Abstract

This study sets out to address the challenges of improving precision, stability, and efficiency in corn seed metering systems. A novel clip-based precision seed metering device was developed, integrating an optimised seed-filling clip to enhance seed capturing and metering accuracy. The overall structure and working principles of the device were described, focusing on key components such as the seed-filling clip, clamping slot, and torsion spring. The coupled DEM-MBD simulation method was employed to analyse the interaction forces and trajectories of corn seeds during the filling and metering process, enabling parametric optimisation of the device. The effects of clip protrusion width, clamping slot length, and metering speed on seeding performance were systematically investigated. Field validation tests demonstrated a qualification rate of 90.76%, a missing rate of 4.83%, and a multiple rate of 4.4%, with an error of 1.4% compared to simulation results. The results confirm the device’s ability to stably and accurately meter seeds, showcasing its potential for mechanized corn seeding with enhanced precision and operational stability.

Similar content being viewed by others

Introduction

One of the major global staple crops, corn faces a significant challenge due to the imbalance between supply and demand1. The quality of corn seeding directly affects crop growth, yield, and ultimately its economic return2. In the context of agricultural modernisation, enhancing the precision and efficiency of corn planting has become a critical issue that needs to be urgently addressed in agricultural production3. The precision seed metering device, a pivotal component of the corn seeding system, facilitates precision seed metering device enables precise control of seed spacing, quantity, and seeding depth, thereby ensuring uniform crop distribution and optimising the growth environment4. The performance of the seed metering device is a pivotal factor in determining seeding quality5.

At present, the field of corn precision seed metering devices are primarily divided into pneumatic and mechanical types6. Mechanical seed metering devices, have been shown to exhibit consistent performance under low to medium operating speeds, and they are widely utilised in corn planting operations due to their simple structure, minimal environmental requirements, and reduced manufacturing and operational costs7. Consequently, enhancing the performance of mechanical precision seed metering devices is of paramount importance for improving the efficiency and quality of corn planting operations8. The development of computer simulation technology, has led to the increased use of simulation techniques in the analysis and design of key components of mechanical seed metering devices has become increasingly widespread9. For instance, Shi et al.10. designed a direct insertion corn precision hole seeder by sizing the seed metering slot based on graded seeds, thereby reducing the rate of missing seeds. Wu et al.11. employed EDEM simulation analysis on key components of the seed metering device, adjusting parameters such as the opening angle of the seed filling block to achieve an optimal seeding qualification rate. Du et al.12. focused on enhancing seed group disturbance to reduce inter seed interaction forces, designing a self disturbance inner filled hole wheel precision seed metering device for corn. EDEM simulation experiments indicated that when the cone angle of the seed metering disc was set to 38.6°, the seeding performance was superior to that of spoon wheel seeders. Dong et al.13. colleagues addressed the issues of declining precision and instability in mechanical corn seeders by proposing a method using linear posture adjustment teeth and unit type holes to regulate the filling posture of corn seeds, and designing a posture control guided precision seed metering device. Li et al.14. addressed the issue of seed blockage in the seed filling hole inserts by grading corn seeds and using EDEM to analyse the effects of different seeds on the structural parameters of the hole inserts for design and optimisation. Pan et al.15. aimed to address the instability of seed release points in seed metering devices and improve seed spacing uniformity, designed a hyperbolic guide groove based on a prerelease adaptive principle. It has been demonstrated by previous studiesthat the seed filling clip has a significant effect on seeding performance. Therefore, it is essential to optimize the clip parameters in order to enhance the device’s performance.

This paper presents the design of a clip type corn precision seed metering device, with a parametric design of its seed filling clip. The present study set out to investigate the impact of seed grading on seeding performance. To this end a corresponding simulation model was established, and the mechanism of corn seed capture by the seed filling clip was analysed. The postural changes of corn seeds during the filling process were examined through the utilisation of DEM-MBD simulation, and the structural parameters of the seed filling clip were optimized. Finally, bench tests were conducted to ascertain the efficacy of the optimised clip structure.

Materials and methods

Overall structure and operating principle

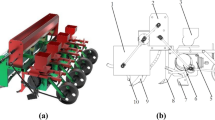

The configuration of the clip type precision seed metering device is shown in Fig. 1. The device consists of a seed box and the primary body of the seed metering device, which are interconnected via a hose. The seed metering device comprises a fixed disc, a seed filling disc fixing ring, a push rod clip clamping module, a duckbill hole forming component, an adjustment cam, a core disc, an end cap, a pressure plate, and a connecting shaft. All components are securely fixed together by bolts.

The seeds, contained within the seed box, are propelled by gravity through the hose into the working chamber of the precision seed metering device. Once inside, they pass through five stages: Seed filling stage I, Seed carrying stage II, Seed clearing stage III, First seed delivery stage IV, and Second seed delivery stage V, as shown in Fig. 2. In Seed filling stage I, the corn seeds contained within the precision seed metering device coalesce to form a rolling seed population as the device operates. The drive lever makes contact with the adjustment cam, which results in the opening of the seed filling clip, thereby creating a filling space. Under the influence of gravity and inter seed interactions, the corn seeds move towards the space and enter it. In Seed carrying stage II, the drive lever gradually disengages from the adjustment cam, and the seed filling clip closes under the action of the torsion spring, thereby providing support to the clamped seed. During this process, any seeds that have been improperly clamped fall back into the rolling seed population. In Seed clearing stage III, the competing seeds are brushed back into the rolling seed population by the brush. In First seed delivery stage IV, the support from the inner wall of the end cap on the clamped corn seed is removed, and the seed is ejected into the duckbill component by the torsion spring force. In Second seed delivery stage V, the duckbill component penetrates the soil, and under soil resistance, the movable duckbill rotates relative to the fixed duckbill. Then corn seed falls into the soil, thereby completing a seeding cycle.

Corn seed model

The present study investigates the impact of corn seed grading on seeding performance. To this end, Zhengdan 958 corn seeds were subjected to grading. 1,000 seeds were graded into three types based on size characteristics: horse tooth type, spherocone type, and spheroid type, as shown in Fig. 316. The dimensions of the seeds were measured using an electron microscope, and the average values were calculated. The measuring process is shown in Fig. 4, and the results are listed in Table 1.

The parameter measurement results were then utilised to create three-dimensional models of corn seeds according to their characteristic dimensions. These models were then imported into the EDEM (Version 2023.0)software for the purpose of spherical particle filling. In order to reduce the simulation time, the three types of corn seeds were simplified according to their characteristics. The Horse tooth type was represented by nine spherical particles of different diameters, the Spherocone type by three spherical particles of different diameters, and the Spheroid type by two spherical particle, as shown in Fig. 5.

Structural design of the L-type seed filling clip

The structure of the seed filling clip directly determines the seeding performance. Conventional seed filling clips have been observed to result in multiple seeds being deposited during the process of seeding multiple seeds in a lateral arrangement. To address the issue, an L-type seed filling clip is proposed. The basic dimensions of the seed filling clip include the clip thickness (H), the diagonal length of the clamping slot protrusion (Lt), the length of the seed guide slot (L1), the length of the clamping slot (L2), the tail length (Lw), and the tail angle (θ). The structure of the seed filling clip is shown in Fig. 6.

Unlike the flexible aperture design proposed by Mahapatra et al.17. which primarily uses variable apertures to manage seed variability, this study focuses on a flexible clamping mechanism. The clamping structure applies adaptable holding forces to accommodate irregular seed geometries while minimizing mechanical seed damage during high-speed operations. This approach offers additional operational flexibility at higher metering speeds and provides greater control over seed retention and release dynamics.

The L-type seed filling clip is characterised by a flexible protrusion arranged laterally, which endows the clamping slot with an L-shape, with one side narrow and the other side wide. In the event of multiple seeds entering the clamping slot through the seed guide slot concurrently, the thicker spheroid and spherocone corn seeds are able to enter solely through the wide side. The length of the clamping slot restricts the capacity for subsequent seeds to continue filling, and the narrow side is unable to accommodate seeds as the wide side is already occupied, thereby preventing multiple seeding. In contrast, the dent type corn seeds, with a thickness less than the height of the narrow side, can enter the clamping slot. Once the clip closes, the flexible protrusion compresses the Horse tooth type corn seeds, causing deformation and securing the seeds in place. The scenarios of different seed filling clips handling multiple seeds are shown in Fig. 7.

Single corn seeds were selected for the purpose of studying the grip posture. During the seed filling stage, seeds undergo three processes: they are first captured by the clip, then enter the filling space, and finally are securely held by the clip. The force analysis of single seeds for the three types is shown in Fig. 8.

Initially, the clip makes contact with the seed. Under the influence of the support force FN from the clip, gravity, and inter-seed interactions, the seed moves towards the filling space. As the point of contact between the seed and the clip is at the seed’s edge, the seed center of mass and the direction of the support force are misaligned, resulting in the generation of a torque M1. This torque causes an adjustment in the seed’s posture and a subsequent movement closer to the clip, enabling the clip to capture it.

After the capture is complete, the seed moves along the seed guide slot into the clamping slot under the influence of the support force. At this point, the clamping slot remains open, and the seed experiences friction and support forces from the seed filling disc, the end cap, and the clip. These forces generate a torque M2, which causes the seed to rotate and align tightly against the clamping slot of the clip, thus completing the filling process. Once the filling is complete, the seed maintains a steady posture, exerting pressure against the clamping slot of the clip. At this stage, the torsion spring drives the clip to close the filling space, clamping the seed.

The L-type seed filling clip, with its unique flexible protrusion compression design, effectively prevents multiple seeds from entering the unit at the same time, eliminating the problem of multiple seeding. It offers significant advantages during the seed filling process. When the flexible protrusion compresses the seed, the seed is slightly compressed and deform, effectively securing the seed in place and preventing any movement or dropping of the seed during subsequent operations. The analysis reveals that the clamping slot of the seed filling clip is divided into two regions. Figure 9 shows the bottom view of the seed filling clip with the division of the seed clamping slot area. Region 1 accommodates Dent type and Spherocone type seeds, while Region 2 is designed for Spheroid type seeds. To ensure the precision seed metering device maintains an optimal state during operation and achieves the objective of capturing only one seed per cycle, the seeds and the seed filling clip move in a circular motion. However, the clamped seeds are obscured by the clip, which hinders observation of the seed posture during clamping. Through experimental investigation, EDEM (Altair, Troy, Michigan, USA) was utilised to study and analyse the optimal clamping posture of corn seeds and the optimal structural parameters of the seed filling clip.

Design of the protrusion shape of the seed filling clip

Significant variations in the corn seed filling process give rise to competitive interactions that result in the occupation of available space, thereby leading to the absence of a seed. During such competitive interactions, the forces that predominantly drive the seed into the clamping slot are primarily attributed to centrifugal force and inter seed interaction forces. When the resultant force of centrifugal force, friction, and the support force acting on the seed is balanced, the seed attains a state of equilibrium, wherein it becomes impeded within the seed filling clip. This results in the seed being unable to enter the clamping slot correctly, which consequently leads to seed missing. Therefore, a protrusion was added to alter the shape of the seed filling slot thereby effectively mitigating the competition issue. The support force was assumed to remain constant, and as the protrusion width increased, the narrow side of the clamping slot also narrows. When the protrusion width increases to a certain value, it disrupts the equilibrium state of the competing seeds, allowing the seeds to enter the clamping slot with ease. Whether the seed can enter the clamping slot smoothly depends on the protrusion width and the slot length, with no direct relationship to other parameters. To investigate the effect of the protrusion width and slot length on the stuck situation, a series of shaped seed filling clips with varying protrusion widths and slot lengths were designed for bench testing. The mean measured width of the corn seeds was 9 mm. When the seed width is slightly larger than the narrow side of the clamping slot, the flexible protrusion compresses the seed, resulting in slight deformation and effective seed filling. Therefore, the protrusion width was set to 2 mm, 3 mm, and 4 mm. The average length of the corn seeds was measured to be 10 mm. When the seed length is shorter than the clamping slot length, the clip can still clamp multiple seeds after securing one, causing multiple seeding. Therefore, the clamping slot length was set to be slightly shorter than the average length of the corn seed, with lengths of 9 mm, 10 mm, and 11 mm. Other parameters were based on reference literature. The experimental devices are shown in Fig. 10, and the results are presented in Table 2.

In Table 2, it can be seen that when the protrusion width is 3 mm, the seed filling clip can stably clamp corn seeds. Conversely, when the clamping slot length is 11 mm, the seed filling clip successfully holds only one corn seed. In order to ensure that the L-type seed filling clip does not undergo significant deformation during the seed collection process, ABS material was selected for the main body of the clip, while the flexible protrusion was made of TPU material with a Shore hardness of 90 A. The L-type seed filling clip was manufactured using 3D printing technology, with the two materials bonded together. The primary objective of incorporating the flexible protrusion was to enhance the durability of the seed filling clip, as opposed to directly impacting the seed planting qualification rate. To expedite the simulation process, the simulation settings were configured to utilise solely ABS material parameters.

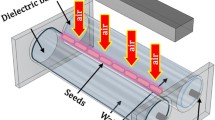

Flexible construction of Co simulation model on the DEM-MBD

The 3D model of the precision seed metering device was constructed using SolidWorks (Version 2022 SP5.0) software, and a simplified model was imported into RecurDyn. EDEM (Version 2023.0) was connected to RecurDyn (Version V9R2) via the wall interface module, and the fast filling particles function in EDEM was utilised to obtain a multi spherical discrete element model of corn seeds. The co-simulation model is shown in Fig. 11. The field working speed of the tractor was set between 1 km/h and 5 km/h, resulting in a calculated rotational speed for the precision seed metering device of between 13.26 rpm and 66.31 rpm. A driving function, step (0, 0, 1, a), was added in RecurDyn (Version V9R2). At 0 s, the precision seed metering device’s rotational speed was set to 0, and after 1 s of acceleration, the rotational speeds were set to 20, 50, 70 rpm. There was no adhesion between the corn seeds and the seed metering device, which necessitated the implementation of the Hertz-Mindlin’s nonslip model. The material of the precision seed metering device was set as Acrylonitrile Butadiene Styrene (ABS), the contact parameters between particles and core components were, as shown in Table 3. In the simulation experiment, the EDEM (Version 2023.0) particle factory was set to generate 500 seeds at 1000 seeds s-1, with a total time of 0.5s. The total simulation time was set to 11s, with the first 1s allocated for the precision seed metering device to reach stable seeding.

Results and discussion

Simulation of seeding horse tooth type seeds

To investigate the influence of the shape and dimensions of the Horse tooth type corn seeds on the structural parameters of the seed filling clip, a seeding simulation of the Horse tooth type seed was conducted using a single seed. EDEM (Version 2023.0) software was used to analyse the factors affecting seeding performance and to optimise the structural parameters of the seed filling clip. The relationship between the optimal parameters of the seed filling clip and the size of corn seeds is shown in Eq. 122.

First, based on Eq. 1 and Table 1, the seed filling clip was designed and subjected to simulation testing. The simulation results indicated that when the protrusion width was set to 5 mm, the corn seeds could not be properly guided into the clamping slot, failing to meet the seeding performance requirements. The primary cause of the seed missing was the excessive width of the protrusion, resulting in an effective clamping slot width that was significantly less than 8 mm.

Where w is the thickness of corn seed, and a is the length of corn seed, and b is the width of corn seed. To ascertain the optimal protrusion width, seed filling clips with varying protrusion widths were designed at 0.5 mm intervals and subjected to simulation testing. The impact of the corn seed posture during the seed filling stage on seeding performance was analysed with EDEM (Version 2023.0) software. To study the effect of seeding speed on the filling posture of corn seeds, the speed of the precision seed metering device was set to 20 rpm, 50 rpm, and 70 rpm. The filling posture of the seeds during the seed filling stage was observed and analysed, and some of the simulation results were extracted, as shown in Fig. 12.

As demonstrated in Fig. 12, at varying seeding speeds, the corn seeds near the seed guide slot primarily adopt a semi flat or flat posture, as shown in Fig. 12(a) and (b). Upon attaining a velocity of 70 rpm, it has been observed that on sporadic occasions, a pair of corn seeds find themselves entering the clamping slot in a lateral alignment through the seed guide slot. This phenomenon gives rise to a corn competition for position, resulting in an upright posture, as shown in Fig. 12(c). When this competition occurs, the two seeds make contact with the clamping slot, resulting in a deviation in the force direction, making it difficult for the corn seeds to maintain a stable posture. Consequently, the lower corn seed driven by friction enters the clamping slot, while the upper corn seed is blocked by the protrusion and falls back into the seed-filling area. In the context of the competition scenario, the lower corn seed was selected for analysis. A force analysis was conducted, as shown in Fig. 13. The force equilibrium equation for the corn seed is given as follows:

In this context, G represents gravity, and f1 is the static friction force exerted by the upper seed on the lower seed, and f2 is the dynamic friction force exerted by the precision seed metering device on the seed, and N1 is the normal force exerted by the upper seed on the lower seed, and N2 is the support force from the seed metering device on the seed, and Fr is the centripetal force acting on the seed.

In the presence of a torque, the corn seed rotates within the clamping slot, eventually settling into a flat or semi-flat posture under the influence of the torque. By the end of the seed filling stage, the corn seed under pressure exerted by the seed filling clip further adjusts to a flat posture. Consequently, regardless of the seeding speed, the clamping posture of the corn seeds remains generally consistent, primarily displaying a flat orientation. In a few cases, multiple small corn seeds may simultaneously enter the seed filling clip and pile up, resulting in other filling postures.

As demonstrated in Fig. 14, the simulation results show that when the protrusion width exceeds 4 mm, the missing rate is relatively high at varying seeding speeds. The primary cause of the seed missing is that when corn seeds enter the seed filling clip in a flat posture, corn seeds become stuck at the entrance of the clamping slot, thereby hindering their unobstructed descent to the bottom of the slot. The force equilibrium equation of the corn seed is as follows:

Where, G represents gravity, and f1 is the static friction force exerted by the seed filling clip on the seed, and f2 is the dynamic friction force exerted by the precision seed metering device on the seed, and N1 is the pressure from the seed filling clip on the seed, and N2 is the support force from the seed metering device, and Fr is the centripetal force acting on the seed.

When the support and friction forces exerted on the corn seed are large, the resultant force directed into the clamping slot is rendered zero. This phenomenon consequently leads to the obstruction of the corn seed, thereby impeding its entry into the slot smoothly. As a result, it is eventually removed during the seed clearing process.

As the protrusion width decreases, the force analysis of a flat positioned corn seed is shown in Fig. 15. The force equilibrium equation of the corn seed is as Eq. 4. At this point, the component of the support force on the corn seed in the direction of the clamping slot is greater than the friction force, resulting in a net force greater than zero. The issue of seed blockage in Fig. 13 is resolved, and the missing rate is significantly reduced. As the protrusion width decreases, the filling rate of multiple seeds gradually increases, leading to an increase in the multiple rate, as shown in Fig. 16. The simulation results are shown in Fig. 17.

As demonstrated in Fig. 17, the simulation results indicate that the seeding performance remains consistent across a range of seeding speeds. When the protrusion width is set to 3 mm, the seeding performance is optimal, with a qualification rate of 92.19%, a multiple rate of 3.76%, and a missing rate of 4.05%.

The clamping slot length was set to 10 mm, and seed filling clips with varying clamping slot lengths at 1 mm intervals, were designed for simulation tests at different seeding speeds to determine the optimal clamping slot length. When the clamping slot length is too short, the length of the corn seed exceeds that of the clamping slot. When the corn seed enters the clamping slot in a flat posture, it cannot be fully enclosed by the seed filling clip, as shown in Fig. 18.

As the corn seed is compressed into the bottom of the slot, it experiences increased support and friction forces from the seed filling clip, resulting in a net force of zero in the filling direction. The seed filling clip then closes, clamping the corn seed in place. When the clamping slot length is too short, the net force exerted on the corn seed is in the opposite direction to the filling direction. This results in the clamped corn seed remaining unstable and being easily removed during the seed clearing process, leading to a higher missing rate. As the clamping slot length increases, the issue of seed missing is improved. However, when the clamping slot length approaches 1.6 times the length of the corn seed, multiple seeds may be clamped simultaneously, causing the multiple rate to rise, as shown in Fig. 19. The simulation results are illustrated in Fig. 20.

From Fig. 19, when the clamping slot length is set to 12 mm, the qualification rate under different seeding speeds is 93.31%, a multiple rate of 3.21%, a missing rate of 3.48%. indicating that the seeding performance of the device is good.

Simulation of seeding spheroid seeds

To investigate the influence of the shape and dimensions of spheroid type corn seeds on the structural parameters of the seed filling clip, a simulation was conducted using a single seed type. EDEM (Version 2023.0) software was used to analyse the factors affecting seeding performance and to optimise the structural parameters of the seed filling clip. The optimal structural parameters of the seed filling clip designed for Horse tooth teach corn seeds were used as a reference. Then, seed filling clips with varying protrusion widths were designed at 0.5 mm intervals. To study the effect of seeding speed on the clamping posture of corn seeds, the speed of the precision seed metering device was set to 20 rpm, 50 rpm, and 70 rpm. The simulation results indicated that at different seeding speeds, the seeds near the seed guide slot exhibited upright, side lying, and flat postures, as shown in Fig. 21.

Upon contact between the corn seed and the seed guide slot, the contact area is found to be relatively small, thereby hindering the seed’s ability to maintain a stable posture. In the presence of inter seed interactions and the support force from the seed filling clip, a rotational torque and a force directed towards the clamping slot are generated, as shown in Fig. 22. The force analysis equation for the corn seed is as follows:

In the simulation process, when the protrusion width exceeds 4 mm, the missing rate is high across different seeding speeds. The main reason for this issue is that when corn seeds enter the clamping slot in a rotating posture, they become stuck in the slot’s entrance. In this situation, as shown in Fig. 23, the force conditions are similar to those of the Horse tooth type seeds. As a result, the corn seeds are not properly clamped in the slot and are subsequently removed during the seed clearing process. When the protrusion width is reduced to 3.5 mm, the corn seeds can correctly enter the clamping slot, and the missing rate gradually decreases. As the corn seed fills the clamping slot, the flexible protrusion undergoes slight deformation, providing support and ensuring the seed is securely held. As the protrusion width continues to decrease, the width of the clamping slot increases, but the effective filling width of the slot does not exceed twice the seed thickness. Therefore, the slot can only accommodate a single corn seed. However, due to inter seed interactions during seeding and insufficient clearing of seeds, instances of multiple seeding continue to occur, contributing to the multiple rate.

As demonstrated in Fig. 24, the simulation results indicate that seeding performance remains consistent across different seeding speeds. When the protrusion width is set to 2.5 mm, the seeding performance is good, with a qualification rate of 91.56%, a multiple rate of 4.36%, and a missing rate of 4.08%.

The clamping slot length was set to 10 mm, and seed filling clips with varying slot lengths at 1 mm intervals were designed. Simulation tests were conducted on these different seed filling clips to determine the optimal clamping slot length. When the clamping slot length is too short, the seed width exceeds the vertical length of the clamping slot when it is open. In this scenario, upon the insertion of the corn seed into the clamping slot and its subsequent clamping, the contact point with the slot is located at the rear of the seed, as shown in Fig. 25. Under the pressure exerted by the clamping slot, the corn seed experiences a force directed away from the seed filling clip, causing instability. As a result, the seed is removed during the seed clearing process, leading to a higher missing rate.

When the clamping slot length is set to 11 mm, the missing rate is significantly reduced, as shown in Fig. 26. At this length, the force contact point when the corn seed is clamped is located at the front of the seed, altering the direction of the resultant force. The force analysis equation for the corn seed is similar to that of a correctly clamped Horse tooth type seed. The resultant force acting on the corn seed, comprising the support force and friction force from the clamping slot, is zero, thus placing the corn seed in a stable state. As the length of the clamping slot increases, the effective clamping length also increases. However, the effective clamping length does not exceed 1.6 times the thickness of the seed, thus allowing the slot to accommodate only a single corn seed. N Nonetheless, due to inter-seed interactions within the seed population, size variability among seeds, and insufficient clearing during the seeding process, instances of multiple seeding still occur, contributing to the multiple rate.

As demonstrated in Fig. 27, the simulation results indicate that seeding performance is similar across different seeding speeds. When the clamping slot length is set to 11 mm, the seeding performance is good, with a qualification rate of 92.71%, a multiple rate of 3.49%, and a missing rate of 3.8%.

Simulation of seeding Spherocone type seeds

To investigate the influence of the shape and dimensions of spherocone type corn seeds on the structural parameters of the seed filling clip, a simulation was conducted using a single seed type. EDEM software was used to analyse the factors affecting the seeding performance of the precision seed metering device, and to optimise the structural parameters of the seed filling clip. The head of the spherocone type corn seed is similar to that of spheroid seed, while its length falls within the same range as horse tooth type seeds. Therefore, the optimal structural parameters of the seed filling clips designed for horse tooth type and spheroid corn seeds were used as references, and seed filling clips with varying protrusion widths at 0.5 mm intervals were designed. To study the effect of speed on the clamping posture of spherocone type corn seeds, the seeding speeds were set to 20 rpm, 50 rpm, and 70 rpm. The filling posture of the corn seeds during the seed filling stage was observed and analysed, and some simulation results were extracted, as shown in Fig. 28.

The simulation results indicate that at different seeding speeds, the corn seeds directed towards the seed guide slot predominantly adopt a flat posture, as shown in Fig. 28(a) and (b). In a few instances, two corn seeds enter the seed guide slot side by side, leading to competition for position, as illustrated in Fig. 28(c). When such competition occurs, the two corn seeds may become locked, causing both to simultaneously enter the seed filling space, resulting in multiple rate. To further analyse this competition scenario, the two competing corn seeds are analysed under force to examine their relationship, as shown in Fig. 29. The force equilibrium equations for each of the two corn seeds are as follows:

Where G represents gravity, and f1 is the static friction force between the seed filling clip and the seeds, and f2 is the static friction force between the lower and upper seeds, and N1 is the pressure exerted by the seed filling clip on the seeds, and N2 is the support force exerted by the precision seed metering device, and Fr is the centripetal force acting on the seeds.

When corn seed competition for position occurs, the two corn seeds remain relatively stationary, reaching a “mutual locking” equilibrium state. In this state, both seeds are unlikely to fall out, leading to multiple rate. By adjusting the protrusion width of the seed filling clip, the force equilibrium between the competing seeds can be disrupted. This adjustment alters the inter seed friction force, breaking the critical threshold and causing relative sliding, thereby reducing the occurrence of competition for position. The simulation results show that when the protrusion width is set to 3.5 mm, the competition issue is improved. At this width, the upper corn seed, when filling into the clamping slot, is obstructed by the protrusion, disrupting the force equilibrium, and it slides out of the slot due to inter seed interaction. Meanwhile, the lower corn seed, driven by friction and inter seed forces, enters the clamping slot and completes the seeding process. The force conditions for the corn seeds in this scenario are similar to those of spheroid type corn seeds. However, due to the uneven inter seed forces and size distribution during seeding, corn seed competition for position still occurs among the corn seeds. The simulation results are shown in Fig. 30. The results indicate that the seeding performance varies at different seeding speeds. When the protrusion width is set to 3 mm and the seeding speed is 50 rpm, the seeding performance is optimal, with a qualification rate of 91.52%, a multiple rate of 4.28%, and a missing rate of 4.28%.

The length of spherocone type corn seeds is similar to that of horse tooth type corn seeds. Therefore, using the optimal structural parameters of the seed filling clip designed for horse tooth type seeds as a reference, the clamping slot length was set to 14 mm, and various slot lengths were designed at 1 mm intervals. Single seed type simulation tests were conducted to determine the optimal clamping slot length. Given the similarity in length and shape between the two types of corn seeds, their postures during the seeding process are also similar. The simulation principles for determining the clamping slot length are consistent for both types of corn seeds. The simulation results are shown in Fig. 31. When the clamping slot length is set to 13 mm, the seeding performance is optimal, with a qualification rate of 93.02%, a multiple rate of 3.38%, and a missing rate of 3.6%.

Quadratic regression equation

Experimental design

The impact of graded seeds on seeding performance, the width of the flexible protrusion (w), the length of the clamping slot (l), and the operating speed of the seed metering device (v) were selected as the test factors for the response surface optimisation. According to the GB/T6973 2005 standard, the qualification.

n rate (y1), the multiple seeding rate (y2), and the missed seeding rate (y3) were used as experimental indicators23. The factor codes of experiment shown in Table 4. For each test group, 100 corn seeds were counted after the seeding device had stabilized, and each experiment was repeated three times.

Analysis of experimental results

The results are shown in Table 5. The significance analysis of the experimental result on are presented in Table 6.

From Table 5, the regression models for the qualification rate, multiple rate, and missing rate are all highly significant (P ≤ 0.01), while the lack of fit terms are not significant (P > 0.05), indicating that the regression models have a high degree of fit. Additionally, all models have an R2 value greater than 0.94, demonstrating that the models can explain over 94% of the variation in the evaluation indicators.

For the qualification rate (Y1), the factors X1、X2、X3、X1 X3、X12、X22、X32have a highly significant effect. For the multiple rate (Y2), the factors X1、X2、X3、X1 X3、X12、X22、X32 also have a highly significant effect. For the missing rate (Y3), the factors X3、X12、X22、X32 show a highly significant impact. After removing the non significant terms, the quadratic are as follows:

To visually analyses the interactive effects of the factors on each evaluation indicator, response surfaces with significant interactions were plotted, as shown in Fig. 32.

By observing the movement pattern of corn seeds during the simulation and combining this with the response surfaces, it can be seen that as the protrusion width increases, the qualification rate initially increases and then decreases, the multiple rate gradually decreases, and the missing rate gradually increases. As the clamping slot length increases, the qualification rate also initially increases and then decreases, the multiple rate gradually increases, and the missing rate gradually decreases.

To determine the optimal structural parameters of the seed filling clip, an optimization process was conducted with the objective of maximizing the qualification rate while minimizing the missing and multiple rates. The optimization function is as follows:

Through analysis and calculation, the optimal parameter combination was deter-mined as follows protrusion width of 2.94 mm, clamping slot length of 12.70 mm, and seeding speed of 45.5 rpm. Under these conditions, the qualification rate is 93.43%, the multiple rate is 3.42%, and the missing rate is 3.14%.

Equipment testing

The simulation test results indicate that the shape and size of seeds influence the structural parameters of the seed filling clip., It has been demonstrated that the high speed filling postures of seeds remain generally consistent at different seeding speeds. Spherocone and Horse tooth type corn seeds have more complex shapes and structures, typically enter the slot in a flat or semi flat posture during filling. In contrast, spherical seeds, being simpler in shape and structure, primarily enter the slot in a flat posture. The filling posture of corn seeds directly affects the performance of the seed filling clip. Therefore, the optimal structural parameters of the seed filling clip need to be designed and analysed based on the seed filling posture and force conditions. In the context of the utilisation of horse tooth type or spherocone corn seeds for the purpose of seeding, it has been observed that the efficacy of the process is found to be comparatively deficient. Conversely, the employment of spheroid seeds has been demonstrated to yield a superior outcome with respect to seeding performance. This observation serves to underscore the notion that the process of seed grading exerts a substantial influence on the efficiency of seeding.

In order to verify the effectiveness of the optimal structural parameters of the seed filling clip, inserts with the optimal slot shape were manufactured based on the simulation results. Furthermore, equipment testing was conducted. This testing consisted of a seeding test bench, a clip type precision seed metering device, a high speed camera, and a high performance computer. The clip type precision seed metering device was driven by a motor, as shown in Fig. 33. The corn seeds utilised for the testing process were Zhengdan 958 corn seeds, which were graded, as shown in Fig. 34. During the test, the plant spacing was set to 250 mm, and the rotation speed of the seeding disc was set to 45 rpm. The seed metering device contained seven slots.

A comparison of the simulation results with the experimental results revealed that the seed filling clip demonstrated optimal performance when utilised with spheroid corn seeds, with subsequent effectiveness observed in spherocone and horse tooth type seeds. The seeding performance indicators derived from the experimental findings exhibited lower values in comparison to those obtained from the simulation test, as illustrated in Table 7. The analysis of the results revealed that the seed dimensions used in the simulation test were average and simplified, whereas the Zhengdan 958 corn seeds used in the experiment had shapes and sizes consistent with actual field seeding conditions. Therefore, the results from the two tests were not entirely identical. Additionally, manufacturing errors in the precision seed metering device may have influenced the experimental results, with a deviation between the two tests of less than 1.4%. Consequently, the experimental results confirm the validity of the optimal structural parameters of the seed filling clip.

Conclusion

In this paper, a roller-type clip precision seed metering device was designed to improve the precision and stability of seed placement. The structure and working principles of the device were explained, with the seed filling clip being parametrically designed. Mechanical and dynamic simulations using DEM-MBD were conducted to identify the factors influencing seeding performance. The study also included grading corn seeds, revealing its significant impact on seeding performance. Additionally, the clamping posture of seeds was consistent at varying seeding speeds, which directly affected the performance of the seed filling clip. As a result, the structural parameters of the clip should be analyzed and designed based on the seed’s clamping posture. The main conclusions are as follows:

-

1.

A quadratic orthogonal rotational experiment was conducted, with the protrusion width of the seed filling clip, the length of the clamping slot, and the seed speed serving as test factors. The qualification rate, multiple seeding rate, and missing seeds rate were used as evaluation indicators. The simulation parameters were optimised, yielding an optimal parameter combination of a protrusion width of 2.94 mm, a clamping slot length of 12.70 mm, and a seeding speed of 45.5 rpm. Under these conditions, the qualification rate was 93.43%, the multiple seeds rate was 3.42%, and the missing seeds rate was 3.14%. Subsequent experimental bench conducted with the optimal parameter combination showed that the deviation between the seeding performance in the experiment and the simulation was 1.4%, validating the effectiveness of the optimal structural parameters of the seed filling clip.

-

2.

Future research should aim to address these limitations through a more comprehensive evaluation of the device in real-world conditions. One important area of future investigation is the incorporation of field vibrations and environmental variability into the simulation and testing scenarios. Field conditions, such as vibrations caused by uneven terrain, varying soil compositions, and machinery operation, could significantly impact the performance and accuracy of the device. By simulating and analyzing these conditions, researchers could refine the device’s design and optimize parameters to ensure that it functions reliably and effectively in diverse agricultural environments. This step would not only strengthen the robustness of the device under practical conditions but also improve its applicability to a wider range of farming scenarios.

-

3.

Another essential aspect for future research is the study of user-centric factors, such as operator ergonomics, ease of use, and device safety. While this study primarily focuses on technical performance metrics, such as seeding accuracy and seed protection, the practical adoption of the device in agricultural operations will heavily depend on how intuitive and safe it is for users to operate. Addressing ergonomic considerations, such as reducing operator strain and ensuring the device is easy to control and adjust, would significantly improve its acceptance among farmers. Furthermore, prioritizing safety aspects, such as minimizing risks of malfunction or injury during operation, would make the device more reliable and trustworthy.

-

4.

In addition to ergonomics and safety, future research could examine the accessibility of the device for operators in different farming contexts. For example, adapting the device for use by individuals with limited technical knowledge or physical capabilities could broaden its applicability and social impact. Exploring these user-centric dimensions not only aligns with principles of human-centered engineering but also ensures the device can be integrated seamlessly into diverse agricultural systems with varying technological backgrounds and infrastructure.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

Change history

15 September 2025

The original online version of this Article was revised: The Acknowledgements section was missing in the original version of this Article. The correct Information now accompanies the original Article.

References

Zhao, X. Maize cultivation technology and extension of agricultural technology. Hebei Agricultural Mach. (16), 91–93. https://doi.org/10.15989/j.cnki.hbnjzzs.2024.16.044 (2024).

Song, J. & Li, Y. Effect of sowing date on maize growth and yield. Mod. Agric. (06), 30–32. https://doi.org/10.14070/j.cnki.15-1098.2019.06.015 (2019).

Yue, L. Analysis of maize planting technology under agricultural modernization. World Trop. Agric. Inform. 09, 101–102 (2024).

Zhou, S. & Liu, S. Application of precision sowing in maize production. Mod. Agricultural Sci. Technol. 20, 152 (2007).

Hong, L., Guo, Q. & Deng, G. The influence of the seeding device of maize seeder on the quality of precision seeding. Agricultural Mach. Qual. Superv. 39(09), 14–15 (2021).

Zhang, K. & Yi, H. Research progress in precise seeding device for maize. Agricultural Mechanization Res. 40 (07), 257–262. https://doi.org/10.13427/j.cnki.njyi.2018.07.047 (2018).

Li, D., Jin, H., Lei, D. & Ren, S. Research progress of pneumatic corn precision seed distributor in China. Mod. Agricultural Sci. Technol. 52(16), 136–138 (2023).

Wang, J., Tang, H., Zhou, W., Yang, W. & Wang, Q. Improved design and experiment on pickup finger precision seed metering device. Trans. Chin. Soc. Agricultural Mach. 46 (09), 68–76 (2015).

Wu, M., Wang, X. & Ji, H. Application status and development trend of discrete element simulation in seeding device design. Digit. Agric. Intell. Agricultural Mach. 06, 19–22 (2024).

Shi, L. et al. Study on the intercropping mechanism and seeding improvement of the cavity planter with vertical insertion using DEM-MBD coupling method. Agriculture 12, 1567. https://doi.org/10.3390/agriculture12101567 (2022).

Wu, H., Zhang, X., Shi, Z., Fu, H. & Yu, Y. Design and test of pendulum clamped corn precision seed metering device. Agric. Res. Arid Areas. 41 (06), 291–302 (2023).

Du, X. et al. Design and experiment of self-disturbance inner-filling cell wheel maize precision seed-metering device[J]. Trans. Chin. Soc. Agricultural Eng. (Transactions CSAE). 35 (13), 23–34. https://doi.org/10.11975/j.issn.1002-6819.2019.13.003 (2019).

Dong, J. et al. Development of a novel perforated type precision metering device for efficient and cleaner production of maize. J. Clean. Prod. ,Volume443,2024,140928,ISSN0959–6526 ,https://doi.org/10.1016/j.jclepro.2024.140928

Li, C. et al. Design shaped hole inserts by simulating and analyzing the high-speed filling posture of maize seed particles. Biosyst. Eng. 232, 29–50. https://doi.org/10.1016/j.biosystemseng.2023.06.008 (2023).

Xue, P. et al. Design and test of a double-curved guiding groove for a high-speed precision seed-metering device. Trans. ASABE (Am Soc. Agric. Biol. Eng). 63 (5), 1349–1360. https://doi.org/10.13031/trans.13331 (2020).

Shi, L., Zhao, W., Rao, G., Guo, J. & Wang, Z. Modeling of typically shaped corn seeds and calibration of the coefficient of rolling friction. Agronomy 13, 1573. https://doi.org/10.3390/agronomy13061573 (2023).

Mahapatra, J. et al. Flexible orifice seed metering plate to address variability in seed shape, size and orientation enhances field performance of a pneumatic planter. Discov Appl. Sci. 6, 609. https://doi.org/10.1007/s42452-024-06275-5 (2024).

Takayama, T. Vickers hardness mechanical models and thermoplastic polymer Injection-Molded products’ static friction coefficients. J. Manuf. Mater. Process. 8, 11 (2024).

Horabik, J. & Molenda, M. Parameters and contact models for DEM simulations of agricultural granular materials. Rev. Biosyst Eng. 147, 206–225 (2016).

Markauskas, D., Ramírez-Gómez, Á., Kačianauskas, R. & Zdancevičius, E. Corn grain shape approaches for DEM modelling. Compute Electron. Agric. 118, 247–258 (2015).

Sun, Y. H., Guo, J. H. & Shi, L. R. Design and parameter optimization of air Suction wheel type of seed-metering device with elastic pad for maize. Int. J. Agric. Biol. Eng. 17 (4), 116–127 (2024).

China Academy of Agricultural Mechanization Sciences. Agricultural Machinery Design Manual. China Agricultural Science and Technology Press, Beijing, China; (2007).

Standardization Administration of China. Test Methods for Precision Seeders: GB/T 6973 – 2005[S] (China Standards, 2005).

Acknowledgments

The authors acknowledge that this work was financially supported by the Fuxi Young Talent Cultivation Project of Gansu Agricultural University (Grant No. gaufx-05y02), National Natural Science Foundation of China (Grant No. 52365030), and The Science and Technology Innovation Fund of Gansu Agricultural University-Young Mentor Support Fund Project (Grant No. GAUQDFC-2024-06).

Author information

Authors and Affiliations

Contributions

Methodology, T.D., W.Z. and L.S.; investigation, H.L., T.Q., and T.D.; software, T.D. and H.L.; formal analysis, L.S. and H.L.; resources, L.S., W.Z. and B.S.; writing—originaldraft, L.S.; writing—review and editing, T.D., B.S. and L.S.; funding acquisition, L.S. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Deng, T., Zhao, W., Shi, L. et al. Analytical design and test of a clip-based precision corn seed metering device using DEM-MBD coupling. Sci Rep 15, 9349 (2025). https://doi.org/10.1038/s41598-025-92833-9

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-92833-9