Abstract

Per- and polyfluoroalkyl substances (PFAS) are a class of synthetic chemicals that are highly resistant to degradation because of the strong C-F bond and their unique physico-chemical properties. Several techniques, both destructive and non-destructive, have been explored for removing PFAS from contaminated water. However, the most desirable techniques, ideally capable of effective separation and complete PFAS destruction and mineralization, have not progressed beyond bench-scale testing. This paper provides an overview of the existing treatment techniques demonstrated at laboratory, pilot, and industrial scales, and their associated treatment mechanisms. Insufficient data on pilot-scale and full-scale applications for PFAS remediation has limited the optimization and advancement of these systems at a large scale. Most research related to PFAS-remediation is based on laboratory-scale studies under ideal conditions that do not represent the complexity of PFAS-contaminated media. Factors such as inhibition by competing background compounds and secondary water or air pollution limit the application of some PFAS removal techniques at full-scale. Additionally, high energy intensity, cost, and inappropriate reactor design restrict the scalability of some proposed innovations. Here, we propose integrated systems and treatment trains as potential approaches to effectively remove and destroy PFAS from contaminated waters. This review also offers and contextualizes implementation barriers and scalable approaches for PFAS treatment.

Similar content being viewed by others

Introduction

Per- and polyfluoroalkyl substances (PFAS) are a class of amphipathic molecules with a hydrophilic, charged head group and a hydrophobic, fluorinated tail. Their reactivity and toxicity vary greatly depending on the type and size of these two groups. PFAS are thermally stable and highly resistant to various forms of degradation, including biodegradation, photolysis, and hydrolysis, due to the strong carbon–fluorine (C–F) bond (105 kcal/mol)1,2,3,4. They are commonly referred to as ‘forever chemicals’ because of their persistence in the environment. Other properties of PFAS, such as hydrophilicity and solubility, also pose significant challenges in conventional wastewater treatment processes, as the treatment plants are not equipped to adequately remove PFAS5. There are over 15,000 types of PFAS, but only a select few; such as perfluorooctanoic acid (PFOA) and perfluorooctane sulfonate (PFOS) (both of which contain 8 carbon atoms) have been studied extensively6.

Among several emerging pollutants discovered between 1839 and 2019, PFOA and PFOS garnered a relatively high increase rate of consideration of 18.8% and 13.6% in the years 2018 and 20197. While PFOA and PFOS are the most widely used PFAS in various applications7, shorter chain PFAS can be generated during degradation processes of the long chain PFAS7,8,9,10,11,12. While high PFOA removal rates are standard in many reports, removal of short chain PFAS is much lower. This is because the degradation of long chain PFAS, like PFOA, leads to the generation of shorter chain PFAS, like PFBA, increasing their concentration overtime if they are not immediately degraded13,14,15,16,17,18. Figure 1 illustrates how shorter chain PFAS are generated by the breakdown of longer chain PFAS, here via photocatalytic or photolytic catalysis. In the case of direct photolysis, the C7F15· and CO2 will be generated from perfluorinated carboxyl anions as a result of photoelectrons facilitating the breakage of the C-C bond.

Concluded common pathway for photo-oxidative degradation of PFOA173.

The United States Environmental Protection Agency (USEPA) has set limits for five PFAS, i.e., PFOA, perfluorooctane sulfonic acid (PFOS), perfluorononanoic acid (PFNA), perfluorohexanesulphonic acid (PFHxS), and hexafluoropropylene oxide dimer acid (HFPO-DA—often referred to as GenX Chemicals). The maximum contamination levels for drinking water are 4.0 ppt (ng/L) for PFOA and PFOS, and 10 ppt for PFNA, PFHxS, and HFPO-DA19. In China the drinking water limit is 80 ng/L for PFOA and 40 ng/L for PFOS20. These limits are extremely low and pose a significant challenge for the quantitative detection of these contaminants in aqueous media. Other nations have implemented standards that limit total organofluorine, making complete degradation of PFAS crucial21.

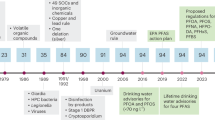

PFAS were developed in the 1940’s as part of the Manhattan project to enrich uranium, and their use grew and diversified rapidly, which resulted in widespread environmental pollution1,22. While high levels are usually found near PFAS manufacturing or discharge sites, some level of PFAS is nearly ubiquitous in water sources worldwide23,24. Even in the least inhabited parts of the world, PFAS contamination is present; for instance, blood tests have revealed PFAS in arctic polar bears25. Other data relating to the bioaccumulation of PFAS and their adverse health effects on humans have been reported4. PFAS exposure has been linked to many negative health effects, including liver and kidney diseases, reproductive issues, impaired immune system function, thyroid dysfunction, pregnancy hypertension, heightened cholesterol levels, and testicular cancer26. In infants, PFAS have been reported to delay mammary gland development, reduce growth, and inhibit response to vaccines27. Two of the commonly used PFAS (PFOA and PFOS) have also been reported as carcinogenic to humans (Group 1) and possibly carcinogenic to humans (Group 2B), for PFOA and PFOS respectively28. Furthermore, PFOS and PFOA concentrations in blood are reported to be much higher than any other PFAS6.

There are several sources from which PFAS may emanate, including manufacturing facilities, industrial complexes, and military fire training sites29,30. However, two of the most dominant sources of PFAS are landfill sites and wastewater treatment plants, both industrial and municipal30. From these sources, PFAS may enter the environment through spills, wastewater discharge, and surface water run-offs31. In order to curb the impacts of PFAS in the environment, there is a need for regulatory interventions from all countries. Past regulatory interventions have halted the production of long-chain PFAS with carbon chain length greater than six32. Short-chain PFAS were developed to replace historical PFAS, but both long-chain and short-chain PFAS persist in the environment and necessitate remediation27. Emerging information on the toxicity of short-chain PFAS has highlighted knowledge gaps surrounding their potential hazardous and bio-accumulative consequences.

Due to PFAS toxicity at extremely low concentrations, many sensitive removal technologies have been developed (Fig. 2). However, most of these technologies have limited efficiency and are not currently feasible for scale up. High cost and energy consumption, new infrastructure requirements, hazardous chemical usage, and the need for pretreatment or preconcentration hinders the use of many technologies in real-world settings33,34. These limitations have warranted a need to identify and develop new technologies at large scale that can eliminate PFAS efficiently to avoid contamination of the environment.

This review examines various destructive and non-destructive techniques for the removal of PFAS from water and discusses research needs and opportunities to enhance. We provide an overview of current PFAS treatment techniques by summarizing the progress made to date and discussing the removal or degradation mechanisms underlying each technique and include suggestions for improvements. Additionally, recent progress in integrating non-destructive and destructive techniques to enhance cost-effectiveness in PFAS remediation will be discussed.

Remediation techniques of PFAS: fundamentals, mechanisms, applications, and limitations

Non-destructive separation techniques

Adsorption, ion exchange, and membrane separation are typical examples of non-destructive or phase separation techniques that remove PFAS without transforming them35. The merits and limitations of each technique are discussed, and applications of these techniques at laboratory, pilot and full-scale are compared. Additionally, factors hindering commercialization of these techniques are examined. Overall, non-destructive techniques do not eliminate liability and are hindered by the generation of PFAS-concentrated streams or waste, which require additional treatment before discharge into the environment36. The advantages and disadvantages of non-destructive technologies are presented in Fig. 3 and discussed in detail in the subsequent sections.

Ion exchange

Ion exchange (IX) is used in the removal of long and short-chain PFAS from water with high removal efficiency and long lifetime because of the ability of the resin to be regenerated37. IX takes advantage of the amphiphilic nature of PFAS through using the electrostatic interactions between the functional group head of PFAS molecules in the appropriate pH range37. The principle of action of these IX resins is as follows: (i) for non-anionic resins, PFAS are removed through the hydrophobic effect38; (ii) for anionic resins, PFAS are adsorbed via electrostatic interactions. Resins are comprised of a hydrophobic polymer backbone and charged functional groups, allowing the polymer to attract PFAS tails via hydrophobic interactions and attract PFAS anionic head groups by exchanging its counterions with the PFAS present in the liquid phase39.

The performance of PFAS-specific resins varies with properties of the resin and matrix composition (presence of other competing species). There are three main characteristics of a resin that influence the removal of PFAS: polymer composition, pore structure, and charged functional group. The polymer composition can be either styrene or acrylic, the pore structure can be gel or microporous, and functional groups are mostly amino complexes, quaternary amines, or tertiary amines39. A comparative study of PFAS removal in the presence of natural organic matter (NOM) used PFAS-specific (A592, polystyrene) and organic scavenger (A860, polyacrylic) resins, and showed high removal efficiency for both short and long-chain PFAS > 90%) while removing 12–15% of NOM38. In contrast, the organic scavenging resin was effective in removing NOM (60–70%) but required 3-fold higher contact time to reach a similar removal efficiency as the PFAS specific resin38. These results corroborate another study showing that polyacrylic-based resins were not as effective for PFAS removal40.

Mechanisms of PFAS removal using IX

Electrostatic and hydrophobic interactions are the fundamental mechanisms of IX41,42. DuPont recently detailed a mechanism of one of their commercial IX resins (IX AMBERLITE™ PSR2 Plus). This resin, like other resins that are used in PFAS applications, is functionalized with tri-N-butylamine, making the exchange sites more hydrophobic and subsequently increasing their affinity for PFAS tails. The hydrophobic effect is the result of PFAS moving towards non-polar hydrophobic surfaces with the help of entropy. It was demonstrated that the hydrophobic effect increases with the C-F chain length43,44. The impact of solution pH on PFAS absorption provided further evidence of the prevalence of electrostatic interactions during the IX process. The uptake of anionic PFAS is directly impacted by the surface charge of IX, which can be changed by protonating the surface functional groups through pH adjustments. Figure 4 depicts PFAS removal through IX principle and mechanism.

(i) A Typical IX resins have charged sites able to attract the oppositely charged ions, here a positively charged resin attracts negatively charged Cl-ions and PFAS. When PFAS and NOM-containing water is passed through the resin, PFAS and Cl-ions are exchanged resulting in the resin absorbing the PFAS, B PFAS is comprised of hydrophobic tail and hydrophilic head- the hydrophobic tail tends to gravitate towards non-polar entities, C the removal of PFAS through IX is impacted by the hydrophobic effect resulting in PFAS associating with NOM, further NOM can compete with PFAS on the resin. (ii) Anion resin comprised of positively charged exchange sites, divinylbenzene cross links, and neutral hydrophobic backbone38,39.

Laboratory-scale and pilot-scale IX applications in the removal of PFAS

IX resins have been extensively used at laboratory-scale, wherein most studies compared the effectiveness of GAC and IX in rapid small-scale column tests (RSSCT) that are considered a model for pilot-scale. Unlike GAC, IX had better PFAS removal efficiency, but at a higher cost. A recent study demonstrated that IX had better adsorption capability than GAC due to both electrostatic and hydrophobic interactions of the IX resin43. Elsewhere, IX resin Amb XAD4 outperformed Dow V493, Dow L493 and removed over 99.99% PFOS at a flow rate of 15 mL/min and was regenerated using a simple organic solvent45. When the performance of two full-scale treatment plant using IX was assessed for PFAS removal. The process was found effective in removing long-chain sulphonated PFAS with an efficiency of more than 92% and less effective in the removal of short-chain PFAS46. At pilot-scale, Woodard et al.38 examined the effectiveness of GAC and IX in the removal of PFAS. The pilot plant treated 422.645 gallons of water and was comprised of 2 parallel pilot test process units (GAC and IX) as depicted in Fig. 5a. For IX, the resin vessels were connected in series; in each vessel were 9 gallons of Sorbix A3F resin providing 2.5 min empty bed contact time (EBCT). The results showed that IX effectively removed PFOA and PFOS, and a mass-to-mass comparison illustrated that IX removed 1.66 mg total PFAS per gram of Sorbix A3F before breakthrough was observed. Key in this study was evaluating Sorbix A3F’s regeneration capability through successive regeneration tests. Using brine and an organic solvent to desorb the PFAS on the resin, the performance of the Sorbix A3F in the lead vessel was restored to near virgin performance. The regenerated resin treated 77.455 gallons of water and the detected PFAS concentration was 4.1 μg/L after 6.824 BVs of treatment. PFOS removal in chromium-plating wastewater was assessed using the pilot plant as shown in (Fig. 5b)47. Interestingly in this work, despite AER being known to effectively adsorb anionic PFAS, it exhibited different adsorption performance for the PFOS and 6:2 FTS. In this study, to estimate the cost to remove PFOS and 6:2 FTS, the costs of virgin adsorbents, disposal costs and power supply were taken into account and linked to the volume treated. Based on the calculations, it would cost $0.24/m3 and $1.99/m3 wastewater to remove PFOS and 6:2 FTS respectively. Elsewhere, anion exchange and GAC were used to treat PFAS concentrate after nanofiltration at pilot scale (Fig. 5c)48. Both raw untreated water and the reject from the membrane were passed through a 400 mL AIX resin A600 and flowrate maintained between 70 and 80 mL min−1. Data showed that the long chain PFAS were better removed than the shorter chain PFAS due to the adsorption of long chain PFAS such as PFOS, PFHxA, PFOA, and PFHxS driven by hydrophobic effects. The data obtained in this work shed light on the practicality of applying AIX to treat membrane reject. Some factors to consider include knowing the quality of the feedwater and the concentrations of PFAS in the water. The AIX noticeably removed 4.1-fold more PFAS mass per AIX volume from the membrane concentrate. Polystyrene and polyacrylic AER resins were applied in a pilot system capable of treating >180.000 BVs (2 min EBCT) and >750.000 BVs (0.5 min EBCT) in the 2 media vessels and lead vessels respectively (Fig. 5d). Single use AERs removed long chain PFCAs and PFSAs more efficiently than regenerable AERs up to 8 times. For the short chain, it was less significant i.e., >50% PFBA breakthrough within 50.000 BVs.

a A groundwater treatment plant building pilot test equipment installed with 2 parallel pilot test process units IX and GAC, b the system is comprised of parallel GAC adsorption unit and AER adsorption unit, prior to entering the parallel GAC adsorption unit and AER adsorption units the feed was passed through a bag filter. The primary focus of the pilot research took place in column 1 and column 2 was to solely guarantee the effluent's quality, c two nanofiltration membranes were connected in series to treat PFAS contaminated raw water, additionally the raw water and membranes’ reject were subjected to GAC and AIX, d pilot with 24 vessels arranged in eight parallel columns, grey vessels were omitted from the study due to cost constraints38,47,48,174.

Practical considerations and cost estimations of using IX in the removal of PFAS

Despite lab-scale success of IX, there are limitations, such as the cost of secondary waste management. Treating secondary waste uses expensive techniques and requires temperatures of ~1000 °C for incineration. In addition, incineration may emit volatile PFAS into the air, causing environmental concerns. While spent IX resin may be regenerated with brine which presents a safer option, brine still needs further treatment to eliminate toxicity. Other limitations of IX technique include the presence of competing anionic inorganic and organic species which reduces the efficiency of the resins. To select appropriate resins for IX, operators need to know the PFAS concentrations and type (i.e., long or short chained PFAS). Single-use resins have quaternary amines and long hydrocarbon chains which allow hydrophobic attractions and enhances PFAS uptake. Polystyrene resins too, have hydrophobic features allowing PFAS uptake. In locations where long chain PFAS are predominant, high-capacity single-use AERs would be ideal. However, where short chain PFAS are more abundant operators may consider regenerable resins. The configuration of the vessels of the resins in a pilot is something worth considering too. A configuration arranged in series and ensuring the lead vessel is operated to enhance breakthrough prior to media change is ideal. With this setup, operators will be able to swap out the resin with high PFAS loading in the lead vessel while still facilitating adsorption in the lag vessels that would ordinarily be swapped out at a single vessel changeout. Regarding EBCT; ≥2 min was found to optimal unlike shorter EBCTs (i.e., 0.5 min) as rapid detection of PFAS analytes were observed at shorter EBCTs. From an operation and maintenance perspective, the operational costs are often estimated by taking virgin resin costs, used resin disposal, analytical costs, and in other instances power supply costs are also included49. It is worthy of consideration that in full-scale other factors such as labor costs, water quality, depreciating equipment may be considered in estimating operating costs47. Media costs and disposal of IX were estimated at $17.60/kg and $5.300 (per changeout event) respectively50,51. Jiang et al.47 estimated it would cost $7.143–11.429/t (¥50.00080.000/t) to remove PFAS using AER. Operators could consider deploying reverse osmosis (RO) to treat the volume of effluent requiring incineration52. This has been demonstrated to reduce operational costs related to disposal costs and it was shown to reduce ~96.5% of the regeneration volume. In certain instances, cationic polymer-based hydrogels have been proven to be effective in the above.

Adsorption

Heterogeneous adsorption is widely used due to its economic feasibility and ability to adsorb various organic contaminants44. Carbon materials have been used extensively in PFAS removal from water via adsorption45. In PFAS applications, activated carbon is used in several forms: granular activated carbon (GAC) in carbon adsorption columns, commonly found in water and wastewater purification systems; powder-activated carbon (PAC), known as the carbon-activated sludge process for wastewater treatment; and activated carbon filter (ACF)53. GAC, PAC, and ACF differ in their morphological characteristics, such as particle size, surface charge, surface area, and composition. GAC has carbon particles with diameters ranging from 1.2 to 1.6 mm, PAC particles are ~0.1 mm, and ACF ranges from 5 to 30 μm54. The surface charge and carbon composition of AC are mostly determined by the activation process and the type of carbon material used during synthesis55,56. Based on performance, ACF exhibits the best adsorption characteristics for PFAS, followed by PAC, and then GAC57. The high efficiency of ACF is ascribed to its porous structure, large, exposed surface area, concentrated pore size distribution, and smaller fiber diameter57. However, ACF systems are mainly limited by cost of production, as they are synthesized from relatively expensive carbonaceous fibrous precursors such as pitch, phenolic resin, cellulose, and polyacrylonitrile fibers57,58. GAC and PAC are made from less expensive carbonaceous materials such as wood, lignite, coconut, peat, and coal. PAC’s smaller particle size compared to GAC necessitates the incorporation of a primary clarifier to remove PAC, increasing the energy usage and cost of PAC systems. Therefore, the use of GAC is common for PFAS removal. GAC effectively removes long-chain PFAS until breakthrough occurs, but is less effective for shorter-chain PFAS, leading to faster breakthrough and lower GAC loading capacities59.

In addition to carbon-based materials like AC used as adsorbents, metals such as Zn, Fe, and Cu have been used to modulate multi-walled carbon nanotubes for PFOA removal60. Another class of emerging adsorbents include β-Cyclodextrin polymers (CDPs), which was recently used as an alternative to remove 20 target PFAS61. In the study, two CDPs consisting of β‑ cyclodextrin monomers crosslinked with rigid aromatics containing weakly basic or permanently cationic functional groups were found to remove nearly all the PFAS from water after 4-h of contact time61.

Mechanism of PFAS removal with adsorption

The removal of PFAS through adsorption is based on the hydrophobic and electrostatic interactions, ligand exchange, and hydrogen bonding properties of the adsorbent (AC) and adsorbate (PFAS)61. In aqueous solutions of PFAS with pKa values up to 1 form a negatively charged head group61. This negatively charged head is attracted by the positively charged AC surface groups making electrostatic interactions the driving force for the adsorption process61,62. For hydrophobic adsorption mechanisms, an adsorption energy and site preference creates a force-field which displaces water from the hydrophobic surface. This enables short range attractive interactions between hydrophobic PFAS and the AC to take place62, thus facilitating PFAS adsorption. To cater for positively charged and neutral PFAS, AC surface chemistry is important in improving their removal. The significance of AC surface chemistry for PFAS adsorption may be due to the extraordinarily low pKa values (high acid strength) of PFAS, which restrict the charge neutralization during adsorption. In addition, positively charged surface groups in a mostly nonpolar environment are ideal conditions for adsorption of anionic perfluoroalkyl acids (PFAAs) and hydrophobic tail interactions61. Moreover, the presence of NOM molecules which mostly exist in a negatively charged state can lead to repulsive electrostatic interactions toward the anionic PFAS and in some cases hydrophobic interactions. This limits efficiency due to competition for adsorption on limited AC surface area44. Figure 6 depicts various PFAS adsorption removal mechanisms.

a Due to opposing charges, the negatively charged PFAS heads will be attracted to the positively charged surface (electrostatic attraction), b similar charges will result in repulsion, the negatively charged PFAS heads will repel a negatively charged surface (electrostatic repulsion), c when the hydrophobic tails of the PFAS interact with hydrophobic surfaces they tend to cluster together minimizing water interaction (hydrophobic interactions).

Pilot-scale and full-scale application of adsorption for removal of PFAS

The efficiency of a full-scale drinking water treatment plant using GAC was evaluated in removing 15 types of PFAS40. The treatment plant (Fig. 7a) had the following treatment steps: aeration, softening, filtration (dual media) and disinfection. Comparative studies were carried out to assess how a “young” GAC filter (63 operation days) and “old” GAC filter (264 operation days) performed at full-scale. The flowrates of 35 L s−1–45 L s−1 were initially modified to 30 L s−1 and subsequently to 15 L s−1. From the work it was clear that the treatment steps in the treatment plant (i.e., aeration, softening, filtration and disinfection) had no impact on PFAS removal. The GAC filters removed 67–100% of the PFAS, and long chained PFAS were removed more efficiently than short chained PFAS. The removal efficiency of the GAC was influenced by the individual operating times of the filters (young vs old). In addition, lower flow rates enhanced the removal of PFAS. Decreasing the flowrate from 39 to 18 L s−1 after having reached the treatment goal could prolong the lifespan of the GAC by 50%40. It is important when conducting pilot studies to ensure that the results obtained can be utilized and applicable at full-scale. Therefore, hydraulic loading rate is important and enables accurate projections of what would occur at full-scale63. From the study, GACs effectively removed PFAS and exhibited low exhaustion over period, later initial breakthrough, and adsorbed PFSAs better than PFCAs. When comparing F400 GAC to Sorbix A3F resin F400 GAC had lower adsorption capacity; suggesting that the treatment system may require minimal mass of adsorbent/resin if they have high adsorption capacity. The large media volume, high number of pressure vessels needed for GACs made the capital costs higher compared to IX.

a Evaluation of full-scale treatment efficiency (denoted by circles), effect of flowrate (denoted by squares) and long-term efficiency of GAC (denoted by triangles) in the removal of PFAS in a water treatment plant, b depiction of GAC skids equipped with 4 columns and an IX/alternative adsorbent skid equipped with 6 columns, c four GAC columns connected in series in the removal of PFAS, d full-scale plant using columns made up of biological activated carbon (Norit 830 W) and rapid sand filtration at pH 6.840,58,63,64.

Medina et al.63 studied the removal efficiency of PFAS using GAC in a pilot study as shown in Fig. 7b. The pilot-system comprised 3 adsorbent media skids and pre-filtration skid. Of the skids, 2 had 4 columns loaded with GAC. Skid 3 had 6 columns: 2 loaded with AAs and the other 4 loaded with IX. Two 30-µm cartridge filters connected in parallel were found in the prefilter skid. All columns have an effluent sampling port, low totalizer, influent variable area flow meter (5.68–56.8 L/h). All GAC skids had influent pressure gauges while the columns had an effluent sampling port and 1 variable area flow meter (5.68–56.8 L/h).

Elsewhere, in Colorado, to better understand PFAS breakthrough Liu et al.58 evaluated the removal of PFAS in contaminated groundwater. In the system, the feedwater was fed at 2 GPM, passed through a 50 μm cartridge filter, and distributed to separate GAC columns at 0.5 GPM (Fig. 7c). Automated valves (controlled using supervisory control and data acquisition system) were used to regulate the flowrate in the columns. Before use, GACs were immersed for 24 h in deionized water and backwashed to 30% bed expansion. The columns were assembled to 10 min EBCT. The results obtained showed that breakthrough proved to be dependent on chain length, except for PFHpA and PFHpS. For the non-chain length dependent trends of the PFHpA and PFHpS. these were attributed to low influent concentrations and preferential sorption sites. Performance wise, compared to F600 and GCN1240, F400 and GAC400 outperformed them by 40-50% due to the minimal intraparticle diffusion limitations. GAC was assessed in removing PFAS and other organics at full-scale64. The treatment plant is comprised of conventional treatments steps including biological activated carbon filtration, microsieving, and secondary disinfection (Fig. 7d). Based on their findings, the researchers recommended to study novel, cost-efficient treatment techniques for PFAS and desorption trends in GAC filters and through the train of a drinking water treatment plant process.

Comparing the performance of GAC (Filterasorb 400) and anion exchange (EA purolite), short-chain PFAS had short-time breakthrough65. In a separate study38, regenerated GAC (F400) removed PFAS to below the limit of detection and was successfully regenerated to near-virgin conditions. In other 18-month pilot-study comparing GAC, biochar, and anthracite in removal of both short-chain and long-chain PFAS, GAC was found to have high removal efficiency followed by biochar66. Similar behavior for the removal of short-chained PFAS such as PFBA, PFPnA, and PFHxA, were observed, and high concentration of dissolved organic carbon (DOC) reduced the adsorption of PFAS; this study employed an ACF system with adsorption capacity of 108 L/kg at pH 7 for PFOA62. In the study 15 different PFAS were analyzed for the effect of flow rate on the removal efficiency and long-term performance (aging) (Fig. 8). The removal efficiency with the virgin GAC ranged from 92 to 100% whereas the removal efficiency of the spent GAC was between 7% and 100%. The decrease of flowrate by 10 L.s−1, increased the removal efficiency by 14% and 6.5% for used GAC and virgin GAC, respectively. The full-scale results concurred with laboratory and pilot scale studies demonstrating that GAC is less effective in removing short-chain PFAS58. A pertinent challenge in removal efficiency of PFAS was the presence of NOM, which reduces the exposed surface for adsorption and can lead to deactivation. Water samples were collected at different stages of the treatment process except for the disinfection unit. In the post disinfection unit, samples were collected from storage in the underground reservoir which were free of chlorine. The GAC F400 performed better most likely due to the higher surface area of 1050 m2 g−1 for enhanced PFAS removal compared to AquaSorb® 2000 with 950 m2 g−167. Other results also showed that the BET specific surface area was a significant factor affecting PFAS removal55. Strong interactions and sufficient adsorptive surface area accelerate the reaction rate during the PFAS removal process68. Out of several used GAC, one GAC labeled GAC 9, achieved up to 99% removal efficacy for PFAS within 30 days, while another GAC (GAC 8) achieved 67% removal in 360 days. The GAC 8 system exhibited lower adsorption capacity for shorter-chained perfluoroalkyl carboxylic acids (PFCAs) but higher adsorption capacity for branched PFAS. Specifically, GAC 8 removed 66% of linear PFAS, while GAC 9 achieved up to 100% removal of linear PFAS. For branched PFAS, GAC 8 and GAC 9 had a removal efficiency of 37% and 100%, respectively40. Adsorption of 9 short and long-chained PFAS by PC systems was also investigated69. A total of 90% removal efficiency was achieved for long chained PFAS within 120 min (Table 1), whereas for short-chained PFAS only 85% removal was achieved after 240 min. This trend was also observed with RSSCT and batch tests70. Batch tests achieved up to 95% PFAS removal whereas the RSSCT achieved a 50% breakthrough throughput. The positively charged AC surface increased the affinity for PFAS resulting in higher adsorption capacities.

A Filtrasorb® 400 (GAC 1), B Filtrasorb® 400 (GAC 2), C Filtrasorb® 400 (GAC 3), D Filtrasorb® 400 (GAC 4), E 80–90% AquaSorb® 2000 and 10–20% Filtrasorb® 400 (GAC 8) and F Filtrasorb® 400 (GAC 5) (circle denotes PFCAs and triangle denotes PFSAs)40.

Practical considerations and cost estimations of using GAC in the removal of PFAS

The greatest limitation associated with adsorption is its inability to degrade PFAS, resulting in the creation of secondary waste. Further is inefficiency to remove short chain PFAS which is important to some industries like semiconductor manufacturers. The presence of competing species such as NOM and the deactivation of GAC media over time requires constant changeout which is labor intensive and costly. In addition, the spent GAC media requires safe disposal, which if not handled well, may result in secondary contamination55. Although the used GAC can often be regenerated; its efficiency tends to decrease, leading to faster PFAS breakthrough and necessitating the flow rate to be adjusted. Another challenge is that the regenerating spent sorbents typically requires energy-intensive thermal treatment to eliminate PFAS, which can potentially release more toxic byproducts into the atmosphere71. This concern led to a temporary ban on the incineration of PFAS-saturated sorbents, which was lifted in July 202372. Addressing these challenges through the functionalization of GAC-based filters with adsorptive catalytic nanoparticles would offer numerous advantages in the treatment of PFAS73. This functionality would enhance filtering and adsorbing and catalytic properties of GAC, extending its lifetime and reducing replacement costs.

To effectively estimate the operational parameters and costs of using GAC at full-scale depends largely on the treatment goal for the plant40. For a plant with a 25 ng L−1 treatment goal, the cost is estimated at 0.058 euro per m−3. In earlier work, McNamara et al.55 estimated the operating costs (for a plant with a 70 ng L−1 treatment goal) to be 0.038-euro m−3 and 0.025-euro m−3 for regenerated and virgin GAC filters respectively. The costs for GAC regeneration typically account for the majority of the yearly operating costs. Belkouteb et al.40 demonstrated that by adjusting the flowrates to prolong the lifespan of the GAC filters can reduce the costs by 26%. Further, reducing the regeneration costs by 20% also lowers the unit cost by 20%. It must be noted when selecting GAC to opt for a high efficiency and quality as this can lower unit costs by 16%. The costs for media for IX and disposal were $256–$322 per cubic foot and $0.50 per lb respectively. However, the disposal costs are dependent on state regulations which are subject to change. Operators should assess the impact of source water quality and identify the most appropriate IX for individual circumstances at the different sites.

Membrane separation

Membranes used in water treatment are typically ceramic or polymer membranes, and the separation of PFAS is mostly through size exclusion74. RO and nanofiltration (NF) membranes are effective in the removal of PFAS due to their narrow pore sizes which has a diameter that range from 0.0001 to 0.001 μm for RO and 0.001–0.01 μm for NF75. Microfiltration (MF) and ultrafiltration (UF) have a low removal efficiency as their pore sizes are large to reject PFAS. Due to the difficulties of fabricating the ceramic membranes with pore sizes of RO and NF range, there are few studies available on ceramic membranes to remove PFAS from water. Polymeric membranes can be fabricated with RO and NF pores sizes and are the most investigated and applied in the separation of PFAS76.

Mechanisms of PFAS removal with filtration membranes

Membranes can drive separation through adsorption, sieving (size exclusion), and electrostatic interactions (Fig. 9a–c). The separation in membranes is mostly determined by membrane surface properties such as porosity, zeta potential, pore size, and hydrophobicity and/or hydrophilicity. The efficiency of PFAS rejection by a membrane is affected by several parameters such as pH, organic matter concentration, ions, and ionic strength76. Changes in solution pH can affect membrane pore size, flux, and rejection, as well as the surface charge of the membrane depending on the isoelectric point of the membrane material and the associated groups on the membrane surface77. Organic matter present in the solution can also influence PFAS separation by coupling or reacting with the target PFAS compounds, thus changing the membrane surface charge and causing membrane fouling. Electrostatic interactions between PFAS and ions present in water could also cause the ions to bind with the PFAS to form larger clusters, causing partial pore clogging78.

a Physically sieving solutes that are bigger than the membrane molecular weight cut-off (size exclusion), b elevating pH may deprotonate the carboxyl groups on membrane as a result increasing negative charge which enhances the rejection (electrostatic interaction), c adsorption efficiency can be impacted and influenced by variations in pH as well as ionic strength; mono/divalent cations typically enhance removal efficiency, while increased pH levels tend to decrease adsorption capacity (adsorption) [modified from refs. 74,91,175.

The size exclusion mechanism is mainly applicable to NF and RO membranes that reject PFAS. These membranes have a low molecular weight cut-off (MWCO), which is smaller than the molecular weight of most PFAS78. The molecular weight of PFAS detected in surface water ranges from 213.03 to 613.09 Da, and the MWCO of NF membranes range from 200 to 10,000 Da and for RO is below 200 Da78. By comparing the molecular weight of PFAS and the MWCO of membranes, RO membranes can generally remove all the short-chain and long-chain PFAS, but NF, cannot remove all short-chain PFAS. The size exclusion of PFAS by NF and RO membranes was also confirmed in a study that reported PFAS removal efficiencies of 90–99% for NF and over 99% for RO membranes79.

Electrostatic interactions between charged membrane surfaces and PFAS are another mechanism that influences the removal of PFAS. Most PFAS exist as anions in water, therefore, electrostatic attraction may occur if membrane surface charge is positive79. However, the adsorbed PFAS on the membranes may block the pores of the membranes which in turn reduces water flux and consequently causes membrane fouling80. Electrostatic repulsion between PFAS and the membrane is an ideal interaction to achieve maximum rejection in the removal of short-chain PFAS. This mechanism is highly dependent on the pH.

Generally, when the membrane surface charge is negative, excess protons protonate the negatively charged surface to neutral or positive on the surface, and that could reduce the repulsion forces and allow for PFAS adsorption. The performance of two NF membranes (NF 270 and NTR-7450) were investigated in removal of PFHxA at different pHs (3, 7, and 10). One membrane (NTR-7450) was not affected by the change in pH, but the other membrane exhibited poor performance at pH 3. A general trend of increase in performance with the increase in pH was observed80. The poor performance at pH 3 was attributed to the membrane (NF 270) being negatively charged at low pH and consequently reducing the repulsion forces. It is, therefore, crucial to consider the surface charge of the membranes to achieve maximum rejection through electrostatic repulsion.

Pilot-scale and full-scale application of membranes for removal of PFAS

Coupling membrane technology with adsorption techniques such as activated carbon, and ion exchange resins has been investigated in pilot studies to mitigate the challenge of handling concentrated streams48. NF membranes were used to remove PFAS from water and then the PFAS-concentrated streams were treated with GAC and IX. Membrane technology can also be coupled with catalytic treatment of PFAS, targeting the high concentration brine. Concentration polarization is a common challenge in membrane technology but is of greater concern when the retentate contains PFAS. It is paramount to manage or treat the membrane concentrate to avoid secondary contamination. Regulations state that the total volume of the membrane concentrate waste should always be lower than the daily treatment capacity of the post-treatment systems81. Therefore, it is necessary to optimize water recovery (Y) to reduce the environmental impacts. The water recovery (Y) is defined by Eq. 1:

where qP and qO are the volumetric flow rate of the permeate and the raw-feed water respectively.

The water recovery can be enhanced by shutting down the membrane concentrate’s valve, based on the linear relationship of the flux of the permeate and transmembrane pressure. Another approach is by recycling the concentrate, as shown in Fig. 10a, and through this approach the velocity of the cross is increased which in turn reduces the thickness of the concentration boundary layer81.

a Illustration of single-stage membrane used as single stage and concentrate recycling that can be reduced through reducing thickness of the concentration boundary layer where qO is the volumetric flow rates of the raw-feed water, qF the feed, qP the permeate, qC the retentate and qD the concentrate discharge and CO denotes raw-feed water, CF the feed water, CC, the retentate and finally CP denotes the permeate concentration of the contaminant, b rejection of PFAA using single 4 long high-pressure membranes assembled to hold three 8 × 40 inch spiral membranes equipped with a single membrane spacer81,82.

A pilot-scale membrane filtration system was used to assess the efficiency in rejecting PFAA using high-pressure membranes82. The system operated in a closed-circuit had 4 long pressure vessels housing 8 ×40-inch spiral wound membranes and a membrane spacer. The pilot system was automated with sensors installed in the various probes, the feed flowrate maintained at 10 gpm and flux of 12 gfd (Fig. 10b)82. The membranes used in the pilot were included loose (NF270) and tight (NF90) NF membranes, RO (CR100), and seawater RO (SW30) membranes. A rejection rate higher than 98.3% was observed in the NF90, CR100, and SW30 membranes. The results were correlated with previous studies that indicated that large molecular weights and anionic features facilitated better separation. On the contrary, NF270 had the poorest PFAA rejection.

Hybrid NF and UV-sulfates were coupled for degradation of concentrated streams at pilot scale83. In this specific system, NF rejected 95% of PFAS and the UV-sulfate degraded about 90% PFAS from the concentrated streams after 8 h of treatment. Figure 11 shows results from studies on PFAS removal at laboratory48,84,85,86,87 pilot83, and full scale44,83,88,89.

Practical considerations and cost estimations of using membrane technology in the removal of PFAS

Overall, membrane technology has proven to be a viable approach for removing PFAS from water. However, there are still many challenges that need careful consideration. The major challenges of membrane technology in treatment of PFAS includes generation of concentrated PFAS streams that require further treatment before safe disposal and membrane fouling. To overcome these limitations, researchers have been focusing on the development of hybrid membranes to simultaneously degrade and filter PFAS. Hybrid membranes that have been studied include reactive electrochemical membranes (REM), electromagnetic ceramic membranes, and photocatalytic membranes89,90. These approaches mitigate the challenge of handling concentrated PFAS waste streams. Of the various membranes used in the removing PFAS; NF and RO membrane have recorded significant removal efficiencies. However, the energy consumption requirements increase the costs. The costs to treat wastewater containing PFAS using NF membranes is estimated to be between 0.016 and 0.16 $/m3 and 0.11 $/m3 in a drinking water plant91. Treating landfill leachate containing PFAS using RO was estimated to cost between 1.06 and 2.09 $/m392. As discussed in earlier sections, treatment or management of membrane concentrate is key. As such, integrating other technologies with membrane technology presents a viable solution. However, the cost associated integrated technologies cannot be ignored. In a study where the NF concentrate was treated using GAC and IX, the incurred costs were in the range 0.86 and 3.34 $/m3 respectively51. The estimation when using membrane-adsorption was estimated at 0.28 and 1.31 $/m3. Even higher treatment costs up to 13.1 $/m3 can be expected when integrating electrochemical oxidation and membrane technology as both technologies have high energy requirements91,93. When deciding on which technologies to integrate with membranes, practitioners ought to understand: the composition of the feedwater, PFAS concentrations, and type of PFAS present in the feedwater. Further, special attention needs to be paid when selecting membrane that is fit for purpose, this includes understanding the membrane’s structure, factors affect fouling and cleaning strategies. All these factors combined affect the lifespan and performance of the membranes. Other considerations when handling/treating membrane concentrate include exploring pre-treatment options and developing systems that are energy efficient.

Remediation of PFAS using destructive techniques

Destructive techniques involve the partial or complete breakdown of PFAS bonds, ideally resulting in mineralization, which is often assessed by extent of fluoride release. Supercritical water oxidation, sonochemical oxidation, electrochemical oxidation, and photocatalytic oxidation are examples of such techniques. These techniques are useful in the removal of PFAS at the bench scale. The major limitations to upscaling and commercialization to date include large space requirements, reactor design, high energy consumption, and high capital requirements for new treatment infrastructure. For instance, electrochemical oxidation may need costly electrodes and electrolytes. Table 2 shows the electrical energy per order of reaction for PFAS (PFOA and PFOS) destruction techniques.

On the other hand, destructive techniques namely plasma94, SWO95, and photocatalysis96 revealed higher degradation efficiency for PFOA and PFOS amounting to >99%, 99,9%, and 88% respectively. This review will focus on supercritical water oxidation, sonochemical oxidation, electrochemical oxidation, and photocatalytic oxidation. Further emphasis will be on emerging technologies such as plasma, hydrothermal alkaline treatment (HALT), advanced reduction process (ARP) and electron beam. Figure 12 illustrates an overview of the advantages and disadvantages of several destructive PFAS remediation techniques.

Supercritical water oxidation (SCWO)

SCWO is considered a clean technology because it results in complete mineralization of PFAS while producing no hazardous materials in the process. SCWO relies on heating water to above 374 °C under a pressure of 221.1 bar in the presence of an oxidant to achieve complete degradation of PFAS to CO2, water, and non-toxic substances97. SCWO has been applied to degrade persistent organics that do not easily undergo natural degradation such as polychlorinated biphenyl and 1,4-dioxane98. SCWO is one of the fastest destruction methods and could rapidly treat a variety of waste (i.e., wastewater, sludge/slurry, and biosolids)88.

The SCWO process consists of pumping the contaminated waste and oxidants into the reaction chamber with controlled temperature and pressure. Under these conditions, water is brought to its supercritical point where it resembles the properties of gas and low-polar organic solvents. Supercritical water dissolves oxidants (oxygen) and organics, creating a homogeneous solution that facilitates the oxidation of organics98. The SWCO technology has been tested98,99. Oxidation of PFOS to HF and CO2 can be achieved (only 70% of PFOS conversion) via SCWO using a stainless-steel batch reactor at temperatures up to 500 °C and 60 min. Autogenic operation of a SCWO reactor can be sustained by a reaction mixture of ethanol and air100,101. The reactor operated in continuous flow up to 650 °C and destroyed 99.999% of PFOS, PFHpS, and PFOA in ~30 s. This is an improvement from earlier results101 obtained from batch reactor, at low temperature 500 °C and longer residence time of 60 min.

Mechanism of PFAS degradation using SCWO

The chief degradation mechanisms of SCWO can occur either via hydrothermal reaction or oxidation95. Typically, the hydrothermal degradation will occur before the supercritical point and is known as sub-critical hydrothermal processes. PFOS degradation and defluorination by hydrothermal reaction has been studies using different acidic, basic, oxidative, and reductive amendments96,102. Alkali amendments such as NaOH and Ca(OH)2 increased degradation efficiency of PFAS at sub-critical water region. The degradation mechanism under basic conditions was catalyzed by OH−. Under hydrothermal conditions PFOA is unstable, and therefore undergoes decarboxylation to form perfluorocarboxylates while releasing 2 F− stepwise until it completely mineralizes to CO2, F−, and HF.

Another study probed the influence of amendments of metals (Fe, Cu, Al, and Zn) at subcritical water oxidation conditions103. Among these metals, Fe was the most influential metal in degradation of PFOS followed by Zn, Cu, and Al with the degradation efficiencies of 99%, 77%, 15.3%, and 6.4%, respectively. On the other hand, HALT is an alternative destructive technique to SCWO and researchers have demonstrated that HALT can effectively degrade PFAS in contaminated groundwater104 and soil104, in aqueous film-forming foam105, in spent GAC96.

Laboratory and pilot-scale application of SCWO in the removal of PFAS

SCWO can achieve PFAS degradation efficiency of over 99% and break the carbon-fluorine bond (C-F) to facilitate PFAS mineralization106. The reaction that takes place is shown in Eq. 2:

Pilot-scale studies have been reported at Battelle (Columbus USA), Aquarden Technologies (Skaeving, Denmark) and 374water (Durhan, USA). These pilot treatment plants operate at maximum temperatures of 590 °C, 590 °C and 595 °C, respectively. For full-scale applications, it is known that some if not most of the companies that commercialized this technique had to shut down the operation due to corrosion and salt precipitation. In applications specific to PFAS, Danish company Aquarden Technologies have successfully scaled up SCWO to full-scale operation. The system includes combination PFAS-selective adsorbents that are then treated with SCWO85. Using a continuous flow SCWO reactor operating in an autogenic regime, the degradation of PFHpS, PFOS, and PFOA were assessed106. The reactor (Fig. 13a) is comprised of 4 influent streams: (i) pilot fuel (EtOH-H2O mixture), (ii) air-H2O mixture, (iii) reagent-H2O mixture and (iv) quench water injection port. A titanium-lined vessel with an approximate volume of 164 mL was used to insulate the reactor. Titanium was used to minimize the likelihood of corrosion failures instead of iron-based alloys as Ti has proven anti-corrosion properties107.

a Illustration of reactor with corresponding sample collection points where TC1 and TC2 are the thermocouples used to track influent temperature, TC3–TC5 track internal reactor fluid temperature, TC6 tracks temperature effluent before the cooler and TC7 temperature after cooler while TC8 and TC9 are used to monitor temperature of the external wall reactor, b continuous mass flow SCWO reactor balance, where AFFF aqueous film-forming foam, SCWO supercritical water oxidation, kg/min kilograms per minute, L liters, NaOH sodium hydroxide, and HP high pressure106,107.

A co-axial nozzle positioned on top of the reactor was used to inject air and fuel. PFAS were injected into near-uniform temperature region using 2 injection ports, and the destruction of the PFAS was evaluated at temperature range of 410–650 °C. For PFOS experiments at low temperatures; a pool of PFCA were observed in the liquid effluents and emissions in gas stream. However, in the PFOA experiments, no PFCAs were detected in the liquid effluent even at the lowest temperature tested. Therefore, the rate-limiting step in PFOS decomposition was the PFOS and PFHpS transition to PFCAs. An intermediate that could only be destroyed at 650 °C trifluoroacetic acid was also detected in the liquid effluents.

Elsewhere, McDonough et al.107 assessed the efficiency of SWCO in destroying 12 PFAAs. The system was equipped with an air-compressor, fuel-fired preheater, titanium-lined insulated reactor, holding tanks and appropriate connections and piping as depicted in Fig. 13b. Results obtained showed a >99.999% destruction and removal efficiency of the12 PFAAs after two successive ~120-min continuous flow. The recorded defluorination % was estimated to be 62.6%. The total PFAS, fluoride concentrations and fluorine mass balance at various temperatures are presented in Fig. 14a. Based on the results obtained and identified possible decomposition pathways PFOS was presented in Fig. 14b96. The ·OH likely attacks the PFOS by cleaving the C-S bond, C8F17· radical, C8F17· radicals are formed which will recombine with ·OH forming C8F17OH through hydroxylation. The weakened C8F17OH will form C7F15COF via F elimination. Through hydrolysis perfluoric acid will be formed from perfluoroketone. Alternatively, PFOS can be destroyed through volatile organic fluorides (VOFs) (depicted by the dashed line in Fig. 14c)96. To understand this pathway a comparison between VOFs yield and composition during PFOS decomposition must be assessed.

a Concentration of PFAS (PFOS, PFHpS and PFCA) intermediates from LC-MS/MS analysis, and the fluoride concentration obtained from ion chromatography, b the quantity of both organic and inorganic fluorine in liquid effluents, c proposed decomposition pathways of PFOS obtained from SWCO using intermediates from GC-MS. Noteworthy: although 1H-perfluorohexane was the only volatile organic fluoride identified other volatile organic fluorides cannot be excluded96.

Practical considerations and energy requirements of using SCWO in the degradation of PFAS

Despite the degradation efficiency of PFAS using SCWO, there are some limitations that hinder upscaling and commercialization efforts, including extensive energy use, salt precipitation, and resilient infrastructure for high temperature and high-pressure operation108. Elevated temperatures are required to achieve the desirable high destruction effectiveness, which unfortunately translates to increased energy requirements. These challenges necessitate reactor designs capable of managing corrosive and exothermic conditions109,110, as well as facilitating effective salt separation. Moreover, it is costly and challenging to produce pressure vessels that can resist the high temperatures and pressures of the SCWO process at industrial scale. The other disadvantage of SCWO is the high energy consumption, however this limitation can be compensated if the energy can be recovered from exothermic reactions as the concentrated waste is treated. In order to determine the financial viability of SWCO, it is essential to determine the energy consumption. In doing these calculations most practitioners may want to analyse per mass of destroyed PFAS. However, these analyses and calculations may not be a true representation as the influent PFAS concentration is directly linked to the required energy needed to destroy PFAS in SCWO. The majority of the energy required in SCWO is used to heat the water to supercritical state. Recently107, electric energy per mass (EEM) was determined to be 1.1 × 105 kW·h/kg PFAS. Even considering the energy required for the air compressor and the transfer pump, it was found that the energy source (diesel) was significant. In addition to the corrosion and salt precipitation, the production of hazardous gases produced during the process are not readily investigated. More research is needed on establishing whether the emitted gases from these full-scale of SWCO are toxic.

Sonochemical oxidation

Sonochemical oxidation uses sound waves to generate large volumes of reactive oxygen species (ROS). It involves the propagation of acoustic waves with a high frequency ranging from 20 to 1000 kHz in a liquid resulting in the formation of acoustic bubbles which are known as acoustic cavitation. Acoustic cavitation produces high temperature, pressure, and free oxidizing radicals70,111. Sonochemical degradation occurs in two ways; via thermal degradation and free radical oxidation112. There have been several studies that have incorporated the sonochemical technique with various catalytic chemicals such as sulfate, persulfate, periodate, and permanganate to improve PFAS degradation efficiency113. The catalyst additives have shown a great improvement in degradation efficiency of PFAS. Among the different oxidizing chemicals that have been incorporated with sonochemical oxidation, persulfate (which generates sulfate radicals) has demonstrated high enhancement in the degradation of PFAS. The performance of sonochemical techniques is directly dependent on the operational parameters such as frequency of ultrasound waves, power density, and solution temperature114. The ultrasonic frequency determines the growth size of the acoustic cavitation bubble. When the cavitation bubbles grow, they absorb the energy of the waves up to the maximum point and then collapse. However, when frequency is increased beyond optimum value, it causes the PFAS degradation rates to decrease due to the rapid collapsing of bubbles115. The cavitation bubble size, duration of the bubble before collapse, transient temperature, and internal pressure of the cavitation bubble are also governed by the power intensity115. Increasing the ultrasound power intensity could raise the maximum collapse temperature as well as the number of collapsed cavities created, and subsequently sonochemical degradation. PFOA and PFOA degradation efficiency has been reported to increase with power density (varied from 30 to 262 W L−1)114. Thus, frequency and power density are crucial parameters for the degradation of PFAS via sonochemical systems.

Mechanism of PFAS degradation using sonochemical technique

The degradation of PFAS with sonochemical technique is via two mechanisms: pyrolysis and oxidation by free radicals. When degradation takes place via pyrolysis it is because of cavitation of the bubbles which releases a very high transient temperature116, while oxidation happens when water undergoes thermal decomposition to form hydroxyl (•OH) radicals as demonstrated in Eq. 3.

In the presence of catalytic additives such as sulfate112, persulfate112, periodate112, sodium hypochlorite (bleach)117, and permanganate112, numerous oxidation species and radicals are formed (IO3•, IO4•, SO4• −, Cl•, MnO2) which increases the degradation rate as illustrated in Eqs. 3–6. Among these radicals, SO4−• has the greatest influence on the degradation of PFAS as it has the highest redox potential (E0 = 2.5–3.1 V). However, not all the radicals formed are able to initiate the degradation of PFAS due to the strength of C–F and C–C bonds118. Pyrolysis initiates the degradation of PFOA via decarboxylation (Eq. 4). Subsequently, the radicals from the catalytic additives react with oxidative radicals to produce perfluorocarbonyl, carbon dioxide and hydrogen fluoride (Eq. 4). The resulting PFAS molecule (C6F13COF) undergoes hydrolysis to produce a shorter chain PFAS (C6F13COOH, PFHpA) (Eq. 5). The C6F13COOH again undergoes the same reactions (Eqs. (4–6)) until it is completely mineralized to CO2 and HF.

Laboratory and pilot-scale apphlication of sonochemical technique for PFAS removal

The defluorination of PFOA and 6:2 fluorotelomer sulfonate (6:2FTS) was reported to increase by over 40% in the presence of persulfate (Fig. 15a–d)70. Similarly, a pilot-scale sonochemical oxidation of PFAS in aqueous film-forming foams reported removal efficiencies from 27% to 91.5% at lower energy costs118. The major challenge with scaling up to full-scale includes the issue of existing infrastructure which represents inertia, people are skeptical about discarding what they have and replacing it with new infrastructure, hence there must be innovation in how to seamlessly integrate new system in existing treatment trains. Fuller et al.119 assessed the extent of degradation of PFAS in resin regeneration stream using the sonochemical technique. In the study the optimal frequency and power were 1000 kHz and 400 W respectively. This yielded the best PFAS removal rates resulting in mineralization forming inorganic fluoride, however it must be noted that small fractions of VOFs were detected. The effects of chlorides, carbonates, organic material on the PFAS degradation were assessed. The efficiency of the PFAS degradation was adversely impacted by TOC and methanol to about 50 g/kg; 5% w:w. However, the addition of chloride enhanced the PFAS degradation, and this was more evident in the longer chained PFAS. The trend indicates that PFAS with higher hydrophobicity were impacted significantly by the enhanced chloride. The improved degradation was also confirmed by high defluorination rates.

a PFOA, b PFOS, c 6:2 FTS and d defluorination. Panels (a–c) display equations and first-order fitting curves70.

Using a 10-litres reactor equipped with 2 transducers operated at 700 and 950 kHz, Kewalramani et al.120 evaluated the scalability of destroying PFAS using sonochemical oxidation (Fig. 16). To fully understand the system the following factors were assessed: frequency, power density, the relative position of the transducer on KI oxidation and calorimetric power. The energy conversion efficiency was recorded at ~50%. Notably, an increase in power density due to reduction in reaction volume enhanced the sonochemical activity. However, as the power density increased, the rate was lowered. Regarding the positioning of the transducer, it can be deduced that the activity was not significantly affected by the transducer’s positioning along the reactor’s side and bottom walls.

Practical considerations and cost estimations of using sonochemical in the degradation of PFAS

The major challenges of implementing sonochemical oxidation on an industrial scale include the extensive energy usage and insufficient comprehensive understanding of the required operating parameters104. Karla et al.121 recently estimated to run a reactor operating at 0.4 kWh in the USA would cost ~$0.12/kWh, $0.18/gal. To reduce the overall energy consumption practitioners ought to decrease the power density, optimize the frequency of the ultrasound, and optimize matrix chemistry to enable efficient transfer from electrical energy to ultrasound. It must be however noted that optimizing frequency in complex water matrices may not be achieved easily as the frequency is pollutant-specific122. For enhanced sonochenical degradation, the integration with other technologies may enhance the degradation123. Additionally, designing large sonochemical reactors and determining the optimal operating frequency of these reactors are significant hurdles. The geometry of the reactors used, the position of transducers, and the total number of transducers used are all crucial in the efficiency of the sonochemical reactor as it impacts on how cavitational occurrences are distributed. It is important to note in sonochemical reactions a low liquid height is not ideal and will not achieve the desired degradation efficiency, therefore altering liquid height significantly impacts on the degradation124,125. The usage of multifrequency transducers unlike the single-frequency transducers also stands to improve the efficiency. More research is needed to design suitable configurations and integrate sonochemical oxidation with other destructive techniques to reduce the energy input and reaction time104.

Electrochemical oxidation

Electrochemical oxidation (EO) requires a direct current power supply, electrolytic cell and electrode array (anode and cathode) as depicted in Fig. 17a, b. When current is applied to an electrolytic cell, the electrons flow from anode to cathode, making the anode oxidative towards any oxidizable solutes present in the solution126. This process involves the transfer of electrons for direct oxidation and production of •OH radicals in situ that can be responsible for the degradation of PFAS. EO processes have demonstrated to be useful techniques in degrading PFAS, with degradation efficiency of over 99%127.

a Typical experimental set-up in EO experiments, b typical degradation pathway using EO where an electron is transferred to the anode or SO4•− resulting in Kolbe decarboxylation reaction, subsequent repeating of a series of CF2-unzipping cycle takes place [adapted from ref. 129], c PFAAs removal using EO in laboratory and semi-pilot scale systems. Inset depicts the pseudo-first-order removal rate for PFAAs for both laboratory and semi-pilot scale systems176.

The efficiency of EO is mostly influenced by anode material, electrolytes, oxidative species generated, and current density127,128. The electrode can either be an active or non-active electrode. The ideal electrodes for degradation of PFAS are those electrodes that have less or no interaction with the generated oxidative species and haves a high oxygen overpotential129. The active electrodes include ruthenium (RuO2), platinum, carbon, graphite and iridium (IrO2). Complete mineralization of PFAS is most likely to occur in non-active electrodes due to high oxygen overpotential and poor interactions with oxidizing species. Non-active electrodes that have been applied in degradation of PFAS include boron-doped diamond (BDD), tin oxide (SnO2), Magneli phase titanium suboxide (TSO), and lead dioxide (PbO2)127. Among these anode electrodes, BDD and TSO are the most investigated electrodes due to their high degradation efficiency towards PFAS129.

Titanium suboxide anode electrodes have also been receiving extensive attention due to their porosity and large surface area which facilitate the electrochemical oxidation of pollutants on the surfaces of the electrodes and are also considered to be inert towards generated ROS. Titanium suboxide can also be applied in fabricating REM130. Other advantages include lower current density and low charge transfer which favors production of OH radicals129. Liang et al.128 reported the degradation of PFOA and PFOS using Magneli phase Ti4O7 in NaSO4 electrolyte solutions. The degradation was found to be 96 and 98.9%, respectively, and the electrolyte was found to enhance the degradation. Electrolytes in electrochemical oxidation serve as charge carriers, however they can also participate in degradation of PFAS through generating oxidative radicals. The common electrolytes are: NaCl, NaClO4, and NaSO4. If chlorinated salts are used, oxidizing chloride species may be formed and lead to the formation of toxic halo-organic compounds. It is important to find ways to inhibit formation of toxic chlorinated byproducts from chlorinated electrolytes. For example, Yang et al.131 probed the formation of these unwanted byproducts by adding hydrogen peroxide (H2O2) to the reaction solutions. The findings showed that ~88% of the chlorinated radicals were suppressed. Improving electrode selectivity is essential to limiting competition between oxidizable species and unwanted side reactions for occurring. One way to do this is concentrating the desired species, PFAS, on the surface of the electrode by using a selective electrode or coating that preferentially adsorbs target compounds. The ‘trapped’ target compounds can then be more efficiently oxidized or “zapped” at the active surface. This strategy has been used before by Yin et al. who coated an anode with a hydrophobic material that adsorbed high levels of PFOA for efficient defluorination once potential was applied132. The disadvantage of EO is the high cost of the electrode, incomplete degradation of PFAS, formation of by-products, and loss of efficiency because of the accumulation of matter on the anode.

Mechanism for PFAS degradation with electrochemical oxidation

The mechanism for degradation of PFAS in EO is either indirect electron transfer (IET) or direct electron transfer (DET) oxidation129 as shown in Fig. 17c. IET is when the anode oxidizes water into OH radicals or electrolytes into oxidative radicals such as Cl•, ClO4•−, or SO4•− which actively degrade PFAS. In DET the pollutant gets oxidized on the surface of the anode by transferring its electrons to the anode. Due to insufficient energy of •OH radical to initiate the degradation of PFAS, degradation is initiated through DET as shown in Eq. 7. The unstable PFAS radicals quickly undergo Kolbe decarboxylation and desulfonation forming perfluoralkyl radicals, shown in Eq. 8. These radicals subsequently react with •OH and form perfluorinated alcohol as shown in Eq. 9. Further reaction with •OH leads to formation of a PFAS radical as shown in Eq. 10. These PFAS radicals can release COF2 to form a shorter chain PFAS as shown in Eq. 11. This shorter chain PFAS repeats Eqs. 9–11 (CF2-unzipping cycle) until it completely mineralizes to CO2 and F−.

Laboratory-scale and pilot-scale electrochemical oxidation in the degradation of PFAS

Recent studies reported 95% degradation efficiency of 17 PFAS using BDD anodes in electrooxidation of municipal landfill leachates133, and 94–99% efficiency for PFAS in IX concentrate133 (Fig. 17c). However, low defluorination was observed, and this was attributed to the foaming of PFAA. There are several modifications that have been done to improve functionality of BDD electrodes such as coupling with other electrodes materials, metals, and non-metals. All electrode modifications exhibited improvement in the degradation of PFAS with efficiency of more than 95%. However, the defluorination remained low. Another studying that the degradation efficiency of 12 PFCAs using BDD doped with silicon (Si/BDD) was dependent on the length of the PFAS chain; the short-chain PFAS were not effectively degraded (removal efficiency of 16–67%) as compared to long-chain PFAS (64–91%), but the with Si/BDD was higher than when a pristine BDD anode was used134. Combining BDD with SiO2, PbO2, and SnO2-F can improve the performance of the BDD anode135. Among these combinations, BDD/SnO2-F had outstanding performance compared to the pure BDD. The extent of defluorination was 62%, compared to 50% using pristine BDD anode electrode135.

Liang et al.14 used an EO reactor to degrade PFAS from spent resin regeneration in still bottoms (Fig. 18) part of the treatment train. The operation of the plant enabled the removal of PFAS from ~260,000 gallons contaminated water. The EO system (utilizing Ti4O7 electrodes) recorded an 80–98% destruction rate for the PFOA and PFOS. The EE/O for removing PFOA and POS was in the range 0.131–0.161 kWh/m3 and 0.071–0.094 kWh/m3 respectively.

Schematic of the pilot-scale IXR-EO treatment train and sampling locations used in the study14.

Practical considerations and energy requirements of using electrochemical oxidation in the removal of PFAS

Electrochemical oxidation mostly uses BDD anodes, which are relatively expensive and difficult to produce. More research is needed to develop affordable and resilient electrodes to minimize costs. Titanium sub-oxides electrodes, for example, have shown comparable performance with BDD electrodes at a much lower cost136,137. Chaplin et al.138 estimated the cost to produce Ti4O7 electrodes to be ~$0.36 per m2 compared to the estimated $7125 per m2 to produce BDD. Although cost effective unlike BDD, Ti4O7 electrodes do relatively have shorter electrode lifespans compared to BDD139. Regarding energy use, Ti4O7-electrooxidation is reported to be ~80% less energy intensive unlike BDD, the EEO was 3.6 kWh/m3 when using Ti4O7 electrodes and 19.9 kWh/m3 when using BDD139. Furthermore, the excessive amount of perchlorate generated cannot be ignored, as some researchers reported the concentrations to be 65–220 mg/L. To minimize the perchlorate generated, practitioners may consider NF membranes to remove chlorides prior. Additionally, utilizing free chlorine during treatment may reduce the perchlorate generation. Other alternatives of reducing perchlorate include applying H2O2 (50 Mm) and MeOH (100–1000 mM)140. The formation of by-products (i.e., trihalomethanes and haloacetic acids) and incomplete degradation can be minimized through coupling EO with other AOPs preferably photochemical oxidation and photocatalysis. This can enhance the performance and subsequently reduce accumulation of matter on the surface of the electrode which reduces efficiency.

Photocatalytic oxidation

Photocatalytic oxidation uses light as an energy source and catalysts as an active site for PFAS oxidation, which typically occurs through the Decarboxylation, Hydroxylation, Elimination, Hydrolysis (DHEH method). The degradation efficiency of photocatalytic oxidation towards PFAS mostly depends on the activity of the photocatalyst, oxidant and operational parameters such as light sources, pH, dissolved oxygen (DO), and composition of the water141. Increasing the solution temperature improves the photolysis efficiency and increases the photocatalytic rate, but too high a temperature (higher than calcination of photocatalyst, usually 400–500 °C) can destroy the molecular morphology and thus render the catalyst inactive. In addition, pH affects the dissociation of PFAS in solution, which affects photocatalytic performance. Acidic pH favors effective PFAS degradation. Lastly, DO in solution can cause the formation of reactive oxygen species which may participate in unwanted side reactions141. Reactive oxygen species generated from the photocatalytic reactions may participate in the degradation of PFOA, but these ROS species are unable to initiate degradation of PFAS molecules.142,143. Therefore, photocatalysts must provide an active site for PFAS adsorption and direct electron transfer to be effective.

Mechanism of PFAS degradation with photocatalysis

In photocatalytic oxidation PFAS are degraded either via indirect oxidation (radical oxidation) and direct oxidation when the light of suitable energy is radiated to the solution with photocatalyst. Under light irradiation the electrons (e−) in the semiconductor are excited from the valence band to the conduction band leaving positive holes (h+). The excited electrons react with free oxygen to produce ROS and the photogenerated holes can react with PFAS to directly oxidize. In indirect oxidation, the photogenerated hole scavenges water to produce \(\bullet\)OH radicals. However, this is unfavorable because it creates competition between PFAS and water to react with the holes. Photocatalytic degradation of PFOA using titanium dioxide-peroxymonosulfate (TiO2/PMS) as the photocatalyst under visible and UV light can be driven by both sulfate ion radicals and photogenerated holes, indicating both direct and indirect oxidation141. However, this study did not report the repeatability of their experiments and did not offer fluorine balances to assess extent of mineralization. Since other studies have indicated that \(\bullet\)OH radicals are not effective at initiating the decomposition of PFAS, photogenerated holes are essential to achieve enhanced degradation of PFAS. Radical scavenging tests (to discern the importance of hydroxyl radical, superoxide, and photogenerated holes) has also been studied144 have demonstrated the importance of photogenerated holes for initiating PFOA photocatalytic degradation with UV-irradiated hBN144 (Fig. 19).

a Scavenger experiments prove that photogenerated holes are the only species capable of initiating PFOA degradation in a BN-driven photocatalytic system, b in TiO2-driven photocatalytic systems, it was demonstrated that other radical species participate in degradation of PFOA and this was assessed using EDTA (to scavenge holes), SOD (to scavenge superoxide/hydroperoxyl) and TBA (to scavenge hydroxyl radicals)144.

Laboratory-scale and pilot-scale application of photocatalytic oxidation of PFAS

The potential of operating under standard atmospheric conditions and using solar energy has propelled photocatalytic oxidation to be a promising technology for PFAS degradation. Other advantages of photocatalysis include the recyclability and re-use of photocatalyst. At pilot, Liu et al.83 employed an integrated NF/UV-sulfite system. The results showed the membranes achieved rejection ≥95% and the PFAS concentrated streams were effectively destroyed using the UV treatment. The general trend of destruction showed the longer-chain PFAS had preferential degradation compared to the shorter chained PFAS. Elsewhere, the degradation and defluorination utilizing photocatalytic silica-based granular media and NaOH and Na2S2O3 were assessed in a packed column (Fig. 20)145. TiO2 was immobilized on the silica to maximize adsorption of PFAS reduce the electron-hole pair recombination. From the 4-hr long experiments 17 PFAS were assessed; in the experiment where NaOH was added 59% of the detected PFAS were degraded with an efficiency of over 88%.

Schematic representation of the column reactor packed with immobilized TiO2 on the silica145.

To date, direct photocatalysis has been proposed as a cost- and time-effective method for degrading PFAS146. However, compared to other destructive procedures, it has a lower efficiency and might not be the ideal choice for process scale up. Even though photo-enhanced methods for PFAS degradation have produced some interesting results, more research is still needed to determine whether or not highly effective materials could be used in ambient reaction conditions. Table 3 summarizes and compares the degradation efficiency, defluorination rate and the reaction time of some photocatalysts that have been applied in the degradation of PFAS.

Practical considerations, costs and energy requirements of using photocatalysis in PFAS degradation

Some challenges associated with photocatalytic degradation generally include the incomplete degradation of PFAS (defluorination), photocatalyst deactivation, low energy conversions and requires a long reaction time. The low energy conversions are due to absorption, scattering and reflection by other particles present in wastewater147. Finding efficient and effective photocatalysts that are relatively inexpensive for easy commercialization is required. Further, some challenges preventing up-scaling of photocatalysis for the degradation of PFAS is that most of the reported work was done using artificial wastewater or surface water and spiked clean water which are not real representatives of real wastewater.