Abstract

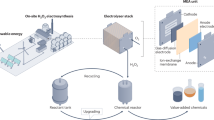

Hydrogen peroxide (H2O2) can be sustainably synthesized through the electrochemical oxygen reduction reaction in a dual-chamber water electrolyzer separated by expensive ion exchange (IX) membranes. The development of an IX membrane-free electrolyzer has been limited by direct anodic degradation of the produced H2O2. Here, we devise a bubble shielding strategy by using a low-cost polytetrafluoroethylene hydrophobic porous layer (HPL) on the anode that enables numerous sites for anodically generated oxygen bubbles and significantly suppresses H2O2 degradation in the electrolyte. The H2O2 production increases by ~600% compared to that using non-bubble shielded anode. A high H2O2 concentration of 10.05 ± 0.05 g L−1 at 40 mA cm−2 can be obtained with both HPL-coated anode and cathode. A solar-driven disinfection device equipped with HPL-coated electrodes achieves >99.9% E. coli inactivation within 60 min. This innovative approach for achieving high electrochemical H2O2 concentrations in IX membrane-free electrolyzers more generally provides insights for fine tuning three-phase interfaces and could be applicable to other reactions pathways in electrochemical applications.

Similar content being viewed by others

Introduction

Hydrogen peroxide (H2O2) is an important chemical material that has been widely used in chemical engineering industries such as pulp or textile bleaching, water/wastewater treatment, and energy conversion1,2. The traditional anthraquinone-based process for producing H2O2 has high energy consumption, produces large amounts of organic solvent wastes, and raises safety concerns for its transportation and storage3. Electrochemical reduction of oxygen, a simple and economical alternative, has therefore emerged as an attractive strategy for H2O2 production4,5. This method is based on the oxygen reduction reaction through a two-electron oxygen reduction reaction (ORR) at the cathode.

This approach offers numerous advantages compared to traditional anthraquinone processes that include: green and safe synthetic route; no organic by-products generation; ease of operation; and in-situ and on-demand production6.

To improve electrochemical H2O2 production, current approaches focus on enhancing the ORR catalytic activity of the cathode and optimizing the cathode structure2,7,8,9. A series of electrocatalysts such as noble metal-based catalysts (Pt–Hg, Au–Pd, Pt/TiC, etc.)10,11,12, nonmetal carbon-based catalysts (nitrogen-doped carbon, oxidized CNTs, etc.)13,14, and M–N–C single-atom catalysts (Co–N–C, Ni3(HITP)2, Fe-CNT, etc.)15,16,17 with suitable binding energy of *OOH intermediate, have been developed to improve 2e− ORR activity and selectivity18. Specifically, the commercial carbon black (CB) itself exhibited fairly high 2e– ORR activity19,20, and boron or sulfur doping could further boost the H2O2 production21. Water oxidation reaction catalysts such as oxygen-deficient Pr1.0Sr1.0Fe0.75Zn0.25O4-δ perovskite oxides and ZnGa2O4 were also developed to produce H2O2 by lowering the overpotential below 1000 mV and increasing faradaic efficiency over 80%22,23. Confining localized oxygen could also boost water oxidation to H2O2 on a carbon paper/PTFE anode with a low overpotential of 640 mV24. Other approaches have been based on optimizing cathode structures by developing enhanced three-phase interfaces for effective charge (electrons and protons) and mass transfer (O2, H2O, and H2O2)25,26. The gas diffusion electrode-based reactor configuration significantly advanced the field by directly using air as an oxygen source and avoiding aeration, which enhanced O2 transfer and improved overall H2O2 production9,27. The utilization of solid electrolytes can further shorten transport pathways and enable continuous extraction of high-concentration H2O228. A superhydrophobic polymethylhydrosiloxane-coated air cathode obtained a high H2O2 production of 1875 mg L−1 at 360 min in single compartment cell29. The integration of hollow fibers in an air cathode boosted O2 transport through the axial microchannel and radial nanopores with about 79.3 mM H2O2 production in 1 h30.

Despite these important efforts in improving the catalyst activity and optimizing cathode mass transfer, the economical and sustainable production of H2O2 is still limited by the use of expensive ion exchange (IX) membranes31, further limiting the application in low-resource or remote areas. The use of an IX membrane has been necessary to separate ion transport from the H2O2 because H2O2 can be easily oxidized to O2 on the anode32.

However, cation IX membranes (CEMs) are relatively expensive (about $1400 m−2)33. In addition, the membranes are subject to complex water conditions and their ion-conducting performance would degrade over time, resulting in substantial costs for regular replacement in practical applications34. One previous approach to avoid the use of IX membranes is based on an electro-fenton technique with both the anode and cathode in the same chamber. These low concentrations result from H2O2 oxidation at the anode (Eq. (2)), H2O2 reduction on the cathode (Eq. (3)), and H2O2 decomposition (Eq. (4))3,32,35,36,37,38,39.

Therefore, an alternative strategy would be necessary to avoid these consumption reactions in order to achieve a high concentration of H2O2 in the electrolyte.

To enable high product concentrations of H2O2 we developed a bubble shielding strategy based on using coatings on the electrodes with a low-cost polytetrafluoroethylene (PTFE) hydrophobic porous layer (HPL). Apart from the hydrophobic nature of HPL, it was demonstrated to provide ample sites for gas bubble evolution while shielding the electrode from the H2O2 and thus minimizing its degradation. The shielding effect was identified for both anode and cathode from H2O2 consumption testing. To demonstrate the effectiveness of this approach, we assembled a membrane-free electrolyzer with paired HPL electrodes and evaluated the H2O2 generation and electrode stability. Furthermore, we designed a solar-driven disinfection prototype device powered by a commercial polycrystalline silicon solar panel to showcase the applicability of HPL-coated electrodes in the service of on-site surface water disinfection in low-resource rural areas. The paired HPL electrodes system obtained high H2O2 production in a membrane-free electrolyzer. The system provided a simple, low-cost, and practical use by eliminating the ion-exchange membrane, yet inspiring a practical strategy for electrochemical H2O2 production towards industrial applications and rural drinking water disinfection. In the future, more efforts will be necessary to optimize the structure and composition of HPL, further enhancing the H2O2 concentration in membrane-free electrolyzers. The incorporation of more efficient electrocatalysts and optimization of reactor configuration with improved mass transport would also benefit higher H2O2 production.

Results

Fabrication and characterization of HPL-coated anode

In a common membrane-free electrolyzer (Fig. 1a), the commercial RuO2–IrO2 anode showed a typical microcrack structure resulting from the cleavage of some metal oxides during the high-temperature fabrication, which would allow direct transport of the electrolyte into crevices on the anode surface (Fig. 1c)40. The average surface roughness (Ra) of the noncoated anode was originally 376 ± 88 nm and decreased to 126 ± 37 nm after HPL coating (Fig. 1d and f). After coating with HPL of 1.0 mg cm−2 PTFE, the surface appeared to be more uniform and smoother, displaying an interconnected porous structure with pore sizes ranging from 0.22 to 1.6 μm (Figs. 1e, S1, and S2). The HPL surface became more uniform with an average pore depth of 16 ± 0.5 μm based on a 3D optical profilometer (Fig. S3). The color of the coated anode changed from black to slightly white (Fig. 1c and e inset) and energy dispersive X-ray spectroscopy (EDS) mapping showed an enhanced signal intensity for C and F elements and a weaker signal intensity for Ru, Ir, and O elements (Figs. 1g, i and S4), confirming the successful coverage by the HPL41,42. The CF2 and CF3 functional groups appeared on X-ray photoelectron spectroscopy (XPS) spectra, and Ru-related peaks completely diminished, further proving the successful coating of HPL on the anode (Figs. 1h, j and S5). The relatively hydrophilic property with a small water contact angle of 34° and a large bubble contact angle of 137° (Fig. 1k), would also promote direct electrolyte contact and lead to fast H2O2 anodic oxidation (Eq. 2). The surface property of HPL-coated anode was completely reversed with a large water contact angle of 146° and small bubble contact angle of 40° (Fig. 1l), demonstrating both hydrophobicity hindering direct electrolyte contact and aerophilic affinity to bubbles.

Schematic diagram of membrane-free electrolyzer with a noncoated and b HPL-coated anodes. Scanning electron microscope (SEM) images of c noncoated and e HPL-coated anodes (c and e insets: photographic images of noncoated and HPL-coated anodes). Three-dimensional atomic force microscopy (AFM) images of d noncoated and f HPL-coated anodes (Ra is the average surface roughness). Energy dispersive X-ray spectroscopy (EDS) mapping (Ir, Ru, C, and F elements) of g noncoated and i HPL-coated anodes. X-ray photoelectron spectroscopy (XPS) spectra (C 1s spectra) of h noncoated and j coated-HPL anode. Water contact angle and bubble contact angle for k noncoated and l HPL-coated anodes (γsv, γsl, and γlv are the surface free energy acting on the solid–vapor (γsv), solid–water (γsl), and water–vapor (γlv) interfaces, respectively). Source data for h and j are provided as a Source Data file.

Suppressed anodic H2O2 degradation by bubble shielding

The membrane-free electrolyzer equipped with an HPL-coated anode produced significantly higher H2O2 concentrations than that with a noncoated anode at the same set current. With the HPL-coated anode, the H2O2 accumulation quickly reached 2.40 ± 0.19 g L−1 at 20 mA cm−2 after 1 h operation, and further increased to 4.80 ± 0.14 g L−1 after 5 h (Fig. 2a), which was about 600% higher compared to that for the noncoated anode. The noncoated anode system exhibited low H2O2 accumulation of only 0.69 ± 0.05 g L−1 after 5 h operation (Fig. 2a), which was similar to previous studies using dimensionally stable anode (DSA) and carbon air cathode at a relevant current density of about 20 mA cm−2 8,36.

a H2O2 accumulation using HPL-coated (w/ HPL) and noncoated (w/o HPL) anodes in membrane-free electrolyzer at the current density of 20 mA cm−2. b Nyquist plots (Dotted line: experimental data; Dashed line: fitting data. Rs, solution resistance; Rct, charge transfer resistance; and W, warburg diffusion. w/o HPL: Rs = 1.89 ± 0.04 Ω cm−2, Rct = 5.38 ± 0.36 Ω cm−2; w/ HPL: Rs = 2.03 ± 0.04 Ω cm−2, Rct = 3.69 ± 0.75 Ω cm−2; W = 459 ± 22.5 Ω cm−2) and c CV curves (non-iR corrected) of noncoated and HPL-coated anodes in 10 mM H2O2 solution with 100 mM PBS. The error bars in panel a represent the standard deviation and were calculated on the basis of at least three experimental data points. Source data for a–c are provided as a Source Data file.

Electrochemical impedance spectroscopy (EIS) was used to examine the influence of the HPL on the charge and mass transfer of the anode. The Nyquist diagram of HPL-coated anode exhibited a slightly depressed semicircle at high frequency and an oblique line at low frequency (Fig. 2b), implying the resistance of HPL-coated anode was dominated by Warburg diffusion (W), which was related to H2O2 mass transfer43 (Rs, solution resistance; Rct, charge transfer resistance and W details summarized in Table S1). The Nyquist plot of the uncoated anode showed an apparent semicircle in the high-frequency range (Fig. 2b), indicating that the resistance of the uncoated anode was primarily associated with Rct44. Both Rs and Rct were similar for anodes without and with HPL, indicating the HPL did not influence the bulk solution and charge transfer processes (electrons and protons transfer)25,26. However, W increased dramatically to 459 Ω cm−2 for the anode with HPL, indicating the diffusion of H2O2 species was hindered by the HPL coating2.

Cyclic voltammetry (CV) tests further revealed the presence of HPL-suppressed H2O2 oxidation on the anode. The H2O2 oxidation peak was clearly seen for the unmodified anode at the potential of 1.10 V by adding 10 mM H2O2 in the phosphate buffer solution (PBS) electrolyte (Figs. 2c and S6), indicating anodic oxidation of H2O232. However, this oxidation peak was not present for the HPL-coated anode, demonstrating suppressed H2O2 oxidation (Fig. 2c). The shielding effect of the HPL was also evaluated by determining the electrochemical active surface area (ECSA) in electrochemical tests24,45. The ECSA of the anode with HPL of 1.0 mg cm−2 of PTFE loading was 2100 ± 230 cm2, one-third lower than that of the uncoated anode (3150 ± 120 cm2) under the same conditions (Fig. S7 and Table S2). The ECSA of the anode further decreased to 930 ± 120 cm2 at a PTFE loading of 1.5 mg cm−2, and 820 ± 120 cm2 at 2.0 mg cm−2. These results confirmed that the increasing of HPL loading decreased anode active surface area, but this change benefitted suppression of the H2O2 oxidation reaction. However, this change comes at the cost of increasing the electrode resistance. Adding too much PTFE on the surface will decrease H2O2 production (Fig. S8) due to the reduction of reaction sites (Fig. S7 and Table S2). An optimized PTFE loading of 1.0 mg cm−2 PTFE with a coating thickness of 17.3 ± 0.7 μm (Figs. S8 and S9) was selected for further experiments.

Role of HPL in alleviating anodic H2O2 oxidation

Due to the hydrophobic nature of HPL and inherent affinity to gas, different anode potentials relative to water oxidation were selected to evaluate the effect of bubble shielding on H2O2 degradation. It is worth noting that no H2O2 was produced via a 2e− water oxidation reaction by anode under the set testing conditions (Fig. S10). At the potential of 1.2 V (below oxygen evolution potential under standard conditions), the HPL-coated anode showed only about 20% of H2O2 oxidation during 5 h operation, which was lower than 42% oxidation for wetted PL-coated anode (without hydrophobicity interference) and 48% for noncoated anode at the same duration (Fig. 3a). The higher H2O2 degradation percentage from both the ethanol wetted PL-coated anode and the noncoated anode, demonstrated that anode hydrophobicity is important in minimizing H2O2 oxidation. At this potential, no oxygen bubbles were present on all anode surfaces regardless of whether it was coated with HPL or not (Fig. 3a inset and b). The PTFE particles scattered on the anode surface can block active sites for H2O2 oxidation compared to the noncoated anode (Fig. 3c), but overall they only slightly reduced the H2O2 oxidation from 48% (noncoated anode) to 42% (PL-coated anode) at 5 h operation (Fig. 3a).

H2O2 consumption and HPL-coated and noncoated anodes at a 1.2 V, d 1.8 V, and g 2.4 V vs. RHE (non-iR corrected). a, d, and g insets: underwater in-situ photographic images of HPL-coated and noncoated anodes at different potentials). b, e, and h The corresponding statistics of bubble size distribution. c, f, and i Schematic diagram of bubble shielding mechanism for protecting H2O2 from anodic oxidation. The error bars in panels a, d, and g represent the standard deviation and were calculated on the basis of at least three experimental data points. Source data for a, b, d, e, g, and h are provided as a Source Data file.

At an elevated potential of 1.8 V (slightly higher than oxygen evolution potential), the HPL-coated anode maintained a high H2O2 concentration (35 ± 0.5% reduction) followed by the PL-coated anode (72 ± 0.2% reduction), while H2O2 was almost entirely oxidized by the noncoated anode (97 ± 0.2% reduction) during 5 h operation (Fig. 3d). At 1.8 V, oxygen bubbles started to be visible on both HPL and PL-coated anodes, while no bubbles were retained on the noncoated anode due to the lack of PTFE coating (Fig. 3d insets), consistent with previous studies that hydrophobic PTFE is affinitive to gas bubbles46. The bubble size distribution of HPL-coated anodes expanded to a range of 200–1500 μm in diameter, compared to <100 μm for noncoated anodes (Fig. 3e), proving the effective bubble retaining capability of HPL. After wetting the HPL, the bubble size distribution decreased and shifted to a smaller size range (Fig. 3e), suggesting that maintaining the hydrophobicity of HPL is also important for bubble shielding. The wetted PL-coated anode showed much less H2O2 degradation percentage compared to the noncoated anode at 1.8 V, while a similar degradation percentage was observed for the two anodes at 1.2 V, indicating the key role of bubble retention. The contact angle of wetted PL-coated anode was found to be slightly enhanced (from 0° to 18°) after the H2O2 degradation test at a potential of 1.8 V (Fig. S12), demonstrating that bubbles were able to restore the anode surface hydrophobicity47. This restored and maintained hydrophobicity was critical in suppressing anodic H2O2 oxidation (Fig. 3f), as the H2O2 degradation percentage decreased from 39 ± 0.5% for wetted PL-coated anode after the first cycle of 2 h of testing, to only 19 ± 3% reduction at the fourth cycle (Fig. S13). Quartz crystal microbalance with dissipation (QCM-D) analysis showed no significant mass change on the PTFE HPL surface upon sequentially contacting pure H2O, 1 mM H2O2, 10 mM H2O2, and 100 mM H2O2 (Fig. S14), demonstrating negligible specific adsorption or repulsion of H2O2 by the PTFE HPL surface. The contact angles on the PTFE HPL surface with the different H2O2 solutions also did not significantly change (Fig. S15), which further indicated no specific wetting or interaction between H2O2 and PTFE HPL surface. The kinetic degradation of H2O2 on the HPL-coated anode was also found to be independent of H2O2 concentration (Fig. S16), demonstrating consistent degradation behavior and no specific interaction between H2O2 and HPL surface.

When further polarized at 2.4 V over the oxygen evolution potential under standard conditions (1.63 V vs. RHE, pH = 6.8), more bubbles began to generate and nucleate near the hydrophobic porous cavities on HPL and PL coated anode, while bubbles were still free to release for the non-coated anode (Figs. 3g insets and S11). The corresponding bubble size distributions for all three anodes at 2.4 V were similar to those at 1.8 V despite the more frequent growth and detachment at higher anodic potential (Figs. 3h and S11). The typical residence time of bubbles on HPL-coated electrodes could reach between 100 and 350 s (Fig. S11), which is much longer than <15 s for non-coated electrodes and would effectively promote the bubble shielding effect. The HPL-coated anode showed only 6 ± 5% reduction in H2O2 concentration and 30% for PL-coated anode at 1 h, while 86 ± 0.3% reduction was observed for the noncoated anode (Fig. 3g). This enlarged degradation difference for three anodes at 2.4 V compared to 1.8 V indicated that bubble generation rate also impacted the anodic oxidation of H2O2. The EIS testing of wetted PL-coated anode showed increased mass transfer resistances when elevating anode potentials from 1.2 to 2.4 V with faster bubble generation (Fig. S17). Owing to the higher applied anodic potential, frequent bubble generation and nucleation known as Oswald ripening, occurred immediately after the detachment of the previous cluster of bubbles (Fig. 3f)24. The bubbles have been reported to cause microflow in the electrode boundary layer48, which restricted H2O2 transfer to the anode surface. The growth of bubbles on the anode could also increase the ohmic overpotential49, constricting the passage of current and further deactivating H2O2 oxidation. Overall, the HPL on the anode surface played dual roles in maintaining surface hydrophobicity and providing bubble attachment sites to suppress anodic H2O2 oxidation via bubble shielding.

Effect of bubble shielding on cathodic H2O2 reduction

Although H2O2 consumption mainly occurred through anodic oxidation, it also partially resulted from the reduction of H2O2 to H2O at the cathode (Eq. (3)). Cathodic H2O2 reduction might take place on catalysts or current collectors50, but the specific component (carbon paper (CP) current collector, carbon black (CB) catalysts or PTFE binder) responsible for H2O2 reduction have not previously been systematically examined. To eliminate the possibility of H2O2 production on the cathode from air, the air cathode was water-sealed, and N2 gas was pumped into the chamber. When −0.1 V was applied on the cathode, only 10% of H2O2 was consumed by solely CP current collector after 5 h operation, while over 73% of H2O2 was consumed by CP/CB (Fig. 4a). Additionally, the current response was greater for CP/CB cathode compared to CP cathode at any potential (Fig. 4b). These results demonstrated that the CB catalyst was the main cathode component responsible for H2O2 degradation. Interestingly, the use of the PTFE binder in the cathode (CP/CB+binder) showed slightly less (13 ± 2% after 5 h operation) H2O2 degradation over time compared to that for CP/CB cathode (Fig. 4a), as also evidenced from a moderate decline of current response from the linear sweep voltammetry (LSV) curve (Fig. 4b).

a H2O2 consumption by different cathode compositions all without a PTFE HPL at the cathodic potential of −0.1 V vs. RHE (CP carbon paper, CP/CB carbon paper loaded with carbon black, CP/CB+binder carbon paper loaded with carbon black, and a binder of PTFE). b LSV curves (non-iR corrected) for cathodes with CP, CP/CB, and CP/CB+binder compositions without HPL in 10 mM H2O2 solution with 100 mM PBS. c H2O2 consumption and by HPL-coated and noncoated cathodes at –0.1, –0.6, and –1.1 V vs. RHE. The error bars in panels a and c represent the standard deviation and were calculated on the basis of at least three experimental data points. Source data for a–c are provided as a Source Data file.

To verify that bubble shielding minimized cathodic H2O2 reduction, we selected three cathode potentials relative to the reversible hydrogen evolution potential (−0.1, −0.6, and −1.1 V) to investigate the impact of hydrogen bubbles on the HPL-coated cathode for alleviating H2O2 reduction. The H2O2 degradation percentage on both noncoated (from 60% at –0.1 V to 72% at –1.1 V) and HPL-coated cathode (from 23% at –0.1 V to 34% at –1.1 V) increased with the rising of cathodic potential due to the improved electron transfer rate (Fig. 4c)51. While under each same potential, the H2O2 consumption of HPL-coated cathode was significantly lower than that of uncoated cathode (Fig. S18b), demonstrating that the HPL on cathode similarly induced bubble shielding effect to reduce H2O2 self-reduction. The shielding effect of HPL on the cathode was not as prominent as that on the anode, likely due to the uneven cathode surface morphology and large pore sizes (from 50 to 100 μm) of the carbon catalyst layer (Fig. S19a and d)52. However, these results still verified that HPL was able to partially protect H2O2 from being reduced to H2O. Future studies could focus on tuning the cathode surface to be more uniform to take full advantage of bubble shielding.

Performance of paired HPL-electrodes in membrane-free electrolyzer

The performance of the paired HPL-coated electrodes changed in response to the set current density. At 10 mA cm−2, the HPL-coated electrodes produced 4.35 ± 0.28 g L−1 of H2O2, and increasing the current density to 40 mA cm−2 further improved the concentration to 10.05 ± 0.05 g L−1 after 5 h operation (Fig. 5a). The electrochemical performance (CV for anode and LSV for cathode) and surface morphology (SEM images) of both the anode and cathode were well maintained before and after electrochemical testing at 40 mA cm–2 (Figs. S20 and S21), demonstrating high stability of HPL-coated electrodes. A moderate current density should be selected to maintain high H2O2 production by avoiding fast degradation of H2O2 on both anode (anodic oxidation) and cathode (cathodic reduction) (Fig. S22). Lowering electrolyte pH to 3 or 5 further promoted H2O2 production in a current density range of 10–50 mA cm−2 (Fig. S23). This enhanced rate of production at the lower pH occurs because increased concentrations of H+ are known to be beneficial for the breaking of the *−O bond to produce H2O220,53. In the future, the use of advanced electrocatalysts such as noble metal-based catalysts (Pt–Hg, Au-Pd, Pt/TiC, etc.)10,11,12, nonmetal carbon-based catalysts (nitrogen-doped carbon, oxidized CNTs, etc.)13,14, and M–N–C single-atom catalysts (Co–N–C, Ni3(HITP)2, Fe-CNT, etc.)15,16,17 might be examined to further enhance H2O2 production and overall system efficiency18.

a Effect of current density (10, 20, 30, 40, and 50 mA cm−2) on H2O2 accumulation in membrane-free electrolyzer with 0.1 M Na2SO4 solution after 5 h operation. b H2O2 production using HPL-coated electrodes in membrane-free electrolyzer over 100 h continuous operation at 20 mA cm−2. The inset of b shows the H2O2 concentration before and after 100 h operation by using the potassium titanium (IV) oxalate method. c Comparison of H2O2 production rate in membrane-free electrolyzer with the literature (H2O2 concentration at 1 h). The c inset zooms in the current density of c between 0 and 50 mA cm–2 on the horizontal axis and 0–0.5 g L–1 on the vertical axis. d Schematic illustration and e digital image of the solar-driven membrane-free electrolyzer for H2O2 electrosynthesis and disinfection. f Surface water sterilization of the solar-driven membrane-free electrolyzer. The inset of f shows the pictures of the flat colony of E. coli in effluent. g Cost comparison between traditional electrolyzer and membrane-free electrolyzer. The error bars in panels a and f represent the standard deviation and were calculated on the basis of at least three experimental data points. Source data for a, b, f, and g are provided as a Source Data file.

The HPL-paired electrode systems maintained consistently high performance at a current density of 20 mA cm−2 over a 100 h period. A consistent production of 7.3 ± 0.4 g L−1 of H2O2 was stably maintained during the 100 h operation (Fig. 5b) and obtained a relatively high current efficiency of 75 ± 4% (Fig. S24), which was comparable, or slightly higher than the literature by using membrane-free electrolyzer (Fig. S25). The cell voltage for HPL-coated electrodes was 6.7 ± 0.05 V at 20 mA cm−2, which was not significantly different from 6.8 ± 0.1 V for noncoated electrodes (p > 0.05) (Fig. S26), demonstrating minimal voltage loss or efficiency decrease due to the additional HPL coating. The electrochemical performance (CV for anode and LSV for cathode) and surface morphology (SEM images) of both the anode and cathode were well maintained before and after 100 h stability testing at 20 mA cm–2 (Figs. S27 and S28), demonstrating high stability of HPL-coated electrodes.

The paired HPL-coated electrode system examined here achieved a high H2O2 concentration reported to date for membrane-free electrolyzer across the current densities tested here (10–50 mA cm−2) (Figs. 5c and S29). The HPL electrodes produced H2O2 at a rate of 4.20 ± 0.15 g L−1 h−1 at a current density of 40 mA cm−2 (Fig. 5c), which is about 400% higher than previous studies. Most H2O2 production rates are in the range of 0.02–0.50 g L−1 h−1 at current densities of 5–50 mA cm−2 (Fig. 5c inset). Modified catalysts such as pitaya peels modified biochar could produce 0.83 g L−1 h−1 H2O2, but this required a current density of 100 mA cm−236. With an improved air-breathing cathode configuration using CB and graphite catalyst, the H2O2 production rate could only reach about 0.80 g L−1 h−1 at a current density of 20 mA cm−235. Other studies obtained just much lower H2O2 production rates in membrane-free electrolyzers despite substantial efforts in optimizing catalysts and reactor configurations8,36,37,38,39,54,55. The current efficiency of the HPL-coated cathode was 76 ± 6%, which was 29 ± 2% higher than 59 ± 2% for noncoated cathode (Fig. S30). The current efficiency of the HPL-coated cathode in our study was similar or slightly higher than that in previous studies (Fig. S25)3,8,19,32,35,38,39,54,55,56,57,58,59,60, demonstrating comparable energy conversion efficiency to literature. Moreover, the fabrication of HPL-coated electrodes only required a low-cost PTFE coating followed by a simple heating process, which can be easily scaled up for practical use.

Low-cost and readily available rural drinking water disinfection is emerging as a global concern, we, therefore, designed a household disinfection device prototype powered by a commercial polycrystalline silicon solar panel with an output voltage of 2.2–2.4 V (Fig. 5d and e). This disinfection prototype achieved complete inactivation (103 colonies forming unit (CFU) mL−1 removal) for representative pathogenic bacteria (as E. coli for example) in real surface water within 60 min (Fig. 5f). More importantly, the proposed membrane-free electrolyzer eliminated the use of expensive IX membranes (about $1400 m−2), and avoided frequent replacement and maintenance of the system (Fig. 5g). Although the DSA and carbon paper-based cathode were still relatively expensive, but can be easily replaced with cheaper titanium anode and stainless steel-based cathode9,61. Based on the Sustainable Development Goals (SDGs) of the United Nations, about 1/3 of the global population is short of safe drinking water supply62,63. Simply powered by solar panels, the membrane-free electrolyzer can readily provide robust surface drinking water disinfection in these rural and low-resource community areas.

Discussion

An innovative bubble shielding strategy was shown here to suppress H2O2 degradation by coating the electrodes with low-cost PTFE. This coating formed a hydrophobic porous layer on the electrode that slowly released the gas into the solution and alleviated H2O2 contact with the electrode surface. Bubbles formed on the PTFE surface and resulted in suppressed anodic H2O2 degradation by hindering H2O2 transfer to the anode reactive sites. As a result of this coating, the overall H2O2 production increased by about six times compared to unmodified anodes. The same coating on the cathode also reduced the loss of H2O2, although to a lesser extent than that observed for the anode. The paired HPL electrode system generated a very high H2O2 concentration of 10.05 ± 0.05 g L−1 at 40 mA cm−2 after 5 h operation, which exhibited a high H2O2 concentration among reported studies in membrane-free electrolyzers. A solar-driven membrane-free electrolyzer prototype was designed to realize in-situ H2O2 production and on-site surface water disinfection, delivering complete E. coli inactivation within 60 min and suitable for rural areas lacking electricity supply and sanitation facilities. Overall, this approach of using the HPL electrodes provides a practical pathway for achieving high rates and concentrations of H2O2 in membrane-free electrolyzers. The approach used here may inspire future studies on utilizing bubbles to fine-tune the transport of reactive species and also provide ways to improve other gas–water–electrode systems.

Methods

Chemicals and materials

All chemical reagents were analytical grade or higher purity. Sodium sulfate (Na2SO4) was purchased from TGREAG, China. Sodium dihydrogen phosphate dihydrate (NaH2PO4·H2O) and dibasic sodium phosphate (Na2HPO4) were provided by Aladdin, China. Poly(tetrafluoroethylene) (PTFE, 60 wt%) was obtained from Sinopharm Chemical Reagent Co., Ltd, China. Carbon black (CB) powder was supplied by XFNANO, China. Ethyl alcohol was procured from Xilong Scientific Co., Ltd, China. The carbon paper (TGP-H-060, 20 cm × 20 cm) was purchased from TORAY, Japan. All solutions were prepared using deionized (DI) water prior to experiments.

Preparation of the bubble shielding anodes

Bubble shielding anodes were formed by coating them with PTFE to form a hydrophobic and highly porous surface. The PTFE solution was dispersed in 15 mL absolute ethyl alcohol for 10 min by using an ultrasonic cell cracker (SCIENTZ-IID, SCIENTZ, China). The diluted PTFE solution was spray-coated onto the dimension stable anode (DSA, 3.8 cm in diameter, RuO2/IrO2 coating) at a loading of 1 mg cm−2. During the spray-coating process, a heated panel was placed beneath the electrode maintaining a uniform temperature of 80 °C to evaporate the ethyl alcohol solvent. Then, the PTFE-coated anodes were heated in a muffle furnace (KSL-1000X, KEJING, China) at 330 °C for 30 min to form the hydrophobic porous layer (HPL).

Fabrication of CB air cathodes and HPL-coated cathodes

The CB air cathode was fabricated by spraying a carbon catalyst mixture onto carbon paper (3.8 cm in diameter). The carbon catalyst mixture was prepared by sonicating CB powder (4 mg cm−2) with a PTFE binder (mass ratio of CB/PTFE = 3:1) in 15 mL ethyl alcohol for 20 min. The catalyst mixture was then evenly sprayed onto the carbon paper using an airbrush (SIBONGD, China). After that, the cathodes loaded with CB were sintered in a muffle furnace (KSL-1000X, KEJING, China) at 330 °C for 30 min. Finally, diluted PTFE solution was spray-coated onto the carbon black air cathode at a loading of 1 mg cm−2 to obtain the HPL-coated cathode.

Physical and electrochemical characterization of fabricated electrodes

Scanning electron microscopy and X-ray spectroscopy analysis (SEM-EDS, Merlin Compact, ZEISS, Germany) were used to determine electrode surface morphology and chemical compositions. The pore sizes distribution of noncoated and HPL-coated anodes were obtained by mercury intrusion porosimetry (Micromeritics AutoPore V 9620, GA, USA) operated from vacuum to 420 MPa at 293 K. Three-dimensional atomic force microscopy (AFM) was conducted to characterize the surface topography by Dimension Icon-PT (Bruker, USA). X-ray photoelectron spectroscopy (Thermo Scientific K-Alpha) was used to analyze the surface functional groups of noncoated and HPL-coated anodes. The contact angles (CA) of the HPL-coated electrodes were measured using a CA meter (DSA30, Kruss, Germany) to evaluate the surface hydrophobicity. The surface topology of the HPL-coated electrodes was characterized with a 3D optical profilometer (S neox, Sensofar, Spain).

A multichannel potentiostat (VMP-3e, BioLogic, France) was employed for electrochemical characterization. All potentials reported in this study were converted to reference the reversible hydrogen electrode (RHE) using:

All electrochemical characterization tests were carried out at room temperature. Linear sweep voltammetry (LSV) was conducted to evaluate the ORR characteristics of the cathodes, and set at a scan rate of 1 mV s−1 over a potential range of −0.2 to −1.6 V64. Cyclic voltammetry (CV) was performed to investigate the reaction mechanism involving anodic H2O2 and water oxidation at a scan rate of 10 mV s−1 over a potential range of 0.6–1.8 V65. Electrochemical impedance spectroscopy (EIS) measurement was carried out at a potential of 1.2 V over a frequency range of 1 mHz–100 kHz with an amplitude of 10 mV. EIS data were analyzed by ZView software and fitted to an equivalent circuit. The electrochemically active surface area (ECSA) was determined by measuring the capacitive current associated with double-layer charging from the scan-rate dependence of CV24. By plotting the difference in the current density (j) between the anodic sweeps (Δj) at a fixed potential against the scan rate, a linear trend was observed. The fitting slope was twice the double-layer capacitance (Cdl), which is linearly proportional to the ECSA determined from Eq. (6),

where Cdl is the double-layer capacitance, and it depends on the slope of the scan rates versus current yields plots from the CV data. Cs is the standard specific electrochemical double-layer capacitance, and the value of 40 µF cm−2 was taken as an estimate of the flat metal oxide surface66. To determine Cdl for anodes, the potential window of the CV was set between 0.6 and 0.7 V, with the scan rates ranging from 2 to 10 mV s−1. All data were collected by the multichannel potentiostat and processed by Excel and origin except as noted.

All electrochemical measurements of the electrodes were conducted in a two-chamber electrochemical cell (2 cm in length, 3 cm in diameter, 14 mL in each compartment) separated by a cation exchange membrane (CMI-7000, 40 mm × 40 mm × 0.45 mm, Membrane International Inc., USA). The CEM was soaked in deionized water for 12 h before use to reduce dimensional variation and improve the stability of the membrane67. All electrochemical measurements were carried out at room temperature. The electrolyte was a 0.1 M phosphate buffer solution (PBS) (NaH2PO4·H2O, 35.54 mM; Na2HPO4, 64.46 mM; pH = 7.2 ± 0.1). The working electrode was a noncoated and HPL-coated anode/cathode (3.8 cm in diameter), and the counter electrode was a platinum mesh (2 cm in length and 1 cm in width). An Ag/AgCl reference electrode (CHI111; +0.597 V vs. RHE, pH = 6.8) was located 1 cm from the center of the working electrode. The Ag/AgCl reference electrode was calibrated by using Pt foil as both the working electrode and counter electrode and CV was carried out at a scan rate of 1 mV s–168. The electrolyte for calibration (0.1 M Na2SO4 solution at 25 °C, pH = 6.8 ± 0.1) was saturated with H2 for at least 30 min before performing the electrode calibration.

A microscope (SZ-CTC, OLYMPUS) equipped with a high-speed CCD camera (X-Motion, AOS Technologies) was used to in-situ monitor the bubble-releasing process (Fig. S31)69,70. The illumination was achieved by a fiber-optic illuminator system (Multi-Position, Nikon).

Measurement of H2O2 production and degradation rates

Electrochemical production of H2O2 tests was performed in single-chamber electrochemical cells (4 cm in length, 3 cm in diameter) without ion exchange membranes. A 0.1 M Na2SO4 electrolyte (pH = 6.8 ± 0.1) was used unless otherwise noted. Tests were conducted in galvanostatic mode with a DC power supply (DP305C, Mestek, Shenzhen, China) at current densities of 10, 20, 30, 40, and 50 mA cm−2. The electrolyte was sampled (2 mL) every hour, and H2O2 concentrations were measured at 400 nm using a spectrophotometer (UV-1800, Shimadzu, Japan) using the potassium titanium (IV) oxalate method (0.1 M C4H2K2O10Ti, Macklin)71. In the case of accurate quantification, standard H2O2 strips (Lohand Biological) and standard potassium permanganate (0.1 N KMnO4 solution, Merda) titration process were further confirmed24. The current efficiency (CE) or Faradaic efficiency of the electrolytic cell for H2O2 generation was calculated based on Eq. (7)72. All experiments were operated at room temperature (25 ± 1 °C) except as noted, and tests were carried out in at least triplicate.

where \(n\) is the number of electrons transferred for oxygen reduction to H2O2, \(F\) is the Faraday constant (96,486 C mol−1), \({C}_{{{{H}}}_{2}{{{O}}}_{2}}\) stands for the concentration of H2O2 (mol L–1), \(V\) is the bulk volume (L), \(I\) is the current (A), and \(t\) is the time (s).

To investigate H2O2 oxidation on the anode, the electrolyzer was separated into two chambers using a cation exchange membrane (CMI-7000, Membrane International Inc., USA). The anolyte was a 0.1 M Na2SO4 with a set initial H2O2 concentration of 10 mM. Different anode potentials 1.2, 1.8, and 2.4 V were selected to evaluate the impact of anodically generated bubbles on H2O2 oxidation. The three potentials were chosen based on H2O2 oxidation potential (\({E}_{{{{O}}}_{2}/{{{H}}}_{2}{{{O}}}_{2}}=1.09\,{{{V}}\; vs}.\,{{{RHE}}}\), Eq. (2)) and oxygen evolution potential (\({E}_{{{{O}}}_{2}/{{{H}}}_{2}{{{O}}}_{2}}=1.63\,{{{V}}\; {{vs}}}.\,{{{RHE}}}\), Eq. (8)). H2O2 oxidation was not visibly observed based on bubble formation at a potential of 1.2 V, while bubbles were noticed at both 1.8 and 2.4 V. The HPL was also pre-wetted by ethanol (denoted as PL) to separately examine the role of bubble generation apart from nascent hydrophobicity, and the same anode potentials (1.2, 1.8, and 2.4 V) were selected as above mentioned.

For cathodic consumption of H2O2, three potentials were selected (−0.1, −0.6, and −1.1 V) using the two-chamber electrochemical cell to determine whether bubble shielding occurred for cathodic H2O2 reduction. The air side of the cathode was water-sealed to block O2 transfer, and the liquid in sealed sample compartments was pumped with N2 prior testing to eliminate oxygen and ensure only H2O2 reduction occurred.

Membrane-free electrolyzer stability test

The performance stability of the H2O2 production system with HPL-coated electrodes was evaluated by maintaining a current density of 20 mA cm−2 over a 100 h testing period. The electrolyte was refreshed at intervals of 5 h. The cell voltage was recorded by a computer connected to the digital DC power supply during the entire operation period. The electrochemical performance of the electrodes (CV for anodes and LSV for cathodes) was monitored before and after the operation. CVs were performed at a scan rate of 10 mV s−1 and the LSVs at a scan rate of 1 mV s−1 over a potential range of −0.2 to −1.6 V. All experiments were conducted at room temperature (25 ± 1 °C), and tests were carried out at least in triplicate.

Solar-driven membrane-free electrolyzer disinfection

A commercial polycrystalline silicon solar panel (2 V, 81 cm2) was used for solar-driven membrane-free electrolyzer disinfection. The system testing was conducted on a sunny and cloudless day (with solar radiation intensity of 410–530 W m−2) at 39°9941′N, 116°3150′E, Beijing, China. The reactor was a membrane-free and continuous flow reactor (net volume of 100 mL) equipped with paired HPL-coated electrodes (both anode and cathode were 10×10 cm2). The inlet was real surface water (Weiming Lake, Beijing, China) containing about 103 colony forming unit (CFU) mL−1 of representative pathogenic bacteria (such as E. coli, for example) with a flow rate of 100 mL h−1. The sample was taken at the outlet every 30 min, and diluted with deionized water by 10 times. Then, 0.1 mL of the diluted samples were spread evenly on the Luria–Bertani (LB) agar plates and incubated for 16 h. The concentrations of live bacteria were calculated by counting colonies.

Data availability

The data generated in this study are provided in the main text and Supplementary information, where the source data are listed in the Source Data file. Source data are provided with this paper.

References

Lu, Z. et al. High-efficiency oxygen reduction to hydrogen peroxide catalysed by oxidized carbon materials. Nat. Catal. 1, 156–162 (2018).

Zhang, Q. et al. Highly efficient electrosynthesis of hydrogen peroxide on a superhydrophobic three-phase interface by natural air diffusion. Nat. Commun. 11, 1–11 (2020).

Li, H., Quispe-Cardenas, E., Yang, S., Yin, L. & Yang, Y. Electrosynthesis of >20 g/L H2O2 from Air. ACS Est. Eng. 2, 242–250 (2021).

Kim, H. W. et al. Efficient hydrogen peroxide generation using reduced graphene oxide-based oxygen reduction electrocatalysts. Nat. Catal. 1, 282–290 (2018).

Shi, X. et al. Understanding activity trends in electrochemical water oxidation to form hydrogen peroxide. Nat. Commun. 8, 1–6 (2017).

Wang, K., Huang, J., Chen, H., Wang, Y. & Song, S. Recent advances in electrochemical 2e oxygen reduction reaction for on-site hydrogen peroxide production and beyond. Chem. Commun. 56, 12109–12121 (2020).

Xu, J. et al. Organic wastewater treatment by a single-atom catalyst and electrolytically produced H2O2. Nat. Sustain. 4, 233–241 (2021).

Sheng, Y. et al. Electrogeneration of hydrogen peroxide on a novel highly effective acetylene black-PTFE cathode with PTFE film. Electrochim. Acta 56, 8651–8656 (2011).

Yi, K., Yang, W. & Logan, B. E. Defect free rolling phase inversion activated carbon air cathodes for scale-up electrochemical applications. Chem. Eng. J. 454, 140411 (2023).

Meng, Y. et al. Structure–property relationship of bifunctional MnO2 nanostructures: highly efficient, ultra-stable electrochemical water oxidation and oxygen reduction reaction catalysts identified in alkaline media. J. Am. Chem. Soc. 136, 11452–11464 (2014).

Chang, Q. et al. Promoting H2O2 production via 2-electron oxygen reduction by coordinating partially oxidized Pd with defect carbon. Nat. Commun. 11, 2178 (2020).

Gu, H., Yang, Y., Tian, J. & Shi, G. Photochemical synthesis of noble metal (Ag, Pd, Au, Pt) on graphene/ZnO multihybrid nanoarchitectures as electrocatalysis for H2O2 reduction. ACS Appl. Mater. Interfaces 5, 6762–6768 (2013).

Zhao, H. & Yuan, Z. Y. Design strategies of non-noble metal-based electrocatalysts for two-electron oxygen reduction to hydrogen peroxide. ChemSusChem 14, 1616–1633 (2021).

Bu, Y. et al. Carbon-based electrocatalysts for efficient hydrogen peroxide production. Adv. Mater. 33, 2103266 (2021).

Shen, H. et al. Boosting oxygen reduction for high-efficiency H2O2 electrosynthesis on oxygen-coordinated Co–N–C catalysts. Small 18, 2200730 (2022).

Lian, Y. et al. Unpaired 3d electrons on atomically dispersed cobalt centres in coordination polymers regulate both oxygen reduction reaction (ORR) activity and selectivity for use in zinc–air batteries. Angew. Chem. Int. Ed. 59, 286–294 (2020).

Jiang, K., Zhao, J. & Wang, H. Catalyst design for electrochemical oxygen reduction toward hydrogen peroxide. Adv. Funct. Mater. 30, 2003321 (2020).

Sun, Y. et al. Efficient electrochemical hydrogen peroxide production from molecular oxygen on nitrogen-doped mesoporous carbon catalysts. ACS Catal. 8, 2844–2856 (2018).

Zhang, H., Li, Y., Zhao, Y., Li, G. & Zhang, F. Carbon black oxidized by air calcination for enhanced H2O2 generation and effective organics degradation. ACS Appl. Mater. Interfaces 11, 27846–27853 (2019).

Du, Y. X. et al. Carbon black-supported single-atom Co–N–C as an efficient oxygen reduction electrocatalyst for H2O2 production in acidic media and microbial fuel cell in neutral media. Adv. Funct. Mater. 33, 2300895 (2023).

Xia, Y. et al. Highly active and selective oxygen reduction to H2O2 on boron-doped carbon for high production rates. Nat. Commun. 12, 4225 (2021).

Kim, C. et al. Concurrent oxygen reduction and water oxidation at high ionic strength for scalable electrosynthesis of hydrogen peroxide. Nat. Commun. 14, 5822 (2023).

Li, L. et al. Electrochemical generation of hydrogen peroxide from a zinc gallium oxide anode with dual active sites. Nat. Commun. 14, 1890 (2023).

Xia, C. et al. Confined local oxygen gas promotes electrochemical water oxidation to hydrogen peroxide. Nat. Catal. 3, 125–134 (2020).

Shi, R., Shang, L. & Zhang, T. Three phase interface engineering for advanced catalytic applications. ACS Appl. Energy Mater. 4, 1045–1052 (2021).

Wang, X. X., Swihart, M. T. & Wu, G. Achievements, challenges and perspectives on cathode catalysts in proton exchange membrane fuel cells for transportation. Nat. Catal. 2, 578–589 (2019).

Zhang, H., Li, Y., Li, G. & Zhang, F. Scaling up floating air cathodes for energy-efficient H2O2 generation and electrochemical advanced oxidation processes. Electrochim. Acta 299, 273–280 (2019).

Zhang, X. et al. Electrochemical oxygen reduction to hydrogen peroxide at practical rates in strong acidic media. Nat. Commun. 13, 2880 (2022).

Xia, P. et al. Polymethylhydrosiloxane-modified gas-diffusion cathode for more efficient and durable H2O2 electrosynthesis in the context of water treatment. Appl. Catal. B: Environ. 343, 123467 (2024).

Gu, Y., Wu, S., Zhao, K., Liu, M. & Yu, H. Electrosynthesis of H2O2 over aerated cathode assembled by aligned titanium hollow fibers. Chem. Eng. J. 476, 146703 (2023).

Deng, F. et al. A dual-cathode pulsed current electro-Fenton system: improvement for H2O2 accumulation and Fe3+ reduction. J. Power Sources 466, 228342 (2020).

Ma, P., Ma, H., Galia, A., Sabatino, S. & Scialdone, O. Reduction of oxygen to H2O2 at carbon felt cathode in undivided cells. Effect of the ratio between the anode and the cathode surfaces and of other operative parameters. Sep. Purif. Technol. 208, 116–122 (2019).

Angioni, S. et al. Novel composite polybenzimidazole-based proton exchange membranes as efficient and sustainable separators for microbial fuel cells. J. Power Sources 348, 57–65 (2017).

Li, C., Yi, K., Hu, S. & Yang, W. Cathodic biofouling control by microbial separators in air-breathing microbial fuel cells. Environ. Sci. Ecotechnol. 15, 100251 (2023).

Zhao, Q. et al. The UV/H2O2 process based on H2O2 in-situ generation for water disinfection. J. Hazard. Mater. Lett. 2, 100020 (2021).

Wang, S. et al. Oxygen self-doping formicary-like electrocatalyst with ultrahigh specific surface area derived from waste pitaya peels for high-yield H2O2 electrosynthesis and efficient electro-Fenton degradation. Sep. Purif. Technol. 289, 120687 (2022).

Gu, Y.-y et al. O/F co-doped CNTs promoted graphite felt gas diffusion cathode for highly efficient and durable H2O2 evolution without aeration. J. Clean. Prod. 341, 130799 (2022).

Zhang, Z. et al. Fabrication of graphene@ graphite-based gas diffusion electrode for improving H2O2 generation in electro-fenton process. Electrochim. Acta 260, 112–120 (2018).

Wang, S. et al. Natural bamboo-derived O-doped rocky electrocatalyst for high-efficiency electrochemical reduction of O2 to H2O2. Int. J. Hydrog. Energy 47, 5961–5973 (2022).

Malpass, G. R., Neves, R. S. & Motheo, A. J. A comparative study of commercial and laboratory-made Ti/Ru0.3Ti0.7O2 DSA® electrodes: “In situ” and “ex situ” surface characterisation and organic oxidation activity. Electrochim. Acta 52, 936–944 (2006).

Shao, W. et al. Study on favorable comprehensive properties of superhydrophobic coating fabricated by polytetrafluoroethylene doped with graphene. Adv. Compos. Hybrid Mater. 4, 521–533 (2021).

Chen, Y., Zhao, Z., Dai, J. & Liu, Y. Topological and chemical investigation on super-hydrophobicity of PTFE surface caused by ion irradiation. Appl. Surf. Sci. 254, 464–467 (2007).

Dutta, A. K. et al. Non-enzymatic amperometric sensing of hydrogen peroxide at a CuS modified electrode for the determination of urine H2O2. Electrochim. Acta 144, 282–287 (2014).

Li, X., Shao, C., Yu, J. & Zhu, K. Preparation and investigation of nickel–antimony co-doped tin oxide anodes for electro-catalytic oxidation of organic pollutions. Int. J. Electrochem. Sci. 14, 205–218 (2019).

Zhang, P. et al. Dendritic core–shell nickel–iron–copper metal/metal oxide electrode for efficient electrocatalytic water oxidation. Nat. Commun. 9, 381 (2018).

Li, M., Xie, P., Yu, L., Luo, L. & Sun, X. Bubble engineering on micro-/nanostructured electrodes for water splitting. ACS Nano 17, 23299–23316 (2023).

Li, M., Xu, L. & Lu, W. Effect of extra gas amount on liquid outflow from hydrophobic nanochannels: enhanced liquid–gas interaction and bubble nucleation. Langmuir 36, 4682–4688 (2020).

Eigeldinger, J. & Vogt, H. The bubble coverage of gas-evolving electrodes in a flowing electrolyte. Electrochim. Acta 45, 4449–4456 (2000).

Raman, A. et al. Potential response of single successive constant-current-driven electrolytic hydrogen bubbles spatially separated from the electrode. Electrochim. Acta 425, 140691 (2022).

Weng, C., Chuang, Y.-H., Davey, B. & Mitch, W. A. Reductive electrochemical activation of hydrogen peroxide as an advanced oxidation process for treatment of reverse osmosis permeate during potable reuse. Environ. Sci. Technol. 54, 12593–12601 (2020).

Lei, Y., Liu, H., Jiang, C., Shen, Z. & Wang, W. A trickle bed electrochemical reactor for generation of hydrogen peroxide and degradation of an azo dye in water. J. Adv. Oxid. Technol. 18, 47–56 (2015).

Zhang, Z. et al. Electrophoretic deposition of chitosan/gelatin coatings with controlled porous surface topography to enhance initial osteoblast adhesive responses. J. Mater. Chem. B 4, 7584–7595 (2016).

Zhao, X. & Liu, Y. Origin of selective production of hydrogen peroxide by electrochemical oxygen reduction. J. Am. Chem. Soc. 143, 9423–9428 (2021).

Fu, D. et al. In-situ efficient electrosynthesis of H2O2–NaClO based on the media pH and catalyst mutual selection mechanism. J. Power Sources 553, 232306 (2023).

Reis, R. M. et al. Use of gas diffusion electrode for the in situ generation of hydrogen peroxide in an electrochemical flow-by reactor. Ind. Eng. Chem. Res. 51, 649–654 (2012).

Lu, J., Liu, X., Chen, Q. & Zhou, J. Coupling effect of nitrogen-doped carbon black and carbon nanotube in assembly gas diffusion electrode for H2O2 electro-generation and recalcitrant pollutant degradation. Sep. Purif. Technol. 265, 118493 (2021).

Pérez, J. F. et al. Improving the efficiency of carbon cloth for the electrogeneration of H2O2: role of polytetrafluoroethylene and carbon black loading. Ind. Eng. Chem. Res. 56, 12588–12595 (2017).

Kuang, C. et al. Integrating anodic sulfate activation with cathodic H2O2 production/activation to generate the sulfate and hydroxyl radicals for the degradation of emerging organic contaminants. Water Res. 229, 119464 (2023).

Valim, R. B. et al. Electrogeneration of hydrogen peroxide in gas diffusion electrodes modified with tert-butyl-anthraquinone on carbon black support. Carbon 61, 236–244 (2013).

Salmerón, I. et al. Optimization of electrocatalytic H2O2 production at pilot plant scale for solar-assisted water treatment. Appl. Catal. B: Environ. 242, 327–336 (2019).

Yang, W., He, W., Zhang, F., Hickner, M. A. & Logan, B. E. Single-step fabrication using a phase inversion method of poly (vinylidene fluoride)(PVDF) activated carbon air cathodes for microbial fuel cells. Environ. Sci. Technol. Lett. 1, 416–420 (2014).

Wang, M. et al. Accounting for interactions between Sustainable Development Goals is essential for water pollution control in China. Nat. Commun. 13, 730 (2022).

Peydayesh, M. & Mezzenga, R. Protein nanofibrils for next generation sustainable water purification. Nat. Commun. 12, 3248 (2021).

Wang, H. et al. Electronic modulation of non-van der Waals 2D electrocatalysts for efficient energy conversion. Adv. Mater. 33, 2008422 (2021).

Fricke, K., Harnisch, F. & Schröder, U. On the use of cyclic voltammetry for the study of anodic electron transfer in microbial fuel cells. Energy Environ. Sci. 1, 144–147 (2008).

Browne, M. P., Nolan, H., Duesberg, G. S., Colavita, P. E. & Lyons, M. E. Low-overpotential high-activity mixed manganese and ruthenium oxide electrocatalysts for oxygen evolution reaction in alkaline media. ACS Catal. 6, 2408–2415 (2016).

Majumder, S., BM, S. M. & BM, P. Impact of different electrodes, mediators, and microbial cultures on wastewater treatment and power generation in the microbial desalination cell (MDC). Water Sci. Technol. 88, 3194–3225 (2023).

Niu, S., Li, S., Du, Y., Han, X. & Xu, P. How to reliably report the overpotential of an electrocatalyst. ACS Energy Lett. 5, 1083–1087 (2020).

Lu, Z. et al. Ultrahigh hydrogen evolution performance of under-water “superaerophobic” MoS2 nanostructured electrodes. Adv. Mater. 26, 2683–2687 (2014).

Qin, J. et al. Kinetic study of electrochemically produced hydrogen bubbles on Pt electrodes with tailored geometries. Nano Res. 14, 2154–2159 (2021).

Sellers, R. M. Spectrophotometric determination of hydrogen peroxide using potassium titanium (IV) oxalate. Analyst 105, 950–954 (1980).

Zhao, Q. et al. Superhydrophobic air-breathing cathode for efficient hydrogen peroxide generation through two-electron pathway oxygen reduction reaction. ACS Appl. Mater. Interfaces 11, 35410–35419 (2019).

Acknowledgements

This work was supported by the National Nature Science Foundation of China under Grants No. 52100021 (W.Y.).

Author information

Authors and Affiliations

Contributions

W.Y. conceived the research. W.Y. and K.Y. designed the experiments. W.Y. and K.Y. performed most of the experiments and data analysis. W.Y., K.Y., C.L., S.H., and X.Y. participated in various aspects of the experiments and discussions. W.Y. and K.Y. wrote the paper. W.Y. and B.E.L. supervised the paper. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Qing Xu, Xiaofei Zhang, and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yi, K., Li, C., Hu, S. et al. High H2O2 production in membrane-free electrolyzer via anodic bubble shielding towards robust rural disinfection. Nat Commun 16, 1893 (2025). https://doi.org/10.1038/s41467-025-57116-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-57116-x