Abstract

Lately, transformer-less Researchers in the fields of power electronics and renewable energy have taken notice of photovoltaic inverters because of their great efficiency, low cost, and small size. However, higher efficiency typically results in more components, making the inverter costly and bulky. This article proposes a single-phase seven-level transformer-less with common ground topology. The proposed topology utilizes 10 switches, 4 capacitors and 1 diode. This article also suggests an improved Phase Shift (PS) Modulation Technique which reduces overall losses. When implemented with improved Phase Shift (PS), the total highest attainable efficiency of the proposed topology is 98.05% at 15 W. The THD% of voltage harmonics is reduced to 15.29% from 17.20% and for current harmonics is reduced to 5.07% from 10.15%. The reliability of the proposed inverter has also been analyzed. The simulation as well as hardware results have been presented to validate the performance of the proposed inverter.

Similar content being viewed by others

Introduction

A Multilevel Inverter (MLI) is commonly employed in applications that require high voltage and high current.

The desired stepped AC voltage waveform is derived from many levels of DC voltage. Using a multi-level inverter offers several advantages over a traditional two-level inverter, including reduced switching losses and frequency. As the number of levels increases, the total harmonic distortion (THD) decreases. However, this level increase is accompanied by a substantial increase in the number of components. As the number of components in an inverter increases, the inverter gets larger, more expensive, and less efficient, so negating its advantages1.

Among all renewable energy sources, solar photovoltaics (PV) is one of the purest, most dependable, emission-free, and most readily accessible. PV generation has grown significantly in both business and residential buildings in recent years. Global solar power generation reached 1270.5 GW by the end of 2022, predicted Solar Power Europe’s global market projection for 2018–2022. It was anticipated to reach 209 GW in China and 78.4 GW in India2. Power electronic converters are essential for integrating renewable energy sources with the utility system. The two steps of a typical grid-connected photovoltaic system are dc–dc and dc–ac conversion. A dc–ac conversion stage is required for grid-tied PV systems in order to input AC electricity into the utility grid. The two main categories for these grid-tied inverters are galvanic-isolated systems and non-isolated systems2,3.

To overcome the above issue, higher efficiency, and low cost, several transformer-less inverters (TIs) with inherent voltage boosting ability are proposed in the literature3,4. However, the absence of galvanic isolation and high-frequency switching excites the ground leakage current as the PV panels are grounded to meet electrical codes and safety standards. These topologies lower the leakage current by either connecting the grid neutral to the midpoint of the dc-link bus, isolating the PV array from the utility grid to maintain a constant common mode (CM) voltage, or connecting the grid neutral to the negative terminal of the PV array4,5.

Significant efforts are needed to control the leakage current by structural alterations in order to maintain a consistent common mode voltage. On the other hand, researchers have been able to build a number of inverter topologies utilizing this approach because a common ground connection can prevent ground leakage current6.

Since all components share the same ground, there is less potential for ground loops, which can introduce noise, reduced noise, and electromagnetic interference (EMI). Components and subsystems can be easily interfaced with each other when they share a common ground. This is particularly useful in complex systems where multiple modules are needed to communicate or share signals. These are just a few of the advantages that make this topology so widely used in a wide range of applications.

By establishing a common ground connection between the PV negative line and grid neutral, the common ground type (CGT) inverter eliminates leakage current and avoids the PV parasitic capacitance. While typical CGT-based inverters do not use leakage current, they are more expensive and need more volume since they use at least one capacitor rated for maximum output voltage. Larger voltage-rated capacitors are needed for the majority of CGT inverters that are currently on the market, which increases ripple losses and energy storage. Even if some of the less complex capacitor-stored energy-based CGT topologies handle this problem, more compact and simplified structures can still be created7,8.

The evolution of power electronics topology has been transformative, driven by advancements in efficiency, power density, and component optimization to meet the demands of modern high-power applications. The field initially relied on conventional DC–DC and DC–AC converter topologies, such as buck, boost, and basic inverter designs, which allowed basic energy conversion with limited efficiency. As technology progressed, the need for better power quality and reduced switching losses spurred the development of multilevel inverters (MLIs), which include topologies like Neutral Point Clamped (NPC), Flying Capacitor, and Cascaded H-Bridge inverters. These topologies improved output waveform quality, reduced harmonic distortion, and mitigated voltage stress on power switches, resulting in more efficient and durable designs suitable for high-voltage, grid-connected applications9,10.

Recent years have witnessed substantial research into optimizing power converters with reduced component count and simplified structures. Innovations in switch reduction strategies reflect significant progress toward achieving high efficiency with fewer components. Such designs not only improve system efficiency but also reduce costs and complexity, making them ideal for medium- and high-voltage applications11.

The hybridization of inverter topologies has also introduced adaptive designs that combine elements from different MLIs, such as the Hybrid Cascaded H-Bridge and Modular Multilevel Converters (MMCs), which are particularly advantageous for renewable energy integration and DC transmission. Hybrid inverters offer scalability, reduced harmonic content, and enhanced control flexibility, achieving efficiencies up to 97.8% at full load while operating with lower voltage stress on components12,13. MMCs have furthered this progression by offering modularity, fault tolerance, and scalability, which are essential for the evolving landscape of grid-tied and high-voltage direct current (HVDC) systems, where power quality and reliability are paramount12.

More recently, the adoption of wide-bandgap (WBG) materials like Gallium Nitride (GaN) and Silicon Carbide (SiC) has been a game-changer in topology development. These materials enable higher switching frequencies and lower conduction losses compared to traditional silicon-based devices. For example, SiC-based NPC topologies have achieved up to a 3% improvement in efficiency at switching frequencies exceeding 50 kHz, a milestone in high-frequency power applications that require minimal loss and high durability. Looking forward, AI-driven adaptive switching mechanisms are emerging as a cutting-edge addition to power electronics, enabling real-time adjustments to optimize performance across variable loads. This evolution from basic converters to intelligent, high-efficiency topologies reflects the ongoing pursuit of power density, cost reduction, and control precision to address the complex requirements of modern power systems and renewable energy applications13.

Modulation techniques for multi-stage inverters are diverse. A multilayer inverter uses the modulation approach to obtain the regulated output voltage and so synthesizes a sinusoidal waveform.

Phase Shift Modulation (PS) is a modulation technique in which the digital signal data modifies the carrier signal’s phase. Because of PS’s dependability and effectiveness, digital communication systems employ it extensively. The main benefit of PS modulation is that it can withstand noise and interference, which makes it appropriate for situations where there is a lot of signal distortion. This robustness results from the information being transmitted through phase shifts, which are less vulnerable to noise-induced amplitude alterations.

When Phase Shift Modulation (PS) is implemented in DC–DC inverters, the system can experience high losses primarily due to switching and conduction inefficiencies. In PSM, the output voltage is regulated by adjusting the phase shift between the control signals driving the inverter’s switches. This modulation technique typically involves high-frequency switching to achieve precise control over the power flow, which inherently increases switching losses. Each transition from on to off state (and vice versa) of the power transistors generates switching losses, proportional to the switching frequency and the voltage and current during the transition. Higher switching frequencies exacerbate these losses14,15. In an attempt to eliminate these drawbacks, many methods of improving phase shift modulation have been proposed.

Recently, many multi-level topologies have been proposed. Jakhar et al.16 proposed a 7-level single phase topology which utilizes around 12 switches and 6 capacitors, with efficiency up to 95%. The main drawback in the proposed topology here is that the proposed topology uses a higher component count, providing less efficiency. This reduced component count not only lowers costs but also simplifies installation, also reducing thermal stress for medium voltage systems. Meraj et al.17 proposed a dual circuit. For seven level circuit proposed it utilizes 12 switches and 2 capacitors giving 94% efficiency. The design also utilizes H-bridge for extension of levels. The proposed circuit utilizing around 10 switches, and 4 capacitors provides 98.05% efficiency at lower loads, making it reliable for medium voltage circuits. Meraj et al.18 proposed a 9-level inverter topology utilizing 12 power switches (10 switches, and two of which are bidirectional) 2 capacitors and also 2 DC sources, providing 94.5% efficiency and lower for varying loads. One of the main drawbacks is the use of two DC sources, which requires high input voltage overall increasing voltage stress. Although it gives a higher number of levels, its losses are still comparatively high. Neti et al.19 proposed a 5-level CGT utilizing 7 power switches (6 switches, out of which one is bidirectional). The topologies proposed above are mainly, with high component count, high voltage stress and less efficiency when compared to the proposed topology.

The researchers have developed many multilevel inverters that give several voltage levels and high gain. As many aim to achieve high gain, they cannot handle the increasing voltage stress on the components and thus reduce overall efficiency. The topologies proposed in20 are 19-level ANPC-SCMLI inverters, which utilize four switched capacitors and two DC link sources. The highest efficiency achieved is 94.42% at 500W. The topology provides a very high gain, which results in high voltage stress and thus reduces efficiency. The topology proposed in21 is a 5-level CGT, utilizing 8 switches and two capacitors with an efficiency of 97.2%, giving a dual boost. The topology proposed in1 is a 17-level inverter that utilizes 5 half-bridge switches, 4 capacitors, and 5 diodes, providing an efficiency of 95.4%. The topology proposed in13 is a 5-level CGT- inverter that can be extended to further higher levels; its highest attainable efficiency is 96.20%. It utilizes 8 switches and 2 capacitors. The topologies proposed have a high voltage gain and require less input voltage, which is of great significance. The high gain and low input create a higher voltage stress on switches used, which in turn impacts the performance and efficiency of the inverter. Another 13-level topology has also been recently proposed in13, which utilizes 15 switches and three capacitors and has an efficiency of about 97%. The topologies proposed here all are of higher or lower level, providing higher gains.

The major drawback of all the topologies mentioned above is voltage stress or component count.

The design of the proposed inverter and the implementation of the proposed modulation scheme help in reducing losses and enhancing efficiency, providing a triple boost. This paper proposes a seven-level CGT inverter with a reduced component count, less bulky, cost-effective with enhanced efficiency and an improved phase shift modulation technique which gives a highest attainable total efficiency of 98.05%, reducing both switching and conduction losses-.

The features of this paper are:

-

Proposed topology with reduced number of components and reduced THD.

-

Proposed an improved phase shift modulation resulting in lower losses and enhanced efficiency.

-

Overall enhanced efficiency when Improved phase shift is implemented on the proposed topology.

Proposed Seven-level inverter and improved phase shift (IPS)

This section discusses the proposed topology, its operating principle and improved phase shift modulation technique.

Proposed technology

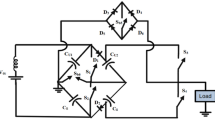

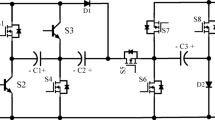

The proposed seven-level inverter has 10 power switches, of which two are connected antiparallel making a bidirectional switch, SB8, 4 capacitors, two of which are charged to 1VDC and the other two to 2VDC, and 1 diode. Figure 1 shows the proposed circuit.

The circuit consists of 4 switch legs, leg 1 consisting of S1 and S6, leg 2 consisting of S4 and S5, leg 3 consisting of S3 and S3’and leg 4 consisting of S7 and SB8.

Operation principle

Figure 2 shows the various operating modes of the proposed circuit. C1 and C2 are charged to 1VDC whereas C3 and C4 are charged to 2VDC. SB8 allows current to flow in either direction, helping in generating ± 3VDC levels.

Table 1 shows the switching states of all the switches for generating various levels.

As per Table 1, + 3VDC is developed at the output by turning on the switches S1, S2, S3, S4 and S5. In this state, C1 and C4 are charged to + 1VDC. + 2VDC is developed at output by switching on the switches S2, S3’, S4 and S5, here C1 is charged to + 1VDC. + 1VDC is developed by switching on the switches S1, S2, S3, S5 and S7. In this state C1 and C4 are charged to + 1VDC and C2 and C3 are charged to + 2VDC, here the current direction is opposite to the charging of capacitors, thus charging the switches to − 2VDC.

0 VDC is developed by turning on switches S6, S7, SB8, S4 and S3’. − 1VDC is developed at the output by turning on S1. S2, S3’, S5 and S7. In this state, C1 is charged to + 1VDC and C2 and C3 are charged to + 2VDC. The current direction is opposite to charging, so the switches are charged to − 2VDC. − 2VDC is developed at the output by turning on S3’, S4, S8 and SB8, here C1 is charged to + 1VDC. − 3VDC is developed at the output by turning on the switches S1, S2, S3’ S5, S6, S7 and SB8, in this state, C1 is charged to + 1VDC and C2 and C3 are charged to + 2VDC. The current direction is opposite to charging, so the switches are charged to − 2VDC. Orange coloured lines show the current path, the blue dashed lines and red dashed lines show the charging paths of capacitors C1 and C4 and capacitors C2 and C3.

Proposed topology

Switched capacitor multilevel inverters (SCMLI) have several limitations when applied to medium voltage systems. One of the primary issues is the increased switching losses due to the frequent charging and discharging cycles of capacitors. In medium voltage applications, where the inverter must respond quickly to changes in load or operational conditions, these losses can significantly impact overall efficiency and heat generation. Additionally, the challenge of voltage balancing across multiple capacitors becomes more pronounced as the number of capacitors increases, leading to uneven charge distribution. This imbalance can result in capacitor failure or degradation of performance, compromising the reliability of the inverter22.

Moreover, traditional SCMLI architecture often requires a large number of capacitors to achieve the desired output voltage levels, which adds complexity to the design and increases the overall size and cost of the inverter. This is particularly problematic in medium voltage applications, where space and weight constraints are critical. Consequently, the limitations inherent in SCMLI designs can hinder their practical implementation in medium voltage systems.

The proposed inverter offers a promising solution to these challenges. By employing a configuration with four capacitors and two bidirectional switches, the design reduces the overall component count compared to traditional MLI topologies. This simplification enhances reliability and minimizes potential points of failure. Additionally, the innovative charging strategy of charging two capacitors to 1 VDC and two to 2 VDC facilitates better voltage control and distribution. Arrangement allows for smoother voltage transitions, thereby enhancing efficiency, as demonstrated by the inverter’s performance of 98.05% at 150W and approximately 97.35% at 1 kW.

Furthermore, this configuration enables the generation of multiple output voltage levels with fewer components, making it particularly well-suited for medium voltage applications. The efficient management of voltage levels not only ensures stable operation under varying load conditions but also reduces the risk of thermal issues commonly associated with high switching frequencies. The ability to maintain high efficiency and effective voltage regulation makes the proposed inverter a reliable option for medium voltage systems.

When compared to other branches of multilevel inverters, such as diode-clamped or cascaded H-bridge inverters, the proposed topology offers advantages in medium voltage scenarios. Diode-clamped inverters often require multiple diodes and capacitors, leading to increased component count and complexity, whereas the proposed topology requires only one diode. Cascaded H-bridge inverters, while modular, still necessitate significant space for multiple H-bridges and associated components, which can be a limitation in compact installations.

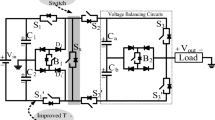

Improved phase shift modulation technique

The Improved Phase Shift modulation technique utilizes Phase Shift PWM, shifting the carrier waves by phase. The reference waves used here to improvise the modulation technique are trapezoidal, resulting in lesser harmonics and, therefore, reduced THD (%) and improved efficiency. Figure 3 shows the phase shift and Improved phase shift modulation techniques.

Average switching loss analysis for IPS

The equations given describe the following: i(t) represents the current flowing through the switch; v(t) represents the voltage across the switch; and Esw,on and Esw,off represent the energy losses that occur to the switch during its turn-on and turn-off transition periods, respectively.

Turn-on switching and turn-off switching losses are given by8:

The values of Esw, on* and Esw, off* in (3) and (4) represent the experimentally recorded energy losses during the transistor’s turn-on and turn-off processes. VCC and ICC represent the maximum voltages and currents required to activate and deactivate the intended state of the switch. VCC* and ICC* are the specified voltages and currents for the energy losses that occur when transistor switches are turned on and off. These values can be found in the datasheets of the transistor switches.

By employing the methodology suggested in the reference8, we compute the mean switching turn-on and turn-off losses for each switch.

The average switching turn-on power loss is given by8:

where,

T = period time considered, Tp = period for a single pulse (here for ON state), n = number of switching operations performed during time T.

Similarly, the average switching turn-off power loss is given by:

where, T = period time considered, Tp = period for a single pulse (here for OFF state), n = the number of switching operations performed during time T.

where, Psw = total average switching loss. Tp is calculated utilizing the method mentioned in8, similarly, Eon(t) and Eoff(t) are also calculated using the parameters i(on)(t) and i(off)(t).

Table 2 presents the different factors used to calculate the average switching losses of each switch. The voltage at the common collector (VCC) remains constant for both the turn-on and turn-off durations, as the pulse for each switch has a rectangular shape. The terms "ICC,on" and "ICC,off" refer to the currents required to turn on and turn off a single pulse. These currents are calculated for a maximum of n switching operations and the power consumption, denoted as Psw, is calculated with reference to sources8 and14. After simplifying the aforementioned process, we can utilize MATLAB Simulink or PLECS to determine the duration of a single pulse for each switch. By referring to the energy loss data provided in the data sheets, we can calculate the average switching losses. However, it is important to note that these calculated values may slightly deviate from the values obtained through power loss analysis using PLECS, due to the inclusion of additional factors such as various losses and thermal considerations. The aforementioned method is an approximation for determining switching losses.

Comparison of proposed topology and improved phase shift (IPS)

Comparison of proposed topology

In this section, we compare different 7-level CGT inverters to highlight and understand the advantages of the proposed topology. Table 3 discusses switch count, diode count, capacitor count, overall component count and voltage gain of different topologies.

The number of switches used in a topology plays a major role in its efficiency. A lower switch count and higher-level output always result in enhanced efficiency, whereas a higher switch count results in reduced efficiency for it makes the topology bulky and cost ineffective.

Inverters comprising a reduced number of components are expected to exhibit greater efficiency and cost-effectiveness. The second weakest component in power electronic converters is the capacitor. A large amount of the inverter’s bulk, volume, and cost can be attributed to the capacitor. Reducing the number of capacitors and their rating is therefore crucial.

Meraj et al.15 utilizes 13 switches, 3 capacitors and 3 diodes for a seven-level output, comparatively higher switch and diode count. The topology discussed in23 utilizes 10 switches, 4 diodes and 2 capacitors, while it utilizes the same number of switches, but it utilizes a comparatively higher number of diodes. The topology discussed in24 utilizes 12 switches, 4 diodes and 4 capacitors, all components are higher in count making the topology comparatively bulky. The topology discussed in25 utilizes 12 switches, 2 diodes and 3 capacitors and discussed in26 utilizes 11 switches, 3 diodes and 3 capacitors.

Hosseinpour et al.28 utilize 8 switches, 2 diodes and 2 capacitors with total component count of 12 giving 11 levels, but giving an efficiency of only 94%. It gives lesser efficiency due to higher voltage stress on capacitors. Meraj et al.27 utilizes 12 power switches but its main drawback is the usage of 5 DC sources, which requires a very high input voltage, reducing efficiency and not making it ideal for medium voltage circuits. The total component count of inverter proposed in29 is 10, although less than the proposed, but its efficiency is comparatively less due to voltage stress and design.

The proposed topology [PT] utilizes 10 switches, 1 diode and 4 capacitors, resulting in overall reduced topology and thus enhanced efficiency. A lower capacitor count with a higher rating of the capacitor decreases the efficiency. The proposed topology [PT] consists of 4 capacitors with two capacitors being charged to + 1VDC and two capacitors being charged to + 2VDC, the rating of the capacitors is not high, not affecting the efficiency much. The topology also provides a triple boost with higher efficiency.

One of the main reasons for the enhanced efficiency of the proposed inverter is not only due to reduced component count as being compared to few its slightly high, but also reduced voltage stress, two of the capacitors are directly charged from the source to 1VDC without creating much stress and also due to less input voltage required (only 1 DC source), thus increasing efficiency on low loads. Hence the proposed topology achieves qualitative superiority.

Comparison of IPS PWM and PS PWM

This section compares the PS PWM and IPS PWM in terms of THD(%) and efficiency when implemented on the proposed topology. Figure 4 compares the THD(%) of the two modulation techniques at 500W and 10 kHz switching frequency (Fig. 5).

Figures 6 and 7 shows the efficiency and THD (current harmonics) comparison of Phase Shift PWM, Improved Phase Shift PWM, Simplified Sinusoidal PWM30, hysteresis band-based discontinuous PWM9 and Nearest vector modulation PWM31. NVM in31 has been implemented on a 3-phase inverter, when modulation schemes implemented on 3 phase are most likely to generate lower harmonics and around 5–10% higher when the same is implemented on single phase. From the figure, it can be seen that the IPS PWM generated the lowest THD %.

It is also important to note that the proposed modulation scheme serves the purpose of improving the original Phase Shift PWM, as many advantages are unique to PS PWM only. There are many recent publications of algorithms like32 and33 when implemented for Selective harmonic Elimination, produce lower THD, as harmonics can be selected, which are desired to be eliminated by the user, but the major purpose served by algorithms for SHE is to eliminate individual harmonics, while IPS PWM serves several advantages which include Modular Multi-Level Topology Support. That is it allows each module (or submodule) within the converter to operate independently in phase, which effectively reduces the switching stress on each individual switch. Moreover, Due to the phase-shifted nature of IPS-PWM, harmonics are naturally attenuated at the output without the need for additional filtering. By phase-shifting the carrier signals for each module, high-frequency harmonics are distributed across a wide spectrum, which results in significant harmonic cancellation at specific frequencies. The proposed modulation scheme not only improvises this quality by reducing THD significantly (compared to PS PWM), it reduces losses and enhances efficiency significantly.

Power loss analysis

The power losses of an inverter can be imputed for different reasons, including conduction and switching losses induced by other components of the inverter, such as diodes and capacitors. Evaluating power loss is crucial to ensure reliable, economical, and effective operation. The efficiency of the system improves when losses are minimized.

In this section, the power loss of the proposed topology when implementing PS PWM and IPS PWM are analysed. This analysis has been performed on the software PLECS. Table 4 provides the required details of the components used when performing the analysis (Fig. 8).

Figure 9 shows the switching and conduction losses on 500W and switching frequency 10 kHz.

Figure 10 compares the total power loss when implementing PS PWM and IPS PWM. Efficiency is one of the most important parameters for the analysis and application of an inverter. Efficiency vs Power curve is shown in Fig. 5. It can be seen in Fig. 5, that the maximum attainable efficiency is 98.05% at 150 W.

Figure 9 compares switching and conduction losses when implementing PS PWM and IPS PWM. It can be observed that switching losses have been reduced significantly while conduction losses either remain the same or are reduced.

The total power loss of switches is obtained as follows10:

The power losses of the switches in the first, second, third and fourth switch legs are denoted as ΔPhbt1, ΔPhbt2, ΔPhbt3, and ΔPhbt4 respectively.

The expression for the power loss of a diode is:

The variables Tch, vsd, ich(t), Rdn, fsw, and Edoff show how long it takes for the diode to charge, the ON-state reverse voltage of the diode, instantaneous current, ON-state resistance of the diode, and the wasted energy due to the reverse recovery stage of the diode.

The power losses of the nth capacitor due to ESR is given as10:

The total power loss of the proposed inverter is given as follows:

Reliability analysis

A measuring system’s stability, dependability, and consistency are evaluated using reliability analysis. Reliability analysis is a tool used by researchers and practitioners to assess the consistency and dependability of the instruments they use. A trustworthy measurement equipment can be recognized by its dependable and constant operation. The reliability of inverters is critical to the overall stability and efficacy of these systems. As long as the device is operated within its designated safe operating range, reliability is defined as the possibility that it will carry out its intended functions (such as turning on, off, and changing states) for a predetermined amount of time during normal operation. The Markov approach is a widely used method for assessing a system’s reliability. Because Markov chains are good at representing systems with probabilistic state transitions across time, they are frequently used in reliability analysis. The system under analysis is represented by Markov models in the Markov chain technique. Generally, this procedure comprises identifying discrete states (e.g., functioning properly, malfunctioning, or breaking down) in which the system is capable of existing and computing the likelihood of the system changing between these states. The suggested inverter’s Markov chain diagram is shown in Fig. 11.

The reliability analysis for the proposed inverter is performed at 500W load which gives efficiency of about 98.05%. The inverter is characterized by three states, namely P1, P2, and P3. The state p1 represents the condition in which all components are in good condition. The state p2 indicates a faulty condition where the inverter fails to produce any waveform levels due to the failure of one or two components. The state p3 represents a failure condition where the output fails to generate any waveform levels11. The mathematical definition of the following is possible using P1(t), P2(t), and ƛx, which represent the occupational probability of the state p1 and the failure rate of the element x, respectively:

The reliability of the proposed inverter can be written as:

The failure rate of each component can be defined as:

The symbol λb represents the base failure rate of the component, which is 0.012 for the switch and 0.00254 for the capacitor11. The variable n represents the number of α factors that impact the failure rate of component x. These factors include temperature (αT), quality (αQ), application (αA), and environment (αE). As a result, the subsequent data delineates the rates at which a switch (λS) and capacitor (λC) fail):

When assessing reliability, it is presumed that the semiconductor device is in perfect working order; thus, αQ = αA = 1. Moreover, αE = 1 can be chosen under the assumption that all components function in an identical environment. All factors, with the exception of αT, are assumed to remain constant11. The computation of αT for a semiconductor switch is as follows:

where Tj is the device junction temperature and is determined using the following relations:

The variables denoted as Ta, θca, θjc and Ploss are as follows: θjc represents the thermal impedance of the switch, which is assumed to be 0.45 °C/W; θca represents the case-to-ambient thermal impedance, which is 62 °C/W; Ta is assumed to 25 °C11and Ploss signifies the overall power loss incurred by the switch. The computation of the capacitance factor αCV and stress factor αS for the capacitor is as follows:

In this case, the operating voltage to rated voltage ratio is represented by Vs, while the capacitance, expressed in microfarads, is indicated by C. Utilizing PLECS, a thorough thermal analysis of the inverter topology of study is carried out. Table 5 shows power losses obtained in PLECS, \({\varvec{\alpha}}_{{\varvec{T}}}^{{{\varvec{switch}}}}\) and \({\varvec{\lambda}}_{{\user2{si }}}\) of the switches in a healthy state.

Regarding the Markov chain in Figure 8, the corresponding probabilities are calculated as:

Table 5 shows the power loss and failure rated of individual switches at healthy state. The matrix [A] calculates the values based on the state transfers of switches, specifically from a healthy state to a fault state, from a healthy state to a failure state, and from a fault state to a failure state. All of these statuses are taken into account for every switch and all potential pairings of two switches, in the event of a simultaneous failure.

The final \(\left[ {\varvec{A}} \right]\) is as follows:

The resulting equations are as follows:

Mean Time to Failure (MTTF) or Mean Time before Failure (MTBF):

Reliability comparison with literature

This section compares the reliability of different topologies in terms of Mean Time to Failure (MTTF) or Mean Time Before Failure (MTBF).

For34

For35

For36

From Eqs. (37), (39) and (41), showing the MTBF in years and hours, when compared to (35), it can be observed that the reliability of the proposed inverter is better. The topology proposed in34 used 16 switches, the one35 utilizes 12 and the one in36 utilizes 16. It can be noted that35 utilizing lesser number of switches has better reliability. The proposed topology utilizes 10 power switches in total and thus enhancing reliability. The reliability function, Eq. (34), for the proposed topology is for a seven level, furthermore, no redundant switch is required in the proposed topology, which implies no switch remains unutilized during healthy operation implying full utilization of all switches, thus resulting in higher reliability. The proposed topology’s reliable function solution is more superior.

Simulation and experimental results

The performance parameters of the proposed inverter are assessed by conducting a laboratory experiment and using a MATLAB/Simulink model. The simulation model incorporates the integration of the proposed inverter with the PV unit using a PI controller. The effectiveness of the suggested inverter and modulation technique is evaluated using a load that can be easily accessed within the experiment.

Simulation results

The simulation of the two modulation techniques is performed, their waveforms and THD(%) are shown in Figs. 12 and 13.

It can be clearly observed that the THD (%) when implementing IPS PWM has been significantly reduced.

Further simulation results are taken while implementing IPS PWM.

Table 6 shows the specifications of the parameters used for obtaining simulation results.

Figure 14 shows the waveforms when varying R load simultaneously. This shows the efficient working of the proposed topology, working under simultaneously varying R load.

Figure 15 shows the waveforms when varying RL load simultaneously. This shows the efficient working of the proposed topology under simultaneously varying RL load.

Figure 16 shows the voltage and current waveforms of capacitors C1 and C2.

Figure 17 shows the voltage and current waveforms through capacitors C3 and C4.

Figure 18 shows the current and voltage waveforms when the modulation index is simultaneously varied.

Experimental results

A This section uses an experimental setup to assess the proposed topology. The outcomes of the suggested topology are validated through an experimental configuration conducted within the laboratory and experimentally observed voltage and current waveforms under R load and RL load, where R = 40 Ω and L = 120 mH are depicted in Fig. 19a and b.

A seven-level stepped waveform is generated at power factor unity for voltage at both R load and RL load, whereas a sinusoidal wave is generated for RL load and a stepped seven level is generated for current at R load.

Table 7 shows the specifications of the parameters used for obtaining the results.

Figure 20 shows the voltage and current waveforms through capacitors.

Figure 21 shows the waveforms when the load is switched from RL load to R load. This shows that the inverter worked for both R and RL loads even when the loads were being switched simultaneously.

Figure 22 shows the waveforms when the frequency is switched from 50 to 100 Hz at power factor unity. This shows the capability of the inverter to work accurately at different frequencies.

Figure 23 shows the voltage and current waveforms when the modulation index increases from 0.7 to 1. This shows a reduction in levels in voltage stepped waveform, from seven to five levels and a change in amplitude of the current sinusoidal waveform.

Figure 24 shows the experimental results of voltage and current harmonics.

All the results are taken for load R = 40 Ω and L = 120 mH. The above results show the accuracy and efficiency of the proposed topology and the modulation scheme. All the results are taken for the proposed modulation scheme implemented on the proposed topology, hence validating its working and efficiency.

Conclusion

This article proposes a single-phase CGT inverter generating seven levels, utilizing fewer switches and thus reducing component count, making it less bulky, when compared to seven level MLIs. This article also proposes an Improved Phase Shift (IPS) PWM which reduces THD (%) by 5% for current and by 2% for voltage when compared to original PS PWM, reduces losses and thus enhances efficiency. It is evident through simulation and experimental results that when IPS, when implemented on the proposed topology, there are lower losses and thus the efficiency increases. The proposed inverter was shown to be possible and workable through simulations, tests, and an analysis of power loss in PLECS.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Anand, V., Singh, V., Sathik, J. & Almakhles, D. Single-stage five-level common ground transformerless inverter with extendable structure for centralized photovoltaics. CSEE J. Power Energy Syst. 9(1), 37–49. https://doi.org/10.17775/CSEEJPES.2022.02700 (2023).

Kumari, S., Verma, A. K., Sandeep, N., Yaragatti, U. R. & Pota, H. R. Multilevel common-ground inverter with voltage boosting for PV applications. IET Power Electron. 14(5), 901–911. https://doi.org/10.1049/pel2.12073 (2021).

Siddique, M. D. et al. Reduced switch count based single source 7L boost inverter topology. IEEE Trans. Circuits Syst. II Express Br. 67, 3252–3256 (2020).

Anjaneya Vara Prasad, P. & Dhanamjayulu, C. An overview on multi-level inverter topologies for grid-tied PV system (Hindawi Limited, 2023). https://doi.org/10.1155/2023/9690344.

Ali, A. I. M., Sayed, M. A. & Mohamed, A. A. S. Seven-level inverter with reduced switches for PV system supporting home-grid and EV charger. Energies (Basel) https://doi.org/10.3390/en14092718 (2021).

Vijayakumar, A., Alexander Stonier, A., Peter, G., Kumaresan, P. & Reyes, E. M. A modified seven-level inverter with inverted sine wave carrier for PWM control. Int. Trans. Electr. Energy Syst. 2022, 7403079. https://doi.org/10.1155/2022/7403079 (2022).

Lakshmikhandhan, Andy, S. & Mohamed Ali, J. S. Single DC source-based multilevel converter topology with reduced power switches and conduction losses. J. Electr. Eng. (2017).

Arulmozhiyal, R., Murali, M. & Manjeri, K. R. Design and analysis of 7 level multilevel inverter for industrial applications (2021).

Anand, V., Sathik, J., Garcia, C., Blaabjerg, F. & Rodríguez, J. ANPC switched-capacitor 19L inverter using SHE PWM for 1-ϕ HFAC PDS applications. IEEE J. Emerg. Sel. Top. Power Electron. 12(5), 4494–4505. https://doi.org/10.1109/JESTPE.2024.3432133 (2024).

Singh, V., Pattnaik, S., Anand, V. & Neti, S. S. Comparison of two-stage and single-stage photovoltaic inverter for grid-connected system. In 2024 Third International Conference on Power, Control and Computing Technologies (ICPC2T) 462–467 (2024). https://doi.org/10.1109/ICPC2T60072.2024.10474657.

Singh, V., Pattnaik, S., Anand, V. & Dhananjaya, M. Design & analysis of PV interface hybrid two-stage transformerless inverter. In 2023 International Conference on Power, Instrumentation, Energy and Control (PIECON) 1–6 (2023). https://doi.org/10.1109/PIECON56912.2023.10085783.

Anand, V., Singh, V. & Sathik, M. J. A. Reduced component high voltage boost single-source switched capacitor inverter. Sādhanā 47(2), 59. https://doi.org/10.1007/s12046-022-01838-x (2022).

Anand, V. & Singh, V. A 13-level switched-capacitor multilevel inverter with single DC source. IEEE J. Emerg. Sel. Top. Power Electron. 10(2), 1575–1586. https://doi.org/10.1109/JESTPE.2021.3077604 (2022).

Chowdhury, M. R., Rahman, M. A., Islam, M. R. & Mahfuz-Ur-Rahman, A. M. A new modulation technique to improve the power loss division performance of the multilevel inverters. IEEE Trans. Ind. Electron. 68, 6828–6839 (2021).

Meraj, M., Rahman, S., Iqbal, A., Ben-Brahim, L. & Abu-Rub, H. A. Novel level-shifted PWM technique for equal power sharing among quasi-Z-source modules in cascaded multilevel inverter. IEEE Trans. Power Electron. 36(4), 4766–4777. https://doi.org/10.1109/TPEL.2020.3018398 (2021).

Jakhar, A., Sandeep, N. & Verma, A. K. Seven-level common-ground-type inverter with reduced voltage stress. IEEE J. Emerg. Sel. Top. Power Electron. 12(2), 2108–2115. https://doi.org/10.1109/JESTPE.2024.3353266 (2024).

Meraj, S. T. et al. A diamond shaped multilevel inverter with dual mode of operation. IEEE Access 9, 59873–59887. https://doi.org/10.1109/ACCESS.2021.3067139 (2021).

Meraj, S. T. et al. A pencil shaped 9-level multilevel inverter with voltage boosting ability: Configuration and experimental investigation. IEEE Access 10, 111310–111321. https://doi.org/10.1109/ACCESS.2022.3194950 (2022).

Neti, S. S., Singh, V. & Anand, V. Common ground buck type five-level transformerless inverter with less stress. IEEE Trans. Circuits Syst. II Express Br. 71(4), 2419–2423. https://doi.org/10.1109/TCSII.2023.3335148 (2024).

Anand, V., Singh, V. & Mohamed Ali, J. S. dual boost five-level switched-capacitor inverter with common ground. IEEE Trans. Circuits Syst. II Express Be. 70(2), 556–560. https://doi.org/10.1109/TCSII.2022.3169009 (2023).

Anand, V. et al. Seventeen level switched capacitor inverters with the capability of high voltage gain and low inrush current. IEEE J. Emerg. Sel. Top. Ind. Electron. 4(4), 1138–1150. https://doi.org/10.1109/JESTIE.2023.3291996 (2023).

Meraj, S. T. et al. Energy management schemes, challenges and impacts of emerging inverter technology for renewable energy integration towards grid decarbonization. J. Clean Prod. 405, 137002. https://doi.org/10.1016/j.jclepro.2023.137002 (2023).

Hasari, S. A. S., Salemnia, A. & Hamzeh, M. Applicable method for average switching loss calculation in power electronic converters. J. Power Electron. 17(4), 1097–1108. https://doi.org/10.6113/JPE.2017.17.4.1097 (2017).

You, K. & Rahman, M. F. Analytical model of conduction and switching losses of matrix-Z-source converter. J. Power Electron. 9, 275–287 (2009).

Khoun Jahan, H., Abapour, M. & Zare, K. Switched-capacitor-based single-source cascaded H-bridge multilevel inverter featuring boosting ability. IEEE Trans. Power Electron. 34(2), 1113–1124. https://doi.org/10.1109/TPEL.2018.2830401 (2019).

Lee, S. S. A single-phase single-source 7-level inverter with triple voltage boosting gain. IEEE Access 6, 30005–30011. https://doi.org/10.1109/ACCESS.2018.2842182 (2018).

Meraj, S. T., Yahaya, N. Z., Hasan, K. & Masaoud, A. A hybrid T-type (HT-type) multilevel inverter with reduced components. Ain Shams Eng. J. 12(2), 1959–1971. https://doi.org/10.1016/j.asej.2020.12.010 (2021).

Hosseinpour, M., Seifi, A. & Rahimian, M. M. A bidirectional diode containing multilevel inverter topology with reduced switch count and driver. Int. J. Circuit Theory Appl. 48(10), 1766–1785. https://doi.org/10.1002/cta.2810 (2020).

Meraj, S. T. et al. A novel extendable multilevel inverter for efficient energy conversion with fewer power components: Configuration and experimental validation. Int. J. Circuit Theory Appl. 52(6), 2760–2785. https://doi.org/10.1002/cta.3910 (2024).

Meraj, S. T., Kah Haw, L. & Masaoud, A. Simplified sinusoidal pulse width modulation of cross-switched multilevel inverter. In 2019 IEEE 15th International Colloquium on Signal Processing & Its Applications (CSPA) 1–6 (2019). https://doi.org/10.1109/CSPA.2019.8695985.

Meraj, S. T. et al. Three-phase six-level multilevel voltage source inverter: Modeling and experimental validation. Micromachines (Basel) https://doi.org/10.3390/mi12091133 (2021).

Islam, J. et al. Opposition-based quantum bat algorithm to eliminate lower-order harmonics of multilevel inverters. IEEE Access 9, 103610–103626. https://doi.org/10.1109/ACCESS.2021.3098190 (2021).

Xin, Y., Yi, J., Zhang, K., Chen, C. & Xiong, J. Offline selective harmonic elimination with (2N+1) output voltage levels in modular multilevel converter using a differential harmony search algorithm. IEEE Access 8, 121596–121610. https://doi.org/10.1109/ACCESS.2020.3007022 (2020).

Haji-esmaeili, M. M., Naseri, M., Khoun-Jahan, H. & Abapour, M. Fault-tolerant structure for cascaded H-bridge multilevel inverter and reliability evaluation. IET Power Electron. 1(1), 1–26 (2016).

Song, W. & Huang, A. Q. Fault-tolerant design and control strategy for cascaded H-bridge multilevel converter-based STATCOM. IEEE Trans. Ind. Electron. 57(8), 2700–2708 (2010).

Meraj, S. T. et al. A novel extendable multilevel inverter for efficient energy conversion with fewer power components: Configuration and experimental validation. Int. J. Circ. Theor. Appl. 52(6), 2760–2785. https://doi.org/10.1002/cta.3910 (2024).

Acknowledgements

The authors extend their appreciation to King Saud University for funding this work through Researchers Supporting Project number (RSP2025R387), King Saud University, Riyadh, Saudi Arabia. The authors would also like to acknowledge the facilities provided by Non-Conventional Energy Lab, Department of Electrical Engineering, Aligarh Muslim University, Aligarh, India for carrying out the research work.

Funding

This research has received funding from King Saud University through Researchers Supporting Project number RSP2025R387), King Saud University, Riyadh, Saudi Arabia.

Author information

Authors and Affiliations

Contributions

Conceptualization, B. S., A. S., and S. A.; formal analysis, B. S., A. S., and S. A.; investi-gation, B. S., A. S., and S. A.; software, B. S., and A. S.; methodology, B. S., and A. S.; data curation, B. S., and A. S.; visualization: B. S., and A. S.; funding acquisition, H.-D. L.; supervision, H.-D. L.; writing—original draft, B. S., A. S., S. A., S.-D. L., and H.-D. L.; writing—review and editing, B. S., A. S., S. A., S.-D. L., and H.-D.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Saif, B., Sarwar, A., Ahmad, S. et al. A single-phase seven-level switched capacitor with common ground inverter and improved phase-shift modulation technique. Sci Rep 15, 4209 (2025). https://doi.org/10.1038/s41598-025-86180-y

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-86180-y