Abstract

High-fidelity capture of physiological signals across a broad frequency spectrum requires soft vibration sensors with exceptional performance. However, existing devices fail to achieve uniformly high sensitivity across the full spectrum while maintaining reliable, low-power operation. Here we report a piezoelectric-powered capacitive vibration sensor that overcomes these limitations. In this design, a piezoelectric diaphragm serves as a non-contact power source, generating a stable bias field and actively modulating the signal to enable self-powered operation. To further enhance performance, we implement a device architecture featuring in-plane air ventilation and maximized sensor array density. The resulting sensors exhibit a linear sensitivity of 626 mV g−1, a flat frequency response from 80 to 5,000 Hz, an ultralow detection limit of 0.01 g and a signal-to-noise ratio of 80 dB, representing substantial improvements over conventional devices. We demonstrate that the hyperpacked, piezoelectric-powered sensor array enables high-fidelity detection of music, voice and respiratory signals by capturing subtle mechanical vibrations.

Similar content being viewed by others

Main

Vibration, a fundamental mechanical stimulus, transmits dynamic signals that extend beyond quasi-static responses such as strain1, shear2 and pressure3,4. Unlike these, vibration conveys unique information due to its (1) ultralow-intensity signals and (2) broad frequency range. These characteristics make it indispensable for applications including structural health monitoring, industrial maintenance and human physiological sensing5,6. Notably, many vital physiological signals manifest as minute vibrations spanning a wide frequency spectrum—for example, cardiac activity in the 10–250 Hz range7, human voice in the 150–450 Hz range8 and respiration from 100 to 2,000 Hz (ref. 9). Capturing these signals with high fidelity is crucial for next-generation wearable health monitoring10,11 and human–machine interfaces12,13,14.

To address this need, flexible vibration sensors capable of conforming to curved and soft surfaces, such as human skin, have garnered substantial attention15,16,17,18,19,20. Capacitive sensors stand out for their inherently flat frequency response and linear sensitivity5, and designs incorporating microstructured hydrogels21,22 or through-hole patterned diaphragms23,24,25,26, for example, enable stable frequency characteristics, facilitating precise broadband physiological signal detection. However, existing designs face some critical limitations: they often rely on bulky external power sources21,23,25 or environmentally unstable electret materials24,27 to provide a bias voltage, which limits their practicality in wearable applications. Fabrication is also complex, often involving intricate features such as air vents, array configurations or microscale patterning21,24. Moreover, their performance—and broader applicability—is constrained by a narrow flat frequency range, limited sensitivity and poor signal-to-noise ratio (SNR)21,23,24.

In this Article we report a hyperpacked capacitive vibration sensor array that achieves high-fidelity broadband detection through a non-contact piezoelectric effect. Unlike conventional capacitive sensors that require external power sources or electret materials to generate a bias voltage, our design makes use of a piezoelectric poly(vinylidene fluoride-trifluoroethylene) (PVDF-TrFE) thin film as the diaphragm. Piezoelectric charges from the diaphragm sustain a built-in bias field and drive the signal response, enabling stable and efficient self-powered operation. To ensure scalable fabrication, we introduce a one-step photolithography process in which star-shaped supports promote in-plane air ventilation through side vent holes, eliminating the need for intricate structures and allowing an ultracompact array configuration. As a result, the sensor exhibits a linear sensitivity of 626 mV g−1, a flat frequency response spanning 80–5,000 Hz and an SNR of 80 dB, substantially outperforming existing vibration/acoustic sensors in key performance metrics. Demonstrated as a soft-contact microphone, a laryngophone and a wearable healthcare device, it enables high-fidelity detection of music, voice and respiratory signals, offering important opportunities for next-generation human–machine interfaces and health monitoring.

Hyperpacked vibration sensor array

The hyperpacked capacitive vibration sensor array consists of a 15-μm-thick PVDF-TrFE film attached to a 40-μm-thick star-shaped patterned support layer, which is laminated onto a parylene substrate (Fig. 1a). Each unit sensor is supported by four star-shaped structures and features a central 1,600-μm-diameter circular region, where the suspended piezoelectric film acts as a diaphragm to detect vibrations (Fig. 1b,c and Supplementary Fig. 1). Gold electrodes, positioned on the upper surfaces of both the piezoelectric film and the parylene substrate, detect capacitance variations induced by diaphragm motion (Fig. 1b). The star-shaped support structures are arranged in a regular array, enabling the formation of multiple unit vibration sensors densely connected in parallel (Fig. 1c and Supplementary Fig. 2). Additionally, an intermediate Au layer between the support and diaphragm layers enhances adhesion and suppresses noise from non-diaphragm regions.

a, Schematic of the hyperpacked vibration sensor array. b, Schematic of a unit sensor and its diaphragm structure. Cgap is the variable capacitance formed between the diaphragm and the bottom electrode. c, OM and SEM images of the star-shaped support architecture, which enables the hyperpacked sensor configuration (OM scale bar, 2 mm; SEM scale bar, 1 mm). d, Schematic highlighting the key differences between a conventional capacitive sensor (left) and the proposed hyperpacked sensor array (right). e, Schematic illustration of the operating mechanism in the proposed sensor (left), and the simulated piezopotential distribution during diaphragm oscillation (right).

Our hyperpacked vibration sensor array is an important advancement over conventional capacitive vibration sensors, both in device architecture and material integration. From a design perspective, the star-shaped support structure plays a crucial role in enabling high-fidelity sensing, a hyperpacked sensor configuration and enhanced processability. In previous studies, air vent holes were introduced in the diaphragm or backplate to mitigate air-squeezed damping (Fig. 1d, left)23,24,25. In contrast, our approach eliminates air-squeezed damping by facilitating horizontal air circulation through individualized star-shaped supports (Fig. 1d, right). Numerical airflow simulations verify that this architecture provides effective, well-distributed ventilation across all unit cells (Supplementary Fig. 3 and Supplementary Video 1). This in-plane air ventilation minimizes thermal noise and improves sensitivity, as aligned airflow and diaphragm deflection can cause energy loss.

Furthermore, the circular regions enclosed by the star-shaped supports function as diaphragms, allowing a hyperpacked sensor configuration with zero wasted area (Fig. 1d, right). Eliminating air holes in the diaphragm or backplate not only simplifies fabrication via one-step photolithography (Supplementary Figs. 4 and 5), but also preserves a larger proportion of the diaphragm as the active sensing area compared with conventional designs (Supplementary Fig. 6). Although removing through-holes increases the effective stiffness of the circular diaphragm region, the star-shaped support configuration enables greater overall displacement of the diaphragm layer within the unit cell (Supplementary Fig. 7). This architecture also yields a substantially lower initial capacitance than conventional designs. Together, these features enhance the relative capacitance change and thereby improve sensitivity (Supplementary Fig. 8). Furthermore, supporting each diaphragm with four discrete anchoring structures, rather than a single bulk frame, markedly improves flexibility under bending (Supplementary Fig. 9).

From a materials standpoint, the device further distinguishes itself by incorporating a non-contact piezoelectric diaphragm—a simple yet highly effective strategy for more efficient, stable and sensitive operation. This approach removes the need for bulky external power sources23,25 or the unstable electret layers24,28 typically required for biasing in conventional capacitive sensors (Fig. 1d). Instead, remnant polarization within the piezoelectric material provides intrinsic charges that establish a stable initial bias field across the sensor. Mechanical vibrations drive diaphragm oscillations, inducing stress-dependent polarization and generating additional charges that directly contribute to the electrical output (Fig. 1e). Although the diaphragm does not physically contact the bottom electrode, the top and bottom electrodes are electrically connected through the interface circuitry (CKT), enabling charge redistribution (ΔQ). At the same time, diaphragm motion changes the electrode spacing, producing a capacitance variation (ΔC). The sensor’s electrical output is therefore governed by the combined effects of ΔQ and ΔC.

In capacitive sensors, accumulated charge is typically required to convert small capacitance variations into measurable voltage signals—a process facilitated by an interface circuit with an amplifier, as described by V = Q/C (Supplementary Fig. 10)21,23,24. In this context, the sensing mechanism of our device can be described by a governing relation that incorporates simultaneous variations in both Q and C (Supplementary Note 1). In our device, piezoelectric charges from remnant polarization provide a stable bias for capacitive sensing, while motion-induced piezoelectric charges contribute as a smaller secondary term. The capacitive variation is expected to dominate the signal, with sensitivity maximized when the phases of ΔQ and ΔC are optimally aligned (Supplementary Note 1 and Supplementary Fig. 11).

Characterization of the piezoelectric diaphragm

The thin piezoelectric diaphragm was fabricated by spin-coating PVDF-TrFE dissolved in an organic solvent. Traditionally, highly polar solvents such as dimethylformamide (DMF)29, dimethyl sulfoxide (DMSO)30 and N-methyl-2-pyrrolidone (NMP)31 have been predominantly used for PVDF-TrFE processing. However, these solvents pose notable health risks, including liver damage and reproductive toxicity. To mitigate these concerns, we employed propyl acetate (PA), a less hazardous alternative, which fully dissolved the PVDF-TrFE (Supplementary Fig. 12) and yielded a film with a high β-phase content. Fourier-transform infrared (FT-IR) analysis confirmed characteristic β-phase peaks at 1,400 cm−1, 1,288 cm−1 and 850 cm−1, comparable to those observed with DMF, demonstrating PA’s suitability as a safer solvent (Fig. 2a).

a, FT-IR spectra of PVDF-TrFE films fabricated using DMF and PA solvents. b, TrWAXS spectra of unpoled and poled PVDF-TrFE films. c, Measured d31 of unpoled and poled PVDF-TrFE films. d, Comparison of contact stability between the electret film (CYTOP, left) and the piezoelectric film (PVDF-TrFE, right). Stability was evaluated following direct contact with water, artificial sweat and human skin, with measurements taken 2 h after contact removal. The piezoelectric output voltage was measured at 300 Hz under the same vibrational amplitude. Each dot represents the relative surface potential or piezoelectric output voltage from an independent sample, and data are presented as mean ± s.d. (n = 5).

Conventionally, the degree of poling in PVDF-TrFE has been assessed using one-dimensional (1D) X-ray diffraction (XRD), focusing on the peak intensity changes of the (110)/(200) β-phase diffraction peak near 20° and the (021) diffraction peak around 40.8°, which can emerge after poling32. However, this method has limited precision in evaluating the α-to-β phase transition and the alignment of β-phase crystals, as 1D XRD integrates diffraction data from all orientations into a single spectrum (Supplementary Fig. 13).

To overcome the limitations of 1D XRD in assessing the α-to-β phase transition and crystallite alignment, we used 2D transmittance wide-angle X-ray scattering (TrWAXS) in both vertical and horizontal X-ray exposure directions (Supplementary Fig. 14). Vertical TrWAXS analysis revealed that, before poling, both α- and β-phases were present, whereas after poling, a clear α-to-β phase transition was observed (Fig. 2b, top). This transition was further corroborated by out-of-plane d-spacing measurements, which revealed that the polymer chains in the α-phase initially exhibited a d-spacing of 4.92 Å, while those in the β-phase exhibited 4.59 Å. After poling, the α-phase disappeared, and the d-spacing of the β-phase decreased a little bit to 4.57 Å, indicating a slightly denser molecular arrangement characteristic of the (110)/(200) β-phase diffraction (Supplementary Fig. 15 and Supplementary Table 1).

Meanwhile, horizontal TrWAXS analysis confirmed the well-aligned β-phase crystallites, demonstrating enhanced molecular ordering along the poling direction (Fig. 2b, bottom). Additionally, azimuthal angle-dependent intensity analysis revealed a pronounced increase in out-of-plane orientation, indicating preferential β-phase domain alignment (Supplementary Fig. 16). These results confirm that the poling process not only facilitated the α-to-β phase transition but also promoted β-phase crystallite alignment along the external electric field, which is perpendicular to the film thickness. To further validate this structural transition, we measured the piezoelectric coefficient (d31) of the poled PVDF-TrFE film, which exhibited a substantially higher d31 value of ~15 pC N−1 compared to the unpoled sample (Fig. 2c and Supplementary Fig. 17). This value falls within the range of previously reported d31 values for poled PVDF-TrFE (∼10–20 pC N−1)33,34,35,36, reinforcing the reliability of our results (Supplementary Table 2).

Although some β-phase was present in the unpoled PVDF-TrFE film, and thermal annealing may have induced partial dipole alignment, the dipoles within the β-phase domains largely remained randomly oriented (Fig. 2b, bottom). As a result, their contributions tended to cancel out, leading to the observed low d31 value. Similar contrasts in piezoelectric performance between poled and unpoled (thermally annealed) PVDF-TrFE have been reported in previous studies33,37,38, further supporting the validity of our results. This enhancement in d31 strongly correlates with the observed structural transition, confirming the efficacy of the corona poling process.

To evaluate the environmental stability of the piezoelectric diaphragm in comparison with a conventional electret diaphragm, we measured the relative output voltage of the PVDF-TrFE film and the relative surface potential of the CYTOP film before and after exposure to deionized water, artificial sweat and direct skin contact (Fig. 2d). The PVDF-TrFE film retained most of its initial output voltage under all conditions, whereas the electret CYTOP film lost over 90% of its surface potential. The PVDF-TrFE film also maintained a stable d31 across all conditions (Supplementary Fig. 18).

This stark contrast arises from their fundamentally different charge mechanisms: piezoelectric materials retain stable remnant polarization and generate dynamic charges through lattice distortion, both inherently resistant to moisture and skin contact, whereas electret materials rely primarily on surface-trapped charges, which readily degrade under environmental exposure. As a result, PVDF-TrFE maintains long-term performance without requiring additional protective measures, whereas electrets such as CYTOP necessitate careful handling to prevent charge loss. Its exceptional moisture and skin-contact stability make PVDF-TrFE particularly well-suited for skin-attachable electronics.

Vibration sensing performance of the hyperpacked sensor array

The hyperpacked vibration sensor array was optimized by carefully tuning key structural parameters: the number of diaphragms and the thicknesses of both the support layer and the diaphragm (Fig. 3a,b). Increasing the diaphragm count and reducing the support layer thickness improved sensitivity (Fig. 3b, left and middle), with a maximum of 64 diaphragms accommodated within the 16 × 18-mm2 sensor area. Because the diaphragms are connected in parallel, their capacitance variations add linearly, producing a proportional increase in signal (Supplementary Fig. 2)23,39,40. Furthermore, because the first-mode resonant frequency lies well above the sensor’s operating bandwidth, all diaphragms oscillate in the first vibration mode with in-phase motion (Supplementary Fig. 19), ensuring that this proportional relationship between diaphragm count and sensitivity is fully realized. However, thinning the support layer below 40 µm proved impractical, as it caused the diaphragm to adhere to the bottom electrode during fabrication and drastically reduced production yield (Supplementary Fig. 20). Interestingly, the optimal diaphragm thickness for maximum sensitivity was found to be ~15 μm (Fig. 3b, right), contradicting previous reports that associate thinner diaphragms with higher sensitivity due to reduced stiffness and increased displacement23. This discrepancy arises because the piezoelectric diaphragm must retain sufficient thickness to provide enough piezoelectric charge; beyond 15 μm, excessive stiffness counteracts this effect, reducing sensitivity.

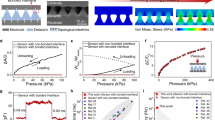

a, Schematic of the hyperpacked vibration sensor, highlighting the key parameters optimized in this study. b, Effects of the number of diaphragms, support thickness and diaphragm thickness on vibration sensitivity. Each dot represents the mean sensitivity calculated from 800 frequency-sweep points across the bandwidth of an independent sensor. Data are presented as mean ± s.d. (n = 4). c, Vibration sensitivity measured at 500, 1,000, 1,500 and 2,000 Hz under input amplitudes ranging from 0.1 to 2.5 g. The relationship between acceleration and output voltage was analysed using a linear regression model based on repeated measurements at four frequencies (n = 10 per frequency). The model exhibits strong linearity (R2 = 0.9867). d, Frequency response showing the effect of piezoelectric-induced charges on sensor performance, comparing diaphragms made of poled and unpoled PVDF-TrFE and SU-8. e, Limit of detection of the hyperpacked vibration sensor under a 500-Hz input. f, SNR of the hyperpacked vibration sensor under a 1-g input vibration at 500, 1,000, 1,500, 2,000 and 2,500 Hz.

The optimized device exhibited a high sensitivity of 626 mV g−1 while maintaining excellent linearity over a broad vibration acceleration range of 0.1–2.5 g (Fig. 3c). This superior linearity was attributed to the device structure, which features thin diaphragms. Each diaphragm, with fixed boundaries set by four star-shaped supports, undergoes vertical displacement linearly proportional to the vibration amplitude (Supplementary Fig. 21)41. Furthermore, the sensor demonstrated outstanding long-term stability and durability, retaining both sensitivity and linearity even after 210 days under identical vibration conditions with 1,000 cycles (Supplementary Fig. 22). The sensor also showed remarkable environmental stability, preserving its sensitivity even after immersion in water (Supplementary Fig. 23).

Beyond its high sensitivity and stability, the sensor featured an exceptionally flat frequency response within ±3 dB over a broad frequency range of 80–5,000 Hz (Fig. 3d). Although this flat response was not maintained below 50 Hz, the sensor still reliably detected static and low-frequency vibrations (Supplementary Fig. 24). In contrast, sensors fabricated using unpoled PVDF-TrFE and epoxy-based SU-8 diaphragms produced unstable signals, with outputs nearly indistinguishable from noise. Similarly, a control sensor with a PTFE diaphragm (a highly tribonegative material) generated only unstable, noise-like signals, ruling out triboelectric effects as the primary sensing mechanism (Supplementary Fig. 25). When the PVDF-TrFE diaphragm was slightly poled (d31 = 4 pC N−1), the sensor immediately produced a stable and clearly readable signal, further confirming the critical role of piezoelectric charge in its operation (Supplementary Fig. 26). Additionally, air ventilation between the star-shaped supports effectively suppressed air-squeezed damping, as evidenced by the absence of the high-frequency roll-off characteristic of such damping (Supplementary Fig. 27)23,42,43. This ensured both high sensitivity and a stable, flat frequency response across a wide range.

Moreover, the sensor exhibited an ultralow limit of detection, detecting minute vibration inputs as low as 0.01 g—a level corresponding to skin vibrations produced by soft breathing (Fig. 3e)44. Furthermore, the sensor achieved an exceptionally high SNR of ~80 dB across broad frequencies (Fig. 3f). Even when the noise power spectral density within the auditory frequency range was considered, the sensor maintained a high SNR of ~43 dB(A) under A-weighted conditions (Supplementary Fig. 28). This remarkable performance was attributed to the inherently low mechanical and electrical noise of the capacitive device structure45, as well as the exceptional sensitivity of our piezoelectric-powered capacitive sensor. These results indicate that the sensor is tailored for high-fidelity vibration detection across a wide amplitude and frequency range, capable of precisely measuring signals from extremely small to large amplitudes, even beyond the telephonic range (~3,000 Hz). This breakthrough paves the way for a diverse range of vibration-based applications.

High-fidelity audio recording via vibration sensing

A sound-producing object generates subtle vibrations that propagate through solid media and can be captured for audio recording. Leveraging this principle, our sensor enables high-fidelity sound acquisition by precisely detecting mechanical vibrations. We validated its performance by benchmarking it against a commercial high-resolution accelerometer (352C33, PCB Piezotronics). Both devices were placed on a vibration speaker during recording (Supplementary Fig. 29), and the volume of the played music was kept constant to ensure a fair comparison. For the recordings, we used Spring (Movement 1) from The Four Seasons by Vivaldi, which features distinct cello and violin solo passages. The short-time Fourier-transform (STFT) spectrogram of the original music revealed characteristic differences between the two instruments: the cello exhibited strong energy concentration in the lower frequency range with clear harmonic overtones, and the violin showed energy concentrated in the higher frequency range with finer, more detailed spectral features (Fig. 4a).

a–c, Output waveforms and STFT spectrograms of the original music (a), the recording captured by the hyperpacked sensor array (b) and the recording captured by a commercial high-resolution accelerometer (c). All recordings were obtained by attaching the sensor and accelerometer to a vibration speaker at the same sound pressure level (SPL), with no post-processing applied.

The audio recording obtained with our sensor closely matched the original music, exhibiting an almost identical time-domain output waveform and STFT spectrogram while clearly capturing the distinct characteristics of both the cello and violin (Fig. 4b). More importantly, even when compared to the commercial accelerometer, our sensor demonstrated comparable performance, producing a similar output waveform and STFT spectrogram across a broad frequency range of up to 5,000 Hz (Fig. 4b,c). The recorded music exhibited minimal distortion and maintained high sound quality across the detection frequency range (Supplementary Video 2). While achieving similar audio recording performance to the commercial high-resolution accelerometer, our sensor offers distinct advantages: it is thinner, smaller and, most importantly, highly flexible rather than rigid.

Acoustic sensing performance of the hyperpacked vibration sensor array

Owing to its exceptional flexibility (Supplementary Fig. 9), our sensor conforms seamlessly to the neck, ensuring excellent skin contact and efficient vibration transfer. The amplitude of neck skin vibrations induced by vocalization has been reported to exhibit a linear correlation with vocal sound pressure23,46. Using this relationship, the sensor’s vibration sensitivity was mapped to an inferred acoustic sensitivity (Fig. 5a). The output voltage was recorded for input vibrations up to 2.5 g at 200, 300 and 400 Hz—within the human fundamental vocal frequency range (150–450 Hz)8. To account for inter-individual variability, we used the lower bound of the measured correlation between skin acceleration and vocal sound pressure (Supplementary Fig. 30), yielding an inferred acoustic sensitivity of 6.07 V Pa−1 with a linear response. We emphasize that this inferred value is not an intrinsic sensor property and will vary between users.

a, Inferred acoustic sensitivity of the hyperpacked vibration sensor array. Sac represents the sensitivity calculated from the output voltage and voice pressure at fundamental human vocalization frequencies of 200, 300 and 400 Hz. The relationship between acceleration and output voltage at vocal fundamental frequencies was analysed using a linear regression model based on repeated measurements (n = 10 per frequency). The model exhibits strong linearity (R2 = 0.9851). b, Comparison of voice detection capabilities between a commercial microphone and the hyperpacked vibration sensor array attached to the neck. c, Comparison of dynamic range and sensitivity with previously reported sensors. The dynamic range of our sensor reflects the measurements from Supplementary Fig. 30. Human vocalizations, including whispers, typically range from 25 to 60 dBSPL, while sound levels above 85 dBSPL may negatively affect hearing. d, Comparison of frequency range and SNR with existing sensors.

When attached to the neck, the sensor captured high-fidelity voice signals with clear waveform and spectral features (Fig. 5b and Supplementary Fig. 31). Because capacitive sensors are inherently susceptible to electromagnetic interference (EMI), we encapsulated the sensor within a compact, flexible shielding case (Supplementary Fig. 32) before attachment to minimize EMI effects. To evaluate its performance, we recorded a complex sentence (‘Hi, my name is Kang Hyuk Cho. I am researching vibration sensors at POSTECH.’) and analysed the resulting waveforms and harmonic structures using STFT47. The spectral characteristics closely matched those captured by a commercial microphone (Fig. 5b: top, our sensor; bottom, a commercial microphone). Moreover, even in acoustically challenging environments, the sensor effectively captured voice signals with minimal interference from ambient noise (Supplementary Fig. 33). This was achieved by detecting voice through neck skin vibrations rather than airborne sound waves, and the flexible EMI shielding case further blocked external acoustic waves from reaching the diaphragm, ensuring that background noise had a minimal impact.

Importantly, for effective use in speech communication, the sensor must maintain high sensitivity across the dynamic range corresponding to normal conversation levels (40–60 dBSPL). However, most state-of-the-art vibration and acoustic sensors exhibit low sensitivity in this range, or worse, their dynamic range does not fully cover it, instead focusing on levels above 60 dBSPL (Fig. 5c and Supplementary Table 3). Many of these sensors are characterized at sound levels exceeding 90 dBSPL, which are classified as harmful and can cause hearing damage with prolonged exposure. Measuring sensitivity at such high levels is impractical for everyday speech applications. In contrast, our sensor features a broad dynamic range, spanning from ~20 dBSPL (equivalent to whispering) to 90 dBSPL (comparable to the noise of a heavy truck), while maintaining consistently high linear sensitivity throughout (Fig. 5c).

In addition to a broad dynamic range, maintaining a high and stable SNR across a wide frequency spectrum is essential for accurately capturing broadband physiological signals beyond voice. However, many existing sensors exhibit highly non-flat frequency responses, often reporting the SNR only at their resonant frequency rather than across the full spectrum (Fig. 5d and Supplementary Table 3). In real-world applications, this results in substantial signal distortion, requiring extensive post-processing for high-fidelity detection. Some recent designs incorporate multichannel resonant frequency arrays to address this limitation, but they still experience a gradual SNR decline at higher frequencies, resembling damping effects. Capacitive sensors provide a more stable SNR, but their absolute values remain relatively low. In contrast, our sensor achieves an exceptionally high and consistent SNR across a broad frequency range (80–5,000 Hz), ensuring high-fidelity broadband signal acquisition.

Respiratory disease diagnosis via vibration sensing

Respiratory signals provide critical diagnostic information, yet their detection is often hindered by ambient noise and the weak signal strength of breath sounds48. A vibration sensor placed on the skin near the vocal cords offers a direct and reliable approach for capturing these signals by detecting subtle laryngeal vibrations. As the vocal cords open during inhalation and partially close during exhalation, they generate airflow-induced vibrations that propagate through surrounding tissue. Positioning the sensor between the vocal cords and ribcage facilitates the detection of respiratory sounds associated with disorders such as stridor and crackles. Recent studies have demonstrated the feasibility of this method, underscoring its potential for diagnosing respiratory disease49. Notably, our sensor’s high-fidelity vibration detection allows for precise differentiation of respiratory sounds, improving diagnostic accuracy.

To evaluate this capability, the sensor was placed on the skin near the vocal cords (Fig. 6a), and natural conversation was recorded for 20 s. The recorded output signals were transformed into a spectrogram using STFT to visually distinguish speech from respiratory sounds (Fig. 6b). The speech signals exhibited multiple harmonics spanning a broad frequency range, originating from the fundamental frequency of the vocal cord vibrations. In contrast, respiratory sounds appeared as short, low-amplitude harmonic signals concentrated below 1 kHz with minimal spectral complexity. The sensor could detect breathing sounds at different respiration rates (slow, normal and fast), with clear inhale and exhale events recorded for all conditions (Supplementary Fig. 34). This contrast enabled a clear separation between speech and respiratory signals.

a, Schematic of the vibration sensor attached to the neck for monitoring voice and respiration signals. b, STFT spectrogram of recorded voice and respiration signals. c, Output waveform of normal breathing, with inhale and exhale phases labelled. d, STFT spectrogram and PSD of normal respiration during a single inhalation–exhalation cycle. e, Output waveform of abnormal breathing. f, STFT spectrogram and PSD of stridor—a pathological breathing sound—during a single inhalation–exhalation cycle.

In normal breathing, inhalation and exhalation waveforms followed a regular pattern (Fig. 6c), with power spectral density (PSD) analysis showing no notable differences in frequency distribution between the two phases (Fig. 6d). In contrast, breathing signals from patients with stridor exhibited distinct differences in pitch between inhalation and exhalation, with sharp waveform peaks observed during the inhalation phase (Fig. 6e)50. PSD analysis of the signals from patients with stridor revealed a distinct inhalation spectral peak at ~350 Hz—a hallmark of turbulent airflow resulting from airway narrowing (Fig. 6f). The vibration sensor also captured a distinctive spectral peak characteristic of coarse crackles, another class of abnormal respiratory sounds (Supplementary Fig. 35). These results demonstrate that our sensor can effectively detect pathological respiratory signals, with observations closely aligning with previously reported clinical findings. This consistency suggests that the sensor may serve as a non-invasive and reliable tool for respiratory disease diagnostics.

Conclusions

We have reported a hyperpacked, piezoelectric-powered capacitive sensor array for broadband mechanical stimuli detection. The device architecture is based on a star-shaped support structure fabricated via a facile one-step photolithography process. This design facilitates air ventilation through side vent holes—eliminating the need for intricate structures—and enables an ultracompact array configuration. Distinguishing itself from existing approaches, the sensor incorporates a non-contact piezoelectric diaphragm, a simple yet highly effective strategy for boosting sensitivity, stability and energy efficiency. As a result, the device demonstrates a substantial leap in sensing performance compared to previously reported vibration/acoustic sensors, with a linear sensitivity of 626 mV g−1, a flat frequency response spanning 80–5,000 Hz, an SNR of 80 dB and excellent temporal and environmental stability—all without requiring an external bias voltage. We have demonstrated high-fidelity recording of music, voice and respiratory signals by detecting subtle mechanical vibrations. This architecture- and materials-driven approach advances broadband mechanical sensing, offering progressive solutions for voice-enabled Internet of Things systems and personalized mobile healthcare technologies.

Methods

Fabrication of hyperpacked vibration sensor array

A PVDF-TrFE solution (18 wt%) was prepared by dissolving PVDF-TrFE powder (FC30, Piezotech) in PA and stirring for 24 h. A glass wafer was sequentially coated with a Ti/Al (15/100 nm) sacrificial layer via thermal evaporation and a 50-nm Au top electrode via sputter deposition (E-1030 ion sputter, Hitachi). The PVDF-TrFE solution was then spin-coated to form an ~15-µm-thick diaphragm. To induce β-phase crystallization, thermal annealing was performed on a hotplate at 60 °C for 10 min, 80 °C for 60 min, and 130 °C for 180 min. A second Au layer was sputtered onto the diaphragm to enhance adhesion with the support structure and suppress noise from non-diaphragm regions. A negative photoresist (SU-8 3050, Micro Chem) was spin-coated and patterned to define a 40-µm-thick star-shaped support. The Au layer not covered by the SU-8 support, forming the diaphragm region, was then etched (gold etchant, standard, Sigma Aldrich). The piezoelectric diaphragm was subsequently poled via corona poling (see next section for details). The Al sacrificial layer was removed using an Al etchant (aqueous solution: CuCl2, H2O, HCl), completing the electrode/diaphragm/support stack. For the bottom electrode, a Ti/Au (5/50 nm) layer was thermally deposited onto a 20-µm-thick parylene-C substrate, which had been pre-coated with Ti/Al sacrificial layers. A diluted SU-8 2000 solution (17.8 wt%) was used to form an ultrathin adhesive layer on the bottom electrode. The top stack was laminated onto the bottom electrode/substrate assembly on a hotplate at 60 °C, while mechanical pressing was applied simultaneously to ensure strong bonding. Final etching of the Al sacrificial layer yielded the free-standing, hyperpacked vibration sensor array.

Corona poling of the piezoelectric diaphragm

The diaphragm was poled using a corona discharge method. The experimental set-up was constructed within a plastic chamber to ensure electrical isolation from the surrounding environment. Inside the chamber, a conductive needle array and a grounded metal plate were positioned 4 cm apart, facing each other. Poling was performed by placing the diaphragm directly beneath the needle array. The needle, fabricated from stainless steel, had a tip curvature radius of ~50 μm and a cone angle of ~6°. A direct current (d.c.) voltage was supplied by a function generator (33510B, KEYSIGHT) and subsequently amplified using a high-voltage amplifier (20/20C-HS, Trek). The amplified voltage was applied to the conductive needle, while the metal plate was grounded. The poling process was carried out at room temperature by applying a d.c. voltage of 10 kV for 30 min.

Evaluation of piezoelectric properties

To compare the degree of α- and β-phase formation in PVDF-TrFE diaphragms depending on solvent selection, free-standing PVDF-TrFE films prepared using DMF and PA as solvents were analysed via FT-IR (Vertex 70V, Bruker). The transition to the β-phase and the degree of molecular alignment following poling were further investigated using XRD (D/MAX-2500-PC, Rigaku) with CuKα radiation over a 2θ range of 5°−50°, as well as TrWAXS. TrWAXS measurements were conducted at the 3C SAXS-I beamline of the Pohang Accelerator Laboratory (PLS-II, PAL), Korea, and the acquired images were processed using p-GIXS software. The piezoelectric coefficient was measured following a previously reported method33, using a universal tensile machine (LS1, AMETEK) in conjunction with an electrometer (B2987A, Keysight).

Device characterization

Diaphragm thickness was measured using an optical profilometer (Alpha-step D-500, KLA). To ensure accurate thickness determination, measurements were taken at three different locations on more than three samples. Optical microscopy (OM) and scanning electron microscopy (SEM) images were acquired using an optical microscope (Zeiss) and a scanning electron microscope (S-4800, Hitachi), respectively. Numerical simulations were performed using COMSOL Multiphysics 6.2, incorporating the solid mechanics, electrostatics, pressure acoustics and nonlinear physics modules. The output voltage and real-time fast Fourier transform data were recorded using an oscilloscope (TDS 3054 C, Tektronix) and a signal analyser (SR785, Stanford Research Systems), respectively, and mechanical input vibrations were generated using a mini vibration exciter (Type 4810, Brüel & Kjær) (Supplementary Fig. 36). Vibration sensitivity was defined as the output voltage of the device relative to that of a reference accelerometer (352C33, PCB Piezotronics), which has a constant sensitivity of 100 mV g−1 across 10 Hz to 10 kHz. To eliminate potential interference from electromagnetic waves emitted by nearby electronic devices, the sensor and circuit were enclosed in an aluminium shielding box. During the frequency sweep (80–5,000 Hz), over 800 measurement points were acquired, uniformly distributed on a logarithmic scale. All data were plotted using Origin (Origin 2018, OriginLab).

Vibration-based audio recording

A vibration speaker (VBT-001, Newadin Technology) was used for music playback, with both a commercial accelerometer (352C33, PCB Piezotronics) and a fabricated sensor positioned on the vibrating disk to capture the music signal. To ensure a fair performance comparison, the playback volume was kept constant across all measurements. The fabricated sensor was covered with a Ni/Al (10/100-nm)-coated polyimide film (thickness, 150 μm) and electrically connected to ground to provide EMI shielding. For the recording demonstration, excerpts from orchestral music (Spring, movement 1, The Four Seasons, Vivaldi) were used. To comply with copyright regulations, the original audio was obtained from Musopen (https://musopen.org/music/), which distributes content under the Creative Commons Public Domain Dedication 1.0. The recorded signals were acquired using an external oscilloscope (TBS 2000 Series, Tektronix) and processed in MATLAB (R2023a, MathWorks) to generate STFT spectrograms and reconstruct the audio signal.

Attachment to skin for voice and respiratory signal detection

Before application on the human neck, the sensor was encapsulated with the aforementioned flexible EMI shielding case. To ensure secure adhesion to the skin, a biocompatible adhesive (LP-001, ABLE C&C Co.), commonly used in cosmetics and easily removable with a makeup remover, was applied to the bottom substrate. Additionally, an ultrathin, transparent medical film (Tegaderm Film 1622W, 3M) was placed over the sensor and electrical connections to enhance stability and minimize motion artefacts. For voice and respiratory signal acquisition, the sensor was positioned near the vocal cords (Supplementary Fig. 22). A commercial microphone (Mic-12, Actto) simultaneously recorded speech for comparative analysis. To evaluate sensor performance in a noisy environment, artificial background noise at 80 dBSPL was introduced during one of the recordings. For normal respiratory signal acquisition, data were directly obtained from the sensor attached near the vocal cords. For abnormal respiratory signals, open-access pathological breathing sounds were played through the vibration speaker. A rubber layer was added to the vibrating disk to mimic the mechanical properties of soft human tissue, such as the larynx. Pathological breathing sounds like stridor were recorded in the laryngeal region. All signals were recorded using the oscilloscope and processed in MATLAB.

Statistics and reproducibility

Statistical analyses were performed using Origin software. The coefficient of determination (R2) was calculated to quantify the linear relationship between acceleration or sound pressure and output voltage, with values closer to 1 indicating stronger linearity. Differences in sensitivity between sensors with distinct ΔQ and ΔC phases were evaluated using two-sample t-tests, with P < 0.05 considered statistically significant. All experiments were independently repeated at least three times. The number of biological replicates (n) is specified in the figure legends. Data are presented as mean ± standard deviation (s.d.). Imaging experiments, including optical and electron microscopy, were also independently repeated three times with consistent results; representative images are shown.

Ethical approval

This study was approved by the Institutional Review Board of Pohang University of Science and Technology (PIRB-2025-052). All procedures were conducted in accordance with the approved guidelines and regulations. Informed consent was obtained from the participants prior to their involvement in the study. Additionally, all individuals depicted in the images provided written consent for publication.

Reporting Summary

Further information on research design is available in the Nature Portfolio Reporting Summary linked to this Article.

Data availability

Data that support the findings of this study are available from the corresponding author on reasonable request. Source data are provided with this paper.

Code availability

No custom code or mathematical algorithm that was central to the conclusions was used in this study.

References

Kim, K. K. et al. A substrate-less nanomesh receptor with meta-learning for rapid hand task recognition. Nat. Electron. 6, 64–75 (2023).

Peng, Y., Peng, H., Chen, Z. & Zhang, J. Ultrasensitive soft sensor from anisotropic conductive biphasic liquid metal-polymer gels. Adv. Mater. 36, 2305707 (2024).

Kim, S. W. et al. Mechanically robust and linearly sensitive soft piezoresistive pressure sensor for a wearable human-robot interaction system. ACS Nano 18, 3151–3160 (2024).

Lee, J. H. et al. Rational design of all resistive multifunctional sensors with stimulus discriminability. Adv. Funct. Mater. 32, 2107570 (2022).

Lee, J. H., Cho, K. H. & Cho, K. Emerging trends in soft electronics: integrating machine intelligence with soft acoustic/vibration sensors. Adv. Mater. 35, 2209673 (2023).

Shen, R. et al. High-sensitivity and high-resolution triboelectric acoustic sensor for mechanical equipment monitoring. Nano Energy 133, 110450 (2025).

Nayeem, O. G. et al. All-nanofiber-based, ultrasensitive, gas-permeable mechanoacoustic sensors for continuous long-term heart monitoring. Proc. Natl Acad. Sci. USA 117, 7063–7070 (2020).

Melton, J., Bradford, Z. & Lee, J. Acoustic characteristics of vocal sounds used by professional actors performing classical material without microphones in outdoor theatre. J. Voice 36, 733.e23–733.e29 (2022).

Sabry, A. H., Dallal Bashi, O. I., Nik Ali, N. H. & Al Kubaisi, Y. M. Lung disease recognition methods using audio-based analysis with machine learning. Heliyon 10, e26218 (2024).

Wang, R. et al. Molecular ferroelectrics for highly sensitive detection toward low-frequency sound recognition. Adv. Mater. 37, 2409251 (2025).

Hui, X. et al. Acoustically enhanced triboelectric stethoscope for ultrasensitive cardiac sounds sensing and disease diagnosis. Adv. Mater. 36, 2401508 (2024).

Qiao, W. et al. A highly-sensitive omnidirectional acoustic sensor for enhanced human–machine interaction. Adv. Mater. 36, 2413086 (2024).

Lan, B. et al. Multichannel gradient piezoelectric transducer assisted with deep learning for broadband acoustic sensing. ACS Appl. Mater. Interfaces 15, 12146–12153 (2023).

Xiang, Z. et al. High-performance microcone-array flexible piezoelectric acoustic sensor based on multicomponent lead-free perovskite rods. Matter 6, 554–569 (2023).

Gao, S. et al. High-bandwidth self-powered vibration sensors based on triboelectric particle-surface interactions. Nano Energy 119, 109060 (2024).

Yu, Z. et al. Integrated piezo-tribo hybrid acoustic-driven nanogenerator based on porous MWCNTs/PVDF-TrFE aerogel bulk with embedded PDMS tympanum structure for broadband sound energy harvesting. Nano Energy 97, 107205 (2022).

Jin, B. et al. Flexible hair-like piezoelectric acoustic particle velocity sensor with enhanced sensitivity for speaker recognition. Adv. Funct. Mater. 35, 2417164 (2024).

Shao, H. et al. Efficient conversion of sound noise into electric energy using electrospun polyacrylonitrile membranes. Nano Energy 75, 104956 (2020).

Gong, S. et al. A soft resistive acoustic sensor based on suspended standing nanowire membranes with point crack design. Adv. Funct. Mater. 30, 1910717 (2020).

Wang, H. S. et al. Biomimetic and flexible piezoelectric mobile acoustic sensors with multiresonant ultrathin structures for machine learning biometrics. Sci. Adv. 7, eabe5683 (2021).

Guo, H. et al. Iontronic dynamic sensor with broad bandwidth and flat frequency response using controlled preloading strategy. ACS Nano 18, 5599–5608 (2024).

Yang, R. et al. Iontronic pressure sensor with high sensitivity over ultra-broad linear range enabled by laser-induced gradient micro-pyramids. Nat. Commun. 14, 2907 (2023).

Lee, S. et al. An ultrathin conformable vibration-responsive electronic skin for quantitative vocal recognition. Nat. Commun. 10, 2468 (2019).

Lee, S. et al. An electret-powered skin-attachable auditory sensor that functions in harsh acoustic environments. Adv. Mater. 34, 2205537 (2022).

Lee, S. et al. A high-fidelity skin-attachable acoustic sensor for realizing auditory electronic skin. Adv. Mater. 34, 2109545 (2022).

Peng, T. H. & Huang, J. H. The effect of compliant backplate on capacitive MEMS microphones. IEEE Sens. J. 24, 17803–17811 (2024).

Lin, S. et al. Multiplying the stable electrostatic field of electret based on the heterocharge-synergy and superposition effect. Adv. Sci. 9, 2203150 (2022).

Yasuda, T. et al. Ultra-rapidly responsive electret-based flexible pressure sensor via functional polymeric nanoparticle synthesis. Adv. Funct. Mater. 34, 2402064 (2024).

Jiang, Y. et al. Ultrathin eardrum-inspired self-powered acoustic sensor for vocal synchronization recognition with the assistance of machine learning. Small 18, 2106960 (2022).

Park, J. et al. Frequency-selective acoustic and haptic smart skin for dual-mode dynamic/static human-machine interface. Sci. Adv. 8, abj9220 (2022).

Zhang, Z. et al. Enhanced flexible piezoelectric sensor by the integration of P(VDF-TrFE)/AgNWs Film with a-IGZO TFT. IEEE Electron Device Lett. 40, 111–114 (2019).

Zhang, N. et al. Ultra-high electrostriction and ferroelectricity in poly (vinylidene fluoride) by ‘printing of charge’ throughout the film. Nat. Commun. 16, 744 (2025).

Yan, W. et al. Single fibre enables acoustic fabrics via nanometre-scale vibrations. Nature 603, 616–623 (2022).

Wang, K., Godfroid, T., Robert, D. & Preumont, A. Electrostrictive PVDF-TrFE thin film actuators for the control of adaptive thin shell reflectors. Actuators 9, 53 (2020).

Ducrot, P.-H., Dufour, I. & Ayela, C. Optimization of PVDF-TrFE processing conditions for the fabrication of organic MEMS resonators. Sci. Rep. 6, 19426 (2016).

Wang, H., Zhang, Q. M., Cross, L. E. & Sykes, A. O. Piezoelectric, dielectric, and elastic properties of poly(vinylidene fluoride/trifluoroethylene). J. Appl. Phys. 74, 3394–3398 (1993).

Hu, X., You, M., Yi, N., Zhang, X. & Xiang, Y. Enhanced piezoelectric coefficient of PVDF-TrFE films via in situ polarization. Front. Energy Res. 9, 621540 (2021).

Wen, D. et al. Piezoelectric and magnetoelectric effects of flexible magnetoelectric heterostructure PVDF-TrFE/FeCoSiB. Int. J. Mol. Sci. 23, 15992 (2022).

Kronast, W., Muller, B., Siedel, W. & Stoffel, A. Single-chip condenser microphone using porous silicon as sacrificial layer for the air gap. Sens. Actuators A: Phys. 87, 188–193 (2001).

Wang, W., Yang, T., Chen, X. & Yao, X. Vibration energy harvesting using a piezoelectric circular diaphragm array. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 59, 2022–2026 (2012).

Kang, D. et al. A self-powered, highly sensitive, and frequency-tunable triboelectric acoustic sensor inspired by the human cochlea. Adv. Funct. Mater. 34, 2408344 (2024).

Yang, Y.-J. & Senturia, S. D. Numerical simulation of compressible squeezed-film damping. In Proc. Solid-State Sensors, Actuators and Microsystems Workshop 76–79 (Transducer Research Foundation, Inc., 1996).

Ranjbar, A., Mehrabani, M. T. & Pary, F. T. A numerical study on the viscous damping effect for a condenser microphone. IEEE Sens. J. 11, 1307–1316 (2011).

Kano, S. & Mekaru, H. Preliminary comparison of respiratory signals using acceleration on neck and humidity in exhaled air. Microsyst. Technol. 27, 1–9 (2021).

Martin, D. T. et al. A micromachined dual-backplate capacitive microphone for aeroacoustic measurements. J. Microelectromech. Syst. 16, 1289–1302 (2007).

Švec, J. G., Titze, I. R. & Popolo, P. S. Estimation of sound pressure levels of voiced speech from skin vibration of the neck. J. Acoust. Soc. Am. 117, 1386–1394 (2005).

Jung, Y. H. et al. Deep learning-based noise robust flexible piezoelectric acoustic sensors for speech processing. Nano Energy 101, 107610 (2022).

Mitsuke, T., Shimakawa, H. & Harada, H. Respiratory disease diagnosis through comprehensive analysis of spectrograms of lung sounds. In Proc. Human Interaction & Emerging Technologies (IHIET 2023): Artificial Intelligence & Future Applications Vol. 111 (eds Ahram, T. & Taiar, R.) 573–583 (AHFE International, 2023).

Gong, S. et al. Hierarchically resistive skins as specific and multimetric on-throat wearable biosensors. Nat. Nanotechnol. 18, 889–897 (2023).

Lee, K.-R. et al. A wearable stethoscope for accurate real-time lung sound monitoring and automatic wheezing detection based on an AI algorithm. Engineering https://doi.org/10.1016/j.eng.2024.12.031 (2025).

Acknowledgements

This work was supported by National Research Foundation of Korea (NRF) grants funded by the Ministry of Science and ICT (MSIT) (grants nos. 2021M3C1C3097512 and RS-2025-24523645 to K.C.).

Author information

Authors and Affiliations

Contributions

K.H.C. and J.-H.L. conceived the idea, performed the experiments, analysed the data, created the figures, and wrote the manuscript. S.Y., S.L. and S.C. conducted material characterizations and numerical simulations. W.K. and W.M. designed the experimental set-ups. Y.K. and Y.C. developed the interface circuit for the sensor. K.C. supervised the entire research project.

Corresponding author

Ethics declarations

Competing interests

K.H.C., J.-H.L. and K.C. are inventors of a KR patent (10-2025-0124113) related to this work. The remaining authors declare no competing interests.

Peer review

Peer review information

Nature Sensors thanks the anonymous reviewers for their contribution to the peer review of this work. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary notes 1 and 2, Figs. 1–36, Tables 1–3 and references.

Supplementary Video 1

Air flow simulation during diaphragm fluctuation.

Supplementary Video 2

Demonstration of high-fidelity audio recording via vibration sensing.

Supplementary Data

Source data for the Supplementary Information.

Source data

Source Data Figs. 2–6

Source data for Figs. 2–6.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cho, K.H., Lee, JH., Yun, S. et al. Hyperpacked piezoelectric-powered capacitive sensor array for high-fidelity vibration detection. Nat. Sens. 1, 73–84 (2026). https://doi.org/10.1038/s44460-025-00003-1

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s44460-025-00003-1