Abstract

The anion-exchange-membrane fuel cell (AEMFC) is an attractive and cost-effective energy-conversion technology because it can use Earth-abundant and low-cost non-precious metal catalysts. However, non-precious metals used in AEMFCs to catalyse the hydrogen oxidation reaction are prone to self-oxidation, resulting in irreversible failure. Here we show a quantum well-like catalytic structure (QWCS), constructed by atomically confining Ni nanoparticles within a carbon-doped-MoOx/MoOx heterojunction (C-MoOx/MoOx) that can selectively transfer external electrons from the hydrogen oxidation reaction while remaining itself metallic. Electrons of Ni nanoparticles gain a barrier of 1.11 eV provided by the QWCS leading to Ni stability up to 1.2 V versus the reversible hydrogen electrode (VRHE) whereas electrons released from the hydrogen oxidation reaction easily cross the barrier by a gating operation of QWCS upon hydrogen adsorption. The QWCS-catalysed AEMFC achieved a high-power density of 486 mW mgNi−1 and withstood hydrogen starvation operations during shutdown–start cycles, whereas a counterpart AEMFC without QWCS failed in a single cycle.

Similar content being viewed by others

Main

There is an urgent need to develop low-cost non-precious-metal catalysts for low-temperature alkaline fuel cells1,2, but this development is extremely difficult3, especially for catalysts for the hydrogen oxidation reaction (HOR)4,5. The HOR occurs at a relatively high anodic potential compared with metal oxidation6, where most non-precious metals easily lose their metallic properties and cannot maintain oxide-free surfaces for bonding of adsorbed hydrogen atom (Hads) intermediates7,8.

Attenuation of the binding energy of oxygen species and optimization of hydrogen binding are regarded as the main strategies to improve the intrinsic catalytic activity of non-precious metal catalysts, especially for Ni-based catalysts9,10,11,12,13,14,15,16. Several Ni catalysts, such as nitrogen-doped carbon support (NC)-embedded Ni nanoparticle catalysts17,18,19, with Pt-like activity20,21, have been developed. However, few studies have addressed the stability of Ni22,23.

The oxidation potential for Ni-metal catalysts is as low as 0.108 V at pH 13, beyond which Ni is transformed into HNiO2− or Ni(OH)2 (ref. 24). During the HOR at high overpotentials (beyond ~0.1 V versus the reversible hydrogen electrode (VRHE)) or under fuel starvation during fuel cell operation (probably at ~0.7 VRHE)25, the anodic reaction changes from the HOR to Ni oxidation at the anode26. Oxygen-containing species, such as hydroxides, rapidly occupy the active sites, leading to irreversible oxidation of Ni27,28,29,30. This eventually passivates or deactivates the Ni catalysts31, resulting in fuel cell failure14,32.

The use of a surface-nitrogen-doped carbon coating was recently reported to improve the apparent oxidation potential of Ni to 0.4 VRHE (refs. 33,34,35). However, Ni corrosion still occurred even at a relatively low potential of 0.1 VRHE, as oxygen-containing species could still penetrate the non-uniform carbon-shell coating. Disordering the atomic arrangement of Ni within a bulk alloy of Ni, Mo and Nb can also extend the stable potential window to 0.8 VRHE in an alkaline electrolyte36, but the specific surface area of active Ni is greatly sacrificed, resulting in a much lower catalytic efficiency of Ni. The low Ni oxidation potential undoubtedly impedes the practical application of Ni-based catalysts for the HOR37; thus, the simultaneous improvement of stability and specific activity is essential38.

Herein we have constructed a quantum well catalytic structure (QWCS) by atomically confining Ni nanoparticles into a heterojunction, that is, crystallized carbon-doped MoOx (C-MoOx) as the low energy valley and amorphous MoOx as the high energy barrier (the catalyst is named Ni@C-MoOx). Ni@C-MoOx can selectively transfer external electrons produced via catalysis of the HOR but does not transfer electrons from the Ni catalyst within the valley of the QWCS. Like a quantum well transistor39, where the on/off state depends on the applied voltage to change the electronic conductivity of the electronic channel, the QWCS is activated by hydrogen adsorption on Ni by gaining electrons but shielded by the adsorption of oxygen-containing species.

Structural characterization

The QWCS, as shown in Fig. 1 and Supplementary Fig. 1, is a simplified five-layer structure based on the electron pathway. The corresponding Ni@C-MoOx nanocatalyst with the QWCS was prepared by a hydrothermal reaction plus H2 reduction (Methods). Sodium copper chlorophyllin was introduced as a carbon-doping precursor to construct quantum wells around the Ni nanoparticles because of its strong coordination with Mo atoms (Supplementary Figs. 2 and 3 and Supplementary Note 1). The carbon-metal coordination induced a new phase of C-MoOx coated on metallic Ni in the obtained catalyst, as evidenced by the newly emerged X-ray diffraction (XRD) peaks of the MoOC (111) and MoOC (220) planes at 37° and 64°, respectively. As shown in Supplementary Fig. 4, neither a Ni–C related phase nor a shift of the Ni metallic peaks was observed in the XRD pattern of the obtained catalyst. These results further indicate that the doped carbon atoms were connected to the Mo atoms rather than to the Ni atoms and that no NiMo alloy was formed in the final catalyst.

a, The structure of a quantum well transistor. In a quantum well transistor, the on/off state between the source and drain depends on the voltage applied to the gate, which changes the electronic conductivity of the electronic channel. b, Diagram of the quantum well catalytic structure for Ni@C-MoOx in the QWCS. The on/off state between the catalytic centre (Ni or Ni-C-MoOx) and current collector (MoOx or carbon) depends on the adsorption of reactants, which changes the electron conductivity of C-MoOx (acting as an electron channel). c, Schematic diagram of the band structures and the corresponding electron transfer process for the QWCS and traditional Ni catalyst, where VB is the valence band and CB is conduction band. Electrons of the Ni nanoparticles are confined by the barrier of QWCS, and Ni electrooxidation was forbidden (off state); whereas the QWCS gained electrons from the adsorption of donor-doped hydrogen, increasing the Fermi level and the electronic conductivity for the HOR reaction.

According to the X-ray photoelectron spectroscopy (XPS) and energy-dispersive X-ray spectroscopy analysis, as shown in Supplementary Table 1, the O/Mo atomic ratio of 2.65 ~ 3.26/1 was closer to that of MoO3 than to that of MoOC, indicating the combination of the MoOx phase and the C-MoOx phase in the final catalyst. The photoluminescence spectrum of Ni@C-MoOx, as shown in Supplementary Fig. 5, presents a characteristic emission maximum at 463 nm under an excitation wavelength of 390 nm, indicating that a quantum well-like structure was successfully fabricated.

Figure 2a and Supplementary Fig. 6 show that the nanocomposite of C-MoOx/MoOx has a highly pleated gauzy morphology. The C-MoOx phase, identified by the C-MoOx (200) lattice fringe of 1.95 Å (Fig. 2i), has a relatively high crystallization degree (Fig. 2g). The MoOx phase, inserted within the film, is amorphous (Supplementary Fig. 7). This indicates that carbon doping partially crystallized the MoOx nanofilm and a locally continuous ring interface was constructed to form a quantum well structure between the two phases with differentiated electron-trapping abilities. The metallic Ni nanoparticles, with a size of approximately 20–30 nm, were effectively surrounded by and connected to each other through the C-MoOx nanofilms after being subjected to H2 reduction at 500 °C, which facilitated the formation of a whole assembly by the dispersed Ni nanoparticles.

a, Scanning transmission electron microscope (STEM) image of the Ni@C-MoOx catalyst. b–e, Annular dark field (ADF)-STEM images and EELS elemental maps of Ni (red), Mo (yellow) and O (green) in the Ni@C-MoOx catalyst. f–i, ADF-STEM image of a typical Ni nanoparticle and the corresponding interface of the Ni@C-MoOx; the red dashed circle shows the Ni nanoparticle core, the yellow dashed circle shows the C-MoOx nanofilm shell. j, Intensity profiles along the cyan lines in rectangular regions 1 and 2 shown in i.

The 1-nm-thick C-MoOx layer was highly concentrated at the near surface of Ni nanoparticles compared to that away from the Ni particles, according to the electron energy loss spectroscopy (EELS) results (Fig. 2b–e). Abundant defects and nanopores were present on the C-MoOx thin layer with 1-nm thickness (Supplementary Fig. 8). The sizes of the defects and nanopores were around 0.5 to 1 nm, which are large enough for the penetration of H2 (0.289 nm), OH− ion (0.137 nm) and H2O (~0.4 nm). Further observation revealed that each Ni particle was atomically connected to C-MoOx via Ni–Mo bonds (Fig. 2f–i). The matched atomic arrangement between Ni (111) with a lattice fringe of 2.03 Å and C-MoOx (200) with a lattice fringe of 1.95 Å allowed the Ni–Mo metallic connection to form at the interface. The length of the Ni–Mo bond was calculated to be 2.49 Å, which is longer than the Ni–Ni bond (2.17 Å) in metallic Ni and the Mo–Mo bond (2.33 Å) in C-MoOx (Fig. 2j and Supplementary Figs. 9 and 10).

Density functional theory (DFT) calculations focusing on the interface structure show that a Ni–Mo connection was spontaneously assembled after structural optimization with a Ni–Mo distance of 2.54 ~ 2.66 Å. This is in good agreement with the atomic distance of Ni–Mo observed by high resolution transmission electron microscopy (HRTEM) (Supplementary Figs. 11 and 12). The PDOS (partial density of states) profiles of Ni and Mo also demonstrated a notable resonance between Mo and Ni after carbon doping, indicating a thermo-dynamical trend for Mo–Ni connecting at the interface of Ni@C-MoOx (Supplementary Figs. 13 and 14). Such a metallic Ni–Mo connection could benefit reversible electron transfer between Ni nanoparticles and C-doped MoOx nanofilms, which resulted in the same barrier of the C-MoOx well to electrons of metallic Ni nanoparticles.

HOR electrocatalysis evaluation

The HOR catalytic activity of the Ni@C-MoOx with QWCS was evaluated in a H2-saturated 0.1 M KOH solution using a three-electrode cell set-up (Supplementary Fig. 15). As shown in Fig. 3a, the Ni@C-MoOx electrode showed a similar HOR activity to those of the conventional NiMoOx catalyst prepared without carbon doping and commercial Pt/C (Pt/Ccom) electrodes in the low overpotential range of 0 ~ 0.10 VRHE. The intrinsic activity of the as-prepared Ni@C-MoOx catalyst was comparable to that of Pt/Ccom (Supplementary Fig. 16, Supplementary Tables 2 and 3 and Supplementary Note 2). However, it was surprising to find that the Ni@C-MoOx with QWCS behaved like a precious metal electrode and delivered a significant current density when catalysing the HOR up to 0.8 VRHE (Fig. 3a). In contrast, the conventional NiMoOx catalyst was significantly passivated when the anodic potential reached only ~0.1 VRHE, after which a sharp decrease in current density was observed (Fig. 3a and Supplementary Fig. 17).

a, HOR polarization curves recorded on Ni@C-MoOx, NiMoOx and 20 wt% Pt/Ccom electrodes in H2-saturated 0.1 M KOH electrolyte; data were obtained using a rotating disk electrode at a rotation rate of 2,500 rpm with a potential scan rate of 5 mV s−1. b, Cyclic voltammograms recorded on the Ni@C-MoOx electrode in H2- and N2-saturated 0.1 M KOH electrolyte; data were obtained using a rotating disk electrode at a rotation rate of 1,600 rpm with a potential scan rate of 5 mV s−1. c,d, Chronoamperometry curves recorded on Ni@C-MoOx- and NiMoOx-coated GDEs in H2-saturated 0.1 M KOH at 0.3 VRHE (c) and 0.7 VRHE (d). The NiMoOx catalyst totally lost its activity for the HOR within 0.2 hour, and the break in the x-axis in (c) shows the details of current decline in the stability test of NiMoOx catalyst at 0.3 VRHE. e,f, Ni 2p3/2 XPS spectra of Ni@C-MoOx (e) and NiMoOx (f) catalsyts before and after subjected to the step-potential stability test, where the satellite peak (Sat.) of Ni 2p3/2 and the KLL auger peak of F (F KLL) from ionomer were present (Methods provide fitting details).

Further comparisons with the catalyst produced at different conditions revealed that the Mo was crucial for active site formation and that carbon doping was the key for electrooxidation resistance (Supplementary Figs. 18–20 and Supplementary Note 3). Such an unusual phenomenon was further investigated by cyclic voltammetry at different anodic upper potentials from 0.4 to 1.2 VRHE. As shown in Fig. 3b, the Ni@C-MoOx electrode delivered a high anodic current density in both forward/positive and backward/negative potential sweeps in H2-saturated 0.1 M KOH even with a high potential up to 1.2 VRHE, indicating a well-maintained Ni metallic property for catalysing the HOR in such a wide anodic potential range.

To eliminate possible contribution of Ni self-oxidation to anodic current during catalysis of the HOR, chronoamperometry experiments were carried out on the electrodes modified by the Ni@C-MoOx with QWCS and typical NiMoOx catalyst under an overpotential in the range of 0.1 to 1.2 V for 5 minutes. As shown in Supplementary Fig. 21, the Ni@C-MoOx electrode catalysed the HOR with a steady anodic HOR current of 1.5 mA cm−2 (at 1,600 rpm) under all the applied potentials. The NiMoOx electrode, however, only steadily catalysed the HOR at a potential of 0.1 VRHE, beyond which a dramatic current decrease occurred or no current was produced at all (for example, at 0.2 VRHE).

However, oxidation of the Ni@C-MoOx with QWCS occurred when the potential reached an extremely high level, for example, at a potential higher than 0.7 VRHE. As shown in Supplementary Figs. 22 and 23, the HOR current density on the Ni@C-MoOx electrode decreased from 2.00 to 0.13 mA cm−2 at 0.1 VRHE but remained at 2.32 mA cm−2 at 1.2 VRHE after cycling to 1.2 VRHE. Such behaviour is fundamentally different from active site passivation. As shown in Supplementary Fig. 24, a dramatic decrease in the HOR activity (of 86%) was observed at all potentials for Ni@C-MoOx passivized by air at 60 °C (that is, oxidized by oxygen in air). This result indicates that the QWCS is effective for the HOR electrocatalysis and anti-electrooxidation but susceptive of chemical oxidation by oxygen.

In contrast to chemical oxidation, the high potential electrooxidation of the QWCS (>0.7 VRHE) decreased the Fermi level of the gate of the QWCS rather than passivizing metallic Ni, causing the QWCS to need more electrons or energy to reopen the gate for reaction (Fig. 1). This anti-electrooxidation ability was consistent with the property of QWCS as shown in Fig. 1: the electrons were selectively confined within the valley of the QW based on the filling level of the local state, regulated by the electron transfer direction of the reactions concerned, that is, to (HOR) or from (Ni oxidation) the metal catalyst.

To deeply evaluate the effect of the QWCS for HOR catalysis and anti-electrooxidation, three critical stability tests were further carried out by using a catalyst-coated gas diffusion electrode (GDE), an electrode technology approaching practical fuel cell applications. As shown in Supplementary Fig. 25, the Ni@C-MoOx-coated GDE presented an excellent HOR current response and a steady current output as the potential increased from 0.1 to 0.7 VRHE (ref. 40). In contrast, the NiMoOx-coated GDE completely lost the HOR current output during step-potential cycling, and no current was generated at a potential of 0.3 VRHE. The XPS results showed no change in the chemical state of Ni@C-MoOx after the step-potential-cycling test. The content of surface metallic Ni remained as high as that of fresh electrode after the 7-h stability test (Fig. 3e, Supplementary Fig. 26 and Supplementary Table 4). In contrast, the NiMoOx catalyst completely lost its metallic property, with highly oxidized Ni and Mo elements detected, regardless of the kind of binder used (Fig. 3e and Supplementary Fig. 27).

We further analysed the Ni k-edge of the Ni@C-MoOx electrode after the harsh stability test by using the QPCBP-10 ionomer as the binder (Supplementary Note 4) by using X-ray absorption spectrum. As shown in Supplementary Fig. 28, the Ni in Ni@C-MoOx maintained a metallic state with a slight positive shift of 0.7 eV in the Ni k-edge. However, the Ni@MoOx catalyst exhibited considerable losses in its metallic properties and catalytic activity under the same stability test, with a significant positive shift of 1.8 eV in the Ni k edge. This result, together with the in situ XRD and ex situ TEM (transmission electron microscope) experimental results (Supplementary Figs. 29 and 30 and Supplementary Note 5), indicate that most of the Ni nanoparticles were well protected by the QWCS.

Moreover, the Ni@C-MoOx-coated GDE continuously catalysed the HOR over 100 h without notable activity loss (Fig. 3c); and even under an extremely high anodic potential of 0.70 VRHE in an accelerated test for 10 h, which is an ultimate operation for fuel cell applications, it still showed a high stability without significant activity loss (Fig. 3d). For the conventional NiMoOx-coated GDE, it only survived for 7 min in continuous operation even at a much lower potential of 0.3 VRHE (Fig. 3c). Further experiments and DFT calculations suggest that the active sites for the HOR is still the metallic Ni rather than the surface oxides and that the amount of metallic Ni is positively correlated with the HOR activity (Supplementary Figs. 31–37, Supplementary Tables 5 and 6 and Supplementary Note 6). H2 molecules and OH− species in the alkaline electrolyte can penetrate through defects or pores of C-MoOx thin layer to reach Ni sites where they reacted to form water and electrons.

The performance of an AEMFC employing the Ni@C-MoOx with QWCS as anode is shown in Fig. 4. The maximum power output of the AEMFC reached 486 mW cm−2 and 400 mW cm−2 with H2–O2 and H2–air feedings, respectively. Notably, the Ni loading was as low as 1 mgNi cm−2 at the anode. In contrast, the conventional NiMoOx anode-catalysed AEMFC produced a maximum power output of only 67 mW cm−2 with H2–O2 feedings at the same metal loading of 1 mgNi cm−2 at the anode (Supplementary Fig. 38). The specific power output of the Ni@C-MoOx-catalysed AEMFC was two times higher than recently reported values based on the Ni metal loading (Fig. 4b and Supplementary Table 7)9,22,33,36,41,42,43,44,45. These results indicate that the HOR activity was enhanced rather than sacrificed when the stability was promoted by quantum confinement.

a, H2/O2 and H2/air AEMFC performance testing using Ni@C-MoOx as the anode and 60% Pt/Ccom as the cathode catalysts. Test conditions: cell temperature, 80 °C; cathode humidifier temperature, 80 °C; anode humidifier temperature, 65 °C; H2 flow rate, 0.5 l min−1; O2/air flow rate, 1.0 l min−1; and with back pressure on both anode and cathode sides, 200 kPa. b, Comparison of the peak power density per unit mass of the membrane electrode assembly (MEA) with other previously reported data of non-Pt anodes. c, H2 starvation test for the MEA using Ni@C-MoOx anode and NiMoOx anode, respectively. d, H2 starvation test for the MEA using Ni@C-MoOx anode. In c and d, ‘fuel on’ means supplying H2 fuel for the anode, whereas ‘fuel off’ means supplying N2 instead of H2 for the anode.

In addition, the Ni@C-MoOx-catalysed AEMFC continuously output a satisfactory current density after repeated H2 fuel-feeding shutdown–start cycles without any loss of performance (Fig. 4d). The conventional NiMoOx-catalysed AEMFC, however, was prone to Ni oxidation at the anode after H2 fuel-feeding shutdown, resulting in irreversible failure in a single cycle (Fig. 4c); even after the anode re-activation by hydrogen continuous feeding at ~0 VRHE and 80 °C, only 50% power was recovered (Supplementary Fig. 39). Notably, fuel-feeding shutdown–start cycles are common operations in real-world fuel cell applications, although they are not well documented in most studies of non-precious-metal catalyst-based AEMFC. These comprehensive testing results demonstrate the promising potential for practical applications of the Ni@C-MoOx catalyst for AEMFC.

Mechanism studies

Such unique anti-electrooxidation properties and high HOR reactivity were quite unexpected for Ni metallic nanoparticles, therefore, an in-depth investigation was performed by using X-ray absorption near-edge structure (XANES) and extended X-ray absorption fine structure (EXAFS) spectroscopies to understand the mechanism (Fig. 5). As shown in Fig. 5a, Supplementary Figs. 40 and 41 and Supplementary Table 8, no obvious chemical shift in the k-edge and no coordination change were observed for Ni in the Ni@C-MoOx compared with those in the traditional NiMoOx catalyst and Ni foil; accordingly, the obtained electrochemical properties could not be attributed to modification of the coordination environment of Ni metal (Supplementary Fig. 42, Supplementary Table 9 and Supplementary Note 7).

a, Normalized Ni k-edge XANES spectra of Ni@C-MoOx (the inset shows the corresponding Fourier transforms of k3-weighted EXAFS spectra) and the spectra of NiMoOx and Ni foil for comparison. b, Normalized Mo k-edge XANES spectra. c, Normalized C k-edge XANES spectra. d, Corresponding Fourier transforms of k3-weighted EXAFS spectra for Mo. e, Schematic diagrams of the distorted octahedron structure of MoOx and the less-distorted octahedron structure of C-MoOx after carbon doping to replace some Mo–O with Mo–C coordination, where the cyan ball represents Mo, the red ball represents O and the grey ball represents C (note: MoO3 adopts a distorted octahedron structure, whereas MoO2 adopts an octahedron structure. In a–c, χμ is the absorption coefficient of component; in d, χ(R) represents the reduced distance between atoms.

For the k-edge of Mo, however, a negative energy shift in the k-edge and a weakened pre-peak at ~20,005 eV were observed for the quantum well-structured Ni@C-MoOx in comparison to MoO3 (Fig. 5b)46. The negative shift in the k-edge indicates a decreased energy level of the antibonding orbitals (4d and 5p orbitals) but an increased energy level of the bonding orbitals for Ni@C-MoOx. The weakened pre-peak at ~20,005 eV observed for Ni@C-MoOx in comparison with that for MoO3 indicates that a less-distorted octahedron structure of O–Mo–C coordination (Fig. 5e) was formed after partial carbon doping, which resulted in the replacement of some Mo–O bonds by Mo–C coordination (Supplementary Note 8). This result agrees with the observations in the Fourier transform infrared, UV‒vis, XRD data (Supplementary Figs. 2–5) and the k3-weighted extended EXAFS spectra (Fig. 5d). The non-uniformity of Mo–C and Mo–O coordination caused a split in the band energy of 4d in Ni@C-MoOx (Fig. 5d, Supplementary Figs. 41 and 43, Supplementary Tables 10 and 11 and Supplementary Note 9), which in turn led to changes in the electronic structure, charge storage and transport ability.

The C = C π* bond peak at 285.6 eV was also obviously weakened in the C k-edge for Ni@C-MoOx, which indicated that there was electron back donation from the 4d orbitals of Mo to the π* bonds of carbon (Fig. 5c). This could imply that conjugated carbon with incompletely filled π and π* orbitals could also influence the charge storage and transport ability of carbon-doped MoOx.

The valence band structure of the quantum well-structured Ni@C-MoOx was further analysed as it can provide more information about the charge storage and transport ability of the catalyst by using ultraviolet photoelectron spectroscopy (UPS). As shown in Fig. 6a,c, a significantly changed slope was observed near the Fermi level for Ni@C-MoOx compared to the NiMoOx catalyst, which indicates a splitting of the valence band, that is, the valence band maximum (VBM) at a bonding energy of −0.21 eV for Mo–C and the VBM-2 at −3.43 eV for Mo–O. The VBM (−3.20 eV) of NiMoOx was attributed to the Mo–O bond, which was slightly higher than that of the Mo–O bond but lower than that of the Mo–C of Ni@C-MoOx. This is in consistency with the calculated density of states, where a clear negative shift was observed for O 2p after the carbon doping (Supplementary Fig. 44), proving that the Mo–C formation at relatively high energy levels and the Mo–O bonding at relatively low energy levels. This result indicates that different from the original MoOx with a VBM being far away from the Fermi level, the newly formed Mo–C bond in Ni@C-MoOx was close enough to the Fermi level to easily participate in the charge storage and transport processes.

a, UPS spectra of Ni@C-MoOx. b, Band structure diagram of Ni@C-MoOx (Ef, Fermi level and Ev, the top level of valence band) and the redox level of oxidation of H2 or Ni (Er, the balance level of reaction versus the standard hydrogen electrode, SHE) according to the Gerischer model. c, UPS spectra of NiMoOx. d, Band structure diagram of NiMoOx and the oxidation of H2 or Ni according to the Gerischer model. e, Schematic diagram of electron confinement and transfer process. In b and d, SHE is the standard hydrogen electrode.

After setting the vacuum level to zero, the energy of the surface orbitals was summarized and compared with the HOR redox level and Ni redox level. As shown in Fig. 6b,d, the additionally formed Mo–C orbitals lowered the Mo–O energy level and increased the work function of C-MoOx (4.93 eV) compared with that of MoOx (3.82 eV), thus providing an energy valley for electrons. Therefore, a gap of 1.2 eV was generated between the Fermi level and the HOR redox level for the Ni@C-MoOx, leading to a delayed oxidation potential of Ni to 1.2 VRHE. In contrast, the HOR redox level (−3.73 eV) was close to Fermi level of NiMoOx (−3.82 eV), leading to a narrow catalytic window of 0.11 V, beyond which the Ni oxidation occurred during the catalysis.

It is noted that carbon doping could induce a dopant band near to Fermi level, which should promote the mobility of electrons (Supplementary Figs. 45 and 46) rather than confined electrons against electrooxidation (Fig. 6 and Supplementary Fig. 40). In-depth investigation was performed by using DFT calculations to reveal how the quantum confinement would work. As shown in Supplementary Fig. 47, an interfacial dipole effect was produced at the interface between Ni and Mo in Ni@C-MoOx, that is, electron state at Mo and hole-like state at Ni. There were approximately 0.3 e− negative charges transferred onto the interfacial Mo, where one-third of them (0.2 e−) were from Ni (Supplementary Table 12). This is consistent with the observation of the negative shift in Mo 3d and positive shift in Niσ+ 2p XPS spectra of Ni@C-MoOx, as compared to that of NiMoOx. Therefore, the Fermi level of metallic Ni is decreased by such an interfacial dipole effect, which confines the electrons within Mo atoms of the interface against Ni electrooxidation. More Mo in higher oxidation states (+6 + 5 instead of +4) in Ni@C-MoOx (74.23 atm%) relative to that of NiMoOx (67.90 atm%) could provide a valley for storage of electrons (Supplementary Fig. 42d and Supplementary Table 9).

When hydrogen atom adsorbed on the Ni sites, as in the case of the HOR process, an obvious loss of electrons was clearly observed for the Mo atoms (Supplementary Fig. 48 and Supplementary Table 12). This indicates that the confinement is relieved for charge transfer in the gating operation. This is very similar to the case of quantum confinement where produced excitons are confined in all three spatial dimensions and vanished with photon generated (Supplementary Fig. 49). The charge at the interface between Ni and Mo in NiMoOx, however, exhibited a tiny change of ~2% under the same condition (Supplementary Fig. 47), indicating that the quantum confinement is different from the traditional interaction at interface. Further evidence including Bader analysis (Supplementary Fig. 50), carbon-doping regulation experiments (Supplementary Fig. 51) and in situ X-ray absorption spectrum experiments (Supplementary Fig. 52) proved that electrons were transferred back from Mo to Ni by hydrogen chemical adsorption on Ni for gating operation during the HOR process (Supplementary Note 10). In this way, it further demonstrates the distinctive interfacial electron transfer, namely the vanishing of the interface dipole effect against the electrochemical oxidation of Ni.

More specifically, the QWCS gained electrons from the adsorption of donor-doped hydrogen, increasing the Fermi level and the electronic conductivity. The conductivity of Ni@C-MoOx was increased by 52% after hydrogen adsorption compared with the original Ni@C-MoOx (Supplementary Fig. 53). Thus, the electron pathway was turned on for the electrooxidation of hydrogen. When oxygen-containing species were adsorbed on the QWCS, the Fermi level and the electronic conductivity were consequently reduced. The conductivity of Ni@C-MoOx was decreased by a factor of 2.3 after oxygen adsorption compared to hydrogen-adsorbed Ni@C-MoOx (Supplementary Fig. 53). Thus, the electron pathway was in the ‘off state’, and Ni electrooxidation was forbidden, otherwise each metallic Ni atom would lose two electrons and then be combined with two OH− species to form Ni(OH)2. However, for chemical oxidation of Ni by oxygen/air, electrons were transferred directly from Ni to oxygen atoms without passing through the QWCS, leading to chemical oxidation of Ni to NiO (or even Ni2O3). The anti-electrooxidation of QWCS was fundamentally different from other methods that usually generate chemical oxidation resistance sites.

Conclusions

In summary, we report here a finding that quantum-confined metallic nickel nanoparticles exhibited both robust anti-electrooxidation properties and excellent durability and reactivity for the HOR in alkaline media; they were highly stable even at high anodic potentials (for example, up to 1.2 VRHE). An interfacial dipole effect was produced at the interface between Ni and Mo (electron state at Mo and hole state at Ni) to confine the electrons within the interface against electrooxidation of Ni and vanished with hydrogen atom adsorbed on Ni to relieve confinement for unlocking the electrocatalysis of the HOR. As a result, the as-prepared Ni@C-MoOx nanocatalyst showed an excellent HOR catalytic stability in both a 100-h continuous operation under harsh conditions at 0.3 VRHE and a 10-h accelerated test at an extremely high anodic potential of 0.7 VRHE. The as-prepared Ni@C-MoOx anode-catalysed alkaline fuel cell exhibited a high specific power density of 486 mW mgNi−1, and no performance loss was observed in repeated fuel switching off/on cycles, a typical hydrogen starvation operation during shutdown–start cycles. This work provides an efficient strategy that applies the quantum confinement effect to enhance the anti-electrooxidation ability of nanoparticles of low-cost and Earth-abundant non-precious metals for (electro-)catalysis of the HOR in fuel cells and beyond.

Methods

Materials

Nickel acetate (Ni(CH3COO)2·6H2O), ammonium molybdate ((NH4)6Mo7O24), urea, sodium copper chlorophyllin, Vulcan XC-72R (Cabot Co.), ultrapure water (18.20 MΩ cm), potassium hydroxide (KOH), isopropanol (C3H8O) and Nafion solution (5 wt%) were used.

Synthesis of Ni@C-MoOx

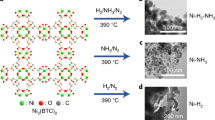

A typical method for the synthesis of Ni@C-MoOx included 1 g Ni(CH3COO)2, 0.353 g (NH4)6Mo7O24, 1 g urea and 0.1 g sodium copper chlorophyllin being added in 35 ml deionized water. After stirring vigorously for 0.5 h, the solution was transferred to a 50 ml Teflon-lined stainless-steel autoclave, then heated to 180 °C and maintained for 12 h. The autoclave was then cooled to room temperature. The obtained product was washed with deionized water and ethanol to remove ionic residue and then dried in an oven at 60 °C overnight. The resulting powder was heated in a tube furnace up to 500 °C at a ramp rate of 5 °C min−1 under H2/N2 (with 1:9 mole ratio) gas flow, and the heating was maintained at 500 °C for 2 h. Afterwards the furnace was cooled to room temperature under N2 flow, the product Ni@C-MoOx was collected.

Synthesis of NiMoOx

The NiMoOx was synthesized in the same way as Ni@C-MoOx except replacing sodium copper chlorophyllin with carbon black (Vulcan XC-72R).

Synthesis of Ni/CuChl

The Ni/CuChl was synthesized in the same way as Ni@C-MoOx except without adding ammonium molybdate ((NH4)6Mo7O24).

Synthesis of Ni@C-MoOx-N2

The Ni@C-MoOx-N2 was synthesized in the same way as Ni@C-MoOx except annealed in N2 instead of H2.

Synthesis of Ni@C-MoOx-TP

The Ni@C-MoOx-TP was synthesized in the same way as Ni@C-MoOx except using tetraphenyl porphyrin (TP) instead of CuChl.

Synthesis of MoOx

One g (NH4)6Mo7O24 was heated in a tube furnace up to 500 °C at a ramp rate of 5 °C min−1 under H2/N2 (with 1:9 mole ratio) gas flow, and the heating was maintained at 500 °C for 2 h. Afterwards the furnace was cooled to room temperature under N2 flow, and the product MoOx was collected.

Synthesis of C-MoOx

A 0.353 g amount of (NH4)6Mo7O24 and 0.1 g sodium copper chlorophyllin were added in 35 ml deionized water; after drying at 65 °C, the powder was heated in a tube furnace up to 500 °C at a ramp rate of 5 °C min−1 under H2/N2 (with 1:9 mole ratio) gas flow, and the heating was maintained at 500 °C for 2 h. Afterwards the furnace was cooled to room temperature under N2 flow, the product C-MoOx was collected.

Electrochemical measurements

All electrochemical experiments were performed in a standard three-electrode cell at room temperature. The cell consists of a glassy carbon (GC) working electrode (a rotating disc electrode with 5 mm in diameter, PINE: AFE3T050GC), a Hg/HgO (in saturated KCl) reference electrode and a carbon rod counter electrode. All potentials in this study are given relative to a reversible hydrogen electrode (RHE). The working electrodes were prepared by applying catalyst ink onto GC disk electrodes or carbon paper (1 × 3 cm2, HCP120, HESEN Inc.) electrodes. In brief, the electrocatalyst was dispersed in ethanol with Nafion solution (5 wt% in isopropyl alcohol) and ultrasonicated for 15 min to form a uniform catalyst ink. The well-dispersed catalyst ink was then applied onto a pre-polished GC disc to the designed catalyst loading. The total catalyst loading on GC was 0.5 mg cm−2 for all Ni-based catalysts, respectively. The catalyst-modified gas diffusion electrode (GDE) was prepared by using carbon paper as electrode substrate. A 1 × 1 cm2 catalyst-coated active area was formed by pipetting the catalyst ink onto the carbon paper and drying at 40 °C. All the electrodes were pretreated by cycling the potential between 0 and 0.3 V at a sweep rate of 10 mV s−1 for 30 cycles to remove any surface contamination before the hydrogen oxidation reaction (HOR) testing. The HOR measurements were conducted in 0.1 M KOH electrolyte, which was saturated with H2 gas by continuous purging. The HOR polarization curves were collected on the catalyst-coated GC rotation disc electrode at a controlled rotation speed of 2,500 rpm or 1,600 rpm and a potential scan rate of 5 mV s−1.

Calculation of exchange current density

Exchange current density (j0) can be deduced from the Butler–Volmer equation:

where α is the charge transfer coefficient, R is the universal gas constant (8.314 J mol−1 K−1), T is the operating temperature (303 K in this work), F is Faraday’s constant (96,485 C mol−1) and η is the overpotential, respectively. In a small potential window of the micro-polarization region near the equilibrium potential (±10 mV), jk approximately equals to j. In this case, the Butler–Volmer equation can be expanded by Taylor’s formula and simplified as:

By linearly fitting the polarization curve in the micro-polarization region, the j0 for Ni-based catalysts can be obtained.

Acidic etching experiments

Cyclic voltammetry with a potential scan rate of 5 mV s−1 at the potential range of 0–0.3 VRHE in 0.1 M HClO4 was employed for several cycles until the cyclic voltammetry curve was stable, indicating all the metallic Ni in the sample had been dissolved.

Electrical resistance measurements

The electrical resistances were determined by using a homemade button cell47. The sample was inserted between two polished smooth steel discs. A Solartron SI 1287 electrochemical interface equipped with a Solartron SI 1260 impedance/gain-phase analyser coupling system was used. The operating frequency range was between 0.1 Hz and 10 kHz, the d.c. potential was 0 V compared to an open circuit, and the a.c. amplitude was 10 mV. In this case, the phase angle between the voltage applied and the current induced is zero; the impedance of the sample as a function of frequency is present as a horizontal line. The value of resistance of sample is equal to the impedance; and the resistance can be directly read from the |Z |-axis in the Bode.

Membrane electrode assembly measurements

The catalyst ink was prepared by adding the catalyst, Vulcan XC-72 carbon (as conductive agent) and ionomer to isopropanol as solvent, followed by sonication for 0.5 h. The weight ratio of Ni@C-MoOx catalyst and the Vulcan XC-72 carbon was 5:4, and the weight ratio of the QPCBP-10 ionomer was 0.20 and 0.22 of the total mass for the anode and cathode, respectively. Next, the ink was sprayed onto the polymer (carbazolyl aryl piperidinium)48 membrane by airbrush to produce a gas diffusion electrode of 1 cm2 for the anode. The final catalyst loading was 1.0 mgNi cm−2 for anode and 0.3 mgPt cm−2 for cathode. After drying at 40 °C, the membrane electrode assembly (MEA) was immersed in H2-saturated 1 M KOH aqueous solution for 12 h for ion exchange. The MEA was assembled into the fuel cell with a fluorinated ethylene propylene gasket, two pieces of carbon paper as the gas diffusion layer, a graphite bipolar plate with 1 cm2 flow field and a gold-coated current collector on each side to complete the anion-exchange-membrane fuel cell. A fuel cell test station (Scribner 850e) with back-pressure regulators was used to measure the polarization curves and stability under H2/O2 or H2/air feeding conditions.

Characterizations

X-ray diffraction patterns were collected with a Rigaku D/MaXIIIA for Cu Kα (λ = 1.540598 Å) radiation at room temperature with a scanning speed of 10° min−1. The in situ Fourier transform infrared absorption spectra were recorded on IRTracer100 with Autolab302N. The UV–vis spectra were collected on UV-3600. The morphology and microstructures of all the catalysts were characterized by field-emission SEM (JEOL JEM-2100). TEM and HRTEM images were recorded on a JEOL JEM-2100F electron microscope equipped with a high-brightness field-emission gun and an energy-dispersive X-ray spectroscopy analyser. The ADF-STEM and EELS were recorded on Spectra 300 electron microscope. XPS spectra were recorded on a Thermo Scientific K-Alpha spectrometer equipped with a monochromatic Al X-ray source (Al KR, 1.4866 keV), charge calibration for all high-resolution spectra were carried out with the standard C 1s peak of 284.80 eV. In situ XPS measurements were conducted under similar conditions; the catalysts are directly reduced under the H2 atmosphere in the chamber of XPS without contacting any air or oxygen. XPS data were fitted using Avantage software, peak fit parameters: peak background is smart, maximum iterations is 100, convergence is 0.0001, fitting algorithm is Powell, Gauss–Lorents mix is product.

UPS measurements were performed in a Thermo ESCALAB 250XI PHI5000 Versa Probe III with a He Iα UV source (21.20 eV), applying a −5.00 V bias to the sample. Work function (Φ) was calculated as the energetic difference between the Fermi level and the vacuum level, as defined by the secondary-electron edge, which is based on the Einstein’s equations for photoelectricity:

The hν is the energy of He1α, the W0 is the energy of the cut-off edge and Φ is the calculated work function. The ionization energy is estimated as the onset of the density of states at the top of the valence band. The W0 for Ni@C-MoOx and NiMoOx are 16.27 eV and 17.38 eV, so that the calculated Φ are 4.93 eV and 3.82 eV, respectively49.

The X-ray absorption spectra of Ni, Mo and C were collected at the Singapore Synchrotron Light Source centre in the transmission mode, where a pair of channel-cut Si (111) crystals were used in the monochromator. The X-ray absorption fine structure (XAFS) spectroscopy in the stability test for Ni was carried out using the RapidXAFS 2 M (Anhui Absorption Spectroscopy Analysis Instrument Co.) by transmission mode at 20 kV and 30 mA, and the Si (551) spherically bent crystal analyser with a radius of curvature of 500 mm was used for Ni. The first inflection point (the first peak in the first derivative of XANES) of its XANES was defined to be E0 as the reference value (20.00 keV for Mo and 8.33 keV for Ni). XAFS data were analysed with ATHENA and ARTEMIS, linear function was subtracted from the pre-edge region, then the edge jump was normalized using Athena software. The absorption curves were normalized to 1, and the EXAFS signals χ(k) were obtained after the removal of the pre-edge and post-edge background. The k3 weighted χ(k) data were Fourier transformed after applying a Hanning window function in the range of 3–12 Å−1. The models of MoO3 and Mo2C were used to calculate the scattering paths of Mo; the model of Ni was used to calculate the scattering path of Ni in Ni@C-MoOx. First, feeff paths were obtained by calculating the feeff input files through FEEFF package in ARTEMIS; secondly, the EXAFS fitting results were got by setting different structure parameter until the fitting data highly consistent with experimental data50. Hama Fortran.exe software was used to calculate the wavelet transform of EXAFS spectra; the Morlet wavelet with finite length is used as the fundamental wave51.

k and σ are the programme parameters kappaMorlet and sigmaMorlet.

The model function is a sum of two sinuses modulated by Gaussian.

The input parameters: Mother wavelet function-Morlet function, Kappa Morlet = 1, Sigma Morlet = 10.

The equation used to model and interpret EXAFS is:

Where the sum could be over shells of atoms or over scattering paths for the photoelectron, the f(k) and δ(k) are photoelectron scattering properties of the neighbouring atom (and λ(k) is the photoelectron mean-free-path).

In situ XRD test

In situ electrochemical measurements were conducted in a polytetrafluoroethylene electrochemical cell containing Ni@C-MoOx-coated carbon paper as the working electrode, carbon rod as the counter electrode and Hg/HgO electrode as the reference electrode. The electrochemical cell was assembled, and 0.1 M KOH solution was used as the electrolyte. In situ XRD experiments were performed using a laboratory X-ray powder diffractometer (EX-CalibueR, with Cu Kα1 radiation) at room temperature with a scanning speed of 2° min−1. XRD characterizations of Ni@C-MoOx were tested during step-potential test from 0.1 to 0.7 V (vs RHE) at 1 h 0.1 V−1.

ICP-OES test

I CAP 6300 Duo instrument of Thermo Fisher Technology Co. was used for the inductively coupled plasma-optical emission spectrocopy (ICP-OES) testing to accurately analyse the actual content of metal elements in the sample. The catalyst was placed in a clean corundum crucible and heated to 900 °C min−1 at 5 °C min−1 in Muffle furnace, maintained for 2 h. After cooling to room temperature, the crucible was placed on a 180 °C furnace and boiled in aqua regia to dissolve the metal/metal oxide obtained after high temperature calcination. Then 50-ml ultrapure water was used to prepare a clear and transparent solution with a certain concentration. Before the ICP-OES test, the standard solution with the configured concentration gradient was tested to obtain a standard curve (correlation coefficient > 0.999) and then compared the results of the sample to determine the actual content of metal elements.

Computational details

All the periodic models of density functional theory (DFT) in this work were calculated with Vienna Ab-initio Simulation Package code52. The electron-exchange correlation can be described by the Perdew–Burke–Ernzerhof function with generalized gradient approximation53, and the electron-ion correlation energy was determined by the projector-augmented-wave pseudopotential method54. The cut-off energy of the plane wave basis set was selected at 500 eV, and (3 × 1 × 1) Monkhorst–Pack k-point was set for the k-space integration. The calculation exits after the energy and the force have converged to 10−5 eV and 0.02 eV Å−1 with dipole correction and spin polarization. The implicit solvation model VASPsol was used to simulate the effect of water solvent on species adsorption55,56.

The MoOx/Ni(111) model was constructed by a stick model of a MoOx(001) nanorod supported on four layers of Ni(111) (3 × 8) unit cell, and the MoOC/Ni(111) model was loaded with MoOC(002) on four layers of Ni(111) (4 × 8) unit cell. A vacuum layer of 15 Å was placed in the z axis direction of the model to eliminate the interaction between the periodic images. The bottom two layers of Ni were fixed during DFT calculations. The adsorption-free energy of intermediate species was obtained by

where ∆G, ∆E, ∆ZPE and ∆S are the free energy change, the adsorption energy, the zero-point energy change and the entropy change, respectively, and T denotes the temperature of 298.15 K. The adsorption energy was calculated by

where E*ads, E* and Eads are the energies of the surface with adsorbates, clean surface and adsorbates. The reference state of H* was derived from isolated H2 according to EH = ½ EH2 (ref. 57).

The Bader analysis used in this work is a common method that defines the electron density zero flux plane as the interface between atoms. The independent space of each atom is the atomic basin, and the Virial theorem is satisfied in each atomic basin. Therefore, the atomic charge can be obtained by:

where Ω is obtained by integrating the electron density in the atomic pot and calculating the difference with the nuclear charge. A stands for atomic pot58.

Data availability

The authors declare that all data supporting the findings of this study are available within the paper and Supplementary Information files. Source data are provided with this paper.

References

Bullock, R. M. et al. Using nature’s blueprint to expand catalysis with Earth-abundant metals. Science 369, eabc3183 (2020).

Firouzjaie, H. A. & Mustain, W. E. Catalytic advantages, challenges, and priorities in alkaline membrane fuel cells. ACS Catal. 10, 225–234 (2020).

Sheng, W., Gasteiger, H. A. & Shao-Horn, Y. Hydrogen oxidation and evolution reaction kinetics on platinum: acid vs alkaline electrolytes. J. Electrochem. Soc. 157, B1529 (2010).

Truong, M. et al. Platinum and platinum group metal-free catalysts for anion exchange membrane fuel cells. Energies 13, 582 (2020).

Lu, S., Pan, J., Huang, A., Zhuang, L. & Lu, J. Alkaline polymer electrolyte fuel cells completely free from noble metal catalysts. Proc. Natl Acad. Sci. USA 105, 20611–20614 (2009).

Elbert, K. et al. Elucidating hydrogen oxidation/evolution kinetics in base and acid by enhanced activities at the optimized Pt shell thickness on the Ru core. ACS Catal. 5, 6764–6772 (2015).

An, L., Zhao, X., Zhao, T. & Wang, D. Atomic-level insight into reasonable design of metal-based catalysts for hydrogen oxidation in alkaline electrolytes. Energy Environ. Sci. 14, 2620–2638 (2021).

Xiao, F. et al. Recent advances in electrocatalysts for proton exchange membrane fuel cells and alkaline membrane fuel cells. Adv. Mater. 33, e2006292 (2021).

Ni, W. et al. An efficient nickel hydrogen oxidation catalyst for hydroxide exchange membrane fuel cells. Nat. Mater. 21, 804–810 (2022).

Zhao, G., Jiang, Y., Dou, S.-X., Sun, W. & Pan, H. Interface engineering of heterostructured electrocatalysts towards efficient alkaline hydrogen electrocatalysis. Sci. Bull. 66, 85–96 (2021).

Yang, Y. et al. Enhanced electrocatalytic hydrogen oxidation on Ni/NiO/C derived from a nickel-based metal-organic framework. Angew. Chem. Int. Ed. 58, 10644–10649 (2019).

Tian, X., Zhao, P. & Sheng, W. Hydrogen evolution and oxidation: mechanistic studies and material advances. Adv. Mater. 31, e1808066 (2019).

Xiong, B. et al. Nickel-tungsten nano-alloying for high-performance hydrogen electro-catalytic oxidation. Chem. Eng. J. 432, 134189 (2022).

Yang, F. L. et al. Boosting hydrogen oxidation activity of Ni in alkaline media through oxygen-vacancy-Rich CeO2/Ni heterostructures. Angew. Chem. Int. Ed. 58, 14179–14183 (2019).

Wang, G. W. et al. Exploring the composition-activity relation of Ni-Cu binary alloy electrocatalysts for hydrogen oxidation reaction in alkaline media. ACS Appl. Energy Mater. 2, 3160–3165 (2019).

Gao, L. et al. A nickel nanocatalyst within a h-BN shell for enhanced hydrogen oxidation reactions. Chem. Sci. 8, 5728–5734 (2017).

Wang, J. et al. Ultrafine nickel nanoparticles encapsulated in N-doped carbon promoting hydrogen oxidation reaction in alkaline media. ACS Catal. 11, 7422–7428 (2021).

Zhao, X. et al. Nitrogen-inserted nickel nanosheets with controlled orbital hybridization and strain fields for boosted hydrogen oxidation in alkaline electrolytes. Energy Environ. Sci. 15, 1234–1242 (2022).

Ni, W. et al. Ni3N as an active hydrogen oxidation reaction catalyst in alkaline medium. Angew. Chem. Int. Ed. 58, 7445–7449 (2019).

Long, H. et al. Progress of Pt-based catalysts in proton-exchange membrane fuel cells: a review. J. Electrochem. 28, 2108061 (2022).

Alia, S. M., Pivovar, B. S. & Yan, Y. Platinum-coated copper nanowires with high activity for hydrogen oxidation reaction in base. J. Am. Chem. Soc. 135, 13473–13478 (2013).

Men, Y. et al. Oxygen-inserted top-surface layers of Ni for boosting alkaline hydrogen oxidation electrocatalysis. J. Am. Chem. Soc. 144, 12661–12672 (2022).

Ni, W. Y. et al. Efficient hydrogen oxidation catalyzed by strain-engineered nickel nanoparticles. Angew. Chem. Int. Ed. 59, 10797–10801 (2020).

Schrebler Guzmán, R. S., Vilche, J. R. & Arvía, A. J. The kinetics and mechanism of the nickel electrode—III. the potentiodynamic response of nickel electrodes in alkaline solutions in the potential region of Ni(OH)2 formation. Corros. Sci. 18, 765–778 (1978).

Zhou, F., Andreasen, S. J. & Kær, S. K. Experimental study of cell reversal of a high temperature polymer electrolyte membrane fuel cell caused by H2 starvation. Int. J. Hydrog. Energy 40, 6672–6680 (2015).

Liang, D., Shen, Q., Hou, M., Shao, Z. & Yi, B. Study of the cell reversal process of large area proton exchange membrane fuel cells under fuel starvation. J. Power Sources 194, 847–853 (2009).

Davydova, E. S., Speck, F. D., Paul, M. T. Y., Dekel, D. R. & Cherevko, S. Stability limits of Ni-based hydrogen oxidation electrocatalysts for anion exchange membrane fuel cells. ACS Catal. 9, 6837–6845 (2019).

Wang, M. et al. Alloying nickel with molybdenum significantly accelerates alkaline hydrogen electrocatalysis. Angew. Chem. Int. Ed. 60, 5771–5777 (2021).

Su, L. et al. Modification of the intermediate binding energies on Ni/Ni3N heterostructure for enhanced alkaline hydrogen oxidation reaction. Adv. Funct. Mater. 31, 2106156 (2021).

Li, W. et al. Confinement engineering of electrocatalyst surfaces and interfaces. Adv. Funct. Mater. 32, 2207727 (2022).

Zhao, G., Chen, J., Sun, W. & Pan, H. Non-platinum group metal electrocatalysts toward efficient hydrogen oxidation reaction. Adv. Funct. Mater. 31, 2010633 (2021).

Li, Q. et al. A model for the anodic carbonization of alkaline polymer electrolyte fuel cells. J. Electrochem. 26, 731–739 (2020).

Gao, Y. et al. A completely precious metal-free alkaline fuel cell with enhanced performance using a carbon-coated nickel anode. Proc. Natl Acad. Sci. USA 119, e2119883119 (2022).

Zhuang, Z. et al. Nickel supported on nitrogen-doped carbon nanotubes as hydrogen oxidation reaction catalyst in alkaline electrolyte. Nat. Commun. 7, 10141 (2016).

Song, F. et al. Interfacing nickel nitride and nickel boosts both electrocatalytic hydrogen evolution and oxidation reactions. Nat. Commun. 9, 4531 (2018).

Gao, F. Y. et al. Nickel–molybdenum–niobium metallic glass for efficient hydrogen oxidation in hydroxide exchange membrane fuel cells. Nat. Catal. 5, 993–1005 (2022).

Li, M., Zheng, X., Li, L. & Wei, Z. Research progress of hydrogen oxidation and hydrogen evolution reaction mechanism in alkaline media. Acta Phys. Chim. Sin. 37, 2007054 (2020).

Gottesfeld, S. et al. Anion exchange membrane fuel cells: current status and remaining challenges. J. Power Sources 375, 170–184 (2018).

Iannaccone, G. et al. Quantum engineering of transistors based on 2D materials heterostructures. Nat. Nanotechnol. 13, 183–191 (2018).

Strmcnik, D. et al. Improving the hydrogen oxidation reaction rate by promotion of hydroxyl adsorption. Nat. Chem. 5, 300–306 (2013).

Gao, Y. F. et al. Improving the antioxidation capability of the Ni catalyst by carbon shell coating for alkaline hydrogen oxidation reaction. ACS Appl. Mater. Interfaces 12, 31575–31581 (2020).

Kabir, S. et al. Platinum group metal-free NiMo hydrogen oxidation catalysts: high performance and durability in alkaline exchange membrane fuel cells. J. Mater. Chem. A 5, 24433–24443 (2017).

Roy, A. et al. Nickel-copper supported on a carbon black hydrogen oxidation catalyst integrated into anion-exchange membrane fuel cell. Sustain. Energy Fuels 2, 2268–2275 (2018).

Yang, Y. et al. Suppressing electron back-donation for a highly co-tolerant fuel cell anode catalyst via cobalt modulation. Angew. Chem. Int. Ed. 61, e202208040 (2022).

Tian, X. et al. Metal-support interaction boosts the stability of Ni-based electrocatalysts for alkaline hydrogen oxidation. Nat. Commun. 15, 76 (2024).

Zheng, Y. et al. Molybdenum oxide, oxycarbide, and carbide: controlling the dynamic composition, size, and catalytic activity of zeolite-supported nanostructures. J. Phys. Chem. C. 123, 22281–22292 (2019).

Ding, W. et al. High-performance poly (carbazolyl aryl piperidinium) anion exchange membranes for alkaline fuel cells. J. Membr. Sci. 657, 120676 (2022).

Yuan, W. et al. Space-confinement-induced synthesis of pyridinic- and pyrrolic-nitrogen-doped graphene for the catalysis of oxygen reduction. Angew. Chem. Int. Ed. 52, 11755–11759 (2013).

Hou et al. A generic interface to reduce the efficiency-stability-cost gap of perovskite solar cells. Science 358, 1192–1197 (2017).

Ravela, B. & Newville, M. ATHENA, ARTEMIS, HEPHAESTUS: data analysis for X-ray absorption spectroscopy using IFEFFIT. J. Synchrotron Rad. 12, 537–541 (2005).

Funke, H., Chukalina, M. & Rossberg, A. Wavelet analysis of extended X-ray absorption fine structure data. Phys. Scr. T. 115, 232–234 (2005).

Kresse, G. & Furthmuller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comp. Mater. Sci. 6, 15–50 (1996).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Blochl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994).

Mathew, K. et al. Implicit self-consistent electrolyte model in plane-wave density-functional theory. J. Chem. Phys. 151, 234101–234107 (2019).

Mathew, K. et al. Implicit solvation model for density-functional study of nanocrystal surfaces and reaction pathways. J. Chem. Phys. 140, 084106–084113 (2014).

Xu, H. et al. A universal principle for a rational design of single atom electrocatalysts. Nat. Catal. 1, 339–348 (2018).

Bader, F. W. Atoms in Molecules: A Quantum Theory (Oxford Univ. Press, 1994).

Acknowledgements

The National Key Research and Development Program of China (2021YFA1502000 to W.D.); National Natural Science Foundation of China (22179012 and 22022502 to W.D.; 22090032 and 52021004 to Z.W.); Chongqing Outstanding Youth Fund (cstc2020jcyj-jqX0013 to W.D.); Natural Science Foundation of Chongqing, China (CSTB2023NSCQ-LZX0084 to W.D.) and the UK EPSRC (EP/W03784X/1 to W.-F.L.) are gratefully acknowledged. We also would like to acknowledge D.-L. Zhang of Institute of Advanced Interdisciplinary Studies, Chongqing Univeristiy, for the assistance of structural characterization, S.-J. Chen of College of Physics, Chongqing University, for the discussion on quantum well and X. Lin of Department of Chemical Engineering and Biotechnology, University of Cambridge, for the helpful discussion and some help on final revision. We also thank the Anhui Absorption Spectroscopy Analysis Instrument Co. for XAFS measurements.

Author information

Authors and Affiliations

Contributions

Y.Z. carried out the experiments. Z.X. and X.S. contributed to the materials synthesis and characterization. M.L. and Y.Y. performed DFT calculations. Y.Z., W.Y. and J.W. contributed to fuel cell tests. W.D., L.L., W.-F.L., Y.Z., M.L. and Y.Y. contributed to the analysis of DFT calculations. W.D., Z.W. and Y.Z. analysed the experimental results. Y.Z., W.D. and W.-F.L. wrote the manuscript. W.D. designed the project. W.D., W.-F.L. and Z.W. conceived the ideas. W.D., W-F.L. and Z.W. supervised the project.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Energy thanks Elena Davydova, Marcel Risch, and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–53, Tables 1–12, Notes 1–16 and Refs. 1–7.

Supplementary Data 1

Statistical source data for Supplementary Figs. 2–5; 13a,b; 17a,b; 18b; 19a–c; 20; 21b; 22a–e; 23a–e; 24; 25a,b; 26a–d; 27a–d; 28a–d; 29; 31; 34; 35; 36a–f; 37; 38a,b; 39; 42a–d; 51; 52a,b and 53b,c.

Source data

Source Data Fig. 3

Statistical source data for Fig. 3.

Source Data Fig. 4

Statistical source data for Fig. 4.

Source Data Fig. 5

Statistical source data for Fig. 5.

Source Data Fig. 6

Statistical source data for Fig. 6.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhou, Y., Yuan, W., Li, M. et al. Quantum confinement-induced anti-electrooxidation of metallic nickel electrocatalysts for hydrogen oxidation. Nat Energy 9, 1297–1309 (2024). https://doi.org/10.1038/s41560-024-01604-9

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41560-024-01604-9

This article is cited by

-

Bioinspired Sulfo oxygen bridges optimize interfacial water structure for enhanced hydrogen oxidation and evolution reactions

Nature Communications (2025)

-

Recent achievements on the modification of microenvironment for fuel cell catalysis

Science China Materials (2025)