Abstract

Wall shear stress is one of the key parameters in turbulent boundary layers, playing a pivotal role in aerodynamic optimization and fuel efficiency enhancement. Although MEMS-based direct measurement stands as the most promising approach for wall shear stress quantification, the inherent limitations of floating sensing structures under harsh environments lead to mechanical failure, representing persistent technical barriers in practical applications. This work presents a novel MEMS sensor equipped with a protective floating cover plate, achieving high-robustness measurement through coordinated structural-process innovations. Based on the Dual Silicon-On-Insulator (DSOI) fabrication process, a protective floating configuration is developed. The critical process techniques, including deep silicon etching, wet etching of glass through vias, and silicon-glass anodic bonding synergistically establish protection for the sensing structures. The established electromechanical coupling mathematical model elucidates quantitative mapping relationships between critical structural parameters and sensing performance. Experimental characterization reveals a linear sensitivity of 28.3 mV Pa−1 and a resonance frequency of 2.9 kHz. In supersonic tunnel experiments at Mach 2.0, the sensor achieves unprecedented full-cycle dynamic capture from establishment through stabilization to dissipation with millisecond-level transient response characteristics. This work provides a robust, high-precision solution for aerodynamic and fluid dynamics applications, paving the way for improving energy efficiency and flow control strategies.

Similar content being viewed by others

Introduction

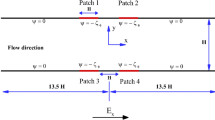

Wall shear stress is a pivotal parameter for evaluating the aerothermal performance of high-speed vehicles and flow losses in engine combustion chambers1,2. Accurate measurement of this parameter is essential for aerodynamic optimization and fuel efficiency enhancement3,4,5. In supersonic flows, challenges such as viscous effect, shock wave/boundary layer interference, and contamination of flow-borne combustion byproducts (e.g., unburned soot and atomized fuel droplets) create barriers for conventional measurement techniques, as shown in Fig. 1a. Although theoretical and experimental frameworks exist for low-speed wall shear stress measurement (e.g., NACA standard models and hot-wire anemometry), current methods still suffer from delayed dynamic response and insufficient reliability when applied to realistic supersonic harsh environments6,7.

Although various techniques for measuring wall shear stress have been developed, direct measurement methods, which correlate floating element displacement with shear force through linear mapping, have become mainstream solutions due to their independence from flow model assumptions8,9,10,11,12,13. Traditional direct measurement devices like skin-friction balances fail to resolve microscale fluid structures in supersonic flow due to size effects. The development of MEMS (Micro-Electro-Mechanical Systems) technology offers a new perspective for wall shear stress measurement. In comparison with traditional skin-friction balances, MEMS wall shear stress sensors feature revolutionary improvements in spatial and temporal resolution, enhancing measurements by two orders of magnitude14,15,16,17,18. In terms of sensing mechanisms, MEMS sensors with floating sensing structures can be mainly divided into piezoresistive19,20, piezoelectric21,22,23, optical24,25,26, and capacitive27,28,29,30,31,32,33,34 types, among which the capacitive approach is widely adopted because of its exceptional precision, cost-effectiveness, and suitability for high-resolution applications.

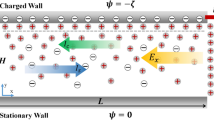

Since the 1990s, MEMS capacitive wall shear stress sensors have emerged with trends towards a standardized design. Typically, the floating sensing structure consists of a floating element, comb fingers, and folded beams. The floating element is connected with interdigitated capacitive comb fingers, which are suspended by folded beams serving as springs. Therefore, changes in the gap between the capacitive electrodes due to shear-induced displacement of the floating element lead to the output voltage via capacitive transduction, as shown in Fig. 1b. Standardized MEMS shear stress sensors integrate mechanical sensing and signal transduction through a floating element suspended by folded beams, with displacement detected via interdigitated capacitors. This highly integrated architecture exposes movable components (beams, comb fingers) directly to the flow, requiring simultaneous mechanical load-bearing and electrical stability maintenance. As a result, the electrically active structures are vulnerable to fuel droplet adhesion and soot accumulation, which can lead to signal drift or mechanical blockage, thereby limiting their environmental robustness17,18, as illustrated in Fig. 1c.

To address these challenges, decoupling the mechanical sensing and signal transduction functions can be an effective approach. This innovative design incorporates a floating cover plate onto the sensing structure for wall shear stress detection, while maintaining the sensing structure’s exclusive role in capacitive signal transduction. Importantly, critical components such as folded beams and comb fingers are protected beneath the cover plate, effectively preventing contamination by flow-borne particles.

However, this design presents substantial challenges in both process design and microfabrication implementation. The cover plate thickness must be precisely controlled, as excessive mass would compromise the system’s dynamic response characteristics. Furthermore, the integration of the floating cover plate with the underlying thin floating sensing structure introduces significant complexities in bonding or deposition processes35,36,37. Additionally, maintaining a sufficient gap between the floating cover plate and the sensing structure is crucial to prevent mechanical interference, including potential collisions and stiction phenomena between the cover plate and comb fingers and folded beams. In summary, the fabrication of a cover plate on floating sensing structures requires the development of a novel process design and addresses critical challenges in etching precision, wafer bonding, and so on throughout the microfabrication process.

In this work, one kind of DSOI (Double Silicon-On-Insulator) process is systematically explored to resolve bonding challenges associated with double thin floating structures (the floating cover plate and the floating structure) in microfabrication. The approach demonstrates broad applicability for fabricating various double-layer floating structures. Critical processes such as deep silicon etching and wet etching of through-glass vias in the microfabrication implementation are thoroughly investigated and analyzed. Based on the DSOI process, a novel wall shear stress sensor with a floating cover plate is developed, which effectively protects sensing structures (comb fingers and folded beams) during practical measurements. The innovative design substantially improves reliability and durability, rendering it particularly suitable for challenging environments. The sensor exhibits a static sensitivity of 28.3 mV/Pa and a measurement range of 13.4 Pa within a compact dimension, delivering competitive performance compared to conventional designs, while significantly enhancing environmental adaptability, as summarized in Table S3. In the Mach 2.0 supersonic flow experiments, the sensor not only demonstrated robust survival capabilities but also successfully captured the complete flow period, validating its operational effectiveness.

Results and Discussion

Sensor design

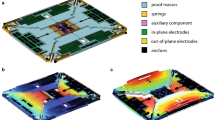

The multilayered architecture of the proposed wall shear stress sensor is schematically illustrated in Fig. 2a, consisting of five vertically stacked components: a top silicon layer, a middle silicon dioxide layer, a bottom silicon layer, a glass ring, and a glass substrate. Serving as the primary force-receiving element, the floating cover plate within the top silicon layer undergoes displacement in response to wall shear stress induced by the flow field. This mechanical displacement is subsequently transmitted through the rigid connection of the middle silicon dioxide layer to the floating sensing structure in the bottom silicon layer. The floating sensing structure serves as the transduction element, which transforms the mechanical displacement into measurable capacitance variations through the interdigitated comb fingers, enabling precise wall shear stress quantification, as shown in Fig. 2c. The structural design integrates a glass ring featuring a suspended cavity to provide the necessary space for the movement of the floating sensing structure, while the glass substrate serves as the mechanical support. Furthermore, TGVs (through glass vias) are implemented to establish back-lead wiring, which enables signal transmission from the floating sensing structure to external circuitry, as shown in Fig. 2b.

Figure 2d depicts a simplified mechanical model of conventional wall shear stress sensors, which feature a floating sensing structure comprising three mechanically interconnected components: the floating element, comb fingers, and folded beams. The deformation of the folded beams is driven by the resultant force generated from the wall shear stress over the surfaces of the floating element, comb fingers, and folded beams. This intricate mechanical coupling results in significant complexity in the theoretical modeling of the sensor, particularly in establishing the relationship between the applied wall shear stress and the corresponding output voltage.

In contrast, the proposed wall shear stress sensor incorporating a floating cover plate can have a simplified mechanical model, as shown in Fig. 2e. Since the floating cover plate serves as the sole element directly withstanding wall shear stress, the fluid viscous force on its surface is effectively converted into a concentrated load on the sensing structure, which is subsequently transmitted to the folded beams dominating its displacement. This innovative design fundamentally enhances the force transmission mechanism through the establishment of a direct, linear relationship between beam deformation and applied shear stress, thereby achieving effective decoupling of the force-receiving and transduction functions as previously described. Theoretically, this design significantly simplifies both the modeling process and sensor calibration, while maintaining measurement accuracy.

The key structural parameters of the floating cover plate and floating sensing structures are shown in Fig. S1. The expressions for the main performance of wall shear stress sensors, including measurement range \({\tau }_{w}\), natural frequency \({f}_{0}\), resolution \({\tau }_{w,\min }\), and sensitivity \(S\), are derived as follows. Details of the mathematical modeling are described in Eqs S1–S15.

where \(E\) represents Young’s modulus of the silicon, \(t\) represents the thickness of the folded beam, \({W}_{t}\) represents the width of the folded beam, \({L}_{t}\) represents the length of the folded beam, r represents the radius of the floating cover plate, \(\delta\) represents the displacement of the floating element, k represents the stiffness of the sensor, m represents the equivalent mass of the movable structure, \({\varepsilon }_{a{ir}}\) represents the air damping coefficient, \(\triangle {C}_{\min }\) represents the minimum capacitive change detectable by the circuitry, \(N\) represents the number of comb finger pairs, \({d}_{0}\) represents the gap distance between the comb fingers, \(\lambda\) represents the offset ratio of the comb fingers.

Equations 1–4 reveal the multi-parametric dependence of sensor performance. To systematically optimize these competing characteristics, the response surface methodology (RSM) is implemented to quantify the complex interactions among multiple design variables. Figure S2 displays the effects of the width-to-length ratio (Wt/Lt) of folded beams, the radius of the floating cover plate (r), and the gap between comb fingers (d0) on the sensor performance. The analytical results demonstrate that increasing the width-to-length ratio enhances both the measurement range and natural frequency of the proposed sensor, while concurrently reducing its resolution and sensitivity.

Notably, although the floating cover plate is employed to sense wall shear stress, the sensing structure composed of folded beams and comb fingers remains unchanged. As derived in Eq. 4, the static sensitivity primarily depends on the stiffness of the folded beams and the comb fingers. The mechanical decoupling allows independent design of the cover plate and the sensing structure, ensuring that the introduction of the cover plate does not degrade sensitivity.

For accurate quantification of wall shear stress in supersonic boundary layers, the sensor must meet performance requirements of over 2 kHz natural frequency. Based on the aforementioned analysis, the optimized design parameters are summarized in Table S1. Finite element analysis is employed to validate the sensor performance, where the structural parameters are consistent with those in Table S1. Specifically, the static and dynamic performances of the proposed sensor are obtained to analyze the discrepancies between the simulated and theoretically predicted values. Under a 10 Pa load of the wall shear stress, the floating cover plate undergoes a displacement of 0.190 μm (δ), with strain localization predominantly occurring at the ends of the folded beams. The peak stress magnitude reaches 1.17 MPa, which is three orders of magnitude lower than the 700 MPa yield strength threshold of single-crystal silicon. Figure 2f demonstrates the good agreement between simulation and theoretical calculations, with a relative deviation of 1.6%. The modal analysis results present the first three vibrational modes, as shown in Fig. S3. The fundamental modal shape is in-plane deformation aligning with the wall shear stress sensing axis, with the frequency of 2983.7 Hz, exhibiting a 1.5% deviation from the theoretical prediction of 2937 Hz. The other resonant frequencies are all higher than 16 kHz, indicating that vibrations in higher-order modes will not affect the measurement results.

Although the sensor is primarily designed for wind tunnel environments containing particulate contaminants, certain application scenarios, such as hypersonic vehicles and aero-engine combustion chambers, may also involve elevated thermal conditions. To evaluate sensor performance under such environments, a series of finite element simulations was conducted, covering thermally induced deformation, temperature-dependent material properties, and transient heat propagation. The results indicate that, within the range of 25 to 200 °C, the differential capacitance drift remains below 0.002% due to the symmetric structure and material configuration, confirming excellent thermal stability. Detailed analysis can be found in Figs S6–S10 and Tables S4, S5.

Sensor fabrication

In this work, the fabrication process of the wall shear stress sensor with a floating cover plate can be broadly divided into three parts: (Ⅰ) Fabrication of the floating sensing structure on a DSOI wafer, (Ⅱ) Fabrication of the suspended cavity with backside through glass vias on a Boronfloat 33 (Bf33) wafer, and (Ⅲ) Bonding of the two previous wafers followed by frontside etching processing to finalize the floating cover plate, as shown in Fig. 3a, while the detailed fabrication process is illustrated in Fig. S4.

a Simplified schematic of the fabrication process. b The front and c the back view of photographs of the sensor die. d Optical microscope images of the floating cover plate. e Optical microscope images of the floating sensing structures. f SEM image photos of the floating sensing structure. g PCB circuit of the sensor. h Metal casing of the sensor packaging

The fabrication of the floating sensing structure begins on the first silicon device layer (50 µm thick) of a Double Silicon-On-Insulator (DSOI) wafer. A 30 nm chromium (Cr) layer and a 100 nm gold (Au) layer are sputtered to form electrodes. The floating structure is then defined by inductively coupled plasma (ICP) dry etching, followed by release through 49% hydrofluoric acid (HF) etching of the underlying buried oxide layer.

Next, the suspended cavity and through-glass vias are fabricated on a Borofloat 33 (Bf33) glass wafer. A chromium mask is sputtered and patterned with AZ4620 photoresist to define the cavity, which is etched in 49% HF while protecting the backside with a UV film. For the through-glass vias, a Cr/Au mask is applied to the opposite side, patterned, and etched in HF solution for 100 min to penetrate the 300 µm glass substrate. All masks are stripped post-etching to ensure clean vias.

Finally, floating cover plate completion is achieved by bonding the DSOI and Bf33 wafers via anodic bonding after surface activation in a sulfuric acid-hydrogen peroxide solution. Electrodes are deposited into the vias using a hard mask, and the DSOI substrate is removed via ICP etching. The second buried oxide layer (1 µm) is etched in HF to expose the 5 µm thick second silicon device layer, which is patterned with EPI680 photoresist and dry-etched to form the floating cover plate. The photoresist is stripped, finalizing the complete sensor structure.

Sensor packaging

After precision dicing, individual sensor dies were obtained and successfully fabricated. Front and back views of the sensor die appear in Fig. 3b, c, respectively. Optical microscopy images in Fig. 3d, e demonstrate the exceptional dimensional precision achieved for both the floating cover plate and the floating sensing structure. Scanning electron microscopy (SEM) analysis follows the controlled removal of the suspended cover plate to evaluate etching fidelity. The SEM images in Fig. 3f show micron fabrication accuracy for the floating cover plate and sensing structure, consistent with Table S1 design parameters.

The signal processing architecture of the wall shear stress, schematically illustrated in Fig. S5, begins with sinusoidal excitation to modulate the capacitance of comb fingers onto a carrier signal. This modulated signal undergoes sequential conversion through a charge amplifier (transforming capacitance C₁ and C₂ to voltages V₁ and V₂), followed by a differential voltage amplifier and a phase-locked loop (PLL)-based demodulation with filtering, culminating in data acquisition.

To minimize parasitic capacitance interference, the charge amplification and voltage differential functionalities implement triple-layer PCB integration (Fig. 3g), where the sensor die is epoxy-bonded to the first layer interfaces vertically with the second layer (hosting the charge amplifier), and the third layer (hosting the voltage differential). The entire assembly is encapsulated in a precision-machined metal casing (Fig. 3h), providing electromagnetic shielding while maintaining mechanical stability through precise machining accuracy.

Critical fabrication processes

Several critical processes in the fabrication implementation require detailed discussion, particularly inductively coupled plasma (ICP) deep silicon etching, wet etching of through-glass vias, and silicon-glass anodic bonding. These fabrication processes significantly impact the overall performance and production yield of the wall shear stress sensors.

ICP deep silicon etching

In ICP deep silicon etching, the etching rate exhibits significant dependence on feature size. Compared with narrow trenches, wide trenches demonstrate higher etching rates, which is known as the lag effect38,39,40. This disparity leads to premature exposure of the buried oxide layer in wider trench regions, where the accumulation of reactive ions induces localized charging effects. These charging effects subsequently cause electrostatic deflection, resulting in lateral ion migration and consequent undercutting at the trench bottom41,42,43,44.

As a result, the phenomenon of lateral etching at the base of the sensing structure occurs, particularly reducing the thickness of comb fingers and folded beams and degrading the device’s reliability. Furthermore, the undercutting effect deteriorates the fracture strength of silicon structures from over 1 GPa to below 200 MPa due to stress-concentrating microcracks. Figure 4a demonstrates the lag effect observed under microscopy. According to Fig. 4a, when the 50 μm wide trenches are fully etched to the buried oxide layer, the adjacent 10 μm trenches retain unetched regions. Besides, narrower comb finger gaps (3 μm) present significantly greater etching challenges, particularly in achieving complete etching to the buried oxide layer, which cannot be effectively characterized using conventional optical microscopy. Though there are alternative characterization methods, such as the SEM analysis, they are incompatible with in-process monitoring during fabrication. Therefore, monitoring of both etch depth and profile characteristics in ICP etching processes is critical for preventing the undercutting effect and improving process quality. However, efficient and user-friendly monitoring solutions remain unavailable during actual fabrication steps.

a Lag effect in etching processes. b Resistance measurement between movable and fixed comb fingers. c Effect of corrosion window size on wet corrosion morphology of glass. d Wet corrosion rate of glass in the depth direction. e Wet corrosion rate of glass in the width direction. f Adhesion of comb teeth due to uneven bonding voltage loading. g Key process parameters in the silica glass bonding process

To address this issue, a simple and practical electrical detection method is developed by utilizing the inherent properties of capacitive wall shear stress sensors. When fully etched to the buried oxide layer, the comb fingers become completely separated, creating an open-circuit state with infinite resistance. In contrast, incomplete etching results in a measurable resistance. The resistance between the comb fingers is monitored to determine whether the microsensor is fully etched. As shown in Fig. 4b, this method allows for precise monitoring of the etching process, which avoids the effects of undercutting.

Wet etching of through-glass vias

The wet etching process of through glass vias has been widely used for signal paths in the fabrication of MEMS devices and their packages. In this process, the endurance of masks in high-concentration HF solution and their adhesive properties with glass wafers play an important role in the quality of wet etching results35,36,45,46. The most popular masks for wet etching of glass wafers are the Cr/Au film together with photoresist, which has been proven as a good way to fabricate through vias on glass wafers. However, considering the aspect ratio of the glass through vias, the optimized parameters, special process, and the undercutting etching should be thoroughly investigated47,48.

To etch through-glass vias in 49% HF solution, a Cr/Au mask reinforced with dehydrated AZ4620 photoresist is used. Two strategies are adopted to improve mask integrity. First, a two-step gold sputtering process is implemented: a 100 nm Au layer is deposited and naturally cooled to relieve thermal stress and release microcracks, followed by a second 100 nm layer to seal these defects and enhance overall durability. Second, AZ4620 photoresist—known for its strong acid resistance and excellent adhesion to gold—is applied to further strengthen the Cr/Au mask. After patterning, the mask is baked at 120 °C for 30 min to remove residual moisture and form a dense, acid-resistant film.

To investigate the factors influencing the wet etching process, corrosion windows of varying sizes are designed to examine the changes in profile and etching rate. The glass via profiles are characterized by the AMBIOS DEKTAK-XT profilometer, and the results for different etching window sizes and etching times are presented in Fig. 4c. The results reveal that the profile of the through-glass vias remains consistent during the wet etching process. The sidewalls of the TGVs exhibit a tilt angle of approximately 45° and maintain uniformity, which facilitates the formation of electrodes during metal filling and ensures strong adhesion between the electrode and the substrate.

Based on Fig. 4c, the etching rate during the wet etching process is computed. It is found that larger etching windows result in higher etching rates. However, as the etching time progresses, the accumulation of chemical reaction byproducts at the bottom of the vias leads to a decrease in the etching rate along the depth direction. Since the lateral etching rate is approximately 1.5 times larger than that in the depth direction, as shown in Fig. 4d, e, the depth-to-width ratio of the glass vias produced by wet etching is constrained. Based on the above analysis, the optimal process parameters are chosen as the etching time of 65 min on a 300 μm thick glass wafer with a mask window diameter of 500 μm. The obtained through glass vias have an entry diameter of approximately 1-1.2 mm and an exit diameter of approximately 500-600 μm.

Silicon-glass anodic bonding

The principle of silicon-glass anodic bonding can be described as the sodium ions in the glass migrating toward the cathode under an electric field, while oxygen ions react with silicon to form a SiO₂ layer, facilitating the bonding37. In conventional SOI-glass anodic bonding, the buried oxide layer functions as a capacitor, and thicker oxide layers increase the resistance to the applied DC voltage49,50. Standard anodic bonding typically requires SOI wafers with buried oxide layers ≤2 μm for effective bonding under voltages ranging from 200 to 1000 V. However, the buried oxide layer in the DSOI wafer used in this paper is 4 μm thick, exceeding the conventional limit.

Anodic bonding between the DSOI wafer and the Bf33 wafer is successfully achieved using the parameters listed in Table S2. However, several critical considerations must be addressed: (I) Voltage uniformity: Pre-released structures (e.g., comb fingers, folded beams) are at risk of stiction failure if potential differences induce electrostatic discharge, as shown in Fig. 4f. (II) Voltage limitation: Excessive electrostatic forces may fracture structures or cause unintended substrate adhesion.

To overcome these challenges, the wafer is interconnected using silicon traces to ensure uniform voltage distribution during the bonding process. Additionally, a stepwise increase in bonding voltage is employed to mitigate the adverse effects of electrostatic forces on the bonding outcome. The bonding voltage parameters are shown in Fig. 4g. The initial bonding voltage of 100 V is sufficient to initiate the bonding process without affecting the sensor structure. Subsequently, the bonding voltage is gradually increased to 600 V, during which the strength of the electrostatic field does not increase significantly, ensuring that the electrostatic force between the sensor’s sensitive structure and the cavity bottom of the glass wafer remained at a low level.

Static measurement

As shown in Fig. 5a, a laminar flow cell with channel dimensions of 500 mm in length, 15 mm in width, and 1 mm in height is used to calibrate the mean wall shear stress, which is assumed to exhibit two-dimensional Poiseuille flow. The expression for the wall shear stress of the steady and fully developed two-dimensional flow within the channel is given by51

where \({\tau }_{w}\) represents the wall shear stress, h is the height of the channel, and dp/dx represents pressure gradients along the channel.

a Schematic diagram of the static calibration system. b The pressure distribution in the laminar flow cell. c Typical static output characteristics. d Sensor sensitivity at different frequencies. e The curve fitting sensitivity. f SEM image of conventional wall shear stress sensor under polluted flow with graphite particulates. g SEM image of the wall shear stress sensor with the floating cover plate under polluted flow with graphite particulates

The pressure distribution along the wall of the flow field inside the laminar flow cell is shown in Fig. 5b. Due to the flow development and outlet effects, the pressure distribution near the inlet and outlet exhibits nonlinear characteristics at high driving pressures, while the middle section maintains a linear distribution. Therefore, the wall shear stress sensor is positioned at x = 345 mm, within the linear region of the pressure distribution, ensuring the accuracy of the wall shear stress calculation.

Unlike conventional MEMS sensors designed for acceleration or pressure, the wall shear stress sensor exhibits unique static characteristics due to its direct interaction with the flow field. As shown in Fig. 5c, the output characteristics of the wall shear stress sensor can be divided into three regions: a low-sensitivity region during laminar flow, a high-sensitivity region during turbulent flow, and a nonlinear region. When the flow inside the channel is laminar, calibration shows that the sensitivity of the wall shear stress sensor is relatively low, approximately 17.6 mV Pa−1. However, as the Reynolds number increases and the flow transitions from laminar to turbulent, the static sensitivity of the sensor increases to approximately 28.3 mV Pa−1. It is worth noting that although different flow conditions in the flow cell lead to variations in the sensitivity of the wall shear stress sensor static output, the output results under both laminar and turbulent flow conditions exhibit linear characteristics.

Dynamic measurement

A plane-wave tube system is utilized to calibrate the dynamic properties of the wall shear stress sensor52,53. The calibration system includes a function generator, a power amplifier, a speaker, and a pulsating pressure sensor. The function generator produces a sinusoidal excitation signal, which is amplified by the power amplifier and used to drive the loudspeaker, emitting a sinusoidal sound wave. This sound wave travels through the tube, forming a stable plane wave. Both the pulsating pressure sensor and the wall shear stress sensor are flush-mounted on the upper and lower walls of the plane-wave tube. The pulsating pressure sensor measures the sound pressure acting on the shear stress microsensor probe, enabling the calculation of the applied wall shear stress. The formula for calculating shear stress is given by

where \({\tau }_{w}\) is the wall shear stress, p is the fluctuating pressure along the wall, j is the imaginary unit (j2 = -1), ω is the angular frequency of near-wall particle oscillation driven by sound pressure, t is the propagation time, x is the propagation direction distance, k is the wave number, c is the speed of sound in air, μ is the kinematic viscosity of the fluid, ρ is the fluid density, v is the dynamic viscosity of the medium, and a is the half-width of the tube.

Figure 5d, e illustrate the output voltage of the wall shear stress sensor under various sinusoidal excitation frequencies. The sensor’s output voltage increases with excitation frequency. At an excitation frequency of approximately 2.9 kHz, the maximum dynamic sensitivity of about 320 mV Pa−1 indicates that the sensor’s movable structure is in a resonant state. The sensor reaches resonance around 2.9 kHz, which closely matches the theoretical and simulation results of 2987 Hz.

Reliability testing

In practical aerospace environments, contamination-induced sensor failure can arise primarily from two mechanisms: electrical short-circuiting and mechanical jamming. To evaluate the reliability of the proposed wall shear stress sensor, micron-sized graphite particulates (1–5 µm in diameter) are introduced into a laminar flow cell. This particle size distribution was strategically selected to match the critical dimensions of the sensor’s structures: the 3 µm interdigitated comb fingers gap and the 2 µm floating cover plate gap, enabling systematic assessment of particulate-induced obstruction risks in both narrow sensing structures and critical structural components under non-ideal aerodynamic conditions. Additionally, due to its electrical conductivity, graphite serves as a surrogate for metallic debris in the simultaneous evaluation of mechanical interference and potential electrical effects under non-ideal aerodynamic conditions.

Figure 5f illustrates a conventional wall shear stress sensor without protective shielding, exhibiting complete functional failure from particulate occlusion within the comb fingers. Comparatively, Fig. 5g demonstrates the proposed sensor with a floating cover plate, where, while particulate deposits are observable on the surface of the protective barrier, negligible particle infiltration is measured within the shielded comb fingers, confirming the cover plate’s efficacy in preserving electromechanical functionality in harsh environments.

Supersonic flow measurements

The direct-connect supersonic combustion tunnel at China Aerodynamics Research and Development Center (CARDC) is capable of generating the supersonic flow across Mach 1.5–4.0, with the reported experiments conducted at Mach 2.0. As detailed in Fig. 6a, the proposed wall shear stress sensors are strategically positioned along the isolator and expansion section of the scramjet combustor’s upper surface54, with synchronized wall pressure measurements. This dual-measurement configuration enables systematic characterization of compressible flow parameter evolution during varied aerodynamic phases.

Prior to these tests, a series of high-temperature arc-heated wind tunnel experiments was also conducted to verify the sensor’s thermal stability and signal repeatability. The results confirmed excellent output consistency under a 400 °C high-enthalpy flow, as detailed in Fig. S12. The present section focuses on supersonic flow measurements in the direct-connect supersonic combustion tunnel.

Figure 6b presents time-synchronized wall shear stress and pressure results measured from the scramjet isolator section. Flow establishment initiates at t = 650 ms, triggering rapid increases in both parameters that achieve dynamic equilibrium after 300 ms, yielding an average wall shear stress of 790 Pa with about ±20% fluctuation amplitude. The Van-Driest theoretical prediction of 802 Pa55 closely matches the experimental value with only a 1.5% deviation. Notably, the synchronized variation trends between wall shear stress and pressure confirm the sensor’s capability to precisely track the complete flow development process - from initial establishment through the stable process to eventual dissipation.

Figure 6c presents time-synchronized wall shear stress and pressure results measured from the scramjet expansion section under cold flow conditions. During flow development, both parameters exhibit rapid transient increase, achieving stabilization at 465 Pa mean shear stress with ±46.3% fluctuation amplitude from triplicate tests. This enhanced fluctuation amplitude reflects the complex vortical structures characteristic of expansion-dominated compressible flows.

Figure 6d demonstrates the coupled aerodynamic responses in the scramjet expansion section under combustion flow conditions. As the flow field is established, wall shear stress and pressure demonstrate synchronous transient increase, reaching 480 Pa mean shear stress that matches non-reactive cold flow measurement results. Subsequent injection of 1 MPa premixed hydrogen into the combustion chamber induces abrupt wall shear stress attenuation to 390 Pa, accompanied by turbulence suppression. The experimental results validate the thermal throat effect: combustion-induced boundary layer thickening effectively reduces near-wall velocity gradients, thereby attenuating wall shear stress generation.

Conclusion

In this work, a novel MEMS-based wall shear stress sensor incorporating a floating cover plate was developed to overcome contamination challenges in harsh aerodynamic environments. The innovative design decouples the mechanical sensing and signal transduction functions by incorporating a floating cover plate, which protects internal sensing structures while maintaining high measurement precision. Additionally, a novel process design and microfabrication implementation based on the DSOI process were systematically investigated, accomplishing the sensor manufacture.

Experimental evaluations demonstrated that the sensor achieves a linear sensitivity of 28.3 mV Pa−1 and exhibits a frequency response with a resonance frequency of 2.9 kHz, achieving competitive performance alongside significantly enhanced environmental robustness. Supersonic wind tunnel experiments at Mach 2.0 demonstrated stable operation in particulate-laden flow and confirmed the consistency of the measured results with theoretical predictions, thereby validating both the reliability and accuracy of the device.

These results highlight the sensor’s applicability for high-speed flow measurement in environments previously inaccessible to MEMS wall shear stress sensors. The sensor shows strong potential for deployment in scramjet boundary layer monitoring, arc-heated flow facilities, and reusable aerospace systems such as reentry vehicles.

Materials and Methods

Numerical Simulations

Finite element simulations of structural movement and modal frequency were conducted using the commercial software COMSOL Multiphysics 6.1. Theoretical models and RSM analysis were established using MATLAB 2021b.

Fabrication of the wall shear stress sensor

The complete fabrication process is discussed in Fig. S4. The deep silicon etching process was carried out using an ICP ASE model inductively coupled plasma etcher. The silicon-glass bonding process was achieved with a SUSS XB8 model semi-automated wafer bonder. Wet etching was performed using a 49% concentration hydrofluoric acid.

Experimental process and measuring equipment

The plane-wave tube system for dynamic characterization had internal dimensions of 1 cm × 1 cm, employing a Crown XLS1500 power amplifier, XCE-062-30a pulsating pressure sensor, and JBL 2425HS speaker. Sensor morphologies were characterized using a field-emission scanning electron microscope (ZEISS Sigma 500). Measurement data were acquired through an NI PXIe-4499 data acquisition card interfaced with a desktop computer, with LabVIEW 2016 processing and displaying real-time signals. Supersonic flow measurements were conducted on a direct-connect supersonic combustion test facility at the China Aerodynamics Research and Development Center, operating under stagnation conditions of 950 K and 0.82 MPa, with a Mach number of 2.0 at the isolator entrance. The airflow in the scramjet test section was composed of a molar mixture of 21% O₂, 12% H₂O, and 67% N₂, with a total mass flow rate of 2.68 kg/s. Two MEMS wall shear stress sensors were flush-mounted on the top wall of the combustor: the first was positioned at x = 103 mm in the isolator section, and the second at x = 525 mm in the expansion section, downstream of the cavity.

Data availability

All data are available in the manuscript or the Supplementary Materials or from the author.

References

Alfredsson, P. H., Johansson, A. V., Haritonidis, J. H. & Eckelmann, H. The fluctuating wall-shear stress and the velocity field in the viscous sublayer. Phys Fluids 31, 1026–1033 (1998).

Tong, F. et al. Wall shear stress and wall heat flux in a supersonic turbulent boundary layer subjected to concave surface curvature. Phys Rev Fluids 8, 124602 (2023).

Dong, S. et al. Positive and negative pairs of fluctuating wall shear stress and heat flux in supersonic turbulent boundary layers. Phys Fluids 34, 085113 (2022).

Naughton, J. & Sheplak, M. In 21st Aerodynamic Measurement Technology and Ground Testing Conference, 2000–2521 (AIAA, Denver, USA, 2000).

Tong, F. et al. Wall heat flux in a supersonic shock wave/turbulent boundary layer interaction. Phys Fluids 34, 065121 (2022).

Cafiero, G. & Iuso, G. Drag reduction in a turbulent boundary layer with sinusoidal riblets. Exp Therm Fluid Sci 139, 110723 (2022).

Ou, Z. et al. Hierarchical nested riblet surface for higher drag reduction in turbulent boundary layer. Phys Fluids 36, 105166 (2024).

Örlü, R. & Vinuesa, R. Instantaneous wall-shear-stress measurements: Advances and application to near-wall extreme events. Meas Sci Technol 31, 112001 (2020).

Wang, D. et al. Temperature dependence of constant current hot-film sensors: Investigation with application to temperature correction for wall-shear stress measurements. Flow Meas Instrum 97, 102616 (2024).

Deng, J. et al. Fabrication and static calibration of double-layer thermal film sensor for fluid wall shear stress measurement. J Micromech Microeng 30, 115019 (2020).

Vinuesa, R. & Örlü, R. Measurement of wall-shear stress. Exp Aerodyn 1, 36 (2017).

Ghouila-Houri, C. et al. Flight-testing of a MEMS wall shear stress thermal sensor on a microlight aircraft. Proceedings of the 2023 IEEE SENSORS Conference, 1–4 (2023).

Meritt, R. J. et al. A summary of AFOSR BOLT II direct wall shear stress measurements. In AIAA Aviation 2023 Forum, 3452 (AIAA, 2023).

Sheplak, M., Cattafesta, L., Nishida, T., & McGinley, C., MEMS shear stress sensors: Promise and progress. In 24th Aerodynamic Measurement Technology and Ground Testing Conference, 2004-2606 (AIAA, Portland, Oregon, USA, 2004).

Hu, F. et al. Waterproof, anti‐impacted, and ultrathin carbon‐based air pressure sensors toward aerodynamic tests on high‐speed trains. Adv Eng Mater 24, 2101781 (2022).

Ho, C.-M. & Tai, Y.-C. Micro-electro-mechanical-systems (MEMS) and fluid flows. Annu Rev Fluid Mech 30, 579–612 (1998).

Naughton, J. W. & Sheplak, M. Modern developments in shear stress measurement. Prog Aerosp Sci 38, 515–570 (2002).

Yan, Y., Jiang, C., Ma, B., Luo, J. & Deng, J. A pre-verifiable calibration model of wall shear stress thermal sensor driven by constant current. Flow Meas Instrum 69, 101591 (2019).

Barlian, A. A., Park, S.-J., Mukundan, V. & Pruitt, B. L. Design and characterization of microfabricated piezoresistive floating element-based shear stress sensors. Sens Actuators A: Phys 134, 77–87 (2007).

Nguyen, T.-V. et al. A wall shear stress sensor using a pair of sidewall doped cantilevers. J Micromech Microeng 27, 075017 (2017).

Kim, T. et al. Piezoelectric floating element shear stress sensor for the wind tunnel flow measurement. IEEE Trans Ind Electron 64, 7304–7312 (2017).

Williams, R. P., Kim, D., Gawalt, D. P. & Hall, N. A. Surface micromachined differential piezoelectric shear-stress sensors. J Micromech Microeng 27, 015011 (2016).

Kamat, A. M. et al. Undulating seal whiskers evolved optimal wavelength-to-diameter ratio for efficient reduction in vortex-induced vibrations. Adv Sci 11, 2304304 (2024).

Zhou, H., Mills, D. A., Vera, A., Garraud, A. & Oates, W. A high-temperature optical sapphire pressure sensor for harsh environments. In AIAA Scitech 2019 Forum, 2019–2044 (AIAA, San Diego, California, USA, 2019).

Mills, D. A., Chen, T.-A., Horowitz, S. & Sheplak, M. Development of a differential optical wall shear stress sensor for high-temperature applications. In AIAA Scitech 2019 Forum, 2019–2112 (AIAA, San Diego, California, USA, 2019).

Ebrahimzade, N., Portoles, J., Cumpson, P., Wilkes, M. & Whalley, R. D., Optical MEMS sensors for instantaneous wall-shear stress measurements in turbulent boundary-layer flows. In 12th Int. Symposium on Turbulence and Shear Flow Phenomena (Osaka, Japan, 2022).

Chandrasekharan, V. et al. A microscale differential capacitive direct wall-shear-stress sensor. J Microelectromech Syst 20, 622–635 (2011).

Lv, H. et al. Design of a micro floating element shear stress sensor. Flow Meas Instrum 30, 66–74 (2013).

Mills, D. A., Barnard, C. & Sheplak, M. Characterization of a hydraulically smooth wall shear stress sensor for low-speed wind tunnel applications. In 55th AIAA Aerospace Sciences Meeting, 2017-0478 (AIAA, Grapevine, Texas, USA, 2017).

Ding, G., Ma, B., Deng, J., Yuan, W. & Liu, K. Accurate measurements of wall shear stress on a plate with elliptic leading edge. Sensors 18, 2682 (2018).

Mills, D. A., Patterson, W. C.,0 Keane, C. & Sheplak, M. Characterization of a fully-differential capacitive wall shear stress sensor for low-speed wind tunnels. In 2018 AIAA Aerospace Sciences Meeting, 2018-0301 (AIAA, Kissimmee, Florida, USA, 2018).

Ding, G., Ma, B., Deng, J., Luo, J. & Yuan, W. Temperature drifts of the floating element wall shear stress sensor with capacitive sensing. In 20th International Conference on Solid-State Sensors, Actuators and Microsystems, 2049–2052 (IEEE, Berlin, Germany, 2019).

Freidkes, B. R., Mills, D. A., Patterson, W. C., Fournier, P. M. & Sheplak, M. A flush-mounted dual-axis wall shear stress sensor. J Microelectromech Syst 29, 748–754 (2020).

Bu, Z. et al. Design and manufacturing of shear stress sensor for high-temperature applications with embedded capacitive floating unit. IEEE Sens J 24, 36551–36559 (2024).

Xia, Q. et al. A state-of-the-art review of through-silicon vias: Filling materials, filling processes, performance, and integration. Adv Eng Mater 27, 2401799 (2025).

Ding, G., Ma, B., Yan, Y., Yuan, W. & Deng, J. Through glass vias by wet-etching process in 49% HF solution using an AZ4620 enhanced Cr/Au mask. In Proc. 16th International Conference on Nano/Micro Engineered and Molecular Systems, 872-875 (IEEE, Xiamen, China, 2021).

Liu, M., Dong, X., Cui, J. & Zhao, Q. Investigation of the reliability of the interconnection between metal electrode and silicon anchor in silicon-on-glass process. In 16th International Conference on Nano/Micro Engineered and Molecular Systems, 1102-1105 (IEEE, Xiamen, China, 2021).

Feng, J., Zdenka, F., Liu, X., Chang, H. & Pavel, N. Microfluidic device based on deep reactive ion etching process and its lag effect for single cell capture and extraction. Sens Actuators B: Chem 269, 288–292 (2018).

Laermer, F., Franssila, S., Sainiemi, L. & Kolari, K. Handbook of Silicon-Based MEMS Materials and Technologies (3rd ed.). Elsevier, 417-446 (2020).

Tan, Y., Zhou, R., Zhang, H., Lu, G. & Li, Z. Modeling and simulation of the lag effect in a deep reactive ion etching process. J Micromech Microeng 16, 2570 (2006).

Pham, P. H. & Dang, L. B. Influence of the side etching effect in DRIE on performance of electrostatic linear comb-drive actuators. Microsyst Technol 24, 2215–2222 (2018).

Zhang, P. & Li, D. The features of surface charging on rectangle mask holes in plasma etching. Phys Plasmas 29, 103506 (2022).

Zhang, H., Huang, J., Yuan, W. & Chang, H. A high-sensitivity micromechanical electrometer based on mode localization of two degree-of-freedom weakly coupled resonators. J Microelectromech Syst 25, 937–946 (2016).

Zhang, H., Chang, H. & Yuan, W. Characterization of forced localization of disordered weakly coupled micromechanical resonators. Microsyst Nanoeng 3, 17023 (2017).

Shubhava, J. A., Kannarpady, G. K., Kale, S., Prabhu, S. & Pinto, R. Chemical etching of glasses in hydrofluoric acid: A brief review. Mater Today: Proc 55, 46–51 (2022).

Kyeonggon, C., Seung-Wook, K., Jae-Hyoung, L., Chu, B. & Dae-Yong, J. Eco-friendly glass wet etching for MEMS application: A review.

Vishal, S. et al. A study on chromium thin film with positive photoresist as a masking layer towards the wet bulk micromachining of borofloat glass. Micro Nano Syst. Lett., 12 (2024).

Konstantinova, T. G., Andronic, M. M., Baklukov, D. A., Stukalova, V. E. & Ezenkova, D. A. Deep multilevel wet etching of fused silica glass microstructures in BOE solution. Sci Rep. 13, 5228 (2023).

Chen, Z., Gao, C., Guan, T., Yang, F. & Shi, L. Effect of thin SiO2 layer on silicon-on-glass anodic bonding. In 19th International Conference on Nanotechnology, 19–22 (IEEE, Macao, China, 2019).

Knowles, K. M. & Van Helvoort, A. T. J. Anodic bonding. Int Mater Rev 51, 273–311 (2006).

White, F. M., Fluid Mechanics (8th ed.). McGraw-Hill, New York (2015).

Sheplak, M., Padmanabhan, A., Schmidt, M. A. & Breuer, K. S. Dynamic calibration of a shear-stress sensor using Stokes-layer excitation. AIAA J 39, 819–823 (2001).

Chandrasekaran, V., Cain, A., Nishida, T., Cattafesta, L. N. & Sheplak, M. Dynamic calibration technique for thermal shear-stress sensors with mean flow. Exp Fluids 39, 56–65 (2005).

Ye, T., Han, Y., Yang, S., Zhong, F. & Le, J. Investigation of fluctuating characteristics of wall shear stress in supersonic flow. Phys Fluids 31, 125110 (2019).

Ma, C. et al. A high-temperature MEMS surface fence for wall-shear-stress measurement in scramjet flow. Sensors 17, 2412 (2017).

Acknowledgements

This work was supported by the National Key Research and Development Program of China (Grant no. 2024YFB3408804) and the National Natural Science Foundation of China (Grant nos. 52205602 & 52475571).

Author information

Authors and Affiliations

Contributions

The design, fabrication, and characterization of the proposed wall shear stress were completed by Y. Liu, C. Wang, and G. Ding. The supersonic experiments were tested by Y. Liu and G. Ding. Y. Liu, C. Wang, and X. Zhang contributed to the writing of the manuscript. X. Zhang, Y. He, B. Ma, and W. Yuan supervised the overall research.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Liu, Y., Wang, C., Ding, G. et al. A MEMS wall shear stress sensor with floating cover plate for aerospace flow monitoring in harsh environments. Microsyst Nanoeng 11, 183 (2025). https://doi.org/10.1038/s41378-025-01050-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41378-025-01050-x