Abstract

Microbial production of chemicals may suffer from inadequate cofactor provision, a challenge further exacerbated in yeasts due to compartmentalized cofactor metabolism. Here, we perform cofactor engineering through the decompartmentalization of mitochondrial metabolism to improve succinic acid (SA) production in Issatchenkia orientalis. We localize the reducing equivalents of mitochondrial NADH to the cytosol through cytosolic expression of its pyruvate dehydrogenase (PDH) complex and couple a reductive tricarboxylic acid pathway with a glyoxylate shunt, partially bypassing an NADH-dependent malate dehydrogenase to conserve NADH. Cytosolic SA production reaches a titer of 104 g/L and a yield of 0.85 g/g glucose, surpassing the yield of 0.66 g/g glucose constrained by cytosolic NADH availability. Additionally, expressing cytosolic PDH, we expand our I. orientalis platform to enhance acetyl-CoA-derived citramalic acid and triacetic acid lactone production by 1.22- and 4.35-fold, respectively. Our work establishes I. orientalis as a versatile platform to produce markedly reduced and acetyl-CoA-derived chemicals.

Similar content being viewed by others

Introduction

Over the past three decades, since its inception, metabolic engineering has notably revolutionized the way chemicals, materials, pharmaceuticals, and energy are produced1,2,3,4. It offers distinct environmental benefits relative to the petrochemical sectors, including the utilization of renewable biomass and the prospect of carbon-negative production processes. In general, conventional strain engineering endeavors have centered on improving enzyme activities through protein discovery or engineering and maximizing flux from substrates to main products through overexpression and deletion of specific genes. However, in certain instances, an insufficient supply of cofactors may constitute the bottleneck for the biosynthesis of target molecules5,6,7.

Unlike in bacteria, the metabolisms of cofactors including acetyl-CoA and NAD(P)+/NAD(P)H are highly compartmentalized in yeast cells or any eukaryotic cells8,9,10. There are no known transporters that can directly exchange these cofactors between different pools (cytosol and organelles, such as mitochondria and peroxisomes). Instead, yeast cells depend on shuttle systems, including the ethanol-acetaldehyde11, glycerol-3-phosphate12, and malate-aspartate shuttles13, to exchange dehydrogenase products, which can either accept or donate electrons to form NAD(P)+ or NAD(P)H in the adjacent pool, respectively. Therefore, while cofactors, such as NAD(P)+/NAD(P)H, have been extensively manipulated to enhance the fermentative performance of engineered strains, cofactor engineering is still more challenging in yeasts than in bacteria14,15.

This challenge may be addressed by an organelle compartmentalization strategy focusing on the localization of a metabolic pathway from the cytosol to a subcellular compartment, which offers better access to the cofactors and precursors that are not readily sufficient in the cytosol (Fig. 1A)16,17,18. For example, metabolic pathways were localized into the yeast mitochondria to exploit the higher availability of the precursor α-ketoisovalerate and the cofactors NADH and iron–sulfur cluster for improved production of branched-chain alcohols19. However, the advantages of metabolic compartmentalization depend on the resources that naturally build up in the compartments, restricting its use to certain products20. Furthermore, most biosynthetic pathways are expressed in the cytosol in yeast metabolic engineering efforts since the cytosol has a large volume and a high coverage of enzymes and metabolites21,22. Thus, we hypothesize that it is still important to enhance the cofactor levels in the cytosol. Moreover, we hypothesize that it is possible to perform the opposite process of compartmentalization, or ‘decompartmentalization’ by localizing enzymes responsible for the high levels of cofactors from subcellular organelles to the cytosol to increase their cytosolic levels (Fig. 1A). To our knowledge, there have been no efforts to transport or shuttle electrons from subcellular compartments to the cytosol for the production of highly reduced chemicals.

A Compartmentalization relies on localizing a metabolic pathway from the cytosol to a subcellular organelle to exploit the organelle’s cofactor supply, while decompartmentalization focuses on localizing the enzymes contributing to the high level of cofactor from the organelle to the cytosol to increase the cytosolic cofactor provision. Dots indicate metabolites, while arrows indicate transport or enzymatic reactions. B A schematic diagram for enhanced SA production in I. orientalis through the decompartmentalization of mitochondrial metabolism. The genes in the rTCA pathway are marked in blue, while pyruvate dehydrogenase and the genes associated with the glyoxylate shunt are marked in red. OAA oxaloacetate, PYC pyruvate carboxylase, MDH malate dehydrogenase, FUMR fumarase, FRD fumarate reductase, PDH pyruvate dehydrogenase, CIT citrate synthase, ACO aconitase, MLS malate synthase, ICL isocitrate lyase.

To demonstrate our decompartmentalization-based cofactor engineering strategy, we chose one of the top 12 bio-based platform chemicals identified by the United States Department of Energy, succinic acid (SA), as a representative product, whose production using yeasts is highly hindered by a lack of the reducing equivalent NADH23,24,25,26. In yeasts, the majority of cytosolic NADH is generated through glycolysis, which splits 1 mole of glucose into 2 moles of pyruvate, producing 2 moles of NADH in the process. However, the conversion of 1 mole of pyruvate into 1 mole of SA through the reductive tricarboxylic acid (rTCA) pathway – which contains pyruvate carboxylase (PYC), malate dehydrogenase (MDH), fumarase (FUMR), and fumarate reductase (FRD) – requires 2 moles of NADH. Thus, assuming all available cytosolic NADH is used for SA production, the yield of SA is limited to only 1 mol/mol glucose (or 0.66 g/g glucose) with equal pyruvate overflow according to the following redox balance reaction: C6H12O6 + CO2 → C4H6O4 + C3H4O3 + H2O. Previously, we metabolically engineered the non-conventional acid-tolerant yeast Issatchenkia orientalis SD108 for SA production at low pH using the rTCA pathway27. The engineered strain SA (reported previously as g3473∆/PaGDH-DAK/p101a) contained overexpression of its endogenous PYC, MDH, and FUMR and the heterologous FRD, which was from Trypanosoma brucei and codon-optimized for expression in Saccharomyces cerevisiae. The strain also contained overexpression of a dicarboxylic acid transporter to facility the export of SA and deletion of a dicarboxylic acid importer to reduce the uptake of extracellular SA. Furthermore, pyruvate decarboxylase (PDC) and glycerol-3-phosphate dehydrogenase (GPD) were deleted to remove ethanol and glycerol production, respectively. In shake flask fermentations with glucose as the substrate, the strain SA could produce SA at a titer of 24.6 g/L and a yield of 0.49 g/g glucose with a concomitant accumulation of pyruvate at 19.8 g/L. Metabolic flux analysis (MFA) also indicated that our engineered strain could efficiently direct most cytosolic NADH toward SA production and that the pyruvate overflow resulted from the inadequate supply of cytosolic NADH. Thus, further engineering of NADH supply through targeting pathways in the cytosol would not be helpful.

In this study, we perform the decompartmentalization of the yeast mitochondrial metabolism to localize relevant enzymes from the mitochondria, which harbor the pyruvate dehydrogenase (PDH) complex and the TCA cycle and perform in total 3 decarboxylation reactions to create energy in the form of NADH, to the cytosol to generate more cytosolic NADH and improve SA production. First, we localize its endogenous PDH complex to the cytosol of I. orientalis to increase cytosolic NADH provision, leading to a 1.19-fold increase in SA titer and a 2.60-fold decrease in maximal pyruvate accumulation. Further NADH engineering is then performed by coupling the rTCA pathway with a glyoxylate shunt, which partially bypasses the NADH-dependent MDH and provides the rTCA pathway with more reducing power. This necessitates additional decompartmentalization of mitochondrial metabolism to localize a citrate synthase (CIT) and an aconitase (ACO) to the cytosol. In fed-batch fermentations using minimal medium at pH 3, the improved strain can produce SA at a titer of 104 g/L, a yield of 0.85 g/g glucose, and a productivity of 0.96 g/L/h from glucose as the sole carbon source. Finally, to demonstrate its generality, we apply our decompartmentalization-based cofactor engineering strategy to improve the production of the acetyl-CoA-derived citramalic acid and triacetic acid lactone by 1.22- and 4.35-folds, respectively.

Results

Decompartmentalization of mitochondrial pyruvate oxidation through functional reconstitution of a PDH complex in the cytosol of I. orientalis

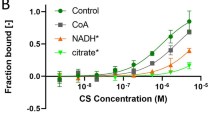

Additional NADH for improved SA production through the rTCA pathway can be produced through the pyruvate oxidation catalyzed by a PDH complex. Due to a lack of NADH transport between the cytosol and the mitochondria, we attempted to express a PDH complex directly in the cytosol to generate more cytosolic NADH (Fig. 1B). PDH is a ubiquitous protein complex present in all organisms and performs the oxidative decarboxylation of pyruvate to acetyl-CoA with the simultaneous transfer of electrons to NAD+ to form NADH28,29. It consists of three catalytic subunits: pyruvate dehydrogenase (E1), dihydrolipoyl transacetylase (E2), and dihydrolipoyl dehydrogenase (E3), which together form a multimeric complex. Furthermore, PDH uses thiamine, FAD, NAD+, and lipoic acid (LA) as cofactors. While thiamine, FAD, and NAD+ are readily available in the cytosol of yeast, LA is produced in mitochondria and considered unable to traverse the mitochondrial membrane30. We introduced into the strain SA the PDH complex from Escherichia coli (EcPDH), encoded by AceE, AceF, and LpdA31. Furthermore, to enable the functional lipoylation of the E2 subunit through the scavenging pathway that utilizes exogenous LA32 (Supplementary Fig. 1A), the lipoate-protein ligases from Bacillus subtilis (BsLplJ) and E. coli (EcLplA) were co-expressed with the EcPDH structural genes in the strain SA, resulting in strains SA-EcPDH-BsLplJ and SA-EcPDH-EcLplA. The strains SA, SA-EcPDH-BsLplJ, and SA-EcPDH-EcLplA were evaluated for SA production in shake-flask fermentations using minimal medium (SC-URA) containing 50 g/L of glucose. For the strains with expression of a lipoate-protein ligase, 1 µg/L of LA was supplemented in the SC-URA medium. Nevertheless, compared to the parental strain SA, the strains expressing EcPDH and the lipoate-protein ligases showed no significant increase in the SA titers or significant decrease in the maximum accumulation of pyruvate (Fig. 2 and Supplementary Fig. 2A–C).

SA titers and pyruvate accumulation for the strain SA and the derived strains expressing a PDH complex and a lipoate-protein ligase. SA titers represent the final titers at the end of the fermentation process on day 3, while pyruvate accumulation reached a maximum on day 2. Fermentations were performed in shake flasks using SC-URA media containing 50 g/L of glucose and 5 g/L of calcium carbonate and supplemented with 1 µg/L of LA as indicated. Error bars, mean ± SD (n = 3 biologically independent samples). Two-tailed unpaired t-test was used to calculate p values. Source data are provided as a Source Data file.

Since it was likely the bacterial EcPDH might not function properly in the yeast cellular environments, we therefore localized its endogenous PDH complex (IoPDH) to the cytosol of I. orientalis. Furthermore, compared to the model yeast S. cerevisiae, I. orientalis has higher pyruvate oxidation and TCA fluxes33, suggesting that the IoPDH might have high activity and thus should be a better target than the EcPDH for expression in the cytosol. While the PDH complex from prokaryotes contains only three subunits, the PDH complex from eukaryotes contains five subunits, encoded by PDA1, PDB1, LAT1, LPD1, and PDX134,35. PDA1 and PDB1 constitute the α and β subunits of the E1 component of the PDH complex, respectively; while LAT1 and LPD1 are the E2 and E3 subunits of the PDH complex, respectively. Moreover, PDX1 is the E3-binding protein of the PDH complex, which structurally binds and positions the E3 subunit to the E2 subunit36. The mitochondrial targeting sequences (MTSs) from these five subunits of I. orientalis SD108 were identified by TargetP 2.037, and the MTS-free endogenous PDH structural genes were expressed in the strain SA, leading to strain SA-IoPDH. The BsLplJ and EcLplA were then expressed in the strain SA-IoPDH, resulting in strains SA-IoPDH-BsLplJ and SA-IoPDH-EcLplA, respectively.

Furthermore, to determine whether the subunits of the endogenous PDH complex that lacked their MTSs were retained in the cytosol, we individually expressed each truncated subunit, fused with a His tag at the C-terminus, in wild-type I. orientalis SD108 and extracted the cytosolic fraction. Through Western blotting, we found that LPD1 remained in the cytosol (Supplementary Fig. 3A). We suspected that the absence of the bands corresponding to PDA1, PDB1, PDX1, and LAT1 was due to the His tag being buried within the proteins. To address this, we fused a GFP to each truncated subunit. Using an anti-GFP as the primary antibody, we observed the presence of LAT1 in the cytosolic fraction (Supplementary Fig. 3B). Additionally, we observed that the GFP levels were low for the GFP-fused PDA1, PDB1, and PDX1, likely falling below the detection limit of Western blotting (Supplementary Fig. 3C).

However, since the chosen lipoate-protein ligases are from bacteria, they may not properly perform lipoylation on the E2 subunit of the yeast I. orientalis. Furthermore, the high cost of LA would limit the application of a cytosolic PDH complex in industrial settings, and there is no proof suggesting the existence of a lipoylation machinery through LA scavenging in yeasts38. Thus, we also tested a semisynthetic lipoylation pathway that uses octanoyl-ACP as a substrate for lipoylation, which could potentially bypass the limitations of the native LA biosynthesis in yeast (Supplementary Fig. 1B)39. First, to enable the cytosolic production of octanoyl-ACP from octanoic acid, we expressed an acyl-ACP synthetase (AasS), an acyl carrier protein (ACP), and an ACP activator. We chose the AasS from Vibrio harveyi, which is a soluble enzyme that can ligate free fatty acid to ACP to form acyl-ACP40. Furthermore, the ACP1 and PPT2 (ACP1 activator) from S. cerevisiae were chosen as we were unable to identify their homologs in I. orientalis through BLAST analysis. Lastly, the homologs of genes involved in the yeast lipoylation pathway41, including LIP2, LIP3, LIP5, and GCV3, from I. orientalis were expressed to enable the transfer of the octanoyl moiety from octanoyl-ACP to the target apo-LAT1 following the synthesis of LA. ScACP1, ScPPT2, IoLIP2, IoLIP3, IoLIP5, and IoGCV3 without their MTSs predicted using TargetP 2.0 and VhAasS were expressed in the strain SA-IoPDH, leading to strain SA-IoPDH-SemiLip.

The strains SA-IoPDH-BsLplJ, SA-IoPDH-EcLplA, and SA-IoPDH-SemiLip were evaluated for SA production in shake-flask fermentations using SC-URA media containing 50 g/L of glucose and supplemented with 1 µg/L of LA or 5 mg/L of octanoic acid appropriately. Here, we observed a significant decrease in the maximal pyruvate accumulation from 17.44 g/L to 5.75 g/L as well as a significant increase in the SA titer from 26.45 g/L to 30.54 g/L for the strain SA-IoPDH-BsLplJ compared to the parental strain SA (Fig. 2, Supplementary Fig. 2A, and Supplementary Fig. 4A). On the other hand, no significant changes in the SA titer or the pyruvate accumulation were observed in the strain SA-IoPDH-EcLplA (Fig. 2, Supplementary Fig. 2A, and Supplementary Fig. 4B). Furthermore, the strain SA-IoPDH-SemiLip produced only 6.18 g/L of SA and accumulated 14.77 g/L of pyruvate; it also could not fully utilize all 50 g/L of glucose with the glucose uptake rate decreasing over time, which might be due to the cytotoxicity exerted by octanoic acid in yeasts42,43 (Supplementary Fig. 4C).

These results suggested that a functional PDH complex was expressed in the cytosol of I. orientalis in the strain SA-IoPDH-BsLplJ, increasing the supply of cytosolic NADH to further improve the conversion of pyruvate to SA. Furthermore, to test the necessity of BsLplJ expression and LA supplementation, we conducted shake flask fermentations using the strains SA-IoPDH-BsLplJ and SA-IoPDH in SC-URA medium without LA. Surprisingly, compared to the SA titer produced in the shake flask fermentation of the strain SA-IoPDH-BsLplJ with LA supplementation, we found that similar SA titers were achieved even without the addition of LA to the fermentation medium or the expression of BsLplJ (Fig. 2 and Supplementary Fig. 5A, B). Expression of only the cytosolic IoPDH improved the SA titer to 31.47 g/L and decreased the pyruvate accumulation to 7.38 g/L (Fig. 2 and Supplementary Fig. 5A). Additionally, we expressed the cytosolic IoPDH in the strain SD108/pdc∆/gpd∆, in which PDC and GPD were deleted to reduce cytosolic NADH consumption through the ethanol and glycerol production pathways, respectively. Consistently, we found that NADH/NAD+ ratio in the strain SD108/pdc∆/gpd∆/IoPDH was higher than that in the strain SD108/pdc∆/gpd∆ (Supplementary Fig. 6).

Decompartmentalization of partial TCA cycle to couple a glyoxylate shunt with the rTCA pathway in the cytosol of I. orientalis

While the cytosolic IoPDH expression increased the cytosolic NADH supply for improved SA production, carbon was lost in the form of acetyl-CoA (Fig. 1B). To redirect the acetyl-CoA to SA synthesis, the rTCA can be coupled with a glyoxylate shunt or an oxidative TCA (oTCA) pathway. According to redox balance, the maximum stoichiometric SA yield is 1.714 mol/mol glucose, and 7 moles of glucose can be consumed and 6 moles of CO2 can be fixed to produce 12 moles of SA as shown by the following reaction: 7C6H12O6 + 6CO2 → 12C4H6O4 + 6H2O44. To achieve such a yield while satisfying redox balance through the coupling of the rTCA pathway with the glyoxylate shunt, 71.4% of the carbon needs to flow to the rTCA pathway and 28.6% of the carbon flows to the glyoxylate shunt45 (Fig. 3A). While the MDH-mediated conversion of oxaloacetate to malate requires NADH, the glyoxylate shunt serves as a partial MDH bypass, in which oxaloacetate is converted to malate without requiring NADH. In contrast, if the rTCA pathway is coupled with the oTCA pathway, we calculated that 85.7% of the carbon needs to flow to the rTCA pathway and 14.3% of the carbon flows to the oTCA pathway (Supplementary Fig. 7). While the net carbon fixation is similar in both scenarios, the bicarbonate requirement and the release of CO2 are different. The coupling of the rTCA pathway with the glyoxylate shunt contains only one decarboxylation catalyzed by PDH and requires 10 moles of bicarbonate with 4 moles of CO2 released per 7 moles of glucose consumed. On the other hand, the oTCA pathway contains two additional decarboxylation reactions catalyzed by isocitrate dehydrogenase and α-ketoglutarate dehydrogenase, and the coupling of the rTCA and oTCA pathways requires 12 moles of bicarbonate with a loss of 6 moles of CO2 per 7 moles of glucose consumed.

A Flux distributions through glycolysis, rTCA pathway, glyoxylate shunt, and mitochondria. A maximum SA yield of 12 molar units can be obtained for a glucose consumption of 7 molar units based on redox balance. Fluxes are shown in units of flux per glucose uptake of 7 molar units. Black: the fluxes under the maximum theoretical yield of SA. Red: the fluxes determined by MFA informed by [U-13C]glucose and [1,2-13C]glucose tracing, metabolite and oxygen uptake and excretion, and growth rate of the strain EcGS-FF-gltA. OAA: oxaloacetate, PYC: pyruvate carboxylase, MDH: malate dehydrogenase, FUMR: fumarase, FRD: fumarate reductase, cPDH: cytosolic pyruvate dehydrogenase, mPDH: mitochondrial pyruvate dehydrogenase, CIT: citrate synthase, ACO: aconitase, MLS: malate synthase, ICL: isocitrate lyase, SDH: succinate dehydrogenase, SCS: succinyl-CoA synthetase. B SA titers and C pyruvate accumulation and malate titers in the strain SA-IoPDH and the derived strains with modulation of metabolic fluxes through the rTCA pathway and the glyoxylate shunt. SA and malate titers represent the final titers at the end of the fermentation process on day 3 for SA-IoPDH and on day 4 for the derived strains, while pyruvate accumulation reached a maximum on day 2 for SA-IoPDH and on day 3 for the derived strains. Fermentations were performed in shake flasks using SC-URA medium containing 50 g/L of glucose and 5 g/L of calcium carbonate. Error bars, mean ± SD (n = 3 biologically independent samples). Two-tailed unpaired t-test was used to calculate p values. Source data are provided as a Source Data file.

CO2 generated by decarboxylation is in gaseous state intracellularly and would quickly exit the liquid phase46. Furthermore, in large-scale fermentations using bioreactors, bicarbonate is commonly supplied by injecting gas streams enriched in CO2 into the culture medium47. Due to the low solubility of CO2 and its low transfer rate to the liquid medium, the concentration of bicarbonate produced from dissolved CO2 can be inadequate. Therefore, obtaining a higher bicarbonate concentration in the liquid phase would require using higher CO2 concentrations, which can increase the production cost47. While I. orientalis has high TCA fluxes33 and the expression of its oTCA pathway in the cytosol might be potentially successful, similar to the expression of the cytosolic IoPDH, the coupling of the rTCA and the oTCA pathways requires the higher demand of bicarbonate and leads to the higher loss of CO2. Thus, we chose to focus our efforts on coupling the rTCA pathway with the glyoxylate shunt.

The glyoxylate shunt shares CIT and ACO with the TCA cycle and contains two dedicated enzymes: isocitrate lyase (ICL) and malate synthase (MLS)48,49. ICL performs the aldol cleavage of isocitrate to SA and glyoxylate, while MLS converts glyoxylate and acetyl-CoA to malate. Furthermore, MFA was previously performed on I. orientalis SD108 growing in minimal media with and without nutrient limitations; all CIT and ACO activities were localized in the mitochondria for all conditions, while minimal ICL and MLS activities were observed in the cytosol33. Therefore, to couple the rTCA pathway with the glyoxylate shunt, decompartmentalization of partial TCA cycle is needed to express functional CIT and ACO in the cytosol (Fig. 1B).

We first attempted to express the endogenous versions of the genes involved in the glyoxylate shunt. S. cerevisiae has three homologs for CIT: ScCIT1, ScCIT2, and ScCIT350. However, through BLAST analysis using these CITs against the genome of I. orientalis SD108, only one CIT homolog (IoCIT) could be identified in I. orientalis. Furthermore, I. orientalis contained two ACO genes (g931 and g3381), but only g3381 was found to be expressed in I. orientalis grown on glycerol from our previous study27. Consistently, we observed that g3381 had much higher mRNA levels compared to g931 in I. orientalis grown on glucose (Supplementary Fig. 8), and we assumed g3381 (IoACO) was the major ACO in I. orientalis. IoCIT and IoACO without their MTSs predicted using TargetP 2.0, IoMLS, and IoICL were expressed in the strain SA-IoPDH, resulting in strain IoGS. Western blotting confirmed the localization of IoCIT and IoACO without their MTSs to the cytosol (Supplementary Fig. 3A). However, further improvement in the SA titer and decrease in the pyruvate accumulation were not observed (Fig. 3B, C, Supplementary Fig. 5A, and Supplementary Fig. 9A). We then expressed the genes involved in the glyoxylate shunt from E. coli (citrate synthase gltA, aconitase AcnA, isocitrate lyase AceA, and malate synthase AceB) in the strain SA-IoPDH, resulting in strain EcGS. Fermentation of the strain EcGS further improved the SA titer from 31.47 g/L to 33.77 g/L as well as decreased the pyruvate accumulation from 7.38 g/L to 4.45 g/L (Fig. 3B, C, Supplementary Fig. 5A, and Supplementary Fig. 9B).

Modulations of carbon fluxes in the rTCA pathway and the glyoxylate shunt to enhance SA production

Following the characterization of the strain EcGS, we attempted to modulate the carbon fluxes through the rTCA pathway and through the glyoxylate shunt to further improve the production of SA. First, we observed an accumulation of 2.69 g/L of malate in the strain EcGS (Fig. 3C). To further channel more carbon flux from malate to SA, an additional copy of FUMR and FRD were expressed in the strain EcGS, resulting in strain EcGS-FF. This strategy further increased the SA titer from 33.77 g/L to 35.58 g/L while decreasing the malate titer from 2.69 g/L to 1.69 g/L and the pyruvate accumulation from 4.45 g/L to 2.04 g/L (Fig. 3B, C and Supplementary Fig. 9B, C), suggesting more carbon flux was channeled from malate to SA.

Then, to further modulate the carbon fluxes in the glyoxylate shunt, all genes or individual genes involved in the glyoxylate shunt pathway from E. coli (gltA, AcnA, AceA, and AceB) were further expressed in the strain EcGS-FF, resulting in strains EcGS-FF-EcGS, EcGS-FF-gltA, EcGS-FF-AcnA, EcGS-FF-AceA, and EcGS-FF-AceB. Compared to the strain EcGS-FF, we observed that the introduction of an additional copy of gltA improved the SA titer from 35.58 g/L to 39.22 g/L (Fig. 3B and Supplementary Fig. 9C, D). There was no further significant decrease in the pyruvate accumulation, but we observed no malate production in the strain EcGS-FF-gltA (Fig. 3C and Supplementary Fig. 9D). On the other hand, there was no significant increase in the SA titers in the other strains with additional expression of AcnA, AceA, AceB, or all four genes (Supplementary Fig. 9E). The SA titer of the strain EcGS-FF-AcnA was lower than that of the strain EcGS-FF, which was likely due to incomplete utilization of glucose (Supplementary Fig. 9F). The increase in the SA titer resulting from the gltA expression was likely due to that CIT is generally considered the rate-limiting enzyme of the TCA cycle51, and the higher gltA expression might channel more flux to the glyoxylate shunt. Lastly, various gene overexpressions were also attempted in the strain EcGS-FF-gltA, including additional copies of gltA, MTS-free IoPDH structural genes, and IoPYC. Nevertheless, no significant increase in the SA titer was observed (Supplementary Fig. 10). Taken together, in shake flask fermentations, our improved strain EcGS-FF-gltA could produce SA at the titer of 39.22 g/L and the yield of 0.78 g/g glucose, exceeding the performance of the previously reported parental strain SA with the titer of 26.45 g/L and the yield of 0.53 g/g glucose (Figs. 2, 3B, Supplementary Fig. 2A and Supplementary Fig. 9D).

Isotope tracing and metabolic flux analyses

Next, we characterized the metabolic flux distributions in our improved strain EcGS-FF-gltA (Fig. 3A) and the parental strain SA using 13C MFA. Fluxes were constrained by experimental data obtained from [U-13C]glucose and [1,2-13C]glucose tracing (each 50:50 with unlabeled glucose), including glucose and oxygen uptake rates, metabolite excretion rates, and growth rate and biomass composition (Supplementary Fig. 11A–C). MFA verified that the strain EcGS-FF-gltA had higher SA production and cytosolic rTCA fluxes compared to the strain SA (Fig. 4A and Supplementary Fig. 11D, E). The strain EcGS-FF-gltA also contained cytosolic PDH and glyoxylate shunt fluxes, which were absent in the strain SA (Fig. 4B, C and Supplementary Fig. 11F). These differences in fluxes were inferred mainly by the changes to input and output fluxes rather than the 13C isotope labeling patterns, which were almost identical between the strains (Supplementary Fig. 12A). This reflected whole cell labeling being ‘blind’ to compartmentation. Instead, the ratios of glucose and oxygen consumptions and SA production were informative (Fig. 4A, Supplementary Fig. 11B, C and Supplementary Fig. 12B, C). Notably, MFA revealed a flux ratio of 10:1.51 between FRD and ICL in the improved strain, approaching the desired 10:2 ratio under maximum SA yield (Fig. 3A).

Improvement in A SA production flux, B cytosolic PDH flux, and C cytosolic ICL flux in the strain EcGS-FF-gltA compared to the strain SA suggested by MFA. Error bars denote the 95% confidence intervals computationally determined by parameter continuation. D Schematic of [4-2H]glucose tracing. [4-2H]glucose labels cytosolic NADH (NAD2H) produced through glycolysis, while NADH produced through cytosolic PDH is unlabeled. FBP fructose-1,6-bisphosphate, DHAP dihydroxyacetone phosphate, GAP glyceraldehyde-3-phosphate, GAPDH glyceraldehyde-3-phosphate dehydrogenase, OAA oxaloacetate, MDH malate dehydrogenase, FUMR fumarase, FRD fumarate reductase, CIT citrate synthase, PDH pyruvate dehydrogenase. E 2H-labeled M + 1 fraction of SA in the wild-type strain (WT), the parental strain SA, and the improved strain EcGS-FF-gltA. The wild-type strain showed no labeling of SA that was synthesized only in mitochondria. The parental strain SA showed 2H-labeling of SA produced through the rTCA pathway driven by NAD2H produced from GAPDH. The improved strain EcGS-FF-gltA showed lower 2H-labeling of SA because NAD2H was diluted with unlabeled NADH produced by cytosolic IoPDH and the glyoxylate shunt produced unlabeled SA without requiring NADH. Error bars, mean ± SD (n = 3 biologically independent samples). Two-tailed unpaired t-test was used to calculate p value. Source data are provided as a Source Data file.

Given that 13C-labeling was relatively uninformative, we then performed isotope tracing analysis using deuterated glucose to assess the rTCA pathway and cytosolic PDH and glyoxylate shunt activities (Fig. 4D). [4-2H]glucose labels cytosolic NAD+ at the glyceraldehyde-3-phosphate dehydrogenase (GAPDH) step of glycolysis, generating 2H-labeled NADH (NAD2H). 2H-labeling was accordingly observed in glucose-6-phosphate but not in the intermediates downstream of GAPDH (Supplementary Fig. 13A–C). No labeling of SA was seen in the wild-type strain, which produced SA in the mitochondria (Fig. 4E and Supplementary Fig. 13D). In contrast, cytosolic SA synthesis via the rTCA pathway driven by NAD2H generated 2H-labeled SA in the parental strain SA (Fig. 4E and Supplementary Fig. 13D). In the improved strain EcGS-FF-gltA, the 2H-labeling of SA decreased in the presence of the cytosolic IoPDH, which produced unlabeled NADH that diluted NAD2H. Furthermore, the glyoxylate shunt was not labeled by cytosolic NAD2H, as evidenced by minimal citrate/isocitrate labeling, and produced unlabeled SA through a redox-neutral mechanism that did not require NADH (Fig. 4E and Supplementary Fig. 13D, E). The 2H-labeling of malate, an intermediate in the rTCA pathway, was also lower in the strain EcGS-FF-gtA compared to the strain SA, mirroring the labeling pattern observed with SA (Supplementary Fig. 13F). Thus, 2H isotope tracing supported PDH and glyoxylate shunt activities in the cytosol.

Fed-batch fermentations of the improved strain and implications for financial viability and environmental benefits

While shake flask fermentations are typically used to evaluate and optimize engineered strains, high fermentative performance achieved at small scale must be consistently transferable to a more industrially relevant scale to enable practical application. The strain EcGS-FF-gltA was cultivated in fed-batch fermentations at pH 3 in bioreactors. The fermentation conditions were optimized to determine the optimal flow rates of O2 and CO2, and the highest SA yield was attained at 0.025 vvm O2 and 0.33 vvm CO2 (Supplementary Fig. 14). Under this condition, the strain could produce SA at a titer of 104.28 g/L, a yield of 0.85 g/g, and a productivity of 0.97 g/L/h using SC-URA medium with glucose as the sole carbon source (Fig. 5A and Supplementary Fig. 15A). Pyruvate was detected as a by-product at 3.47 g/L. On the other hand, the parental strain SA could produce SA at a titer of 88.86 g/L, a yield of 0.55 g/g, and a productivity of 0.37 g/L/h with high pyruvate accumulation reaching up to 24.40 g/L during the fermentation process (Supplementary Fig. 16A, B). Furthermore, instead of using amino acid dropout mixture, corn steep liquor (CSL) was utilized as a cheaper nitrogen source. Using CSL medium with glucose as a sole substrate, the strain could produce SA at a titer of 101.86 g/L, a yield of 0.80 g/g, and a productivity of 0.94 g/L/h (Fig. 5B and Supplementary Fig. 15B).

Fed-batch fermentations of the strain EcGS-FF-gltA in (A) SC-URA medium and (B) CSL medium containing glucose as a sole carbon source at pH 3. Fermentations were performed in duplicate (n = 2 independent experiments). The fermentation profile shown here for each medium represents the result of one fed-batch fermentation; the result of another replicate is shown in Supplementary Fig. 15. Source data are provided as a Source Data file.

We also performed techno-economic analysis (TEA) and life cycle assessment (LCA) under uncertainty (2000 Monte Carlo simulations) to characterize the financial viability and carbon intensity (CI) of potential biomanufacturing facilities that leveraged the parental strain SA and the improved strain EcGS-FF-gltA. The strain SA could enable SA production at an estimated minimum product selling price (MPSP) of $1.30/kg [$1.17 − 1.46/kg; 5th−95th percentiles, hereafter in brackets; Supplementary Fig. 17A]. On the other hand, the improved strain could enable SA production at an MPSP of $0.97/kg [$0.84 − 1.19/kg], which was lower than the market price range in 100% of simulations and lower than the reported bio-based SA MPSP range in >79% of simulations (Supplementary Fig. 17A). The improved strain also represents substantially enhanced financial viability over a previously reported MPSP of $1.06/kg [$0.96 − 1.22/kg, lower than the reported bio-based MPSP range in >50% of simulations] for I. orientalis in a study that used the same process models as this study, primarily due to the substantially greater fermentation SA yield achieved in this study (0.83 vs. 0.57 g-SA/g-glucose-added)27. For both the parental (1.32 kg CO2-eq./kg [0.95 − 1.71 kg CO2-eq./kg]) and improved (1.34 kg CO2-eq./kg [1.09 − 1.68 kg CO2-eq./kg]) strains, the estimated CI was consistently lower than the CI range of fossil-based SA as well as the range of CIs reported for other bio-based SA production routes (Supplementary Fig. 17B).

Enhanced production of acetyl-CoA-derived molecules through cytosolic expression of the endogenous PDH complex

Through the decompartmentalization of mitochondrial pyruvate oxidation to enhance cytosolic NADH levels, we were able to improve the SA production in I. orientalis. In addition to NADH, acetyl-CoA is a product of pyruvate oxidation catalyzed by PDH. It is a central metabolite and an important precursor for the production of various industrially relevant chemicals10,52. In non-oleaginous yeasts, such as S. cerevisiae and I. orientalis, cytosolic acetyl-CoA is mainly synthesized through the native PDH bypass, which consists of pyruvate decarboxylase (PDC), acetaldehyde dehydrogenase (ALD), and acetyl-CoA synthetase (ACS)53 (Fig. 6A). This pathway proceeds through the intermediate acetaldehyde, which is toxic to the cells, and is energetically expensive as the conversion of acetate to acetyl-CoA catalyzed by ACS requires 2 ATP equivalents39. On the other hand, the production of acetyl-CoA through the PDH in the mitochondria does not involve acetaldehyde or require ATP and thus provides an energetic advantage over the analogous PDH bypass pathway in the cytosol. Here, we sought to expand I. orientalis into a platform organism for the production of molecules derived from acetyl-CoA. Citramalic acid (CA) is an important platform chemical that can be converted to methacrylic acid, a precursor for methyl methacrylate54. The key enzyme to produce CA is citramalate synthase, which performs a Claisen condensation to generate CA from pyruvate and acetyl-CoA. A codon-optimized citramalate synthase (cimA) from Methanocaldococcus jannasch was expressed in I. orientalis SD108 using the PiggyBac transposon system previously, enabling the production of 2.0 g/L of CA in shake flask fermentations55. We expressed cimA in the wild-type I. orientalis SD108 and generated strain SD108-cimA that could produce CA at a titer of 3.33 g/L (Fig. 6B). Glycerol and ethanol were the by-products and produced at titers of 3.26 g/L and 3.95 g/L, respectively. Co-expression of cimA with the MTS-free IoPDH structural genes in the wild-type I. orientalis SD108 resulted in strain SD108-IoPDH-cimA. As expected, the CA titer of the strain SD108-IoPDH-cimA reached 4.08 g/L, a 1.22-fold increase compared to the CA titer of the strain SD108-cimA (Fig. 6B). We also observed no production of ethanol and a higher accumulation of glycerol in the strain SD108-IoPDH-cimA, which reached 10.71 g/L.

A A schematic diagram for enhanced production of acetyl-CoA-derived products in I. orientalis. Genes involved in the PDH bypass are marked in blue. PDC pyruvate decarboxylase, ALD aldehyde dehydrogenase, ACS acetyl-CoA synthetase, PDH pyruvate dehydrogenase, cimA citramalate synthase, 2-PS 2-pyrone synthase, OAA oxaloacetate. B CA, glycerol, and ethanol titers in SD108-cimA and SD108-IoPDH-cimA. C TAL, glycerol, and ethanol titers in SD108-GhPS and SD108-IoPDH-GhPS. Fermentations were performed in shake flasks using SC-URA medium containing 50 g/L glucose and 5 g/L of calcium carbonate. Error bars, mean ± SD (n = 3 biologically independent samples). Two-tailed unpaired t-test was used to calculate p values. Source data are provided as a Source Data file.

Since I. orientalis can tolerate highly acidic conditions, it has been used as a host to produce mainly organic acids27,56,57. To further expand the repertoire of molecules that can be produced using I. orientalis, we attempted to engineer I. orientalis to produce triacetic acid lactone (TAL), which is another acetyl-CoA-derived molecule. TAL is a platform chemical to produce food ingredients and commercially valuable chemical intermediates and end products58. 2-Pyrone synthase catalyzes the formation of TAL via two iterative decarboxylation/condensation reactions using a starter acetyl-CoA and two extender malonyl-CoA molecules. The 2-pyrone synthase from Gerbera hybrida (GhPS) codon-optimized for expression in S. cerevisiae59 was introduced to the I. orientalis SD108 strain, leading to strain SD108-GhPS that could produce 28.83 mg/L of TAL, 2.00 g/L of glycerol, and 7.52 g/L of ethanol in shake flask fermentation (Fig. 6C). Expression of the MTS-free IoPDH structural genes in the strain SD108-GhPS led to strain SD108-IoPDH-GhPS with a TAL production of 125.27 mg/L, or a 4.35-fold improvement compared to strain SD108-GhPS (Fig. 6C). Additionally, the strain SD108-IoPDH-GhPS produced no ethanol, and glycerol accumulated at a titer of 4.99 g/L. Unlike the SA production, the CA and TAL productions do not require the reducing equivalent NADH. The glycerol accumulation was likely due to redox balance to overcome the additional NADH produced by the cytosolic IoPDH expression. On the other hand, overexpression of the endogenous PDH bypass in the strains SD108-cimA and SD108-GhPS did not lead to significant increases in the CA and TAL titers, respectively, further reinforcing the fact that the PDH bypass route suffers from low flux and high energy input requirements (Supplementary Fig. 18A,B). Overall, our results indicated that higher acetyl-CoA and NADH were successfully generated in the cytosol, benefiting the production of chemicals requiring such precursor and cofactor.

Discussion

Due to the highly compartmentalized cofactor metabolisms in eukaryotes, the production of highly reduced chemicals, such as SA, in yeasts remains more challenging than in bacterial counterparts. Organelle compartmentalization can mitigate such challenges and focuses on targeting a metabolic pathway from the cytosol into a subcellular compartment to exploit the desired resources, such as precursors and cofactors, in situ. For example, to leverage the elevated NADH concentration in the mitochondria, the rTCA pathway was localized to the mitochondria and coupled with the oTCA pathway in an engineered Yarrowia lipolytica60. With the rTCA pathway serving as a sink of NADH produced by the oTCA pathway, the engineered Y. lipolytica produced SA at a titer of 111.9 g/L and a yield of 0.79 g/g glucose in fed-batch fermentations using minimal medium. Nevertheless, while metabolic compartmentalization has been successfully employed to produce various molecules, it still suffers from drawbacks such as product and intermediate transport and accumulation61. Furthermore, targeting long biosynthetic pathways containing multiple enzymes into an organelle with smaller volume than the cytosol can potentially induce metabolic burden and interfere with the organelle’s native functions61. Therefore, cytosolic engineering remains more mainstream than organelle engineering.

Previously, we engineered I. orientalis SD108 to produce SA using the rTCA pathway at low pH27. However, the lack of cytosolic NADH remained the major bottleneck for higher fermentative performance and limited the yield to only 1 mol/mol or 0.66 g/g using glucose as sole carbon source. In this study, we decompartmentalized the mitochondrial metabolism by expressing relevant mitochondrial enzymes in the cytosol to increase cytosolic NADH level and SA production. First, we found that the localization of its endogenous IoPDH to the cytosol in the strain SA significantly improved the SA production and reduced the pyruvate accumulation (Fig. 2). In contrast, the strain SA without cytosolic IoPDH expression exhibited a clear diauxic growth with an initial glucose consumption phase that produced 25.26 g/L of SA and 17.44 g/L of pyruvate (Supplementary Fig. 2A). Upon glucose exhaustion, the pyruvate was then consumed with negligible increase in the SA titer. Previous MFA consistently suggested that the high accumulation of pyruvate was due to low mitochondrial activity before glucose depletion and that the utilization of the pyruvate in the later stage of fermentation occurred in the mitochondria27. Therefore, during the pyruvate consumption phase, the NADH produced through pyruvate oxidation in the mitochondria could not be utilized by the rTCA pathway in the cytosol, leading to insignificant increase in the SA titer. On the other hand, the strain SA-IoPDH showed maximal pyruvate accumulation at 7.38 g/L and produced 31.47 g/L of SA and 3.36 g/L of pyruvate when glucose was all consumed (Fig. 2 and Supplementary Fig. 5A). The lower pyruvate accumulation in the strain SA-IoPDH suggested that the reducing equivalents of mitochondrial NADH, which were produced through mitochondrial pyruvate oxidation during the late-stage pyruvate consumption in the strain SA and did not contribute to the cytosolic SA production, were effectively shuttled to the cytosol, increasing the SA production.

Next, we performed further decompartmentalization of partial TCA cycle to couple a glyoxylate shunt with the rTCA pathway. The glyoxylate shunt partially bypasses the NADH-dependent MDH, enabling malate production from oxaloacetate without consuming NADH and thereby conserving NADH. Thus, it is an ideal complement to the rTCA pathway, which suffers from limited NADH availability. We found that the expression of the genes associated with the glyoxylate shunt from E. coli further improved the SA titer (Fig. 3B). On the other hand, the expression of the endogenous counterparts did not enhance the SA production, possibly because the yeast ICL is inactivated through phosphorylation in the presence of glucose62. Further modulations of carbon fluxes through the rTCA pathway and the glyoxylate shunt were performed, and the improved strain EcGS-FF-gltA produced SA entirely in the cytosol at the titer of 104.28 g/L and the yield of 0.85 g/g in fed-batch fermentations (Fig. 5A and Supplementary Fig. 15A). Such a yield surpasses the yield biologically limited by the shortage of cytosolic NADH (0.66 g/g) and outperforms the yields achieved in previously engineered organisms using minimal medium containing only glucose as a carbon source under low pH conditions. (Table 1). Furthermore, 2H-isotope tracing analysis showed the dilution of 2H-labeled SA and thus suggested the presence of both cytosolic PDH and glyoxylate shunt activities in our improved strain (Fig. 4D, E).

MFA suggested that the ratio of metabolic flux between FRD and ICL (10:1.51) in the improved strain closely matched the corresponding ratio (10:2) at the theoretical yield of SA (Fig. 3A). Also, the flux ratio between PYC and PDH in our improved strain (10:2.19) was higher than that at the maximum SA yield (10:4) (Fig. 3A), indicating either excessive PYC flux or inadequate PDH flux than necessary. Although we did not observe further improvement in the SA production when another copy of the MTS-free IoPDH structural genes was expressed in the strain EcGS-FF-gltA (Supplementary Fig. 10), improvement in the SA production could potentially be attained by further modulation of the carbon fluxes at the pyruvate node, such as by lowering PYC activity or limiting pyruvate consumption in the mitochondria. Finally, the reduction in SA titer in the strain EcGS-FF-EcGS could be attributed to a decrease in FRD flux and an increase in ICL flux, compared to the improved strain EcGS-FF-gltA (Supplementary Fig. 11G). MFA thus suggested that overexpression of an additional copy of the glyoxylate shunt pathway diverted more flux from the rTCA cycle to the glyoxylate shunt. This shift explained the reduced SA titer as the rTCA pathway still contributes more toward SA production than the glyoxylate shunt.

The successful reconstitution of the endogenous IoPDH to the cytosol indicated the potential of I. orientalis to produce molecules derived from acetyl-CoA, which is another product of the pyruvate oxidation catalyzed by PDH. In yeasts, cytosolic acetyl-CoA is mainly synthesized through the PDH bypass, which is energetically costly39. Furthermore, ACS is subjected to feedback inhibition by high acetyl-CoA levels, and carbon fluxes usually go from acetaldehyde to ethanol, instead of acetate, during glucose fermentation. On the other hand, the direct conversion of pyruvate to acetyl-CoA through the oxidative decarboxylation catalyzed by PDH requires less ATP and involves no intermediates. Accordingly, we showed that cytosolic IoPDH expression further enhanced the production of CA and TAL by 1.22- and 4.35-folds, respectively (Fig. 6B, C).

Also, for PDH to have catalytic function, the E2 subunit needs to contain a lipoyl group that is covalently attached to a lysine residue of the enzyme38. Because all the known proteins and protein complexes containing a lipoyl group (including PDH, α-ketoglutarate dehydrogenase, the branched chain α-keto acid dehydrogenase complexes, and the H protein of the glycine cleavage system) are found in the mitochondria in eukaryotes, it has long been believed that the lipoylation machinery, including the synthesis and the attachment of the lipoyl group, is also localized in the same compartment38,63. In this study, we found that the cytosolic IoPDH was functional without co-expression of a lipoylation machinery dependent on LA or octanoic acid in the cytosol, and its activity in the cytosol was supported by 2H isotope tracing and 13C metabolic flux analyses (Fig. 4). This is not unprecedented, however, as two previously studies also reported that the cytosolic expression of PDH complexes from E. coli or S. cerevisiae improved the production of chemicals derived from acetyl-CoA, including 1-butanol and TAL, in S. cerevisiae without expression of a lipoylation pathway in the cytosol34,64. Further studies are necessary to determine how cytosolic PDH can remain functional without a cytosolic lipoylation machinery in yeasts. Still, the industrial applications of our engineered I. orientalis with the cytosolic IoPDH expression would not be hampered by the high cost of LA.

In conclusion, we performed decompartmentalization of mitochondrial metabolism to redistribute mitochondrial functions to the cytosol to enhance cytosolic NADH level and boost SA production. Beyond its conventional use for increasing cytosolic acetyl-CoA levels, we demonstrated the use of a cytosolic PDH to shuttle the reducing equivalents of mitochondrial NADH to the cytosol, enabling the production of a markedly reduced chemical whose synthesis demands significantly more reducing cofactors than are naturally available in the cytosol. Furthermore, to our knowledge, this study provides the earliest report of coupling a glyoxylate shunt with an rTCA pathway in the cytosol to enhance SA production in a yeast species. Our study has established a foundation for using I. orientalis as a platform organism to produce both highly reduced chemicals as well as acetyl-CoA-derived chemicals.

Methods

Strains, media, and chemicals

The strains used in this study are listed in Supplementary Data 1. E. coli DH5α was used to maintain and amplify plasmids and was grown in Luria Bertani medium (1% tryptone, 0.5% yeast extract, 1% NaCl) at 37 °C with ampicillin (100 µg/mL). S. cerevisiae HZ848, I. orientalis SD108, and their mutants were propagated at 30 °C in YPAD medium (1% yeast extract, 2% peptone, 0.01% adenine hemisulphate, and 2% glucose). Yeast transformants were cultured or selected in the Synthetic Complete (SC) dropout medium lacking uracil (SC-URA) (5 g/L of ammonium sulfate, 1.67 g/L of yeast nitrogen base, 0.83 of g/L synthetic complete supplement mixture of amino acids without uracil, and 20 g/L of glucose). LB broth, bacteriological grade agar, yeast extract, peptone, yeast nitrogen base (w/o amino acid and ammonium sulfate), and ammonium sulfate were purchased from Difco (BD, Sparks, MD), while synthetic complete supplement mixture of amino acids without uracil was obtained from MP Biomedicals (Solon, OH). All restriction endonucleases and Q5 DNA polymerase were purchased from New England Biolabs (Ipswich, MA). QIAprep Spin Miniprep Kit was purchased from Qiagen (Valencia, CA), and Zymoclean Gel DNA Recovery Kit and Zymoprep Yeast Plasmid Miniprep Kits were purchased from Zymo Research (Irvine, CA). All other chemicals and consumables were purchased from Sigma-Aldrich (St. Louis, MO), VWR (Radnor, PA), and Fisher Scientific (Pittsburgh, PA). Oligonucleotides including gBlocks and primers were synthesized by Integrated DNA Technologies (Coralville, IA).

Plasmids and strains construction

The plasmids and primers used in this study are listed in Supplementary Data 2 and 3, respectively. Genes were codon optimized and synthesized by Twist Bioscience (San Francisco, CA). Plasmids were generated by the DNA assembler method in S. cerevisiae65 and Gibson assembly66 in E. coli. For DNA assembly, 100 ng of PCR-amplified fragments and restriction enzyme digested backbone were co-transformed into S. cerevisiae HZ848 via the electroporation method. Transformants were plated on SC-URA plates and incubated at 30 °C for 48–72 h. Yeast plasmids were isolated and transformed to E. coli for enrichment. E. coli plasmids were extracted and verified by restriction digestion. The lithium acetate-mediated method was used to transform yeast strains with plasmids and donor DNA fragments67. The details of plasmid construction procedures are described in Supplementary Method 1, while the details of strain construction procedures are described in Supplementary Method 2.

qPCR analysis

The strain SA was inoculated in YPAD medium and grown at 30 °C with constant shaking at 250 rpm overnight. The cells were then subcultured into fresh YPAD medium with the initial OD600 of 0.2 and grown until the OD600 reached 1. Cells were collected from 1 mL of culture, and total RNA was extracted using the RNeasy mini kit from Qiagen (Valencia, CA). cDNA synthesis was performed using iScript™ Reverse Transcription Supermix from BioRad (Hercules, CA), and iTaq Universal SYBR Green Supermix from BioRad (Hercules, CA) was used for qPCR following the manufacturer’s protocol. Primers for qPCR were designed using the IDT online tool (Primer Quest). The endogenous gene alg9, encoding a mannosyltransferase, was used as the internal control. Expression of the selected gene was normalized by the alg9 expression level. Raw data was analyzed using QuantStudioTM Real-time PCR software from Applied Biosystems (Waltham, MA). qPCR analysis was performed with two biological duplicates.

Fermentation experiments

For shake flask fermentations, single colonies of I. orientalis strains were inoculated into 2 mL of liquid YPAD medium with 20 g/L of glucose and cultured at 30 °C for 1 day. Then, the cells were subcultured into 2 mL of liquid SC-URA medium with 20 g/L of glucose and grown at 30 °C for 1 day to synchronize the cell growths. Cells were diluted to an initial OD600 of 0.2 and transferred into 20 mL of SC-URA liquid medium containing 50 g/L glucose and 5 g/L of calcium carbonate in 125 mL Erlenmeyer flask. The SC-URA medium was supplemented with 1 µg/L of lipoic acid or 5 mg/L of octanoic acid as necessary. The cells were cultivated at 30 °C at 250 rpm. Samples were collected every 24 h for HPLC analysis. Shake flask fermentations were conducted with three biological replicates.

For fed-batch fermentations in bench-top bioreactors (DASbox, Eppendorf, Hamburg, Germany), single colonies of I. orientalis strains were inoculated into 2 mL liquid YPAD medium with 20 g/L of glucose and cultured for 1 day. Then, the cells were subcultured into 2 mL liquid SC-URA medium with 20 g/L of glucose and grown for 1 day. 1 mL of culture was then added into 100 mL of liquid SC-URA medium or CSL medium containing 50 g/L of glucose in the DASbox. The CSL medium contained 10 g/L of corn steep liquor, 5 g/L of ammonium sulfate, 1 g/L of monopotassium phosphate, 0.5 g/L of magnesium sulfate, 0.1 g/L of sodium chloride, and 0.1 g/L of calcium chloride and was supplemented with trace metals (500 μg/L of boric acid, 40 μg/L of copper sulfate, 100 μg/L of potassium iodide, 200 μg/L of ferric chloride, 400 μg/L of manganese sulfate, 200 μg/L of sodium molybdate, and 5 mg/L of zinc sulfate) and vitamins (2 μg/L of biotin, 400 μg/L of calcium pantothenate, 2 μg/L of folic acid, 2 mg/L of inositol, 400 μg/L of niacin, 200 μg/L of p-aminobenzoic acid, 400 μg/L of pyridoxine hydrochloride, 200 μg/L of riboflavin, 400 µg/L of thiamine hydrochloride). The cells were cultivated at 30 °C and 800 rpm. pH was maintained at 3 using 4 N HCl and 4 N KOH. Industrial-grade CO2 and O2 gasses were continuously sparged into the bioreactors at flow rates of 0.2–0.417 vvm and 0.025-0.05 vvm (volume per working volume per min), respectively. One drop of Antifoam 204 (Sigma-Aldrich, St. Louis, MO) was added to control foaming if necessary. Upon glucose depletion, additional glucose was added to the bioreactors. Samples were collected every 24 h for HPLC analysis. Fed-batch fermentations were conducted with two biological replicates.

Analytical methods

Extracellular glucose, pyruvate, SA, malate, CA, glycerol, and ethanol concentrations in fermentation broths were analyzed using the Agilent 1200 HPLC system equipped with a refractive index detector (Agilent Technologies, Wilmington, DE) and Rezex ROA-Organic Acid H+ (8%) column (Phenomenex, Torrance, CA). The column and detector were run at 50 °C, and 0.005 N H2SO4 was used as the mobile phase at flow rate of 0.6 mL/min.

TAL quantification was carried out on an Agilent 1260 Infinity series instrument equipped with a diode array detector using a Phenomenex Kinetex® 5 µm EVO C18 100 Å LC column (150 × 4.6 mm2; Phenomenex). The solvent system included solvent A (water supplemented with 0.1% trifluoroacetic acid) and B (acetonitrile supplemented with 0.1% trifluoroacetic acid). The elution process ran the following program: 2% B to 7% B (linear gradient, 0–5 min), 7% B to 95% B (5–6 min), 95% B (isocratic elution, 6–8 min), 95% B to 2% B (8–9 min), 2% B (isocratic elution, 9–11 min). Full wavelength scanning (UV/Vis) and liquid chromatography-mass spectrometry (LC-MS) were performed to determine the specific absorbance and molecular weight of the target products using >98.0% purity TAL as a reference. LC-MS analysis was performed on a Waters Synapt G2-Si ESI/LC-MS, equipped with ESI-positive ion mode (Bruker, Amazon SL Ion Trap) and a Kinetex 2.6-μm XB-C18 100 Å (Phenomenex).

Western blot analysis

The plasmids for expression of His-tagged proteins or GFP fusion proteins were transformed to SD108/ura3∆. Colonies were picked and cultivated in 2 mL of liquid SC-URA medium containing 20 g/L of glucose at 30 °C with shaking at 250 rpm for 2 days. Then, the cultures were subcultured into 2 mL of liquid SC-URA medium containing 50 g/L of glucose for 2 days. The cells were collected and washed twice with water. To extract the cytosol, the yeast mitochondria isolation kit (ab178779, Abcam, Waltham, MA) was used to isolate the mitochondria from the cytosol, and the cytosol was concentrated by Microcon® Centrifugal Filters (MRCPRT010, Millipore, Burlington, MA). After sample preparation, SDS-PAGE was run at standard condition, and the Western blot was then performed. To determine the expression of His-tag proteins, 6x-His Tag Monoclonal Antibody (HIS.H8), HRP (Thermo Fisher Scientific, Waltham, MA) was used as the primary antibody. To determine the expression of GFP fusion proteins, GFP Monoclonal Antibody (GF28R) (Thermo Fisher Scientific, Waltham, MA) was used as the primary antibody. The antibodies were used at 1:1000 dilution. Western blot analysis was performed with one biological replicate.

NADH quantification

Three colonies of the strains SD108/pdc∆/gpd∆ and SD108/pdc∆/gpd∆/IoPDH were inoculated into 2 mL of liquid YPAD medium with 20 g/L of glucose and cultivated at 30 °C with shaking at 250 rpm for 1 day. The resulting cultures were subcultured into 2 mL of liquid YPAD medium with 20 g/L of glucose and grown for 1 day. Then, 14 mL of 60% methanol (pre-chilled to –40 °C) was added to the cultures, and the resulting mixtures were mixed for 1 s. The cells were collected and washed with water twice at 4 °C. Cells were lysed using FastPrep-24 5 G for 20 s (6.0 m/s), and the lysed cycle was repeated twice. In each interval, the samples were placed on ice for 2 min. NAD+/NADH Assay Kit (MAK460, Sigma-Aldrich, St. Louis, MO) was used to determine intracellular NADH and NAD+ concentrations and NADH/NAD+ ratios. NADH quantification was performed with three biological replicates.

13C metabolic flux and 2H isotope tracing analyses

To determine growth rate and uptake fluxes of glucose and oxygen, the strains SA, EcGS-FF-gltA, and EcGS-FF-EcGS were grown overnight in yeast nitrogen base (YNB) medium without amino acids (Y0626, Sigma-Aldrich, St. Louis, MO) consisting of 0.5% glucose and then inoculated in YNB medium at OD600 of 0.05. Growth rates (μ) and glucose consumption rate were determined by sampling cultures at 4–6 different times points (t) during the exponential growth phase, starting from an OD600 of about 0.1 after allowing the culture to adapt in fresh medium (about 3 h for parental strain and 12 h for improved strain). At each time point, the OD600 was measured, and the supernatant was saved for analysis of metabolite concentration. Glucose concentration was electrochemically measured using 2900D Biochemistry Analyzer with 2324 glucose starter kit (YSI Incorporated, Yellow Springs, Ohio). The growth rate was determined by assuming OD600 changes exponentially, while the glucose was assumed to be depleted linearly with time.

Oxygen consumption rate (OCR) was measured with a Clark-type dissolved oxygen probe (B40PCID, 89231624, VWR, Radnor, PA). Similarly to growth and glucose flux measurement, the yeasts were inoculated into fresh YNB medium at 2% glucose and an initial OD of 0.05. The culture was transferred into a glass vial. The temperature during the measurement was maintained at 30 °C using a water bath. The culture was first manually oxygenated by shaking the glass vial for 15 s and then sealed in with the temperature-equilibrated probe. Dissolved oxygen was measured every 20 s for 5 min or until the oxygen dropped to 60% saturation. During measurements, the culture was gently mixed with a magnetic stirrer. The resulting OD600 during the oxygen measurement 0.2 to 0.3 for the strain SA and 0.6 to 0.8 for the strain EcGS-FF-gltA. The OCR was then calculated by linear fitting of the oxygen concentration change over time.

For 13C isotope tracing analysis, the strains SA, EcGS-FF-gltA, and EcGS-FF-EcGS were cultured in media with [U-13C6] glucose or [1,2-13C2] glucose (Cambridge Isotope Laboratories, Tewksbury, MA) at 50% enrichment. The strains were first grown overnight and then inoculated into fresh media at OD600 of 0.1. The cultures were allowed to grow for 24-36 h to reach OD600 of 1.5. For 2H isotope tracing analysis, the wild-type, SA, and EcGS-FF-gltA strains were cultured in media with [4-2H1] glucose (Omicron Biochemicals Inc., South Bend, IN) at 100% enrichment. The strains were first grown overnight and then inoculated into fresh media at OD600 of 0.2. The cultures were allowed to grow for 12-20 h to reach OD600 around 1.5. Isotope tracing analysis was performed with three biological replicates.

For intracellular metabolite extraction, about 1000 µL of cell culture at OD600 around 1.5 was quickly vacuum filtered through a GVS Magna™ Nylon membrane filter with 0.5 µm pore size (Fisher Scientific, Pittsburgh, PA), quenched in 1 mL of ice-cold solution of 40:40:20 methanol:acetonitrile:water with 0.5% formic acid for about 1 min, and then neutralized with 88 µL of 15.8% ammonium bicarbonate. The extracts were centrifuged at 17,000 x g for 10 min, and the supernatants were analyzed by LC-MS.

LC analysis was performed using a Vanquish UHPLC system (Thermo Fisher Scientific, Waltham, MA) and Xbridge BEH Amide HILIC column (2.1 mm × 150 mm, 2.5 µm particle size, 130 Å pore size). The LC method has a 25-min solvent gradient at a flow rate of 150 µL/min, with the following gradient parameters: 0 min, 90% B; 2 min, 90% B; 3 min, 75%; 7 min, 75% B; 8 min, 70%, 9 min, 70% B; 10 min, 50% B; 12 min, 50% B; 13 min, 25% B; 14 min, 25% B; 16 min, 0% B, 20.5 min, 0% B; 21 min, 90% B; 25 min, 90% B, where Solvent A was 95:5 water:acetonitrile with 20 mM ammonium hydroxide and 20 mM ammonium acetate (pH 9.4) and solvent B was acetonitrile. The autosampler temperature was 4 °C, the column temperature was 25 °C, and the injection volume was 5 μL. LC was coupled to a quadrupole Orbitrap Exploris 480 mass spectrometer (Thermo). The MS scan was operated in negative mode, with the following parameters: resolution, 140,000; scan range, m/z 70–1000; normalized AGC target 1000; ITmax, 500 ms. Other instrument parameters are spray voltage 3000 V, sheath gas 35 (Arb), aux gas 10 (Arb), sweep gas 0.5 (Arb), ion transfer tube temperature 300 °C, vaporizer temperature 35 °C, internal mass calibration on, RF lens 50. Data were collected with XCalibur (Thermo Fisher Scientific, Waltham, MA).

Raw LC/MS data were converted to mzXML format by msconvert from ProteoWizard68 (https://proteowizard.sourceforge.io, version 3). Peak extraction of the raw data for cells growing in unlabeled media was performed using the El-Maven software package (https://elucidatainc.github.io/ElMaven, v.0.12.1-beta). 13C natural isotope abundance was corrected using the Accucor R package69 (https://github.com/lparsons/accucor). A conversion factor of 0.34 grams dry weight per OD600 per liter was used to convert OD600 to a cell dry weight unit.

13C metabolic flux analysis was performed with a customized core atom mapping model with redox balance (Supplementary Data 4) in the INCA2.3 Suite70. The flux solution that best fit the mass isotope distribution of 26 metabolites under the constraint of glucose, oxygen, malate, pyruvate, SA secretion fluxes, and growth rate was determined. SA and byproduct secretion fluxes were estimated by scaling the measured glucose uptake with the mean fermentation yield. Flux lower and upper bounds were obtained using parameter continuation using a 5% confidence level71.

Biomanufacturing facility design, techno-economic analysis, and life cycle assessment

To perform the techno-economic analyses and life cycle assessment presented in this work, we leveraged BioSTEAM, an open-source platform in Python72. Briefly, influent and effluent streams of each unit were simulated by BioSTEAM and coupled with operating parameters and equipment cost algorithms for unit design and cost calculations. The MPSP was estimated in 2016$. The functional unit of the TEA and LCA was 1 kg of SA in the product stream. Carbon intensity was estimated as 100-year global warming potential using the IPCC 2013 100-year global warming potential methodology with a cradle-to-grave LCA scope (assuming the end-of-life degradation of SA entirely to CO2). The system boundary of the LCA was the entire biorefinery, including feed sugarcane juicing and clarification, fermentation, separation, wastewater resource recovery, a boiler, and a turbogenerator27. All process modeling assumptions were identical to those reported previously27, except the altered baseline values and uncertainty distributions for fermentation titer, yield, and productivity to represent the fermentation performance achieved in this study (Supplementary Table 1). All assumed environmental impacts and prices (with references), Python scripts for BioSTEAM and the biomanufacturing facility (including facility setup and system analyses), baseline values and uncertainty distributions of all key parameters, and full system reports (including detailed process flow diagrams, stream composition and cost tables, unit design specifications, and utilities for the baseline simulations) are available in the online repository73.

Reporting summary

Further information on research design is available in the Nature Portfolio Reporting Summary linked to this article.

Data availability

The data supporting the findings of this work are available within the paper and its Supplementary Information files or uploaded through public repositories. The data are also available from the corresponding author upon request. The LC-MS data generated in this study have been deposited to MassIVE with the dataset identifier MSV000098422 [https://massive.ucsd.edu/ProteoSAFe/dataset.jsp?task=cfd28e8eabd04f239c4f77c6e1fdfa7a]. The DNA sequences of all plasmids constructed in this study are provided as Supplementary Data 5. Source data are provided with this paper.

Code availability

Python scripts for BioSTEAM, the biomanufacturing facility, and full system reports can be found on Github [https://github.com/BioSTEAMDevelopmentGroup/Bioindustrial-Park/tree/master/biorefineries/succinic].

References

Kim, G. B., Choi, S. Y., Cho, I. J., Ahn, D.-H. & Lee, S. Y. Metabolic engineering for sustainability and health. Trends Biotechnol. 41, 425–451 (2023).

Volk, M. J. et al. Metabolic engineering: Methodologies and applications. Chem. Rev. https://doi.org/10.1021/acs.chemrev.2c00403 (2022).

Yuan, S. F. & Alper, H. S. Metabolic engineering of microbial cell factories for production of nutraceuticals. Microb. Cell Factories 18, 46 (2019).

Han, T., Nazarbekov, A., Zou, X. & Lee, S. Y. Recent advances in systems metabolic engineering. Curr. Opin. Biotechnol. 84, 103004 (2023).

Chen, R. et al. Engineering cofactor supply and recycling to drive phenolic acid biosynthesis in yeast. Nat. Chem. Biol. 18, 520–529 (2022).

Berrıos-Rivera, S. J., Bennett, G. N. & San, K. Y. Metabolic engineering of Escherichia coli: increase of NADH availability by overexpressing an NAD+-dependent formate dehydrogenase. Metab. Eng. 4, 217–229 (2002).

Yu, T. et al. Metabolic reconfiguration enables synthetic reductive metabolism in yeast. Nat. Metab. 4, 1551–1559 (2022).

Bakker, B. M. et al. Stoichiometry and compartmentation of NADH metabolism in Saccharomyces cerevisiae. FEMS Microbiol. Rev. 25, 15–37 (2001).

Croft, T., Venkatakrishnan, P. & Lin, S. J. NAD+ metabolism and regulation: lessons from yeast. Biomolecules 10, 330 (2020).

Krivoruchko, A., Zhang, Y., Siewers, V., Chen, Y. & Nielsen, J. Microbial acetyl-CoA metabolism and metabolic engineering. Metab. Eng. 28, 28–42 (2015).

Bakker, B. M. et al. The mitochondrial alcohol dehydrogenase Adh3p is involved in a redox shuttle in Saccharomyces cerevisiae. J. Bacteriol. 182, 4730–4737 (2000).

Larsson, C. et al. The importance of the glycerol 3-phosphate shuttle during aerobic growth of Saccharomyces cerevisiae. Yeast 14, 347–357 (1998).

Easlon, E., Tsang, F., Skinner, C., Wang, C. & Lin, S. J. The malate–aspartate NADH shuttle components are novel metabolic longevity regulators required for calorie restriction-mediated life span extension in yeast. Genes Dev. 22, 931–944 (2008).

Liu, J., Li, H., Zhao, G., Caiyin, Q. & Qiao, J. Redox cofactor engineering in industrial microorganisms: strategies, recent applications and future directions. J. Ind. Microbiol. Biotechnol. 45, 313–327 (2018).

Chen, X., Li, S. & Liu, L. Engineering redox balance through cofactor systems. Trends Biotechnol. 32, 337–343 (2014).

Jin, K. et al. Compartmentalization and transporter engineering strategies for terpenoid synthesis. Microb. Cell Factories 21, 92 (2022).

Duran, L., López, J. M. & Avalos, J. L. Viva la mitochondria!: harnessing yeast mitochondria for chemical production. FEMS Yeast Res. 20, foaa037 (2020).

Chen, L., Xiao, W., Yao, M., Wang, Y. & Yuan, Y. Compartmentalization engineering of yeasts to overcome precursor limitations and cytotoxicity in terpenoid production. Front. Bioeng. Biotechnol. 11, 1132244 (2023).

Avalos, J. L., Fink, G. R. & Stephanopoulos, G. Compartmentalization of metabolic pathways in yeast mitochondria improves the production of branched-chain alcohols. Nat. Biotechnol. 31, 335–341 (2013).

DeLoache, W. C., Russ, Z. N. & Dueber, J. E. Towards repurposing the yeast peroxisome for compartmentalizing heterologous metabolic pathways. Nat. Comm. 7, 11152 (2016).

Zhang, Y. et al. Engineering yeast mitochondrial metabolism for 3-hydroxypropionate production. Biotechnol. Biofuels Bioprod. 16, 64 (2023).

Hammer, S. K. & Avalos, J. L. Harnessing yeast organelles for metabolic engineering. Nat. Chem. Biol. 13, 823–832 (2017).

Zhou, S., Ding, N., Han, R. & Deng, Y. Metabolic engineering and fermentation optimization strategies for producing organic acids of the tricarboxylic acid cycle by microbial cell factories. Bioresour. Technol. 379, 128986 (2023).

Liu, H. et al. Recent advances and perspectives on production of value-added organic acids through metabolic engineering. Biotechnol. Adv. 62, 108076 (2023).

Dai, Z. et al. Bio-based succinic acid: an overview of strain development, substrate utilization, and downstream purification. Biofuels. Bioprod. Biorefin. 14, 965–985 (2020).

Ahn, J. H., Jang, Y.-S. & Lee, S. Y. Production of succinic acid by metabolically engineered microorganisms. Curr. Opin. Biotechnol. 42, 54–66 (2016).

Tran, V. G. et al. An end-to-end pipeline for succinic acid production at an industrially relevant scale using Issatchenkia orientalis. Nat. Commun. 14, 6152 (2023).

Palmieri, E. M. et al. Pyruvate dehydrogenase operates as an intramolecular nitroxyl generator during macrophage metabolic reprogramming. Nat. Commun. 14, 5114 (2023).

Škerlová, J., Berndtsson, J., Nolte, H., Ott, M. & Stenmark, P. Structure of the native pyruvate dehydrogenase complex reveals the mechanism of substrate insertion. Nat. Commun. 12, 5277 (2021).

Nielsen, J. Synthetic biology for engineering acetyl coenzyme A metabolism in yeast. mBio 5, 10–1128 (2014).

Quail, M. A., Haydon, D. J. & Guest, J. R. The pdhR–aceEF–lpd operon of Escherichia coli expresses the pyruvate dehydrogenase complex. Mol. Microb. 12, 95–104 (1994).

Jin, J. et al. A novel lipoate-protein ligase, Mhp-LplJ, is required for lipoic acid metabolism in Mycoplasma hyopneumoniae. Front. Microbiol. 11, 631433 (2021).

Shen, Y. et al. Mitochondrial ATP generation is more proteome efficient than glycolysis. Nat. Chem. Biol. 20, 1123–1132 (2024).

Lian, J., Si, T., Nair, N. U. & Zhao, H. Design and construction of acetyl-CoA overproducing Saccharomyces cerevisiae strains. Metab. Eng. 24, 139–149 (2014).

Pronk, J. T., Yde Steensma, H. & Van Dijken, J. P. Pyruvate metabolism in Saccharomyces cerevisiae. Yeast 12, 1607–1633 (1996).

Forsberg, B. O. The structure and evolutionary diversity of the fungal E3-binding protein. Commun. Biol. 6, 480 (2023).

Armenteros, J. J. A. et al. Detecting sequence signals in targeting peptides using deep learning. Life Sci. Alliance 2, e201900429 (2019).

Pietikäinen, L. P., Rahman, M. T., Hiltunen, J. K., Dieckmann, C. L. & Kastaniotis, A. J. Genetic dissection of the mitochondrial lipoylation pathway in yeast. BMC Biol. 19, 1–15 (2021).

Lian, J. & Zhao, H. Functional reconstitution of a pyruvate dehydrogenase in the cytosol of Saccharomyces cerevisiae through lipoylation machinery engineering. ACS Synth. Biol. 5, 689–697 (2016).

Jiang, Y., Chan, C. H. & Cronan, J. E. The soluble acyl-acyl carrier protein synthetase of Vibrio harveyi B392 is a member of the medium chain acyl-CoA synthetase family. Biochem 45, 10008–10019 (2006).

Schonauer, M. S., Kastaniotis, A. J., Kursu, V. S., Hiltunen, J. K. & Dieckmann, C. L. Lipoic acid synthesis and attachment in yeast mitochondria. J. Biol. Chem. 284, 23234–23242 (2009).

Borrull, A., López-Martínez, G., Poblet, M., Cordero-Otero, R. & Rozès, N. New insights into the toxicity mechanism of octanoic and decanoic acids on Saccharomyces cerevisiae. Yeast 32, 451–460 (2015).

Liu, P. et al. Membrane stress caused by octanoic acid in Saccharomyces cerevisiae. Appl. Microbiol. Biotechnol. 97, 3239–3251 (2013).

Skorokhodova, A. Y., Morzhakova, A. A., Gulevich, A. Y. & Debabov, V. G. Manipulating pyruvate to acetyl-CoA conversion in Escherichia coli for anaerobic succinate biosynthesis from glucose with the yield close to the stoichiometric maximum. J. Biotechnol. 214, 33–42 (2015).

Meng, J. et al. High-yield anaerobic succinate production by strategically regulating multiple metabolic pathways based on stoichiometric maximum in Escherichia coli. Microb. Cell Factories 15, 1–13 (2016).

Qin, N. et al. Increased CO2 fixation enables high carbon-yield production of 3-hydroxypropionic acid in yeast. Nat. Comm. 15, 1591 (2024).

Ndiaye, M., Gadoin, E. & Gentric, C. CO2 gas–liquid mass transfer and kLa estimation: Numerical investigation in the context of airlift photobioreactor scale-up. Chem. Eng. Res. Des. 133, 90–102 (2018).

Yang, P., Liu, W., Chen, Y. & Gong, A. D. Engineering the glyoxylate cycle for chemical bioproduction. Front. Bioeng. Biotechnol. 10, 1066651 (2022).

Chew, S. Y., Chee, W. J. Y. & Than, L. T. L. The glyoxylate cycle and alternative carbon metabolism as metabolic adaptation strategies of Candida glabrata: perspectives from Candida albicans and Saccharomyces cerevisiae. J. Biomed. Sci. 26, 1–10 (2019).

Graybill, E. R., Rouhier, M. F., Kirby, C. E. & Hawes, J. W. Functional comparison of citrate synthase isoforms from S. cerevisiae. Arch. Biochem. Biophys. 465, 26–37 (2007).

Rosenkrantz, M., Keil, C. S., Pennell, E. A. & Devenish, L. J. The HAP2, 3, 4 transcriptional activator is required for derepression of the yeast citrate synthase gene, CIT1. Mol. Microbiol. 13, 119–131 (1994).

Ku, J. T., Chen, A. Y. & Lan, E. I. Metabolic engineering design strategies for increasing acetyl-CoA flux. Metabolites 10, 166 (2020).

Shiba, Y., Paradise, E. M., Kirby, J., Ro, D. K. & Keasling, J. D. Engineering of the pyruvate dehydrogenase bypass in Saccharomyces cerevisiae for high-level production of isoprenoids. Metab. Eng. 9, 160–168 (2007).

Wu, X. & Eiteman, M. A. Production of citramalate by metabolically engineered Escherichia coli. Biotechnol. Bioeng. 113, 2670–2675 (2016).

Wu, Z. Y. et al. Metabolic engineering of low-pH-tolerant non-model yeast, Issatchenkia orientalis, for production of citramalate. Metab. Eng. Commun. 16, e00220 (2023).

Xi, Y. et al. Metabolic engineering of the acid-tolerant yeast Pichia kudriavzevii for efficient L-malic acid production at low pH. Metab. Eng. 75, 170–180 (2023).

Park, H. J. et al. Low-pH production of d-lactic acid using newly isolated acid tolerant yeast Pichia kudriavzevii NG7. Biotechnol. Bioeng. 115, 2232–2242 (2018).

Cao, M. et al. Metabolic engineering of oleaginous yeast Rhodotorula toruloides for overproduction of triacetic acid lactone. Biotechnol. Bioeng. 119, 2529–2540 (2022).

Sun, L. et al. Complete and efficient conversion of plant cell wall hemicellulose into high-value bioproducts by engineered yeast. Nat. Comm. 12, 4975 (2021).

Cui, Z. et al. Reconfiguration of the reductive TCA cycle enables high-level succinic acid production by Yarrowia lipolytica. Nat. Commun. 14, 8480 (2023).

Yin, M. Q. et al. Metabolic engineering for compartmentalized biosynthesis of the valuable compounds in Saccharomyces cerevisiae. Microbiol. Res. 286, 127815 (2024).

Ordiz, I., Herrero, P., Rodicio, R. & Moreno, F. Glucose-induced inactivation of isocitrate lyase in Saccharomyces cerevisiae is mediated by the cAMP-dependent protein kinase catalytic subunits Tpk1 and Tpk2. FEBS Lett. 385, 43–46 (1996).

Sulo, P. & Martin, N. C. Isolation and characterization of LIP5. A lipoate biosynthetic locus of Saccharomyces cerevisiae. J. Biol. Chem. 268, 17634–17639 (1993).

Cardenas, J. & Da Silva, N. A. Engineering cofactor and transport mechanisms in Saccharomyces cerevisiae for enhanced acetyl-CoA and polyketide biosynthesis. Metab. Eng. 36, 80–89 (2016).

Shao, Z., Zhao, H. & Zhao, H. DNA assembler, an in vivo genetic method for rapid construction of biochemical pathways. Nucleic Acids Res. 37, e16 (2009).

Gibson, D. G. et al. Enzymatic assembly of DNA molecules up to several hundred kilobases. Nat. Methods 6, 343–345 (2009).

Gietz, R. D., Schiestl, R. H., Willems, A. R. & Woods, R. A. Studies on the transformation of intact yeast cells by the LiAc/SS-DNA/PEG procedure. Yeast 11, 355–360 (1995).