Abstract

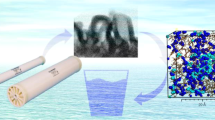

In this study, we explore the possibility of reusing end-of-life seawater reverse osmosis (RO) membranes to treat brackish water and industrial effluent. Prior to cleaning the end-of-life RO membranes, we conducted several autopsies in order to assess the extent of degradation. Based on these results, three cleaning protocols were tested and Ultrasil10 and/or chlorine solution were selected for further investigation. The cleaning capacity of the chlorine treatment at 4000 ppm.h was tested but proved inefficient as it leads to a denser cake and a significant decrease in hydraulic permeability. Therefore, we recommend commencing chemical cleaning with Ultrasil10 to remove foulants, thereby reconditioning the end-of-life RO membranes to meet nanofiltration membrane specifications. The cleaned end-of-life RO membranes exhibited enhanced hydraulic permeability (1.97 L·h⁻¹·m⁻²·bar⁻¹) and achieved a salt rejection of 85% for brackish water (6 g/L NaCl). With a molecular weight cutoff of 86 Da, these membranes effectively reduced brackish water conductivity to below 1000 µS/cm at 10 bars, complying with Tunisian drinking water standards (300–2500 µS/cm). Additionally, they demonstrated high efficiency in treating industrial effluents, achieving turbidity levels below 2 NTU and conductivity of 180 µS/cm. Operating at lower pressures, these membranes provided cost-effective, sustainable solutions and performed comparably to commercial new NF membranes, validating their potential for reuse in brackish water and wastewater treatment applications.

Similar content being viewed by others

Introduction

Due to the increasing demands from industry, energy production, and population growth, the demand for water continues to grow. The UN predicts a 50% surge in demand by 2030, making water an increasingly scarce resource. To meet this growing need, many countries have opted for desalination plants as unconventional alternative sources of water. Most of the plants worldwide (64%) use reverse osmosis (RO) technology. The membranes used in RO have a lifespan of about 3–5 years, after which they contribute significantly to plastic waste (polymers). Finding ways to reuse these membranes, instead of incinerating1 them, could be very worthwhile.

The harmful effects of discharging saline wastewater have become more evident in recent years, saline wastewater, such as production water, tannery wastewater, textile wastewater, and aquaculture wastewater, contains various organic pollutants and inorganic dissolved ions, which are of a significant public concern. Treating these effluents not only helps meet discharge standards but also offers opportunities for water reuse and nutrient recovery. Membrane technology is a recognized advanced process for water reclamation2,3, and nutrient recovery4 as well as extraction of metals from different sources5. Various pressure-driven membrane processes, including RO, microfiltration (MF), ultrafiltration (UF), and nanofiltration (NF) also have potential applications in reclaimed water production, with RO being the most established desalination technology. It is estimated that more than 840,000 end-of-life RO membrane modules (> 14000t of plastic waste) are discarded annually in landfills worldwide6,7. Considering these challenges, the current research suggests adopting a circular economic approach to membrane technology and proposes an alternative system to manage end-of-life membranes. According to previous studies, recycled membranes could be technically comparable to NF and UF commercial membranes8,9,10, and they could even offer competitive economic advantages11,12. Rodríguez et al. (2002) suggest that aged RO membranes could be recycled using chemical treatments13. Veza and Rodriguez-Gonzalez (2003) transformed aged RO membranes by surface oxidation using potassium permanganate, producing an efficient filtration membrane for the tertiary treatment of municipal wastewater9. Mohamedou et al. (2010) performed autopsies on aged RO membranes and found that aged RO membranes could be directly reused as nanofiltration (NF) membranes for seawater pretreatment14. Lawler et al. (2012) posited that the treatment of the surface of aged ROs membranes prior to recycling could increase the sustainability of this technology7.

Furthermore, Pontié (2015) highlighted different strategies for recycling aged RO membranes, one of which was to transform aged RO membranes into ultrafiltration (UF) membranes after oxidation with sodium hypochlorite15. Pype et al. (2016) reported that sodium hypochlorite transformed the selective layer of aged membranes by introducing chlorine into the molecular structure of the membrane, resulting in increased permeability and decreased rejection of selected compounds16. Rodríguez-Sáez et al. (2022) explored the use of recycled UF (r-UF) membranes, derived from end-of-life RO membranes, in an aerobic membrane bioreactor (aMBR) system for wastewater treatment. Performance tests revealed that r-UF membranes offer comparable rejection to commercial MF membranes (c-MF), with higher fouling resistance but lower permeability decline rates. Preliminary economic analysis highlights the cost competitiveness of r-UF membranes (5.9–10.9 EUR·m²) and potential scaling challenges for industrial applications17. Rehman et al. (2023) demonstrated that recycled RO membranes could be converted into UF membranes with performance metrics comparable to commercial UF membranes, particularly in terms of turbidity removal and water recovery rates18. Khanzada et al. (2024) highlighted that recycling membranes and using recycled materials such as plastics and cellulose for membrane fabrication can mitigate environmental impacts and enhance sustainability19. Along these lines, recycled membranes with NF and UF properties can be obtained through controlled exposure to an oxidizing agent20,21,22,23. These recycled membranes have potential NF applications, including agricultural and water supply for irrigation (e.g., for golf courses and green recreational areas), or as sacrificial membranes, or for pretreatment in RO seawater desalination24,25. One particularly attractive aspect of NF membranes is their water softening properties for water treatment and more recently, in the recovery of lithium from brines, especially from mixed lithium–magnesium natural saltwaters4,5. The effectiveness of NF in water and wastewater treatment has now become one of the most reliable standard techniques to obtain high-quality drinking water10,26,27. End-of-life RO membranes and recycled NF-like membranes could be suitable options for urban wastewater treatment (i.e., tertiary treatment). No rapid fouling was detected, and ion rejection was more than 75% of all studied cases23. Senán-Salinas et al. (2022) analyzed the direct recycling of end-of-life RO membrane modules into NF membranes. The study finds that recycled membranes exhibit rejection coefficients comparable to commercial NF models, suggesting their viability as alternatives in water treatment applications28. Somrani et al. (2025) explored dual repurposing of end-of-life BWRO membranes into UF membranes for wastewater treatment and cation exchange membranes (CEMs) for fungal microbial fuel cells (MFCs). Both processes demonstrated effective performance, extending membrane utility and promoting sustainability. The research supports circular economy initiatives by reducing waste and enhancing resource efficiency29. The transformation of end-of-life RO membranes has been carried out using an oxidizing agent10. The main objective of the present work is to convert end-of-life RO membranes into technically viable lower selectivity membranes, specifically NF and to test their performance in the treatment of saltwater and wastewaters. We examined end-of-life RO membranes collected from a commercial seawater desalination plant and compared their hydraulic permeability and salt rejection using two streams of different quality, namely brackish water (6 g/L NaCl) and industrial wastewater (ink effluent from the cartridge rinsing process). We validated the experimental results with simulation data. In order to assess the level of degradation of the end-of-life RO membranes before cleaning, several autopsies were conducted using scanning electron microscopy (SEM), atomic force microscopy (AFM) and energy dispersive X-ray spectrometry (EDX) analysis. Based on these results, different cleaning protocols were proposed and tested under various conditions, and the best solution was selected for subsequent experimentation.

Materials and methods

Membranes

The EoL RO membranes used in this study were SW30-2540 models provided by Dow Chemical Company (Midland, MI, USA), obtained from a commercial seawater desalination plant operated by the Tunisian Electricity and Gas Company (STEG) in Gabes, Tunisia. This plant normally produces 5 m3/h of desalinated water30. After being used for a period exceeding 10 years, these membranes exhibited substantial performance deterioration attributed to clogging. To identify the underlying causes, a detailed autopsy was performed. The aged membranes were sectioned into appropriately sized pieces for UF/NF/RO testing, each with an effective filtration surface area of 200 cm2. The specifications of these membranes can be found on Dow Chemical’s website31.

Bench-scale laboratory unit

The experiments were carried out using the bench-scale NF/RO laboratory unit, described in Fig. 1. The unit, which is capable of operating at a maximum pressure of 69 bar was supplied by OSMONICS (module OSMONICS, Osmonics Inc. Minnesota, USA). The surface area of the membrane specimen placed in the high pressure module is 200 cm2. All experiments were done using a low flow yield ratio (5%) and a tangential velocity of around 0.2 m s−1, corresponding to a Reynolds number of 4005. The applied transmembrane pressures are in the 0–45 bar range. The temperature was maintained at 23 °C.

The pure water flux through the membrane is given by Eq. (1):

where J is the flux (L h-1 m−2), A is the hydraulic permeability (L h−1 m−2.bar−1), σ is the coefficient of reflection (between 0 and 1), ΔP is the transmembrane pressure (bar) and Δπ is the transmembrane osmotic pressure (bar).

The osmotic pressure can be calculated using Eq. (2):

where π is the osmotic pressure, i is the van’t Hoff index, c is the molar concentration of solute, R is the ideal gas constant, and T is the temperature.

The retention (or rejection) of salts denoted R is defined by Eq. (3):

where Cp and C0 are the permeate and in-feed solution concentrations, respectively.

ROSA™ software

To simulate the membrane performance, we ran ROSA™ software (version 9.1), developed by the membrane manufacturer. In our study, SW30-2540 and NF90-2540 membranes were used as references to check the properties of new membranes. The simulation conditions were set as follows; a temperature of 23 ºC, well water with a low silt density index (SDI < 3), recovery rates of < 20%, and applied pressure ranging between a few bars to 25 bars, as per the osmotic pressure of the feed. The SW30-2540 membrane is able to achieve 99.4% salt rejection with 8% permeate recovery when the NaCl concentration is less than 2000 ppm. After entering the relevant data and conditions into the software, we could compare the hydraulic permeability and salt rejection in our case study, i.e. 6 g/L (brackish water) and 35 g/L (sea water) of total dissolved solids for an aged membrane.

Membrane characterization

The membranes were analyzed under a scanning electron microscope using the SEM EVO equipment manufactured by Zeiss (USA). The apparatus operated at a 7 KeV acceleration voltage to minimize irradiation damage and obtain a resolution of a few nanometers (nm) with a working distance of 13 mm. Observations were conducted up to ×5000 magnification. To enhance image quality, the analyzed surfaces were covered with an ultra-thin layer of carbon (2–5 nm thickness) deposited by evaporation under a vacuum5.

A Nanoscope III AFM device from the VEECO Company (USA) was used to assess membrane topography. The equipment was operated in contact mode, in the air, with a scan rate of 1 Hz and a resolution of 400–400 pixels. Cantilevers from the Brucker company (Dourdan, France) were used for imaging. They operated at a bounded resonant frequency between 17 and 20 kHz with a spring constant ranging between 0.44 and 0.63 nN. Moreover, all AFM images were examined using WSxM, 5.0 free software which allows for full analysis of detailed surface features, such as average roughness and peak-to-valley ratios. Prior to imaging, the procedure for treatment of the membranes was as follows5: first, the membrane samples were dried at room temperature in a desiccator, then attached to steel discs coated in double-sided adhesive tape. Imaging focused on tiny membrane areas measuring 50 μm × 50 μm. The images were processed taking the average roughness Ra as the mean value of surface point height with respect to the central plane within the defined area, as given by Eq. (4):

Membrane cleaning protocol

The SW30 membrane module was collected from Gabes seawater desalination plant after being replaced. The membrane was carefully cut to fit into the filtration module. Ultrasil10, a cleaning product created by ECOLAB for industrial and professional use, is specially designed to clean membranes by removing clogging. It is composed of sodium hydroxide (NaOH) and ethylenediaminetetraacetic acid (EDTA). The chlorine solutions were prepared by diluting commercial sodium hypochlorite (NaOCl) with Milli-Q water. For the end-of-life RO membrane transformation, NaOCl was diluted with a K2HPO4/KHPO4 buffer solution (pH = 8.2). The oxidation protocol from a previous study was used10.

Three modification protocols were applied to the aged membrane sample to prepare it for the treatment of brackish water and wastewater. In the first protocol, the aged membrane was cleaned with Ultrasil10 by preparing and introducing a 0.4 g/L solution into the driver. We then operated the system at 23 °C without applying any pressure for one hour. Later, using the same solution, we applied a pressure of 10 bar at 23 °C for an additional hour. In the second protocol, the membrane was treated with Cl2 solution and then cleaned with Ultrasil10. This consisted of soaking our membrane specimen in a 4000 ppm bleach solution for one hour, then cleaning it in the filtration module at 10 bar with the Ultrasil10 solution (0.4 g/L) for an additional hour. In the third protocol, we soaked the membrane sheet in Ultrasil10 solution (0.4 g/L) for one hour at 10 bar, then ran the experiment with the bleach at 4000 ppm for 30 min at 23 °C.

Ink effluent from old cartridge rinsing

In the cartridge recycling process, the French company Valor’ink generates ink effluent from cartridge rinsing. During the construction of the industrial ink water recycle loop, the ability of the cleaned end-of-life RO membrane to filtrate the effluent generated by this industry was tested.

UV-visible spectroscopy

The UV-Visible spectrophotometer used in this study was the Evolution™ 201/220 manufactured by Thermo Scientifique™. UV-Visible spectroscopy works on the principle that pollutant molecules in the water can absorb UV-Visible light of a specific wavelength. Spectra were recorded for two solutions: the industrial effluent diluted five times and the permeate after filtration through the end-of-life RO membrane.

Results and discussion

Investigation of membrane performance

Permeability and rejection results

The effect of operating pressure on the pure water permeates flux Jv for the end-of-life RO membrane and simulation results of the SW30-2540 at 23 °C are shown in Fig. 2. First, after placing the membranes in the module the time taken to fill a constant volume (v = 20 mL) at different pressures (5–25 bars) was measured. The permeate flux (determined from the collected flow rate volume) as a function of pressure is presented in Fig. 2.

At 23 °C, the values for hydraulic permeability of the end-of-life RO and SW30-2540 simulation membranes are 0.981 L h−1m−2bar−1 and 1.614 L h−1m−2bar−1, respectively. After a temperature correction at 20 °C (a 3% viscosity correction per degree), the hydraulic permeability values are 0.9853−1 m−2bar−1 and 1.403 Lh−1m−2bar−1for the end-of-life RO and SW30-2540 simulation membranes, respectively. Our reference membrane, SW30, has a lower hydraulic permeability than a pristine BW30 membrane (3.5 Lh−1m−2bar−1 as reported earlier25,27,29).

As shown in Fig. 2, the hydraulic permeability of the end-of-life RO membrane decreased compared to the reference membrane which shows that it doesn’t have the same properties as a new RO membrane. This difference in hydraulic permeability indicates fouling on our end-of-life RO membrane even though the membrane was cleaned.

Subsequently, the conductivity of the permeate was measured under different pressures (5–35 bar) which allows salt rejection to be calculated for 35 g/L and 6 g/L of total dissolved solids (see Figs. 3 and 4).

Salt rejection refers to the percentage of the feed water (TDS) that has been removed in the permeate water. RO membranes are typically expected to remove 95–99% of the dissolved salts and other contaminants from the feed water. However, in Figs. 3 and 4 it can be seen that salt rejection reaches only 85% for water at 35 g/L (ΠΤh = 28 bar) and 95% for brackish water (ΠΤh = 4.6 bar).

The retention observed for synthetic seawater (35 g/L) and brackish water (6 g/L) differs greatly between an end-of-life membrane and a SW30-2540 simulation membrane. The salt rejection of the end-of-life RO membrane is lower than the simulated rejection of the SW30-2540 membrane. Indeed, as reported by other authors, aged membranes have lower salt rejection than new membranes due to the damage incurred during their life time and they propose a new membrane cleaning technique that uses a saturated CO2 solution to alleviate membrane fouling caused by organic matter, without any additional chemicals32.

Autopsy experiments

The results of SEM, AFM and EDX analysis for the pristine BW 30 membrane and the end-of-life RO membrane are shown in Figs. 5, 6 and 7. These images confirm the results obtained and provide a basis for a rigorous comparison with an unused membrane, as discussed in the sequel.

It is clear that it is not possible to compare end-of-life RO membranes with new ones because of the fouling and consequences of aging, as shown in Fig. 5. Fouling results in different roughness of the membrane (Fig. 6). Furthermore, the membrane roughness increased significantly from 296 nm to 1160 nm, indicating the presence of a fouling/scaling layer on the membrane surface. It is important to highlight that a high Ra indicates a higher fouling propensity of the membrane. Also, the EDX spectrum in Fig. 7 shows clogging, with the presence of clay particles (Si, Al, Ca and Mg). The presence of Sulfur on the spectrum comes from the polysulfone support layer of the membrane. Furthermore, the presence of iron can be explained by corrosion and/or the use of FeCl3 in the pre-treatment of seawater. The decline in membrane performance necessitated its replacement. The aim of this step was to find a simulated membrane with a performance similar to our end-of-life RO membrane. The ROSA software was used to test several membranes such as BW30, and NF270. Ultimately, we found that the NF90-2540 membrane has similarities with our membrane as shown in Fig. 8.

From Fig. 9, we observe that the hydraulic permeabilities of the two membranes are very different, a discrepancy that can be explained by the fouling of our end-of-life RO membrane. Comparison with a new NF90-2540 membrane confirmed this membrane clogging. Based on these results, we can conclude that an old RO membrane produces outcomes similar to those of a new NF membrane usable for the treatment of brackish water and wastewater.

Cleaning protocols for end-of-life RO membranes

To treat the aged membrane for reuse, various cleaning protocols were applied and the best option was selected. For example, chemical cleaning improved the hydraulic permeability and a chemical treatment with bleach removed the polyamide layer to evaluate the effects.

First protocol

The aged membrane was cleaned using Ultrasil10. We prepared and introduced a solution of Ultrasil10 0.4 g/L into the driver. We then operated the system without any pressure for one hour. Later, using the same solution, we applied a pressure of 10 bars for one hour at 23 °C.

As can be seen in Fig. 10, chemical cleaning improved the hydraulic permeability. The membrane nature changed to the point where the performance of the reference membrane was exceeded. The permeability started at 1.22 L h−1 m−2 bar −1 and increased to 1.72 L h−1 m−2 bar −1, bearing in mind that the hydraulic permeability of our reference membrane is 1.61 L h− 1 m−2 bar −1.

As shown in Fig. 11, the analyses reveal similarities confirming that the cleaning process is efficient in removing fouling, although further efforts need to be made and a chemical treatment with bleach10 should be considered.

The comparison of salt rejection levels (Fig. 12) confirms our assumption that cleaning removes foulants, making the end-of-life RO membrane less efficient than the reference membrane.

Second protocol

The aged membrane was treated with Cl2 solution and then cleaned with Ultrasil10. It consisted of soaking the membrane sheet in a 4000 ppm bleach solution for one hour, then cleaning it in the filtration module with the Ultrasil10 solution (0.4 g/L) at 10 bar for an additional hour10 at 23 °C.

This experiment showed, as illustrated in Fig. 13, that starting with a chlorine treatment lowers the performance of the end-of-life RO membrane. The bleach did not attack the polyamide layer but rather the clogging layer and therefore removed the clays forming a denser cake on the surface. It is therefore important to start with cleaning to condition the end-of-life RO membrane.

Third protocol

The aged membrane was first treated with Ultrasil10 and then cleaned with a Cl2 solution. This section discusses the results obtained by the cleaning process outlined earlier23, where the membrane sheet was first soaked in the Ultrasil10 solution (0.4 g/L) for one hour at 10 bar and then treated with the bleach at 4000 ppm for 30 min at 23 °C.

The effects of the third cleaning protocol on the PA layer are illustrated in Fig. 14. The presence of sulfur in the spectrum comes from the polysulfone support layer. It can be concluded that cleaning effectively removes clogging, and the results indicate that aging increases the porosity of the RO membrane, bringing it closer to the characteristics of the NF90 membrane.

This method produced a gradual increase in the hydraulic permeability of the treated membrane. As shown in Fig. 15, the value rose from 1.065 to 1.968 L.h− 1.m− 2bar− 1. These findings align with prior research conducted by Garcia-Pacheco et al. (2019), which demonstrated that the observed increase in membrane permeability can be attributed to mechanical or chemical degradation of the polyamide layer following oxidative exposure.

Conversely, retention lessens, indicating that the membrane became more porous compared to its initial performance. As seen in Fig. 16, salt rejection barely reaches 85% at 25 bars. To make this membrane reusable, we recommend always starting with chemical cleaning to remove the fouling. The subsequent manipulations will then be more effective.

Pore diameter, molecular weight cutoff and hydraulic permeability at 20 °C for the NF 90 membrane, the SW 30-2540 membrane, the end-of-life RO membrane after soaking and the end-of-life RO membrane after soaking and chlorine treatment, are reported in Table 1. Using Poiseuille’s law and the Eq. (5) we can determine the pore diameter of a given membrane, dp, as being 0.45 nm.

Knowing the pore diameter (dp), we used Eq. (6) to calculate the molecular weight cutoff of the membrane.

where dp is in nm and MWCO is molecular weight cutoff in Da as previously described by Siebel et al. (2021)23).

These values confirm that the performance of our end-of-life RO membrane is comparable to that of an RO membrane with a molecular weight cutoff of 86 Da after soaking and mild chemical treatment.

The potential chemical interactions between Ultrasil10 and chlorine with the polyamide layer of the end-of-life RO membrane are illustrated in Fig. 17. The schematic highlights critical mechanisms, including the removal of fouling during the chemical cleaning process and the mechanical or chemical degradation of the polyamide layer induced by oxidative exposure.

Applications of the cleaned end-of-life RO membrane

Our previous results show that the third cleaning protocol was the optimal one and we recommend always starting with chemical cleaning to remove fouling. We then investigated applications of this cleaned membrane in the treatment of brackish water and wastewaters.

Brackish water treatment

The cleaned end-of-life RO membrane was tested for the treatment of synthetic brackish water (6 g/L). As previously noted in Fig. 3, the end-of-life RO membrane has a lower salt rejection than a new membrane and is unsuitable for the treatment of sea water. Although its performance may have diminished, it may still work for brackish water at a certain pressure. According to Tunisian drinking water standards33, water is considered potable if its conductivity ranges between 300 and 2500 µS/cm at 25 °C. Our results show that the conductivity of brackish water falls below 1000 µS/cm at 10 bars (Fig. 18). This suggests that cleaned end-of-life RO membranes can be used for the treatment of brackish water (6 g/L) with a system operating over 10 bars.

Industrial effluent treatment

After cleaning the ink cartridges, the water is turbid, colored, and cannot be used, as illustrated in Fig. 19a right. The goal is to establish a filtration loop running the water through our end-of-life RO membranes so that it can be used to clean the cartridges again. The results revealed that after treatment, absorbance in all the UV-Visible spectra is nearly 0 (see Fig. 19b). Therefore, the treatment is considered efficient as indicated by the color of the effluent after passing through the cleaned end-of-life RO membrane (Fig. 19a left).

The analysis results of the industrial effluent and permeate after filtration through the end-of-life RO membrane are presented in Table 2. We performed conductivity, pH, and turbidity measurements and it can be seen that at 5 bars, the turbidity falls below 2 NTU which is the maximum turbidity level acceptable by the Tunisian drinking water standards33.

The treatment of effluent is therefore a possible application which would give our end-of-life RO membranes a second life after cleaning. It also provides a way to reuse wastewater from the ink cartridge cleaning process.

Comparison of energy use by RO when applied to seawater, brackish water and industrial water treatment

To carry out a comparison of the energy consumption when RO is applied to seawater, brackish water and industrial water, we used ROSA to obtain the specific energy use in the RO operation in each case. As shown in Table 3, energy consumption increases as the concentration of the feed solution increases and consequently with transmembrane pressure. In the case of brackish water, at a pressure of 15 bars, RO operation consumes twice as much energy as NF. The high energy consumption for seawater is to be expected due to the absence of an energy recovery device. Based on these results, the use of the end-of-life RO membrane as an NF membrane is advantageous in the treatment of industrial wastewater operating under 5 bars. Furthermore, NF membranes could present a more viable option to other technologies, particularly when the removal of hardness and color is required. For reuse applications, the NF process is more cost-effective than RO. In future studies, we intend to perform a life cycle analysis for various applications using end-of-life RO membranes.

Conclusion

In this study, the successful reuse of end-of-life RO membranes is demonstrated for different applications. Membrane performance indicators, such as hydraulic permeability, salt rejection and autopsy using SEM, AFM and EDX analysis were investigated. The results showed that hydraulic permeability and salt rejection of the end-of-life RO membrane were lower than those of the reference membrane, suggesting that an end-of-life RO membrane doesn’t have the same properties as a new one. SEM, AFM and EDX analysis results confirm the presence of a fouling and scaling layer on the membrane surface. To treat the membrane for reuse, three cleaning protocols were tested and the best method identified, which was to treat the membrane with Ultrasil10, followed by a Cl2 solution. After reconditioning the end-of-life RO membranes by applying our cleaning recommendations, it was shown experimentally and confirmed with simulations that the membrane specifications approached those of a NF membrane, when tested in the treatment of brackish water (6 g/L, applied pressure 10 bars) and industrial effluents. The membrane offers a sustainable option for the recycling of ink-cartridges wastewater, contributing to the circular carbon economy. Regarding the cleaning protocol, it could be worthwhile to extend the duration of the chemical treatments with bleach to see if this might modify the membrane to resemble an ultrafiltration membrane. This approach opens doors for other applications, including surface water treatment and seawater RO pretreatment. The in-situ process of modification, reconditioning and application would contribute to a reduction in the overall carbon footprint of the value chain.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author on request.

References

Matin, A., Laoui, T., Falath, W. & Farooque, M. Fouling control in reverse osmosis for water desalination & reuse: Current practices & emerging environment-friendly technologies. Sci. Total Environ. 765, 142721 (2021).

Garcia-Ivars, J. et al. Nanofiltration as tertiary treatment method for removing trace pharmaceutically active compounds in wastewater from wastewater treatment plants. Water Res. 125, 360–373 (2017).

Son, H. S. et al. Towards sustainable circular brine reclamation using seawater reverse osmosis, membrane distillation and forward osmosis hybrids: An experimental investigation. J. Environ. Manag. 293, 112–836 (2021).

Yan, T., Ye, Y., Ma, H., Zhang, Y., Guo, W., Du, B. et al. A critical review on membrane hybrid system for nutrient recovery from wastewater. Chem. Eng. J. 348, 143–56 (2018).

Somrani, A., Hamzaoui, A. H. & Pontie, M. Study on lithium separation from salt lake brines by nanofiltration (NF) and low pressure reverse osmosis (LPRO). Desalination 317, 184–192 (2013).

Landaburu-Aguirre, J. et al. Fouling prevention, preparing for re-use and membrane recycling. Towards circular economy in RO desalination. Desalination 393, 16–30 (2016).

Lawler, W. et al. Towards new opportunities for reuse, recycling and disposal of used reverse osmosis membranes. Desalination 299, 103–112 (2012).

García-Pacheco, R. et al. Validation of recycled membranes for treating brackish water at pilot scale. Desalination 433, 199–208 (2018).

Veza, J. M. & Rodriguez-Gonzalez, J. J. Second use for old reverse osmosis membranes: wastewater treatment. Desalination 157, 65–72 (2003).

García-Pacheco, R. et al. Free chlorine exposure dose (ppm h) and its impact on RO membranes ageing and recycling potential. Desalination 457, 133–143 (2019).

Terrero, P. et al. Transformation of end-of-life RO membrane into recycled NFand UF membranes: results of the transformation process and its validation at pilot scale. IDAWC15. (2015). San Diego. 15 WC-51551.

García-Pacheco, R. et al. Landfill leachate treatment by using second-hand reverse osmosis membranes: Long-term case study in a full-scale operating facility. Membranes 12 (11), 1170 (2022).

JJ Rodríguez V Jiménez O Trujillo JM Veza 2002 Reuse of reverse osmosis membranes in advanced wastewater treatment Desalination 150 219 225

E Ould Mohamedou DBP Suarez F Vince P Jaouen M Pontié 2010 New lives for old reverse osmosis (RO) membranes Desalination 253 62 70

M Pontié 2015 Old RO membranes: Solutions for reuse Desal. Water. Treat. 53 1492 1498

ML Pype MG Lawrence J Keller W Gernjak 2016 Reverse osmosis integrity monitoring in water reuse: The challenge to verify virus removal-a review Water. Res. 98 385 395

L Rodríguez-Sáez SI Patsios J Senán-Salinas J LandaburuAguirre S Molina E García-Calvo 2022 A novel application of recycled ultrafiltration membranes in an aerobic membrane bioreactor (aMBR): A proof-of-concept study Membranes 12 218

Rehman, Z. U. et al. Performance evaluation of UF membranes derived from recycled RO membrane, a step towards circular economy in desalination. Membr 13, 628 (2023).

NK Khanzada RA Al-Juboori M Khatri FE Ahmed Y Ibrahim N Hilal 2024 Sustainability in membrane technology: Membrane recycling and fabrication using recycled waste Membranes 14 52

Molina, S. et al. Transformation of end-of-life RO membrane into recycled NF and UF membranes, surface characterization. IDAWC15. (2015). San Diego. 15 WC-51551.

García-Pacheco, R. et al. Transformation of end-of-life RO membranes into NF and UF membranes: evaluation of membrane performance. J. Memb. Sci. 495, 305–315 (2015).

Lawler, W. et al. Production and characterisation of UF membranes by chemical conversion of used RO membranes. J. Memb. Sci. 447, 203–211 (2013).

Seibel, F. I. et al. End-of-life reverse osmosis membranes: recycle procedure and its applications for the treatment of brackish and surface water. J. Appl. Res. Water Wastewater. 8, 77–87 (2021).

Scheumann, R. & Kraume, M. Influence of hydraulic retention time on the operation of a submerged membrane sequencing batch reactor (SM-SBR) for the treatment of greywater. Desalination 246, 123–130 (2009).

M Pontié H Dach J Leparc M Hafsi A Lhassani 2008 Novel approach combining physico-chemical characterizations and mass transfer modelling of nanofiltration and low pressure reverse osmosis membranes for brackish water desalination intensification Desalination 221 174 191

Aimar, P., Bacchin, P., Maurel, A. Filtration membranaire (OI, NF, UF, MFT)-Aspects théoriques: perméabilité et sélectivité. Editions TI| Techniques de l’Ingénieur (2010).

Dach, H. Comparison of the operations of nanofiltration and reverse osmosis for the selective desalination of brackish water: of the scale of the laboratory to the industrial pilot. Ph.D. Dissertation, Angers University. France (2008).

J Senán-Salinas J Landaburu-Aguirre R García-Pacheco E García-Calvo 2022 Recyclability definition of recycled nanofiltration membranes through a life cycle perspective and carbon footprint indicator Membranes 12 854

Somrani, A. et al. Dual repurposing of end-of-life BWRO membranes: Ultrafiltration membranes for Advanced Wastewater Treatment and Cation Exchange membranes for fungal microbial fuel cells. Membranes 15, 5 (2025).

Rehouma, A. & Hannachi, A. Scenarios of RO brines valorization in power plants. Desal Water Treat. 88, 25–32 (2017).

Available online: https://www.dow.com/en-us (accessed on 17 January 2024).

H Alnajjar A Tabatabai A Alpatova T Leiknes N Ghaffour 2021 Organic fouling control in reverse osmosis (RO) by effective membrane cleaning using saturated CO2 solution Sep. Purif. Technol. 264 118 410

Norme NT 09.14. Norme Tunisienne relative à la qualité des eaux destinées à la consommation humaine (2013).

Acknowledgements

The authors are grateful to Angers University microscopy platform (denoted SCIAM: https://sfricat.univ-angers.fr/fr/plateformes/sciam.html) and particularly to Mr. Romain Mallet. Many thanks also to Ahmed Hannachi, Professor at ENIG Gabes (Tunisia) and iMermaid project, for providing membrane modules and for fruitful discussions, and to Laurent Van Beekum from Valor’ink company for providing ink effluents.

Funding

This work was funded by the Deanship of Scientific Research at Jouf University in Saudi Arabia under Grant Number (DRS2022-RG-0140).

Author information

Authors and Affiliations

Contributions

S.A.: methodology, writing of original draft. Z.M. & K.A.: draft manuscript preparation. S.L.: data collection. N.G.: review and editing. M.P.: supervisionAll authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Somrani, A., Mohamed, Z., Abohelal, K. et al. Transforming end-of-life SWRO desalination membranes into nanofiltration membranes for the treatment of brackish water and wastewater. Sci Rep 15, 4557 (2025). https://doi.org/10.1038/s41598-025-88818-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-88818-3

This article is cited by

-

Reprocessing spent-life reverse osmosis membranes into nanofiltration membranes via controlled polyamide layer degradation

Journal of Material Cycles and Waste Management (2026)