Abstract

Sodium-ion batteries have been attracting extensive attention in both academic and industrial fields. However, the lack of large-area and ultrathin sodium (Na) metal foil hinders basic research on and commercialization of energy-dense Na-ion batteries. Here we successfully fabricated a metre-length, ultrathin (≤50 μm), mechanically strengthened Na metal foil by a roll-to-roll calendaring process with interfacial lubrication and functional modification. By developing self-lubricating polydimethylsiloxane as the multifunctional agent, the poor processibility of metallic Na is addressed by forming a mechanically strong interface as well as a surface lubricant film during rolling. Furthermore, polydimethylsiloxane-derived (Si–O)n-Na interphases can guide Na+-ion interfacial diffusion and enable a robust solid electrolyte interphase. Consequently, the large-area ultrathin Na foil exhibits a stable electrode potential and stripping capacity, as well as prolonged lifespan compared with bare Na anodes. This approach enables the realization of amp-hour-level Na metal pouch cells under a low negative-to-positive capacity ratio of 1.9, showing an energy density of 180.2 Wh kg−1. This scalable ultrathin Na foil establishes a materials foundation for fundamental studies on Na-ion batteries and the potential manufacture of high-energy-density Na metal batteries.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data supporting the findings of this study are available in the article and its Supplementary Information. Source data are provided with this paper.

References

Zhu, G. et al. Rechargeable Na/Cl2 and Li/Cl2 batteries. Nature 596, 525–530 (2021).

Zhuang, R. et al. Fluorinated porous frameworks enable robust anode-less sodium metal batteries. Sci. Adv. 9, eadh8060 (2023).

Deysher, G. et al. Design principles for enabling an anode-free sodium all-solid-state battery. Nat. Energy 9, 1161–1172 (2024).

Deng, T. et al. Interfacial-engineering-enabled practical low-temperature sodium metal battery. Nat. Nanotechnol. 17, 269–277 (2021).

Zheng, J. et al. Reversible epitaxial electrodeposition of metals in battery anodes. Science 366, 645–648 (2019).

Zhao, C. et al. Rational design of layered oxide materials for sodium-ion batteries. Science 370, 708–711 (2020).

Jin, Y. et al. Low-solvation electrolytes for high-voltage sodium-ion batteries. Nat. Energy 7, 718–725 (2022).

Usiskin, R. et al. Fundamentals, status and promise of sodium-based batteries. Nat. Rev. Mater. 6, 1020–1035 (2021).

Li, M. et al. Multifunctionalized safe separator toward practical sodium-metal batteries with high-performance under high mass loading. Adv. Funct. Mater. 33, 2214759 (2023).

Zheng, X. et al. Knocking down the kinetic barriers towards fast-charging and low-temperature sodium metal batteries. Energy Environ. Sci. 14, 4936–4947 (2021).

Wang, C. et al. A weakly coordinating-intervention strategy for modulating Na+ solvation sheathes and constructing robust interphase in sodium-metal batteries. Nat. Commun. 15, 6292 (2024).

Hatzell, K. B. Anode-less or anode-free? ACS Energy Lett. 8, 4775–4776 (2023).

Wu, W., Luo, W. & Huang, Y. Less is more: a perspective on thinning lithium metal towards high-energy-density rechargeable lithium batteries. Chem. Soc. Rev. 52, 2553–2572 (2023).

Yang, T., Luo, D., Liu, Y., Yu, A. & Chen, Z. Anode-free sodium metal batteries as rising stars for lithium-ion alternatives. iScience 26, 105982 (2023).

Wang, A. et al. Processable and moldable sodium–metal anodes. Angew. Chem. Int. Ed. 56, 11921–11926 (2017).

Wang, X. et al. Addressing the low solubility of a solid electrolyte interphase stabilizer in an electrolyte by composite battery anode design. ACS Appl. Mater. Interfaces 13, 13354–13361 (2021).

Han, J. & He, G. Capacity-limited Na–M foil anode: toward practical applications of Na metal anode. Small 17, 2102126 (2021).

Li, G. et al. Enhanced processability and electrochemical cyclability of metallic sodium at elevated temperature using sodium alloy composite. Energy Storage Mater. 35, 310–316 (2021).

Chen, H. et al. Free-standing ultrathin lithium metal–graphene oxide host foils with controllable thickness for lithium batteries. Nat. Energy 6, 790–798 (2021).

Peppou-Chapman, S., Hong, J. K., Waterhouse, A. & Neto, C. Life and death of liquid-infused surfaces: a review on the choice, analysis and fate of the infused liquid layer. Chem. Soc. Rev. 49, 3688–3715 (2020).

Tang, M. et al. Low-temperature anode-free potassium metal batteries. Nat. Commun. 14, 6006 (2023).

Han, S. et al. Sequencing polymers to enable solid-state lithium batteries. Nat. Mater. 22, 1515–1522 (2023).

Wang, M. J., Chang, J.-Y., Wolfenstine, J. B. & Sakamoto, J. Analysis of elastic, plastic, and creep properties of sodium metal and implications for solid-state batteries. Materialia 12, 100792 (2020).

Yang, C. et al. Roll-to-roll prelithiation of lithium-ion battery anodes by transfer printing. Nat. Energy 8, 703–713 (2023).

Zhang, D. et al. A sandcastle worm-inspired strategy to functionalize wet hydrogels. Nat. Commun. 12, 6331 (2021).

Tan, J. et al. Scalable customization of crystallographic plane controllable lithium metal anodes for ultralong-lasting lithium metal batteries. Adv. Mater. 36, 2403570 (2024).

Zheng, J. et al. Textured electrodes: manipulating built-in crystallographic heterogeneity of metal electrodes via severe plastic deformation. Adv. Mater. 34, 2106867 (2021).

Chen, H. et al. Synthesis of monocrystalline lithium for high-critical-current-density solid-state batteries. Nat. Synth. 4, 552–561 (2025).

He, X., Larson, J. M., Bechtel, H. A. & Kostecki, R. In situ infrared nanospectroscopy of the local processes at the Li/polymer electrolyte interface. Nat. Commun. 13, 1398 (2022).

Dazzi, A. & Prater, C. B. A. F. M.-I. R. Technology and applications in nanoscale infrared spectroscopy and chemical imaging. Chem. Rev. 117, 5146–5173 (2016).

Wang, H., Zhang, X., Li, Y. & Xu, L. W. Siloxane-based organosilicon materials in electrochemical energy storage devices. Angew. Chem. Int. Ed. 61, e202210851 (2022).

Li, Y. et al. Sole-solvent high-entropy electrolyte realizes wide-temperature and high-voltage practical anode-free sodium pouch cells. Adv. Mater. 37, 2419764 (2025).

Yang, X. et al. Synchronous dual electrolyte additive sustains Zn metal anode with 5600 h lifespan. Angew. Chem. Int. Ed. 62, e202218454 (2023).

Wei, Y. et al. Enabling all-solid-state Li metal batteries operated at 30 °C by molecular regulation of polymer electrolyte. Adv. Energy Mater. 13, 2203547 (2023).

Huang, S. et al. Interfacial friction enabling ≤20 μm thin free-standing lithium strips for lithium metal batteries. Nat. Commun. 14, 5678 (2023).

Liu, G. X. et al. Revealing the high salt concentration manipulated evolution mechanism on the lithium anode in quasi-solid-state lithium-sulfur batteries. Angew. Chem. Int. Ed. 61, e202212744 (2022).

Hwang, J. et al. Enhanced mechanical properties of graphene/copper nanocomposites using a molecular-level mixing process. Adv. Mater. 25, 6724–6729 (2013).

Huang, Z. et al. Effects of polymer coating mechanics at solid-electrolyte interphase for stabilizing lithium metal anodes. Adv. Energy Mater. 12, 2103187 (2021).

Huang, Z., Lyu, H., Greenburg, L. C., Cui, Y. & Bao, Z. Stabilizing lithium-metal electrodes with polymer coatings. Nat. Energy 10, 811–823 (2025).

Fang, C. et al. Quantifying inactive lithium in lithium metal batteries. Nature 572, 511–515 (2019).

Wang, S., Zhang, X.-G., Gu, Y., Tang, S. & Fu, Y. An ultrastable low-temperature Na metal battery enabled by synergy between weakly solvating solvents. J. Am. Chem. Soc. 146, 3854–3860 (2024).

Lopez, J. et al. Effects of polymer coatings on electrodeposited lithium metal. J. Am. Chem. Soc. 140, 11735–11744 (2018).

Zhao, Y. et al. Tailoring grain boundary stability of zinc–titanium alloy for long-lasting aqueous zinc batteries. Nat. Commun. 14, 7080 (2023).

Wan, S. et al. Reductive competition effect-derived solid electrolyte interphase with evenly scattered inorganics enabling ultrahigh rate and long-life span sodium metal batteries. J. Am. Chem. Soc. 145, 21661–21671 (2023).

Feng, G. et al. Imaging solid–electrolyte interphase dynamics using operando reflection interference microscopy. Nat. Nanotechnol. 18, 780–789 (2023).

Gao, L., Chen, J., Chen, Q. & Kong, X. The chemical evolution of solid electrolyte interface in sodium metal batteries. Sci. Adv. 8, eabm4606 (2022).

Zhu, Q. et al. A 110 Wh kg−1 Ah-level anode-free sodium battery at −40 °C. Joule 8, 482–495 (2024).

Liang, H. P. et al. Polysiloxane-based single-ion conducting polymer blend electrolyte comprising small-molecule organic carbonates for high-energy and high-power lithium-metal batteries. Adv. Energy Mater. 12, 2200013 (2022).

Tomich, A. W. et al. A carboranyl electrolyte enabling highly reversible sodium metal anodes via a “fluorine-free” SEI. Angew. Chem. Int. Ed. 61, e202208158 (2022).

Fang, H. et al. Dual-function presodiation with sodium diphenyl ketone towards ultra-stable hard carbon anodes for sodium-ion batteries. Angew. Chem. Int. Ed. 62, e202214717 (2022).

Lu, G. et al. High-voltage electrosynthesis of organic-inorganic hybrid with ultrahigh fluorine content toward fast Li-ion transport. Sci. Adv. 10, eado7348 (2024).

Wang, E. et al. Mitigating electron leakage of solid electrolyte interface for stable sodium-ion batteries. Angew. Chem. Int. Ed. 62, e202216354 (2022).

Niu, C. et al. Balancing interfacial reactions to achieve long cycle life in high-energy lithium metal batteries. Nat. Energy 6, 723–732 (2021).

Da, X. et al. CO2-assisted induced self-assembled aramid nanofiber aerogel composite solid polymer electrolyte for all-solid-state lithium-metal batteries. Adv. Energy Mater. 14, 2303527 (2024).

Kang, Q. et al. Engineering a dynamic solvent-phobic liquid electrolyte interphase for long-life lithium metal batteries. Adv. Mater. 36, 2308799 (2024).

Xue, Y. et al. Molecular design of mono-fluorinated ether-based electrolyte for all-climate lithium-ion batteries and lithium-metal batteries. Angew. Chem. Int. Ed. 64, e202414201 (2024).

Zhang, H. et al. A ‘tug-of-war’ effect tunes Li-ion transport and enhances the rate capability of lithium metal batteries. Chem. Sci. 14, 2745–2754 (2023).

Cao, L. et al. A rooted multifunctional heterogeneous interphase layer enabled by surface-reconstruction for highly durable sodium metal anodes. Adv. Funct. Mater. 34, 2313962 (2024).

He, J. et al. Tuning the solvation structure with salts for stable sodium-metal batteries. Nat. Energy 9, 446–456 (2024).

Zuo, C., Dong, D., Wang, H., Sun, Y. & Lu, Y.-C. Bromide-based nonflammable electrolyte for safe and long-life sodium metal batteries. Energy Environ. Sci. 17, 791–799 (2024).

Acknowledgements

We thank L. Gu and T. Lin of Tsinghua University for data analysis and discussion. This research was supported by the high performanced computing resource and Analysis and Testing Center at Beihang University. We acknowledge the technicians at Shenzhen HUASUAN Technology Co., Ltd. for assistance with finite element calculations (https://huasuankeji.com). This work was supported by the International Cooperation Project of National Key Research and Development Program of China (grant nos. 2020YFA0710403 to L.G. and 2022YFE0126300 to H.W.), National Natural Science Foundation of China (grant nos. 52225208 to X.T.; 12374284, 52172178 and 52302287 to H.W.; 52494930 and 52450002 to L.G.; 52222317 to J.N.; and 52302287 to J.W.).

Author information

Authors and Affiliations

Contributions

M.T., H.W. and L.G. conceived the idea. M.T., S.D., J.W. and H.L. cowrote the manuscript. M.T., S.D., J.Z., L.C. and H.L. designed and performed the experiments and analysed the data. K.Y., S.S., Y.L., J.N. and X.T. assisted in cryo-TEM characterizations for materials. Q.Z. performed the density functional theory calculation. R.L. and R.W. contributed to AFM characterizations for materials. P.C. assisted in the fabrication of Na foils in Jiaxing Changgao New Material Technology Co., LTD. M.T., L.W., B.Z. and D.Y. provided pouch cells. W.L. and X.W. performed the SEM characterization. All authors discussed the results.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Synthesis thanks Kaifu Huo, Soojin Park and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Primary Handling Editor: Peter Seavill, in collaboration with the Nature Synthesis team.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–53, Tables 1–7, Videos 1–4 and References 1–22.

Supplementary Video 1

FE simulations of the thinning process of Na foils with and without lubricating oil.

Supplementary Video 2

Air stability tests of p-Na and Na in dry condition.

Supplementary Video 3

Air stability tests of p-Na and Na in humid condition.

Supplementary Video 4

Roll-to-roll fabrication of meter-scale ultrathin Na metal foils.

Source data

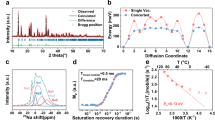

Source Data Fig. 2

Statistical source data.

Source Data Fig. 3

Statistical source data.

Source Data Fig. 5

Statistical source data.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tang, M., Dong, S., Yue, K. et al. Scalable ultrathin sodium metal anodes. Nat. Synth (2025). https://doi.org/10.1038/s44160-025-00934-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s44160-025-00934-0