Abstract

Engineering materials exhibit an undesirable tradeoff between strength and resistance to crack propagation (fracture toughness). Here we demonstrate how this tradeoff can be circumvented by thermo-mechanical processing that produces a partially recrystallized, heterogeneous microstructure. An equimolar CrCoNi alloy was forged at room temperature (298 K) to produce high densities of three-dimensional crystallographic defect networks. Post-deformation heat treatments caused localized recrystallization that resulted in a bimodal microstructure with hard, non-recrystallized grains and soft, recrystallized grains. In this condition, the yield strength at 298 K is 2.75x the values previously obtained for the same alloy in the fully recrystallized state while the fracture toughness remains the same. The yield strength is further enhanced at 77 K without compromising the fracture toughness. This outstanding strength-toughness combination at 77 K exceeds those reported for other metallic materials and appears to result from the composite nature of the microstructure with non-recrystallized grains providing strength and recrystallized grains enabling plasticity that dissipates stresses during crack propagation. Our findings indicate that by tuning the degree of recrystallization through thermomechanical processing techniques, it will be possible to further expand the envelope bounding the strength and toughness of a range of structural metals at engineering component scales.

Similar content being viewed by others

Introduction

Structural engineering materials must be both strong (resistant to deformation) and tough (able to resist fracture in the presence of a crack or other discontinuity). However, metallic materials generally exhibit an undesirable tradeoff between these properties, so increasing the strength of a metal reduces its toughness. Broadly, this tradeoff occurs because strengthening a metal necessarily makes it more resistant to plastic deformation, but plastic deformation is a critical pathway for internally distributing or delocalizing high stresses. In the absence of such a pathway, stresses and strains concentrate at internal discontinuities and commence fracture1,2.

Recent developments of high-toughness materials have followed this trend. For example, high-toughness medium/high-entropy alloys have relatively low yield strengths and undergo extensive strain hardening prior to fracture, resulting in high elongations and ultimate tensile strengths3,4. However, engineers generally use the yield strength rather than ultimate tensile strength of a material for design purposes, because most engineering components are considered to have failed if they permanently deform. Therefore, it is desirable to increase the yield strength of such alloys without compromising their toughness.

One promising strategy involves fabricating materials with “heterogeneous” or “hierarchical” microstructures. These terms encompass many processing routes and material conditions, but they broadly indicate that an alloy has been deliberately processed such that the microstructure and mechanical properties vary through the material across multiple length scales5. For example, such materials may comprise multi-scale cellular structures6 or alternating bands of recrystallized and non-recrystallized grains7. Heterogeneous microstructures have demonstrated excellent combinations of strength and ductility in a wide variety of materials8,9,10,11,12,13,14, but measurements of fracture toughness have been limited15,16. Although ductility may be an important property, structural materials are more often evaluated on their fracture toughness, so it is critical to characterize and understand the toughness of a material if it is to be considered for engineering applications.

One challenge associated with heterogeneous microstructures is that many implementations to date have relied on laboratory-scale processing techniques such as high-pressure torsion, equal channel angular pressing, or other experimental methods17,18,19. Although these methods are valuable for understanding the fundamental properties of such materials, the associated equipment is not widely used in industrial manufacturing processes and can only produce limited component sizes and shapes.

The focus of the present paper is on measurement of the fracture toughness and crack propagation mechanisms of an equimolar CrCoNi alloy after creating a heterogeneous, partially recrystallized (PRX) microstructure. This microstructure was created using a simple forging and heat treatment process that can be performed with widely available equipment and across different component sizes and shapes. We found that the PRX condition is much stronger than the fully recrystallized alloy without an appreciable decrease in fracture toughness, placing it at the edge of the strength-toughness envelope for metallic materials at room temperature and outside the current strength-toughness envelope at 77 K.

Results

Microstructure

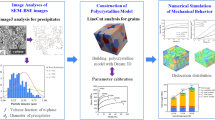

A CrCoNi MEA with a heterogeneous microstructure was produced by arc-melting high-purity elements ( > 99.9% pure), followed by a homogenization treatment and forging at room temperature to heavily deform the material ( ~ 70% reduction in thickness). Subsequently, an annealing treatment at 600 °C for 4 hours was performed to partially recrystallize the material. Two forgings (hereafter designated as “Block 1” and “Block 2”) were produced for mechanical testing. The partially recrystallized blocks have anisotropic microstructures because of directional deformation during forging. Figure 1a shows the general layout of the forged blocks and the microstructure in different orientations, which are referred to by the forging direction, long transverse (LT) direction, and short transverse (ST) direction.

a Overview of test specimens taken from each forged block. b, c Representative microstructures are shown after the material was cold-forged and annealed. For ease of viewing, EBSD maps are filtered to show only recrystallized grains (internal misorientation <1°). d A representative EDS spectrum from the forging plane.

Irregular, alternating bands of recrystallized (RX) and non-recrystallized grains (n-RX) were present on the planes perpendicular to each of the three primary directions. Figures 1b and 1c show examples of such bands in the LT and forging planes. As discussed in more detail below, the n-RX volume fraction was approximately 0.50–0.85. The bands of RX grains are easily observed using SEM electron backscatter diffraction (EBSD) orientation image mapping (OIM). In Fig. 1b, c, the colored inverse pole figure maps indicate the crystallographic orientation at each point. The maps shown in these images were processed to include only RX grains (as defined by having internal crystallographic misorientations less than or equal to 1 degree). Black regions on the maps correspond to highly deformed n-RX grains, i.e., areas that were removed during post-processing for ease of viewing. (Supplementary Fig. 1 shows the forging plane map with both RX and n-RX grains included for comparison.) Bands of RX grains were generally aligned along the forging plane (perpendicular to the forging direction) and had apparent widths ranging from tens to hundreds of micrometers in each band. Based on OIM measurements and data processing using EDAX OIM Analysis software, the average grain size in the RX regions was approximately 1.9 ± 0.1 μm excluding annealing twins.

The local fraction of RX grains varied through the material. In general, areas near the center of the forging (i.e., halfway along the blue axis in Fig. 1a) had higher fractions of RX grains than either of the surfaces (i.e., the ends of the blue axis in Fig. 1a). However, a mixture of RX and n-RX grains was present throughout the full thickness of the forging, including near the center and outer surfaces. Stitched SEM images showing the microstructure through the full thickness of the forging are included in Supplementary Fig. 2. Based on 300 ×300 μm OIM scans acquired on the LT plane, the n-RX volume fraction was approximately 0.50–0.85 (i.e., the RX volume fraction was approximately 0.15–0.50). The microstructures were consistent in Blocks 1 and 2. The scanning electron microscopy energy dispersive X-ray spectroscopy (SEM-EDS) spectrum in Fig. 1d shows that the composition of the forgings is consistent with equiatomic CrCoNi. X-ray diffraction (XRD) measurements shown in Supplementary Fig. 3 show the alloy has a single-phase, face-centered cubic structure.

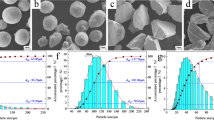

Strength and ductility

Uniaxial tensile testing was performed at room temperature (298 K) and 77 K using flat, “dog bone”-shaped tensile specimens. Test results are shown in Fig. 2. The average yield strength and ultimate tensile strength of the PRX CrCoNi alloy at room temperature were 1213 ± 13 MPa and 1286 ± 24 MPa, respectively. The average uniform elongation was 4.8 ± 1.1%, which is similar to previous results reported for PRX CrCoNi7. However, there was a significant difference in total elongation (elongation to fracture) between the forgings: the average elongation in “Block 1” was ~4% and the average elongation in “Block 2” was ~24%. The variation in strain after the onset of plastic instability was likely caused by the heterogeneous microstructure, which may promote strain localization. All four tested specimens (two from each forging) had visible evidence of necking (i.e., localized plastic deformation) adjacent to the fracture.

The strength and ductility of the PRX CrCoNi alloy simultaneously increased at 77 K compared to 298 K. The average yield strength increased to 1556 ± 31 MPa (an increase of 28%) and the average ultimate tensile strength increased to 1678 ± 29 MPa (an increase of 30%). The average uniform elongation also increased by more than two times to 12 ± 4.4%. Differences in elongation between the specimens from the “Block 1” and “Block 2” forgings were less pronounced than at room temperature. This change from room temperature was likely due to differences in deformation mechanisms that are described in more detail in a subsequent section. The average elongation to fracture was ~18 ± 11%.

Fracture toughness

The fracture toughness of the PRX CrCoNi alloy was investigated using non-linear elastic fracture mechanics in the form of R-curves. The corresponding R-curves, i.e., non-linear elastic strain energy release rate (J-Integral) vs. crack extension, ∆a, at 298 K and 77 K, are plotted in Fig. 2b. Here, J accounts for the contribution from both elastic and inelastic deformation during fracture. At 298 K, the average crack initiation fracture toughness value, JIc, is ~186 KJ.m−2, which decreases to 146 KJ.m−2 at 77 K. The average value of crack growth fracture toughness, Jss, which is characterized as the J value at a crack extension, ∆a, of ~2 mm, is 377 KJ.m−2 at 298 K and 269 KJ.m−2 at 77 K. All the fracture toughness measurements in this study satisfy the plane strain condition of the J-dominance defined by b, B >> 10(J/σf), where b is the width of uncracked ligament, B is the thickness of the samples, and σf is flow stress defined as σf = (σy + σu)/2), where σy is yield strength and σu is the ultimate tensile stress at respective temperatures20. The Mode I crack initiation fracture toughness, KJIc, in terms of stress intensity factor, is computed by KJIc = (J*(E/(1-ν2)) based on the J-K equivalence relationship. Here, E is Young’s modulus, and ν is Poisson’s ratio taken from an earlier study on the CrCoNi alloy in the fully recrystallized state4. Since elastic constants are structure-insensitive we assume them to be the same in the PRX alloy. The average crack initiation fracture toughness, KJIc of PRX CrCoNi at 298 K is 217 MPa.m0.5, which marginally decreases by 9% to 197 MPa.m0.5 at 77 K. The average crack growth toughness, KJss, is ~309 MPa.m0.5 and ~266 MPa.m0.5 at 298 K and 77 K, respectively. During one fracture toughness test at 77 K, the crack apparently propagated unstably after an initial stable growth of ~0.45 mm. However, after an unstable crack extension, ∆a, ~3 mm, the sample showed a KJSS of ~250 MPa.m0.5 during further measurements (Supplementary Fig. 4). The apparent unstable crack growth may reflect the microstructural heterogeneity of the material or an anomalous measurement, because as described in the next section, there was no apparent change in the fracture morphology across the C(T) specimen. The microstructure around the crack and fractography from this specimen are shown in Supplementary Fig. 4. The high KJSS measurement after apparent unstable crack growth and the result from the second sample tested at 77 K demonstrate the excellent fracture resistance of the PRX CrCoNi with heterogeneous microstructure.

Compared to fully recrystallized CrCoNi4, the yield strength of PRX CrCoNi is 175% and 136% higher at 298 K and 77 K, respectively. Furthermore, the KJIc of PRX CrCoNi is ~4% higher at 298 K, and ~28% lower at 77 K than that of fully recrystallized CrCoNi. The following sections discuss the reasons for such an exceptional combination of strength and fracture resistance in PRX CrCoNi.

Deformation and failure mechanisms

After fracture toughness testing, at least one compact tension (C(T)) fracture toughness specimen from each temperature was cyclically loaded until fatigue failure occurred and the specimens completely separated, exposing the fracture surfaces. Figure 2c shows an overview of a representative C(T) sample after testing and separation. Post-fracture SEM imaging of tensile and C(T) specimens showed ductile fracture for all specimens by microvoid coalescence (Fig. 2d). The microvoids in the tensile samples were of uniform size, but there was a bimodal size distribution in the C(T) specimens (Supplementary Fig. 5). Additionally, small (1–5 µm) chromium-rich oxide inclusions were present inside some of the microvoids. Two such oxide particles are shown in Supplementary Fig. 6, which also shows an SEM-EDS spectrum demonstrating the local enrichment in chromium and oxygen compared to the adjacent base metal. Similar microvoid nucleation from oxide inclusions was also reported during previous fracture toughness testing of the fully recrystallized CrCoNi alloy4. Apparent differences in microvoid size distribution between the C(T) and tensile specimens are likely caused by differences in stress state. For example, stress triaxiality is likely higher at the center of relatively thick CT specimens where fractographic imaging was performed compared to the relatively thin ( ~ 1.2 mm), flat tensile specimens.

One C(T) sample from each test temperature was cross sectioned to assess the crack propagation path and the deformation mechanisms. Cross sectioning was performed through the mid-plane to expose the region of highest stress triaxiality. Figure 3a, b show optical micrographs of the crack paths for representative samples tested at 298 K and 77 K. The crack paths were tortuous and had abrupt steps where the cracks deflected. Based on SEM backscattered electron (BSE) imaging and IPF maps such as those shown in Fig. 3c, d, the cracks appeared to deflect wherever they encountered boundaries between the RX and n-RX areas. In some instances, the cracks appeared to preferentially propagate on or parallel to deformation twins in n-RX grains (Supplementary Fig. 7).

a, b Light optical microscope (LOM) images of the crack path in specimens tested at 298 K and 77 K, respectively. Red dots indicate the approximate locations of STEM FIB foil lift-outs. c, d Higher-magnification orientation image maps showing grain orientations around the crack tips in specimens tested at 298 K and 77 K, respectively, and the locations of the STEM samples extracted via FIB.

The fracture toughness values indicate that substantial plastic deformation occurred ahead of the crack tips in samples tested at both 298 K and 77 K. To understand the plasticity mechanisms, focused ion beam techniques were used to extract site- and orientation-specific thin foils for scanning transmission electron microscopy (STEM). Thin foils were extracted from regions immediately adjacent to the crack tips (i.e., within the crack tip plastic zone). Foil extraction sites (marked in Fig. 3c, d) contained both RX and n-RX regions. Figure 4 shows characteristic microstructural features of PRX CrCoNi and representative deformation mechanisms at both temperatures, as viewed using bright-field STEM diffraction contrast imaging (BF-STEM-DCI) and high-angle annular dark-field STEM (HAADF-STEM) at resolutions up to the atomic scale.

a, d BF-STEM-DCI overview showing the presence of both fully recrystallized (RX) and non-recrystallized (n-RX) regions. b, e Details demonstrate that RX grains also contain a high density of of plastic deformation-induced defects at both 298 K and 77 K. The COS analyses (c, f) performed on the areas from the insets (white dashed rectangles in (b, e)) reveal the difference between the deformation mechanisms acting at 298 K and 77 K. c While a combination of extended ISFs and deformation twinning with twins of about 20 nm in thickness are found at 298 K, (f) the plastic deformation at 77 K is accommodated by various planar defects including extended ISFs, thin nano-scale twins, and closely spaced HCP bands. Viewing direction for (b, c, e, f) is with the electron beam parallel to [011] zone axis.

BF-STEM-DCI in Fig. 4a shows an overview of the foil extracted from the room-temperature sample, including RX grains in the top half of the image and an n-RX region in the bottom half of the image. Plastic deformation was generally accommodated by dislocation slip and deformation twinning. Figure 4b shows a higher-magnification view (electron beam parallel with [011] zone axis) within an RX region. Based on our observations in prior work7 and EBSD-OIM performed on these samples prior to testing, RX regions generally have very low crystallographic defect density after annealing. However, after fracture toughness testing, these RX regions contained many planar defects (mostly dissociated ½<110> dislocations forming extended intrinsic stacking faults (ISFs) and deformation nano-twins), as well as a high dislocation density between planar defects. Many deformation nano-twins were approximately 15–25 nm thick. These defects were generated in response to high stresses ahead of the crack tip during fracture toughness testing. As shown in Fig. 4b, generation, propagation, and intersection of planar defects significantly refined the microstructure and reduced the mean free path for dislocations compared to the as-recrystallized grains. The inset in Fig. 4b obtained via HAADF-STEM shows a representative intersection between two deformation twins (highlighted in red in the inset). This intersection is shown at higher magnification in Fig. 4c through an atomic-resolution Center-of-Symmetry (COS) map, which demonstrates a curved, non-planar incoherent interface between two deformation twins. Such interactions frustrate subsequent dislocation slip and promote work hardening. In addition to deformation twins, extended stacking faults can produce a similar effect. Many ISFs were observed in the 298 K sample.

Similar microstructures were observed in the sample tested at 77 K. Figure 4d shows an overview of the foil from this sample. The planar defect density appeared to be even higher in the cryogenic sample compared to the room temperature sample, and deformation twins were generally thinner than in the room temperature sample. We also observed evidence of a localized, deformation-induced phase transformation from the equilibrium face-centered cubic (FCC) structure to a hexagonal close-packed (HCP) structure. Such a transformation has previously been reported in CrCoNi alloy that was severely deformed at 298 K and 77 K21. In the present work, we only observed evidence of the HCP structure in the fracture toughness sample that was tested at 77 K. The inset in Fig. 4e shows examples of several planar defects including an HCP region (blue shading), deformation twins (red shading), and an intrinsic stacking fault (yellow shading). The intrinsic or extrinsic character (i.e., stacking sequence) and structure of these defects was verified by the corresponding atomic-resolution COS map shown in Fig. 4f. Notably, the COS map illustrates the extreme refinement of the RX grains during subsequent deformation. For example, in the same field of view as shown in Fig. 4c for the room temperature sample (in which the plastic deformation is accompanied by one deformation twin), the 77 K sample contains an array of multiple planar defects that are each only a few atomic layers thick. The average distance between these planar defects is only approximately 3–4 nm (see Fig. 4f).

Discussion

Most metallic alloys exhibit a tradeoff between yield strength and fracture toughness1,2. This trade-off occurs because metallic alloys are intrinsically toughened by plasticity ahead of the crack tip, and when the alloy strength is increased by restricting dislocation movement, it also lowers their resistance to crack propagation. However, the present work demonstrates the remarkable ability to engineer a 175% increase in the yield strength of a CrCoNi alloy with no impact to its fracture toughness (compared to prior work performed on fully recrystallized material4). The yield strength is even further enhanced at cryogenic temperatures without a significant decrease in fracture toughness. The combination of strength and damage-tolerance of PRX CrCoNi is exceptional, especially in the cryogenic regime.

The origin of these outstanding properties appears to be the composite nature of the PRX hetero-structure, which comprises relatively hard n-RX regions and relatively soft RX regions. The high yield strength originates from n-RX grains that retain high densities of crystallographic defects imparted by cold work during the original forging process. The microstructure in such grains is significantly refined by the prior deformation. Previous micro-scale digital image correlation measurements have demonstrated preferential plastic strain partitioning to soft RX regions7. There may be an additional strengthening contribution in the PRX material from hetero-deformation induced (HDI) hardening22, i.e., “hard domains” (n-RX grains) may cause significant back-stresses to develop in “soft domains” (RX grains) if deformation cannot be transmitted across domain boundaries. Such back-stresses may suppress yield or cause additional strain hardening in RX grains.

The high fracture resistance of the heterogeneous microstructure arises from a combination of intrinsic and extrinsic toughening mechanisms. The RX regions ahead of the crack tip promote intrinsic toughening by strain hardening. Such regions plastically deform by a sequence of dislocation activity, stacking fault formation, and deformation twinning, all of which dissipate energy that otherwise would contribute to crack propagation. In addition to these mechanisms, a stress-induced phase transformation is activated at 77 K (Fig. 4f), further contributing to the intrinsic toughening at cryogenic temperatures. The same stress-induced transformation has previously been identified in fully recrystallized CrCoNi during the late stages of tensile testing at room temperature and the intermediate stages of tensile testing at 77 K21, and during fracture toughness testing at 20 K23. Notably, n-RX regions likely also contribute to intrinsic toughening, albeit to a lesser degree than RX regions, because of strain hardening generated by nano-twinning and stress-induced transformation. Additionally, HDI hardening caused by the PRX structure may cause additional strain hardening, and therefore intrinsic toughening, in RX grains.

Extrinsic toughening is supported by boundaries between RX and n-RX domains, which appear to cause changes in the crack propagation direction. In some instances, the crack also preferentially propagates along or parallel to prior deformation twins in n-RX domains even when the twins are not aligned with the Mode I direction, effectively reducing the driving force for crack propagation (Supplementary Fig. 7). In both RX and n-RX regions, the fracture is strain-controlled and requires plastic deformation, i.e., the crack propagates by microvoid nucleation and coalescence either on inclusions or on / parallel to pre-existing deformation twins (Supplementary Fig. 7). In summary, intrinsic toughening is primarily promoted by RX regions through a sequence of deformation mechanisms, and extrinsic toughening is primarily promoted by RX / n-RX interfaces and preferred crack propagation directions in n-RX regions.

The outstanding combination of room temperature strength and fracture toughness in PRX CrCoNi alloy compared to other engineering materials is shown in Fig. 5, where the dashed black lines envelop the best combinations of toughness and strength for metals. The fracture toughness of PRX CrCoNi compares favorably to even the most advanced steels such as high-Ni maraging steels. Additionally, the present work demonstrates that the PRX strengthening concept does not inherently compromise fracture toughness. It is remarkable that the strength of the CrCoNi alloy can be increased by such a large extent without a corresponding decrease in toughness. The PRX strategy is promising for other materials such as austenitic stainless steels that have similar deformation characteristics.

Comparison of data for fully recrystallized CrCoNi (ref. 4) and partially recrystallized CrCoNi (present work) with historical data for various engineering alloys, as extracted from the Plane Strain Fracture Toughness (KIc) Data Handbook for Metals41. Additional data was also sourced from ref. 6. Fracture toughness values for CrCoNi alloy are KJIC measurements. Dashed black lines schematically indicate the strength-toughness envelope.

Notably, the n-RX / RX fractions may be engineered through different combinations of deformation and heat treatment. These fractions strongly affect the material yield strength7. However, the current work shows that with n-RX volumes of 50–85%, the toughness is approximately the same as in fully recrystallized material (i.e., n-RX volume of 0%). Therefore, toughness is relatively insensitive to the n-RX volume in CrCoNi alloy4.

This work demonstrates a simple, scalable thermo-mechanical processing route that expands the yield strength-toughness envelope. It may also be possible to create PRX microstructures in additively manufactured components that have high internal stresses and dislocation densities in as-built components24,25,26,27,28,29. If careful heat treatments are applied to such components, it may be possible to create extraordinarily strong, ductile, and tough PRX microstructures in net-shape or near-net shape components. Indeed, there is some evidence for this effect in additively manufactured CrCoNi alloy components30,31,32. PRX microstructures may also be relevant for enhancing the strength and toughness of sprayed coatings that have very high crystallographic defect densities as deposited33,34,35.

Methods

Materials processing and microstructural characterization

The CrCoNi MEA was produced from high-purity elements ( > 99.9% pure) which were arc-melted under argon atmosphere and drop-cast into rectangular cross-section copper molds. The castings were homogenized in vacuum and cold-forged from an initial thickness of 35 mm to a final thickness of approximately 11 mm (a reduction of approximately 70%).

Small cracks were present on the LT plane in the as-forged condition. Supplementary Fig. 8 shows a representative image of such cracks. These cracks were generally perpendicular to the crack propagation plane of the compact-tension fracture toughness test specimens. In other words, the tensile stresses imposed during fracture toughness testing would not be expected to propagate these forging cracks.

Sections were cut from the forging and heat treated under the following conditions: 600 °C/1 h, 600 °C/4 h, 650 °C/1 h, 650 °C/4 h, and 700 °C/1 h. The microstructures of the as-forged and heat-treated conditions were assessed using a scanning electron microscope (SEM) as described below. The 600 °C/4 h heat treatment produced a microstructure that appeared to be most qualitatively similar to our previous work7, so this heat treatment was selected for the present tensile and compact-tension specimens. However, there were still some differences with respect to microstructure and tensile properties between the current specimens and those in our previous work. These differences were caused by two factors: first, different mechanical processing routes with different stress states were used to generate PRX microstructures in these two studies (rolling in the original work versus forging in the current study). Second, the forged blocks used in the current work were larger and thicker than the cold-rolled plate used in the previous work. Sample thickness and overall mass may substantially affect the heating and cooling rates during heat treatment, which in turn affect the final microstructure and mechanical properties.

Specimens were examined using a Thermo Fisher Scientific (TFS) Apreo 2 SEM. The imaging conditions were optimized to enhance the signal collected by backscattered electrons, which facilitated distinguishing between RX and n-RX regions. Specifically, we used larger working distances and lower accelerating voltages, which reduced effects from crystallographic defects such as dislocations. However, more pronounced crystallographic defects such as thicker deformation twins within n-RX regions were still visible. Using a concentric backscatter (CBS) detector, the final imaging conditions were 10 kV of accelerating voltage, 6.4 nA of beam current, and 10 mm of working distance (WD). To see the internal defects the WD was decreased to 6 mm and accelerating voltage was increased to 30 kV.

EBSD-OIM was performed using an EDAX Hikari Super EBSD camera in conjunction with acquisition software EDAX TSL DC7 and analysis software EDAX TSL OIM 8. Scans were acquired using an accelerating voltage of 20 kV and a beam current of 6.4 nA at a working distance of 20 mm. Lower magnification scans were 300 ×300 μm with a step size of 500 nm and higher magnification scans were 60 × 60 μm with a step size of 100 nm.

Recrystallized grain size measurements were made as follows: SEM-BSE imaging was used to identify bands of recrystallized grains. EBSD scans were performed within these recrystallized bands on a 60 × 60 μm area with a step size of 100 nm. After acquisition, the data were filtered to exclude any points with Confidence Index lower than or equal to 0.01. (Confidence Index is a proprietary EDAX algorithm that reflects pattern indexing quality at each collected data point. A low Confidence Index indicates low confidence that a given pattern was indexed correctly.) The data were also filtered to remove any points assigned to grains smaller than 300 nm (i.e., only grains larger than 300 nm were retained for this analysis). Finally, RX grains were defined as grains with a Grain Orientation Spread less than or equal to 1 degree of internal misorientation. Grain size measurements were performed on the remaining grains and reported as average equivalent diameter.

For multi-scale characterization of the microstructure, orientation- and site-specific TEM specimens were prepared. First, the areas of interest were identified and analyzed using a TFS Apreo SEM equipped with an EBSD detector. A TFS/FEI Helios dual-beam system equipped with focused ion beam (FIB) was then used for thin foil nanofabrication. The specimens were sharpened with Ga ions down to a ~ 50 nm thickness using a final energy of 5 kV and a current of 16 pA to remove regions with severe Ga implantation.

Microstructure and defect analysis was performed using S-CORR probe aberration-corrected and mono-chromated TFS Themis-Z scanning transmission electron microscope (STEM) at an accelerating voltage of 300 kV. STEM diffraction contrast imaging (DCI) was performed with bright (BF) and high-angle annular dark-field (HAADF) detectors by selection of the appropriate camera length36. Atomic resolution imaging of the microstructure was performed by tilting the thin foils into specific low-index crystallographic zones. Data were collected and processed using TFS Velox software. STEM micrographs were corrected for potential sample drift and scanning beam distortions using the drift-corrected frame integration function of Velox. Center of Symmetry (COS) analysis was performed to determine the degree of centro-symmetry for each atomic column in the experimental HAADF-STEM image and thus identify distortions in the stacking sequence. COS analysis was performed according to the procedure described by Heczko et al.37 and Pandey et al.38

XRD data were acquired by a θ:2θ scan on a Rigaku SmartLab diffractometer equipped with copper X-ray tube with Ni β filter, parafocusing (Bragg-Brentano) optics, computer-controlled slits, and a 1D strip detector. Scans were performed over a 2θ angular range of 20–100° with a step size of 0.02°.

Mechanical characterization

The tensile and compact-tension C(T) specimens were machined from the forged and PRX CrCoNi blocks in orientations illustrated by the schematic in Fig. 1 by wire electrical discharge machining (EDM) for tensile and fracture toughness tests at 298 K and 77 K. Dog bone tensile specimens with gauge length, width, and thickness of ~16.8 mm, 3 mm, 1.5 mm, respectively, were used for the tensile tests. The oxide layer formed on the surface of the tensile specimens during the EDM process was removed by grinding. Quasi-static tensile tests were performed at a strain rate of 10−3 s−1 on a servo-hydraulic load frame (MTS Corp., Eden Prairie, MN, USA) operated by an Instron digital controller (Instron Corp., Norwood, MA, USA) following the recommendation in ASTM Standard E839. The elongation during the tensile tests was measured using an Epsilon clip-on extensometer attached to the specimens. The extensometer was suitable for use in the 4 K to 498 K temperature range.

For the non-linear elastic fracture toughness tests, C(T) specimens of width, W ~ 16 mm, and thickness, B ~ 8 mm, were machined from the forged and PRX blocks with the direction of crack growth (V-notch) aligned to short transverse direction (Fig. 1). The V-notch of the C(T) specimens was further sharpened by a mechanical micro-notcher equipped with a razor blade to achieve a notch root radius, ρ ~ 150 μm. The relatively sharper notch reduces the initial load required to initiate the crack and promotes uniform crack initiation through the thickness of the specimen during pre-cracking. During pre-cracking, crack growth in the C(T) specimens was monitored using a digital camera mounted on a long-distance microscope, for which both sides of the specimens were mirror polished. The fatigue pre-cracking of the C(T) samples was performed on a 100 kN servo-hydraulic 810 MTS load frame (MTS Corp., Eden Prairie, MN, USA) operated using an Instron 8800 digital controller (Instron Corp., Norwood, MA, USA). The fatigue loading was of a sinusoidal waveform of frequency 15 Hz with constant amplitude and a load ratio of ~0.1. The final crack length after pre-cracking was in the range a/W = 0.45–0.55, where a is the crack length, and W is the width of the specimen. The pre-cracked specimens were side grooved by 0.75 to 1.5 mm on each side to ensure a straight crack path during fracture. The fracture toughness was measured using nonlinear-elastic fracture toughness measurements, where both the elastic and in-elastic contributions to the fracture resistance are measured as J-integral. The resistance to fracture of the materials is measured as R-curve, i.e., non-linear elastic strain energy release rate, J, vs. crack extension, Δa according to methodology prescribed in ASTM E1820.50 After pre-cracking and side-grooving, the specimens were loaded at a crosshead speed of 0.02 mm/s for fracture toughness measurements. The crack extension during the fracture toughness tests was measured using the compliance method, where the compliance is determined from the load-line displacement measured during the unloading cycle by a clip-on gauge. A clip-on gauge with a 3 mm gauge length (Epsilon Technology, Jackson, WY, USA) was used to measure the load-line displacement. The clip-on gauge was capable of measuring displacement in the temperature range of 4 K to 498 K. The crack length during the fracture, ai, is calculated using the following equation from ASTM Standard E1820 based on rotation-corrected compliance:

and where Be = B-(B-BN)2/B and BN is the side grooved thickness of the specimen, E is the elastic modulus, and Cc(i) is the rotation-corrected elastic compliance. The final crack lengths after the fracture toughness tests were verified from the fractographs. The fracture by overload region was distinguishable because the specimens were fractured by fatigue loading after the fracture tests.

The total Ji was measured as a sum of Jel(i) and Jpl(i) corresponding to the crack length, ai. Here, \({J}_{i}={{K}_{i}}^{2}/E^{\prime} +{J}_{{pl}(i)}\), where E’ = E/(1-ν2) and ν is Poisson’s ratio. For the C(T) specimens used in the present case, the \({K}_{i}=\frac{{P}_{i}\,}{{\left(B{B}_{{{{\rm{N}}}}}W\right)}^{1/2}}f({a}_{i}/W)\), where Pi is the load applied and f(ai/W) is a geometry function as defined for C(T) specimens in ASTM Standard E39940. Jpl(i), The plastic component is computed by the following equation:

where bi is uncracked ligament length defined as bi = (W-ai), ηpl(i-1) = 2 + 0.522 b(i-1)/W, γpl(i-1) = 1 + 0.76 b(i-1)/W, and Apl(i)-Apl(i-1) is incremental area under load-displacement curve. The Ji computed using the above equation can be plotted as a function of Δa = ai-ao, where ao is the initial crack length to get an R-curve of individual specimens. From the R-curve, the JQ, i.e., blunting corrected provisional fracture toughness, can be determined by 0.2 mm offset/blunting line J = 2σfΔa, here \({\sigma }_{{{{\rm{f}}}}}=({\sigma }_{y}+{\sigma }_{u})/2\). For all the fracture toughness tests, the measured JQ satisfies the plane-strain and J-dominance conditions, bo, B > 10 J/σf, where bo is the length of uncracked ligament (W-ao), and B is the specimen thickness; therefore, JQ is JIc, a size-independent crack initiation fracture toughness. The Mode I fracture toughness KJIc can be computed from the measured JIc using the equations: KJIc = (JIc*E’)1/2 and KJss = (JSS*E’)1/2 where Jss is the crack growth fracture toughness or steady-state fracture toughness defined as the maximum value of J valid for the geometry considerations defined in ASTM Standard E1820 for the corresponding environmental conditions. An ultrasonic method was used to measure the material’s Young’s modulus E and Poisson’s ratio, ν7. The measured values of Young’s modulus, E, are ~229 and ~241 GPa at 298 and 77 K, respectively. Poisson’s ratios, ν, are 0.31 and 0.3 at 298 K and 77 K, respectively.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Ritchie, R. O. The conflicts between strength and toughness. Nat. Mater. 10, 817–822 (2011).

Launey, M. E. & Ritchie, R. O. On the Fracture Toughness of Advanced Materials. Adv. Mater. 21, 2103–2110 (2009).

Gludovatz, B. et al. A fracture-resistant high-entropy alloy for cryogenic applications. Science 345, 1153–1158 (2014).

Gludovatz, B. et al. Exceptional damage-tolerance of a medium-entropy alloy CrCoNi at cryogenic temperatures. Nat. Commun. 7. https://doi.org/10.1038/ncomms10602 (2016)

Zhu, Y. & Wu, X. Heterostructured materials. Prog. Mater. Sci. 131, 101019 (2023).

Kumar, P. et al. A strong fracture-resistant high-entropy alloy with nano-bridged honeycomb microstructure intrinsically toughened by 3D-printing. Nat. Commun. 15. https://doi.org/10.1038/s41467-024-45178-2 (2024)

Slone, C. E., Miao, J., George, E. P. & Mills, M. J. Achieving ultra-high strength and ductility in equiatomic CrCoNi with partially recrystallized microstructures. Acta Materialia 165, 496–507 (2019).

Jiang, M. et al. Enhanced strength-ductility synergy of selective laser melted reduced activation ferritic/martensitic steel via heterogeneous microstructure modification. Mater. Sci. Eng.: A 801, 140424 (2021).

Liu, Y. et al. Tuning strength-ductility combination on selective laser melted 316 L stainless steel through gradient heterogeneous structure. Addit. Manuf. 48, 102373 (2021).

Chen, M. et al. Excellent cryogenic strength-ductility synergy in duplex stainless steel with heterogeneous lamella structure. Mater. Sci. Eng.: A 831, 142335 (2022).

Sun, J. et al. High strength and ductility AZ91 magnesium alloy with multi-heterogenous microstructures prepared by high-temperature ECAP and short-time aging. Mater. Sci. Eng.: A 734, 485–490 (2018).

Schuh, B. et al. Influence of Annealing on Microstructure and Mechanical Properties of a Nanocrystalline CrCoNi Medium-Entropy Alloy. Materials 11, 662 (2018).

Sathiyamoorthi, P. et al. Exceptional cryogenic strength-ductility synergy in Al0.3CoCrNi medium-entropy alloy through heterogeneous grain structure and nano-scale precipitates. Mater. Sci. Eng.: A 766, 138372 (2019).

Sathiyamoorthi, P. & Kim, H. S. High-entropy alloys with heterogeneous microstructure: Processing and mechanical properties. Prog. Mater. Sci. 123, 100709 (2022).

Shengde, Z., Yang, M., Yuan, F., Zhou, L. & Wu, X. Extraordinary fracture toughness in nickel induced by heterogeneous grain structure. Mater. Sci. Eng.: A 830, 142313 (2022).

Liu, X. et al. Outstanding fracture toughness combines gigapascal yield strength in an N-doped heterostructured medium-entropy alloy. Acta Materialia 255, 119079 (2023).

Sun, J. et al. Developing an industrial-scale ECAP Mg-Al-Zn alloy with multi-heterostructure for synchronously high strength and good ductility. Mater. Charact. 164, 110341 (2020).

Jamalian, M. et al. Creation of heterogeneous microstructures in copper using high-pressure torsion to enhance mechanical properties. Mater. Sci. Eng.: A 756, 142–148 (2019).

An, Z. et al. Hierarchical grain size and nanotwin gradient microstructure for improved mechanical properties of a non-equiatomic CoCrFeMnNi high-entropy alloy. J. Mater. Sci. Technol. 92, 195–207 (2021).

ASTM E1820. Standard Test Method for Measurement of Fracture Toughness.

Miao, J. et al. The evolution of the deformation substructure in a Ni-Co-Cr equiatomic solid solution alloy. Acta Materialia 132, 35–48 (2017).

Zhu, Y. & Wu, X. Perspective on hetero-deformation induced (HDI) hardening and back stress. Mater. Res. Lett. 7, 393–398 (2019).

Liu, D. et al. Exceptional fracture toughness of CrCoNi-based medium- and high-entropy alloys at 20 kelvin. Science 378, 978–983 (2022).

Griffiths, R. J. et al. Solid-state additive manufacturing of aluminum and copper using additive friction stir deposition: Process-microstructure linkages. Materialia 15, 100967 (2021).

Karthik, G. M. & Kim, H. S. Heterogeneous Aspects of Additive Manufactured Metallic Parts: A Review. Met. Mater. Int. 27, 1–39 (2021).

Zhu, Y. Y. et al. The heterogeneous microstructure in an Al-Zn-Mg-Cu-Sc-Zr alloy produced by selective laser melting. IOP Conf. Ser.: Mater. Sci. Eng. 1249, 012024 (2022).

Yao, H. et al. High strength and ductility AlCrFeNiV high entropy alloy with hierarchically heterogeneous microstructure prepared by selective laser melting. J. Alloy. Compd. 813, 152196 (2020).

Luo, S., Zhao, C., Su, Y., Liu, Q. & Wang, Z. Selective laser melting of dual phase AlCrCuFeNix high entropy alloys: Formability, heterogeneous microstructures and deformation mechanisms. Addit. Manuf. 31, 100925 (2020).

Park, J. M. et al. Effect of heat treatment on microstructural heterogeneity and mechanical properties of 1%C-CoCrFeMnNi alloy fabricated by selective laser melting. Addit. Manuf. 47, 102283 (2021).

Han, B. et al. Additively manufactured high strength and ductility CrCoNi medium entropy alloy with hierarchical microstructure. Mater. Sci. Eng.: A 820, 141545 (2021).

Wang, J. et al. Exceptional strength-ductility synergy of additively manufactured CoCrNi medium-entropy alloy achieved by lattice defects in heterogeneous microstructures. J. Mater. Sci. Technol. 127, 61–70 (2022).

Weng, F. et al. Excellent combination of strength and ductility of CoCrNi medium entropy alloy fabricated by laser aided additive manufacturing. Addit. Manuf. 34, 101202 (2020).

Darabi, A. & Azarmi, F. Investigation on Relationship Between Microstructural Characteristics and Mechanical Properties of Wire-Arc-Sprayed Zn-Al Coating. J. Therm. Spray. Technol. 29, 297–307 (2019).

Brassart, L.-H. et al. Effect of Various Heat Treatments on the Microstructure of 316 L Austenitic Stainless Steel Coatings Obtained by Cold Spray. J. Therm. Spray. Technol. 31, 1725–1746 (2022).

Ahn, J.-E., Kim, Y.-K., Yoon, S.-H. & Lee, K.-A. Tuning the Microstructure and Mechanical Properties of Cold Sprayed Equiatomic CoCrFeMnNi High-Entropy Alloy Coating Layer. Met. Mater. Int. 27, 2406–2415 (2020).

Phillips, P. J., Brandes, M. C., Mills, M. J. & De Graef, M. Diffraction contrast STEM of dislocations: Imaging and simulations. Ultramicroscopy 111, 1483–1487 (2011).

Heczko, M. et al. Elemental segregation to lattice defects in the CrMnFeCoNi high-entropy alloy during high temperature exposures. Acta Materialia 208, 116719 (2021).

Pandey, P. et al. On the faulting and twinning mediated strengthening and plasticity in a γʹ strengthened CoNi-based superalloy at room temperature. Acta Materialia 252, 118928 (2023).

ASTM E8 / E8M. Standard Test Methods for Tension Testing of Metallic Materials.

ASTM E399. Standard Test Method for Linear-Elastic Plane-Strain Fracture Toughness of Metallic Materials.

Army Materials and Mechanics Research Center. Plane Strain Fracture Toughness (KIC) Data Handbook for Metals. (1973).

Acknowledgements

Some of the electron microscopy presented in this work was performed at the Center for Electron Microscopy and Analysis (CEMAS) at The Ohio State University. V.M., M.H., B.C., and M.J.M. acknowledge financial support from the National Science Foundation under the contract No. #DMR-1905748. V.M. and M.H. also acknowledge financial support from the Czech Science Foundation under the Junior Star project with contract No. 24-11058 M. P.K. and R.O.R acknowledge the funding support of the Materials Sciences and Engineering Division of the U.S. Department of Energy, Office of Science, Office of Basic Energy Sciences through the Damage-Tolerance in Structural Materials program (KC13) at the Lawrence Berkeley National Laboratory (LBNL) under contract DE-AC02-CH11231. D.H.C. acknowledges the support of an NSF Graduate Fellowship from the National Science Foundation (grant no. DGE 2146752). E.P.G. was supported by the U.S. Department of Energy, Office of Science, Office of Basic Energy Sciences, Materials Sciences and Engineering Division for the melting, casting and forging of the CrCoNi alloy at the Oak Ridge National Laboratory

Author information

Authors and Affiliations

Contributions

C.E.S., E.P.G., M.J.M., and R.O.R. conceived the idea and initiated the project. V.M. performed sample preparation and SEM characterization of the as-received and heat-treated material before testing. B.C. performed the heat treatments. P.K., D.H.C., and Q.Y. performed the mechanical testing. V.M. performed preparation and SEM characterization of specimens after testing, including preparation of TEM specimens. P.K., B.C., and C.E.S. also contributed to post-testing SEM characterization. M.H. performed the TEM characterization and analysis after testing. C.E.S. wrote the manuscript except for the mechanical testing sections, which were written by P.K. The manuscript was reviewed and edited by V.M., P.K., D.H.C., M.H., E.P.G., M.J.M., and R.O.R.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Materials thanks Jia Li and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Primary Handling Editors: Xiaoyan Li and John Plummer. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Slone, C.E., Mazánová, V., Kumar, P. et al. Partially recrystallized microstructures expand the strength-toughness envelope of CrCoNi medium-entropy alloy. Commun Mater 5, 263 (2024). https://doi.org/10.1038/s43246-024-00704-z

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s43246-024-00704-z