Abstract

This study aimed to design, develop, and evaluate the performance of a mechanized henna harvester to mitigate the challenges associated with traditional manual harvesting. Manual henna harvesting is labor-intensive, costly, and poses health risks, necessitating mechanization. To address these issues, a prototype harvester was designed with circular saw blades for efficient cutting. Field evaluations were conducted to assess harvesting efficiency, shattering losses, and field capacity at varying forward and blade speeds. The results indicated that optimal performance was achieved with a blade speed of 1200 rpm and a forward speed of 2.1 km/h, yielding a harvesting efficiency of 86.32%, minimal shattering losses of 2.14%, and a field capacity of 0.22 ha/h. Furthermore, the mechanized harvester significantly reduced operational costs, with a cost of 277 Rs/ha, representing an 80% saving compared to traditional methods. These findings demonstrate that the developed mechanized henna harvester provides a viable solution for improving harvesting efficiency and reducing labor-related challenges, thereby offering significant economic benefits to henna farmers.

Similar content being viewed by others

Introduction

Henna (Lawsoniainermis L.) is a perennial plant with significant applications in medicine, cosmetics, and industry. Commonly known as Mehndi in India, it holds cultural importance and is widely used during social events such as weddings and festival1. Henna is harvested twice annually, in October–November and April–May. The harvesting process involves cutting branches bearing leaves close to the ground, making it a crucial yet labor-intensive operation that accounts for approximately 32% of the total cultivation cost2. Henna harvesting requires immediate attention during the harvest window due to its vulnerability to rainfall, necessitating swift operations3. Traditionally, a sharp-edge curved sickle is used alongside protective leather gloves to cut the rigid stems. This manual harvesting method demands skilled labor, induces drudgery, and poses a high risk of musculoskeletal injuries for workers4. Nawi et al.2 used Rapid Entire Body Assessment (REBA) technique to evaluate risks in working postures and movements corresponding to the harvesting tasks. It was revealed that the REBA score was recorded at the ‘very high’ risk level. Sonawane et al.5 reported that the average overall discomfort score was 6.99 which falls under the category of severe pain while the body part discomfort score for the workers was 39.73. Therefore, workers involved in henna harvesting were under extreme postural discomfort. These findings require immediate action to improve the safety and health of the workers. Consequently, the development of efficient mechanical harvesting solutions is essential to reduce labor intensity, improve productivity, and minimize costs6,7.

Research on mechanical harvesting for similar woody crops like kenaf, mulberry, cassava, and stem willow reveals key challenges due to their hard stems. Savoie et al.8 developed a cutter-baler-shredder equipped with circular saw blades operating at speeds between 10 and 118 m/s for harvesting willow stems. Lungkapin et al.9 designed a cassava stem cutting unit featuring a circular saw blade, cam mechanism, and electric motors for efficient cutting. Additionally, Dauda et al.10 evaluated a tractor-mounted kenaf harvester equipped with a rotary serrated cutting system and gathering mechanism. The majority of the harvesters developed for harvesting crops were equipped with horizontally rotating circular saw type cutting mechanisms. However, despite such advancements, no dedicated mechanical harvester for henna has been developed. In some regions like Pali district, vertical conveyor reapers have been attempted as an alternative, but excessive vibration resulted in significant leaf loss, rendering the method inefficient11. The absence of specialized henna harvesting equipment underscores a critical gap in mechanization technology for this crop. Given the economic importance of henna, there is a compelling need for the development of a dedicated mechanical harvester that can ensure efficient cutting, minimize leaf loss, and reduce labor requirements. With these considerations in mind, this study was undertaken to design and develop a prototype harvester specifically for henna crops. The prototype aims to improve harvesting efficiency, reduce physical strain on workers, and lower operational costs, ultimately contributing to the sustainable cultivation of henna in India.

Materials and methods

Physical properties of henna

Henna crop is a branching glabrous shrub-like tree that grows to a height of 2–6 meters12.Its leaves grow opposite to each other on the stem. The physical properties such as stalk diameter, plant height, and canopy diameter. of the henna plant, which are important in the design of henna harvesting system were determined.To assess the physical properties of the henna plant, a total of 40 plant samples were randomly selected from the experimental field. Measurements were recorded for plant height, canopy diameter, and stem diameter using a measuring tape and digital caliper. Moisture content was determined for 20 samples using the oven-drying method at 105 °C until a constant weight was achieved. The collected data were analyzed to compute the mean, standard deviation, minimum, median, and maximum values for each parameter.

Design and development of henna harvesting mechanism

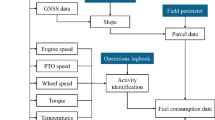

The design of the henna harvester was performed by considering physical properties of the henna crop, field condition, challenges faced during manual henna harvesting and other relevant factors. The different components of the henna harvesting mechanism are shown in Fig. 1. The detailed design of the various components of the henna harvester is explained in following sub-sections. The calculations and selections of various parameters of the machine are mentioned in the Appendix.

Design and selection of cutter head

The cutting unit is the most crucial component of the henna harvesting system. It was observed during manual harvesting that the henna stem is hardest to cut. Therefore, it was required to give special emphasis on the selection of the blade on the cutterhead of henna harvester. Numerous researchers9,13,14,15,16used horizontally rotating circular saw blades on the cutting units developed for the harvesting of woody shrub crops. It was observed that, as a shrub crop henna stems by virtue of their inertia can provide opposing force required for shear cutting by rotating circular saw blade. Therefore, circular saw blades were found suitable for the cutterhead of the henna harvesting system.

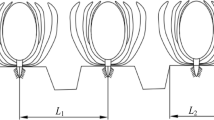

Four different types of circular blades having varying number of teeths from 40 to 100 mm at bore diameter of 25 mm and pitch circle diameter of 250 mm (Fig. 2) were tested at laboratory for the determination of power requirement by different types of blades for cutting of single henna stalk of different diameters. Blades were mounted on the 30 mm mild steel circular shafts. These shafts were placed in position with help of pedestal bearings (UCP). A frame made up of a mild steel square pipes having size of 50 × 50 × 3 mm holds and supports the entire cutter head assembly (Fig. 3). The blades are mounted at the bottom end of the vertical shaft. Tungsten carbide tipped circular saw blade having 80 teeth was found to require minimum power during cutting operation. Therefore, the blades with pitch circle diameter of 250 mm and 80 teeth were selected for henna harvester.

Design of crop guiders

Crop guider is the arrangement to direct/guide the lodged henna stems towards the circular saw cutter blades. It furnishes support for shear cutting of the henna stem also allows proper entry and guides the stems towards cutting system16. The number of crop guiders were provided according to the specific requirements of the henna crop. The spacing between two spikes was decided based on the plant to plant spacing and canopy diameter. The total width of the machine was selected such that it could cover three rows considering easy maneuverability. Two circular saw blades were used to harvest each row. Therefore, each crop divider was placed between two blades in order to provide support during cutting. The distance between each crop divider was kept at 250 mm.

Engine selection

In order to select the engine to provide necessary power to the harvesting mechanism it is required to calculate the power requirementfor different operations within mechanism.The detailed calculations of the power requirement of cutting, towing and transmission are presented in Appendix.Engine power is required to fulfil two operations i.e.,the forward movement of vehicle and the rotational movement of the cutting blades. Therefore, total power requirement of the machine was calculated using Eq. (1)

where,\({\text{P}}_{\text{total}}\) = Total power required by the harvester, kW; \({\text{P}}_{\text{tow}}\)= Power required for forward motion, kW; \({\text{P}}_{\text{cutting}}\) = Total Power required by the cutting unit of harvester, kW; \({\upeta }_{\text{transmission}}\) = Overall Power transmission efficiency

A. Power required to tow the harvesting mechanism

Towed force/rolling resistance force necessary to move the machine in forward direction was calculated by the Eq. (2) given by Wismer & Luth17

where,

TF = Towed force or rolling resistance force, N; \({C}_{n}\)= Wheel numeric = CIbd/W; CI = Cone index of soil on which machine is moving, Pa; b = Tire section width, m; d = Overall tire diameter, m; W = Load of the machine on tires.

Once the force required to tow the machine in idle situation is calculated, the power required to tow the machine is calculated by using Eq. (3)

where,

\({\text{P}}_{\text{tow}}\) = Power required for towing the machine, kW; TF = Towed force, N; \({\text{V}}_{\text{max}}\) = Maximum forward velocity, m/s

B. Power required by blades during cutting operation

Power required by the selected blade was already determined using the methodology mentioned in the previous sections. Since there are 6 blades rotating on vertical shaft, therefore, the total power required by the cutting unit is calculated by the Eq. (4)

where,

\({P}_{cutting}\)= Total Power required by the cutting unit of harvester, kW; n = Number of blades; \({P}_{blade}\)= Power required by the single blade, kW.

C. Transmission power

Transmission of power from engine to the functional components of the henna harvester was accomplished by mechanical means. Figure 3 showsthe power transmission system (Fig. 4).

Operators seat

A well-designed operator seat should allow the operator to change postures as and when required. The operator’s seat dimensions were selected on the basis of International Standards (ISO 4253:1993) and Indian Standard (IS12343:1998) (Fig. 4). Indian workers have a 5th percentile seated popliteal height of roughly 367 mm18. Furthermore, the Indian standard (IS 12,343:1998) specifies that the maximum seat height should not exceed 540 mm. Therefore, the seat height for the henna harvesting system was kept as 300 mm.The Indian Standard (IS 1243:1998) recommended a seat length should be 400 ± 50 mm18. Therefore, the seat length/depth for henna harvester’s operator seat was kept as 350 mm. The seating hip breadth of 95th percentile Indian agricultural worker is 364 mm 18. Therefore, the seat pan width of the henna harvester operator seat was kept as 380 mm (Fig. 5b).The seat backrest’s job is to support the spinal column and maintain a comfortable spinal posture. According to Gite et al.18 the 95th percentile Indian agricultural workers bi-acromial breadth is 402 mm. Therefore, seat backrest width of the harvester was kept as 400 mm (Fig. 5a). Varshney et al.19 suggested that seat backrest height should be such that it should only support the lumbar region. They also suggested to keep height in range of 125–200 mm in order to accommodate sacrum and fleshy part of buttock to firmly support lumbar region. Therefore, seat backrest height of 150 mm was found suitable for the henna harvester.According to Indian Standards (IS 12343:1998) the backrest inclination given should be such that the angle between the operator’s trunk and thigh falls within the range of 95 to 105°19. Therefore, backrest inclination of 100° was provided. The Indian Standards (IS 12343:1998) recommends back tilt of seat pan should fall within range of 3–12°. Therefore, seat pan tilt of 6° was provided (Fig. 5c).

Wheels

The henna harvester system has four pneumatic wheels viz. two rear and two front wheels. The rear wheels were powered while the front wheels were towed. The pneumatic wheels are available in two variants i.e. radial ply and bias ply. Although, the radial ply tires do have much better tractive performance than the bias ply tires20, which was not required in case of henna harvester since, it was not designed for pulling21. Therefore, bias ply tires were preferred over radial ply tires for the henna harvester. The ground clearance necessary for henna harvesters is estimated to be equivalent to that required for power tillers. As a result, common tire sizes available for small tractors were considered for tire selection in henna harvesting mechanism. According to International Standards (IS 13154:1991) tire sizes 5–14 (Sectional width 5 inches and Rim diameter 14 inches)tire were selected (Table 1)which were commercially available for power tillers.

Other important components of the henna harvesting mechanism

The other important components of the henna harvesting mechanism such as frame, chassis, wheel base, steering wheel height etc. are explained in following subsections.

A. Main frame

The main frame served as the basis for connecting all other components of the mechanism. It was constructed from 3 mm thick mild steel sheet. The overall dimension of the main frame was 1640 × 1040 × 70 mm. The length of the main frame was chosen by considering the minimum space requirements in order to accommodate all of the rear wheel drive components.

B. Wheel base and track width

The wheel base and track width of the developed system was 1120 and 1330 mm respectively. The wider track width gives better lateral stability to the harvester system on sharp turns22.

C. Chassis and ground clearance

The henna harvester mechanism’s chassis was constructed by joining mild steel square pipes measuring 50 × 50 × 2 mm. The ground clearance was 290 mm which was automatically achieved on the basis of overall wheel diameter.

Performance evaluation of henna harvesting system in field

The performance of the developed henna harvester was assessed in the field. The field performance was checked to assess its feasibility in accomplishment of its intended task of harvesting. The economic performance was also evaluated to check whether the developed machine is economically feasible for the end user.

The developed henna harvesting mechanism was exposed to field tests to observe its performance during actual use. Before committing to the field test the developed mechanism was checked for any errors in machine functional parts. After confirming that all machine parts were working as expected, the harvester was taken to the field to check its performance. The performance was tested at farmers field at longitude 73° 40′ 55″ East and latitude 25° 51′ 35″ north at an altitude of 289.23 min village of Sojat city, Rajasthan, India. The plot size of 10 × 25 m with three replications was selected for the performance evaluation. Ten samples of the henna stems were randomly collected from the field for the determination of moisture content. The moisture content of the henna stem was determined by keeping the samples in hot air oven at 65 °C for 72 h. The operator was given all the instructions and precautions needed to be follow during the entire testing period.

Harvesting efficiency and shattering losses

The effect of the forward speed and blade rotational speed was observed on the harvesting efficiency, shattering losses and field capacity. The machine was operated with three levels of forward speed and three levels of blade rotational speed. Forward speed levels were set at 1.5, 2.0, and 2.5 km/h, reflecting the optimal harvesting speed of tractor operated harvesters, ensuring controlled movement and minimal crop damage. Speeds below 1.5 km/h reduced field capacity, while speeds above 2.5 km/h may lowered efficiency and increased shattering losses. Blade speeds (600, 900, and 1200 rpm) were chosen based on preliminary trials to ensure effective cutting of woody henna stems. Speeds below 600 rpm resulted in incomplete cutting, whereas speeds above 1200 rpm caused excessive vibration, energy consumption, and excessive shattering loss (Sonawane et al., 2022). To ensure reliable results, three replications were performed for each combination. The experimental design of the field trial is mentioned in Table 2.

The harvesting efficiency of the henna harvester was determined based on the procedure mentioned by Kaes et al.24. In order to estimate the harvesting efficiency of developed system sub-plots of 2 × 2 m were marked at random in the plot that was previously selected for the performance evaluation. Before starting of harvester operation number of henna plant stems present in the selected area were counted and noted down.After this, harvester was allowed to operate through selected plot as per the operating conditions mentioned in Table 2. When harvesting operation was completed number of stems remaining uncut from the selected area were counted and noted down. Finally, the harvesting efficiency was calculated from the following Eq. (5)

Although no specific procedure was available to determine the shattering losses in henna harvester, the procedure adopted for the crop such as rice, soybean etc. discussed by the authors Nipa 25 and Kaes et al.24 was adopted for the determination of shattering losses during developed henna harvester operation. The same sub-plot that was used to calculate harvesting efficiency was used to calculate shattering losses. To avoid an overestimation of shattering loss, any loose green henna leaves were first removed from the designated area. The harvester was then operated as per operating conditions mentioned in the Table 2. After the run was completed the if any loose green leaves that had fallen on the selected surface area were collected weighed. The henna stems harvested from the selected area were carefully collected. Leaves from the collected stems were removed carefully and weighted. Finally, the shattering loss was calculated from the Eq. (6).

Theoretical field capacity

Theoretical field capacity (TFC) is the maximum rate of field coverage by the harvester without considering the time loss and assuming that harvester will operate at its rated width and forward speed. It is expressed in ha/h. Theoretical field capacity was calculated using Eq. (7)

where,

\(\text{TFC}\) = Theoretical field capacity, ha/h.

\(\text{S}\) = Forward speed, km/h.

W = Rated width of harvester, m

Actual/effective field capacity

Actual field capacity (AFC) is the function of the rated width of the harvester, the fraction of rated width actually utilized, forward speed, and amount of field time lost during harvesting operation. It is expressed in ha/h. The actual field capacity was determined using Eq. (8)

Total time lost is the summation of time lost during turning plus the time lost for any minor adjustments.

Field efficiency

Field efficiency (FE) is the ratio of the theoretical field capacity to the actual field capacity. It is expressed in percentage. Field efficiency was calculated from the Eq. (9)

Fuel consumption

The fuel consumed for the harvesting operation was measured at optimized forward and blade by refilling tank method26. The level of fuel in the fuel tank of tractor was maintained up to the full tank level. The precautions were taken to keep harvesting mechanism on level ground. After completion of the test run fuel was refilled to fill the tank on the level ground. The amount of fuel required to top up the tank was measured by the measuring cylinder having least count of 10 ml. The experiments were replicated five times and the fuel consumption was recorded in terms of litres per unit area.

Economic performance of the henna harvesting mechanism

The economic performance of a developed harvesting mechanism was done as per procedure suggested by the Panwar et al.27. The economic performance was estimated in terms of three economic indicators viz. net present worth (NPW), benefit cost ratio (B/C ratio) and payback period. The detailed procedure is presented below.

Net present worth (NPW)

The most straightforward discounted cash flow measure of project worth is the net present worth (NPW). The net present worth can be calculated by Eq. 10

where,

\({B}_{t}\)= Benefit got from harvesting machine each year (₹); \({C}_{t}\) = Cost of operation of harvesting machine each year (₹); \(t\) = 1, 2, ……n; \(i\) = Discounting rate.

Cost–benefit ratio

This is the ratio obtained when the present worth of the benefit stream is divided by the present worth of the cost stream. It can be calculated by using the Eq. 11

Payback period

The payback period is the length of time from the actual working of the harvesting system until the net value of the incremental production stream reaches the total amount of capital investment. It was calculated from the Eq. 12

Statstical analysis

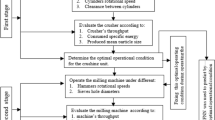

The results were interpreted through statistical analysis using response surface methodology (RSM) in centralcomposite designusing Full Factorial Completely Randomized Design. This statistical analysis was performed using the “Design Expert -13” software. The face-centered central composite design (CCD) was used to understand the significance of variables, viz. blade speed and forward speed in terms of harvesting efficiency, shattering loss and field capacity . At first, the selection of model was done based on the ANOVA table obtained from the software. The selected model was tested for adequacy. In order to test the adequacy of the model, the lack of fit test and coefficient of determination R2 were used. If the lack of fit is not significant, the model is adequate. Whereas, a higher R2 value indicates a better fit. Afterselecting the best model, experimental data were fitted to the selected model to find the effect of each independentvariable on the response and the relationship between independent variables and responses. The diagnosticsanalysis of the applied model was checked using the predicted vs actual plot. After diagnostics analysis, themodel was adequate to describe the effect of blade speed, forward speedon harvesting efficiency, shattering loss and field capacity.Thus, the 3D surface graph is plottedto find the effect of independent variables on the response at various points.

Numerical optimization

After the analysis of each response the optimization of the independent variables is done in terms of response. Numerical optimization was done by considering criteria that the shattering loss should be minimum and field capacity and harvesting efficiency should be maximum. The desirability function was used to optimize the cutter bar speed and reel speed for minimum losses.The desirability function should be such that it should follow the above condition. Thereafter, a table for possible solution is obtained with the optimize value of the independent variables and predicted response value at these optimize value of independent variables. Further, the bar graph plot for desirability of each independent variables was obtained and analyzed. Subsequently a 3D surface graph for overall desirability vs independent variables is generated to find the optimize range of independent variables. Thereafter, validation of predicted results was done.

Results and discussion

Physical properties of the harvester

Table 3 presents the summarized physical properties of the henna plant, which were essential for designing the harvester. Parameters such as plant height, canopy diameter, stem diameter, and moisture content were measured to understand the plant’s physical characteristics. These values provided crucial insights for selecting appropriate cutting mechanisms and operational settings for the harvester.

Design of henna harvester

The developed henna harvester was designed using detailed calculations provided in the Materials and Methods section, which considered crop properties and other key parameters. The design values and technical specifications of the harvester are comprehensively outlined in Table 4 and further explained in the Appendix.

Field performance of henna harvesting mechanism

The developed henna harvesting mechanism was exposed to field tests to observe its performance during actual use (Fig. 6).

The proposed henna harvesting mechanism was evaluated in order to thoroughly investigate the effect of forward speed and rotational blade speed on the harvesting mechanism’s performance. The effect of the independent parameters on the dependent parameters, namely harvesting efficiency and shattering losses, was investigated. Furthermore, the independent parameters were optimized in order to determine the optimal combination of independent parameters that yields the optimal performance from the developed mechanism.

Effect of independent parameters on the dependent parameters of henna harvester

Effect of rotational blade speed and forward speed on the dependent parameters were studied and ANOVA table is presented in Table 5. The Full Factorial Completely Randomized Design (FFCRD) was developed to investigate and statistically assess the influence of independent parameters on dependent parameters.

It was seen that the, the ANOVA table showed that all the independent parameters were highly significant at 0.01 percent level of significance. It was also found that the values of coefficient of determination (R2) were also found suitable to explain the variability (≥ 0.95) in the response. The regression model to predict the harvesting efficiency, shattering losses and field capacity was developed (Eqs. 13, 14 and 15).

The actual versus predicted plot for the harvesting efficiency, shattering losses and field capacity is depicted in Fig. 7. It showed that there is a good agreement between actual and predicted values of the all the dependent parameters. Therefore, the model was accepted for further analysis.The parameters that showed a non-significant effect were removed from further analysis.The effect of individual and interaction parameters on the dependent variables is discussed in the following subsections.

Effect of independent parameters on the harvesting efficiency

Harvesting efficiency of henna harvesting system at different forward speeds and blade speeds is given in Table 6. The average harvesting efficiency was 82.22 percent. Based on the forward speed the maximum harvesting efficiency was 89.21 percent at a forward speed of 1.5 km/h followed by 83.48 percent at a forward speed of 2 km/h and 73.96 percent at a forward speed of 2.5 km/h. As for the blade rpm, the maximum harvesting efficiency was 86.22 percent at 1200 rpm, followed by 82.67 percent at 900 rpm and 77.76 percent at 600 rpm.

It can be seen from the Table 6. that harvesting efficiency of the henna harvesting system possess two factor interaction relationship with the blade speed and forward speed of the mechanism. Individual effect of the blade speed and forward speed was highly significant (p < 0.0001) for harvesting efficiency and their interaction was also significant. The “F” value suggested that forward speed (F = 390.02) has more predominant effect on the harvesting efficiency. The graphical representation for the effect of independent parameters on harvesting efficiency is shown in Fig. 8. The R2 value varies between 0.88 and 0.99 which indicates good agreement between harvesting efficiency and independent parameters. The harvesting efficiency of the harvester increased with increase in blade speed. It was also seen that this relation between blade speed and harvesting efficiency was similiar for each level of forward speed. These results were agree with the findings of Yiljep and Mohammed28.

Kaes et al.24 also observed that increased cutting speed results in increased harvesting or cutting efficiency. The low harvesting efficiency at lower blade speeds may be due to the fact that as blade speed decreases, the number of blade tooth passing through given point also decreases, causing the sawing volume of the single tooth (i.e. the volume of stem material to be handled by a single tooth of circular saw) to increase, which results in the frictional resistance between the circular saw blade and henna stem to increasing29,30. This effect causes the henna stems to be pushed forward rather than chopped, resulting in reduced harvesting efficiency at slower blade speeds. Utkalini and Hifjur31 also discovered that at lower cutterbar speeds, the rice stems flatten and crush, resulting in substantial resistive forces from the rice stem. They did not notice this behavior at higher cutterbar speeds, and the cutting was smooth, with little resistive forces. The harvesting efficiency of the harvester tended to decrease with the decrease in the forward speed of the harvester. These results were consistent with the Verma et al.32. They found that harvesting efficiency of the tractor operated forage harvester cum chopper tended to decrease as the forward speed of the mechanism decreased. Huang et al.33 also observed that forward speed of the harvester significantly affected the cutting efficiency.

Effect of independent parameters shattering losses

Shattering losses of henna harvesting system at different forward speeds and blade speeds are given in Table 7. The average shattering losses were 4.48 percent. Based on the forward speed the maximum shattering losses was 5.26 percent at forward speed of 2.5 km/h followed by, 4.74 percent for forward speed of 2 km/h and 3.45 percent for a forward speed of 1.5 km/h. As per the blade rpm, the maximum shattering losses were 6.22 percent at 600 rpm, followed by 4.89 percent at 900 rpm and 2.33 percent at 1200 rpm.

The shattering losses incurred during operation of henna harvesting system possess two factor interaction relationship with the forward speed and blade speed. Individual effect of the blade speed and forward speed was highly significant (p < 0.0001) for shattering losses. The “F” value suggested that forward speed has more predominant effect than blade speed on the shattering losses (Table 7). The two-way interaction between blade speed and forward speed is also presented in Table 5. The interaction effect for the blade speed and forward speed was found to be highly significant (p < 0.0001) for shattering losses. The Fig. 9. depicts a graphical illustration of the influence of blade speed and forward speed on shattering losses. The R2 value varies between 0.89 and 0.99 which indicated that there is a good agreement between independent parameters and shattering losses. Shattering losses tend to diminish as blade speed increases. This relationship remains similar at all levels of forward speed. This phenomenon may be explained by the fact that during the cutting process, a tremendous amount of pressure is generated by the point contact between the saw tooth and the stem, causing ripping of stem tissues 34. However, at lower blade speeds due to the lower blade pressure and radial impact of the blade on henna stems it increases the vibrations in plant stem which causes greater shattering losses.

The shattering losses of the henna crop tend to increase with increase in the forward speed of the operation. As forward speed of the harvester increases the stem feeding rate to the circular saw blades increases proportionally. Meng et al.30 discovered that increasing the feeding rate/feeding speed significantly enhances the cutting force and corresponding stresses in the circular saw blade. Forward speed increases the radial impact force on the blade. The axial component of the force is caused by the radial impact force. The axial component of the force eventually creates vibrations in the blade. As the forward speed of the henna harvesting mechanism inceasesthe contact pressure created is insufficient to shred the stem tissues, causing the stem to push in a tangential direction. This occurs at each tooth stem contact location. This causes the stem to shake prior to being sliced. Finally, the greater stem shaking leads to larger shattering losses.

Effect of independent parameters field capacity

Field capacity of henna harvesting system at different forward speeds and blade speeds is given in Table 8. The average field capacity was 0.20 ha/h. Based on the forward speed the maximum field capacity was 0.25 ha/h at forward speed of 2.5 km/h followed by, 0.2 ha/h for forward speed of 2 km/h and 0.15 ha/h for a forward speed of 1.5 km/h. As per the blade speed, the maximum field capacity was 0.21 ha/h at 1200 rpm, followed by 0.2 ha/h at 900 rpm and 0.19 ha/h at 600 rpm. The ANOVA presented in Table 5.showed that the blade speed has highly significant (p < 0.0001) effect on the field capacity of the henna harvester. It can be seen from the Fig. 10 that field capacity of the henna harvesting system possesses linear relationship with the blade speed and forward speed of the mechanism.

The “F” value suggest that forward speed does have more predominant effect on the field capacity as compared to the blade speed. The Fig. 10.showed thatthe effect of blade speed and forward speed on the actual field capacity of the harvester. The actual field capacity of the harvester increases as the blade speed increases. This observation was in line with the result obtained by Elyamani et al.35.

Titiwa et al.36 reported that slight increase in field capacity as rotary cutter speed increased was evidenced by the fact that the faster rotational speed of the blades may have improved the harvester forward motion by avoiding blockage occurred due to the low blade speed. Atallah37 also reported similar observations about the effect of rotary cutter speed on the field capacity.

The ANOVA Table5 showed that the forward speed has highly significant effect (p < 0.0001) on the field capacity. It was observed that field capacity of the henna harvester tends to linearly increase with increase in the forward speed of operation These results bear resemblance with the results obtained by Elyamani et al.35, Titiwa et al.36 and Atallah37. The increase in forward speed increases the field capacity due to the fact that increased forward speed lowers the actual field time which automatically increases the actual field capacity of the henna harvester.

Interaction effect of independent parameters on the harvesting efficiency and shattering losses

The significant interactions (Table 5) are investigated using a three-dimensional graphical representation. The three-dimensional graphs in Fig. 11 showed the interaction effects of forward speed and blade speed on harvesting efficiency and shattering losses.

It can be seen from Fig. 11a that, the harvesting efficiency steadily rises as the blade speed increases and the forward speed lowers. The maximum harvesting efficiency was recorded at the slowest forward speed (1.5 km/h) and the fastest blade speed (1200 rpm). Huang et al.33also observed similar behavior of the blade speed and forward speed on the harvesting efficiency. Forward speed and blade speed interaction significantlyaffected the shattering losses. The Fig. 11b showedthat shattering losses increased rapidly as the forward speed increased and blade speed decreased. The lowest shattering losses was observed at highest level of blade speed (1200 rpm) and at lowest forward speed (1.5 km/h).

Numerical optimization of blade speed and forward speed of the henna harvesting system

In order to obtain optimized solution for the operating parameters certain constraints (Table 9) were applied on the responses i.e. harvesting efficiency, shattering losses and field capacity.

However, independent parameters i.e. blade speed and forward speed kept in range for the optimization. The higher values of the harvesting efficiency and field capacity were desirable while lower values of the shattering losses were desirable. Constraints were applied in such manner that optimized solution maximizes desirable responses while minimizes the undesirable values. Some of the optimized solutions suggested by the optimization procedure adopted is presented in Table 10. The fifth solution (bold) with blade speed of 1200 rpm and forward speed of 2.11 km/h was selected as optimized solution because it has lowest shattering losses (2.14 percent) and highest field capacity (0.22 ha/h). However, harvesting efficiency is not at its best value but this is acceptable as it is very close to the best solution for harvesting efficiency (86.32 percent). The selected solution has desirability 0.757 which is within acceptable range. The selected solution is shown graphically through contour graphs in Fig. 12. The optimized solution was obtained at maximum value of the blade speed (i.e. 1200 rpm) while the forward speed at optimized solution was less than the maximum value of the forward speed. Therefore, it was recommended to operate the henna harvesting system at blade speed of 1200 rpm and forward speed of 2.1 km/h to get optimum performance from the henna harvesting system.

Validation of optimized solution

The accuracy and reliability of the regression model was confirmed by comparing the actual and predicted responses at the same level of independent parameters. To achieve this, an experimental runs of developed henna harvesting system was conducted at the optimized values of blade speed (1200 rpm), forward speed (2.1 km/h). The experiment was replicated five times. The confirmation tool available in the Design Expert software (Version: 13.0) was used to validate the obtained results. The data analysis was performed by considering a 5% level of significance, and the results are presented in Table 11

It can be seen from Table 11 that data mean is well within low and high prediction interval for all dependent parameters. Therefore, it can be concluded that regression models are in position to predict the response parameters with excellent accuracy.

Theoretical field capacity

Theoretical field capacity of the henna harvester was calculated on the basis of its rated width (i.e. 1.3 m) and theoretically optimized rated speed of 2.1 km/h. Therefore, theoretical field capacity of the henna harvester mechanism was 0.273 ha/h and fiekd efficiency of 70% was observed.

Fuel consumption

The fuel consumption of the henna harvesting system measured accordance with the standard methodology. The average fuel consumption by the henna harvester was 13.81 lit/ha and 3.04 lit/h at optimized blade and forward speed.

Economic performance of developed henna harvesting system

The economic feasibility of the developed harvesting mechanism was evaluated. The analysis was made by considering the present investment and the following assumptios.

Following assumption were made to be carried out the economic analysis of the system.

-

1.

Operating life of the developed harvesting mechanism was assumed to be 10 years20.

-

2.

Repair and maintenance cost of the developed mechanism was assumed to be 10 percent of total capital cost per year.

-

3.

Operating period was considered to be 90 days in a year, as the henna harvesting is done in very short period.

-

4.

A discount rate at 10 per cent.

The results are presented in Table 12 for economic analysis of the mechanism. It was observed that the investment of the henna harvesting mechanism could be recovered in 5.04 months, which is viable and feasible. The total investment and potential profit are given in Table 12.

The benefit-cost ratio was found to be 2.31 with payback period of 0.42.

The details about the calculation of economic parameters are given in Table 12.

The economic assessment of the developed henna harvesting mechanism demonstrated its strong financial viability, with a benefit–cost ratio of 2.31 and a payback period of just 5.04 months. The system significantly reduced labor costs, achieving 80 percent savings compared to manual harvesting. This rapid return on investment highlights the mechanism’s potential to enhance profitability and promote mechanization in henna cultivation.

Conclusions

The developed mechanical henna harvester effectively mitigates the challenges associated with traditional manual harvesting by providing a more efficient, cost-effective, and labor-saving alternative. Field performance evaluation indicated that optimal operating conditions were achieved at a blade speed of 1200 rpm and a forward speed of 2.1 km/h, resulting in a harvesting efficiency of 86.32%, minimal shattering losses of 2.14%, and a field capacity of 0.22 ha/h. Overall, the developed henna harvester presents a promising solution for enhancing harvesting efficiency, reducing labor dependency, and improving worker safety. Its implementation can significantly contribute to improved profitability and sustainable agricultural practices, particularly in regions with labor shortages and time-sensitive harvesting requirements.

Limitation

The study’s performance evaluation was limited to specific field conditions, which may not reflect the variability in soil type, topography, or crop growth stages across different environments. Additionally, the prototype design may not address the challenges of mass production, including durability, maintenance, and cost efficiency in real-world applications.

Future scope

Thisresearch could explore enhancements in harvester design and broader applications for similar crops, ultimately contributing to the advancement of agricultural mechanization.

Data availability

Data used during the preparation of this manuscript is available within the article.

Change history

04 September 2025

The original online version of this Article was revised: The Funding section was incorrect in the original version of this Article. The correct information now accompanies the original Article.

References

Saksena, J. Art of Rājasthān: Henna and Floor Decorations. (1979).

Chand, K. & Jangid, B. L. Economic viability of henna in semi-arid Rajasthan. Agric. Econ. Res. Rev. 20, 137–141 (2007).

Manojkumar, P., Gamot, M., Meena, S. S. & Komatineni, E. B. Review on enhancing henna harvesting: Addressing manual labor challenges. Int. J. Agric. Ext. Soc. Dev. 7, 104–106 (2024).

Hassan, S. et al. The effect of rotary tiller blade design on soil pulverization. In AIP Conf. Proc.2030, (2018).

Sonawane, S., Mehta, A. K., Sharma, A. K., Agrwal, C. & Meena, S. S. Postural discomfort in henna harvesting workers of pali region. Multilogic Sci. 12, 135–137 (2022).

Khater, A. et al. Modification of the rice combine harvester for cutting and binding wheat crop. J. Agric. Food Res. 14, 100738 (2023).

Awad, M. et al. A combined machine for collecting and chopping rice straw. Heliyon. 8, e10412 (2022).

Savoie, P., D’Amours, L., Lavoie, F., Lechasseur, G., Joannis, H. Development of a Cutter-Shredder-Baler to Harvest Long-Stem Willow. In 2006 Portland, Oregon, July 9–12, 2006 1–9 (American Society of Agricultural and Biological Engineers, 2006). https://doi.org/10.13031/2013.20801

Lungkapin, J., Salokhe, V. M., Kalsirisilp, R. & Nakashima, H. Development of a stem cutting unit for a cassava planter. CIGR ejournal 9, 1–16 (2007).

Dauda, S., Desa, A., Abdan, K. & Jamarei, O. Performance evaluation of a tractor mounted kenaf harvesting machine. Acad. Res. Int. 4, 70–81 (2013).

Singh, A. K., Kushwaha, H. L., Singh, H. & Poonia, S. Study on effect of stem diameter. Moisture Content And Age Of Henna Plant On Cutting. 11, 9238–9241 (2019).

Shukla, M., Regar, R. L. and Jangid, B. L. Henna (Lawsoniainermis L.) Cultivation: AviableAgri-enterprise in arid fringes of western Rajasthan. Den News 14 (2012).

Eisenbies, M. et al.Development and Deployment of a Short Rotation Woody Crops Harvesting System Based on a Case New Holland Forage Harvester and SRC Woody Crop Header. State University of New York College of Environmental Science and Forestry Date vol. 8 (2014).

Gowda, R. V. P., Murthy, A. N. N. & Muniraju, E. Development of design methodology for mechanized harvesting and pruning of shrubs. Indian J. Sci. Technol. 4, 101–106 (2011).

Guerra, S. P. S., Oguri, G. & Spinelli, R. Harvesting eucalyptus energy plantations in Brazil with a modified New Holland forage harvester. Biomass Bioenerg. 86, 21–27 (2016).

Ghahraei, O., Ahmad, D., Khalina, A., Suryanto, H. & Othman, J. Cutting Tests of Kenaf Stems. Trans. ASABE. 54, 51–56 (2011).

Wismer, R. D. & Luth, H. J. Off-road traction prediction for wheeled vehicles. J. Terramechanics 10, 49–61 (1973).

Gite, L., Majumder, J., Mehta, C. & Khadatkar, A. Anthropometric and strength data of Indian agricultural workers for farm equipment design. (Central Institute of Agricultural Engineering,Bhopal, 2009).

Varshney, A. C., Tiwari, P. S., Narang, S. & Mehta, C. R. Data Book for Agricultural Machinery Design. (Central Institute of Agricultural Engineering,Bhopal, 2004).

Kepner, R. A., Bainer, R. & Barger, E. L. Principles of farm machinery. (CBS Publishers and Distributers, 1987).

Roul, A. . Farm Power Sources. in Handbook of Agricultural Engineering 6–30 (Indian Council of Agricultural Reserach, 2013).

Khorsandi, F., Ayers, P. D. & Fong, E. J. ScienceDirect evaluation of crush protection devices for agricultural all-terrain vehicles. Biosyst. Eng. https://doi.org/10.1016/j.biosystemseng.2019.04.025 (2019).

Sonawane, S., Mehta, A. K., Meena, S. S., Panwar, N. L. & Roul, A. K. Effect of blade ’ s constructional and operational features on cutting torque requirement in context of henna harvesting. J. Postharvest Technol. 10, 142–149 (2022).

Kiran, I. K. M., Awal, M. A. & Ali, M. R. Development and performance evaluation of a battery operated small-scale reaper. Agric. Eng. Int. CIGR J. 19, 217–223 (2017).

Nipa, J. F. Study on Performance Evaluation of Self-propelled Reaper. In Proceedings of the 2016 International Conference on Industrial Engineering and Operations Management Kuala Lumpur, Malaysia 1527–1536 (2016).

Mehta, K. H. & Solanki, V. A. A status report on plant pathological work carried out at Main Spices Research Station, Jagudan and Gujarat Agricultural University,. (1990).

Nalawade, R. & Panwar, N. L. Experimental investigation on biomass fired dryer for drying of agricultural products. Int. J. Ambient Energy0, 1–4 (2019).

Yiljep, Y. D. & Mohammed, U. S. Effect of knife velocity on cutting energy and efficiency during impact cutting of sorghum stalk. Agric. Eng. Int. CIGR EJournal 7, 1–10 (2005).

Gao, Y., Wang, Y., Qu, A., Kan, J. & Kang, F. Study of Sawing Parameters for Caragana korshinskii (CK) Branches. Forests 12, 1–21 (2022).

Meng, Y., Wei, J., Wei, J., Chen, H. & Cui, Y. An ANSYS/LS-DYNA simulation and experimental study of circular saw blade cutting system of mulberry cutting machine. Comput. Electron. Agric. 157, 38–48 (2019).

Utkalini, A. & Hifjur, S. Power requirement estimation for cutting paddy crop using a standard cutter bar. J. Inst. Eng. Ser. A101, 477–484 (2020).

Verma, R., Bector, V. & Singh, G. Effect of crop geometry, cutter speed and forward speed on performance characteristics of tractor operated forage harvester-cum-chopper. Agric. Eng. Today 39, 49–54 (2015).

Huang, J. et al. Design and parameters optimization for cutting-conveying mechanism of ramie combine harvester. 13, 94–103 (2020).

Wang, H., Li, Y. & Qing, Y. Current status and prospect of research on combine harvester header for rape. In OP Conference Series: Earth and Environmental Science 1–28 (2021). https://doi.org/10.1088/1755-1315/742/1/012001.

Elyamani, A., Genaidy, S. K. & Drees, A. M. Modification of combine harvester header for. Egypt. J. Agric. Res. 90, 1203–1221 (2012).

Titiwa, K. P., Gavino, H. F., Gavino, R. B. & Malamug, V. U. Development of potato (Solanum Tuberosum L .) haulm cutter. In IOP Conf. Series: Earth and Environmental Science 1–8 (2019). https://doi.org/10.1088/1755-1315/301/1/012009.

Atallah, M. M. Development of a mower for grass harvesting. J. Soil Sci. Agric. Eng. 5, 203–217 (2014).

Funding

This study was funded by the Promoting Innovations in Individuals, Start-Ups and MSMES (PRISM) scheme under the Department of Scientific and Industrial Research, Government of India.

Author information

Authors and Affiliations

Contributions

SS, and AKM designed and wrote the main draft. SS, AKM, RDN, SPS, MK, and MR analyses, write, revised the manuscript and provided comments during the writing and revised it. The authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not aplicable.

Consent for publication

Informed consent was obtained from all study participants (or their legal guardians) for the publication of identifying information and/or images in this open-access publication. Participants were made aware that their data and images may be accessible online and freely available to the public.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sonawane, S., Mehta, A.K., Nalawade, R.D. et al. Design, development and performance evaluation of henna harvester. Sci Rep 15, 13716 (2025). https://doi.org/10.1038/s41598-025-97272-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-97272-0