively low safety awareness of hidden dangers.

Based on word frequency statistics, the keyword cloud map was created automatically, as shown in Fig. 6, where a larger size of the word means more frequent appearance of this word in the reported accidents. The cause “failure to detect hidden dangers in a timely manner” is most important apart from the top ten causes. Inadequate perception of risk is another crucial factor, which can lead to risky behaviors27. Among the 203 crane accidents, 50 were caused by “unrecognized hidden dangers”, such as equipment failure and unsafe behaviors.

The determination of the causative factors

Due to the large number of the factors in Fig. 6, the causative factors in the keyword cloud map were analyzed and categorized based on the standard specification for the classification of unsafe factors and related literature28,29,30,31,32 into four aspects: human, equipment, environment and management, from which an indicator system of the most important 20 causative factors was established as shown in Table 2.

The complex network analysis

Based on the inter-relationship among the causative factors of crane accidents, a complex network was constructed using Gephi, as shown in Fig. 7 and the degree, clustering coefficient and betweenness centrality of the nodes were calculated automatically.

The degree of the nodes

Figure 8 shows the input, output and total degrees of the nodes. It can be noted that the input degree of “cross parallel operations” is highest among the 20 causative factors (12), especially for construction sites. This is mainly because that the space of crane operation sites is often limited, and crane activities require workers to be in constant motion on high-risk sites33, which causes loose management and cross parallel operations. Furthermore, crane operation involves multiple types of operators. For example, the tower crane is widely utilized as the primary machine on construction sites, and crane operation is a collaborative activity involving drivers, lift directors, and riggers, rather than a standalone behavior performed by drivers alone34. Finally, as a variety of operations are carried out at the same time in a tight space, there exist many hidden dangers of accidents, such as overlapping crane work and cross operation with other equipment35.

“Insufficient safety management” has the highest output degree (10). In the 203 crane accidents, 116 are related to safety management. This result shows that insufficient safety management is a key causative factor, which is consistent with the result of text mining. “Insufficient safety management” often results in illegal outsourcing, the inability to stop unsafe behavior in a timely manner and uneliminated hidden dangers. The phenomenon of “escrow in packages” is common in practical operation due to loose management, mainly because that enterprises often illegally contract with private units to maximize profits36.

The total degree of “operation against the procedures” is higher than other nodes (18), indicating that it is the main reason contributing to crane accidents. In the 203 crane accidents, 149 were due to “operation against the procedures”. By analyzing the human factors of the accidents, the types of operation against the procedures include taking a crane ride, improper hanging objects and no or inadequate checking of equipment. For example, a hanging object fell down due to the use of only one lifting rope in 2021 in Hubei Province, resulting in one death. Some workers operate according to their own experience to save time and effort, which can easily lead to a crane accident37. Moreover, safety education and training are important means to improve the safety production ability of workers and prevent accidents38. In some cases, enterprises employ temporary construction personnel with no or inadequate safety education and training, contributing to operation against the procedures.

The clustering coefficient

Figure 9 shows the clustering coefficient of the nodes. The cause “the equipment that doesn’t meet the need” has the largest clustering coefficient (0.583), highlighted by the fact that some enterprises use an inadequate crane for lifting operations for saving cost. In the 203 reported accidents, 20 accidents were caused by “the equipment that doesn’t meet the need”, among which the equipment with an insufficient maximum load is most common (involved in 7 accidents). Furthermore, some manufacturers do not inspect adequately the performance of the crane equipment for design or manufacturing defects, which brings a serious threat to safe production of cranes9.

The betweenness centrality

The betweenness centrality of the nodes is shown in Fig. 10. It is evident that “operation against the procedures” and “cross parallel operations” have the largest betweenness centrality (0.094), which indicates that these nodes have strong relationship with other nodes, which are consistent with the degree analysis of the two nodes. Therefore, enterprises should focus on the standardized behavior of operators and curb unsafe behaviors in a timely manner. For crane operation, communication and coordination with each other in a timely manner is an effective way to avoid crane accidents when there are cross-operations in the operation space.

The hierarchy of the causative factors

Based on the correlation among these causative factors, the adjacency matrix A was established.

Subsequently, the reachable matrix M can be obtained using MATLAB as:

Based on the reachable matrix M, the reachability set (R), the antecedent set (S) and the intersection set (U) were determined, as shown in Appendix A. The elements that satisfy Ri = Ui were at the first level, and then this element will be eliminated from R and S. The above operation was repeated until the hierarchy of all elements was determined39 and the final hierarchy of the causative factors is shown in Table 3.

Based on the hierarchy in Table 3, the ISM analysis of the causative factors can finally be established, as shown in Fig. 11. The equipment factors are at the first level, which can be explained by the fact that equipment is an essential part in crane operation. It was noted in the accident reports that equipment often operated with faults, because the operators ignored safety operation due to the heavy pressure to get the job done40. It can also be seen in Fig. 7 that almost all the equipment factors are related to “operation against the procedures”, which indicates that the equipment operation safety is strongly dependent upon the operator’s behavior. In practical operation, many operators often overlook the quality and integrity inspection of equipment and tools, which could increase the risk of crane accidents.

The management factors are also at the highest level, which are the prerequisites for the occurrence of other hazards. This is mainly due to poor safety management and operation against standard operating procedures, resulting in either the insufficient number of on-site management personnel or chaotic management. For example, a truck crane accident occurred in Nanjing Subway Line 3 in 2014 due to overloading with no special personnel for on-site safety management, which caused three deaths. Furthermore, some enterprises ignore the safety of crane operations by either not providing proper training for the operators or employing unqualified operators, both of which have a detrimental effect on crane operation safety. Clearly, it is vital to standardize the management of crane operation enterprises for reducing accidents.

Model validation

To verify the accuracy of the ISM model of the crane operation causative factors, a tower crane accident investigation report of a crane collapsing was selected to describe the accident chain by the ISM model, which includes the time, place, process and cause of the accident. The crane collapsing accident occurred in the construction site in China due to the lack of the security protection function, resulting in 3 deaths. Based on the crane operation causative factors indicator system in Table 2 and by analyzing the occurrence of this accident, the reasons for the accident were summarized and compared with those given in the investigation report41. It is clear that there is a close correlation and agreement between the two sets of data, verifying the applicability and accuracy of the present method. Table 4 shows the comparison of the reasons determined using this method and those given in the investigation reports.

This accident chain determined based on the ISM analysis is shown in Fig. 12. It can be noted that due to insufficient safety education and training and lack of personnel qualification, workers tended to operate against regulations with poor safety awareness. Moreover, they did not carry out any safety protection measures such as connecting safety pins. At the same time, the workers’ violations behaviors were not discovered and curbed in time due to a lack of special personnel for safety management, which eventually led to the occurrence of accidents. This accident chain of crane accidents in the ISM analysis is consistent with that in the actual accident.

Prevention measures

Based on the results and discussion in previous sections, the following countermeasures were proposed for safe operation of cranes.

-

(1)

For crane operators, enterprises can provide safety education and training regularly to fundamentally prevent violations in crane operations, such as organizing drill activities and VR simulation experience. Moreover, A full-time supervisor should be always on site to supervise the operators and correct any unsafe actions in a timely manner, which can fundamentally ensure safe operation of cranes.

-

(2)

In terms of equipment, crane enterprises can establish a life-cycle management system for cranes, involving installation, trial, inspection, maintenance, repair, scrapping etc. Furthermore, the crane equipment must be designed based on the actual needs on site and closely integrated with specific operational processes.

-

(3)

To eliminate the risks of cross-operations, a fundamental principle of prohibiting simultaneous work activities in shared spaces can be established. And crane operation enterprises can set up some unambiguous safety signage and barriers to strictly avoid multiple work activities within the same space.

-

(4)

To strengthen crane operation safety, a comprehensive management system can be established based on historical accidents, in which clear safety responsibilities need be defined and dedicated management personnel need be assigned. Furthermore, comprehensive safety technical preparations and risk analyses are conducted before crane operations.

Conclusion and future study

Targeted safety management in crane operation is important to prevent crane accidents. This study is aimed at developing and validating an intelligent method to determine the key causative factors and accident chain of crane operation, which can improve the safety of crane operation in the construction. In order to identify the causative factors of crane accidents, the causes were extracted automatically using text mining from 203 crane accident investigation reports, based on which the causative factors were summarized and divided into four aspects. The application of complex network was illustrated to identify the key causative factors, which were then divided into different levels automatically by ISM to determine the complete process of crane accidents. The application of this intelligent method can realize real-time extraction of causative factors of crane accidents based on investigation reports and adjust the indicator system timely. At the same time, the crane operation complex network and accident chain can be expanded according to the extracted results. The conclusions of this study are as follows:

-

(1)

The TF-IDF value of “operation against the procedures” is highest (0.0593), mainly due to the lack of professional safety education and training of operators and weak safety awareness. The TF-IDF value of “insufficient safety management” is also high (0.0582), because of the wide range of on-site activities and the lack of standardization of on-site supervision.

-

(2)

In the complex network analysis, “cross parallel operations” has the highest input degree, “insufficient safety management” the highest output degree and “operation against the procedures” the highest total degree. “The equipment that doesn’t meet the need” has the largest clustering coefficient and “cross parallel operations” and “operation against the procedures” the highest betweenness centrality. These results indicate that these factors play the most important role in the crane operation accident.

-

(3)

In the ISM analysis, the equipment factors are at the first level, which signifies that faulty equipment contributes most to crane accidents. The management factors are also at the highest level, implying that poor management is the prerequisites for the occurrence of other hazards.

This research can determine the key causes by TF-IDF value to decrease the subjectivity of manual identification. Therefore, the key factors and accident chain of crane can be acquired, which is of significance for crane safety management and preventing the crane accident. This intelligent method includes many types of crane operation accidents. For the crane industry, one specific type of crane operation can determine key factors and accident chain more clearly and targeted by this intelligent method, based on this crane type accidents. Moreover, according to the key factors and accident chain, the crane managers can prevent crane operation accidents at the source.

Despite the importance of this research, several limitations of this study could be addressed in future studies. It should be noted that the data and analysis in this study are based on 203 accidents from 2011 to 2022 in China. While it is expected that the causative factors would be largely similar in other countries, some of the specific factors could vary considerably depending on the work ethic and personal behavior. In future studies, the on-site inspection data can be incorporated into the analysis to improve the accuracy of the indicator system and serve precision supervision of crane operation. Meanwhile, the research just stays on the theory without actual application. Therefore, web interfaces can also be developed to automatically abstract the causes of crane accident investigation reports to continuously enrich the content of the case database. Finally, even though this study is focused on crane accidents, the developed methodology as shown in Fig. 5, i.e., combining text mining with complex network and ISM, could be adapted and applied in other types of accidents.

Data availability

The data that support the findings of this study are available from the corresponding author.

References

Zhang, W., Xue, N., Zhang, J. & Zhang, X. Identification of critical causal factors and paths of tower-crane accidents in China through system thinking and complex networks. J. Constr. Eng. Manag. 147 (12), 04021174 (2021).

Yin, J. et al. Dispatching rule design for tower crane scheduling in prefabricated construction via genetic programming. Autom. Constr. 165, 105588 (2024).

Yuan, Z. M. et al. Simulation and optimization of prefabricated Building construction considering multiple objectives and uncertain factors. J. Building Eng. 86, 108830 (2024).

Chen, L. J. et al. Low carbon concrete for prefabricated modular construction in circular economy: an integrated approach towards sustainability, durability, cost, and mechanical performances. J. Building Eng. 90, 109368 (2024).

Fang, Y., Cho, Y. K. & Chen J. A framework for real-time pro-active safety assistance for mobile crane lifting operations. Autom. Constr. 72, 367–379 (2016).

State Administration for Market Regulation of the People’s Republic of China. Notice of the State Administration for Market Regulation on the safety status of special equipment in the country in 2021. (2022). https://www.samr.gov.cn/tzsbj/qktb/tb/art/2022/art_2004df6e933b4f0c9ed7126f8546e878.html

He, W. et al. The comprehensive safety assessment method for complex construction crane accidents based on scenario analysis–A case study of crane accidents. Comput. Ind. Eng. 199, 110716 (2025).

Sadeghi, H. & Zhang, X. Towards safer tower crane operations: an innovative knowledge-based decision support system for automated safety risk assessment. J. Saf. Res. 90, 272–294 (2024).

Chen, Y., Zeng, Q., Zheng, X., Shao, B. & Jin, L. Safety supervision of tower crane operation on construction sites: an evolutionary game analysis. Saf. Sci. 152, 105578 (2022).

Wu, B. J., Jin, L. H., Zheng, X. Z. & Chen, S. Coupling analysis of crane accident risks based on bayesian network and the NK model. Sci. Rep. 14 (1), 1133 (2024).

Ancione, G. & Milazzo, M. F. Identifying risk factors in handing and lifting loads by the analysis of near-miss and accident reports. Saf. Sci. 181, 106701 (2025).

Qiu, Z., Liu, Q., Li, X., Zhang, J. & Zhang, Y. Construction and analysis of a coal mine accident causation network based on text mining. Process Saf. Environ. Prot. 153, 320–328 (2021).

Li, S., You, M., Li, D. & Liu, J. Identifying coal mine safety production risk factors by employing text mining and bayesian network techniques. Process Saf. Environ. Prot. 162, 1067–1081 (2022).

Liu, M., Luo, X., Wang, G. & Lu, W. Z. Intelligent information extraction from government on-site inspection reports of construction projects: A graph-based text mining approach. Adv. Eng. Inform. 58, 102163 (2023).

Liu, C. & Yang, S. A text mining-based approach for Understanding Chinese railway incidents caused by electromagnetic interference. Eng. Appl. Artif. Intell. 117, 105598 (2023).

Guo, S., Zhou, X., Tang, B. & Gong, P. Exploring the behavioral risk chains of accidents using complex network theory in the construction industry. Phys. A: Stat. Mech. Its Appl. 560, 125012 (2020).

Yang, L., Shao, L. J., Nie, Q. W. & Han, X. Cascading failure analysis of causal factors for construction collapse accidents based on network theory. J. Constr. Eng. Manag. 150 (2), 04023163 (2024).

Sakar, C., Koseoglu, B., Toz, A. C. & Buber, M. Analysing the effects of liquefaction on capsizing through integrating interpretive structural modelling (ISM) and fuzzy bayesian networks (FBN). Ocean Eng. 215, 107917 (2020).

Guo, X. T., Yang, Z. J., Sun, J. & Zhang, Y. L. Impact pathways of emerging its to mitigate supply chain vulnerability: A novel DEMATEL-ISM approach based on grounded theory. Expert Syst. Appl. 239, 122398 (2024).

Li, S., Li, Y. M., Liu, J. & D. & Identifying coal mine safety production risk factors by employing text mining and bayesian network techniques. Process Saf. Environ. Prot. 162, 1067–1081 (2022).

Xu, H. et al. Cause analysis of hot work accidents based on text mining and deep learning. J. Loss Prev. Process Ind. 76, 104747 (2022).

Feng, J. R., Zhao, M., Yu, G., Zhang, J. & Lu, S. Dynamic risk analysis of accidents chain and system protection strategy based on complex network and node structure importance. Reliab. Eng. Syst. Saf. 238, 109413 (2023).

Wu, W. S., Yang, C. F., Chang, J. C., Château, P. A. & Chang, Y. C. Risk assessment by integrating interpretive structural modeling and bayesian network, case of offshore pipeline project. Reliab. Eng. Syst. Saf. 142, 515–524 (2015).

Liang, Y., Wang, H. & Zhao, X. Analysis of factors affecting economic operation of electric vehicle charging station based on DEMATEL-ISM. Comput. Ind. Eng. 163, 107818 (2022).

Zhu, Y., Liao, H. & Huang, D. Using text mining and multilevel association rules to process and analyze incident reports in China. Accid. Anal. Prev. 191, 107224 (2023).

Yin, J. J., Alias, A. H., Haron, N. A. & Bakar, N. A. Identification and analysis of hoisting safety risk factors for IBS construction based on the accimap and cases study. Heliyon 10(1), (2024).

Ma, Z. & Chen, Z. S. Mining construction accident reports via unsupervised NLP and accimap for systemic risk analysis. Autom. Constr. 161, 105343 (2024).

GB 6441-. 86 < The Classification for Casualty Accidents of Enterprise Staff and workers> (China State Bureau of Standards, 1986).

GB/T. 13861 – 2022 < Classification and Code for the Hazardous and Harmful Factors in process> (State Administration for Market Regulation, 2022).

T/COSHA. 004-2020 < Hazard identification, Risk Assessment and Plan of Control measures—Guidance> (China Occupational Safety and Health Association, 2020).

Zhou, W., Zhao, T., Liu, W. & Tang, J. Tower crane safety on construction sites: A complex sociotechnical system perspective. Saf. Sci. 109, 95–108 (2018).

Rafindadi, A. D. et al. Data mining of the essential causes of different types of fatal construction accidents. Heliyo, 9(2), (2023).

Duan, P., Zhou, J. & Goh, Y. M. Spatial-temporal analysis of safety risks in trajectories of construction workers based on complex network theory. Adv. Eng. Inform. 56, 101990 (2023).

Fung, I. W., Lo, T. Y. & Tung, K. C. Towards a better reliability of risk assessment: development of a qualitative & quantitative risk evaluation model (Q2REM) for different trades of construction works in Hong Kong. Accid. Anal. Prev. 48, 167–184 (2012).

Hwang, S. Ultra-wide band technology experiments for real-time prevention of tower crane collisions. Autom. Constr. 22, 545–553 (2012).

Mohandes, S. R. et al. Causal analysis of accidents on construction sites: A hybrid fuzzy Delphi and DEMATEL approach. Saf. Sci. 151, 105730 (2022).

Zhang, W., Zhu, S. N., Zhang, X. & Zhao, T. S. Systematic model of construction accident causation and its empirical analysis. China Saf. Sci. J. 29 (06), 56–62 (2019).

Bai, M. et al. Why do major chemical accidents still happen in china: analysis from a process safety management perspective. Process Saf. Environ. Prot. 176, 411–420 (2023).

Li, G. et al. Flood risk assessment by using an interpretative structural modeling based bayesian network approach (ISM-BN): an urban-level analysis of Shenzhen, China. J. Environ. Manage. 329, 117040 (2023).

Lingard, H., Cooke, T., Zelic, G. & Harley, J. A qualitative analysis of crane safety incident causation in the Australian construction industry. Saf. Sci. 133, 105028 (2021).

Nong’an County Runze. Tongtai Park three-phase project 9.13 lifting injury large accident investigation report. (2017). https://www.safehoo.com/Case/Case/Crane/201708/493508.shtml(

Acknowledgements

This study was sponsored by the National Natural Science Foundation of China (No. U2333210) and Fundamental Research Funds for the Central Universities (No. 2025JCCXAQ02).

Funding

This study was sponsored by the National Key Research and Development Program of China (No. 2024YFC3016804) and Fundamental Research Funds for the Central Universities (No. 2025JCCXAQ02).

Author information

Authors and Affiliations

Contributions

Jinlong Zhao: Conceptualization, Methodology, Supervision, Formal analysis, Funding acquisition, Visualization, Writing – Original draft. Huaying Cui: Data curation, Formal analysis, Investigation, Resources, Writing – Original draft. Zhenqi Hu: Visualization, Writing – Original draft. Rongxue Kang: Project administration, Resources, Supervision, Writing – review & editing. Jing Li: Project administration, Resources, Supervision, Writing – review & editing. Jianping Zhang: Supervision, Writing – review & editing.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhao, J., Cui, H., Hu, Z. et al. Intelligent identification of causative factors and construction of accident chain for crane operation. Sci Rep 16, 1886 (2026). https://doi.org/10.1038/s41598-025-31469-1

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-31469-1