Abstract

The present research investigates the impact of eccentric shoulder tools on the microstructure and mechanical properties of friction stir welded (FSWed) aluminum alloy AA6082-T6. Two tools, one with an eccentric shoulder and one with an aligned shoulder, were employed under identical welding parameters: a rotational speed of 600 rpm, travel speed of 250 mm/min, and tilt angles of 0° and 3°. The four FSWed joints produced were characterized using optical microscopy, tensile testing, and hardness testing. The weld nugget zone (WNZ) microstructure showed significant grain size reduction from 5.24 μm for the base material to 1.63 μm, using the eccentric shoulder tool at 0° tilting angle and 2.78 μm at 3° tilting angle. The aligned shoulder tool resulted in an average grain size of 2.79 μm at 0° tilting angle and 2.23 μm of 3° tilting angle. Thus, the eccentric shoulder tool with a tilt angle of 0° exhibited the smallest average grain size. The mechanical properties obtained are consistent with the microstructure, where the joint produced using the eccentric shoulder at a 0° tilting angle showed the highest tensile strength of 216.5 MPa (89.7% joint efficiency) and 7.71% elongation. In contrast, the aligned shoulder tool resulted in coarser grains and a lower mechanical performance. In addition, this joint exhibited the highest hardness recovery in WNZ. The current study implies that the eccentric shoulder tool can eliminate the need for a tilting angle during FSW, which is required in some applications.

Similar content being viewed by others

Introduction

Friction Stir Welding (FSW) is a solid-state joining technique that produces high-quality welds of similar and dissimilar materials1,2,3,4 It is a new joining technology developed in the 1990s and has since become commonly used in industrial applications5,6,7. FSW involves the use of a rotating tool to generate heat and soften the materials. Heat is generated through direct contact between the rotating tool and material, which is then stirred together to produce a joint8,9,10,11. FSW is mainly applied to join aluminum alloys and other non-ferrous metals, which can be challenging to weld using fusion welding methods12,13,14,15,16. FSW technology has been used in many industrial applications such as aerospace, automotive, and shipbuilding17,18. The efficacy of friction stir welded (FSWed) joints depends on a multitude of parameters that must be meticulously established to yield joints that are devoid of defects and possess dependable mechanical properties19,20. The key FSW parameters include the rotational speed, welding speed, axial force, tool geometry, and tilting angle21,22,23,24. The angle of tool inclination is a crucial parameter in the FSW process, necessitating meticulous regulation to attain superior welds because of its impact on the quantity of agitated materials and the heat input throughout the FSW25,26. The FSW process involves inclining the rotating tool at a specific angle from the vertical axis, which is known as the tilting angle. The tilting angle is important in determining the quality of the FSW joints27,28. Selecting a suitable tilting angle is beneficial because it enables the tool shoulder to make contact with the joint material and promotes the movement of the material around the rotating tool29. However, if the tilting angle is excessively large, it can cause the tool pin to rise from the weld root, which can damage the weld26,29. Based on previous studies, a tilting angle ranging from 1° to 3° is considered to be appropriate for most materials25,30. Long et al.29 investigate the impact of a 0 and 2° tilting angle using a 3D thermo-mechanical model and the DEFORM-3D software. Their model considered the tilt angle within the geometrical structure and analyzed two cases with tilt angles of 0 °and 2°. The results showed that the weld had defects in the case of a 0° tilting angle, whereas a 2° tilting angle produced a defect-free weld. Chauhan et al.31 study the formation of defects in FSW under three different tilting angles (0, 1 and 2°) using a Coupled Eulerian and Lagrangian (CEL) method and modeling the process with a cylindrical pin in ABAQUS/Explicit. According to their model, a tilting angle of 2° resulted in a weld without defects. By contrast, an increased tilting angle can lead to an increase in the axial force. This is because as the tool tilts, it exerts more force on the metal, requiring a greater force to move it through the material32. Also, setting the suitable tilting angle for the materials may require a more complex machine design, with additional axes of motion and more advanced control systems to set the required tilting angles31,33,34. This increases the cost of FSW machines. Furthermore, the FSW tool utilized during the FSW process may wear more quickly at higher tilting angles owing to increased heat and friction, particularly because of the FSW of the steel alloys26,32. Thus, the present study explores substitutes that curtail the use of the tilting angle in the FSW procedure while mitigating its negative impact on the cost of the FSW machine and tool life. The objective is to achieve this without affecting the quality of the FSW weldments. One of the solutions proposed to achieve the use of a zero tilting angle during the FSW process is the tool geometry. FSW tool geometry is a critical parameter that has an impact on the quality of the FSW joints35 and should be designed and selected because of its direct effect on the flow of material and the amount of deformation during the FSW process, which can influence the formation of defects, such as voids and cracks36,37. Many studies have studied the effect of tilting angle to solve the problem of defects caused by friction stir welding26,32,38. Where the tilting angle increases the strength and torque on the welding joint, which increases the flow of formed materials from front to back and prevents the occurrence of defects22,25,39. As the research indicated in their use of the tilting angle, it is in the range of 0° to 4°, which makes the goal of searching for the optimal value of the tilting angle that achieves the best results for mechanical properties and microstructure40,41. The lower the tilting angle, the better it is because it reduces the force and torque required for the welding process. It also reduces manufacturing problems on the ground, such as the problems of fixing connections, which require a greater fixation force with the tilting angle owing to the increase in vertical force and torque. On the other hand, with the development of stirred friction welding machines and tools, the simplest designs that help to achieve mobile-stirred friction welding are similar to electric welding and gas welding. The simpler the welding process is, the easier it is to achieve this goal. The objective of this study is to investigate the impact of an eccentric shoulder tool on friction stir welding with and without the application of a tool tilting angle. This is because of the possibility of compensating for the effect of the tilting angle with the eccentric movement of the shoulder, which increases the friction area between the tool and welding joint to achieve the heat generated required to produce an FSWed joint with the highest mechanical properties. Unlike traditional FSW methods, which rely on the tool tilt angle to improve the joint quality, this study demonstrates that an eccentric shoulder tool can eliminate the need for tool tilting, thus simplifying the FSW process without compromising the mechanical properties of the weld.

Experimental procedure

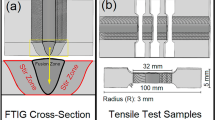

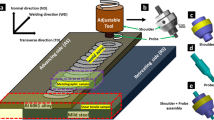

Figure 1 illustrates the experimental procedure applied for FSW of AA6082-T6. The AA6082-T6 plates used in this study were rolled sheets with a thickness of 6 mm (Composition: Si; 0.70, Fe; 0.05, Cu; 0.10, Mg; 0.60, Mn; 0.40, Cr; 0.25, Zn; 0.20, Ti; 0.10, Al; 97.15, all in wt%) were used for friction stir welding of butt joints. Figure 2a shows the microstructural characteristics and grain size analysis (Fig. 2b), which were evaluated using optical microscopy. The plate measurements were 6 mm ×100 × 150 mm3 in size. The FSW tool material employed was a rod made of W302 cold-worked tool steel (5.20% Cr, 0.40% Mn, 0.95% V, 0.39% C, 0.10% Si, 1.40% Mo, and 90.60 wt% Fe), the material was subjected to heat treatment resulting in a hardness of 62 HRC. The tool profile was designed to have a flat shoulder (22 mm diameter) and a 5.7 mm height cylindrical pin (7 mm diameter). Two tools were used for friction stir welding: the first with an eccentric shoulder (0.2 mm as shown in Fig. 3a, and the second with a conventional aligned shoulder, as shown in Fig. 3b.

The study involved the utilization of a vertical milling machine under standard environmental conditions, with consistent parameters (rotational tool speed: 600 RPM, traverse speed: 250 mm/min, and tilting of the tool by 0° and 3°) for both eccentric and aligned shoulder tools, as shown in Fig. 4a-d. The FSW tool was rotated in a clockwise direction for all welding experiments, and the welding direction was parallel to the rolling direction of the joint plates. The tool penetration depth was set to 5.8 mm to ensure that the shoulder made sufficient contact with the workpiece surface while avoiding excessive plunging. A 3° tilt condition for the eccentric shoulder tool was included to provide a comprehensive comparison across different configurations. This allows for a direct evaluation of the effectiveness of the eccentric shoulder, both with and without tilt. Special attention was paid to comparing the results of the 0° tilt eccentric shoulder configuration with other conditions, particularly the 3° tilt aligned shoulder, which represents a common FSW setup26,42. This comparison is crucial for assessing whether the eccentric shoulder can eliminate the need for a tilt angle while maintaining or improving weld quality.

The temperature cycle during the FSW of AA6082-T6 was recorded using an infrared thermometer (Quicktemp 860-T3 model manufactured by Testo Company, Germany. Optical microscopy (OM) was employed to reveal the microstructural characteristics of the FSW joints. Prior to the analysis, the samples underwent a series of preparatory steps, including grinding, mechanical polishing using varying grades of emery papers, and chemical etching with a Keller reagent (190 ml H2O, 5 ml HNO3, 3 ml HCL, 2 ml HF), and then immersed in the Weck solution (100 mL H2O + 4 g KMnO4 + 1 g NaOH) for 7 s to study the microstructure of the FSW joints. Vickers hardness and tensile tests were conducted to investigate the mechanical properties of the specimens. A hardness examination was performed on cross-sectional samples oriented perpendicular to the welding direction and located along the centerline of the cross-section. The examination was conducted using a 1 Kg load. The tensile testing procedure is conducted utilizing an “Instron” tensile testing apparatus with a capacity of 250 kN. The device can operate within the range of 0.0005–1016 mm/min, covering a stroke distance of 1430 mm. The ASTM E8/E8M-16 standard mandates the preparation of flat tensile specimens cut perpendicular to the welding direction. The velocity of the machine head was 0.1 millimeters per second.

Results and discussion

Visual inspection

Photographic images of the FSW joints (top view) are shown in Fig. 5 to detect surface defects of the FSWed joints. FSW surface defects, such as flashes, rough surface textures (ripples), surface grooves, and lack of filling, are common in the FSW process of different materials. One of the critical parameters affecting surface defects is the FSW tool design, which includes shoulder and pin geometry43,44. In addition, surface defects at the upper surface of FSWed joints usually start at a low axial force during the FSW process45. It can be observed that there were no surface defects, such as surface grooves, and there was a lack of filling of the welded joints using both designed tools, as shown in Fig. 5. However, a flash defect with stretch marks was observed for the joint welded by an eccentric shoulder with a 3o tilting angle, as shown in Fig. 4c, because of the softened material at the contact area between the eccentric shoulder with a tilting angle ejected and extruded on the sides of the welding line to form the flash defect. At the same time, the other welded joints (Fig. 5a, b,d) were formed without flash defects, which indicates that the selection of an appropriate combination between the tool design and tilting angle assisted in filling up the defects by extruding the softened materials downward instead of ejecting them up to the sides of the weld surface46. Moreover, the surfaces had the same features as typical FSWed/processed surfaces, such as ripples and keyholes. For ripples, the rotating tool shoulder moves along the joint surface, leaving behind markings called ripples that affect the rough texture of the surface. Figure 5 shows the delicate ripples that indicate a high number of rotations per interval. For ripples, the distance between the two ripples depends on the combination of the travel and rotation speeds applied47,48. Li et al.48 observed that the spacing between ripples is directly related to the ratio of welding speed to rotational speed. This observation is consistent with the observations of the current study. The ripple patterns visible on the weld surfaces (Fig. 5) were a result of the tool rotation and translation during the welding process. The fine ripples observed indicate a high number of rotations per unit distance traveled, which aligns with the welding parameters used (rotational speed of 600 rpm and travel speed of 250 mm/min).

On the other hand, the formation of the keyhole is one of the significant features of the FSW process. The keyhole was a depression in the welding zone formed by the rotating pin after exiting the welded plates. This feature is critical because it provides a visual indicator of the quality of FSWed joints. If the keyhole is correctly formed, it indicates a strong and effective weld. If a keyhole is not correctly formed, it can reveal weaknesses or defects in the welded joint. Thus, the keyhole is an essential feature of the FSW process that assists in ensuring the quality of the produced joints. Figure 5 shows the properly formed keyholes for all applied FSW parameters at a rotation speed of 600 rpm and travel speed of 250 mm/min using a 3° tilting angle for both the designed tools of the aligned and eccentric shoulders. Table 1 lists the visual inspection reports of the FSWed joints using aligned and eccentric shoulders with and without tilting angles. All welded joints were visually accepted on both sides of the joints.

Heat input & measured temperature

The thermal cycle history during the FSW process is essential for detecting the quality of the welded joint by controlling the FSW process parameters, such as the rotation speed, travel speed, and tool geometry, including the pin profile, shoulder features, and tilting angle. Figure 6 plots the thermal FSW cycles on the welding path center recorded using the infrared device for welded joints E0, A0, E3, and A3. The thermal cycles of the welded joints had the same profile and could be divided into three regions: (1) plunging and dwelling, (2) welding, and (3) retracting and cooling, as shown in Fig. 6. In the first region, the rotating tool is inserted into the joint plates to penetrate the plates, generating heat and plastic deformation owing to frictional contact between the tool and the joint plates. During the dwell stage, the rotating tool remained motionless to allow the generated heat to disperse evenly across the weld zone. In the second region, in the welding stage, the rotating tool moved along the joint plates in the welding area, and the heat generation process and stirring action continued. The heat generated in the weld zone reaches its peak point, forming a softened region known as the “thermomechanical affected zone” (TMAZ) on the advanced and retreating sides. Finally, the rotating tool was withdrawn from the welded plates in the tool-exit stage, and the welded joints were cooled to room temperature. It can be noticed that the highest peak temperature of 360 °C recorded during the FSW process of AA6082-T6 is recorded for the E3 joint welded using the eccentric shoulder with a 3° tilt angle. The lowest peak temperature of 298 °C was measured for the A0 joint produced using an aligned shoulder with a tilting angle of 0°. To better understand the effect of using an eccentric shoulder tool on the properties of FSWed joints, the heat generated from different tools is given by the following equation:49.

Figure 7a illustrates the eccentric shoulder paths of point “a” produced by tools with shoulder eccentricities of 0, and 0.2 mm. It can be noted that the tool with a 0.2 mm eccentric shoulder provides a larger friction area between the tool and the materials than an aligned shoulder (Fig. 7b). This is because the eccentric part of the tool creates a dynamic orbit during rotation, which increases the effective area of interaction between the tool and workpiece19. The larger surface area of the eccentric shoulder can concentrate more work in the plasticized region, dragging more material and potentially leading to a wider stir zone compared with the aligned shoulders. Figure 7c shows the effect of the eccentric shoulder on the peak temperature and the calculated heat generation. First, it can be remarked that the eccentric shoulder generally produces higher heat generation and peak temperatures than the aligned shoulder (Fig. 7c). This is primarily due to the increased friction area between the tool shoulder and workpiece material, and the dynamic orbit created during tool rotation and traveling. The larger effective interaction area of the eccentric shoulder led to more material flow, particularly under the tool shoulder, and caused periodic changes in the flow velocity at the WNZ. These factors contribute to the higher heat generation and temperature, especially under the shoulder. Second, the heat generation and peak temperature increased with increasing tilting angle from 0 °to 3° for both eccentric and aligned shoulders (Fig. 7c). The tilting angle affects the heat distribution across the weld, and more heat is generated at the trailing edge of the shoulder when the tilting is applied. The tilted tool created increased friction and material deformation, particularly on the advancing side, resulting in a higher peak temperature50. Zhai et al.51 found that a tilted tool generally leads to higher heat generation than a non-tilted tool (0°), with more heat generated at the trailing edge of the shoulder. Zhang et al.52 observed higher temperatures on the advancing side with tilted tools, which was attributed to incomplete contact at the shoulder/workpiece interface. Meyghani and Awang42 investigated the influence of the tilting angle on the thermomechanical behavior in the FSW of aluminum 6061-T6, observing increases in the welding temperature with tilting angles compared to the tool and without tilting angle. It is important to note that the peak temperature using an eccentric shoulder tool for a 0° tilting angle exceeds that of the aligned shoulder tool by approximately 10% for the same welding parameters and tilting angle. It is clear that both the energy per unit length and peak temperature increase with an increase in the tilting angle to 3° using the two tools. It is important to note that the peak temperature using the eccentric shoulder tool and 0° tilting angle exceeded approximately 10% over the aligned shoulder tool for the same welding parameters and tilting angle. This implies that the heat input available for sound joint formation is slightly higher for the eccentric shoulder tool than for the aligned shoulder tool. This could be an important concept for producing high-strength FSW joints when the energy per unit length is increased.

Microstructure

Figure 8 depicts the nugget zone microstructure of the FSWed joints of (a) E0, (b) A0, (c) E3, and (d) A3. Figure 9 shows the grain-size distribution histograms of the FSWed joints. In the FSW-welded joints of AA6082, the microstructures in the initial plate, HAZ, and TMAZ exhibited distinct characteristics owing to the welding process. The AA6082-T6 initial plate retained its original microstructure, characterized by larger grains, because it was not subjected to welding heat or deformation, as shown in Fig. 8. In contrast, the HAZ experienced thermal exposure without mechanical deformation, leading to grain growth and coarsening compared with the initial plate (Fig. 8). The TMAZ, located between the HAZ and weld nugget zone, undergoes thermal and deformation effects, resulting in a deformed microstructure with elongated grains. Dynamic recrystallization in the TMAZ was incomplete, leading to a mixture of recrystallized and deformed grains, as depicted in Fig. 8. The nugget zone of all welded joints (Fig. 8b-e) was indicated by equiaxed fine grains compared to the initial material (Fig. 2) for all FSWed joints owing to dynamic recrystallization. Dynamic recrystallization occurred during the FSW process, including the formation of new grains in the weld nugget zone. During FSW, the heat generated by the frictional contact between the rotating tool and joint plates softens the materials in the stir zone, allowing them to flow and consolidate under the pressure of the rotating tool53,54. This plastic deformation (stirring action) formed new grains owing to the dynamic recrystallization process. This process plays an essential role in governing the microstructure of the weld nugget zone (WNZ) and can significantly affect the mechanical properties of the welded joints. Several studies have investigated the effects of dynamic recrystallization on the microstructure of FSW joints. They reported that the amount of dynamic recrystallization could be governed by welding parameters such as rotation speed, travel speed, tilting angle, and tool geometry55,56. Prangnell and Heason56 observed that dynamic recrystallization in aluminum alloys during FSW occurs through a continuous mechanism, with new grains formed by the progressive rotation of subgrains. They found that the welding parameters significantly affected the extent of dynamic recrystallization and grain size. Su et al.55 studied the effect of tool rotation speed on dynamic recrystallization in FSW of AA7050 aluminum alloy, noting that higher rotation speeds led to more extensive dynamic recrystallization and finer grain sizes in the nugget zone. They also observed that the size and distribution of recrystallized grains developed during the FSW process could influence the mechanical properties of FSWed joints. In the current study, the results of the developed microstructure show that the heat generated during the FSW process affected by the tilting angle (0 °or 3°) and shoulder geometry (eccentric or aligned) significantly influences the grain size of the WNZ during the FSW process. The average recrystallized grain size was around 1.63 ± 0.7 μm, 2.79 ± 0.4 μm, 2.78 ± 0.4 μm, and 2.23 ± 0.5 μm for E0, A0, E3, and A3 joints, respectively (Fig. 9). In addition, the highest reduction in the average grain size was observed in the joints of E0 (approximately 69%) compared to the AA6082-T6 initial plate.

Mechanical properties

The effect of eccentric and aligned shoulder tools with and without a tilting angle on the tensile properties of the FSWed butt joints was tested using transverse tensile samples containing WNZ at the center. The engineering stress-strain curves of the tensile-tested specimens of the welded joints and Aa6082-T6 initial plate are plotted in Fig. 10a. The results, including the tensile strength, yield strength, and elongation of the tensile tests, are compared in Fig. 10b, which shows the average values of the three tested samples. For the joints welded without a tilting angle, the tensile strength of the welded joint using the eccentric shoulder (E0) was higher than that of the aligned shoulder (A0), as shown in Fig. 10a. The E0 and A0 joints exhibited tensile strength of 216.5 and 183 MPa, respectively, with a joint efficiency of over 90% and 75% of the tensile strength of the initial material (Fig. 10b). On the other hand, for the FSWed joints produced using a tilting angle of 3°, joint E3 exhibited a tensile strength of 170 MPa with 70% efficiency, and the tensile strength increased to 208 MPa with 86% efficiency when the aligned shoulder was applied (Fig. 10b). In addition, the elongation property of the welded joints has the same trend as the tensile strength, which is the highest elongation observed for E0 (highest tensile strength) and the lowest elongation detected for E3 (lowest tensile strength). For joints welded without a tilt angle, the E0 joint exhibited superior mechanical properties compared to the A0 joint. The E0 joint achieved a yield strength of 68.3 MPa, 76% of the 89.8 MPa for the AA6082-T6 initial plate. In contrast, the A0 joint showed a yield strength of 63.4 MPa, corresponding to 70.6% of the base material. Interestingly, for the FSWed joints produced using a tilt angle, A3 joint outperformed E3 joint regarding yield strength. The A3 joint demonstrated the highest yield strength among all welded joints at 69.7 MPa, which is approximately 77.6% of the initial plate, while the E3 joint had the lowest at 58.8 MPa, which is approximately 65.5% of the initial plate. Compared to the welded joints, the E0 joint (eccentric shoulder and 0° tilting angle) achieved a smaller grain size of 1.63 (Figs. 8 and 9). The grain size of the nugget zone significantly affects the mechanical properties of welded joints, including their strength and ductility. In general, smaller grain sizes result in a higher strength and lower ductility. This is because smaller grains provide more hindrances to dislocation motion and improve the tensile strength of the joints but also make it more difficult for the welded material (nugget zone) to deform during the tensile test, which reduces the ductility. Chen et al.57 investigated dissimilar AA6061 and AA7075 joined using single-pass and multiple-pass FSW to investigate the effects of a second overlapping pass and its welding direction on the NZ. Compared to single-pass FSW, multiple-pass FSW resulted in finer grains (20% decrease in average grain size) and increased high-angle grain boundaries (2% increase) in the NZ owing to the prolonged dynamic recrystallization. Reversing the welding direction of the second pass enhanced vertical material flow, leading to even finer grains (from 4.2 μm to 2.1 μm) and improved mixing of the dissimilar alloys. The NZ was strengthened after the second pass, with a 3% increase in the yield strength and ultimate tensile strength compared to the single-pass FSW. Multiple-pass FSW with opposite welding directions produced the highest tensile strength, with the yield strength and ultimate tensile strength increased by over 50/30 MPa compared to single-pass FSW. Robert Kosturek et al.58 examined the mechanical properties and microstructure of 5-mm-thick AA7075-T65 FSWed joints. They reported that a finer grain size in the WNZ was correlated with improved mechanical properties. The highest ultimate tensile strength of 447.7 MPa (76.7% joint efficiency) was achieved for the joint produced using a tool rotation speed of 400 rpm and 100 mm/min welding velocity, which resulted in a WNZ grain size of 5.2 ± 1.7 μm. This joint also exhibited a higher microhardness than joints with higher heat input parameters. Their research demonstrated that a lower heat input (lower rotation speed and higher welding velocity) resulted in a finer grain size in the WNZ and improved the mechanical properties of the FSWed joints. Moustafa et al.59 investigated the microstructural and mechanical properties of dissimilar AA7075 and AA2024 aluminum alloys. They concluded that the FSW process resulted in a fine-grained structure in the stirred zone, with a significant reduction in grain size compared with the base AA7075 and AA2024 aluminum alloys. The average grain size reduced from to 80–180 μm in the initial plates to 12 ± 4 μm in the weld zone. The tensile strength improved with increasing tool rotation speed, and the tensile strength increased by 7.1% when the speed increased from 400 to 560 rpm and by 5.4% when the speed increased from 560 to 700 rpm. Microstructural analysis revealed the formation of fine equiaxed grains in the WNZ, suggesting that the fine-grained structure contributed to these mechanical properties. In this study, compared to the AA6082 initial plate, the E0 joint exhibited the best mechanical performance among the welded samples, with 89.7% UTS and 68.8% elongation, with the finest grain structure having an average grain size of 1.63 μm. In contrast, the E3 joint with a grain size of 2.78 μm showed the lowest mechanical performance, despite having a grain size similar to that of A0. This suggests that factors beyond the grain size, such as the precipitate distribution or residual stresses, may also play a role in determining the final mechanical properties of FSW joints57,60. The fracture locations of tensile-tested specimens were analyzed to understand failure mechanisms in friction stir welded joints. For all joints (E0, A0, E3, and A3), fractures consistently occurred in the TMAZ on the advancing side. This can be attributed to the TMAZ experiencing significant thermal exposure during welding without sufficient dynamic recrystallization, resulting in a mixture of deformed and partially recrystallized grains61,62. This localized softening reduces its load-bearing capacity. Furthermore, the advancing side undergoes higher material flow and strain rates due to tool rotation and translational motion63,64. This leads to greater stress concentrations during tensile loading, making it more prone to failure. In addition, the grain structure in the TMAZ is elongated and less refined (Fig. 8) compared to the WNZ, contributing to reduced hardness. Additionally, precipitate dissolution and coarsening in this region further degrade its mechanical properties. The fracture surfaces of the tensile-tested specimens are depicted in Fig. 11 for the AA6082-T6 initial plate and FSWed joints E3 and E0. The fracture surface of the AA6082-T6 initial plate (Fig. 11a) exhibited a ductile fracture pattern characterized by large and deep dimples (blue area in Fig. 11a). In contrast, E3 joint (Fig. 11b), welded using an eccentric shoulder tool with a 3° tilting angle, shows a mixed fracture mode with both ductile and brittle features. Flat facets alongside shallow dimples (blue and yellow areas in Fig. 11b)suggest that E3 joint experienced plastic deformation and brittle fracture. Meanwhile, the E0 joint (Fig. 11c), created with an eccentric shoulder tool and a 0° tilting angle, predominantly displayed a ductile fracture surface with more uniform, finer, and deeper dimples. This indicates a better plastic deformation and suggests that the welding parameters for E0 resulted in a more homogeneous and ductile weld zone, likely because of the finer grain structure in the WNZ (Figs. 8 and 9). This finer grain structure contributes to the improved ductility and mechanical performance of the E0 joint compared to those of the E3 joint.

Figure 12 illustrates the Vickers hardness (HV) survey on the cross-section of FSWed joints coded with E0, A0, E3, and A3 according to Table X. For all welded joints, typically, “W” shape profiles of hardness were observed for the FSWed joints, as shown in Fig. 12. It can be mentioned that the WZ in the FSWed joints revealed a hardness higher than the other regions of the TMAZ and HAZ. Furthermore, the hardness of the welded joints gradually decreased in the TMAZ and HAZ (Fig. 9). The WZ is characterized by a fine-grained microstructure65,66,67. In contrast, the HAZ and TMAZ exhibit varying degrees of thermal exposure and mechanical deformation, resulting in softer and larger grain sizes compared to grains than those in the WZ microstructure68,69. This difference in the microstructure of the FSW regions and hardness between the WZ, HAZ, and TMAZ is an essential aspect of the variation in the tensile properties of the FSWed joints. Among the various FSW regions, the TMAZ of the FSWed joints obtained a lower hardness. In the TMAZ, the temperature generated during the FSW diffused. In this region, the temperature led to incomplete recrystallization in the generated microstructure, leading to a reduction in hardness compared to the other regions. These hardness results were confirmed by previous studies conducted on heat-treatable aluminum alloys60,70,71,72,73. Scialpi et al.73 studied the effect of shoulder geometries on the hardness properties of AA6082-T6. They reported that the FSW process softened the material in the WZ, causing a reduction in hardness of approximately 35% in the weld zone, and the hardness in the cross-section of the welded joints obtained a “W” shape. Furthermore, the hardness in the WZ was higher than that in the TMAZ and HAZ. The effect of the FSW process on the properties of similar and dissimilar heat-treatable (AA6061-T6 and AA6082-T6) aluminum alloys was investigated by Moreira et al.60. They also concluded that the hardness profiles of similar joints (AA6061-T6 and AA6082-T6) and dissimilar joints (AA6061-T6/AA6082-T6) revealed a “W” shape with higher hardness in the WZ than in other regions of the TMAZ and HAZ. However, compared to the hardness of the AA6082-T6 initial plate, the hardness of the WZ revealed that the hardness of the WZ was remarkably lower than that of the AA6082-T6 initial plate, as shown in Fig. 12. Scialpi et al.73 indicated that the reduction in the hardness values of the WZ compared to the parent material is mainly due to the different differences between the microstructure developed during the FSW process and the nature of the microstructure of the initial plate. Moreira et al.60 reported that the precipitate of B”-Mg5Si6 was mainly responsible for the hardening of AA6082 aluminum alloys. During the FSW, the B”-Mg5Si6 phase dissolved in the WZ, TMAZ, and HAZ. Furthermore, fine precipitates of B”-Mg5Si6 were not detected in the WZ. In the current study, among all the welded joints, the highest WZ hardness of 82 HV was obtained for the E0 joints welded using the eccentric shoulder without tilting angles. This increase in the WZ hardness of E0 was confirmed by the grain-size analysis results, which confirmed the increase in the WZ hardness of E0 (Figs. 8 and 9).

Conclusions

This study examined the influence of an eccentric shoulder on the microstructural and mechanical properties of FSWed AA6082-T6. Two tools were employed, one with an eccentric shoulder and the other with an aligned shoulder, with the welding parameters kept constant. Empirical and theoretical analyses led to the following conclusions:

-

The eccentric shoulder tool with a 0° tilt angle produced the finest grain structure in the weld nugget zone, with an average grain size of 1.63 μm, representing a 69% reduction compared with the base material. AA6082-T6 initial plate.

-

The joints produced using the eccentric shoulder tool at a 0° tilt angle exhibited superior mechanical properties, achieving 89.7% of the ultimate tensile strength of the initial plate (216.5 MPa) and 68.8% of its elongation. The yield strength for this configuration was also notably high at 68.3 MPa, suggesting that the eccentric shoulder design effectively maintains joint integrity without requiring a tilt angle.

-

The eccentric shoulder tool generated higher peak temperatures and heat inputs than the aligned shoulder tool, even without a tilt angle. This increased heat generation is attributed to the larger frictional area and dynamic orbit created by the eccentric design, which enhances material flow and mixing patterns.

-

The results of this study suggest that the use of an eccentric shoulder tool in friction stir welding can simplify the process by eliminating the need for tool tilting, making it an attractive solution for industries such as aerospace, automotive, and shipbuilding. This approach has the potential to reduce the machine complexity and operational costs while maintaining or even improving the mechanical properties of welds.

Data availability

The datasets used and/or analyzed during the current study available from the corresponding author on reasonable request.

References

Mishra, A. & Morisetty, R. Determination of the ultimate tensile strength (UTS) of friction stir welded similar AA6061 joints by using supervised machine learning based algorithms. Manuf. Lett. 32, 83–86 (2022).

Mishra, R. S. & Ma, Z. Y. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 50, 1–78 (2005).

Ahmed, M. M. Z., El-Sayed Seleman, M. M., Fydrych, D. & Çam, G. Review on Friction Stir Welding of Dissimilar Magnesium and Aluminum Alloys: Scientometric Analysis and Strategies for Achieving High-Quality Joints. J. Magnes. Alloy. Accepted, (2023).

Wang, J. et al. Wire-based friction stir additive manufacturing towards isotropic high-strength-ductility Al-Mg alloys. Virtual Phys. Prototyp. 19, (2024).

Sadoun, A. M., Wagih, A., Fathy, A. & Essa, A. R. S. Effect of tool pin side area ratio on temperature distribution in friction stir welding. Results Phys. 15, 102814 (2019).

Hamzawy, N., Mahmoud, T. S., El-Mahallawi, I., Khalifa, T. & Khedr, M. Optimization of thermal drilling parameters of 6082 Al-Alloy based on response surface methodology. Arab. J. Sci. Eng. https://doi.org/10.1007/s13369-023-07628-9 (2023).

Saravana Sundar, A., Radhika, N. & Kumar, A. Role of submerged friction stir welding in reducing intermetallic growth and enhancing microstructure in dissimilar Al-Ti joints. Sci. Rep. 14, 26908 (2024).

Salhan, P., Singh, R., Jain, P. & Butola, R. Prediction of heat generation and microstructure of AA7075 friction stir welding using ANN: effect of process parameters. Manuf. Lett. 32, 5–9 (2022).

Ataya, S. et al. Effective range of FSSW parameters for high Load-Carrying capacity of dissimilar steel A283M-C/Brass CuZn40 joints. Mater. (Basel). 15, 1–25 (2022).

Ahmed, M. M. Z. et al. Crystallographic texture, and mechanical properties of friction stir welded mild steel for shipbuilding applications. Mater. (Basel). 15, 2905 (2022).

Ahmed, M. M. Z. et al. Bobbin Tool Friction Stir Welding of Aluminum Thick Lap Joints: Effect of Process Parameters on Temperature Distribution and Joints’ Properties. Materials vol. 14 at (2021). https://doi.org/10.3390/ma14164585

Mahakur, V. K., Gouda, K., Patowari, P. K. & Bhowmik, S. A review on advancement in friction stir welding considering the tool and material parameters. Arab. J. Sci. Eng. 46, 7681–7697 (2021).

Balamurugan, S., Jayakumar, K. & Subbaiah, K. Influence of friction stir welding parameters on dissimilar joints AA6061-T6 and AA5052-H32. Arab. J. Sci. Eng. 46, 11985–11998 (2021).

Singh, A. & Upadhyay, V. Mechanical and microstructural behavior of similar and dissimilar AA6082-T6 and AA7050-T7 friction stir welded joints. J. Inst. Eng. Ser. D. 103, 225–234 (2022).

Fouad, R. A. et al. The influence of various welding wires on microstructure, and mechanical characteristics of AA7075 Al – alloy welded by TIG process. Sci. Rep. 1–15. https://doi.org/10.1038/s41598-024-69227-4 (2024).

Hu, Q. et al. Influence of solid solution treatment on fatigue crack propagation behavior in the Thickness direction of 2519A aluminum alloy Thick plates. Eng. Fract. Mech. 302, 110069 (2024).

Sharma, A. et al. Friction stir welding of Haynes 282 Ni Superalloy by using a novel hemispherical tool. Sci. Rep. 14, 1–13 (2024).

Ahmed, M. M. Z., El-Sayed Seleman, M. M., Fydrych, D. & Çam, G. Friction stir welding of aluminum in the aerospace industry: the current progress and State-of-the-Art review. Mater. (Basel) 16, (2023).

Ahmed, M. M. Z. et al. Friction stir welding of AA5754-H24: impact of tool pin eccentricity and welding speed on grain structure, crystallographic texture, and mechanical properties. Mater. (Basel) 16, (2023).

Essa, A., Ahmed, M. & Mohamed, A. Weld pitch effects on friction stir welding of aluminum alloys. J. Pet. Min. Eng. 0, 1–8 (2021).

Ahmed, M. M. Z. et al. Microstructure and mechanical properties of friction stir welded 2205 duplex stainless steel butt joints. Mater. (Basel). 14, 1–21 (2021).

Sindhuja, M., Neelakrishnan, S. & Davidson, B. S. Effect of welding parameters on mechanical properties of friction stir welding of dissimilar Metals- A review. IOP Conf. Ser. Mater. Sci. Eng. 1185, 012019 (2021).

Abolusoro, O. P. & Akinlabi, E. T. Review and analysis of mechanical properties of friction stir welds of high strength aluminium alloys. J. Phys. Conf. Ser. 1378, 0–13 (2019).

Singh, A., Upadhyay, V. & Misra, J. P. Effect of tool pin features on mechanical properties of AA7050-T7 friction stir welded joints. in 581–592 (2023). https://doi.org/10.1007/978-981-19-6107-6_41

Dialami, N., Cervera, M. & Chiumenti, M. Effect of the tool Tilt angle on the heat generation and the material flow in friction stir welding. Met. (Basel) 9, (2019).

Kumar, S. S., Murugan, N. & Ramachandran, K. K. Effect of tool Tilt angle on weld joint properties of friction stir welded AISI 316L stainless steel sheets. Meas. J. Int. Meas. Confed. 150, 107083 (2020).

Elyasi, M., Derazkola, H. A. & Hosseinzadeh, M. Investigations of tool tilt angle on properties friction stir welding of A441 AISI to AA1100 aluminium. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 230, 1234–1241 (2016).

Arici, A. & Selale, S. Effects of tool Tilt angle on tensile strength and fracture locations of friction stir welding of polyethylene. Sci. Technol. Weld. Join. 12, 536–539 (2007).

Long, L., Chen, G., Zhang, S., Liu, T. & Shi, Q. Finite-element analysis of the tool Tilt angle effect on the formation of friction stir welds. J. Manuf. Process. 30, 562–569 (2017).

Hemdan, H. et al. Effect of post – weld heat – treatment and solid – state thermomechanical treatment on the properties of the AA6082 MIG welded joints. Sci. Rep. 1–15. https://doi.org/10.1038/s41598-024-53795-6 (2024).

Chauhan, P., Jain, R., Pal, S. K. & Singh, S. B. Modeling of defects in friction stir welding using coupled Eulerian and lagrangian method. J. Manuf. Process. 34, 158–166 (2018).

Aghajani Derazkola, H., Kordani, N. & Aghajani Derazkola, H. Effects of friction stir welding tool Tilt angle on properties of Al-Mg-Si alloy T-joint. CIRP J. Manuf. Sci. Technol. 33, 264–276 (2021).

Aissani, M., Gachi, S., Boubenider, F. & Benkedda, Y. Design and optimization of friction stir welding tool. Mater. Manuf. Process. 25, 1199–1205 (2010).

Banik, A., Saha Roy, B., Deb Barma, J. & Saha, S. C. An experimental investigation of torque and force generation for varying tool Tilt angles and their effects on microstructure and mechanical properties: friction stir welding of AA 6061-T6. J. Manuf. Process. 31, 395–404 (2018).

Shah, L. H., Guo, S., Walbridge, S. & Gerlich, A. Effect of tool eccentricity on the properties of friction stir welded AA6061 aluminum alloys. Manuf. Lett. 15, 14–17 (2018).

Essa, A. R. S., Ahmed, M. M. Z., Aboud, A. R. K., Alyamani, R. & Sebaey, T. A. Prediction of Tool Eccentricity Effects on the Mechanical Properties of Friction Stir Welded AA5754-H24 Aluminum Alloy Using ANN Model. Materials vol. 16 at (2023). https://doi.org/10.3390/ma16103777

Zhang, Y. N., Cao, X., Larose, S. & Wanjara, P. Review of tools for friction stir welding and processing. Can. Metall. Q. 51, 250–261 (2012).

Zhai, M., Wu, C. S. & Su, H. Influence of tool Tilt angle on heat transfer and material flow in friction stir welding. J. Manuf. Process. 59, 98–112 (2020).

Gili, A. B., Hattingh, D. G. & Bernard, D. Relationship between tool Tilt angle, shoulder plunge depth and process energy input for pin-less friction stir welded thin Ti-6Al-4V sheets. IOP Conf. Ser. Mater. Sci. Eng. 655, (2019).

Kumar, S., Katiyar, J. K. & Roy, B. S. Influence of tool Tilt angle on physical, thermal, and mechanical properties of friction stir welded Al-Cu-Li alloys. Mater. Today Commun. 34, 105348 (2023).

Thakur, A., Sharma, V. & Bhadauria, S. S. Effect of tool Tilt angle on weld joint strength and microstructural characterization of double-sided friction stir welding of AZ31B magnesium alloy. CIRP J. Manuf. Sci. Technol. 35, 132–145 (2021).

Meyghani, B. & Awang, M. The Influence of the Tool Tilt Angle on the Heat Generation and the Material Behavior in Friction Stir Welding (FSW). Metals vol. 12 at (2022). https://doi.org/10.3390/met12111837

Gite, R. A., Loharkar, P. K. & Shimpi, R. Friction stir welding parameters and application: A review. Mater. Today Proc. 19, 361–365 (2019).

Khalafe, W. H. et al. The effect of friction stir welding parameters on the weldability of aluminum alloys with similar and dissimilar metals: review. Met. (Basel) 12, (2022).

Kah, P., Rajan, R., Martikainen, J. & Suoranta, R. Investigation of weld defects in friction-stir welding and fusion welding of aluminium alloys. Int. J. Mech. Mater. Eng. 10, (2015).

Podržaj, P., Jerman, B. & Klobčar, D. Welding defects at friction stir welding. Metalurgija 54, 387–389 (2015).

Ahmed, M. M. Z., El-Sayed Seleman, M. M., Eid, R. G., Albaijan, I. & Touileb, K. The influence of tool pin geometry and speed on the mechanical properties of the bobbin tool friction stir processed AA1050. Mater. (Basel). 15, 4684 (2022).

Li, Y., Sun, D. & Gong, W. Effect of tool rotational speed on the microstructure and mechanical properties of bobbin tool friction stir welded 6082-T6 aluminum alloy. Met. (Basel) 9, (2019).

Schmidt, H., Hattel, J. & Wert, J. An analytical model for the heat generation in friction stir welding. Model. Simul. Mater. Sci. Eng. 12, 143–157 (2004).

Ahmed, M. M. Z. et al. Bobbin tool friction stir welding of aluminum using different tool pin geometries: mathematical models for the heat generation. Met. (Basel). 11, 1–19 (2021).

Zhai, M., Wu, C. & Su, H. Influence of tool Tilt angle on heat transfer and material flow in friction stir welding. J. Manuf. Process. 59, 98–112 (2020).

Zhang, S. et al. Effects of tool Tilt angle on the in-process heat transfer and mass transfer during friction stir welding. Int. J. Heat. Mass. Transf. 125, 32–42 (2018).

Ahmed, M. M. Z., Wynne, B. P., El-Sayed Seleman, M. M. & Rainforth, W. M. A comparison of crystallographic texture and grain structure development in aluminum generated by friction stir welding and high strain torsion. Mater. Des. 103, 259–267 (2016).

Ahmed, M. M. Z. et al. Effect of tool geometry and heat input on the hardness, grain structure, and crystallographic texture of Thick-Section friction Stir-Welded aluminium. Metall. Mater. Trans. Phys. Metall. Mater. Sci. 50, 271–284 (2019).

Su, J. Q., Nelson, T. W. & Sterling, C. J. Microstructure evolution during FSW/FSP of high strength aluminum alloys. Mater. Sci. Eng. A. 405, 277–286 (2005).

Prangnell, P. B. & Heason, C. P. Grain structure formation during friction stir welding observed by the ‘stop action technique’. Acta Mater. 53, 3179–3192 (2005).

Chen, Y., Cai, Z., Ding, H. & Zhang, F. The evolution of the nugget zone for dissimilar AA6061/AA7075 joints fabricated via Multiple-Pass friction stir welding. Met. (Basel). 11, 1506 (2021).

Kosturek, R., Torzewski, J., Wachowski, M. & Śnieżek, L. Effect of welding parameters on mechanical properties and microstructure of friction stir welded AA7075-T651 aluminum alloy butt joints. Mater. (Basel). 15, 5950 (2022).

Moustafa, E. B. et al. Microstructural and mechanical characterization of the dissimilar AA7075 and AA2024 aluminum alloys reinforced with different carbide particles welded by friction stir welding. J. Compos. Sci. 7, 448 (2023).

Moreir, P. M. G. P., Santos, T., Tavares, S. M. O., Richter-Trummer, V. & Vilaca, P. De C. Mechanical and metallurgical characterization of friction stir welding joints of AA6061-T6 with AA6082-T6. Mater. Des. 30, 180–187 (2009).

Ghadar, S., Momeni, A., Khademi, E. & Kazemi, S. Effect of rotation and traverse speeds on the microstructure and mechanical properties of friction stir processed 2205 duplex stainless steel. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 263, 114813 (2021).

Wang, L., Zhao, P., Pan, J., Tan, L. & Zhu, K. Investigation on microstructure and mechanical properties of double-sided synchronous TIP TIG Arc butt welded duplex stainless steel. Int. J. Adv. Manuf. Technol. 112, 303–312 (2021).

Hussain, G., Shehbaz, T. & Alkahtani, M. Investigating impact of in-process cooling mediums on microstructural and mechanical properties of FSWed AA2219 T6 joints. Sci. Rep. 14, 29251 (2024).

Zhou, Y. et al. Effect mechanism of serrated joint design on microstructure and mechanical properties of AA2024 and AA7075 alloy friction stir welding. Int. J. Adv. Manuf. Technol. 130, 459–473 (2024).

Ahmed, M. M. Z. et al. Microstructure and mechanical properties evolution of friction stir spot welded high-Mn twinning-induced plasticity steel. Mater. Des. 91, 378–387 (2016).

Ahmed, M. M. Z., Ataya, S., El-Sayed Seleman, M. M., Ammar, H. R. & Ahmed, E. Friction stir welding of similar and dissimilar AA7075 and AA5083. J. Mater. Process. Technol. 242, 77–91 (2017).

Albaijan, I. et al. Optimization of bobbin tool friction stir processing parameters of AA1050 using response surface methodology. Mater. (Basel) (2022).

Refat, M. et al. Microstructure, hardness and impact toughness of Heat-Treated nanodispersed surface and friction Stir-Processed aluminum alloy AA7075. J. Mater. Eng. Perform. 25, 5087–5101 (2016).

Ahmed, M. M. Z., El-Sayed Seleman, M. M., Eid, R. G. & Zawrah, M. F. Production of AA1050/silica fume composite by bobbin tool-friction stir processing: microstructure, composition and mechanical properties. CIRP J. Manuf. Sci. Technol. 38, 801–812 (2022).

MD, S. & Birru, A. K. Mechanical and metallurgical properties of friction stir welded dissimilar joints of AZ91 magnesium alloy and AA 6082-T6 aluminium alloy. J. Magnes Alloy. 7, 264–271 (2019).

Laska, A., Szkodo, M., Koszelow, D. & Cavaliere, P. Effect of processing parameters on strength and corrosion resistance of friction Stir-Welded AA6082. Met. (Basel). 12, 1–16 (2022).

Bhushan, R. K. & Sharma, D. Optimization of friction stir welding parameters to maximize hardness of AA6082/Si3N4 and AA6082/SiC composites joints. Silicon 14, 643–661 (2022).

Scialpi, A., De Filippis, L. A. C. & Cavaliere, P. Influence of shoulder geometry on microstructure and mechanical properties of friction stir welded 6082 aluminium alloy. Mater. Des. 28, 1124–1129 (2007).

Acknowledgements

Open access funding provided by the Science, Technology & Innovation Funding Authority (STDF) in cooperation with the Egyptian Knowledge Bank (EKB). The funding was provided by STDF (Egyptian Knowledge Bank).

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

A.R.S.E, A.R.K.A, M.M.Z.A, A.E.E., and M.I.A.H. designed the study and conducted the experiments, A.R.S.E, A.R.K.A, M.M.Z.A, A.E.E., and M.I.A.H. provided materials, A.R.S.E, A.R.K.A, M.M.Z.A, A.E.E., and M.I.A.H. were involved in writing-original drat preparation, A.R.S.E, A.R.K.A, M.M.Z.A, A.E.E., and M.I.A.H. was involved in writing-review and editing, A.R.S.E, A.R.K.A, M.M.Z.A, A.E.E., A.S.E., and M.I.A.H. provided resources, supervision, and editing. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Correspondence and requests for materials should be addressed to A.R.S.E.

Reprints and permissions information

is available at www.nature.com/reprints.

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Tables.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Essa, A.R., Aboud, A.R., Ahmed, M.M. et al. Friction stir welding of aluminum alloy 6082-T6 using eccentric shoulder tools to eliminate the need for tool tilting. Sci Rep 15, 8801 (2025). https://doi.org/10.1038/s41598-025-91065-1

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-91065-1

Keywords

This article is cited by

-

L-PBF fabricated tools for FSW: effects of geometric design and process parameters on AA6082 joints

The International Journal of Advanced Manufacturing Technology (2026)

-

Mechanical and electrochemical analysis of AA5083-AA7075 dissimilar alloy joints fabricated by friction stir welding

Discover Materials (2026)

-

Tribological and corrosion behavior of Al2O3 interlayer reinforced friction stir welded AA6082-T6 joints

Scientific Reports (2025)

-

Prediction and optimization of mechanical properties in FSWed AA6082-T6 joints using RSM and artificial neural networks

The International Journal of Advanced Manufacturing Technology (2025)

-

Friction stir welding of AA6082-T6 assisted with a novel encapsulated alumina interlayer: surface morphology, tribology, and topographic analysis

The International Journal of Advanced Manufacturing Technology (2025)