Abstract

This paper introduces the characteristics of the harmonic noise of the outdoor unit of air conditioner, analyzes the change of the noise sound pressure level and the corresponding spectral characteristics of the outdoor unit when the harmonic noise is generated, and researches the influence of the core structural components of the outdoor unit such as the motor structure, bracket structure, etc., on the spectral characteristics of the harmonic noise. It is found that with the increase of harmonic content in the power supply, the harmonic noise with 200 Hz frequency characteristics is generated, and the noise peak at a fixed frequency of 200 Hz increases gradually with the increase of harmonic content, and the larger the harmonic content of the power supply, the higher the noise peak. Combined with the analysis of the vibration characteristics of a single motor, whether it is a single motor (no load) or the whole outdoor unit (with load) operation, the iron shell motor in the front and rear direction of the vibration amplitude is higher, while the plastic motor in the three directions of the vibration vibration amplitude of the vibration is relatively uniform, the main reason for this is determined by the motor’s own magnetic field characteristics. The resonance of the motor bracket may be due to the fact that the solid frequency of the motor bracket is equal or similar to the motor excitation frequency. Optimize the modal frequency of the motor bracket to avoid the motor excitation frequency, and its 14th-order modal frequency actively avoids the motor excitation frequency, so that there is no resonance phenomenon in the outdoor unit.

Similar content being viewed by others

Introduction

During normal power output, its current waveform and voltage waveform are presented as sinusoidal waves. As people increase the use of nonlinear appliances, the harmonic content of the current also increases dramatically, which will lead to some remote areas or city centers with peak power consumption, the transmission line voltage and current contain a large number of harmonics1. When the harmonic content of the power supply increases to a certain value, it often results in the generation of harmonic noise.

When harmonics are contained in the power line, the vibration of the single-phase asynchronous motor of the air conditioner’s outdoor unit increases, resulting in an increase in the force transmitted to the bracket and the air blades. Some scholars have done research on the relationship between harmonics and the vibration of air conditioners. Zuo X analyzes in detail the characteristics and working principle of single-phase asynchronous motors, revealing the influence of harmonics on single-phase asynchronous motors. The larger the harmonic content is, the radial excitation force of the single-phase asynchronous motor increases, and the vibration of the structure connected to it increases2. Huang H et al. analyzes the abnormal noise and vibration in the practical application of air conditioning, and the results show that after the odd harmonic voltage content of the power supply reaches a certain value, the vibration of the air conditioning outdoor unit has a significant impact, and the noise of the outdoor unit is mainly originated from the vibration3. Li S analyzed the single-phase asynchronous motor noise and showed that harmonic content and motor resonance are the main factors affecting the noise, and the motor scheme needs to avoid the resonance frequency point4. Gao W studied the noise problem under power harmonics, revealing that the electromagnetic noise of air-conditioning outdoor unit is related to the harmonic content of the power supply, and the influence of odd-ordered harmonics is more significant than even-ordered harmonics, and simulated the harmonic content of user’s home in the experiments to arrive at the purpose of effectively controlling the anti-harmonic ability of the motor5. Zhang J R analyzes the high-frequency noise of the duct machine, revealing that the harmonic current excitation frequency is consistent with the inherent frequency of the whole machine structure, resulting in the resonance phenomenon. By optimizing the structure and avoiding the resonance frequency, the noise value is significantly reduced6. Literature7 analyzed the principle of injecting harmonic current to optimize the radial electromagnetic force, and derived a harmonic current compensation model for the radial electromagnetic force wave of permanent magnet synchronous motor. Literature8 based on the radial vibration suppression model of the multi-frequency current injection method, and designed the optimization algorithm to achieve the comprehensive suppression of radial vibration of each frequency. Lai C Y, Feng G D et al.9.pointed out that harmonic current injection is an important method to counteract the inherent harmonic currents due to inverter nonlinearities, etc., and has a wide range of practical experience in applications such as torque pulsation suppression. Zhang Ch, Guo H and Yuan T et al.10. used LMS Virtual Lab acoustic simulation software to analyze and compare the electromagnetic noise generated by a sinusoidal current source and a low-frequency harmonic current source with the fifth and seventh frequencies. The simulation results show that the addition of the fifth and seventh low-frequency harmonic currents increases the electromagnetic noise of the motor at four and six times the fundamental frequency of the current. E.F. Songong, A.A.N. Djanan, B.R.N. Nbendjo11, a tuned liquid column damper (TLCD) device is used to reduce the amplitude of vibration of a rectangular plate supporting a DC motor acting on a specific area.

Based on the harmonic noise generation mechanism of the outdoor unit of the air conditioner, this paper conducts noise and vibration characteristic tests for the outdoor unit, analyzes the noise sound pressure level change and the corresponding spectral characteristics of the outdoor unit when the harmonic noise is generated, and researches the influence of the core structural components of the outdoor unit such as the motor structure, bracket structure, etc. on the spectral characteristics of the harmonic noise. The ability of the impeller and motor system not to have sudden changes in noise level and sound quality when powered by a harmonic power supply with a specified content is a test of the anti-harmonic ability of the motor, air blade and duct system of the outdoor unit.

Noise test system

The noise vibration test in this paper uses the noise acquisition system of Belgium LMS company, which can measure the noise source spectrum, sound intensity distribution and sound power level. The device is divided into a software system and a hardware system.

The hardware part of the noise test equipment is the LMS SCADAS Mobile, as shown in Fig. 1 (a). The function of the hardware part of the device is the acquisition and transmission of noise data, and the transmitted noise signals are processed in the computer. Hardware equipment has 16 signal channels, each channel’s sampling rate up to 102.4 kHz, data transfer rate of 3.8 M sample points/sec, can synchronize the acquisition of pressure pulsation, vibration, noise and other sources of dynamic signals. Noise test equipment signal acquisition using the U.S. PCB company produced by the high-frequency loudness sensor. The series of high-frequency loudness sensor is characterized by high precision, high intrinsic frequency and wide temperature range, the measurement frequency range of 3.15 Hz-20 kHz, the maximum measured sound pressure level of 146dB, as shown in Fig. 1 (b). shows that the performance parameters are fully able to meet the needs of air-conditioner fan test.

Noise test equipment software system works to display the dynamic signal data of the extracted noise source in real time. In this paper, the parameters of signal data acquisition settings: sampling frequency of 6400 Hz, total time of 30 s. The signal processing using low-pass filtering function can effectively avoid signal aliasing, the time domain data of the noise signal using the Hanning window function to truncate the processing can effectively avoid the signal omission, and the noise signal data can be tested under the conditions of the Fast Fourier Transform (FFT) post-processing.

Harmonic noise characteristics of outdoor unit of air conditioner

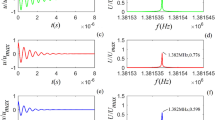

When harmonics are contained in the power supply power line, the asymmetry of the magnetic field inside the motor is greatly induced. By conducting noise tests on the outdoor unit and extracting the frequency spectrum, it was found that at the peak of the motor’s rotational frequency, high harmonics with a fundamental frequency (50 Hz) greater than one integer multiple of the fundamental frequency (50 Hz) appeared, and there was a significant noise peak at frequency 200 ± Fr (rotational frequency), as shown in Fig. 2. This leads to an increase in single-phase asynchronous motor vibration, and ultimately the noise vibration transmitted to the outdoor unit casing also increases.

The influence of power supply harmonic content of outdoor unit on harmonic noise

Based on the mechanism of harmonic noise generation, abnormal fluctuation of harmonic content of power supply may be one of the causes of “strange sound” during the operation of outdoor unit. In order to verify the influence of the harmonic content of the power supply on the noise characteristics, by adjusting the ratio of the harmonic content of the power supply, we compare the noise spectra of different harmonic contents of the power supply and analyze the trend of its change.

The spectrum of different harmonic contents superimposed on the outdoor unit noise test is shown in Fig. 3. Power supply harmonic content changes (0→6.5%→10.5%), the total value of its noise were: 46.6dB (A)→47.2dB (A)→47.4dB (A), the total value of the noise increased by 0.8dB (A). From the figure, it is found that with the increase of harmonic content in the power supply, the harmonic power supply under the frequency of 200 Hz produces noise peaks, and its noise peaks at a fixed frequency at 200 Hz increases gradually with the increase of harmonic content. Spectrum shows that the harmonic content of different noise peaks at 200 Hz can be reduced by up to 9dB (A). The larger the harmonic content of the power supply, the higher the noise peak, and the worse the corresponding sound quality.

The effect of motor type on harmonic noise

The motor structure analysis

As a common driving device for household appliances, the motor is highly utilized in the outdoor unit of air conditioners, and its noise characteristics and sound quality level are directly related to the noise performance of air conditioners. Considering the production efficiency, processing technology and cost, etc., the current motor used in the outdoor unit mostly adopts the metal casing structure. As shown in Fig. 4, its silicon steel sheet exposed in the stator, no corresponding fixed structure, easy to produce a slight vibration during operation.

The motor used in the outdoor unit of the air conditioner is mostly a single-phase asynchronous motor, which realizes the conversion of electromechanical energy by electromagnetic induction through the air gap magnetic field. Single-phase asynchronous motor into the working current, the internal generation of elliptical rotating magnetic field, and three-phase asynchronous motor internal rotating magnetic field for the circular magnetic field, the main difference lies in the asymmetry of its rotating magnetic field. The main difference is the asymmetry of the rotating field. The three-phase asynchronous motor’s circular magnetic field has a better operating performance than the single-phase asynchronous motor’s elliptical magnetic field.

Electromagnetic vibration is generated by the interaction of the rotating air gap magnetic field of the motor and the electromagnetic force generated by the iron core. Electromagnetic vibration can be transmitted to the motor bracket and impeller through the rigid connection of the outdoor unit housing. The motor as a vibration excitation source, when the outdoor unit structural components of the self-oscillation frequency is similar to it, resonance phenomenon is prone to occur, while the noise sound pressure level will be superimposed to enhance.

of iron-case motor of iron-case motor.

This paper proposes to reduce harmonic noise by using a plasticized motor structure, which fixes the exposed silicon steel sheet in the stator, as shown in Fig. 5. The biggest difference between the plastic and the iron shell motor lies in the fixing method of the silicon steel sheet, the outer plane of the silicon steel sheet of the iron shell motor is a piece of sheet connected with the shell through the hot injection process, and the inner plane of the silicon steel sheet is suspended inside the motor, only through the coil and the bottom shell is connected. The plastic motor with engineering plastics will motor stator core, winding and other structures with plastic encapsulation technology as a whole package, the silicon steel sheet, coil and ceramic together with the motor shell is completely wrapped. Eliminate the traditional motor stator insulation process and ordinary motor metal casing, silicon steel sheet of the inner plane to avoid hanging and vibration.

Noise spectrum characterization

Iron shell motor and plastic motor were installed in the same outdoor unit for noise spectrum test, compare its noise spectrum, as shown in Fig. 6. As can be seen from the figure: plastic motor and iron shell motor noise spectrum comparison, the total value of the noise is reduced by 0.7dB (A), in the outdoor electromagnetic noise peak noise peak reduction is obvious, in the spectrum at 200 Hz frequency noise peak reduction of 5dB (A), at 214 Hz frequency noise peak reduction of 4dB (A), this indicates that the plasticized motor has good noise reduction performance and has an effect on the noise sound pressure level.

The single motor vibration characterization

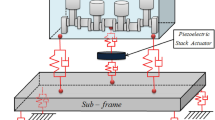

In order to analyze the noise contribution of motor noise in the operation of outdoor unit, this paper carries out a single motor (no load case) vibration test. For single motor vibration test is mainly based on “JB/T 10490 − 2004 small power motor mechanical vibration - vibration measurement methods, evaluation and limit values” standard. Motor vibration and its installation has a very close relationship, in order to ensure the repeatability of the test and test accuracy, motor test installation using free suspension system, the motor is installed in the elastic support or suspended on the spring and other elastic parts, as shown in Fig. 7. The contact between the vibration sensor and the motor during the test should be good, and it should be ensured that there is a reliable connection without affecting the vibration state of the motor under test. In this paper, the measured value of motor vibration is taken as the effective value of vibration acceleration in m/s2.

Vibration testing of the single motor of the outdoor unit, vibration data collection using a single-phase sensor for testing, vibration monitoring point location shown in Fig. 8.

Figures 9 and 10 are the vibration test values of the iron shell motor and the plastic motor, respectively, as can be seen from the figure, the test values in the vibration value and vibration direction have obvious differences: the amplitude of the vibration acceleration of the iron shell motor is significantly higher than the vibration amplitude of the plastic motor, the two vibration acceleration maxima of 0.36 m/s2 and 0.22 m/s2, respectively, to meet the vibration test standards. At the same time in the maximum vibration amplitude appears in the direction of vibration there are also differences, the iron shell motor in the front and rear direction of the larger values, while the plastic motor in the up and down direction of the maximum vibration amplitude, and plastic motor vibration amplitude occurs in the low-frequency domain of the vicinity of 100 Hz.

The outdoor units vibration characterization

This section of the vibration monitoring of the outdoor unit during operation, its vibration monitoring points in addition to the same as the previous section of the motor monitoring points at the location of the same, in order to comprehensively analyze the vibration characteristics of the outdoor unit, in the bracket position at the addition of two vibration monitoring points, monitoring position as shown in Fig. 11.

Figures 12, 13 and 14 show the vibration ratios of the outdoor unit equipped with an iron shell motor and a plastic motor in three different directions. As can be seen from the figure, the amplitude of vibration acceleration of the outdoor unit in the operation of the iron shell motor is significantly higher than the amplitude of vibration of the plastic motor, the maximum vibration amplitude are from the monitoring point 6, that is, the motor bracket position, the next section will focus on the motor bracket to analyze. Iron shell motor in the front and rear direction of the maximum vibration amplitude, while the plastic motor in the three directions of the vibration amplitude is relatively uniform, the plastic motor effectively reduces the amplitude of vibration.

Combined with the previous section of the vibration characteristics of a single motor analysis, whether it is a single motor (no load) or the whole outdoor unit (with load) operation, the iron shell motor in the front and rear direction of the vibration amplitude is higher. While the plastic motor in the three directions of vibration vibration amplitude is relatively uniform, mainly due to the motor’s own magnetic field characteristics of the decision. In both operating conditions, the plastic motor shows good vibration reduction advantages.

The effect of bracket structure on harmonic noise

The motor is one of the main vibration sources of the outdoor unit, which is fixed on the bracket by screws to form an air duct system with the axial flow air blades. The bracket structure is a direct bridge from the motor vibration to the outdoor unit shell, and the inherent structure of the motor bracket and the installation coordination play a crucial role in the noise. The design of the bracket structure is constrained by the size of the outdoor unit casing, the processing method and other requirements, and at the same time, the vibration of the motor bracket is affected by the overall stiffness of the bracket, the thickness of the steel, the motor’s center of gravity and the intrinsic frequency of the motor installation. Usually, the motor bracket is designed as an asymmetric structure with partial flanging for the convenience of alignment, which will affect the strength and intrinsic frequency of the motor bracket.

When designing the motor bracket, its intrinsic frequency should be prevented from coupling with the power supply harmonics and the motor rotational frequency and octave frequency, resulting in resonance during the operation of the outdoor unit. When the intrinsic frequency of the motor bracket is close to the motor frequency and times the frequency of the motor, the resonance of the external housing will be exacerbated, thus increasing the noise during the operation of the outdoor unit, which in turn affects the noise of the outdoor unit. Whether the structural design of the motor bracket is reasonable is directly related to the quality of the outdoor unit noise.

A structural system will vibrate at a specific frequency in response to an instantaneous external excitation, and this specific frequency is known as the intrinsic frequency of the structure. The intrinsic frequency has no relation to the external excitation and is an inherent property of the structural system. For an undamped single-degree-of-freedom system, the formula for calculating the intrinsic frequency is as follows:

Equation: K is the stiffness value; m is the component mass.

Under the harmonic power supply, the resonance of the motor bracket may be caused by the bracket’s solid frequency being similar to the motor’s excitation frequency, leading to the resonance phenomenon.

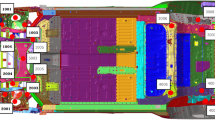

The structure of the motor bracket system of the outdoor unit is shown in Fig. 15, and the bracket system includes the wind blade, motor and bracket. The density, Young’s modulus and Poisson’s ratio of the wind blade and bracket are calibrated according to the material properties. In order to facilitate the simulation calculation and analysis, the motor is assumed to be the same rigid body without considering the differences in the internal structure of the motor, its material properties are set with reference to those of the steel, and the density is derived based on the mass and volume of the actual motor. The main factors affecting the accuracy of the intrinsic frequency calculation are material, shape and mass. Therefore, in addition to keeping the material properties consistent, it is also necessary to keep the mass and shape consistent in the simulation.

In this paper, the modal simulation of the motor bracket system of the outdoor unit is carried out, and the results are shown in Table 1. Because the original motor bracket is designed as an asymmetric left-right flap structure considering the convenience of outdoor unit alignment, the structure is shown in Fig. 16. The optimization scheme is to change the intrinsic frequency and strength of the motor bracket to process the bracket into a left-right symmetric flap structure, and then carry out modal simulation and noise test to verify.

From the results in Table 1, it can be seen that the 14th-order modal frequency of the original bracket, 216.1 Hz, is very close to the motor rotational frequency rate of 214 Hz, and there is a risk of resonance phenomenon, which may lead to poor noise performance of the outdoor unit.

Motor bracket vibration transfer size determines the size of the noise value, the outdoor unit of different motor bracket noise test data comparison, focusing on the analysis of the peak value of the noise spectrum at the power harmonics, motor rotation frequency. As shown in Fig. 17, the optimized motor bracket spectrum at 186 Hz peak reduction of 4dB (A), 200 Hz peak reduction of 2dB (A), 214 Hz peak reduction of 8dB (A), so that the frequency of the noise peak is reduced at the same time, the outdoor unit sound quality has been improved. Meanwhile, the 14th order modal frequency of 236.2 Hz after optimizing the bracket actively avoids the motor excitation frequency, so that the outdoor unit has no risk of resonance phenomenon, and the anti-harmonic performance is better.

Conclusion

This paper introduces the characteristics of harmonic noise of outdoor unit, analyzes the change of noise sound pressure level and spectral characteristics when harmonic noise of outdoor unit is generated, and researches the influence of core structural components of outdoor unit, such as motor structure, bracket structure, etc., on the spectral characteristics of harmonic noise. The main conclusions are as follows:

(1) Power supply harmonic content changes (0→6.5%→10.5%), with the increase of harmonic content in the power supply, produces a harmonic noise with 200 Hz frequency characteristics, the noise peak at a fixed frequency of 200 Hz with the increase of harmonic content increases gradually, the larger the harmonic content of the power supply, the higher the noise peak. Noise spectrum shows that the harmonic content (10.5% → 0) at 200 Hz frequency noise peak value can be reduced by 9dB (A). Power harmonics on the total sound pressure level of the outdoor unit noise impact on average 0.8dB (A), specifically in the power harmonics on the noise peak value of the larger impact.

(2) Compared with the iron shell motor, the noise peak at the peak of electromagnetic noise is significantly reduced: the noise peak at 200 Hz is reduced by 5dB(A), and the noise peak at 214 Hz is reduced by 4dB(A). Plastic-sealed motors have good noise reduction performance, can be changed through the motor structure so as to achieve the purpose of optimizing the harmonic noise of the outdoor unit.

(3) The vibration amplitude of the outdoor unit during operation of the molded motor is significantly lower than that of the iron shell motor, with the maximum vibration amplitude coming from the motor bracket position. The maximum vibration amplitude of the iron shell motor occurs in the front and rear directions, while the vibration amplitude of the molded motor in the three directions is relatively uniform. Combined with the analysis of the vibration characteristics of a single motor, whether it is a single motor (no load) or outdoor unit (with load) operation, the iron shell motor in the front and rear direction of the vibration amplitude is higher, while the plastic motor in the three directions of the vibration amplitude is relatively uniform, mainly due to the motor’s own magnetic field characteristics of the decision. In both operating conditions, the molded motor effectively reduces the vibration amplitude, showing good vibration damping performance.

(4) The resonance of the motor bracket may be caused by the similarity between the solid frequency of the motor bracket and the motor excitation frequency. Optimize the modal frequency of the motor bracket to avoid the motor excitation frequency, and its 14th order modal frequency actively avoids the motor excitation frequency, so that there is no resonance phenomenon of the outdoor unit, and the results show that: the peak noise value is reduced by 4dB (A) at 186 Hz frequency, the peak value is reduced by 2dB (A) at 200 Hz, and the peak noise value is reduced by 8dB (A) at 214 Hz, and the optimization improves the harmonic resistance of the motor bracket. capability after optimization.

Data availability

Original testing data that support the findings of this study have been deposited in the files shared through online storage:Data availability.rarLink: https://pan.baidu.com/s/190RL0-XBxuLmWtDFmELQFwExtracted code: 4nqy.

References

Wang, K. Measurement and Studies on Power Network Harmonics (Shandong University, 2008).

Zuo, X. Analysis of Harmonic and Radial Forces of Multi-Speed Single-Phase Induction Motors With Capacitor Operation (Huazhong University of Science & Technology, 2019).

Huang, H. & Lan, J. H. Relationship between harmonic wave of power supply and noise vibration of air Conditioners. Noise Vib. Control. 34 (04), 219–222 (2014).

Li, S. Single-phase asynchronous motor harmonic noise analysis. Electron. World 14, 108 (2019).

Gao, W. & Lv, J. L. The research and application of power harmonics induced Air-conditioned motors electromagnetic noise problem. Telecom Power Technol. 36 (12), 48–49 (2019).

Zhang, J. Q. & Chen, D. R. High frequency noise analysis and noise reduction method of ducted air-conditioning. Refrig. Air-Conditioning. 17 (09), 46–49 (2017).

Xia, J. K. et al. The model of pole slot radial force wave compensation for surface-mounted three-phase permanent magnet synchronous motor and parameter identification .Trans. China Electrotech. Soc., 36(8), 1596–1606 (2021).

Kang, L. et al. The model of pole slot radial force wave compensation for surface-mounted three-phase permanent magnet synchronous motor and parameter identification. Trans. China Electrotech. Soc. 37(18), 4638–4650 (2022).

Lai, C. Y. et al. Genetic algorithm-based current optimization for torque ripple reduction of interior PMSMs. IEEE Trans. Ind. Appl. 53 (5), 4493–4503 (2017).

Zhang, C. et al. Effect of low frequency harmonic current on electromagnetic noise of permanent magnet synchronous motor. Mach. Electron. 41(8), (2023).

Songong, E. F., Djanan, A. A. N. & Nbendjo, B. R. N. Vibration absorption of a rectangular plate supporting a DC motor with a TLCD. Nonlinear Dyn. 105, 1357–1372 (2021).

Author information

Authors and Affiliations

Contributions

Weijie Zhang is mainly responsible for the conception, writing, and related experiments of the article.Hao Li is mainly responsible for controlling the overall idea of the paper and coordinating related experiments.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, W., Li, H. A study of the effect of motor structural components on harmonic noise. Sci Rep 15, 7670 (2025). https://doi.org/10.1038/s41598-025-91861-9

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-91861-9