Abstract

Stretchable and flexible electronics represent emerging and exciting directions for future electronics, while transfer printing plays an essential and mainstream role in integrating electronics onto application substrates. However, existing transfer printing approaches have restrictions for electronics in terms of stiffness and dimensionality, as well as limitations for substrates in terms of surface and adhesion. Here, we report a versatile soap bubble transfer printing technique that, through a volume modulation strategy, enables the adhesion-independent, damage-free, and low-contamination integration of rigid, flexible, and three-dimensional curved electronics onto substrates with complex surfaces and challenging adhesion. To demonstrate the versatility and compatibility of the soap bubble transfer printing technique, we performed not only special behaviors such as wrap-like, multilayer, selective, and interior printing, but also integrated flexible electronics onto various human organ models, which holds promise for health monitoring in both noninvasive and invasive manners.

Similar content being viewed by others

Introduction

Stretchable and flexible electronics1,2,3 offer superior electrical performances compared to conventional rigid electronics and deform into arbitrary shapes to match complex surfaces, representing emerging and exciting directions for future electronics. However, chemical and thermal treatments4,5 preclude the direct fabrication on the sensitive substrates6,7, such as human organs. Transfer printing8,9, decoupling planar fabrication and spatial integration, plays an essential and mainstream role in retrieving electronics from fabrication substrates and integrating onto application substrates. A typical transfer printing system, as illustrated in Fig. 1a, consists of a stamp, an electronics, and a substrate, while the stamp design is the key issue to widen the versatility and compatibility for both transferred electronics and target substrates. In existing research, various stamps, including solid10,11,12,13,14,15,16, liquid17,18,19,20,21,22,23, and phase-transition ones24,25,26,27,28, have been proposed to successfully assemble either rigid10,11,12,13,14,17,18,19,24 or flexible20,21,23 electronics onto mostly planar10,11,12,13,14,19 and some curved17,20,22,24 substrates.

a A typical transfer printing system includes a stamp, an electronics, and a substrate. The stamp can be either solid (Reproduced with permission11. copyright 2022, Elsevier), liquid (Reproduced with permission17. Copyright 2021, WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim) or phase-transition (Reproduced with permission24. Copyright 2022, American Association for the Advancement of Science.) to transfer electronics (either rigid or flexible) onto the target substrate (either planar or curved). b Schematic illustration of the versatile soap bubble transfer printing: retrieving electronics through the soap bubble hosted by a blowing tube (Step I); when being transferred, flexible electronics (top) conformably deforms with the soap bubble, while rigid electronics (bottom) retains its original shape (Step II); inflating the soap bubble to match the receiver substrate (Step III) and bursting the soap bubble through a finite-sized bar (Step IV) make rigid and flexible electronics respectively printed onto planar (top) and curved (bottom) substrates (Step V). To demonstrate the versatility and compatibility of the soap bubble transfer printing, a 25.3 μm-thick silver circuit denoting rigid electronics and an 850 nm-thick gold circuit representing flexible electronics are integrated onto c low-adhesion reliefs, d a non-uniform ball, and e a fragile flower.

Even though significant advances and encouraging progress have been made in material compatibility, geometry tolerance, and process reliability, challenges still exist for transfer printing techniques. In terms of stiffness and dimensionality, electronics can be either rigid (microscale thickness), flexible (nanoscale thickness), or three-dimensional curved. However, the conformal deformation of flexible electronics impedes the interfacial delamination with solid stamps10,11,12 and causes undesirable crumpling with liquid droplet stamps (see Fig. S1a, Supplementary Information)17,18,19. This indicates that solid and liquid droplet stamps are not feasible for flexible electronics. In contrast, the capillary21,22 and soap film20 techniques enable the transfer printing of flexible electronics, as thin as 100 nm20, but are incapable of transferring rigid electronics. In addition, the challenging three-dimensional curved electronics experience high stress, remarkable contamination, and process complexity problems for existing solid10,11,12,13,14,15, liquid17,18,19,20,21,22,23, and phase-transition24,25,26,27 stamps, respectively. In terms of surface and adhesion, substrates can be either planar or curved and may feature adhesive or non-adhesive properties. Printing onto planar and adhesive substrates is easy. However, printing onto curved and non-adhesive substrates is challenging for solid stamps10,11,12,15 with limited deformability and adhesion switchability conflict29, liquid stamps17,18,19,23 with capillary instability30,31 and poor placement accuracy, and phase-transition stamps24,25,26,27 with remarkable residual contamination. To generate diverse, multi-functional, miniaturized, and highly-integrated electronics, special behaviors such as wrap-like printing32 for curved electronics, multilayer printing33,34 for heterogeneous integration, selective printing13,14 for complex patterns, and interior printing35,36,37 for implantable health monitoring, are expected. However, the high manufacturing complexity10,11 for solid stamps, the aggregated liquid residues17 for liquid stamps as illustrated in Fig. S1b (Supplementary Information), and the poor local controllability24,25,26,27 for phase-transition stamps hinder the implementation of these special behaviors. Therefore, even though various stamp designs have been proposed to facilitate the release of diverse electronics onto different substrates, a versatile transfer printing technique that not only integrates rigid, flexible and three-dimensional curved electronics onto complex substrates with challenging adhesion, but also enables special wrap-like, multilayer, selective and interior printing behaviors in a damage-free, adhesion-independent and low-contamination manner, is still lacking and highly desired.

Here, a versatile soap bubble transfer printing technique, inheriting both the low-contamination merit of solid stamps and the damage-free feature of liquid stamps, is proposed. The related printing mechanism, considering the tilting during transferring and the tombstoning during printing, is investigated through mechanical models, and a volume modulation strategy is proposed to guide transfer printing. Leveraging the ultrathin, rheological, and easy-to-burst features of the soap bubble stamp, this technique not only implements the integration of rigid, flexible, and three-dimensional curved electronics onto topologically and adhesively challenging substrates but also enables wrap-like, multilayer, selective, and interior printing behaviors, significantly broadening the versatility and compatibility of transfer printing. The comparison between soap bubble transfer printing and existing techniques is summarized in Table S1 (Supplementary Information), while the remarkable superiority over the recently-reported soap film20 and liquid droplet17 ones is thoroughly discussed in Section S1 (Supplementary Information) in terms of versatility, complexity, mechanism, and compatibility.

Results

Soap bubble transfer printing

Figure 1b and Movie S1 (Supplementary Information) schematically illustrate the novel concept of the soap bubble transfer printing, featuring a common soap bubble as the stamp. The rigid and flexible electronics are prefabricated on the planar substrate by inkjet printing and mature micro/nanofabrication, respectively. As illustrated in Fig. 1b, we move the blowing tube to initiate contact between the soap bubble and the electronics, and then vertically lift the tube to retrieve the electronics from the donor substrate (Step I). After being separated from the substrate, the soap bubble stamp forms a convex liquid bridge to lift the rigid electronics, while the flexible electronics conformably deforms with the soap bubble (Step II). Subsequently, we inflate the soap bubble to ensure that the contact line between the soap bubble and the receiver substrate progressively propagates in a rheological manner, allowing the electronics to conform to the receiver substrate until the contact line exceeds the electronics (Step III), which effectively helps mitigate the bursting-induced damage. Finally, the soap bubble bursts on demand through puncturing with a finite-size bar (Step IV), allowing for the respective printing of both rigid and flexible electronics onto planar and curved substrates (Step V).

In soap bubble transfer printing, several existing challenging operations, including difficult micro-structure relief design10, narrow-range velocity control15, damage-related preload12, complex external stimuli38,39, and carefully-controlled planking23/attaching20 processes, are no longer required to lower printing difficulty and complexity. During the transfer process, the soap bubble, exhibiting capillary stability superior to that of the liquid droplet stamp40, is capable of hosting rigid, flexible, and three-dimensional curved electronics over a large area, significantly expanding the compatibility of transfer printing. In the printing process, the easy-to-burst property of the soap bubble enables the adhesion-independent printing to tackle switchability conflict for solid stamps29, while the ultrathin (microscale thickness) feature of the soap bubble minimizes the residual contamination for liquid stamps17. In addition, the rheological feature of the soap bubble guarantees the conformal, wrinkle-free, and damage-free printing as shown in Fig. S1c (Supplementary Information). Exemplarily, both rigid and flexible electronics are successfully integrated onto low-adhesion reliefs (Fig. 1c), non-uniform ball (Fig. 1d), and delicate structures such as a fragile flower (Fig. 1e). Furthermore, essentially different from the transfer printing of discrete pixels24, soap bubble transfer printing supports electronics prefabricated on membranes, and a transfer yield of 100% can be readily achieved, while the pattern resolution in electronics is, in principle, unlimited, benefiting from the decoupling between fabrication and transfer printing.

Transfer printing mechanism and volume modulation strategy

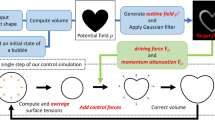

Through the forming and bursting of a soap bubble, prefabricated electronics can be easily retrieved from the donor substrate and printed onto the receiver substrate in an adhesion-independent manner. In Fig. 2 and Movies S2–S4 (Supplementary Information), both tilting during transferring and tombstoning during printing occur for electronics, which have not been reported in existing research. Moreover, the maximum allowable weight, the maximum damage, alignment accuracy, and morphology control for electronics play crucial roles in determining the versatility and compatibility of the soap bubble transfer printing. Here, mechanical models presented in Sections S2–S6 (Supplementary Information) are proposed to tackle the above problems, and a volume modulation strategy is introduced to guide the soap bubble transfer printing.

a A rigid electronics is positioned either tilted for a low-volume soap bubble (left) or horizontally for a high-volume soap bubble (right). b The relation between the tilt angle α of the electronics and the soap bubble volume V corresponding to different initial masses m0. Solid lines and dots respectively represent the theoretical solutions and experimental results. c A rigid electronics is either flipped for a low-volume soap bubble (top), leading to tombstoning and failure of printing, or successfully printed for a high-volume soap bubble (bottom) in an experiment. d Single contact line (top left) and multiple contact lines (bottom left) of electronics, and the relation between the torque M and the soap bubble volume V corresponding to different electronics weights G (right) and the moving distance of the contact line b = 0.1 mm. e A soap bubble deforms when carrying a heavy electronics. f The carrying capacities of both the soap bubble and liquid droplet17 stamps as a function of the volume. Solid lines and dots, respectively, denote the theoretical solutions and experimental results of the soap bubble stamp for L = 10 mm, while the dashed line represents the theoretical solutions of the droplet stamp. g The resistance changes for rigid and flexible electronics transferred through solid and soap bubble stamps11.

During the transfer process, as depicted in Figs. 2a and S2a (Supplementary Information) and Movie S2 (Supplementary Information), both rigid and flexible electronics exhibit tilting when lifted by the soap bubble stamp. This tilting can be adjusted through tuning the soap bubble volume, allowing for the programmable printing onto the inclined surface. The mechanical model in Fig. S2b (Supplementary Information) shows that the initial mass of the soap solution m0 consists of the mass of the soap bubble ms and the one of the residual liquid materials mr, while free mass transfer exists between the soap bubble and the residual liquid materials to prevent the capillary instability and the premature bursting of the soap bubble. The governing torque equilibrium and the spherical surface assumption in Section S2 (Supplementary Information) yield the tilt angle of the transferred electronics as α ≈ C2 (m0−ρhC1V2/3), in which C1 and C2 are to-be-determined coefficients, V is the soap bubble volume, and ρ and ℎ represent the density and thickness of the soap bubble, respectively, as illustrated in Fig. 2b. This indicates that the residual liquid materials are the primary cause of the tilting phenomenon, and the tilt angle α can be effectively controlled by adjusting the initial mass m0 and the soap bubble volume V in experiments. Consequently, a volume modulation strategy through programmable inflation to consume residual liquid materials is proposed to enable printing onto both planar (α = 0) and inclined (α = π/4) substrates, as shown in Fig. S2d (Supplementary Information).

During the printing process, when meeting the receiver substrate as shown in Figs. 2c and S3a (Supplementary Information) and Movie S2 (Supplementary Information), both rigid and flexible electronics might stand up, similar to the tombstoning phenomenon observed in printed circuit board soldering41. The tombstoning during printing is a sequential result of the tilting during transferring. Our experiments in Figs. 2d and S3b (Supplementary Information) reveal that a soap bubble with a low volume V tends to tilt (α > 0) and have a single contact line during printing, which leads to tombstoning. In contrast, a soap bubble with a high volume V tends to have horizontally-placed electronics (α = 0) and multiple contact lines, resulting in successful printing. The mechanical model in Section S3 (Supplementary Information) defines the torque dominating the tombstoning behavior as M = 2γL2(sinθR + sinθP)−ΔPL3/2−GLcosα/2, in which γ represents the surface tension of the soap bubble, L and G represent the length and weight of the electronics, respectively. The Laplace pressure ΔP, contact angles θR and θP, and tilt angle α are all functions of the soap bubble volume V, as illustrated in Fig. S3c (Supplementary Information). The theoretical solutions in Fig. 2d reveal that both the tilt angle α and the torque M decrease with the increase of the soap bubble volume V, eventually leading to α = 0 and successful printing. Therefore, our volume modulation strategy through programmable inflation is capable of preventing undesired tombstoning and guaranteeing successful printing.

The utility range of soap bubble transfer printing is determined by the carrying capability of the soap bubble stamp. The mechanical model in Section S4 (Supplementary Information) defines the maximum allowable weight of the transferred electronics as Gmax = 2πγLcosθe−ΔPπL2/4, in which both the contact angle θe and the Laplace pressure ΔP are functions of the soap bubble volume V and the blowing tube diameter d, as illustrated in Figs. 2e and S4a (Supplementary Information). This indicates that by programmatically adjusting the soap bubble volume V and the blowing tube diameter d, the carrying capability of the soap bubble can be significantly enhanced, as verified in Fig. 2f. Ideally, the soap bubble can be as large as meterscale42, and we have L = d = 1000 mm in principle, leading to the allowable weight as high as Gmax = 193.4 mN, which is two orders of magnitude higher than that of liquid droplet stamp17.

Throughout the entire transfer printing process, the maximum strain in transferred electronics is critical for evaluating potential damage. The mechanical model in Section S5 (Supplementary Information) reveals that, for the insignificant bending of rigid electronics and the remarkable conformal deformation of flexible electronics, the maximum strains are respectively εmaxrigid = 0.003% and εmaxflexible = 0.011%, both are significantly lower than the fracture strain of electronics43. Furthermore, our experiments in Fig. 2g demonstrate that for both rigid and flexible electronics, the resistance change experienced with the soap bubble stamp is much lower than that with a solid stamp11. This indicates that the soap bubble transfer printing technique is physically gentle and damage-free.

Alignment accuracy and morphology control are crucial for guaranteeing circuit performance and preventing wrinkles in soap bubble transfer printing. The low stiffness and fluidic nature of the soap bubble yield undesired motion of the transferred electronics, leading to poor alignment accuracy and limiting its applicability in scenarios requiring strict layer registration, such as multilayer transfer printing33,34. Figure S5, Movie S3 and Section S6 (Supplementary Information) demonstrate that adjusting the nozzle shape, soap solution concentration, and soap bubble volume can significantly enhance stability for transferred electronics, yielding reproducible alignment offsets within hundreds of micrometers for multilayer printing even through manual operation, as shown in Figs. S5d and S6 (Supplementary Information). Moreover, the intrinsic mismatch between the two-dimensional electronics and the three-dimensional soap bubble yields undesirable wrinkles. Figure S7, Movie S4 and Section S6 (Supplementary Information) demonstrate that, by modulating the soap bubble volume, folded electronics can be printed on the substrate in a wrinkle-free manner. Profiling results in Fig. S7b (Supplementary Information) confirm the low surface roughness (~2 µm) of the printed electronics, indicating a high-quality transfer printing.

Electronics and substrate compatibilities of soap bubble transfer printing

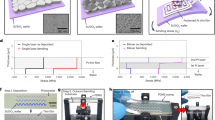

Figure 3a–d demonstrates the compatibility of soap bubble transfer printing for electronics in terms of stiffness, dimensionality, pattern, and size. Without the preload requirement12 for solid stamps and the capillary instability problem for liquid stamps17,18,19, the soap bubble stamp enables the versatile transfer printing. Here, yellow Polyimide (PI) membranes (elastic modulus: 3.5 GPa, thickness: 50 μm) and pink Polydimethylsiloxane (PDMS) membranes (elastic modulus: 1.8 MPa, thickness: 30 μm) are fabricated to simply represent rigid and flexible electronics, respectively. Figures 3a, b and S7c, d (Supplementary Information) reveal that the soap bubble stamp enables the successful lifting of both rigid and flexible electronics, regardless of aspect ratio, pattern, or size. In addition, Fig. 3c, d and Movie S5 (Supplementary Information) demonstrate that three-dimensional curved electronics, including a trapezoid and a buckled island-bridge in Fig. 3c and a porous sponge in Fig. 3d, can be retrieved with insignificant deformation and low stress using the soap bubble stamp. This is essential for sensitive electronics with no resistance to deformation but low tolerance to stress18,27. Therefore, the soap bubble transfer printing is versatile for rigid, flexible, and three-dimensional curved electronics.

a The soap bubble stamp hosts rigid (yellow, PI, 50 μm) and flexible (pink, PDMS, 30 μm) electronics with an aspect ratio of 20:1, in both partial and conformal contact manners, respectively. b Successful transferring of both rigid and flexible electronics with the hexagram pattern using the soap bubble stamp. c Three-dimensional curved electronics, including trapezoidal (left) and buckled island-bridge (right) structures, are retrieved from the donor substrate in a damage-free manner. d Lifting of a porous sponge using the soap bubble stamp. e Flexible electronics with patterns can be conformably printed onto concave (top left), convex (bottom left), and sharp-edged (right) surfaces. f Printing of both rigid (right) and flexible (left) electronics onto a porous sponge, which has no resistance to deformation. g Printing of both rigid and flexible electronics onto low-adhesion surfaces, including a circuit board surface with low contact area (left, diameter: 300 μm, spacing: 1 mm) and a polytetrafluoroethylene plate surface (middle) with low surface energy (right, contact angle: 110.7°).

Figure 3e–g demonstrates the compatibility of soap bubble transfer printing for substrates in terms of surface and adhesion. The remarkable deformability and the rheological feature of the soap bubble42,44 enable conformal printing onto various non-planar substrates with gradually varying curvature, not only concave and convex shapes, but also sharp knife with a curvature radius of 160 µm as shown in Fig. 3e. The soap bubble stamp achieves damage-free printing onto porous sponge without preload and remarkable deformation, as depicted in Fig. 3f. This capability is crucial for sensitive substrates6,7, such as biological tissues. Moreover, the soap bubble enables adhesion-independent printing onto substrates with challenging adhesion. The examples of low-adhesion surfaces include a needle array with a low contact area (needle diameter: 300 μm, spacing: 1 mm) on a circuit board and a polytetrafluoroethylene (PTFE) plate with extremely low surface energy (contact angle of 110.7o)45 in Fig. 3, as well as a low-adhesion plant surface in Fig. S7e (Supplementary Information). For high-adhesion substrates in Fig. S7f (Supplementary Information), such as a PDMS block and a sticky lint roller, successful printing of electronics can be achieved using the soap bubble stamp. However, it remains challenging to achieve conformal and uniform printing onto highly irregular surfaces with locally sharp curvatures, especially for large-area electronics. This can be possibly mitigated by adopting gentle local pressure, lowering the transfer speed, and weakening the interfacial friction to enhance the rheological performance of soap bubble transfer printing.

Special transfer printing behaviors enabled by the soap bubble stamp

Three-dimensional curved electronics46,47 enable superior performance compared to their planar counterparts, delivering low aberration for imaging systems48,49 and wide bandwidth for communication units50,51. However, the creation of three-dimensional curved electronics is significantly challenging. Both multi-fingered printing52 and wrap-like technique32 entail fabrication complexity and intricate manipulation strategy. In this manuscript, the soap bubble transfer printing technique is employed to seamlessly integrate flexible electronics onto three-dimensional objects with complete coverage. As shown in Fig. 4a and Movie S6 (Supplementary Information), a two-dimensional petal-shaped circuit with an LED array (3 × 5, connected by a silver circuit on the PDMS membrane) is printed onto a spherical surface; the LED array successfully illuminates after printing, and the related current–voltage (I–V) relation agrees well with that before printing, indicating the damage-free printing. Our experiments also reveal that the soap bubble facilitates the conformal contact between the electronics and the target substrate in a rheological manner. This enables the complete-coverage integration onto various three-dimensional substrates, including not only convex spherical surfaces, but also flat cube, cylinder and cone frustum, as shown in Fig. S8a (Supplementary Information), in which PDMS membranes (thickness: 30 μm) rather than the hard aforementioned silver circuit (thickness: 120 μm) are used to enhance wrapping performance on substrates with sharp curvature transitions.

a A petal-shaped LED array wrapped around a glass sphere (left), along with I–V curves (right) of the LED array before and after transfer printing. The inset displays the 2D layout and circuit schematic diagram of the petal-shaped LED array, and the illuminated LED array after printing. b Schematic illustration (left) and real-time resistance change during the loading and unloading of a 200 g weight (right) for a flexible pressure sensor. The inset shows the experimental image during loading, as well as the response and recovery time. c Schematic illustration (left) and experimental images (right) of selective transfer printing. Yellow (PI) and black (PET) pellets, respectively, represent target and non-target objects. The selective transfer printing process includes: the syringe array with D-shaped patterns being pulled up and dipped into the soap solution (Step i); these syringes are aligned with target objects and pushed down to generate a related soap bubble array (Step ii); the syringe array is lifted to pick up target objects from the donor substrate (Step iii); the soap bubble array is brought into contact with the receiver substrate (Step iv); the soap bubble array bursts to complete transfer printing in a damage-free manner(Step v), with a top view after printing. d Sequentially deflating and inflating the soap bubble to realize the printing onto an interior cavity of a hollow sphere: deflating the soap bubble to contract the hosted electronics to pass through the small incision (Step i); inflating the soap bubble to expand the electronics to conformably match the curved interior cavity (Step ii); bursting the soap bubble to complete the printing process (Step iii), with the top view after printing.

Multilayer transfer printing realizes the multi-level, multi-material, multi-functional, and highly-integrated hybrid electronics, significantly enhancing the complexity and performance of electronics33,34. However, the random interfacial delamination makes it challenging for solid stamps23, while residual materials trapped between layers reduce the alignment accuracy for both liquid and phase-transition stamps. The transparent and ultrathin features of soap bubbles guarantee high alignment accuracy and minimal residual materials, demonstrating unique advantages in multilayer transfer printing. As shown in Fig. S8b and Movie S7 (Supplementary Information), rigid and flexible electronics with varying patterns and thicknesses are assembled on a polymer plate in different sequences using the soap bubble transfer printing technique. Moreover, Fig. 4b demonstrates the sequential assembly of an SWNT-coated PDMS layer (thickness: 50 μm) and an Ag/PET layer (pattern: interdigital electrodes; thickness: 25.3 μm) onto a PDMS substrate (thickness: 30 μm), leading to a multilayer pressure sensor as shown in Fig. S8c. To validate the performance of the pressure sensor, a weight of 200 g is placed on and removed from the pressure sensor. The related change in resistance effectively captures this behavior, with a response time of ~400 ms.

Selective transfer printing in a programmable manner is capable of achieving the desired layout with irregular patterns, ensuring circuit complexity and diversity13,14. Figure 4c and Movie S8 (Supplementary Information) demonstrate the selective transfer printing procedure, achieved by controlling both the formation and bursting of a soap bubble array in an independent and selective manner. The transfer printing system, featuring a 3 × 3 syringe array (spacing: 40 mm), is utilized to transfer the target objects (yellow PI pellets, 50 µm thick and 15 mm in diameter), while the counterparts (black PET pellets, 50 µm thick and 15 mm in diameter) remain stationary. At the initial stage (Step i), several syringes (D-shaped pattern) corresponding to the target objects are selected, pulled up, and dipped into the soap solution. These syringes are then pushed down to generate a soap bubble array in the desired pattern (Step ii) and establish contact between the target objects and these soap bubbles. Sequentially, the transfer printing system is lifted upward to pick up the target objects from the donor substrate (Step iii) and moved downward again to establish contact between the target objects and the receiver substrate (Step iv), while the soap bubble is further inflated to shield target objects from any potential impact caused by the bursting of soap bubble. Finally, a finite-size bar is employed to burst all soap bubbles, releasing the target objects onto the receiver substrate (Step v). The top view in Fig. 4c shows transferred pellets in a D-shape pattern, demonstrating a successful selective transfer printing process. It is worth noting that the bursting-induced impact of a soap bubble can be effectively eliminated through inflating a soap bubble, as discussed in Section S6. However, the expansion of the soap bubble might lead to a reduction in resolution for transferred pixel arrays. This can be solved by pre-patterning a pixel array on a membrane, and the pixel array/membrane system is transfer printed through our soap bubble stamp.

Interior transfer printing35,36,37 enables the delivery of electronics into the cavities of 3D structures, particularly biological soft tissues, including the heart and brain, through small incisions. This achievement, challenging to achieve through traditional stamps, holds promise for minimally invasive surgeries and therapies53,54. Figure 4d and Movie S9 (Supplementary Information) demonstrate that by sequentially deflating, inflating and bursting the soap bubble stamp, the flexible electronics (20 mm × 20 mm × 850 nm) can be inserted into, intimately contacted with, and printed onto a hollow spherical cavity with a diameter of 40 mm through a small incision with a diameter of 15 mm in a tunable manner. This outperforms both balloon catheters35,37 and the syringes-injected technique36. In addition, a variant of the soap bubble transfer printing technique is introduced for deep cavities. Figure S9a, b (Supplementary Information), respectively, provide schematic and experimental illustrations of transfer printing in deep cavities, and the detailed information can be found in the Movie S10 (Supplementary Information). Figure S9c (Supplementary Information) demonstrates a D-shaped LED array printed within a hollow Y-shaped tube; the LED array can be successfully illuminated, and the change in the I–V relation is negligible before and after transfer printing, indicating successful and damage-free interior printing.

Figure 5 demonstrates the integration of flexible electronics onto different organ models using soap bubble transfer printing, potentially facilitating both invasive and noninvasive health diagnostics and therapies. For wearable and implantable applications, biodegradable and low-toxicity alkyl polyglycosides55, rather than conventional surfactants, are used to generate the soap bubble stamp to mitigate potential health hazards. Figure 5 shows that flexible electronics with a thickness of 850 nm can be successfully integrated onto the finger, tooth, and outer ear for wearable electronics, and assembled onto the eye, brain, heart, and blood vessel for implantable electronics. Moreover, the soap bubble transfer printing guarantees the wrinkle-free integration of ultrathin electronics, providing a maximum working area and superior conformability to prevent undesired motion artifacts and obtain high-quality signals. This facilitates comprehensive, multi-site, and long-term signal acquisition for human health monitoring. It is worth noting that flexible electronics are printed onto organ models in this study. Therefore, further pharmacological and toxicological studies are required to thoroughly validate the safety and efficacy for potential clinical applications. More biocompatible surfactants56,57 will be considered in future studies.

Discussion

In summary, by inheriting both the low-contamination merits of solid stamps and the damage-free features of liquid stamps, we have developed a facile and versatile soap bubble transfer printing method for both rigid (silver circuit with a thickness of 25.3 μm) and flexible (gold circuit with a thickness of 850 nm) electronics, as well as for special behaviors including wrap-like, multilayer, selective and interior printings, which are challenging with existing techniques. We have developed mechanical models to understand the transfer printing mechanisms and have proposed a volume modulation strategy to guide tilting during transferring and prevent tombstoning during printing. In addition, the carrying capability, strain evaluation, alignment, and morphology control for the entire process are also discussed. To demonstrate the capabilities of soap bubble transfer printing, various electronics have been integrated onto topologically and adhesively challenging substrates. In particular, ultrathin flexible electronics have been assembled on different human organ models, holding promise for the system-level health monitoring in both invasive and noninvasive manners.

There are some limitations of the soap bubble transfer printing technique. The self-rupture or meeting of oily/dry substrates leads to the premature bursting of the soap bubble and the failure of transfer printing. For the self-rupture problem, one can select suitable surfactants58, control ambient temperature59 and humidity, and add glycerol/microparticles/polymers42,60 to enhance the mechanical stability and extend the lifetime of the soap bubble as long as 1 year60, which is sufficient for transfer printing. For the substrate limitation problem, one can humidify the substrate or modify the interfacial properties to prevent undesired bursting. A high soap bubble volume is expected to prevent tombstoning and bursting-induced impact during printing, which hampers the transfer printing of small-sized pixel arrays that require high resolution. However, this can be easily solved by pre-patterning the pixel array on a membrane, and the pixel array/membrane system can then be transfer printed through a soap bubble stamp. This strategy not only lowers the difficulty of transfer printing but also enables the large-area transfer printing with high pattern complexity and resolution.

Methods

Preparation of rigid and flexible electronics

To prepare the rigid electronics, a 25 μm-thick commercial polyethylene terephthalate (PET) membrane was rinsed for 1 min in a vacuum plasma cleaner (CSCPIA5, Shanghai Zhongbin Technology Co., Ltd, China). Silver ink was sequentially deposited onto the PET membrane in a serpentine pattern (minimum linewidth: 300 µm, thickness: 300 nm) through inkjet printing (Scientific 3, Shanghai MiFang Electronic Technology Co., Ltd, China). The obtained silver/PET structure was cured on a hotplate at 150 °C for 20 min to create the rigid electronics. To prepare the flexible electronics, a PAA (Polysciences Inc., USA) sacrificial layer was first spin-coated onto a glass substrate at 3000 rpm for 30 s and then cured on a hotplate at 85 °C for 30 min. Subsequently, a 750 nm-thick parylene layer and a 100 nm-thick Au layer were respectively deposited using chemical vapor deposition (SCS Labcoter PDS2010, Specialty Coating Systems, USA) and magnetron sputtering (LAB 18, Kurt J. Lesker, USA). Serpentine patterns (minimum linewidth: 52 µm) and island-bridge (minimum linewidth: 62 µm) patterns were then fabricated using conventional photolithography processes. Finally, the flexible electronics was detached by immersing the glass substrate in deionized water for 2 h to dissolve the PAA sacrificial layer. It is worth noting that an encapsulation layer (PET, parylene) was applied to both rigid and flexible electronics during the electrical performance measurements to prevent any potential pollution from the soap solution.

Preparation of patterned membranes

Figures 3a, b and S7c, d (Supplementary Information) demonstrate the compatibility and versatility of the soap bubble stamp by transferring various membranes with irregular patterns and different sizes. The PDMS membrane with the mix ratio of 10:1 (elastic modulus of 1.8 MPa) and a thickness of 30 μm was adopted to represent flexible electronics, while the commercial PI membrane with a thickness of 50 μm and an elastic modulus of 3.5 GPa was used to represent rigid electronics. A small amount of dye was added to the PDMS membrane for distinction. Different patterns were introduced to both the PDMS and PI membranes through a cutting technique.

Preparation of petal-shaped and D-shaped LED arrays

Stretchable conductive silver ink was printed onto a prefabricated PDMS membrane through a dispensing process (Scientific 3, Shanghai MiFang Electronic Technology Co., Ltd, China), creating both petal-shaped and D-shaped circuits, which were subsequently cured on a hotplate at 120 °C for 20 min. Commercial LED units were then mounted onto the circuits using conductive silver paste. Finally, a PDMS mixture was deposited and heated to complete the encapsulation and curing operations.

Preparation of a flexible pressure sensor

The flexible pressure sensor consists of three layers: a PDMS/SWNT layer (top), a PET/Ag layer (middle), and a PDMS layer (bottom). To create the top PDMS/SWNT layer, a release agent (KF96SP, ShinEtsu, Japan) and PDMS mixture were coated and cured on sandpaper. The following peeling operations resulted in a 50 μm-thick PDMS membrane with microstructures, which was sequentially coated with a single-walled carbon nanotube (SWNT) solution with a concentration of 150 μg mL−1 (XFNANO Materials Technology Co., Ltd, China) and cured at 200 °C. To create the middle PET/Ag layer, a set of interdigitated Ag electrodes was mounted onto a 25 μm-thick commercial PET membrane by inkjet printing (Scientific 3, Shanghai MiFang Electronic Technology Co., Ltd, China), and copper wires were attached to the Ag electrodes with conductive silver paste. The bottom layer with a 30 μm-thick transparent PDMS membrane was directly fabricated. The soap bubble transfer printing technique was utilized to sequentially integrate these three layers. Finally, the PDMS mixture was applied to the sensor edges and cured to avoid possible interfacial delamination.

Transfer printing through a solid stamp

The stiffness modulation-driven bi-material solid stamp11 was adopted to pick up the rigid electronics from the donor substrate. Subsequently, a lateral load was applied to this solid stamp to induce significant profile deviation and modulate the interfacial adhesion, allowing for the transfer of rigid electronics onto the receiver substrate.

Soap bubble transfer printing

A commercially available concentrated soap solution (LePao, Taobao, China) was diluted with deionized water at different ratios. A blowing tube was then dipped into the diluted soap solution to generate the soap bubble stamp, which was capable of picking up both rigid and flexible electronics from the donor substrate. The printing process was completed by bursting the soap bubble. During the transfer printing process, the soap bubble volume was modulated to control the tilting and tombstoning behaviors. Additionally, resistance changes for both rigid (25 μm-thick PET/300 nm-thick Ag/25 μm-thick PET) and flexible (500 nm-thick parylene/50 nm-thick Au/500 nm-thick parylene) electronics were measured using a multimeter (34465A, Keysight Technologies, USA). After printing, strong adhesion can be ensured for flexible electronics, benefiting from conformal contact. For rigid electronics, stable adhesion can be achieved by pretreating the substrate or employing additional fixtures.

Wrap-like transfer printing through a soap bubble stamp

A blowing tube (diameter: 50 mm) was used to generate a soap bubble for picking up the petal-shaped LED array (thickness: 120 μm, arm length: 25 mm) and printing it onto a glass sphere (diameter: 20 mm). As the LED array hosted by the soap bubble met the glass sphere, the contact line propagated along the sphere surface in a rheological manner, ensuring conformal contact between the LED array and the sphere. However, once the contact line exceeds the equator of the glass sphere, further propagation becomes challenging due to the minimization of surface energy. Nevertheless, applying a downward force or further increasing the volume allowed the contact line to continue advancing until the LED array was eventually wrapped around the surface of the glass sphere. Moreover, to demonstrate the compatibility of wrap-like printing through a soap bubble stamp, various receiver substrates, including a cube, a cylinder, and a cone frustum, as shown in Fig. S8a (Supplementary Information), were also considered.

Selective transfer printing through a soap bubble stamp

A pre-prepared 3 × 3 chip array (diameter: 15 mm, spacing: 40 mm, thickness: 50 μm) was arranged on the donor substrate. By independently controlling the syringe array, a soap bubble array with the desired D-shaped pattern was formed to retrieve target chips in a selective manner. Bursting the soap bubble array yielded the printing of the selected chips onto the receiver substrate.

Interior transfer printing through a soap bubble stamp

To address the interior of a hollow sphere (diameter: 40 mm) through an incision (diameter: 15 mm), a soap bubble stamp with a high volume was initially generated to pick up the flexible electronics (20 mm × 20 mm × 850 nm) with an island-bridge pattern (size: 1.6 mm, spacing: 1.28 mm) from the donor substrate. Subsequently, the soap bubble was deflated to pass through the incision. After that, the soap bubble was inflated again to match the flexible electronics to the curved surface of the interior cavity. The printing process was completed by bursting the soap bubble. For the cavity of a Y-shaped tube (diameter: 31 mm, arm length: 120 mm), a soap film stamp as a variant of a soap bubble was introduced. The downward blowing yielded the deformation of the soap film within a plastic ring (diameter: 28 mm) and the contact between the soap film and the D-shaped LED array (17 mm × 17 mm × 120 μm). Upon deactivating the blowing, the deformed soap film restored to its planar configuration, thereby retrieving the LED array from the donor substrate. Subsequently, the ring with a long handle was inserted into the interior cavity of the Y-shaped tube, the downward blowing again yielded contact between the LED array and the target substrate, and the printing process was completed by bursting the soap film.

Body temperature monitoring through an ultrathin temperature sensor

An ultrathin temperature sensor (500 nm parylene/50 nm Au/500 nm parylene) was fabricated by conventional photolithography. External copper wires were connected to the sensor pads using conductive silver paste. The sensor was assembled onto the wrist using the soap bubble transfer printing technique, and superior conformability between the skin and the sensor was achieved without the need for additional adhesives. Body temperature was monitored in real time for 1800 s. To induce a temperature variation, the wrist was treated with a cooling fan. Simultaneously, surface temperature was recorded by an infrared camera (UTi260A, UNI-TREND TECHNOLOGY CO., LTD., China).

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Gu, P. et al. Highly stretchable semiconducting aerogel films for high-performance flexible electronics. Adv. Funct. Mater. 34, 2400589 (2024).

Jiang, Y. et al. A universal interface for plug-and-play assembly of stretchable devices. Nature 614, 456–462 (2023).

Xu, S. et al. Illuminating the brain: advances and perspectives in optoelectronics for neural activity monitoring and modulation. Adv. Mater. 35, 2303267 (2023).

Cheng, C.-W. et al. Epitaxial lift-off process for gallium arsenide substrate reuse and flexible electronics. Nat. Commun. 4, 1577 (2013).

Chen, Z. et al. Three-dimensional flexible and conductive interconnected graphene networks grown by chemical vapour deposition. Nat. Mater. 10, 424–428 (2011).

Jiang, J. J., Zhang, S., Wang, B., Ding, H. & Wu, Z. G. Hydroprinted liquid-alloy-based morphing electronics for fast-growing/tender plants: from physiology monitoring to habit manipulation. Small 16, 2003833 (2020).

He, D., Malu, D. & Hu, Y. A comprehensive review of indentation of gels and soft biological materials. Appl. Mech. Rev. 76, 050802 (2024).

Linghu, C., Zhang, S., Wang, C. & Song, J. Transfer printing techniques for flexible and stretchable inorganic electronics. npj Flex. Electron. 2, 26 (2018).

Park, J., Lee, Y., Lee, H. & Ko, H. Transfer printing of electronic functions on arbitrary complex surfaces. ACS Nano 14, 12–20 (2020).

Kim, S. et al. Microstructured elastomeric surfaces with reversible adhesion and examples of their use in deterministic assembly by transfer printing. Proc. Natl. Acad. Sci. USA 107, 17095–17100 (2010).

Guo, D. et al. Stiffness modulation-driven transfer printing and strain isolation in stretchable electronics. Mater. Des. 217, 110602 (2022).

Zhang, Y. et al. Mechanics of transfer printing for elastomeric stamps with collapse cavities. Extrem. Mech. Lett. 60, 101956 (2023).

Wang, C. et al. Programmable and scalable transfer printing with high reliability and efficiency for flexible inorganic electronics. Sci. Adv. 6, eabb2393 (2020).

Li, C., Luo, H., Lin, X., Zhang, S. & Song, J. Laser- driven noncontact bubble transfer printing via a hydrogel composite stamp. Proc. Natl. Acad. Sci. USA 121, e2318739121 (2024).

Meitl, M. A. et al. Transfer printing by kinetic control of adhesion to an elastomeric stamp. Nat. Mater. 5, 33–38 (2006).

Linghu, C. et al. Universal smp gripper with massive and selective capabilities for multiscaled, arbitrarily shaped objects. Sci. Adv. 6, eaay5120 (2020).

Liu, X. et al. Liquid droplet stamp transfer printing. Adv. Funct. Mater. 31, 2105407 (2021).

Li, H., Wang, Z., Cao, Y., Chen, Y. & Feng, X. High-efficiency transfer printing using droplet stamps for robust hybrid integration of flexible devices. ACS Appl. Mater. Interfaces 13, 1612–1619 (2021).

Hwang, S. H., Lee, J. & Khang, D. Y. Droplet-mediated deterministic microtransfer printing: water as a temporary adhesive. ACS Appl. Mater. Interfaces 11, 8645–8653 (2019).

Che, L. et al. Soap film transfer printing for ultrathin electronics. Small 20, 2308312 (2023).

Zhang, Y. et al. Capillary transfer of soft films. Proc. Natl. Acad. Sci. USA 117, 5210–5216 (2020).

Zhang, Y., Yin, M. & Xu, B. Elastocapillary rolling transfer weaves soft materials to spatial structures. Sci. Adv. 9, eadh9232 (2023).

Chen, Y. et al. Interfacial liquid film transfer printing of versatile flexible electronic devices with high yield ratio. Adv. Mater. Interfaces 8, 2100287 (2021).

Zabow, G. Reflow transfer for conformal three-dimensional microprinting. Science 378, 894–898 (2022).

Liu, G. Y. et al. Graphene-assisted metal transfer printing for wafer-scale integration of metal electrodes and two-dimensional materials. Nat. Electron. 5, 275–280 (2022).

Zhang, Z. et al. Rosin-enabled ultraclean and damage-free transfer of graphene for large-area flexible organic light-emitting diodes. Nat. Commun. 8, 14560 (2017).

Yan, Z. et al. Three-dimensional mesostructures as high-temperature growth templates, electronic cellular scaffolds, and self-propelled microrobots. Proc. Natl. Acad. Sci. USA 114, E9455–E9464 (2017).

Chen, L. et al. Phase-change stamp with highly switchable adhesion and stiffness for damage-free multiscale transfer printing. ACS Nano 18, 23968–23978 (2024).

Linghu, C. et al. Overcoming the adhesion paradox and switchability conflict on rough surfaces with shape-memory polymers. Proc. Natl. Acad. Sci. USA 120, e2221049120 (2023).

Beroz, J., Hart, A. J. & Bush, J. W. M. Stability limit of electrified droplets. Phys. Rev. Lett. 122, 244501 (2019).

Clanet, C. & Lasheras, J. C. Transition from dripping to jetting. J. Fluid Mech. 383, 307–326 (1999).

Chen, X. et al. Wrap-like transfer printing for three-dimensional curvy electronics. Sci. Adv. 9, eadi0357 (2023).

Kim, B. H. et al. Multilayer transfer printing for pixelated, multicolor quantum dot light-emitting diodes. ACS Nano 10, 4920–4925 (2016).

Wang, Y., Xu, C., Yu, X., Zhang, H. & Han, M. Multilayer flexible electronics: Manufacturing approaches and applications. Mater. Today Phys. 23, 100647 (2022).

Han, M. et al. Catheter-integrated soft multilayer electronic arrays for multiplexed sensing and actuation during cardiac surgery. Nat. Biomed. Eng. 4, 997–1009 (2020).

Liu, J. et al. Syringe-injectable electronics. Nat. Nanotechnol. 10, 629 (2015).

Kim, D.-H. et al. Materials for multifunctional balloon catheters with capabilities in cardiac electrophysiological mapping and ablation therapy. Nat. Mater. 10, 316–323 (2011).

de la Rosa, C. J. L. et al. Frame assisted H2O electrolysis induced H2 bubbling transfer of large area graphene grown by chemical vapor deposition on Cu. Appl. Phys. Lett. 102, 022101 (2013).

Guo, C. et al. Large-scale programmable assembly of functional micro-components for advanced electronics via light-regulated adhesion and polymer growth. npj Flex. Electron 6, 44 (2022).

Eggers, J. & Villermaux, E. Physics of liquid jets. Rep. Prog. Phys. 71, 036601 (2008).

Hui, I. K. & Ralph, B. A study of the initiation of the tombstoning effect on leadless chips. Int. J. Mach. Tools Manuf. 35, 1251–1268 (1995).

Frazier, S., Jiang, X. & Burton, J. C. How to make a giant bubble. Phys. Rev. Fluids 5, 013304 (2020).

Li, M., Xia, J., Li, R., Kang, Z. & Su, Y. Design of two-dimensional horseshoe layout for stretchable electronic systems. J. Mater. Sci. 48, 8443–8448 (2013).

Yang, S. & Sharma, P. A tutorial on the stability and bifurcation analysis of the electromechanical behaviour of soft materials. Appl. Mech. Rev. 75, 044801 (2023).

Peng, H. Synthesis and application of fluorine-containing polymers with low surface energy. Polym. Rev. 59, 739–757 (2019).

Liu, J. et al. Self-healing kirigami assembly strategy for conformal electronics. Adv. Funct. Mater. 32, 2109214 (2022).

Cheng, X. et al. Programming 3D curved mesosurfaces using microlattice designs. Science 379, 1225–1232 (2023).

Lü, C. et al. Mechanics of tunable hemispherical electronic eye camera systems that combine rigid device elements with soft elastomers. J. Appl. Mech. 80, 061022 (2013).

Choi, C. et al. Human eye-inspired soft optoelectronic device using high-density MoS2-graphene curved image sensor array. Nat. Commun. 8, 1664 (2017).

Dongjin, K., Hirokawa, J., Ando, M., Takeuchi, J. & Hirata, A. 4 × 4-element corporate-feed waveguide slot array antenna with cavities for the 120 GHz band. IEEE Trans. Antennas Propag. 61, 5968–5975 (2013).

Pfeiffer, C., Xu, X., Forrest, S. R. & Grbic, A. Direct transfer patterning of electrically small antennas onto three-dimensionally contoured substrates. Adv. Mater. 24, 1166–1170 (2012).

Chen, J., Yang, S., Li, Y., Huang, Y. & Yin, Z. Active curved surface deforming of flexible conformal electronics by multi-fingered actuator. Rob. Comput. Integr. Manuf. 64, 101942 (2020).

Kane, M. J., Breen, P. P., Quondamatteo, F. & Ólaighin, G. Bion microstimulators: a case study in the engineering of an electronic implantable medical device. Med. Eng. Phys. 33, 7–16 (2011).

Kim, T.-I. et al. Injectable, cellular-scale optoelectronics with applications for wireless optogenetics. Science 340, 211–216 (2013).

von Rybinski, W. & Hill, K. Alkyl polyglycosides—properties and applications of a new class of surfactants. Angew. Chem. Int. Ed. 37, 1328–1345 (1998).

Ruhs, P.A., Storz, F., Gomez, Y.A.L., Haug, M. & Fischer, P. 3D bacterial cellulose biofilms formed by foam templating. npj Biofilms Microbiomes 4, 21 (2018).

Bai, T. et al. A comparison of different surfactants on foam stability in foam sclerotherapy in vitro. J. Vasc. Surg. 69, 581–591 (2019).

Beneventi, D., Carre, B. & Gandini, A. Role of surfactant structure on surface and foaming properties. Colloids Surf. A Physicochem. Eng. Asp. 189, 65–73 (2001).

Wang, H., Guo, W., Zheng, C., Wang, D. & Zhan, H. Effect of temperature on foaming ability and foam stability of typical surfactants used for foaming agent. J. Surfactants Deterg. 20, 615–622 (2017).

Roux, A., Duchesne, A. & Baudoin, M. Everlasting bubbles and liquid films resisting drainage, evaporation, and nuclei-induced bursting. Phys. Rev. Fluids 7, L011601 (2022).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (12272079, 12172189, 11921002) and fundamental research funds for the central universities (DUT21YG213).

Author information

Authors and Affiliations

Contributions

M.L. conceived the research. M.L. and C.L. supervised the research and wrote the manuscript. M.L., Q.Z., F.S., Z.K., and H.X. contributed to the fabrication of rigid electronics and most of the transfer printing experiments. X.H., J.D., L.C., and J.L. contributed to the fabrication of flexible electronics and characterization. C.L., H.X., Q.Z., and K.L. contributed to theoretical models. All the authors discussed the results and contributed to the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhao, Q., Li, K., Sun, F. et al. A versatile transfer printing technique through soap bubble. npj Flex Electron 9, 76 (2025). https://doi.org/10.1038/s41528-025-00460-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41528-025-00460-1