Abstract

With the continuous development of high-performance copper alloys in modern industries, it becomes increasingly challenging to further enhance their conductivities. The key bottleneck is the existence of an upper limit on the amount of precipitation, leading to inadequate purification of the copper matrix. Here we demonstrate a phenomenon of significant conductivity enhancement in a Cu-Be alloy through undercooling. It shows that lots of spherical Be-rich clusters can spontaneously form in the deeply undercooled alloy. These clusters survive after subsequent solution treatment and are independent from the normal precipitates during aging, thereby leading to additional purification of the copper matrix. Under peak aging, the electrical conductivity of the undercooled alloy reaches up to 80% International Annealed Cu Standard, which is 30% higher than that of the same component alloy prepared in a conventional way, while its strength remains high. Our study provides an alternative way to address the long-standing strength-conductivity trade-off in copper alloys.

Similar content being viewed by others

Introduction

For conducting copper metal and alloys, high electrical conductivity and high mechanical strength are simultaneously expected in many industrial applications1,2,3. However, the methods used to strengthen metal, including alloying, cold working, and grain refinement, generally cause a decrease in electrical conductivity4. The fundamental reason is that all of these strengthening methods introduce lots of defects (solute atoms, dislocations and boundaries) into the matrices and hence increase the scattering barriers to electron motion. In this case, there exists a contradiction between conductivity and strength, and a trade-off must be made for a special application5,6.

The most important factor affecting the conductivity of copper alloys is the concentration of solute atoms in the metal matrix7. This means that the best way to overcome the strength-conductivity trade-off is to lower the content of solute atoms in a matrix as much as possible and at the same time enhance the strength as far as possible. Precipitation-strengthening can satisfy both requirements to a great degree and hence possesses superiority in balancing the conductivity and strength of metal alloys5,8,9,10,11,12,13,14. The problem for precipitation-strengthening alloys is that there exists an inherent upper limit in the volume fraction of precipitation15, which restricts the further improvement of electrical conductivity through matrix purification. Alloys with strength surpassing 600 MPa often exhibit a conductivity below 60% International Annealed Cu Standard (IACS)16. However, with the development of modern industries, the demand for high conductivity and strength is continuously increasing such as in the chip, aerospace, automobile fields, where the strength exceeds 600 MPa and the conductivity exceeds 80% IACS are simultaneously expected5.

In this study, we demonstrate a phenomenon that deep undercooling can break the upper limit of the electrical conductivity of a precipitation-strengthening Cu-Be alloy by producing plenty of spherical Be-rich clusters during solidification. The clusters themselves do not constitute precipitates, allowing additionally enhanced matrix purification and thus minimizing electron scattering. The unusual dense clusters collaborating with the normal precipitates during aging result in high conductivity and maintain good strength.

Results

As-cast normal and undercooled alloy

Via the electromagnetic levitation (EML) method (see Methods), the Cu-0.2Be-1.0Ni-0.2Co (in wt.%) alloy samples with undercoolings ranging from 154 to 310 K were achieved. The electrical conductivities of the as-cast EML samples are consistently around 45% IACS in spite of different undercoolings (Fig. 1a), which is unexpectedly, 44% higher than that, 33.4% IACS, of the same component alloy samples prepared by the normal electromagnetic induction (EMI) method. To explore the underlying reason for the high electrical conductivity generated by deep undercooling, an EML sample with large undercooling ΔT ≈ 200 K (designated as EML-200) and an EMI sample with small undercooling ΔT ≈ 10 K (designated as EMI-10) were chosen and deeply analyzed down to the atomic scale. Figure 1b–d presents the aberration-corrected high-angle annular dark field scanning transmission electron microscope (HAADF-STEM) micrographs of the as-cast EMI-10 sample (Fig. 1b) and the as-cast EML-200 sample (Fig. 1c) with the incident electron beam aligned along the [011] zone axis, which reveal that both samples are lack of typical plate-shaped precipitates in their matrices17. In addition, the X-ray diffraction (XRD) patterns (Supplementary Fig. 1) show that there exists only the single-phase FCC structure in both samples. However, different from the as-cast EMI-10, many dark spherical spots can be clearly observed in the as-cast EML-200 (Fig. 1c, orange arrows). The atomic image of one spot has been taken and the corresponding Fast-Fourier Transform (FFT) patterns for the local areas within and outside the spot have been analyzed (Fig. 1d), which indicate that the spot structure is identical to that of the α(Cu) matrix. Furthermore, the energy-dispersive x-ray spectroscopy (EDS) analyses have been conducted (Supplementary Fig. 2), and the elemental maps display that the Cu, Ni, Co elements in both samples distribute homogeneously (light Be atoms cannot be identified by EDS), eliminating the possibility that the spots are mainly related to the gathering of Ni or Co. Therefore, it is reasonable to infer that the spherical spots are the enriched areas of Be atoms. Because that the contrast in a HAADF-STEM image is directly proportional to the 1.7 power of an atomic number, Z 18, the spherical spots look darker than the surrounding area (ZBe = 4, ZCu = 29, ZNi = 28, ZCo = 27).

a The electrical conductivity variation of the EML samples with undercooling. The standard deviations of the measured electrical conductivities are less than 0.5% IACS. The gray-dashed line denotes the electrical conductivity of the EMI sample. b The HAADF-STEM image of the as-cast EMI-10 sample. c The HAADF-STEM image of the as-cast EML-200 sample. Lots of spherical spots can be observed (orange arrows). d The enlarged atomic image of the blue box area in (c). The insets are the corresponding FFT patterns within and outside the spherical spot. e, f The reconstructed APT atomic maps of the as-cast EMI-10 and EML-200 samples obtained by APT detection. Source data are provided as a Source Data file.

To accurately ascertain the enrichment levels of Be atoms, the atom probe tomography (APT) analyses were carried out. The reconstructed atomic maps of the as-cast EMI-10 and EML-200 samples are shown in Figs. 1e and 1f, respectively. For the as-cast EMI-10, all elements distribute homogeneously, and no observable aggregation appears (Fig. 1e). While, for the as-cast EML-200, Be atoms, other than Ni and Co atoms, display distinct aggregation (Fig. 1f), which confirms that the enrichment of Be atoms at the nanoscale indeed takes place under the deep undercooling condition. Therefore, the dark spherical spots (Fig. 1c) can be definitely regarded as the Be-rich clusters, which are completely different from the common type of Be atomic enrichment zone (GP zone)15,17.

As-aged normal and undercooled alloy

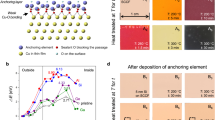

After the above analyses, the as-cast EMI-10 and EML-200 samples were exerted the same solution and aging treatments to investigate the impact of deep undercooling on the final properties. Firstly, the variations in electrical conductivity and microhardness with the aging time were measured for both as-aged samples, as respectively shown in Fig. 2a, b. Within the whole-time range of aging, the electrical conductivity of the as-aged EML-200 exhibits a much higher value than that of the as-aged EMI-10 while its microhardness is almost the same as that of the latter. Under the peak aging state of microhardness (about 420 min), the electrical conductivity of the EML-200 reaches up to 80% IACS, about 30% higher than that, 60% IACS, of the EMI-10. This conductivity value is higher than all the reported Cu-Be alloys19,20, Cu-Ni-Si alloys21,22,23,24,25,26 and Cu-Ti alloys27,28,29, and even exceeds the conductivities of most Cu-Cr-Zr alloys5,30,31,32,33,34 (Fig. 2d).

a, b The variations in electrical conductivity and Vickers microhardness with the aging time under 450 °C. The error bars represent the standard deviations of the measured microhardnesses. Notably, the standard deviations of the measured electrical conductivities are less than 0.5% IACS. c The engineering stress-strain curves under the peak aging condition (420 min, 450 °C). d The comprehensive property comparison between this work (red color) and the reported high conductivity Cu-Be alloys, Cu-Ni-Si alloys, Cu-Ti alloys and Cu-Cr-Zr alloys. Source data are provided as a Source Data file.

In addition, the tensile tests for both peak-aged samples at the room temperature were also implemented. The engineering stress-strain curves of both samples are basically consistent and the yield strengths of the peak-aged EML-200 and EMI-10 are 614 ± 35 and 625 ± 17 MPa (Fig. 2c), indicating that the final mechanical properties are not visibly sacrificed by deep undercooling.

To understand the ultrahigh conductivity performance caused by deep undercooling, we carried out microstructure examinations for both peak-aged EML-200 and EMI-10 samples (Fig. 3). In comparison to the peak-aged EMI-10 (Fig. 3d, e), the peak-aged EML-200 includes not only the usual dense coherent plate-shaped γ′ intermetallic compound, with a body-centered tetragonal (BCT) structure (see also Supplementary Fig. 3) but also the unusual Be-rich clusters observed in the as-cast EML-200 (Fig. 3a, c). Furthermore, we examined the purities of the copper matrices in both samples via EDS analysis, based on the HAADF-STEM observation (Fig. 3f). The black boxes and red circles respectively represent the purity values of the random areas of copper matrices in the current samples. The data clearly indicate that the matrix purity in the peak-aged EML-200 is larger than that in the peak-aged EMI-10. Notably, the gray-dashed line denotes the upper limit of purity value, 98.94 at.%, based on the phase diagram and Thermo-Calc calculations (see Methods). It indicates that deep undercooling can offer extra contribution to matrix purification other than precipitation. This purification route is quite different from promoting precipitation in conventional ways21,26,29,35.

a The HAADF-STEM image of the peak-aged EML-200 showing the coexistence of plate-shaped precipitates with spherical Be-rich clusters. b, c The enlarged atomic images of a precipitate and a Be-rich cluster in the peak-aged EML-200. The insets are the corresponding FFT patterns to the blue box areas. d The HAADF-STEM image of the peak-aged EMI-10, showing the only existence of plate-shaped precipitates. e The enlarged atomic image and the corresponding FFT pattern of a precipitate in the peak-aged EMI-10. f The EDS-based matrix purity values at randomly selected regions. The gray-dashed line represents the upper limit purity of the Cu-0.2Be-1.0Ni-0.2Co alloy under equilibrium. The black and red dotted lines represent the statistical average matrix purities of the peak-aged EMI-10 and EML-200, respectively. The error bars represent the X-ray counting standard deviations. Source data are provided as a Source Data file.

Discussion

Based on the above experimental results, there are four questions worth to be thoroughly discussed. The first is why deep undercooling can induce the spherical Be-rich clusters in the as-cast Cu-0.2Be-1.0Ni-0.2Co (in wt.%, the same below) alloy. The second is why the spherical Be-rich clusters can survive during the solution treatment. The third is why the spherical Be-rich clusters do not function as the nucleation sites of precipitates during the aging treatment. And, the last question is how the unusual spherical Be-rich clusters affect the final properties.

Inducing spherical Be-rich clusters by deep undercooling

Considering that the deeply undercooled liquid alloys usually solidify rapidly, and the solute atoms diffuse slowly in the solidified alloys, we can infer that the Be-rich clusters in the as-cast undercooled alloy should form during solidification. To confirm this, the nucleation rates (I) of the matrix α(Cu) phase, α(Be) phase, NiBe phase, and CuBe phase were calculated using the classical nucleation theory36 (see Methods), and the results are shown in Fig. 4a. Across the whole undercooling range, the nucleation rates of the α(Cu) and α(Be) phases are far larger than that of the NiBe and CuBe phases, while, with increasing undercooling, the nucleation rate of α(Be) phase is very close to (but still smaller than) that of the α(Cu) phase. So, we can conclude that during the solidification of the deeply undercooled Cu-0.2Be-1.0Ni-0.2Co alloy, the nucleation and growth of the α(Cu) matrix phase are dominant but the driving force for the aggregation of Be atoms is also large. As a result, lots of spherical Be-rich clusters (close to FCC structure, not yet HCP structure) can be formed in the as-cast EML samples.

a The heterogeneous nucleation rates of four correlative phases versus the undercooling ΔT of the liquid alloy. The inset is the local magnification in the experimental range of undercooling. b The electrical resistivity increases due to various scattering mechanisms under the as-cast and peak-aged states. c The comparison of electrical conductivities between the calculational and experimental results of the as-cast EML-200 and EMI-10 samples. The error bars represent the standard deviations. The inset shows the comparison of electrical conductivities between the calculational and experimental results of the peak-aged EML-200 and EMI-10 samples. d The variation in relative precipitation volume fraction (φ) with aging time (t) during the aging of the solution-treated EML-200 and EMI-10 samples at 450 °C. The inset shows the theoretical contributions of different strengthening sources to the total yield strengths of the peak-aged EML-200 and EMI-10 samples. The error bars represent the standard deviations of measured yield strengths. Source data are provided as a Source Data file.

The reason for the spherical shape is that it has the lowest interface energy in an isotropic liquid. These spherical products will reduce the solute content in the matrix and greatly enhance the electrical conductivity. Moreover, due to the gentle change in the nucleation rates of the α(Cu) and α(Be) phases within the undercooling range from 154 to 310 K (Fig. 4a inset), the electrical conductivities of the as-cast EML samples are basically consistent (Fig. 1a).

Surviving of spherical Be-rich clusters during solution

The above experimental results show that the spherical Be-rich clusters play a great role in improving the electrical conductivity of the as-aged EML-200. It is natural to suggest that these spherical Be-rich clusters are continued from the undercooling-induced spherical Be-rich clusters. This means that the undercooling-induced spherical Be-rich clusters can survive after the normal solution treatment (940 °C for 60 min). To verify this, the microstructure of the as-cast EML-200 just after the normal solution treatment was examined by TEM (Supplementary Fig. 4). It clearly exhibits that lots of spherical Be-rich clusters still exist after the normal solution treatment, only that their concentrations are diminished by comparison with that in Fig. 1.

As for why they do not disappear easily as the usual plate-shaped precipitates do during normal solution treatment37, we regard that it is mainly because of long diffusion distance. For a spherical Be-rich cluster with a radius of about 8 nm (Fig. 1c, d), the diffusion distance of a Be atom from the cluster center to the surrounding matrix is around 8 nm at all directions. While, for a plate-shaped precipitate with a radius of 7 nm and thickness of 1.3 nm (Fig. 3b, e), the diffusion distance of a Be atom from the precipitate center to the surrounding matrix is around 0.65 nm at the thickness direction. So, under the same temperature, the solution time needed to dissolve the spherical Be-rich clusters may be 150 times that to dissolve the plate-shaped precipitates38. To illustrate this, we have carried out a long time (12 h) solution treatment at high temperature (980 °C) to the peak-aged EML-200. The TEM observation shows that both the γ′ phase and Be-rich clusters have dissolved completely into the copper matrix (Supplementary Fig. 5).

Independent precipitation from Be-rich clusters during aging

Figure 3 demonstrates that the precipitates are independent from the spherical Be-rich clusters. This naturally raises a question of why the survival Be-rich clusters cannot function as the nucleation sites for the precipitates during the aging treatment. We can explain this based on the nucleation theory38. During the aging process, the nucleation of precipitated phase is driven by the difference in chemical free energy between the new phase and the parent phase, while the main resistance arises from interfacial energy, which is intricately connected to the mismatch degree. The GP zones are a transitional phase with a structure between the matrix and γ′ phase, while the Be-rich clusters, which form from isotropic undercooled liquid alloy melt, have the same structure as α(Cu). Consequently, the Be-rich cluster and the γ′ phase exhibit pronounced crystallographic distinctions, resulting in increased mismatch. As a result, the required nucleation energy for the γ′ phase from the Be-rich clusters is much larger than that from the GP zones (Supplementary Fig. 6). Therefore, the GP zones are more beneficial for the nucleation of γ′ phase.

Effect of Be-rich clusters on electrical conductivity

Based on the classical electron scattering theory of Matthiessen’s Rule39, the total electrical resistivity increase of the Cu-0.2Be-1.0Ni-0.2Co alloy arises from electron scatterings of solute atoms, reinforcing phases, grain boundaries and dislocations. Because that the EML-200 and EMI-10 samples are coarse-grained with low dislocation densities, the effects of grain boundary scattering and dislocation scattering are negligible (see Supplementary Notes 1, 2). We subsequently established a multi-scale electron scattering theoretical model to quantitatively evaluate the influence of Be-rich clusters on electrical conductivity (see Supplementary Note 3 for details). The total resistivity increments for the EML-200 and EMI-10 can be calculated by Δρ = Δρclusters + Δργ′ + Δρsolute, where Δρclusters, Δργ′ and Δρsolute represent the resistivity increases contributed by Be-rich clusters, γ′ precipitates, and solute atoms, respectively. Δρclusters and Δργ′ can be described by expressions relate to the resistance of pure copper (ρ0), the resistance of clusters (ρc) and precipitates (ργ′), and the volume fraction of clusters (fc) and precipitates (fγ′). For the current alloy, ρc and ργ′ ≫ ρ05, indicating that Δρclusters and Δργ′ are predominantly governed by fc and fγ′. According to the Nordheim rule40, Δρsolute is proportional to the solute concentration (including cBe, cNi and cCo) in the matrix under dilute condition.

By substituting the experimental parameters of the EML-200 and EMI-10 samples into the model, the total electrical resistivity increments of the samples under the as-cast and peak-aged states were obtained, as shown in Fig. 4b. The contributions of Δρclusters ≈ 0.015ρ0 and Δργ′ ≈ 0.02ρ0 can be ignored and the main contribution comes from Δρsolute. The small contributions of Δρclusters and Δργ′ should be due to the low volume fraction (fc and fγ′ < 1.6%) and the relatively large average size (>10 nm) of the Be-rich clusters and γ′ precipitates, leading to weak scattering. On the other hand, the APT detections (Supplementary Fig. 7) verify that the production of Be-rich clusters has reduced the Be content in the Cu matrix from 0.2 (EMI-10) to 0.1 wt.% (EML-200) in the as-cast samples, and from 0.11 (EMI-10) to 0.01 wt.% (EML-200) in the peak-aged samples. As shown in Fig. 4c, the Be content reductions are right to theoretically explain the electrical conductivity increments of the as-cast and peak-aged EML-200 samples (Figs. 1a and 3a). Therefore, the effect of Be-rich clusters on electrical conductivity is mainly through reduction of Be solute content in the Cu matrix.

Effect of Be-rich clusters on mechanical property

To reveal the strengthening mechanisms involved, statistical analyses of TEM images were first conducted (see Supplementary Table 1 and Supplementary Note 4), which demonstrate that the average size and volume fraction of plate-shaped γ′ precipitates in the peak-aged EML-200 sample are 5% and 11% smaller than those in the peak-aged EMI-10 sample, respectively. Secondly, precipitation kinetics analyses based on the Johnson–Mehl–Avrami equation and Matthiessen’s law were performed (see Supplementary Note 5 for details), which reflect that the precipitation driving force of the solution-treated EML-200 sample is much smaller than that of the solution-treated EMI-10 sample (Fig. 4d), with precipitation rate constants of 0.018 and 0.058, respectively. These two analyses indicate that the contribution of γ′ precipitates to the final mechanical properties is definitely diminished by the presence of Be-rich clusters.

To verify the effect of Be-rich clusters on mechanical properties, a 3% strain specimen from the peak-aged EML-200 sample was analyzed by TEM, which shows that dislocations bypass the Be-rich clusters and γ′ precipitates through the Orowan looping mechanism (Supplementary Fig. 8). Thus, we ascertain that the Be-rich clusters have the capability to strengthen the alloy and can calculate the total yield strength by using σtotal = σ0 + Δσc + Δσγ′ + Δσs, where σ0 ≈ 25 MPa is the intrinsic friction stress of pure Cu; Δσc, Δσγ′ and Δσs represent the yield strength increments contributed by the Be-rich clusters, γ′ precipitates and solute atoms, respectively. According to the Orowan and Fleischer equations, Δσc ≈ 103 MPa, Δσγ′ ≈ 504 MPa and Δσs ≈ 8 MPa are evaluated (Supplementary Note. 6 for details). Consequently, for the peak-aged EML-200 sample, the total yield strength σtotal ≈ 640 MPa, which is close to the experimental value of 614 MPa. The total yield strength of the peak-aged EMI-10 sample is also calculated and compared with that of the peak-aged EML-200 sample (Fig. 4d inset). It illustrates that the Be-rich clusters can compensate for the yield strength loss caused by the reduction in the size and volume fraction of γ′ precipitates.

In summary, we have found an unconventional pathway to obtain high-performance Cu-Be alloys. The key point is to create lots of spherical Be-rich clusters in the as-cast alloy through deep undercooling, which can survive from normal solution treatment and are independent from precipitates during aging treatment. As a result, the upper limitation of matrix purity, usually controlled only by precipitation, can be broken through, leading to high conductivity. Furthermore, the strength contribution from Be-rich clusters can compensate for the strength loss caused by precipitation reduction. This study offers an approach to overcome the strength-conductivity trade-off in the widely used precipitation-strengthening alloys.

Methods

As-cast alloy sample preparation

Firstly, the 10 g mixtures according to the nominal composition of Cu-0.2Be-1.0Ni-0.2Co (in wt.%, the same below) were melted in a 10 kW electromagnetic induction (EMI) melting system under a vacuum environment using raw materials of 99.999% Cu, 99.999% Ni, 99.999% Co, and Cu–1.84Be master alloy. Then, small alloy samples weighing ≈ 2 g were cut out from the as-cast EMI samples and some of them were containerlessly processed in an electromagnetic levitation (EML) melting setup (device details are available in ref. 41) under argon protection. During levitation, the heating and cooling of the EML samples were monitored with an infrared thermometer (IT, METIS M3) and their undercoolings were measured from the corresponding cooling curves. Finally, the as-cast EML samples with a roughly spherical shape and diameter ≈ 8 mm were obtained.

Heat treatment

To obtain optimal properties of the Cu-0.2B-1.0Ni-0.2Co alloy, the as-cast EMI-10 and EML-200 samples were first exerted solution treatment at 940 °C for 1 h, followed by water-quenching, and then exerted aging treatment at 450 °C for various durations. During the heat treatment, the samples were protected in vacuum-sealed quartz tubes.

Microstructure characterization

TEM specimens were lifted out using a FIB/SEM dual-beam system (FEI Helios G4 CX, USA). The specimens were first thinned with a 30 kV Ga beam to ≈200 nm and then polished at progressively lower voltages (10, 5, and 3 kV) to a thickness of ≈50 nm. STEM observations were conducted on a FEI Themis Z instrument (USA) equipped with double spherical aberration corrector lenses. HAADF-STEM observations with Z-contrast imaging were taken using an annular-type detector with a collection angle ranging from 100 to 267 mrad at 300 kV. In this case, the intensities of bright spots depend on atomic number (Z). EDS analyses were performed using Bruker Super-X instrument (Germany) operating at 300 kV. The length (L) and width (h) of precipitates were measured within TEM micrographs with the electron beam oriented parallel to the [001]Cu zone axis. Gatan DigitalMicrograph 3.5 software was employed to analyse the TEM images.

XRD spectra were collected from polished sample surfaces by a Bruker D8 Advance diffractometer (Germany) with Co Kα radiation operating at 40 kV and 40 mA. The diffraction patterns were recorded over a 2θ range from 20° to 100° at a step of 0.04°.

Atom probe tomography

Needle-shaped APT specimens were prepared via standard electropolishing42. APT tests were carried out using a LEAP 5000HR instrument (USA). The running condition for the specimens was 20.0% pulse fraction, 200 kHz pulse rate, base temperature of 50 K and ion collection rate of 0.2% per field evaporation pulse. The APT data were reconstructed using Cameca IVAS 3.8.4 and the reconstruction was calibrated on the basis of elements of crystallography retained within the data, characterized by spatial distribution maps43,44.

Mechanical property testing

Vickers microhardness measurements were conducted using a Vickers hardness tester (MacroVicker HV 10) with a load of 50 g for 10 s. For each sample, at least 15 indents were measured to obtain an average value.

Tensile tests were performed on a WPL-100 machine with a nominal strain rate of 1 ×10−3 s−1 at room temperature. The total length of a dog-bone-shaped tensile specimen was 19 mm, and the gauge dimensions were 7 mm × 2 mm × 1.5 mm. To obtain the dog-bone-shaped specimens, the EMI and EML samples were first cold rolled to a total reduction of ≈50% and then solution treated before aging. The dislocations and internal stresses generated by cold rolling have been almost completely eliminated by solution treatment (annealing), without observable influence on the subsequent aging-precipitation process (Supplementary Fig. 9).

Electrical conductivity testing

Electrical conductivity measurements were implemented by using a conductivity meter (Sigma 2000 B). Each value of electrical conductivity for a sample was obtained by averaging 10 measured values.

Thermo-Calc calculation

The TCCU4 copper-based database was employed to assess the thermodynamic parameters of the Cu-0.2Be-1.0Ni-0.2Co alloy. Based on the equilibrium phase diagram calculation, the maximum volume fraction of precipitates in the Cu-0.2Be-1.0Ni-0.2Co alloy is fmax ≈ 0.02.

Nucleation rate and activation energy calculation

The nucleation rates (I) of different phases in the undercooled alloy were calculated by Eq. (1)36:

where I0 is the nucleation factor, ΔHm the latent heat of crystallization per unit volume, γSL the liquid/solid interface energy, TL the liquidus temperature, Q the activation energy of diffusion, kB the Boltzmann’s constant, and f(θ) the heterogeneous nucleation factor.

The nucleation activation energies (ΔG) of γ′ phase from spherical Be-rich clusters were calculated by Eq. (2):

where r is the critical nucleation radius, ΔGV the chemical free energy change resulting from the precipitation of a new phase per unit volume, and γαβ the phase interface energy.

The relevant physical parameters were obtained from the Thermo-Calc thermodynamic database (see Supplementary Table 2).

Data availability

The data that support the findings of this study are available from the corresponding author upon request. Source data are provided with this paper.

References

Liu, Y. G. et al. Manufacturing of high strength and high conductivity copper with laser powder bed fusion. Nat. Commun. 15, 1283 (2024).

Surekha, K. & Els-Botes, A. Development of high strength, high conductivity copper by friction stir processing. Mater. Des. 32, 911–916 (2011).

Thilly, L. et al. Interface instability in the drawing process of copper/tantalum conductors. Acta Mater. 47, 853–857 (1999).

Lu, L., Shen, Y. F., Chen, X. H., Qian, L. H. & Lu, K. Ultrahigh strength and high electrical conductivity in copper. Science 304, 422–426 (2004).

Yang, K. et al. Recent development of advanced precipitation-strengthened Cu alloys with high strength and conductivity: A review. Prog. Mater. Sci. 138, 101141 (2023).

Lu, K., Lu, L. & Suresh, S. Strengthening materials by engineering coherent internal boundaries at the nanoscale. Science 324, 349–352 (2009).

Morris, M. A., Leboeuf, M. & Morris, D. G. Recrystallization mechanisms in a Cu-Cr-Zr alloy with a bimodal distribution of particles. Mater. Sci. Eng. A. 188, 255–265 (1994).

Zhang, Z. Y., Sun, L. X. & Tao, N. R. Nanostructures and nanoprecipitates induce high strength and high electrical conductivity in a CuCrZr alloy. J. Mater. Sci. Technol. 48, 18–22 (2020).

Nam, H. M., Lee, H., Kim, H., Lee, J. G. & Kim, J. Precipitation strengthening of Cu-Ni-Si-based alloys: experimental and computational insights. J. Mater. Res. Technol. 27, 5372–5379 (2023).

Elibol, C. Effect of severe plastic deformation on the precipitation kinetics and the properties of CuCoNiBe alloys. Mat. Today Commun. 31, 103473 (2022).

Mao, Q. Z., Wang, L., Nie, J. F. & Zhao, Y. H. Enhancing strength and electrical conductivity of Cu-Cr composite wire by two-stage rotary swaging and aging treatments. Compos. Part B. 231, 109567 (2021).

Jiang, Y. H. et al. Precipitation behavior and microstructural evolution during thermo-mechanical processing of precipitation hardened Cu-Hf based alloys. Acta Mater. 245, 118659 (2023).

Semboshi, S. et al. Age-induced precipitating and strengthening behaviors in a Cu-Ni-Al alloy. Metall. Mater. Trans. A 52, 4934–4945 (2021).

Mohammadi, A., Enikeev, N. A., Murashkin, M. Y., Arita, M. & Edalati, K. Developing age-hardenable Al-Zr alloy by ultra-severe plastic deformation: significance of supersaturation, segregation and precipitation on hardening and electrical conductivity. Acta Mater. 203, 116503 (2021).

Tang, Y. C., Kang, Y. L., Yue, L. J. & Jiao, X. L. Mechanical properties optimization of a Cu-Be-Co-Ni alloy by precipitation design. J. Alloy. Compd. 695, 613–625 (2017).

Han, S. Z., Choi, E. A., Lim, S. H., Kim, S. & Lee, J. Alloy design strategies to increase strength and its trade-offs together. Prog. Mater. Sci. 117, 100720 (2021).

Ivan, L., Castillo-Rodriguez, M. & Sauvage, X. Microstructure, mechanical properties and aging behaviour of nanocrystalline copper-beryllium alloy. Mater. Sci. Eng. A. 744, 206–214 (2019).

Lu, X. et al. New insight into the atomic structure of electrochemically delithiated O3-Li(1−x)CoO2 (0≤x≤0.5) nanoparticles. Nano Lett. 12, 6192–6197 (2012).

Jiang, Y. B. et al. Effects of Ni content on microstructure and properties of aged Cu-0.4Be alloy. Trans. Nonferrous Met. Soc. China 31, 679–691 (2021).

Ryou, M., Lee, B. S. & Kim, M. H. Influence of aging treatment on the mechanical and electrical properties of Cu-0.5%Be alloy. J. Mater. Sci. Technol. 24, 120–122 (2008).

Watanabe, C., Takeshita, S. & Monzen, R. Effects of small addition of Ti on strength and microstructure of a Cu-Ni-Si alloy. Metall. Mater. Trans. A 46, 2469–2475 (2015).

Fu, H. W., Yin, Y. W., Zhang, Y., Zhang, M. Y. & Yun, X. B. Enhancing the comprehensive properties of as-cast Cu-Ni-Si alloys by continuous extrusion combined with subsequent thermomechanical treatment. Mater. Des. 222, 111033 (2022).

Ban, Y. et al. Properties and precipitates of the high strength and electrical conductivity Cu-Ni-Co-Si-Cr alloy. J. Mater. Sci. Technol. 93, 1–6 (2021).

Jiang, L. et al. Enhanced mechanical and electrical properties of a Cu-Ni-Si alloy by thermos-mechanical processing. Metall. Mater. Trans. A. 51, 331–341 (2019).

Goto, M. et al. Microstructure-dependent fatigue behavior of aged Cu-6Ni-1.5Si alloy with discontinuous/cellular precipitates. Mater. Sci. Eng. A. 747, 63–72 (2019).

Zhao, Z. et al. Co effects on Cu-Ni-Si alloys microstructure and physical properties. J. Alloy. Compd. 797, 1327–1337 (2019).

Huang, L. et al. Properties and microstructure of copper-titanium alloys with magnesium additions. Rare Met. 43, 2290–2299 (2024).

Si, L. et al. Microstructure and property of Cu-2.7Ti-0.15Mg-0.1Ce-0.1Zr alloy treated with a combined aging process. Mater. Sci. Eng. A. 650, 345–353 (2016).

Nagarjuna, S., Balasubramanian, K. & Sarma, D. S. Effect of prior cold work on mechanical properties, electrical conductivity and microstructure of aged Cu-Ti alloys. J. Mater. Sci. 34, 2929–2942 (1999).

Wang, W. et al. Effects of minor rare earths on the microstructure and properties of Cu-Zr-Cr alloy. J. Alloy. Compd. 847, 155762 (2020).

Watanabe, C., Monzen, R. & Tazaki, K. Mechanical properties of Cu-Cr system alloys with and without Zr and Ag. J. Mater. Sci. 43, 813–819 (2008).

Pan, S. B. et al. Customized development of promising Cu-Cr-Ni-Co-Si alloys enabled by integrated machine learning and characterization. Acta Mater. 243,, 118484 (2023).

Dobatkin, S. V., Bochvar, N. R. & Shangina, D. V. Aging processes in ultrafine-grained low-alloyed bronzes subjected to equal channel angular pressing. Adv. Eng. Mater. 17, 1862–1868 (2015).

Kermajani, M., Raygan, S., Hanayi, K. & Ghaffari, H. Influence of thermomechanical treatment on microstructure and properties of electroslag remelted Cu-Cr-Zr alloy. Mater. Des. 51, 688–694 (2013).

Wang, W. et al. Effects of Nb addition on the properties and microstructure of Cu-Ni-Si-Mg alloy. Mater. Charact. 194, 112451 (2022).

Kurz, W., Fisher, D. J. Fundamental of solidification (Trans Tech Publications Ltd, 1998).

He, S. J., Jiang, Y. B., Xie, J. X., Li, Y. H. & Yue, L. J. Effects of Ni content on the cast and solid-solution microstructures of Cu-0.4 wt%Be alloys. Int. J. Miner. Metall. Mater. 25, 641–651 (2018).

David, A. P., Kenneth, E. E., Mohamed, S. Phase transformations in metals and alloys (CRC Press, 2009).

Soisson, F. et al. Monte Carlo simulations of copper precipitation in dilute iron-cooper alloys during thermal ageing and under electron irradiation. Acta Mater. 44, 3789–3800 (1996).

Rudajevová, A., Stanek, M. & Lukác, P. Determination of thermal diffusivity and thermal conductivity of Mg-Al alloys. Mater. Sci. Eng. A. 341, 152–157 (2003).

Zhang, B. W., Hong, Z. Y., Zhao, H. L., Yan, N. & Hu, L. Microstructure, precipitation behavior, and properties of quaternary Cu–Be–Co–Ni alloy under electromagnetic levitation. Mater. Sci. Eng. A. 868, 144774 (2023).

Miller, M. K. Atom probe tomography: analysis at the atomic level (Springer Science & Business Media, 2012).

Gault, B. et al. Advances in the calibration of atom probe tomographic reconstruction. J. Appl. Phys. 105, 034913 (2009).

Moody, M. P., Gault, B., Stephenson, L. T., Haley, D. & Ringer, S. P. Qualification of the tomographic reconstruction in atom probe by advanced spatial distribution map techniques. Ultramicroscopy 109, 815–824 (2009).

Acknowledgements

This work is financially supported by the National Natural Science Foundation of China (Grant Nos. U24A2034 (Z.H.), U1904214 (Z.H.), U24A20106 (W.W.)) and the Natural Science Foundation of Shaanxi Province (Grant No. 2020JZ-08 (F.D.)). We are grateful to Prof. Bingbo Wei for his consistent support.

Author information

Authors and Affiliations

Contributions

Z.H. proposed and supervised the research. B.Z. designed and performed the experiments. B.Z. and Z.H. drafted the paper. P.X. and J.W. carried out the property measurements. W.W. and F.D. conducted the microstructure and phase analyses.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Yee-Wen Yen, Yuhong Zhao, and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, B., Xu, P., Wang, J. et al. Overcoming the trade-off between conductivity and strength in copper alloys through undercooling. Nat Commun 16, 4978 (2025). https://doi.org/10.1038/s41467-025-60346-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-60346-8