Abstract

Thermal-actuation and piezoresistive-detection effects have been employed to pump the effective quality factor of MEMS resonators, targeting simple self-oscillation and better sensing performance in the air. However, the ratio of the pumped effective quality factor to the inherent mechanical quality factor, crucial for characterizing the amplification, is hard to obtain. The main difficulty stems from hidden Lorentz peaks caused by feedthrough effects and the pump effect once the current is applied. In this paper, we demonstrated the presence of high-order harmonic components in the output of thermal-piezoresistive resonators when the oscillation amplitude is sufficiently large. By utilizing second-order harmonics, we achieved the improvement in signal-to-bias ratio of, 20.85 dB compared to that without feedthrough cancellation and 9.67 dB compared to that using a de-embedded method when the bias current is 6.20 mA. Furthermore, the inherent mechanical quality factor is extracted at a low current of 1.8 mA with a value of 5800 using the second-order harmonics, and a nearly two orders of magnitude enhancement in Q factor can be obtained before entering the self-oscillation regime. An amplitude bias instability as good as 55 ppm and a frequency bias instability as good as 10 ppb are realized in the nonlinear operation regime with a pumped effective quality factor of 576k. The paper contributes to the fundamental understanding of the Q pump effect together with harmonic analysis of the thermal-piezoresistive resonators and also pushes forward the development of low-power consumption self-oscillation resonant sensors.

Similar content being viewed by others

Introduction

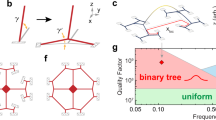

Microelectromechanical (MEMS) resonators have been widely employed in various sensing applications, such as mass sensors1,2,3,4, resonant accelerometers5,6, as well as gyroscopes. The mechanical quality (\({Q}_{{\rm {m}}}\)) factor of resonators is a measure of the energy dissipation during a specific working cycle and a crucial parameter to improve the signal-to-noise ratio (SNR) of force sensors, phase noise of oscillators, and noise rejection of filters7. To improve \({Q}_{{\rm {m}}}\), either intrinsic dissipation, like thermoelastic losses, or extrinsic damping like clamping losses, should be reduced8. In contrast, the effective quality factor (\({Q}_{{{\rm {eff}}}}\)) can be manipulated by feeding energy to the resonator without modifying the intrinsic or extrinsic dissipations. External feedback control has become the most classical method of \({Q}_{{{\rm {eff}}}}\) tuning9.

In the past decade, thermal-actuation and piezoresistive-detection mechanisms have been demonstrated as a beneficial method to increase \({Q}_{{{\rm {eff}}}}\) of resonators working in ambient environments10,11,12,13,14,15,16,17,18. Principally, the nanobeam expands once a bias DC current is applied through it, causing defections due to Joule heating power. Consequently, the energy delivered by the input current compensates for the dissipations of the resonator caused by mechanical motion, resulting in a significant improvement on \({Q}_{{{\rm {eff}}}}\). When thermal compensation is sufficient, self-oscillation can be achieved, even in air-operating conditions19.

The frequency response fitting and ringdown methods are the two classical mechanisms7,20 to extract \({Q}_{{{\rm {eff}}}}\). However, these methods are not feasible in measuring \({Q}_{{\rm {m}}}\) of thermal-piezoresistive resonators (TPRs), because once the mandatory bias DC current is applied, Q will be pumped immediately. Another barrier is that, in contrast to MEMS capacitive resonators designed with differential sensing electrodes to eliminate the feedthrough effect, the outputs of TPRs always have a significant feedthrough signal component, due to no feasible differential sensing method for feedthrough cancellation21. As a result, the voltage output with feedthrough sometimes cannot accurately characterize the motion of a TPR, especially in cases with low bias current the coupling actuation AC signal is too large to monitor the effective motional voltage of the resonators22,23. Even using the ringdown characterization method, the signal is severely affected by the feedthrough signal24. Consequently, in this case, \({Q}_{{\rm {m}}}\) cannot be correctly characterized by a measured frequency response and no previous research experimentally demonstrates how much \({Q}_{{{\rm {eff}}}}\) can be pumped. Furthermore, due to the feedthrough signal, Duffing nonlinear25,26 characteristics of the TPRs are difficult to be studied as the signal-to-bias ratio is too small for identifying the bifurcations27,28,29.

In this paper, we experimentally found that there are high-order (second-order and third-order) harmonic components in the output of TPRs when the oscillation amplitude is sufficiently high, especially in the Duffing nonlinear regime. With a specific actuation level, the amplitude of the second-order harmonic signal is about one order of magnitude lower than that of the signal at the natural frequency. Using these harmonic components, basic information, including vibrating frequency and nonlinear amplitude–frequency (A–f) effect, can be deduced and the feedthrough signal can be suppressed. On the other hand, benefiting from the feedthrough cancellation, Q factor can be calculated precisely, and it is found that the Q factor of a TPR cannot be pumped by the bias current if this current is at a low level, indicating the inherent \({Q}_{{\rm {m}}}\) of the TPR. Besides, we experimentally proved the pumping Q factor of TPRs beneficial for the resolution of oscillators. This paper provides an alternative method of characterizing the frequency response and Q-factor information of thermal-piezoresistive resonators with feedthrough elimination.

Results

Thermal actuation and piezoresistive detection

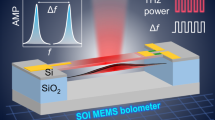

The proposed TPR is constructed with two movable plates supported by four suspension beams and connected by a nanobeam (Fig. 1a). The movement of a TPR results from the periodic thermal expansion and contraction of the nanobeam. The operating principle of a TPR involves several physical domains, combining thermal, mechanical, and electrical effects11 and is illustrated in Fig. 1b. A direct current (\({I}_{{{\rm {dc}}}}\)) flowing through the nanobeam expands the nanobeam with a resistance of R0 to a pre-expansion state due to the Joule heating power of P0 = Idc2R0. The additional harmonic actuation signal (vac) causes periodic expansion and contraction of the nanobeam via Joule heating/cooling, with a power of ∆P ≈ vac2/R0. Consequently, a sinusoidally variable resistance (\(\delta {R}_{{{\rm {ac}}}}\)) is generated due to the negative piezoresistive coefficient with the value of \(\delta {R}_{{{\rm {ac}}}}\) dependent on the actuation voltage vac. The plates are actuated by the nanobeam and oscillating with the same frequency if vac is not high enough to drive the TPR into the Duffing nonlinear regime. The nanobeam deflection is finally transferred to an alternating output voltage (\({\rm{v}}_{{{\rm{out}}}}={\rm{I}}_{{{\rm {dc}}}}\cdot \delta {\rm{R}}_{{{\rm {ac}}}}\)).

The nanobeam can be modeled as the parallel combination of its internal resistance RA and the equivalent RLC circuit of the mechanical resonator, as shown in the inset of Fig. 1b. Energy transformations between different physical domains can be described by the equivalent circuits as illustrated in Fig. 1c. Detailed derivations of the transfer functions in each domain are provided in Supplementary Material Note 1. Simplifying the total transfer function relating output current to input voltage, we have the equivalent conductance of the resonator \({g}_{{\rm {m}}}\)12\(:\)

where \({T}_{{{\rm {ac}}}}\) is the temperature fluctuation, \({v}_{{{\rm {ac}}}}\) the input voltage, \({X}_{{{\rm {th}}}}\) the displacement fluctuation and \({i}_{{\rm {m}}}\) the output current. \({R}_{{{\rm {th}}}}\), \({C}_{{{\rm {th}}}}\) and \(\alpha\) represent thermal resistance, thermal capacitance and thermal expansion coefficient of the actuating nanobeam. \(E\) is the Young’s modulus, \({\omega }_{0}\) the natural frequency of the resonator and \({\pi }_{{\rm {l}}}\) the piezoresistive coefficient. Through the transfer functions of Joule heating and thermal expansion effects, the thermal expansion force can be written as

where \(K\) is the stiffness of the resonator. Specifically in the mechanical domain, the dynamic equations of the resonator can be expressed as

where \(M\) is the effective mass, \(c\) the damping. The effective Q can be derived from the imaginary part with \({X}_{{{\rm {th}}}}={x}_{0}{{\rm {e}}}^{j{\omega }_{0}t}\):

As the piezoresistive coefficient \({\pi }_{l}\) is negative, in particular for resonators with relatively high frequency, there are specific values for \({I}_{{{\rm {dc}}}}^{2}\) keeping \({R}_{{\rm {A}}}{g}_{{\rm {m}}}\subset [-\mathrm{1,0}]\), and pumping the effective quality factor with currents increasing.

Device fabrication and measurement setup

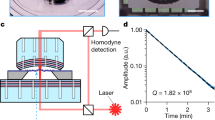

A 10 µm-thickness silicon-on-insulator (SOI) wafer was used to fabricate the device based on a dicing-free fabrication process30. The nanobeam is designed with a width of 1 µm. Due to over-etching, the fabricated width of the nanobeam is measured ~760 nm. An optical image of the resonator is shown in Fig. 2a. The device layer is n-doped with a dopant concentration of 5 × 1018 cm–3, resulting in a negative piezoresistive coefficient. The nanobeam acts simultaneously as an actuator and a displacement sensor.

An open-loop setup, as shown in Fig. 2b was conducted to explore the input-output responses of the TPR. A chirp signal was generated by the internal digital oscillator of a Zurich lock-in amplifier (HF2LI) to actuate the TPR with a frequency of \({f}_{{\rm {d}}}\). Three demodulators were utilized to demodulate the output signal with the frequency of \({f}_{{\rm {d}}}\), \({2f}_{{\rm {d}}}\) and \(3{f}_{{\rm {d}}}\), to extract the harmonic components of the output. All functions were realized with the lock-in amplifier, excluding the bias DC current which was supplied by a power meter.

Harmonics and feedthrough suppression

In the open-loop measurements, a chirp signal around the natural frequency is applied through a bias tee to actuate the resonator. This actuation signal is also directly coupled to the output and is mixed with the motional signal, which causes a feedthrough component to the output.

To characterize the resonance frequency and effective quality factor \({Q}_{{{\rm {eff}}}}\) of the device, open-loop frequency sweeps were conducted with varying direct current \({I}_{{{\rm {dc}}}}\). We took the bias currents striding regimes from attenuation to amplification, all below the threshold of self-oscillation, as illustrated in Fig. 3a. The −3 dB bandwidth method was employed to estimate \({Q}_{{{\rm {eff}}}}\) and the response shows a good match with the Lorentz fitting curve, as shown in Fig. 3b. A significant observation is that using the Lorentz fitting function or −3 dB method to extract Q is only feasible when the bias current is moderate. There is significant nonlinear hysteresis when the bias current is sufficiently high. When the current is very low, the Lorentz peak is insignificant or even disappears whereas an anti-resonance31 is observed, which is attributed to the feedthrough directly coupled from the lock-in amplifier.

a Recorded raw output amplitude–frequency responses of the TPR actuated with various currents. b Lorentz fitting curve of the frequency response with bias current equaling to 6.20 mA. c Processed amplitude-frequency spectrum with the de-embedded feedthrough cancellation method. d Comparison between the responses with and without the de-embedded feedthrough cancellation when bias current is 6.20 and 5.75 mA. Obtained frequency responses of the TPR using the second- (e) and the third- (f) order harmonic components to demodulate the mixing signals. The nonlinearity begins at the current of 6.30 mA and the corresponding signal generates in the response demodulated with the third-order harmonic. g The relationships between the signal-to-bias ratio and the bias current of frequency responses recorded, calculated with the de-embedded method, and dealt with the second-order harmonics

Notably, unobvious signal-to-bias ratios are commonly visible in recorded raw frequency responses, which are demodulated using the same frequency (\({f}_{{\rm {d}}}\)) as the drive AC signal in Fig. 3a. Significant anti-resonance peaks in low current region also can be observed, which indicates feedthrough effects. To achieve pure output by eliminating the mixed feedthrough signal, a de-embedded feedthrough cancellation method has been proposed32, wherein the extracted signal is used to subtract from the input reference signal. This reference signal includes the coupling from the actuation AC but lacks any motional signal. In our device, this reference was achieved by measuring the output while applying direct current Idc = 0 mA. Details of this method are put in Supplementary Material Note 2.

The analysis of Fig. 3c and a suggests that frequency responses, following the removal of feedthrough, demonstrate consistent amplitudes without any signs of anti-resonance. The signal-to-bias ratio is improved by 11.18 dB, from 14.64 to 25.82 dB when the bias current \({I}_{{{\rm {dc}}}}\) is 6.20 mA, as shown in Fig. 3d. Nevertheless, this method requires extra calculations and offline processing, introducing added complexity.

In our experiments, we found that there exist clean outputs without the influence of feedthrough if the signal is demodulated by two or three times of the drive frequency. The second-order harmonic can be explained by the thermal actuation power which is expressed as the combination of \({V}_{{{\rm {dc}}}}\) and \({V}_{{{\rm {ac}}}}\):

There is a component at the frequency of \({f}_{{\rm {d}}}\), inducing the corresponding harmonic signal at \({f}_{{\rm {d}}}\) as well as \({2f}_{{\rm {d}}}\). The demodulated signal with the frequency of \({2f}_{{\rm {d}}}\) is shown in Fig. 3e, indicating a bias voltage of 7 µV and a signal-to-bias ratio ~35.49, 9.67 dB higher than that of the signal using the de-embedded feedthrough cancellation method when the bias current \({I}_{{{\rm {dc}}}}\) is 6.20 mA. In addition, in cases of low DC current, there is no significant anti-resonance, while clear Lorentz peaks are visible. In such a situation, we can measure the Q factor using the −3 dB method with frequency responses.

Also, the signal-to-bias ratios of raw responses, de-embedded responses and responses dealt with harmonics are exhibited in Fig. 3g, illustrating the optimization of feedthrough suppression with harmonics. It is visible that the signal-to-bias ratio enhances as the bias current increases and the ratio of responses dealt with harmonics is commonly higher than that of de-embedded responses. Moreover, the optimization with harmonics is more notable at high currents.

In order to have a better view of the influence of the nonlinearity to the harmonic signal, we recorded the frequency responses of the TPR with variable drive AC voltages while the bias DC current was fixed at \({I}_{{dc}}\) = 6.10 mA. A clear amplitude-frequency (A–f) backbone curve can be observed in Fig. 4a. A phenomenon is that the second-order (Fig. 4b) harmonic signal is observable in both the linear and nonlinear regimes, while the third-order (Fig. 4c) harmonic signal appears only in the nonlinear regime.

Frequency responses of the TPR with a DC current of Idc = 6.10 mA, while the actuation ac level is variable from 0.1 to 200 mV, and the signal is demodulated with the frequency of \({f}_{{\rm {d}}}\) (a), \({2f}_{{\rm {d}}}\) (b) and \({3f}_{{\rm {d}}}\) (c). Nonlinearity occurs at the drive AC voltage of 50 mV

It is believed that the phenomenon is due to the nonlinearity of the device, particularly the Duffing nonlinearity in the mechanical domain. Evidence is that only in the case of the device operating in the nonlinear regime (e.g for Idc = 6.30 mA) we can see the appearance of a harmonic signal at \({3f}_{{\rm {d}}}\), as shown in Fig. 3f. Theoretically, the thermal actuation force when concerning Duffing nonlinearity can be rewritten as

where \({K}_{3}\) represents the coefficient of Duffing nonlinearity. Even if we assume that the simple wave with natural frequency is primary in the displacement, there is still a term of \({{X}_{{{\rm {th}}}}}^{3}\) generating the signal with frequency of \({3f}_{{\rm {d}}}\).

Complete derivation and further explanation of nonlinearity are described in the Supplementary Material Note 3. With the multi-harmonic balance method to solve the dynamic equation considering nonlinear terms, the peak value of the amplitude \({X}_{{\rm {D}}}\) in Fig. 4a is obtained:

The nonlinear coefficient \({K}_{3}\) is calculated to be \(-7186\,{\rm {N/{m}}}^{3}\), using \(K=M{{\omega }_{0}}^{2}\). The detailed parameters and amplitude–frequency curve are shown in Supplementary Material Fig. S2.

Self-oscillation and mechanical Q extraction

Referring to the principle of thermal actuation, as the input DC current increases, the motion of the TPR experiences attenuation, amplification, and finally exhibits self-excited oscillation16 when the threshold is reached.

For the steady oscillation at the frequency of 2.008 MHz, with a sampling rate of 625 MHz at specific amplitudes, mixing harmonic signals are observed with the bias current \({I}_{{{\rm {dc}}}}\) varying from 6.36, 6.56, 6.86 to 7.26 mA. Using a short-time Fourier transform to deal with the mixing signals, the time–frequency diagrams can be obtained, and clear frequency characteristics are visible, as being recorded in Fig. 5. This demonstrates that high-order harmonics normally exist as long as the current reaches a certain value. A higher current creates more harmonics and more significant distortion.

Self-oscillation amplitudes in the time domain and the corresponding spectrograms with various direct currents from 6.36 mA (a), 6.56 mA (b), 6.86 mA (c) to 7.26 mA (d). The distortion of the oscillation signal becomes more and more significant with the increasing of the bias current, and meanwhile, the high-order harmonics gradually appear

Although the high-order harmonic induces distortion, it also suppresses the feedthrough signal as mentioned in the section “Harmonics and feedthrough suppression”. The Lorentz peaks can be recovered even with a very low bias current. Therefore, it is possible to extract the effective quality factor \({Q}_{{{\rm {eff}}}}\) by the −3 dB method anyway. The \({Q}_{{{\rm {eff}}}}\) of the TPR, extracted using second-order harmonics (as shown in Fig. 3e), is illustrated in Fig. 6a for bias currents ranging from 1.80 to 6.3 mA. It is observable that \({Q}_{{{\rm {eff}}}}\) will no longer decrease when the bias current is lower than 1.80 mA, which indicates a convergence phenomenon. In other words, this implies that \({Q}_{{{\rm {eff}}}}\) is being pumped only with a current >1.80 mA. Thus, the \({Q}_{{{\rm {eff}}}}\) with \({I}_{{{\rm {dc}}}}=\)1.80 mA can be considered as the mechanical \({Q}_{{\rm {m}}}\) ~ 5.8k as shown in Fig. 6a. In addition, the relation between \({Q}_{{{\rm {eff}}}}\) and the current can be fitted as

Extracted effective Q factor and the fitting curve of interrelation between effective Q factor and current of the experiment (a) together with the theoretical calculation (b). Theoretical calculation is processed on the basis of Eq. (5) combining the extracted mechanical \({Q}_{{\rm {m}}} \sim 5.8k\), and the following settings: πl = −50 × 10−11 Pa−1, α = 2.6 × 10−6 K−1, E = 169 GPa, \({\omega }_{0}=2\pi \times 2.008\,{\rm{MHz}}\), ρ = 0.0018 Ω cm, the length \(L\) and cross area \(A\) of nanobeam, respectively 14.8 and 0.76 µm × 10 µm, the density of mass ρm = 3 g cm−3, the specific heat capacity cH = 800 J kg−1 K−1, RA = ρmL/A and Cth = cHρmLA

According to the extracted \({Q}_{{{\rm {eff}}}}\) ~ 576k where the resonator goes into self-oscillation, the quality factor has been pumped by a factor of 99.3, nearly two orders of magnitude. The theoretical predication of \({Q}_{{{\rm {eff}}}}\) versus \({I}_{{{\rm {dc}}}}\) can be found in Fig. 6b, matching the experimental results quite well. The disparity in \({I}_{{{\rm {dc}}}}\) when the pumped \({Q}_{{{\rm {eff}}}}\) approaches 576k is attributed to the differences in the simulation settings and the actual properties of the material.

Amplitude and frequency stability under pumped Q

The above results have demonstrated the effective pump of \({Q}_{{{\rm {eff}}}}\) in thermal-piezoresistive resonators. However, it is not clear whether such a pump is beneficial to the amplitude and frequency resolution.

To clarify the influences of the enhanced Q factor on the resolution and stability of the amplitude and frequency, a closed loop configuration was implemented using the lock-in amplifier, in which the drive AC voltages were set to 1 and 300 mV, representing the linear and nonlinear operation regimes. We calculated the corresponding noise density and Allan deviations of the amplitude as well as frequency to evaluate the influence of pumped \({Q}_{{{\rm {eff}}}}\) on the performance of the TPR.

In the linear operation regime, with the current increasing and Q factor being pumped, the amplitude noise density roughly decreases while the signal-to-noise ratio generally increases as shown in Fig. 7a. With the bias current Idc changing from 6.05 to 6.25 mA, the bias instability of the amplitude is enlarged from 320, 400 to 580 ppm as indicated in Fig. 7b.

With a drive AC voltage of 1 mV, amplitude noise density (a), amplitude Allan deviation (b) and frequency Allan deviation (c) with different direct currents. Amplitude noise density (d) at the drive voltage of 300 mV and amplitude Allan deviation (e) as well as frequency Allan deviation (f) at the corresponding bias situations

A much higher drive AC voltage of 300 mV drives the resonator into the nonlinear operation regime. The relevant amplitude noise density of various currents is shown in Fig. 7d. The signal-to-noise ratio slightly increases with the current boosting and is generally higher than that in a linear regime. Also, the amplitude bias instability is significantly improved with increasing currents, from 250 ppm@Idc = 5.95 mA, to 55 ppm@Idc = 6.25 mA, as shown in Fig. 7e.

For the frequency, in the linear regime, the bias instability varies from 57 ppb@Idc = 5.95 mA to 23 ppb@Idc = 6.25 mA as indicated by Fig. 7c, whereas it keeps almost unchanged in the nonlinear operation regime as shown in Fig. 7f. Though the direct currents and drive voltages vary, frequency bias instability has little difference and keeps generally below 10ppb, exhibiting very high stability in short integration time term of 0.1 s.

As the effective quality factor has been pumped from Idc = 5.95 mA to Idc = 6.25 mA, the pumped \({Q}_{{{\rm {eff}}}}\) is beneficial to improve the amplitude stability both in the linear and nonlinear operation regimes, while the frequency stability can only be improved in the linear operation regime.

Discussion

As a promising transduction method, thermal actuation and piezoresistive detection offer an attractive avenue for the development of simple, self-sustained oscillators with low power consumption, while eliminating the need for vacuum packaging. The Joule heating energy generated by the bias current serves to offset the energy consumed by the mechanical motion of the resonators. Consequently, this mechanism enhances the effective quality factor (\({Q}_{{{\rm {eff}}}}\)) which, with an increase in bias current, can reach levels sufficient to sustain self-oscillation. However, the quantification factor of the pumped \({Q}_{{{\rm {eff}}}}\) compared to the mechanical Q remains unexplored. This is due to the masking effect of high feedthrough signals on the observable Lorentz peaks at low bias currents, which hinders the precise extraction of the mechanical quality factor.

Our experimental findings in this study highlight the presence of high-order harmonics that provide crucial insights. The second-order harmonics are linked to quadratic power generation, while the third-order harmonics are presumed to arise from Duffing nonlinearity. Through frequency sweeps of these harmonics, we achieve a notable 20.85 dB enhancement in signal-to-bias ratio at specific bias configuration, facilitating easy and precise extraction of the quality factor regardless of the bias current value. Remarkably, our results indicate a prominent amplification of the quality factor by a factor of 99.3 before the resonator enters into the self-oscillation regime. Although the method using harmonics to eliminate feedthrough has never been applied to capacitive resonators33,34, we extend this application and achieve further nonlinearity derivation with multi-harmonics.

Subsequent performance analysis shows that, for the thermal-piezoresistive resonators, the pumped effective quality factor enhances the amplitude stability both in the linear and nonlinear operation regimes, whereas the frequency stability can only be improved in the linear operation regime. An amplitude bias instability as good as 55 ppm and a frequency bias instability as good as 10 ppb are realized in the nonlinear operation regime with a bias current of Idc = 6.25 mA. This improvement differs from the traditional consideration that stability and resolution are defined significantly by the mechanical quality factor but not the effective quality factor. A deep study should be developed in the future to push forward the fundamental understanding of the quality factor pumping effect based on thermal-actuation and piezoresistive-detection methods, and the applications of thermal-piezoresistive resonators in more engineering fields, like inertial sensing and time references.

References

Naik, A. K. et al. Towards single-molecule nanomechanical mass spectrometry. Nat. Nanotechnol. 4, 445–50 (2009).

Ekinci, K. L. et al. Ultrasensitive nanoelectromechanical mass detection. Appl. Phys. Lett. 84, 4469–71 (2004).

Jiang, C. et al. Single-layer MoS2 mechanical resonant piezo-sensors with high mass sensitivity. ACS Appl. Mater. Interfaces 12, 41991–8 (2020).

Quan, A. et al. A thermal-piezoresistive self-sustained resonant mass sensor with high-Q (>95k) in air. In 21st Conference on Solid-State Sensors, Actuators and Microsystems, 168–171 (Institute of Electrical and Electronics Engineers (IEEE), 2021).

Mustafazade, A. et al. A vibrating beam MEMS accelerometer for gravity and seismic measurements. Sci. Rep. 10, 10415 (2020).

Zhang, Z., Zhang, H., Hao, Y. & Chang, H. A review on MEMS silicon resonant accelerometers. J. Microelectromech. Syst. 33, 174–208 (2024).

Miller, J. M. L. et al. Effective quality factor tuning mechanisms in micromechanical resonators. Appl. Phys. Rev. 5, 041307 (2018).

Imboden, M. & Mohanty, P. Dissipation in nanoelectromechanical systems. Phys. Rep. 534, 89–146 (2014).

Mertz, J., Marti, O. & Mlynek, J. Regulation of a microcantilever response by force feedback. Appl. Phys. Lett. 62, 2344–2346 (1993).

Ramezany, A., Mahdavi, M. & Pourkamali, S. Nanoelectromechanical resonant narrow-band amplifiers. Microsyst. Nanoeng. 2, 1–8 (2016).

Steeneken, P. G. et al. Piezoresistive heat engine and refrigerator. Nat. Phys. 7, 354–359 (2011).

Rahafrooz, A. & Pourkamali, S. High-frequency thermally actuated electromechanical resonators with piezoresistive readout. IEEE Trans. Electron Devices 58, 1205–1214 (2011).

Rahafrooz, A. & Pourkamali, S. Active self-Q-enhancement in high frequency thermally actuated M/NEMS resonators. In 24th International Conference on Micro Electro Mechanical Systems, 760–763 (IEEE, Cancun, Mexico, 2011).

Rahafrooz, A. & Pourkamali, S. Thermal-piezoresistive energy pumps in micromechanical resonant structures. IEEE Trans. Electron Devices 59, 3587–3593 (2012).

Mehdizadeh, E., Kumar, V. & Pourkamali, S. Sensitivity enhancement of Lorentz force MEMS resonant magnetometers via internal thermal-piezoresistive amplification. IEEE Electron Device Lett. 35, 268–270 (2013).

Ramezay, A., Mahdavi, M., Guo, X. & Pourkamali, S. Resonant MEMS piezoresistors for narrow band electronic amplification. In Solid-State Sensor, Actuator and Microsystems Workshop, 95–98 (Transducer Research Foundation, Hilton Head Island, SC, 2014).

Lehée, G. et al. P-type silicon nanogauge based self-sustained oscillator. In 19th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), 444–447 (IEEE, Kaohsiung, Taiwan, 2017).

Janioud, P. et al. Thermal piezoresistive back action enhancement using an innovative design of silicon nanobeam. In 32nd International Conference on Micro Electro Mechanical Systems (MEMS), 157–160 (IEEE, Seoul, Korea, 2019).

Zhang, H. et al. A fast-startup self-sustained thermal-piezoresistive oscillator with >106 effective quality factor in the air. In 35th International Conference on Micro Electro Mechanical Systems Conference (MEMS), 142–145 (IEEE, Tokyo, Japan, 2022).

Petersan, P. J. & Anlage, S. M. Measurement of resonant frequency and quality factor of microwave resonators: comparison of methods. J. Appl. Phys. 84, 3392–3402 (1998).

Chu, C. C., Dey, S., Liu, T. Y., Chen, C. C. & Li, S. S. Thermal-piezoresistive SOI-MEMS oscillators based on a fully differential mechanically coupled resonator array for mass sensing applications. J. Microelectromech. Syst. 27, 59–72 (2018).

Qaradaghi, V., Ramezany, A., Babu, S., Lee, J. B. & Pourkamali, S. Nanoelectromechanical disk resonators as highly sensitive mass sensors. IEEE Electron Device Lett. 39, 1744–1747 (2018).

Jia, H. & Feng, P. X. L. Very high-frequency silicon carbide microdisk resonators with multimode responses in water for particle sensing. J. Microelectromech. Syst. 28, 941–53 (2019).

Ghadimi, A. H. et al. Elastic strain engineering for ultralow mechanical dissipation. Science 360, 764–768 (2018).

Kacem, N. et al. Nonlinear dynamics of nanomechanical beam resonators: improving the performance of NEMS-based sensors. Nanotechnology 20, 275501 (2009).

Chen, D. et al. Feedthrough parasitic nonlinear resonance in micromechanical oscillators. Appl. Phys. Lett. 117, 133502 (2020).

Sage, E. et al. Single-particle mass spectrometry with arrays of frequency-addressed nanomechanical resonators. Nat. Commun. 9, 3283 (2018).

Roy, S. K. et al. Improving mechanical sensor performance through larger damping. Science 360, 6394 (2018).

Mile, E. et al. In-plane nanoelectromechanical resonators based on silicon nanowire piezoresistive detection. Nanotechnology 21, 165504 (2010).

Sari, I., Zeimpekis, I. & Kraft, M. A dicing free SOI process for MEMS devices. Microelectron. Eng. 95, 121–129 (2012).

Pillai, G. & Li, S. S. Piezoelectric MEMS resonators: a review. IEEE Sensors J. 21, 12589–12605 (2020).

Lee, J. E.-Y. & Seshia, A. A. Direct parameter extraction in feedthrough-embedded capacitive MEMS resonators. Sensors Actuators A: Phys. 167, 237–244 (2011).

Kassie, D. A. & Elata, D. Harmonic biasing in a double-sided comb-drive resonator, for resolving feed-through issues in low-power driving. Sensors Actuators A: Phys. 332, 113031 (2021).

Kassie, D. A., Levi, S. & Elata, D. A double-sided comb-drive actuator with a floating rotor: achieving a strong response while eliminating the DC bias. J. Microelectromech. Syst. 29, 1173–1179 (2020).

Acknowledgements

This project is supported by the National Key R&D Program of China No. 2023YFB3208800, the National Science Foundation of China No. 52475606 and 52435012, the Fundamental Research Funds for the Central Universities, Innovation Capability Support Program of Shaanxi (Program No. 2024RS-CXTD-17), and Natural Science Basic Research Plan in Shaanxi Province of China (Program No. 2023JC-XJ-07).

Author information

Authors and Affiliations

Contributions

H. Zhang managed the experimental test, theoretical derivation, and data analysis, and wrote the paper. G. Teng and Chenhao Yang managed the data analysis, figure drawing, and paper writing. A. Quan fabricated the devices. H. Chang and M. Kraft revised the paper.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Teng, G., Yang, C., Quan, A. et al. Extracting mechanical quality factor and eliminating feedthrough using harmonics of thermal-piezoresistive micromechanical resonators. Microsyst Nanoeng 11, 30 (2025). https://doi.org/10.1038/s41378-025-00869-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41378-025-00869-8

This article is cited by

-

Virtually coupled resonators with modal dominance for improved sensitivity and bandwidth

Microsystems & Nanoengineering (2025)