Abstract

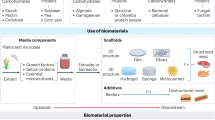

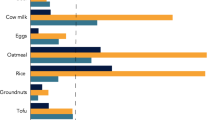

Food processing often overlooks nature’s complexity, favouring purified raw materials. This excessive purification fosters unsustainable practices and diminishes the taste and nutritional quality of food. Given the current global environmental and health crises, we propose three food innovation principles to embrace the complexity of plant raw materials: (1) leveraging the inherent chemical, physical, biological and nutritional potential of raw materials; (2) applying robust food processes that cope with raw material complexity; and (3) designing food products from field to colon. Adhering to these principles will allow the development of technologies that could transform raw materials into healthier, more sustainable food products.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Willett, W. et al. Food in the anthropocene: the EAT–Lancet commission on healthy diets from sustainable food systems. Lancet 393, 447–492 (2019).

Dhir, B. & Singla, N. Consumption pattern and health implications of convenience foods: a practical review. Curr. J. Appl. Sci. Technol. 38, 1–9 (2020).

Mezzenga, R., Schurtenberger, P., Burbidge, A. & Michel, M. Understanding foods as soft materials. Nat. Mater. 4, 729–740 (2005).

Borges, S., Brassesco, M. E., Cunha, S. A., Coscueta, E. R. & Pintado, M. in Enzymatic Processes for Food Valorization (eds Chávez González, M. L. et al.) 265–284 (Elsevier, 2024).

Pouliot, Y., Conway, V. & Leclerc, P. L. in Food Processing: Principles and Applications (eds Clark, S. et al.) 33–60 (Wiley Blackwell, 2014).

Fotschki, J., Ogrodowczyk, A. M., Wróblewska, B. & Juśkiewicz, J. Side streams of vegetable processing and its bioactive compounds support microbiota, intestine milieu, and immune system. Molecules 28, 4340 (2023).

Dwyer, J. T. et al. Fortification and health: challenges and opportunities. Adv. Nutr. 6, 124–131 (2015).

Jang, J. & Lee, D. W. Advancements in plant based meat analogs enhancing sensory and nutritional attributes. npj Sci. Food 8, 50 (2024).

Zhang, X., Zhang, T., Zhao, Y., Jiang, L. & Sui, X. Structural, extraction and safety aspects of novel alternative proteins from different sources. Food Chem. 436, 137712 (2024).

Park, S. H., Lamsal, B. P. & Balasubramaniam, V. M. in Food Processing: Principles and Applications (eds Clark, S. et al.) 1–15 (Wiley Blackwell, 2014).

Toivonen, P. M. A. & Brummell, D. A. Biochemical bases of appearance and texture changes in fresh-cut fruit and vegetables. Postharvest Biol. Technol. 48, 1–14 (2008).

Rani, H. & Bhardwaj, R. D. Quality attributes for barley malt: “the backbone of beer”. J. Food Sci. 86, 3322–3340 (2021).

Avezum, L. et al. Improving the nutritional quality of pulses via germination. Food Rev. Int. 39, 6011–6044 (2023).

Pointner, T. et al. Comprehensive analysis of oxidative stability and nutritional values of germinated linseed and sunflower seed oil. Food Chem. 454, 139790 (2024).

Miyahira, R. F. & Antunes, A. E. C. Bacteriological safety of sprouts: a brief review. Int. J. Food Microbiol. 352, 109266 (2021).

Bilirgen, A. C. et al. Plant-based scaffolds in tissue engineering. ACS Biomater. Sci. Eng. 7, 926–938 (2021).

Ansari, Z. & Goomer, S. Natural gums and carbohydrate-based polymers: potential encapsulants. Indo Global J. Pharm. Sci. 12, 1–20 (2022).

Ghazani, S. M. et al. Oleosome interfacial engineering to enhance their functionality in foods. Curr. Res. Food Sci. 8, 100682 (2024).

Czapalay, E. S., Soleimanian, Y., Stobbs, J. A. & Marangoni, A. G. Plant tissue-based scaffolds filled with oil function as adipose tissue mimetics. Curr. Res. Food Sci. 10, 101002 (2025).

Steinkraus, K. H. Nutritional significance of fermented foods. Food Res. Int. 27, 259–267 (1994).

Ray, R. C. et al. in Trending Topics on Fermented Foods (eds Martin, J. G. P. et al.) 1–57 (Springer, 2024).

Castro-Alba, V. et al. Fermentation of pseudocereals quinoa, canihua, and amaranth to improve mineral accessibility through degradation of phytate. J. Sci. Food Agric. 99, 5239–5248 (2019).

Carrau, F., Boido, E. & Ramey, D. Yeasts for low input winemaking: microbial terroir and flavor differentiation. Adv. Appl. Microbiol. 111, 89–121 (2020).

Bravo-Núñez, Á., Golding, M., Gómez, M. & Matia-Merino, L. Emulsification properties of garlic aqueous extract: effect of heat treatment and pH modification. Foods 12, 3721 (2023).

Buhl, T. F., Christensen, C. H. & Hammershøj, M. Aquafaba as an egg white substitute in food foams and emulsions: protein composition and functional behavior. Food Hydrocoll. 96, 354–364 (2019).

Mishra, K. Foam Formation and Processing of Glyceride Melt Suspensions with Crystal Fraction for Additive Manufacturing Applications. PhD thesis, ETH Zürich (2021).

Lammers, V. R. G. A Novel Technology to Tailor Foam Structure in Gluten-Free Bakery Product Systems. PhD thesis, ETH Zürich (2016).

Koller, C. High-Pressure Micro-Foaming of Fat-Continuous Confectionery Systems. PhD thesis, ETH Zürich (2015).

Oliveira, L. C., Schmiele, M. & Steel, C. J. Development of whole grain wheat flour extruded cereal and process impacts on color, expansion, and dry and bowl-life texture. LWT 75, 261–270 (2017).

Liu, C. et al. Preparation, physicochemical and texture properties of texturized rice produce by improved extrusion cooking technology. J. Cereal Sci. 54, 473–480 (2011).

Ullah, I. et al. Influence of okara dietary fiber with varying particle sizes on gelling properties, water state and microstructure of tofu gel. Food Hydrocoll 89, 512–522 (2019).

Fox, P. F. Proteolysis during cheese manufacture and ripening. J. Dairy Sci. 72, 1379–1400 (1989).

Park, S. H., Na, Y., Kim, J., Kang, S. D. & Park, K. H. Properties and applications of starch modifying enzymes for use in the baking industry. Food Sci. Biotechnol. 27, 299–312 (2018).

Nicholson, R. A. & Marangoni, A. G. Enzymatic glycerolysis converts vegetable oils into structural fats with the potential to replace palm oil in food products. Nat. Food 1, 684–692 (2020).

Frias, J., Peñas, E. & Martinez-Villaluenga, C. in Fermented Foods in Health and Disease Prevention (eds Frias, J. et al.) 385–416 (Elsevier, 2017).

Wollstonecroft, M. M. Investigating the role of food processing in human evolution: a niche construction approach. Archaeol. Anthropol. Sci. 3, 141–150 (2011).

Beane, K. E. et al. Effects of dietary fibers, micronutrients, and phytonutrients on gut microbiome: a review. Appl. Biol. Chem. 64, 36 (2021).

Prückler, M. et al. Comparison of homo- and heterofermentative lactic acid bacteria for implementation of fermented wheat bran in bread. Food Microbiol. 49, 211–219 (2015).

Meignen, B. et al. Optimization of sourdough fermentation with Lactobacillus brevis and baker’s yeast. Food Microbiol. 18, 239–245 (2001).

Dobson, S. & Marangoni, A. G. Methodology and development of a high-protein plant-based cheese alternative. Curr. Res. Food Sci. 7, 100632 (2023).

Harper, A. R., Dobson, R. C. J., Morris, V. K. & Moggré, G. J. Fermentation of plant-based dairy alternatives by lactic acid bacteria. Microb. Biotechnol. 15, 1404–1421 (2022).

Guinee, T. in Advanced Dairy Chemistry Vol. 1B (eds McSweeney, P. & O’Mahony, J.) 347–415 (Springer, 2016).

Hinrichs, J. Incorporation of whey proteins in cheese. Int. Dairy J. 11, 495–503 (2001).

Joo, K. H., Kerr, W. L. & Cavender, G. A. The effects of okara ratio and particle size on the physical properties and consumer acceptance of tofu. Foods 12, 3004 (2023).

Mishra, K. et al. Valorization of cocoa pod side streams improves nutritional and sustainability aspects of chocolate. Nat. Food 5, 423–432 (2024).

Buican, B. C., Colibaba, L. C., Luchian, C. E., Kallithraka, S. & Cotea, V. V. “Orange” wine—the resurgence of an ancient winemaking technique: a review. Agriculture 13, 1750 (2023).

Pswarayi, F. & Gänzle, M. African cereal fermentations: a review on fermentation processes and microbial composition of non-alcoholic fermented cereal foods and beverages. Int. J. Food Microbiol. 378, 109815 (2022).

Houngbédji, M. & Jespersen, J. S. Wilfrid Padonou, S. & Jespersen, L. Cereal-based fermented foods as microbiota-directed products for improved child nutrition and health in sub-Saharan Africa. Crit. Rev. Food Sci. Nutr. 65, 3422–3443 (2025).

Acknowledgements

P.A.R., T.G. and A.B. thank the ETH Foundation for their generous support.

Author information

Authors and Affiliations

Contributions

T.G. and A.B. contributed equally to this work. T.G., A.B., K.M. and P.A.R. conceptualized the work. T.G., A.B., K.M., A.G.M. and P.A.R. wrote the original draft. A.B. created Figs. 1–3. T.G., A.B. and P.A.R. revised the final version of the paper. All authors reviewed the final version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Food thanks Jose Miguel Aguilera, Lilia Ahrné and Caroline Joy Steel for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Germerdonk, T., Bach, A., Marangoni, A.G. et al. Unrefined plant raw materials are key to nutritious food. Nat Food 6, 657–663 (2025). https://doi.org/10.1038/s43016-025-01195-y

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s43016-025-01195-y