Abstract

Extraction of polyphenolic compounds from African nutmeg (Monodora myristica (Gaertn.)) peels using natural acidic deep eutectic solvents coupled to ultrasound-assisted extraction (NADESs-UAE) followed many factors at a time (MFAT) screening with response surface optimization was investigated. Fourteen different NADESs based on citric acid as hydrogen bond acceptor (HBA) were designed and tested. Sucrose, fructose, xylitol, glycerol, glycine, and glucose were used as hydrogen bond donors (HBDs). The responses studied are total phenolic compounds (TPC), total flavonoid compounds (TFC), and antioxidant activity (AA) based on cupric ion reducing antioxidant capacity (CUPRAC) and ferric reducing antioxidant power (FRAP). The UAE procedure was optimized with the most efficient NADES. Quadratic models produced satisfactory fitting of the experimental data regarding TPC (R2 = 0.9999, p < 0.0001), TFC (R2 = 0.9991, p < 0.0001), and AA- CUPRAC (R2 = 0.9988, p < 0.0001) and FRAP (R2 = 1.000, P < 0001). Ultrasound temperature 30°c, extraction time 5 min, solvent volume 25 ml, and solvent concentration 90% (v/v) were considered optimal conditions for the extraction models resulting in TPC 1290.9 ± 5.6 mg/g GAE db, TFC 2398.7 ± 23 µg/g QE db, CUPRAC 38.46 ± 0.4.4 µmol/g TE db, and FRAP 26.15 ± 0.11µmol/g TE db, respectively.

Similar content being viewed by others

Introduction

The extraction of bioactive compounds from agri-food materials is experiencing an ever-growing trends toward green processes hinged on the contexts of sustainability and renewability. This shift is driven by the need to mitigate the environmental and health impacts associated with conventional organic solvent extraction methods, prompting the exploration of safer and more sustainable alternatives. The major benefit today is represented by the reduction in the use of volatile and flammable organic solvents, which are harmful to both human health and the environment1. For this purpose, scientists and industries are pushing to improve extraction protocols and technology that supports a cleaner and sustainable compound recovery from agri-food materials than would be achieved by conventional methods2. Alternative low-toxicity, easy-to-remove and environmentally friendly solvents combined with low-energy, short-term, and cost-effective, innovative technology are gaining momentum1. The development of these solvents represents a revolutionary approach in green chemistry, offering a viable pathway to achieving the desirable goals.

The extraction media of choice for green extractions could very well be deep eutectic solvents (DESs). DESs are solvents that occur when a mixture of substances has a melting point that is much lower than those of the constituents. To form a DES system, a hydrogen bond donor (HBD) and a hydrogen bond acceptor (HBA) needs to be brought together, which when mixed at proper ratios create a new mesh of hydrogen-bond-interconnected molecules with interesting physicochemical properties. DESs can be highly viscous, inhibiting their use in processes that require diffusion or flow, however, research into their chemical structure, as well as the use of additives such as water, largely alleviates the viscosity problems3. The first key interesting point regarding DES is it potential to be synthesized using multiple molecules as constituents creating a fluid mixture that can be used as a solvent. Furthermore, the potential for many naturally occurring molecules to form DES, thus providing a natural solvent system with low vapor pressure, low cost, even at larger industrial scales, in addition to removing the need for solvent retrieval from the process highlights their importance. DES synthesized with both HBA and HBD coming from natural occurring molecules is called natural deep eutectic solvent (NADES). The evolution of DES, and more importantly, NADES, means that a capable and biocompatible storage media, with a readily available active ingredients can be designed as a very efficient catalyst, a molecule or compound carrier, and an extractant making the new solvent focus driven and tuneable4,5. NADESs are emerging solvents with very promising performance in the extraction of plant metabolites6, organic reactions7, and biotransformation8. NADESs are mixtures of pure compounds for which the eutectic point temperature is below the melting point temperature of each participating compound in the mixture9. NADESs have been shown to be an efficient tool for the safe extraction and recovery of polyphenols with high antioxidant capacity from agri-food matrices. The advantages of NADESs are numerous, including their low cost, easy availability, biodegradability, low toxicity profile, and tunability for specific purposes10. The composition of these materials makes them environmentally friendly and safe, and their increased stability and shelf life make them ideal for use in the food, pharmaceutical and cosmetics industries11. However, the “greenness” of NADESs is a function of their constituents912, which must be considered when deciding on proper application, because a garbage-in-garbage-out outcome necessitate the selection of safe, nontoxic, biodegradable, natural constituents for the synthesis of NADES. The combination of NADESs as alternatives to conventional organic solvents(COSs) with nonconventional extraction techniques offers greater improvements aimed at finding more efficient and sustainable extraction processes1. The literature contains numerous examples in which the energy released by methods based on ultrasonication or microwave radiation was successfully exploited to favour the mass transfer of target molecules into the NADES phase.

Monodora myristica(Gaertn.) is a perennial edible berry plant that grows well in African evergreen forests. It is widely used for medicinal and culinary purposes. In Nigeria, it is used as a condiment for different dishes and delicacies. Traditionally, the African nutmeg is used for the treatment of sores from guinea worm infections, constipation, stomachaches and headaches. Seed preparation is used to stop intrauterine bleeding in women after childbirth13. All parts of the plant, including the bark, roots, seeds, and leaves, are very useful for treating various ailments in African traditional medicine; however, the most economically important part is the seed, which is enriched with both nutritive and medicinal values14. The comprehensive utilization of all parts of this plant for health benefits highlights its potential as a source of valuable bioactive compounds, justifying the need to develop effective and sustainable extraction techniques for it, such as those involving NADESs with ultrasound. M. myristica seeds are more commonly used as a drug in Eastern African countries. It is roasted, ground into paste, and rubbed on the skin for the treatment of skin diseases, and it can act as a germicidal or antiseptic agent. The essential oil from the seed is used in pharmaceutical and dental preparations15, and also as a carminative and scenting perfume and soap16. The root is munched to prevent toothaches and arthritis and is also utilized in the management of anaemia, haemorrhoids and sexual weakness17. The stem bark of M. myristica is used to treat haemorrhoids, stomach ache, fever, pain, and eye diseases18. Studies have reported the antioxidant properties of M. myristica seeds192017. The minty smelling seed has also been shown to possess cholesterol-lowering activities18, anti-sickling activity21, antimicrobial activity22, and anthelmintic activity23.Phytochemical screening of hydroalcoholic extracts of the seeds indicated that they are rich in polyphenols, saponins, tannins, carbohydrates, and other valuable substances20.

The well-recognized properties of phenols as antiradical, antioxidant and anti-inflammatory agents and their potential therapeutic application for the treatment of cancers and other chronic diseases are motivating scientists to search for innovative techniques to extract polyphenolic components from several agri-food matrices24. In the present study, innovative extraction process for obtaining polyphenols from African nutmeg peels (ANP) was performed. Polyphenols have been extracted from different agri-food materials like coriander seeds, tea, grape, and apple with characteristics to those of African nutmeg plants using different techniques such as microwave assisted extraction (MAE), maceration (MAC), supercritical fluid extraction (SFE), etc. This study applied MFAT experimental design to screen the extraction properties of fourteen NADESs synthesized with citric acid as HBA and several plant secondary metabolites as HBD, by employing ultrasound-assisted extraction technique to extract bioactive compounds from plant agrifood waste and evaluate the antioxidant and antiradical scavenging activities. The best performing NADES was selected and the process further optimized by a rotatable central composite response surface methodology. The use of MFAT rather than one factor at a time (OFAT) in the screening study is innovative as the design mimics real-world industrial extraction processes. In conjunction with NADES and ultrasound assistance, the study highlights an innovative approach bridging the gap between traditional extraction methods and modern, sustainable techniques. The factors influencing the solvents’ extraction capacity were studied simultaneously providing an insight into real world extraction process. The factors influencing the extraction and antioxidant capacity were optimized and the method validated for total phenolic contents (TPC), total flavonoid contents (TFC), cupric ion reducing antioxidant capacity (CUPRAC), and ferric reducing antioxidant power (FRAP) highlighting a new approach to understanding extraction. The aim of this study is to investigate the capacity of different novel green NADESs to extract phenolic compounds with antioxidant activity from African nutmeg peels (ANP). The second purpose of the study is after the selection of the best NADES, the effect of extraction conditions (ultrasound temperature (UT), extraction time (ET), volume of solvent (SV), and concentration of the NADES (SC)) on the total phenols content and antiradical scavenging activity will be studied and subsequently optimized, and further compared to extracts obtained with conventional solvents (water). The findings could pave the way for more efficient and environmentally friendly extraction processes, contributing significantly to the field of green chemistry and sustainable agriculture.

Results

Screening of NADESs

Fourteen different NADESs were investigated for its use as solvent for the extraction of phenolic compounds from ANP. To characterize the physicochemical behavior of the different NADESs, density, water activity, viscosity and pH were measured, and the results presented in Table 1. The concentration of the NADESs were varied by the addition of distilled water in proportions up to 40% (v/v) according to the design. Adding a higher percentage of water above 40% further reduced the viscosity, but the hydrogen bonding structure characteristic of the NADES could be broken, obtaining a simple solution of its components25. pH values of NADES ranged between 1.7 and 2.6 indicating that all the synthesized solvents are in the acidic range. Surprisingly, the higher pH values correspond to NADES formed with citric acid as HBA and glycine (an amino acid) as HBD.

Figure 1 shows the TPC of extracts from ANP using the synthesized NADES, after eliminating extraction conditions that generated less than 300 mg/g GAE db. of ANP across, it is observed that in all NADESs extracts presented statistically higher TPC from four different experimental conditions. CaFr12 and CaFr11 (908 mg GAE/g db. and 860 mg GAE/g db., respectively) were the best NADESs for TPC extraction at conditions of temperature 40°c, time 20 min, volume 20 ml, and concentration 60%, while CaGc21 (67 mg GAE/g db.) was the worse at the same conditions.

In Fig. 2, the TFC from ANP using NADESs-UAE techniques under the most influencing conditions is presented. Four NADESs (CaFr11, CaXy12, CaGc11, and CaGl21) performed very well at extraction conditions of temperature 40°c, time 10 min, volume 20 ml, and concentration 80%, yielding about 1200 µg/g QE db, 900 µg/g QE db, 1400 µg/g QE db, and 1000 µg/g QE db, respectively. Other conditions yielded less than 800 µg/g QE db across the synthesized NADESs, except in CaGc11 where two other extraction conditions produced above 1000 µg/g QE db. The two conditions in this case are temperature 40°c, time 20 min, volume 20 ml, and concentration 60%, temperature 60°c, time 20 min, volume 20 min, and concentration 80% respectively.

Antiradical scavenging activity measured using two methods of CUPRAC and FRAP is presented in Figs. 3 and 4, respectively. The antiradical scavenging activity of extracts from ANP using fourteen different NADES formulations at four different conditions and measured with CUPRAC showed that temperature 40°c, time 10 min, volume 20, and concentration 80%, the extracts have high scavenging activity among the fourteen with extract from CaFr11 having the highest activity of 12 µmol/g TE db of extract. On the other hand, high antiradical scavenging activity across the fourteen NADESs as measured with FRAP was observed with extraction condition of temperature 40°c, time 20 min, solvent 20 ml, and concentration 60% with extract from CaXy11 having the highest antiradical scavenging activity of 14 µmol/gTE db of sample at that condition Fig. 4.

In general, analyzing phenolic compounds and antiradical scavenging activity simultaneously highlights the importance of considering the capacity of a solvent in extracting these compounds, since each method is based on different interactions between the phenolic compounds and the reagents involved, with different mechanisms of action26. By using more than one method simultaneously, it is possible to obtain complementary information. In summary, the selection criteria of NADES based on good TPC and TFC extraction, and antiradical scavenging activity values indicated NADES, CaFr11, a good candidate for further exploration and therefore was selected and used in the subsequent extraction experiments.

Modelling of the extraction process by central composite Response Surface Methodology (RSM)

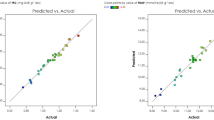

A central composite design RSM was used to study the effect of extraction conditions (UT, ET, SV, and SC) on the response variables TPC, TFC, and antiradical scavenging activity (CUPRAC and FRAP) of ANP by NADES-UAE extraction technique. NADES CaFr11 was used for modelling experiments. The experimental conditions and results of the experimental design are shown in Table 2. TPC varied from 63.07 ± 0.57 mg GAE/g db to 1373.4 ± 7.88 mg GAE/g db, TFC varied from 125.98 ± 2.03 µg QE/g db to 1543.2 ± 18.0 µg QE/g db. Antiradical scavenging activity measured with CUPRAC varied from 3.19 ± 0.06 µmol TE/g db to 15.83 ± 0.08 µmol TE/g db, and antiradical scavenging activity measured with FRAP varied from 0.377 ± 0.01 µmol TE/g db to 13.21 ± 0.0305 µmol TE/g db. Table 3 shows the summary of ANOVA results for the four response variables. On the one hand, the four models (one for each of the response variables) showed p-values lower or equal to 0.0001, which means that the models are highly significant. On the other hand, the insignificant lack of fit values (p > 0.05) indicates that each of the models are adequate to predict the corresponding response. Table 4 shows the regression coefficients (in coded variables) and the coefficients of determination for the TPC, TFC, CUPRAC and FRAP models for all significant terms (p< 0.05). The four models presented high values of coefficient of determination (R2) and adjusted coefficient of determination (R2adj). The values of the predicted coefficient of determination (R2pred) were in good agreement with R2adj. This indicates a high degree of correlation between experimental and predicted values for the four models. As can be seen in Table 4, TPC was positively influenced by a linear ultrasound temperature, a quadratic extraction time, a quadratic solvent volume, a quadratic solvent concentration, and interaction of time with volume, while TFC was positively influenced by a quadratic solvent volume, a linear solvent volume, a linear solvent concentration, a quadratic extraction time, a linear interaction of ultrasound temperature with solvent concentration, and a linear interaction of solvent volume with solvent concentration. On the antiradical scavenging activity, CUPRAC was positively impacted by all quadratic functions in addition to the interaction of temperature with time, temperature with concentration, as well as volume with concentration, while FRAP was positively influenced by linear functions of temperature, time, and volume. It was also positively impacted by squared time, volume, and concentration, as well as the interaction between temperature and volume, and time with volume.

Optimization of the extraction conditions and validation of the models

Numeric optimization of responses was carried out by desirability function following Eqs. (3) and (4) as presented in the methodology section. Optimization was carried out with the goal set to maximize the total phenolic content, total flavonoid content, and higher antiradical scavenging activity using the independent variables of UT, ET, SV, and SC in the ranges that were used in the rotatable central composite response surface experiments. Five different solutions were calculated by Minitab software with different levels of independent variables with good desirability. To verify the models obtained through RSM, nine extractions were performed under the optimum conditions obtained previously. In Table 5, the experimental results along with the values predicted by the models under the optimal extraction conditions are presented. As can be seen, the experimental values of the four responses are within the confidence intervals of the values predicted by the models (with 95% confidence level), which indicates a good degree of prediction of the models obtained in this work under the extraction conditions tested. On the other hand, Table 5 presents the experimental data of TPC, TFC and antiradical scavenging activity using water (conventional solvent) under the same optimal extraction conditions used for the case of NADES (CaFr11) as solvent.

Discussions

Screening of NADESs

The TPC, TFC, and antiradical scavenging activity of extracts from ANP by MFAT screening technique is an excellent process of elucidating the actual conditions governing extraction in real world process. MFAT experiment not only assist in simultaneous determination of both main factors and their interactions in a process. It also helps for a quick glance of comparison among variables. However, understanding and interpreting MFAT design is more complex than an OFAT experiment. In the present study, four conditions at different temperature, time, volume, and concentration showed great impact on the extraction of TPC, TFC, and antiradical scavenging activity among the screened NADESs. As can be seen in Fig. 1, the conditions of UT 40°c, ET 20 min, SV 20 ml, and SC 60% indicate a good potential for polyphenol extraction from ANP among the NADESs especially CaFr11. In Fig. 2, the preferred condition for TFC extraction is UT 40°c, ET 10 min, SV 20 min, SC 80%. The antiradical scavenging activity also shows UT 40°c, ET 10 min, SV 20 ml, and SC 80% for CUPRAC, Fig. 3, and UT 40°c, ET 20 min, SV 20 min, SC 80% for FRAP Fig. 4, respectively. From the screening experiment, it can be deduced that the most important factors for extraction of phenolic compounds and antiradical scavenging activity of ANP extract is ultrasound temperature and solvent volume, followed by extraction time and solvent concentration. This observation agrees with many authors that used OFAT design and concluded that temperature27,28,29 is a significant factor for extraction. The novel values of the present screening over OFAT include simultaneous determination of interactions effects, conduct of fewer experiments to elucidate causality, reduction of experimental time, experimental conditions being true representation of real-world process, and reduction of experimental cost. To date, ultrasound-assisted extraction experiments have been designed and executed using the OFAT technique30,31,32,33,34,35,36, possibly because of the simplicity of the later.

The highest TPC corresponds to extracts obtained from CaFr12 and CaFr11, both with the same HBD molecule at different ratios as can be seen in Table 1. Interestingly, the highest TPC corresponds to the use of CaFr12 as solvent, which presented one of the highest viscosities among all the NADES tested. In this case, the viscosity of the solvent seems to have a greater influence than the pH of the solvent on the TPC of the extracts obtained. Several investigators have reported the importance of low pH values of NADES on the extraction of phenolic compounds from different vegetable matrices38,39,40. According to studies reported by41,42, the improvement in the extraction of phenolic compounds through the use of ionic liquids (whose structure and interactions with phenolic compounds is similar to NADES) with low pH may be due to an increase in hydrogen bond interactions between the solvent and the phenolic compounds, especially in cases where the pH is lower than the pKa of the phenols, where the molecular form predominates.

In relation to the influence of mole ratio of HBD used to prepare the NADES (with the same HBA) on the TPC of the extracts, from Fig. 1, it can be observed that increasing the molar ratio of the HBD of the prepared solvent increases the amount of TPC extract except in the solvents prepared with glycerol where increased HBA ratio gave a better result. The response of the solvents with regards to the conditions of extraction was elucidated to choose the best NADES for further optimization studies, and after considering some compromises, CaFr11 was chosen. All the solvents except CaFr11 have showed limited capacity to some of the responses studied at the screening conditions. Therefore, further optimization of the process was performed with CaFr11.

Modelling of the extraction process by central composite RSM

Recent advancements in the field of extraction suggest response surface methodology (RSM) for optimization studies which aligns with our study approach43,44. Rotatable central composite RSM was used to study the effect of extraction conditions (UT, ET, SV, SC) on the response variables TPC, TFC, and antiradical scavenging activity (CUPRAC and FRAP), using CaFr11 as solvent. The experimental conditions and results of the experimental design are shown in Table 3.

In the case of ultrasound temperature, it is clear from the results that an increase in this variable generates increases in TPC and FRAP, but a decrease in TFC and CUPRAC. Higher temperatures lead to an improvement in the mass transfer of phenolic compounds from the solid matrix to the solvent, mainly due to an increase in the diffusivity of these compounds and a decrease in the viscosity and surface tension of NADES45,46. However, it must be considered that high temperatures can lead to the decomposition of phenolic compounds, mainly flavonoids as shown. This observation agrees with the findings of other researchers45,47,48. Although NADES is a stable solvent, however, it can suffer degradation at high temperatures generally at temperatures higher than the temperatures used in this study46,49. In the present work, no apparent degradation of NADES was observed (evaluated as absence of colour changes, absence of phase separation and absence of precipitation of components when subjecting NADES to the temperatures and extraction times tested). With respect to degradation of phenolic compounds, individual compounds were not evaluated by HPLC, however, we noted as has been reported in similar work by others that the main phenolic compounds present in agrifood materials do not suffer degradation when extracted with temperatures higher than those used in the present work50,51.

With respect to extraction time, a higher TPC, TFC and CUPRAC were observed as extraction time decreases except with antiradical scavenging activity by FRAP which increases with increased extraction time. In the case of TPC, an increase in this variable was observed to increase up to 10 min before decreasing with increase in the extraction time. Increasing the extraction time may not be advantageous technologically and cost wise. Other researchers also observed that long extraction time was disadvantageous with UAE52,53,54.

A fundamental principles of mass transfer, where the concentration gradient between the solid and the liquid bulk serves as the driving force. This gradient is more pronounced when a lower solid–liquid ratio is employed, improving the transfer of phenolic compounds with antioxidant activity from the solid to the solvent26. However, greater quantities of solvent typically have a limited impact on the quantity of phenolic compounds that can be extracted, which is undesirable from both cost and environmental perspectives in the case of the use of organic solvents55 but may be an advantage with NADES. In the present study, increase in NADES volume to a certain level favours TFC extraction and FRAP antiradical scavenging.

In relation to NADES concentration, an increase in antioxidant activity values is observed with increasing NADES concentration with no significant effect of this variable on the TPC values. The increase in antioxidant activity occurs up to values 10% (v/v) of water content, from which the increase is relatively low. A slight decrease in the values of antioxidant activity measured with FRAP is observed for values of water content above 40% (v/v). As disclosed in Sect. 3.1, by increasing the proportion of water in NADES, the viscosity could be further reduced, but this may disrupt the distinctive hydrogen bonding structure inherent to NADES, resulting in a solution comprised of its individual components. Therefore, the addition of water to NADES could lead to an improvement in mass transfer up to a certain point, after which there could be a decrease in the transfer of phenolic compounds with antioxidant activity from the solid matrix to the solvent56. Several researchers have reported this effect in the extraction of phenolic compounds with antioxidant activity from agro-industrial residues using NADES as solvent45,57,58,59.

Optimization of the extraction conditions and validation of the models

As previously pointed out, the conditions that correspond to factor levels necessary to obtain maximum TPC, TFC and antiradical scavenging activity was calculated as the desirability function values. Using the same factor levels and responses obtained in the central composite response surface model, Minitab calculated the desirability function values for TPC, TFC, CUPRAC, and FRAP as 0.9936, 0.9003, 1.000, 0.9605. This agrees with what was analysed in Sect. 3.2, where the effect of extraction conditions on each of the individual responses was discussed. Accordingly, the optimal extraction conditions that maximize the TPC and the antioxidant activity determined by FRAP and CUPRAC were found at a temperature of 30°c, time of 5 min, volume of NADES 25 ml, and concentration of NADES 90% and were selected for verification. To verify the models obtained through RSM, nine extractions were performed under the optimum conditions obtained previously. In Table 5, the experimental results of these extractions along with the values predicted by the models under the optimal extraction conditions is presented. As can be seen, the experimental values of the four responses are within the confidence intervals of the values predicted by the models (with 95% confidence level), which indicates a good degree of prediction of the models obtained in this work under the extraction conditions tested. In the same Table, experimental data of TPC, TFC and antiradical scavenging activity using distilled water as a conventional solvent under the same optimal extraction conditions used for the case of NADES CaFr11 as solvent is also presented. Significantly higher TPC, TFC values and antiradical scavenging activity were achieved for the extracts obtained from CaFr11 compared to the use of water as solvent. Therefore, the designed methodology demonstrated superior extraction characteristics using an environmentally friendly solvent. However, it is necessary to highlight that the comparison with water was carried out in a single extraction condition. Further tests should be performed to expand the extraction conditions using other conventional solvents and thus improve the comparison between these solvents and CaFr11under the optimal extraction conditions found in the present work. The total phenols content obtained in the present study usingCaFr11as solvent under the optimum extraction conditions (1290.9 ± 5.6 mg GAE/g db) cannot be compared with results in the literature from other studies because to the best of our knowledge, this is the first time polyphenol could be extracted from ANP using NADES-UAE technique. However, looking at results presented in the literature from other researchers using other agrifood wastes, we can state that our models have superior performance than what is in the literature. For instance, Fernández-Prior and co used different NADESs with conventional extraction technique to obtain TPC from olive pomace and reported values ranging between 11 and 20 mg GAE/g db at 90°c temperature, and 30–120 min extraction time respectively51. Pontes et al. used different NADESs in conventional extraction from olive pomace and obtained TPC values between 9 and 25 mg GAE/g db at temperatures between 33°c and 60°c, and time of 120 min60. Mansinhos et al. evaluated the effectiveness of ten different NADESs and compared them with COSs for the extraction of phenolic compounds from lavender using UAE and maceration (MAC) as innovative and conventional techniques, respectively. In most cases, the results showed that combining NADESs with UAE improved the extraction of phenols (22.90–56.00 mg GAE/g db) compared to MAC (18.22–50.05 mg GAE/g db). A NADES-MAE-based system was used for the extraction of phenolics from the leaves of cherry plant by Souza et al., and reported that the use of choline chloride: lactic acid at a 1:3 molar ratio with the addition of 20% water w/w improved the extraction of phenolics from hydroethanolic solvent, measured as the total peak area and number of peaks61. Zekovi´c et al. extracted polyphenols from coriander seeds using microwave assistance and compared the effects of microwave-assisted extraction (MAE) with conventional maceration (MAC) on the total phenolic content (TPC) and antioxidant properties determined by 1,1-diphenyl-2-picrylhydrazyl (DPPH) assay and ferric reducing power (FRAP) assay62, and also reported the effectiveness of supercritical fluid extraction (SFE) combined with ultrasound-assisted extraction (UAE) for extracting the nonpolar and polar phenol fractions from coriander seeds63. Palmieri et al. compared different conventional and innovative methods for extracting bioactive compounds from coriander, particularly UAE and rapid solid–liquid dynamic extraction (RSLDE), which revealed improved extraction properties64. NADES-assisted extraction of polyphenols from coriander was investigated by Ianni et al.1. Polyphenols were also extracted from blume using NADES-UAE process by Qin et al.65. Wang et al. studied the extraction of polyphenols from flowering quince using ultrasound (US)-NADES-assisted extraction31. A high-voltage electrical discharge (HVED) combined with NADES and aqueous glycerol was applied for the extraction of polyphenols from grapefruit peels by El Kantar et al.66. There are several more applications of innovative techniques for polyphenol extraction recently driven by the knowledge of the negative effects of conventional organic solvents (COSs) on human health and the environment.

The maximum flavonoid content of the extract at the optimized conditions using CaFr11was 2398.7 ± 23 µg QE/g shows superior performance than those obtained by other researchers using different agrifood matrices such as apple pomace and grape pomace67,68,1,66, except in one study which prepared DESs with citric acid: malic acid: water (1:1:10), and found the TFC values of the persimmon pulp in the extract as 2.5 mg QE/g69. Stupar et al.., for example, optimized the recovery of β-carotene from pumpkins by exploring a series of hydrophobic NADESs and observed that NADESs composed of caprylic acid and capric acid (3:1) led to high affinity and solubility of ß-carotene70. UAE was linked to the intensification of the process, which allowed greater recovery of ß-carotene (151.41 µg/mL) at the optimal process conditions than the 96.74 µg/mL recovered without the use of ultrasonication. Oktaviyanti et al.. performed TFC extraction from the Jungle Geranium plant with ultrasonic assistance using various DESs. They reported a threefold increase when employing the ChCl: oxalic acid combination compared to ethanol derived from organic solvents71. In a comparative study, Zheng et al.. evaluated flavonoid extraction from millet bran using an ultrasonic-assisted DES and conventional ethanol extraction. One study revealed that the TFC yield was twice as high when using green technology and green solvents72. Choline chloride-based solvents formed from 10 different plant varieties were used to obtain TFCs from yellow scale plants. The maximum efficiency was obtained when acetic acid was used in combination with HBD73. Furthermore, similar to our research, the positive impact of extending the sonication time on the TFC yield was also reported by Xu et al. in a study involving lemon peels74.

With respect to antiradical scavenging activity, results obtained in this work are in line with the reports obtained in literature. For instance, Nunes et al.75 reported FRAP values in the range of 111–233 µmol FSE/g db, in their study of olive pomace extraction using ethanol-water 80% (v/v) in a shaking water bath at room temperature for 120 min. Quero et al.76performed extractions from olive pomace by ohmic heating and stirring in water bath with water and ethanol water 50% (v/v) as solvents at 80°c, 30 min, and a solid–liquid ratio of 0.1 g/ml in both methods, and reported FRAP values of 80 µmol FSE/g db for water extracts, and 130–150 µmol FRE/g db for ethanol-water 50% (v/v) extracts. In different works, the antioxidant properties of NADES-UAE extracts were also found to improve significantly34. Antioxidants can slow or prevent the oxidation process. These substances can significantly slow or inhibit the oxidation of easily oxidizable substances even at low concentrations. Phenols and polyphenolic compounds, such as flavonoids, are widely found in many food products derived from plant sources, and they have been shown to possess significant antioxidant activities (AOA). Phenols have also been implicated in the survival of plants under extreme conditions. Consequently, the presence of phenolic compounds in the extracts suggested their important role in the plant. Several studies have successfully correlated the phenolic content with AOA77. Our findings, particularly the enhanced extraction efficiencies and antioxidant activities observed under the optimized conditions, further corroborate the critical role of phenolic and flavonoid compounds in contributing to the AOA of African Nutmeg peels, emphasizing the potential of NADESs in extracting these bioactive compounds78. The phenolic and flavonoid contents in the extracts indicate that African Nutmeg peels are a rich source of phenolic and flavonoid compounds. Additionally, the synthesized NADES is an excellent solvent for the extraction of phenolic compounds and flavonoid compounds from African Nutmeg peels.

Materials and methods

Materials

Chemicals

All the chemicals and solvents used were of analytical and standard grades. Citric acid monohydrate (≤ 100% purity), sucrose (99.8% purity), glucose monohydrate (99.0% purity), fructose (98.5–101.2% purity), xylitol (99% purity), glycerol (99–101% purity), sodium carbonate (99% purity), sodium acetate (99% purity), potassium acetate (99% purity), iron (iii) chloride hexahydrate (99% purity), Glycine (99% purity), and potassium persulfate (≥ 99% purity) were supplied by (Fluka Analytica, Germany), methanol (HPLC grade) (≥ 99.9% purity) was supplied by Sigma‒Aldrich, France, ethanol (96% purity) was purchased from Fillab, Bulgaria, ammonium acetate (≥ 98% purity) was supplied by Sigma‒Aldrich, Netherlands, 2,4,6-tris(2-pyridyl)-s-triazine (TPTZ) (≥ 99% purity), and Folin-Ciocalteu’s phenol reagent were supplied by Sigma‒Aldrich Switzerland, copper (ii) chloride (99% purity) was bought from Sigma‒Aldrich United Kingdom, aluminium (iii) nitrate nonahydrate (98.5% purity) was purchased from Chem-Lab NV Belgium, Neocuprine (99.9% purity) was supplied by Sigma‒Aldrich Austria, (±)−6-hydroxy-2,5,7,8-tetramethylchromane-2-carboxylic acid (Trolox) (≥ 99% purity), 3,4,5-trihydroxybenzoic acid (Gallic acid) (99% purity) were purchased from Sigma‒Aldrich Milan, Italy. Water was purified using a Milli-Q Plus 185 system from Millipore (Milford, MA, USA).

Plant Material

Dried seeds of African Nutmeg (Monodora myristica (Gaertn.) fruits from the 2022 harvest were purchased from the Zuba Fruit Market, Abuja, Nigeria. The seeds were cleaned, packed under vacuum following WTO guidelines on sanitary and phytosanitary measures adopted in Nigeria as provided by the Standards Organisation of Nigeria through (https://epingalert.org/), and brought to the Biotechnology Laboratory at the University of Food Technologies, Plovdiv, Bulgaria. In the laboratory, the seeds were peeled, and the peels were collected and ground with an electric coffee grinder. The ground peels were vacuum sealed and stored in a desiccator until further use.

Methodology

Preparation of Natural Deep Eutectic solvents (NADESs)

The natural deep eutectic solvents (NADESs) used in this study were prepared by combining the components at defined molar ratios and sonicated in an ultrasonic bath operated at a frequency of 35 kHz with a maximum input power of 240 W (USTS 5.7–150 Siel, Gabrovo, Bulgaria) until they form uniform mixture following the methods described in Hsieh et al. with slight modification79. The NADESs and their physicochemical properties are presented in supplementary Table 1 (ST1) and Supplementary Table 2 (ST2) (supplementary data). The NADESs were verified as eutectic solvents through Fourier transform infrared spectroscopy according the methods described in57,80,81 with slight modification as follows: both the individual components and the synthesized NADES were used as is without incorporating any other substance as additive. (FTIR data not included in this manuscript)

Multifactorial (MFAT) NADESs screening study

A NADES screening with 24 fractional factorial experiment (FFE) with eight (8) corners and two (2) central points was carried out to study the effect of the solvent on the phenolic content and the antioxidant activity of ANP extracts. Extraction experiments were performed in 40 mL synthesis glass bottles inside a thermostatic ultrasound bath operated at a frequency of 35 kHz with a maximum input power of 240 W (USTS 5.7–150 Siel, Gabrovo, Bulgaria). All extractions were carried out following the MFAT screening design as shown on Table 6. Then, extracts were centrifuged at 4500 rpm (centrifuge MPW-260R Labtech, Germany) for 10 min, the supernatant was recovered by further filtration through Whatman No 1 with pore size of 11 μm and stored at −4°c until further analysis. Extractions for each of the Fourteen NADESs were performed in triplicate. The results obtained at this stage have been the basis for selecting the solvent in a second series of experiments planned according to the study.

Rotatable Central Composite Response Surface Experimental designs

For the selected solvents from the NADESs screening, an extraction process modelling was performed. A rotatable central composite response surface methodology approach with four factors at five levels (4 corners and 2 axial points) design was used. The design matrix for coded and uncoded values of the independent variables is shown in Table 7. The different levels of the independent variables were selected based on results from the MFAT screening experimentation. A total of thirty experiments with three replicates were performed at random order, and the responses fitted with a second-order polynomial model, Eq. 1:

where βo is the intercept, βi is the linear slope, βii is the quadratic slope and βij is the interaction slope, all relative to the dependent variable Y. Xi and Xj are the levels of the independent variables coded according to the following equation:

where xi and Xi represents the real and coded values of the independent variables i respectively, xmi represents the value of the independent variable i at the central point and Δxi refers to the step change of the independent variable i.

Procedure

Ground African nutmeg peels (1.0 g) were weighed into synthesis bottles, and an appropriate volume of appropriate solvent (NADES) diluted with distilled water to achieve the appropriate concentration was added. The samples were irradiated at the designed temperature and time using an ultrasonic bath operated at a frequency of 35 kHz with a maximum input power of 240 W (USTS 5.7–150 Siel, Gabrovo, Bulgaria) with automatic temperature control. At the end of each extraction, the bottles were removed from the bath, contents transferred to centrifuge tubes and centrifuged at 4500 rpm for 10 min (centrifuge MPW-260R Labtech, Germany). The supernatants were further filtered into solvent bottles using Whatman No.1 filter paper (11 μm pore size), and the bottles properly sealed, and kept in a refrigerator at −4 °C until further analysis.

Optimization methodology

To optimize the operational parameters involved in the extraction process, the desirability function methodology25,26 was used. The main concept of this method is to calculate a desirability value for each of the k responses as an indicator of how closely the fitted value aligns with the desired value at the optimal factor settings. These individual desirability values are then combined to create an overall desirability for a set of k response variables. The desirability function operates on a scale ranging from zero, representing a completely undesirable response, to one, indicating a fully desired outcome.

In the present study, the objective of optimization is to simultaneously maximize the responses of TPC, TFC, and AA measured by CUPRAC and FRAP methods, with respect to the independent variables: ultrasound temperature, extraction time, solvent volume, and solvent concentration. For each of the three responses, the minimum and maximum acceptable values correspond to the minimum and maximum experimental values obtained from the extraction experiments. Predicted values obtained from the model of the response k (yk) were converted to individual desirability values (dk) with the following equation:

where ykmin and ykmax are the minimum and maximum acceptable values of the response k, respectively. The overall desirability function (D) is defined as the geometric mean of the four individual desirability functions (d1, d2, d3 and d4), given by:

Total phenol content (TPC)

The TPC assay was performed spectrophotometrically according to the method of Ianni et al.., with slight modifications1. The Folin–Ciocalteu’s (F-C) reagent method was used to determine the TPC as follows: the phenolic content of the extracts obtained from each of the NADESs under the designed experimental conditions was determined by measuring the absorbance at 765 nm. In the tube (15 mL), 0.1 mL of the NADESs extract samples were mixed with 0.5 ml of F-C reagent. After approximately 1 min, 0.4 mL of 7.5% Na2CO3 was added, the mixture was incubated at 50 °C for 5 min, and the absorbance was measured in a microplate reader (SPECTROstar Nano Microplate Reader, BMG LABTECH, Ortenberg, Germany) against the appropriate blank sample. In this study, the TPC was determined by relying on a calibration curve of gallic acid (prepared from the corresponding extracts and used to validate and standardize the spectrophotometer). The TPC was calculated with the following equation and reported as milligram per gram of garlic acid equivalent (GAE):

Where:

Y = Area of standard curve measured at 765 nm.

X = TPC in mg GAE/L or mg GAE/g.

B = Weight of sample used in the extraction.

C = Volume of solvent used in the extraction.

D = Dilution factor where applicable.

db = Dry weight of sample.

Total flavonoid content (TFC)

The TFC was evaluated according to the method described in Kivrak et al.., with slight modifications82. In Eppendorf tubes (2 mL), aliquots of 0.25 mL of the extracts were added to 0.025 mL of 10% Al (NO3)3, 0.025 mL of 1 M CH3COOK, and 0.95 mL of ethanol. The mixture was incubated at room temperature (RT) for 40 min, after which the absorbance was read at 415 nm in a microplate reader (SPECTROstar Nano Microplate Reader, BMG LABTECH, Ortenberg, Germany) against the appropriate blank sample. The TFC calibration curve was determined by relying on the quercetin equivalence (QE) and was used as a standard (prepared as the corresponding extract and used to validate and standardize the spectrophotometer); Eq. (6) was used to determine and express the TFC as µg/g QE db:

Where:

Y = Area of the standard curve measured at 415 nm.

X = TFC value in µg QE/L or µg QE/g.

B = Weight of sample used in the extraction.

C = Volume of solvent used in the extraction.

D = Dilution factor where applicable.

Cupric Ion reducing antioxidant capacity (CUPRAC)

The CUPRAC assay was performed according to the procedure of Apak et al., as described in Akyuz et al.83,84 with slight modifications. Briefly, 0.25 mL of 1.0 × 10−2 M copper (II) chloride solution, 7.5 × 10−3 M Neocuprine (Nc), 1 M CH3COONH4 buffer (pH 7.0) solution, and distilled water were mixed in a 2 mL Eppendorf tube, after which 0.025 mL of sample was added and mixed. The stirred solutions were allowed to stand at RT for 30 min to incubate. At the end of the incubation period, the absorbance of the prepared mixtures was measured at 450 nm against the blank using a microplate reader (SPECTROstar Nano Microplate Reader, BMG LABTECH, Ortenberg, Germany). Trolox was used to prepare a standard curve, and the total antiradical scavenging capacity of the sample was calculated following Eq. (7), and present as µmol/g of Trolox equivalent (TE) on dry weight basis db:

Where:

Y = Area of the standard curve measured at 450 nm.

X = CUPRAC value in µMTE/mL or µMTE/g.

B = Weight of sample used in the extraction.

C = Volume of solvent used in the extraction.

D = Dilution factor where applicable.

Ferric reducing antioxidant power (FRAP)

The FRAP assay was carried out according to the procedure of Benzie and Strain, described in Lim and Lim with minor modifications85,86. The FRAP reagent was prepared fresh each day and was warmed up to 37 °C before use. The FRAP reagent consists of (1) 300 mM acetate buffer (pH 3.6), (2) TPTZ (10 mM in 40 mM HCl), and (3) (FeCl3.6H2O, 20 mM). Solutions (1), (2), and (3) were mixed at a ratio of 10:1:1 to form the FRAP reagent. In a 15 mL tube, 2.85 mL of freshly prepared and warmed FRAP reagent was mixed with 0.15 mL of sample and incubated at 37 °C for 4 min, after which the absorbance was measured at 593 nm in a microplate reader (SPECTROstar Nano Microplate Reader, BMG LABTECH, Ortenberg, Germany) against the appropriate blank. The result is expressed as µmol/gTE derived from Eq. (8) and present as µmol/g of Trolox equivalent (TE) on dry weight basis db.

Where:

Y = Area of standard curve measurement at 593 nm.

X = FRAP value in µmol/ml TE or µmol/g TE.

B = Weight of sample used in the extraction.

C = Volume of solvent used in the extraction.

D = Dilution factor where applicable.

Statistical analysis

All the samples were prepared in triplicate. The results are expressed as the mean ± standard deviation (n = 3). Statistically significant differences among group means were evaluated using one-way analysis of variance (ANOVA) followed by post hoc Tukey’s multiple comparison tests, response surface analysis, desirability function, and optimization were performed by Minitab Statistical Software version 21.4.0 (Minitab LLC, Penn, USA). In all cases, a 95% confidence limit with a p value < 0.05 indicate statistical significance.

Conclusion

The present work evaluated the use of different NADESs as green solvent in the ultrasound assisted extraction of phenolic compounds with antiradical scavenging activity from ANP produced in Nigeria through a simple process that could be easily adapted to industrial production scale. In this sense, several of the NADES studied showed good characteristics for extracting phenolic compounds with antioxidant activity. However, CaFr11 was selected as the best solvent among the tested NADESs. TPC, TFC, and antiradical scavenging activity of the extracts were significantly affected by the tested variables of the extraction process: ultrasound temperature, extraction time, solvent volume, and solvent concentration. The mathematical models that describe the relationships between the different operating conditions tested and the response variables of the extraction process (TPC, TFC, CUPRAC, and FRAP) were obtained. From these models, the optimal extraction conditions that maximized the TPC, TFC and antiradical scavenging activity were determined: 30°c, 5 min, 25 ml, and 90% of temperature, time, volume, and concentration respectively. The responses of the NADES extraction under optimal conditions were significantly higher than those of corresponding extracts obtained by using conventional solvent (distilled water) under the same optimized extraction conditions. This highlights the suitability of the present extraction method using CaFr11 as solvent to obtain phenolic compounds with antiradical scavenging activity from ANP. The findings further give insights to the capacity of NADESs as powerful solvents for extraction applications. The lack of literature on extraction of bioactive compounds from African nutmeg materials using NADESs with ultrasound techniques gives credence to the originality of the present work. Further research should be carried out to elucidate the individual constituents of the extracts from ANP, and also to study if it is possible to directly apply the extracts obtained by the methodology used in this work to food, pharmaceutical, and cosmetic products, taking advantage of the fact that the components of NADES (citric acid and fructose) are widely used as additives or food ingredients. Further research should also be carried out to consider if a previous stage of separation is needed to obtain a purified extract of phenolic compounds with antiradical scavenging activity before the extracts obtained from this method could be utilized further.

Data availability

The datasets generated and/or analyzed and used in the current study is available from the corresponding author on reasonable request.

References

Ianni, F. et al. NADES-Assisted extraction of polyphenols from Coriander seeds: a systematic optimization study. Antioxidants 12, 2048 (2023).

Mangiapelo, L. et al. Optimization of Ultrasound-assisted extraction of Chlorogenic Acid from Potato Sprout Waste and Enhancement of the in vitro total antioxidant capacity. Antioxidants 12, 348 (2023).

Skarpalezos, D. & Detsi, A. Deep Eutectic solvents as extraction media for Valuable flavonoids from Natural sources. Appl. Sci. 9, 4169 (2019).

Weiz, G., Braun, L., Lopez, R., De María, P. D. & Breccia, J. D. Enzymatic deglycosylation of flavonoids in deep eutectic solvents-aqueous mixtures: paving the way for sustainable flavonoid chemistry. J. Mol. Catal. B: Enzymatic. 130, 70–73 (2016).

Jeong, K. M. et al. Multi-functioning deep eutectic solvents as extraction and storage media for bioactive natural products that are readily applicable to cosmetic products. J. Clean. Prod. 151, 87–95 (2017).

Choi, Y. H. et al. Are Natural Deep Eutectic solvents the Missing Link in understanding Cellular Metabolism and Physiology? Plant Physiol. 156, 1701–1705 (2011).

Nolan, M. D., Mezzetta, A., Guazzelli, L. & Scanlan, E. M. Radical-mediated thiol–ene ‘click’ reactions in deep eutectic solvents for bioconjugation. Green. Chem. 24, 1456–1462 (2022).

Thomas, F. & Kayser, O. Natural deep eutectic solvents enhance cannabinoid biotransformation. Biochem. Eng. J. 180, 108380 (2022).

Martins, M. A. R., Pinho, S. P. & Coutinho, J. A. P. insights into the nature of Eutectic and Deep Eutectic mixtures. J. Solut. Chem. 48, 962–982 (2019).

Choi, Y. H. & Verpoorte, R. Green solvents for the extraction of bioactive compounds from natural products using ionic liquids and deep eutectic solvents. Curr. Opin. Food Sci. 26, 87–93 (2019).

Hikmawanti, N. P. E., Ramadon, D. & Jantan, I. & Mun’im, A. Natural Deep Eutectic Solvents (NADES): Phytochemical Extraction Performance Enhancer for Pharmaceutical and Nutraceutical Product Development. Plants 10, 2091 (2021).

Afonso, J., Mezzetta, A., Marrucho, I. M. & Guazzelli, L. History repeats itself again: will the mistakes of the past for ILs be repeated for DESs? From being considered ionic liquids to becoming their alternative: the unbalanced turn of deep eutectic solvents. Green. Chem. 25, 59–105 (2023).

Oyinloye, B. E. et al. Aqueous extract of Monodora myristica ameliorates cadmium-induced hepatotoxicity in male rats. SpringerPlus 5, 641 (2016).

Chinelo, C. et al. (ed ) Proximate and phytochemical analysis of Monodora myristica (African Nutmeg) from Nsukka, Enugu State, Nigeria. JFNR 6 597–601 (2018).

Ekeanyanwu, R. C. & Njoku, O. U. Acute and subacute oral toxicity study on the flavonoid rich fraction of Monodora tenuifolia seed in albino rats. Asian Pac. J. Trop. Biomed. 4, 194–202 (2014).

Agiriga, A. & Siwela, M. Monodora myristica (Gaertn.) Dunal: a plant with Multiple Food, Health and Medicinal applications: a review. Am. J. Food Technol. 12, 271–284 (2017).

Erukainure, O. et al. Chemical properties of Monodora myristica and its protective potentials against free radicals in vitro Oxid Antioxid Med Sci 1, 127 (2012).

Onyenibe, N. S., Fowokemi, K. T. & Emmanuel, O. B. African Nutmeg (Monodora Myristica) lowers cholesterol and modulates lipid peroxidation in experimentally Induced Hypercholesterolemic Male Wistar rats. Int. J. Biomed. Sci. 11, 86–92 (2015).

Okechukwu, Q. N., Ugwuona, F. U., Ofoedu, C. E., Juchniewicz, S. & Okpala, C. O. R. Chemical composition, antibacterial efficacy, and antioxidant capacity of essential oil and oleoresin from Monodora myristica and Tetrapleura tetraptera in Southeast Nigeria. Sci. Rep. 12, 19861 (2022).

Osukoya, O. A. et al. Antioxidant and antibacterial properties of Monodora myristica (Calabash Nutmeg) seed protein hydrolysates. Food Measure. 15, 2854–2864 (2021).

Erukainure, O. et al. Monodora myristica (AfNutmegnutmeg) modulates redox homeostasis and alters functional chemistry in sickled erythrocytes. Hum. Exp. Toxicol. 37, 458–467 (2018).

Odoh, U., Ezugwu, C. & Ajali, I. Antimicrobial activity of Monodora myristica seed oil. J. Pharm. Allied Sci. 2, 233–236 (2005).

Ekeanyanwu, R. C. In vitro anthelmintic potentials of Xylopia aethiopica and Monodora myristica from Nigeria. Afr J. Biochem. Res 6, (2012).

Li, A. N. et al. Resources and Biological activities of Natural polyphenols. Nutrients 6, 6020–6047 (2014).

Alburquerque, J. Agrochemical characterisation of alperujo, a solid by-product of the two-phase centrifugation method for olive oil extraction. Bioresour. Technol. 91, 195–200 (2004).

Cabrera, L., Xavier, L. & Zecchi, B. Extraction of phenolic compounds with antioxidant activity from olive pomace using natural deep eutectic solvents: modelling and optimization by response surface methodology. Discov Food. 4, 29 (2024).

Zannou, O., Pashazadeh, H., Ghellam, M., Ibrahim, S. A. & Koca, I. Extraction of anthocyanins from Borage (Echium Amoenum) flowers using Choline Chloride and a Glycerol-Based, Deep Eutectic Solvent: optimization, antioxidant activity, and in Vitro Bioavailability. Molecules 27, 134 (2021).

Yu, X. et al. Extraction optimization of tea saponins from Camellia Oleifera seed meal with Deep Eutectic solvents: Composition Identification and properties evaluation. SSRN J. https://doi.org/10.2139/ssrn.4375852 (2023).

Yu, Q. et al. Extraction of flavonoids from Glycyrrhiza residues using deep eutectic solvents and its molecular mechanism. J. Mol. Liq. 363, 119848 (2022).

Nekkaa, A., Benaissa, A., Lalaouna, A. E. D. & Mutelet, F. Canabady-Rochelle, L. Optimization of ultrasound-assisted deep eutectic solvent extraction of polyphenols from Rhamnus alaternus for their antioxidant activity. Biomass Conv Bioref. https://doi.org/10.1007/s13399-023-05182-w (2023).

Wang, W. et al. Ultrasonic-assisted customized natural deep eutectic solvents extraction of polyphenols from Chaenomeles speciosa. Microchem. J. 193, 108952 (2023).

Kutlu, N., Kamiloğlu, A., Abca, T. E. & Yilmaz, Ö. Ultrasound-assisted deep eutectic solvent extraction of bioactive compounds from persimmon calyx. J. Food Sci. 1750-3841 (16849). https://doi.org/10.1111/1750-3841.16849 (2023).

Pusty, K. et al. Ultrasound assisted phytochemical extraction of red cabbage by using deep eutectic solvent: modelling using ANFIS and optimization by genetic algorithms. Ultrason. Sonochem. 102, 106762 (2024).

Mansinhos, I. et al. Ultrasonic-assisted extraction and natural deep Eutectic solvents combination: a Green Strategy to improve the recovery of Phenolic compounds from Lavandula Pedunculata subsp. Lusitanica (Chaytor) Franco. Antioxidants 10, 582 (2021).

Anticona, M., Blesa, J., Lopez-Malo, D., Frigola, A. & Esteve, M. J. Effects of ultrasound-assisted extraction on physicochemical properties, bioactive compounds, and antioxidant capacity for the valorization of hybrid Mandarin peels. Food Bioscience. 42, 101185 (2021).

Abbas, S., Bashari, M., Akhtar, W., Li, W. W. & Zhang, X. Process optimization of ultrasound-assisted curcumin nanoemulsions stabilized by OSA-modified starch. Ultrason. Sonochem. 21, 1265–1274 (2014).

Belwal, T. et al. Optimization model for ultrasonic-assisted and scale-up extraction of anthocyanins from Pyrus communis ‘Starkrimson’ fruit peel. Food Chem. 297, 124993 (2019).

Fernández, M. D. L. Á., Espino, M., Gomez, F. J. V. & Silva, M. F. Novel approaches mediated by tailor-made green solvents for the extraction of phenolic compounds from agro-food industrial by-products. Food Chem. 239, 671–678 (2018).

Cvjetko Bubalo, M., Ćurko, N., Tomašević, M. & Kovačević Ganić, K. Radojčić Redovniković, I. Green extraction of grape skin phenolics by using deep eutectic solvents. Food Chem. 200, 159–166 (2016).

Bertolo, M. R. V., Martins, V. C. A., Plepis, A. M. G. & Bogusz, S. Utilization of pomegranate peel waste: natural deep eutectic solvents as a green strategy to recover valuable phenolic compounds. J. Clean. Prod. 327, 129471 (2021).

Yan-Ying, Y., Wei, Z. & Shu-Wen, C. Extraction of Ferulic Acid and Caffeic Acid with Ionic liquids. Chin. J. Anal. Chem. 35, 1726–1730 (2007).

Fan, J. et al. Solvent extraction of selected endocrine-disrupting phenols using ionic liquids. Sep. Purif. Technol. 61, 324–331 (2008).

Zhang, H. et al. Sustainable ultrasound-assisted extraction of Polygonatum Sibiricum saponins using ionic strength-responsive natural deep eutectic solvents. Ultrason. Sonochem. 100, 106640 (2023).

Kiene, M. et al. Sustainable in Silico-supported Ultrasonic-assisted extraction of Oligomeric stilbenoids from Grapevine roots using natural deep Eutectic solvents (NADES) and Stability Study of potential ready-to-use extracts. Foods 13, 324 (2024).

Ivanović, M., Alañón, M. E., Arráez-Román, D. & Segura-Carretero, A. Enhanced and green extraction of bioactive compounds from Lippia citriodora by tailor-made natural deep eutectic solvents. Food Res. Int. 111, 67–76 (2018).

Craveiro, R. et al. Properties and thermal behavior of natural deep eutectic solvents. J. Mol. Liq. 215, 534–540 (2016).

Dai, Y., Rozema, E., Verpoorte, R. & Choi, Y. H. Application of natural deep eutectic solvents to the extraction of anthocyanins from Catharanthus roseus with high extractability and stability replacing conventional organic solvents. J. Chromatogr. A. 1434, 50–56 (2016).

Wu, L., Li, L., Chen, S., Wang, L. & Lin, X. Deep eutectic solvent-based ultrasonic-assisted extraction of phenolic compounds from Moringa oleifera L. leaves: optimization, comparison and antioxidant activity. Sep. Purif. Technol. 247, 117014 (2020).

Savi, L. K. et al. Natural deep eutectic solvents (NADES) based on citric acid and sucrose as a potential green technology: a comprehensive study of water inclusion and its effect on thermal, physical and rheological properties. Int. J. Food Sci. Technol. 54, 898–907 (2019).

Ghanbari, R., Anwar, F., Alkharfy, K. M., Gilani, A. H. & Saari, N. Valuable nutrients and Functional Bioactives in different parts of Olive (Olea europaea L.)—A review. IJMS 13, 3291–3340 (2012).

Fernández-Prior, M. Á. et al. Deep eutectic solvents improve the biorefinery of alperujo by extraction of bioactive molecules in combination with industrial thermal treatments. Food Bioprod. Process. 121, 131–142 (2020).

Wei, J. et al. Ultrasonic-assisted hydrophobic deep eutectic solvents for the extraction of seven compounds from Piperis longi fructus-rhei radix et rhizoma drug pair and their vitro antioxidant evaluation. Sustainable Chem. Pharm. 32, 100996 (2023).

Xing, C. et al. Ultrasound-assisted deep eutectic solvents extraction of glabridin and isoliquiritigenin from Glycyrrhiza glabra: optimization, extraction mechanism and in vitro bioactivities. Ultrason. Sonochem. 83, 105946 (2022).

Santos-Martín, M. et al. Ultrasound-assisted extraction of phenolic compounds from blueberry leaves using natural deep eutectic solvents (NADES) for the valorization of agrifood wastes. Biomass Bioenerg. 175, 106882 (2023).

Doldolova, K. et al. Optimization and modeling of microwave-assisted extraction of curcumin and antioxidant compounds from turmeric by using natural deep eutectic solvents. Food Chem. 353, 129337 (2021).

Dai, Y., Witkamp, G. J., Verpoorte, R. & Choi, Y. H. Tailoring properties of natural deep eutectic solvents with water to facilitate their applications. Food Chem. 187, 14–19 (2015).

Wu, K. et al. Analysis of NADES and its water tailoring effects constructed from inulin and L-proline based on structure, physicochemical and antifreeze properties. Int. J. Biol. Macromol. 277, 134049 (2024).

Lanjekar, K. J., Gokhale, S. & Rathod, V. K. Utilization of waste mango peels for extraction of polyphenolic antioxidants by ultrasound-assisted natural deep eutectic solvent. Bioresource Technol. Rep. 18, 101074 (2022).

Alasalvar, H. & Yildirim, Z. Ultrasound-assisted extraction of antioxidant phenolic compounds from Lavandula angustifolia flowers using natural deep eutectic solvents: an experimental design approach. Sustainable Chem. Pharm. 22, 100492 (2021).

de Pontes, P. V. Extraction optimization, biological activities, and application in O/W emulsion of deep eutectic solvents-based phenolic extracts from olive pomace. Food Res. Int. 161, 111753 (2022).

Souza, O. A. et al. Combining natural deep eutectic solvent and microwave irradiation towards the eco-friendly and optimized extraction of bioactive phenolics from Eugenia uniflora L. Sustainable Chem. Pharm. 26, 100618 (2022).

Zeković, Z., Vladić, J., Vidović, S., Adamović, D. & Pavlić, B. Optimization of microwave-assisted extraction (MAE) of coriander phenolic antioxidants – response surface methodology approach. J. Sci. Food Agric. 96, 4613–4622 (2016).

Zeković, Z. et al. Coriander seeds processing: sequential extraction of non-polar and polar fractions using supercritical carbon dioxide extraction and ultrasound-assisted extraction. Food Bioprod. Process. 95, 218–227 (2015).

Palmieri, S., Pellegrini, M., Ricci, A., Compagnone, D. & Lo Sterzo, C. Chemical composition and antioxidant activity of Thyme, hemp and coriander extracts: a comparison study of Maceration, Soxhlet, UAE and RSLDE techniques. Foods 9, 1221 (2020).

Qin, G. et al. Eco-friendly and efficient extraction of polyphenols from Ligustrum robustum by deep eutectic solvent assisted ultrasound. Food Chem. 429, 136828 (2023).

El Kantar, S. et al. Green extraction of polyphenols from grapefruit peels using high voltage electrical discharges, deep eutectic solvents and aqueous glycerol. Food Chem. 295, 165–171 (2019).

Vo, T. P. et al. Green extraction of phenolics and terpenoids from passion fruit peels using natural deep eutectic solvents. J. Food Process. Eng. e14503 https://doi.org/10.1111/jfpe.14503 (2023).

Ozturk, B., Parkinson, C. & Gonzalez-Miquel, M. Extraction of polyphenolic antioxidants from orange peel waste using deep eutectic solvents. Sep. Purif. Technol. 206, 1–13 (2018).

Bermúdez-Oria, A., Fernández-Prior, A., Luisa Castejón, M., Rodríguez-Gutiérrez, G. & Fernández-Bolaños, J. Extraction of polyphenols associated with pectin from olive waste (alperujo) with choline chloride. Food Chem. 419, 136073 (2023).

Stupar, A. et al. Recovery of β-carotene from pumpkin using switchable natural deep eutectic solvents. Ultrason. Sonochem. 76, 105638 (2021).

Oktaviyanti, N. D., Mun’im, A. & Kartini & Application and optimization of ultrasound-assisted deep eutectic solvent for the extraction of new skin-lightening cosmetic materials from Ixora Javanica flower. Heliyon 5, e02950 (2019).

Zheng, W. et al. Molecular Transformation and Characterizations of Super-deamidated Wheat Gluten by a tunable Hydrated Ternary Natural Deep Eutectic Solvent. ACS Sustainable Chem. Eng. Acssuschemeng. 3c00655 https://doi.org/10.1021/acssuschemeng.3c00655 (2023).

Benítez-Correa, E., Bastías-Montes, J. M., Acuña-Nelson, S. & Muñoz-Fariña, O. Effect of choline chloride-based deep eutectic solvents on polyphenols extraction from cocoa (Theobroma cacao L.) bean shells and antioxidant activity of extracts. Curr. Res. Food Sci. 7, 100614 (2023).

Xu, K., Xu, P. & Wang, Y. Aqueous biphasic systems formed by hydrophilic and hydrophobic deep eutectic solvents for the partitioning of dyes. Talanta 213, 120839 (2020).

Nunes, R. J., Saramago, B. & Marrucho, I. M. Surface tension of dl -menthol:Octanoic Acid Eutectic mixtures. J. Chem. Eng. Data. 64, 4915–4923 (2019).

Quero, J. et al. Unveiling the antioxidant therapeutic functionality of sustainable olive pomace active ingredients. Antioxidants 11, 828 (2022).

Mihaylova, D., Lante, A. & Krastanov, A. Total phenolic content, antioxidant and antimicrobial activity of Haberlea rhodopensis extracts obtained by pressurized liquid extraction. Acta Aliment. 44, 326–332 (2015).

Vo, T. P. et al. Green extraction of phenolics and flavonoids from black mulberry fruit using natural deep eutectic solvents: optimization and surface morphology. BMC Chem. 17, 119 (2023).

Hsieh, Y. H. et al. Ultrasonication-assisted synthesis of alcohol-based deep eutectic solvents for extraction of active compounds from ginger. Ultrason. Sonochem. 63, 104915 (2020).

Albertini, B. et al. NaDES as a green technological approach for the solubility improvement of BCS class II APIs: an insight into the molecular interactions. Int. J. Pharm. 634, 122696 (2023).

Santana, A. P. R. et al. Sustainable synthesis of natural deep eutectic solvents (NADES) by different methods. J. Mol. Liq. 293, 111452 (2019).

Kivrak, İ. et al. Antioxidant, anticholinesterase and antimicrobial constituents from the essential oil and ethanol extract of Salvia Potentillifolia. Food Chem. 116, 470–479 (2009).

Apak, R., Güçlü, K., Özyürek, M., Bektaşoğlu, B. & Bener, M. Cupric Ion reducing antioxidant capacity assay for antioxidants in Human serum and for Hydroxyl Radical scavengers. in Advanced Protocols in Oxidative Stress II (ed Armstrong, D.) vol. 594 215–239 (Humana, Totowa, NJ, (2010).

Akyüz, E., Türkoğlu, S., Sözgen Başkan, K., Tütem, E. & Apak, M. R. Comparison of antioxidant capacities and antioxidant components of commercial bitter melon (Momordicacharantia L.) products. Turk. J. Chem. 44, 1663–1673 (2020).

Benzie, I. F. F. & Strain, J. J. [2] Ferric reducing/antioxidant power assay: Direct measure of total antioxidant activity of biological fluids and modified version for simultaneous measurement of total antioxidant power and ascorbic acid concentration. in Methods in Enzymology vol. 299 15–27 (Elsevier, 1999).

Lim, C. S. H. & Lim, S. L. Ferric reducing Capacity Versus Ferric reducing antioxidant power for measuring total antioxidant capacity. Lab. Med. 44, 51–55 (2013).

Acknowledgements

OUJ is grateful to the University of Urbino Carlo Bo for the grant of a generous PhD scholarship.

Author information

Authors and Affiliations

Contributions

U.J.O. - Conceptualization, data curation, formal analysis, investigation, methodology, project administration, validation, and writing the original draft.M.M. - Supervision, writing review, and editing.D.M. - Supervision, resources, writing review, and editing.A.C. - Supervision, editing, Funding acquisition.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Okeke, U.J., Micucci, M., Mihaylova, D. et al. The effects of experimental conditions on extraction of polyphenols from African Nutmeg peels using NADESs-UAE: a multifactorial modelling technique. Sci Rep 15, 4890 (2025). https://doi.org/10.1038/s41598-025-88233-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-88233-8