Abstract

The hydrocarboxylation of acrylate with carbon dioxide (CO2) have been achieved through metal-catalysis, photochemistry catalysis or electrochemistry catalysis in recent years. The hydrocarboxylation of acrylamide has rarely been studied so far, because of the electron cloud density of the carbon-carbon double bond in acrylamide molecules is lower than that of acrylates. Herein, we report an electrochemical selective hydrocarboxylation method of acrylamides with CO2. The α-carboxylation and β-carboxylation products can be obtained by adjusting the reaction conditions. The present protocol features mild conditions, good regioselectivity, broad substrare scope and high atom economy. Furthermore, detailed control experiments and DFT calculations results showed that the carboxylation at the α- and β- sites undergo different reaction processes.

Similar content being viewed by others

Introduction

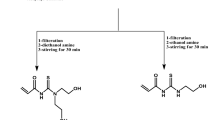

CO2 is the main component of greenhouse gases and has an important impact on climate change1. However, CO2 is also an abundant, sustainable, and non-toxic one-carbon (C1) building block that could react with olefins2,3,4,5,6,7,8,9,10,11,12,13,14, alkynes15,16,17,18, imines19,20, cyclic ethers21,22,23, halides24,25,26,27,28,29,30,31, arenes32,33,34, etc. to synthesize many types of compounds35,36. Electron-deficient alkenes do not react easily with CO2 due to the descend electron cloud density of carbon-carbon double bond37. To date, despite some hydrocarboxylation methods of electron-deficient alkenes with CO2 have been reported, the reaction substrates were mainly focus on acrylates. Mikami’s group used expensive [RhCl(cod)]2 as catalyst and highly flammable ZnEt2 as reducing agent to achieve the hydrocarboxylation of acrylate with CO2 (Fig. 1a i)38. In recent years, with the rise of green organic synthesis, organic photochemistry has developed rapidly. Yu’s lab achieved β-carboxylation of acrylates with CO2 through an electron donor-acceptor (EDA) photochemical strategy (Fig. 1a ii)39.

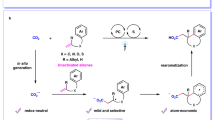

Electrochemistry, as another synthesis strategy of green chemistry, has attracted the attention of organic chemists because it avoids the need for chemical oxidation-reduction agents40,41,42,43,44,45,46,47,48. Buckly’s group successfully accomplished the hydrocarboxylation of acrylate with CO2 through electrochemistry, yielding β-carboxylation products (Fig. 1a iii)49. Unlike acrylate, the conjugation of the nitrogen atom and the carbonyl group in acrylamide molecule results in a more dispersed electron cloud around the carbon-carbon double bond, which weakens the nucleophilicity of acrylamide50. Consequently, the hydrocarboxylation of acrylamide with CO2 presents a significant challenge. Despite relevant research reports, these reactions could only be achieved through photocatalytic methods, and were limited to the β-carboxylation of acrylamide (Fig. 1b)51,52.

Based on our research foundations in electrochemical organic synthesis53,54,55,56,57,58,59, and our research interest in CO2 conversion. Herein, we report an electrochemical approach that enables the selective hydrocarboxylation of acrylamide to obtain α- and β-carboxylation products by adjusting solvents and electrolytes under mild reaction conditions (Fig. 1c).

Results and Discussion

We commenced our study using N-methyl-N-phenylmethacrylamide (1a) as the model substrate in an undivided cell under 1 atm of CO2 atmosphere (Table 1). Pleasantly, the β-carboxylation product 2a was obtained in a 70% isolated yield when a magnesium sheet was used as the anode, and TBAC was used as a supporting electrolyte in DMF at room temperature (entry 1). By substituting Mg with Al or Zn as the anode (entries 2, 3), the reaction efficiency was significantly decreased. Surprisingly, the reaction still occurred when graphite carbon was used as the anode (entry 4). This might be due to the oxidation of chloride ions at the anode. When TBAI (entry 5), TBABF4 (entry 6), TBAPF6 (entry 7), and TBAClO4 (entry 8) were employed as the supporting electrolyte, the yield of 2a was low. Several other solvents, including DMAc, NMP, DMSO, and CH3CN, were evaluated; the results were not satisfactory (entries 9-12). However, interestingly, α-carboxylation product 3a was obtained when using DMSO and CH3CN as solvents. This indicates that the solvent was crucial in determining the reaction site. Subsequently, using CH3CN as the solvent, we examined the electrochemical conditions of the α-carboxylation reaction. After replacing TBAC with other electrolytes, the yield of 3a did not increase significantly, whereas the formation of 2a was markedly reduced (entries 13-16). Notably, the use of TBAClO4 as the electrolyte led to the exclusive formation of the α-carboxylation product 3a (entry 17). The synergistic effect of TBAClO4 and CH3CN enables the selective control of the carboxylation reaction at the α position. Employing TEAClO4 as the electrolyte further improved the yield of 3a (entry 18). This might be because, during the initial stage of the reaction, the tetraethylammonium cation with lower steric hindrance is more conducive to stabilizing the carboxylate formed at the α position60. After reducing the concentration of 1a, the reaction efficiency has improved (entry 19). We speculate that the structure of compound 3a may be thermodynamically unstable compared to compound 2a. Therefore, the reaction for generating 3a might be a kinetic-controlled process, and low temperatures may be beneficial for the reaction. Based on this, we attempted to lower the reaction temperature (entries 20-22). The experimental results were in line with expectations, and the target product 3a was obtained with a yield of 70% at -10 °C (entry 21). In contrast, reducing the temperature will not increase the yield of 2a (entry 23).

With the optimal reaction conditions for the selective hydrocarboxylation of acrylamide in hand, the substrate scope was further investigated under these conditions. We first tested the range of substrates for the β-carboxylation reaction (Fig. 2). N-methyl-N-phenylmethacrylamide bearing either electron-donating or electron-withdrawing groups on the benzene ring all reacted smoothly to afford the desired products 2a-2m in 32 to 90% yields. The substrate containing naphthalene ring or tetrahydroquinoline ring was gained products 2n and 2o with the yield of 75% and 53%, respectively. N-phenylmethacrylamide with different N-substituents showed very high reactivity to afford the corresponding products 2p-2s in good to excellent yields. The acrylamide substrates containing different substituents in the olefin could also undergo the reaction smoothly and yield the corresponding target products (2t-2w). When the benzoyl group was substituted for the phenyl group, the β-carboxylation products 2x-2z were still obtained with moderate yields. The structures of products 2r and 2x were determined by X-ray crystallographic analysis.

Later, a diverse range of aryl-substituted substrates have been examined in the α-carboxylation reaction of acrylamide with CO2, and the results were summarized in Fig. 3. The substrates containing various electron-donating groups on the phenyl group of compounds 1 were more suitable for this method (3a-3g). The yields decreased modestly when the 4-position of the phenyl group was substituted with electron-withdrawing groups (3h-3l). Substrates containing 3,4-dimethyl-substituted benzene ring, naphthalene ring, or tetrahydroquinoline ring also exhibited moderate reactivity (3m-3o). Altering the nitrogen protecting group to isopropyl, cyclohexyl, or benzyl would also lead to the desired products in medium to high yields (3p-3r). To our surprise, the unprotected NH substrates were also able to produce α-carboxylation products (3s-3t), which may be used for further functionalization to synthesize other kinds of important complex molecules. When there are other substituents at the α- or β-position of the double bond, the target products could be obtained with a moderate yield (3 u, 3 v). Unfortunately, the α-phenyl and β-phenyl substituted acrylamides have not yielded the target compounds due to the influence of electronic effects. Unexpectedly, replacing benzene ring with indole ring, the β-carboxylation products (5a-5f) were detected under the conditions of method B (Fig. 4).

To demonstrate the practicability of this electrocarboxylation reaction, large-scale reactions between 1a and CO2 were conducted under the conditions of methods A and B, respectively, the results were shown in Fig. 5a. Next, various control experiments were tested in order to gain more insights into the reaction mechanism. The free radical scavengers were added into the reaction systems of the conditions A and B respectively, the hydrocarboxylation reactions were almost inhibited, which suggested that the reactions presumably adopted a radical pathway (Fig. 5b). Meanwhile, compounds 6 and 7 were observed by HRMS, which indicated the existence of α-carbon radical intermediate in method A and CO2 radical anion intermediate in method B. In addition, sodium formate was discovered in the absence of 1a through 1H NMR and 13C NMR under the reaction conditions of method A and method B respectively, the experiment results showed that CO2 could also be reduced in both method A and B (see Supporting Information S5 for more details)39.

Deuterium labeling experiments confirmed the presence of β-carboanion intermediates in the reaction pathway of method A (Fig. 5c, i and ii)8,19. And in method B, the β-site was easily deuterated in both CO2 and N2 atmospheres (Fig. 5c, iii and iv), indicating that the proton may have undergone an addition reaction with 1a prior to CO2, and water provided protons in the reaction. After that, we conducted the following experiments to investigate the source of water. We conducted experiments using a solvent dried with anhydrous sodium sulfate and found a significant decrease in the yield of 3a (Fig. 5d, i). And 3a-D was detected when using CD3CN as a solvent (Fig. 5d, ii). The above experimental results indicate that protons mainly originate from the trace water present in acetonitrile and acetonitrile itself61. Perchlorate may have facilitated the proton dissociation process of acetonitrile (Fig. S9). At the same time, the results of DFT calculations (Fig. 6) showed that the β-carboxylation product 2a would be gained whether it is 1a reduction or CO2 reduction32, and the carboxylation of α-site was not initiated by single electron reduction62, which is consistent with the results of deuterium labeling experiments.

Cyclic voltammetry experiments were conducted to observe the changes of redox profile (Fig. 7). Compared with CO262, 1a is more difficult to reduce (Fig. 7a, red), and the reduction potential of 1a did not change significantly in different solvents (see Supporting Information Fig. S6 for more details). When the solution was saturated with CO2, the profile of the reduction wave changed significantly (Fig. 7a, green), because of the reaction between the radical anion and CO26. The cyclic voltammetry test results indicate that 4a could not only be reduced (-1.73 V) but also easily oxidized (0.07 V) (Fig. 7b, blue). Therefore, indole-type compounds were detected in the reaction solution47,63. However, under the reaction conditions of Method A, no carboxylation products were observed, which might be related to the presence of multiple reduction peaks in this condition (see Supporting Information S15 and Fig. S8 for more details).

On the basis of the above mechanistic studies, the plausible reaction pathways have been proposed (Fig. 8). In method A, 1a was reduced to a radical anion (Ⅰ), which underwent nucleophilic attack to CO2 to give the carboxylic radical anion (Ⅱ), the radical intermediate (Ⅱ) was reduced through another one-electron reduction process to give the carboxylation product 2a after work-up64. The α-carboxylation process proceeded as follows: 1a and proton undergo Markovnikov’s addition, then two single electron reductions occurred, resulting in the formation of a carbon anion intermediate (Ⅴ). Subsequently, the intermediate Ⅴ was attacked by CO2 to form VI, which was then protonated to yield 3a3,65.

Conclusion

Although there have been reports on the hydrocarboxylation reaction of acrylamide with CO2, effective control over the reaction site has not yet been achieved. This study presents an effective electrochemical selective hydrocarboxylation method of acrylamide with CO2 under mild conditions. By selecting electrochemical conditions such as electrolytes and solvents, the selective carboxylation of the α- and β-positions can be easily achieved. Control experiments and DFT calculations results show that the carboxylation of the α- and β- sites follows different reaction processes. Specifically, β-carboxylation is initiated by the reduction of 1a or CO2, while α-carboxylation is initiated by the hydrogenation reduction of 1a.

Methods

Synthesis of compounds 2a-2z (general procedure)

Acrylamide (1) (0.2 mmol) and TBAC (0.2 mmol, 1.0 equiv.) were added to a 10 mL reaction tube containing a stir bar. The reaction tube is then installed with a graphite carbon cathode and Mg plate anode and evacuated and backfilled with CO2 for at least 3 times. Then dry DMF (3.0 mL) was added to the reaction mixture by syringe. The reaction mixture was electrolyzed under a constant current of 8 mA for 3.5 h at room temperature. After the electrolytic reaction, the mixture was carefully quenched with HCl (2 N, 2 mL) and extracted three times with ethyl acetate (3 × 20 mL). The combined extracts were washed with brine, and dried over anhydrous Na2SO4. The solvents were removed under reduced pressure, and the crude residue was purified by flash column chromatography to give the desired products 2a-2z.

Synthesis of compounds 3a-3v and 5a-5f (general procedure)

Acrylamide (1) (0.1 mmol) and TEAClO4 (0.2 mmol, 2.0 equiv.) were added to a 10 mL reaction tube containing a stir bar. The reaction tube is then installed with a graphite carbon cathode and Mg plate anode and evacuated and backfilled with CO2 for at least 3 times. Then dry CH3CN (3.0 mL) was added to the reaction mixture by syringe. The reaction mixture was electrolyzed under a constant current of 6 mA for 3.5 h at −10 °C. After the electrolytic reaction, the mixture was carefully quenched with HCl (2 N, 2 mL) and extracted three times with ethyl acetate (3 × 20 mL). The combined extracts were washed with brine and dried over anhydrous Na2SO4. The solvents were removed under reduced pressure, and the crude residue was purified by flash column chromatography to give the desired products 3a-3v and 5a-5f.

Data availability

The data generated in this study are provided in the Supplementary Information file. For the experimental procedures, data of NMR and HRMS analysis, and computational details, see Supplementary Information file. The X-ray crystallographic coordinates for structures reported in this study are provided Supplementary Data 1 and have been deposited at the Cambridge Crystallographic Data Centre (CCDC) under deposition numbers 2333919, 2333940, and 2367176. These data can be obtained free of charge from The Cambridge Crystallographic Data Centre via www.ccdc.cam.ac.uk/data_request/cif.

References

Do, T. N., You, C. & Kim, J. A. CO2 utilization framework for liquid fuels and chemical production: Techno-economic and environmental analysis. Energy Environ. Sci. 15, 169–184 (2021).

Meng, Q.-Y., Wang, S., Huff, G. S. & König, B. Ligand-controlled regioselective hydrocarboxylation of styrenes with CO2 by combining visible light and nickel catalysis. J. Am. Chem. Soc. 140, 3198–3201 (2018).

Zhang, W. & Lin, S. Electroreductive carbofunctionalization of alkenes with alkyl bromides via a radical-polar crossover mechanism. J. Am. Chem. Soc. 142, 20661–20670 (2020).

Qin, Y. et al. Straightforward synthesis of functionalized γ-lactams using impure CO2 stream as the carbon source. Nat. Commun. 14, 7604–7612 (2023).

Mu, X., Wu, T., Wang, H.-Y., Guo, Y.-L. & Liu, G. S. Palladium-catalyzed oxidative aryltrifluoromethylation of activated alkenes at room temperature. J. Am. Chem. Soc. 134, 878–881 (2012).

Alkayal, A. et al. Harnessing applied potential: Selective β-hydrocarboxylation of substituted olefins. J. Am. Chem. Soc. 142, 1780–1785 (2020).

Ye, J. H. et al. Visible-light-driven iron-promoted thiocarboxylation of styrenes and acrylates with CO2. Angew. Chem. Int. Ed. 56, 15416–15420 (2017).

Wang, H., Gao, Y., Zhou, C. & Li, G. Visible-light-driven reductive carboarylation of styrenes with CO2 and arylhalides. J. Am. Chem. Soc. 142, 8122–8129 (2020).

Chen, R. et al. Carboxylation of α,β-unsaturated ketones by CO2 fixation through photoelectro-chemistry. ACS Appl. Energy Mater. 3, 5813–5818 (2020).

Wang, H., Du, Y. F., Lin, M. Y., Zhang, K. & Lu, J. X. Electrochemical reduction and carboxylation of ethyl cinnamate in mecn. Chin. J. Chem. 26, 1745–1748 (2008).

Zhang, W. et al. Electroreductive dicarboxylation of unactivated skipped dienes with CO2. Angew. Chem. Int. Ed. 62, e202301892 (2023).

Xie, F. et al. Electroreductive arylcarboxylation of styrenes with CO2 and aryl halides via a radical-polar crossover mechanism. Org. Lett. 26, 4427–4432 (2024).

Zhang, B., Yi, Y., Wu, Z.-Q., Chen, C. & Xi, C. Photoredox-catalyzed dicarbofunctionalization of styrenes with amines and CO2: A convenient access to γ-amino acids. Green. Chem. 22, 5961–5965 (2020).

Yuan, P. F. et al. Deconstructive carboxylation of activated alkenes with carbon dioxide. Angew. Chem. Int. Ed., 63, e202313030 (2023).

Hou, J. et al. Visible-light-driven alkyne hydro-/carbocarboxylation using CO2 via iridium/cobalt dual catalysis for divergent heterocycle synthesis. J. Am. Chem. Soc. 140, 5257–5263 (2018).

Zhao, L., Xie, W.-J., Meng, Z.-Z., Li, H.-R. & He, L.-N. Electrochemical E-selective semireductive dicarboxylation of aryl alkynes with CO2. Org. Lett. 26, 3241–3246 (2024).

Li, C.-H., Yuan, G.-Q., Qi, C.-R. & Jiang, H.-F. Copper-catalyzed electrochemical synthesis of alkylidene lactones from carbon dioxide and 1,4-diarylbuta-1,3-diynes. Tetrahedron 69, 3135–3140 (2013).

Katayama, A., Senboku, H. & Hara, S. Aryl radical cyclization with alkyne followed by tandem carboxylation in methyl 4-tert-butylbenzoate-mediated electrochemical reduction of 2-(2-propynyloxy)bromobenzenes in the presence of carbon dioxide. Tetrahedron 72, 4626–4636 (2016).

Zhang, K., Liu, X.-F., Zhang, W.-Z., Ren, W.-M. & Lu, X.-B. Electrocarboxylation of N-acylimines with carbon dioxide: Access to substituted α-amino acids. Org. Lett. 24, 3565–3569 (2022).

Ju, T. et al. Selective and catalytic hydrocarboxylation of enamides and imines with CO2 to generate α,α-disubstituted α-amino acids. Angew. Chem. Int. Ed. 57, 13897–13901 (2018).

Wang, Y. et al. Electrocarboxylation of aryl epoxides with CO2 for the facile and selective synthesis of β-hydroxy acids. Angew. Chem. Int. Ed. 61, e202207746 (2022).

Zhang, K. et al. Direct and selective electrocarboxylation of styrene oxides with CO2 for accessing β-hydroxy acids. Angew. Chem. Int. Ed. 61, e202207660 (2022).

Yang, D. et al. Electrochemical dicarboxylation of vinyl epoxide with CO2 for the facile and selective synthesis of diacids. Angew. Chem. Int. Ed., 64, e202419702 (2025).

Wang, Y. et al. Metal-free electrochemical carboxylation of organic halides in the presence of catalytic amounts of an organomediator. Angew. Chem. Int. Ed. 61, e202210201 (2022).

Fan, Z., Yi, Y. & Xi, C. Recent advances in light-induced carboxylation of organic (pseudo)halides with CO2. Asian J. Org. Chem. 11, e202200207 (2022).

Ang, N. W. J., Oliveira, J. C. A. & Ackermann, L. Electroreductive cobalt-catalyzed carboxylation: Cross-electrophile electrocoupling with atmospheric CO2. Angew. Chem. Int. Ed. 59, 12842–12847 (2020).

Bazzi, S., Le Duc, G., Schulz, E., Gosmini, C. & Mellah, M. CO2 activation by electrogenerated divalent samarium for aryl halide carboxylation. Org. Biomol. Chem. 17, 8546–8550 (2019).

Meng, Q.-Y., Wang, S. & König, B. Carboxylation of aromatic and aliphatic bromides and triflates with CO2 by dual visible-light-nickel catalysis. Angew. Chem. Int. Ed. 56, 13426–13430 (2017).

Shimomaki, K., Murata, K., Martin, R. & Iwasawa, N. Visible-light-driven carboxylation of aryl halides by the combined use of palladium and photoredox catalysts. J. Am. Chem. Soc. 139, 9467–9470 (2017).

Sun, G.-Q. et al. Nickel-catalyzed electrochemical carboxylation of unactivated aryl and alkyl halides with CO2. Nat. Commun. 12, 7086–7095 (2021).

Yamauchi, Y., Hara, S. & Senboku, H. Synthesis of 2-aryl-3,3,3-trifluoropropanoic acids using electrochemical carboxylation of (1-bromo-2,2,2-trifluoroethyl)arenes and its application to the synthesis of β,β,β-trifluorinated non-steroidal anti-inflammatory drugs. Tetrahedron 66, 473–479 (2010).

Sun, G.-Q. et al. Electrochemical reactor dictates site selectivity in n-heteroarene carboxylations. Nature 615, 67–72 (2023).

Zhao, Z. et al. Site-selective electrochemical C—H carboxylation of arenes with CO2. Angew. Chem. Int. Ed. 62, e202214710 (2022).

Fuchs, P., Hess, U., Holst, H. H. & Lund, H. Electrochemical carboxylation of some heteroaromatic compounds. Acta Chem. Scand. B35, 185–192 (1981).

Liu, Q., Wu, L., Jackstell, R. & Beller, M. Using carbon dioxide as a building block in organic synthesis. Nat. Commun. 6, 5933–5947 (2015).

Ye, J. H., Ju, T., Huang, H., Liao, L. L. & Yu, D.-G. Radical carboxylative cyclizations and carboxylations with CO2. Acc. Chem. Res. 54, 2518–2531 (2021).

Cai, L. et al. Rh(I)-catalyzed regioselective arylcarboxylation of acrylamides with arylboronic acids and CO2. Green. Chem. 22, 7328–7332 (2020).

Kawashima, S., Aikawa, K. & Mikami, K. Rhodium-catalyzed hydrocarboxylation of olefins with carbon dioxide. Eur. J. Org. Chem. 2016, 3166–3170 (2016).

Huang, H. et al. Visible-light-driven anti-markovnikov hydrocarboxylation of acrylates and styrenes with CO2. CCS Chem. 3, 1746–1756 (2020).

Martins, G. M., Zimmer, G. C., Mendes, S. R. & Ahmed, N. Electrifying green synthesis: Recent advances in electrochemical annulation reactions. Green. Chem. 22, 4849–4870 (2020).

Bu, F. et al. Electrocatalytic reductive deuteration of arenes and heteroarenes. Nature 634, 592–599 (2024).

Chen, T. S., Long, H., Gao, Y. & Xu, H. C. Continuous flow electrochemistry enables practical and site-selective C-H oxidation. Angew. Chem. Int. Ed. 62, e202310138 (2023).

Jie, L.-H., Guo, B., Song, J. & Xu, H.-C. Organoelectrocatalysis enables direct cyclopropanation of methylene compounds. J. Am. Chem. Soc. 144, 2343–2350 (2022).

Nie, L. et al. Linear paired electrolysis enables redox-neutral (3 + 2) annulation of benzofuran with vinyldiazo compounds. J. Am. Chem. Soc. 146, 31330–31338 (2024).

Shi, S.-H., Liang, Y. & Jiao, N. Electrochemical oxidation induced selective C—C bond cleavage. Chem. Rev. 121, 485–505 (2020).

Xu, S.-S. et al. Cobalt-catalyzed electrochemical enantioselective reductive cross-coupling of organohalides. CCS Chem. 7, 245–255 (2025).

Yuan, Y. et al. Mn-catalyzed electrochemical radical cascade cyclization toward the synthesis of benzo[4,5]imidazo[2,1-a]isoquinolin-6(5H)-one derivatives. ACS Catal. 10, 6676–6681 (2020).

Luo, M. J. et al. Rhodium-catalyzed electrochemical [2+2+2] cyclotrimerization of 1,3-butadiynes toward hexasubstituted arenes. Green. Chem. 25, 8858–8862 (2023).

Sheta, A. M. et al. Selective electrosynthetic hydrocarboxylation of α,β-unsaturated esters with carbon dioxide. Angew. Chem. Int. Ed. 60, 21832–21837 (2021).

Brown, W. H., Poon, T. Introduction to organic chemistry, 6th edn. John Wiley & Sons Inc (2017).

Hendy, C. M., Smith, G. C., Xu, Z., Lian, T. & Jui, N. T. Radical chain reduction via carbon dioxide radical anion (CO2•–). J. Am. Chem. Soc. 143, 8987–8992 (2021).

Malandain, A. et al. Carbon dioxide radical anion by photoinduced equilibration between formate salts and [11C, 13C, 14C]CO2: Application to carbon isotope radiolabeling. J. Am. Chem. Soc. 145, 16760–16770 (2023).

Wei, Z. X. et al. Electrochemical oxidative dehydrogenation of hydrosilanes to generate silyl radicals: An efficient method for the construction of Si—O/Si—Si bonds utilizing a recyclable ionic liquid catalyst. Green. Chem. 26, 10189–10195 (2024).

Wang, R. J. et al. Versatile electrooxidative amino- and oxyselenation of alkenes. Green. Chem. 25, 3925–3930 (2023).

Yue, Y. C. et al. Electrochemical synthesis of selenyl imidazo[2,1-b]thiazinones three-component reactions. Org. Chem. Front. 11, 5813–5819 (2024).

Zhang, P. et al. Electrochemical synthesis of α-thiocyanated/methoxylated ketones using enol acetates. J. Org. Chem. 88, 16122–16131 (2023).

Dong, X., Wang, R., Jin, W. & Liu, C. Electrochemical oxidative dehydrogenative phosphorylation of N-heterocycles with P(O) —H compounds in imidazolium-based ionic liquid. Org. Lett. 22, 3062–3066 (2020).

Wang, J. et al. Electrooxidative Hofmann rearrangement of phthalimides to access anthranilate derivatives. ACS Omega 8, 35167–35172 (2023).

Wang, R. G. et al. Electrochemical oxidative phosphorylations of glycine derivatives with R2P(O)—H-containing compounds via C(sp3)—H functionalisation. Adv. Synth. Catal. 365, 900–905 (2023).

Wang, H., Xu, X.-M., Lan, Y.-C., Wang, H.-M. & Lu, J.-X. Electrocarboxylation of haloacetophenones at silver electrode. Tetrahedron 70, 1140–1143 (2014).

Zhang, S. et al. Electrochemically generated carbanions enable isomerizing allylation and allenylation of aldehydes with alkenes and alkynes. J. Am. Chem. Soc. 145, 14143–14154 (2023).

You, Y. et al. Electrochemical dearomative dicarboxylation of heterocycles with highly negative reduction potentials. J. Am. Chem. Soc. 144, 3685–3695 (2022).

Gaydou, M., Moragas, T., Juliá-Hernández, F. & Martin, R. Site-selective catalytic carboxylation of unsaturated hydrocarbons with CO2 and water. J. Am. Chem. Soc. 139, 12161–12164 (2017).

Sheta, A. M. et al. Selective electrosynthetic hydrocarboxylationof α,β-unsaturated esters with carbon dioxide. Angew. Chem. Int. Ed. 60, 21832–21837 (2021).

Liu, Z., Ji, X., Zhao, F., Deng, G. & Huang, H. Metal-free photoredox intramolecular cyclization of N-aryl acrylamides. Catalysts 13, 1007–1020 (2023).

Acknowledgements

This research was supported by the Key Program of Natural Science Foundation of Xinjiang Uygur Autonomous Region (2022D01D06), the Xinjiang University Excellent Doctoral Innovation Project (XJU2024BS059), the Shanghai Cooperation Organization Science and Technology Partnership Program and International Science and Technology Cooperation Program (2022E01042), the Tianshan Talents Program for Leading Talents in Science and Technology Innovation (2022TSYCLJ0016), the National Natural Science Foundation of China (22361044, and 22201241), the Tianchi Talents Introduction Program (5105240151a), and the Hexi University President Fund Youth Research Project (QN2022005).

Author information

Authors and Affiliations

Contributions

X.L. Zhao, H.M. Chen, L. Zhang, S. C. Wang, and Y. H. Zhang designed and performed synthetic experiments, analyzed experimental data. F. Xue and B. Wang carried out the NMR analysis. Y. Xia, S. F. Wu, and W. W. Jin analyzed Cyclic voltammetry test results. X.L. Zhao, Y. H. Zhang, Z. R. Chen, and C. J. Liu drafted the manuscript with contributions from all authors. All authors participated in the discussions.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Chemistry thanks the anonymous reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhao, X., Chen, Z., Xue, F. et al. Electrochemical selective hydrocarboxylation of acrylamides with carbon dioxide for precise control of α- and β-carboxylation. Commun Chem 9, 21 (2026). https://doi.org/10.1038/s42004-025-01828-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s42004-025-01828-0