Abstract

Potato peel waste (PPW) is an underutilized substrate which is produced in huge amounts by food processing industries. Using PPW a feedstock for production of useful compounds can overcome the problem of waste management as well as cost-effective. In present study, potential of PPW was investigated using chemical and thermochemical treatment processes. Three independent variables i.e., PPW concentration, dilute sulphuric acid concentration and liberation time were selected to optimize the production of fermentable sugars (TS and RS) and phenolic compounds (TP). These three process variables were selected in the range of 5–15 g w/v substrate, 0.8–1.2 v/v acid conc. and 4–6 h. Whole treatment process was optimized by using box-behnken design (BBD) of response surface methodology (RSM). Highest yield of total and reducing sugars and total phenolic compounds obtained after chemical treatment was 188.00, 144.42 and 43.68 mg/gds, respectively. The maximum yield of fermentable sugars attained by acid plus steam treatment were 720.00 and 660.62 mg/gds of TS and RS, respectively w.r.t 5% substrate conc. in 0.8% acid with residence time of 6 h. Results recorded that acid assisted autoclaved treatment could be an effective process for PPW deconstruction. Characterization of substrate before and after treatment was checked by SEM and FTIR. Spectras and micrographs confirmed the topographical variations in treated substrate. The present study was aimed to utilize biowaste and to determine cost-effective conditions for degradation of PWW into value added compounds.

Similar content being viewed by others

Introduction

Indecent dumping of wastes in many urban areas results into contaminated environment raising health concerns. Incineration and landfilling are generally employed practices for solid waste management in Pakistan1,2. Microbial spoilage of dumped food waste creates severe environmental concern. Industrial application of food wastes appears appealing to provide cost effective substrates as well as to solve the environmental issue. PPW can be converted into various useful products like enzymes, antioxidants, reducing sugars, biogas, biofuel, bio-fertilizers and bioabsorbent3,4,5,6.

Approximately, one-third of global food produced is estimated to be lost7 and these wastes have been cost at 1 trillion USD8.

Potato is a main edible crop with annual production of 370 million tons9. A major part of potato is used as fresh product whereas the residual part is used and consumed as a dried potatoes, starch, crisp, and fries. During processing of potato, 15 to 40% of the initial weight is removed from fresh potatoes and is termed as PPW10,11. Food industry especially the fast food restaurants produce heavy amounts of potato peels. Collection of PPW from such units within a cosmopolitan city would suffice to provide raw material for a second generation bioethanol production unit.

Phenolic compounds are abundantly present in plants and their antioxidant properties prevent the cell from oxidative damage and eventually lessen the burden of chronic and cardiovascular diseases. Synthetic antioxidants abundantly being used in pharmaceutical and food industries to preserve drug and food products and reported to induce various carcinomas. Consequently, the natural antioxidants are being prepared12. In this paper we explored the potential of potato skins as a precursor of various bioactive ingredients which have diverse biotechnological usage. The practical approach is to develop the awareness of proper and sustainable management of agricultural waste as well as the synthesis of various compounds such as lactic acid, biohydrogen, bioabsorbent, enzymes and various food additives which will serve as an excellent source to develop link between different industries.

Various research reports have reported the production of useful compounds from PPW and their use in various sectors, particularly food processing industry such as formulation of yogurt, functional biscuits, fermented juice etc. Addition of potato peel extract in different food products has enhanced the vitamin content, shelf life, antioxidant profile, color and sensory properties13,14,15,16,17. The main purpose of this work was to produce fermentable sugars which can enhance biofuel production from PPW. For microbial fermentation small monomeric sugars are more accessible as compared to complex polymers. PPW conversion into biofuels and biogas offers exceptional alternatives to fossil fuels. Previously, many research reports have confirmed this conversion and have recorded good yield of biofuel employing various lucrative substrates5,18,19,20.

Few novel sophisticated processes for example acidified solvents based extraction21, microwave assisted and ultrasonic extractions22,23 and liquid based pressurized removal24 have been introduced to extract the valuable compounds from PPW. But these methods are highly expensive and complex and the present research has reported time saving, low cost and very simple methods to isolate useful compounds from PPW. Different strategies have been applied for process optimization using ANN (artificial neural network), RSM (response surface methodology), GA (genetic algorithm) and OFAT (one factor at a time)25,26,27. OFAT approach is a time consuming method which often leads to inaccurate results, whereas RSM is an efficient statistical model that analyses the individual and combined effect of different parameters on the yield28. Therefore, scientists are currently using RSM to enhance product yield29,30. Acid and steam assisted acid treatments to obtain value-added products employing various plant biowaste are cost effective approaches in select situations to obtain some useful products31,32,33.

This work was aimed to optimize acidic treatment by using box-behnken design to optimize yield of TS, TP and RS. Of different food wastes, potato peels represent starch rich, antioxidant as well as phenolic compounds and dietary fibers harboring cost-effective resource34,35,36. The process developed in this work is economical for the conversion of a food waste into useful products such as phenolic compounds and fermentable sugars. This effort is promising to provide cheaper feedstock for various biotechnological applications particularly second generation biofuel. Accessory fermentation residues enriched in single cell protein can be used as an excellent ingredient in animal feed.

Materials and methods

Potato peel drying

PPW were obtained from local fries shop (Gate No.4, Quaid-e-azam campus University of Punjab, Lahore, Pakistan. They were properly washed to remove all dirt, sun dried for few days and then oven dried at 60 °C for 24 h till consistent weight. The processed PPW were powdered by electric mill and sieved by strainer to obtain the uniform size of 1–2 mm. The powdered PPW was stored in air tightened containers at room temperature (25 °C ± 5 °C).

Proximate composition of dried potato peels

The compositional analysis of PPW was characterized by determining the content of different components including moisture, ash, crude fat, crude protein, crude fiber and carbohydrates using standard protocols of AOAC37.

Pretreatment

Erlenmeyer flasks were used as pretreatment reactors with a working volume up to 100 ml. Different concentrations of substrate were soaked into different concentration of acid for various time periods, and then autoclaved at 121 °C, 21 psi for 15 min. After autoclaving, the samples were carefully filtered and washed up to neutrality. The clear filtrate free of any solid residue was used to determine the value of sugars and phenolic compounds (Fig. 1).

Experimental Design

To optimize the treatment, box-behnken design was used. Some independent variables including substrate conc. (K1), acid conc. (K2) and the time (K3) were selected in the range of 5–15 g, 0.8–1.2% and 4–8 h, respectively as described in the Table 1.

The yield of dependent variable was calculated by using Statistical Software Minitab (2016), Version 16. Minitab Incorporation, State College from the following equation.

Here response is the I, J0 is constant, linear coefficients are J1K1 to J3K3, quadratic coefficients are J11K12 to J33K32, interactive coefficients are J12K1K2 to J23K2K3.

Substrate characterization

Raw and acid treated samples with maximum fermentable sugars and phenolic content from both chemical and thermochemical treatment were further characterized through fourier transform infrared spectroscopy (FTIR Agilent Technologies Cary630, Santa Clara, USA) to determine the vibration frequency in functional groups. The spectra were measured with a resolution of 4 cm−1 and in the range 3500–500 cm−1. The samples were ground into fine powder using an electric miller and subjected to analysis.

Scanning electron microscopy (SEM JSM-6490LA, Japan) was carried out to confirm the visual deformation to the ultrastructure of PPW. Samples were mounted on aluminum stubs with double-sided carbon adhesive tabs. Specimens were observed using Jeol JSM-6490LA scanning microscope (Tokyo,Japan) at an accelerating voltage of 1.7 kV.

Analytical methods

After completion of pretreatment process, total and reducing sugars and phenolic compounds were measured. Reducing sugar and total sugar were determined by DNS using Miller38 and Dubois method39, respectively. For the determination of phenolic compounds, Carralero Sanz’s method40 method was used.

Acid saccharification of PPW

After acid hydrolysis, saccharification of substrate was determined at various time periods such as 4,6,8 and 10 h. The 250 ml Erlenmeyer flasks were used to conduct experiment containing of acid treated and acid assisted autoclaved treated PPW (5 g). For determination of reducing sugar samples were regularly taken. Saccharification (%) was calculated by using below formula41.

Mass balance

Once pretreatment process is completed, liquid that was obtained was filtered with the help of Whatman filter paper No. 1 to measure mass balance. Residue left on filter paper was washed with 1 M NaOH to neutralize the pH. Afterwards, filter paper having treated substrate were placed at 50 °C in oven until consistent weight was attained. The solubility index (S.I) was measured by following formula:

Ethical concern

There was no use of animal or human in this study, so no ethical concerns was raised during this study.

Research involving plants

The potato peels used of in this study complied with national and international guidelines.

Results and discussion

During this work, pulverized PPW were pretreated by dilute sulphuric acid and acid plus steam. The experiments were conducted in two batches. In first batch of chemical treatment the substrate was treated with dilute acid. In the second batch, thermochemical treatment was applied. Diltue Sulphuric acid treatment was followed by autoclaving at 121 °C, at 15psi for 15 min. The main objective of this experiment was to get maximum degradation of potato peels into RS, TS and TP.

Proximate composition of dried PPW

The chemical composition of potato peels was characterized by proximate analysis expressed as a percentage of weight is shown in Table 1. Proximate analysis reported the incidence of various useful compounds, it comprised moisture content up to 10.29%, ash quantity 8.81%, crude fat 0.44%, crude protein 15.45%, crude fiber 4.4% and carbohydrates 65.01% on dry weight basis.

Carbohydrates were found to be the main component accounting for 65% of the potato peels. Among the carbohydrates, the main component was starch. A work by Kpanja et al.42 has reported approximately similar value of ash content i.e., 7.11% while determining the proximate composition of sun-dried irish potat peels. The quantity of carbohydrate which is mainly starch was in accordance with the value reported by Badr SA and El-Wasif43. Another research report by Adegunloye and Oparinde 201744 has recorded the carbohydrate content of 72.60% in potato peels while determining the effects of fermentation on the proximate composition of Irish (Solanum tuberosum) peels.

This report measured the protein content of 15.45% of potato peels. A research report by Maxwell et al.45 has measured the protein content of 12.5% while reporting the effect of Saccharomyces cerevisiae on protein enrichment of potato peels using solid-state fermentation process. Onuguh et al.46 have recorded almost similar level of fat from potato peels that is 0.28%. Moisture, fiber and ash values were almost agreed with values reported by Rowayshed et al.47.

The notably higher quantity of carbohydrate rendered the waste biomass a lucrative medium encompassing the key nutrients essential for production of valuable compounds. In addition, this waste also contained rich amount of starch, which could serve as an efficient feedstock for biofuel production (Table 2).

To optimize the pretreatment conditions, BBD with three values and three factors was applied. The independent factors such as substrate concentration (K1), sulphuric acid loading (K2) and (K3) as the time were selected for the pre-treatment. These factors with ranges and codes are mentioned in the Table 1. After each pre-treatment, reducing and total sugars and phenolic compounds were calculated. The extraction yield was expressed in mg/gds (gram dry substrate). Result of these analyses is described in Tables 3 and 4. The response was calculated by second order polynominal equation (Eq. 2–7).

Chemical and thermochemical pretreatment effects on the yield

It is clearly demonstrated that the chemical treatments produce maximum production of total sugar upto 188 mg/gds corresponding to 5% w/v of substrate loading in 1.2% v/v of sulphuric acid conc. for 6 h. Optimum production of reducing sugars up to 144.12 mg/gds and phenolic compounds up to 43.68 mg/gds were liberated at run No. 11 and 2, respectively. Thermochemical (acid assisted steam) treatment as described in Table 4 has yielded high production of fermentable sugars and phenolic compounds. It has reported 720.00 mg/gds of total sugars using 5% w/v of substrate loading in 0.8% v/v of sulphuric acid for 6 h. Optimum extraction of reducing sugars up to 660.62 mg/gds and phenolic compounds up to 38.66 mg/gds were observed at run No. 1. It was proved that use of dilute acid assisted autoclaved treatment was more useful in monomerization pf polymeric sugars of PPW. Alot of research was reported that have high record of production of reducing sugar and polysaccharides from dilute acid and dilute acid plus heat-treated PPW for the production of biofuels48,49,50,51.

Significant response was indicated by regression analysis. Squared, interactive and linear effetct of process parameters was measured using analyses of variance (ANOVA). During treatment T.S, R.S and T.P were found significant with p-values of 0.004, 0.043 and 0.056, respectively as depicted in Table 5. During acid treatment the determination of coefficient (R2) values of 89.71%, 97.62% and 76.11% were found significant for T.S, R.S and T.P, respectively predicted the accuracy of the model.

For acid plus steam treatment this model was found significant for the extraction of T.S, R.S, and T.P.C. The value of Pred. R2 and Adj. R2 were found as were found as 0.82, 0.59 and 0.68 and 0.93, 0.71 and 0.00 for R.S., T.S., and T.P.C, respectively.

In thermo-chemical methods, values of T.S, R.S, and T.P.C were observed as 32.83, 9.99 and 19.59, respectively by using Fisher’s f-test. While p-values of 0.004, 0.025, 0.022 were found significant for T.S., R.S. and T.P., respectively as depicted in Table 6. The R2 values of 97.12%, 90.23% and 97.24% for T.S., R.S. and T.P., respectively established the precision of model in acid plus steam treatment. The value of Pred. R2 and Adj. R2 were found as were found as 0.58, 0.65 and 0.82 and 0.81, 0.88 and 0.92 for R.S., T.S., and T.P.C, respectively (Figs. 2, 3).

Regression equation of chemical treatment

The regression model for the production of T.S., R.S., and T.P. is expressed as follows:

Regression equation of thermo-chemical treatments

The figures of 2D surface plots based on regression Eqs. (2–7) of T.S., R.S., and T.P. extracted during pretreatment at various conditions are depicted in Fig. 4 and 5. These plots describe the effect of various pretreatment conditions on the yield of fermentable sugars and phenolic compounds from treated PPW. The main colors are dark red, light pink and blue which represented highest, moderate and lowest yield, respectively. The acid assisted steam treatment caused more degradation of branched and complex substrate and eventually liberated more fermentable sugars.

In our study maximum amount of total sugar (T.S.) up to 720.00 mg/gds and reducing sugar (R.S.) up to 660.62 mg/gds were released after dilute sulphuric acid plus autoclaved treatment. Mushtaq et al.52 have reported high yield of total and reducing sugars upto 28.971and 7.163 mg/ml using alkali treated PPW. A previous report has described dilute sulphuric acid hydrolysis and sonication of PPW as a very promising process to release reducing sugars i.e., 57.03 g/kg53. It has been recorded that dilute acid treatment has significant effect on production of biogas with enhanced biomass reactivity and extraction of sugars54. In this study maximum amount of total phenolic compounds (T.P.C) obtained was 38.66 mg/gds after thermo-chemcial treatement employing 5% PPW with 0.8% loading of dilute sulphuric acid for 6 h.

Different studies have reported valuable extraction of phenolic compounds using using acidified solvent based mixtures. The acidified ethanolic extraction additionally avoids side reactions and product recovery is pure and stable. Many studies have investigated and compared acidic pretreatment with other advanced techniques and have revealed considerable effect on PPW degradation21,51,55. Their work has reported considerable extraction of sugars and other valuable bioactive components from PPW. Albeit in the present study no organic solvent was employed. Therefore, further work is required on these lines to increase purity as well as yields of acid treated PPW.

FTIR spectroscopy

The FTIR test was conducted to assess the changes occurred at different stages in chemical and thermochemical treatments. The findings are presented in Fig. 2a–c.

The FTIR spectrum of raw PPW revealed a band between 3000 and 3500 cm−1, attributed to the presence of free and hydrogen bonded –OH group stretching vibrations derived from the polymers of cellulose, lignin and hemicellulose56,57,58. The peak at 1623 cm−1 may be ascribed to the existence of chemisorbed or physisorbed water molecules on the surface59. With reference to the peak at 1645.6 cm−1, it corresponded to the stretching vibrations of the C=C carbonyl group. Several bands between 1364 and 1103 cm−1 confirmed the lignin structure of substrate. Another peak at 1000 cm−1 attributed to the C–O–C elongations of the cellulose present in potato peel60.

In FTIR spectrum of acid treated substrate, the weak absorption peaks was observed at 2920 cm−1 reflected the stretching of C–H bond. The noticeable peak at 1010.1 cm−1 which resemble starch was attributed to C–O bond stretching61. In acid treated spectra, the strong peak at 1718.3 was attributed to carboxylic acid bond stretching. Additionally, two strong peaks observed at 1645 and 1623 cm−1 corresponding to C=O vibrations in the lignin part of PPW. The disappearance of both these peaks following acid treatment demonstrates that lignin part was degraded using sulphuric acid solution62. The displayed peaks at 1619 cm−1 and 1638 cm−1 indicated the presence of aromatic compounds in substrate particularly in lignin part confirming the bond cleavage63. Aryl OH group was detected at peak 1407 cm−1. The characteristic absorption peaks located at 1371 cm−1, 1381 cm−1 and 1010 cm−1 detected the stretching vibration of carbonyl (–CO) and methyl (–CH) moieties64. The region between 800 and 1500 cm−1 corresponding to cellulose, is a unique fingerprint region in which majority of bonds remained entangled. This indicates that regardless of acid treatment the cellulose maintains its chemical structure to the untreated one65,66. The C–H bond distortion in carbohydrate was quite visible in treated substrate as compared to the control substrate (Fig. 2b).

Spectrum of acid plus autoclaved substrate displayed narrow and lesser number of peaks confirming the degradation of substrate. The sharp peak displayed at 1617 cm−1 confirmed the C=C stretching vibrations of conjugated structures such as esters, ketone and quinone confirming the deconstruction of lignin part. Similar peaks at 1235 cm−1, 1313 cm−1, 1399 cm−1 showed moieties of –C–H and aromatic ring vibrations. Peaks at 1023 cm−1 and 1099 cm−1 depicted the stretching vibrations of C–O–C and C–O Bouhadjra et al.64. These absorption peaks confirmed the substantial deconstruction of PPW due to C–H, C=C, C–O–C and C–O vibrations proving the effectiveness of dilute acid as well as dilute acid assisted autoclaved pre-treatment techniques. The disaapearance of many peaks were observed in the region 800 and 1500 cm−1 as compared to untreated and acid treated spectras. This demostrates that cellullose part of PPW was decnstructed using acidn plus steaam treatment (Fig. 2c).

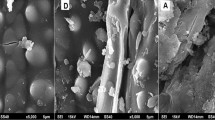

Structural morphology

SEM microscopy was employed to reveal the topographical variations and deformations in substrate after pretreatments. The resulting SEM images of control and treated substrate are depicted in Fig. 3a, b.

Some pore and irregular crack were generated due to the acidic reaction that deform the structural bonds. Difference between structural arrangement of raw and treated samples was prominent and verified by electron micrographs. The raw sample exhibited a complex and compact order whereas treated samples generated a high degree of porosity (Fig. 3a, b). Same observations and disruptions have been described by Ben Taher et al.55. They have confirmed significant deformations, cracks and crevices formation in the micrographs of PPW after thermo-acidic pretreatments. In Fig. 3b, small pore like segments were observed after acid plus steam treatment. This indicates that the acid plus steam treatment may solubilize extracellular polymeric substance67. The ester bond was broken and many bounded phenolic acids were released. We can conclude that the combined treatment of acid plus steam produced smaller segments found in the micrographs. The structure of substrate was altered by the treatment and more bioactive components were released during this process.

Wang et al.68 have also reported perforated and disrupted substrate structure after ultrasonic assisted treatment using SEM micrographs. Frontuto et al.69 have also recorded disruption and deconstruction of PPW after using pulse electric field assisted extraction techniques. Sanusi et al.70 and Atitallah et al.71 have also revealed similar findings while evaluating the potential of PPW for bioethanol production.

Degradation index of PPW

Percentage degradation and mass balance of substrate was calculated was measured after completion of pretreatment process. Results revealed that in acidic treatment max. degradation of 86% was observed with loading of 1.2% acid and time period of 4 h as shown in Fig. 6a. In acid plus steam treatment, 89% of substrate degradation was recorded (Fig. 6b). A major improvement made in present study compared to expensive solvent assisted extraction is that the thermochemical extraction is the low cost, since sophisticated equipment as well as expensive organic solvents are not required. However, if required the value added organic bioactive compounds could be separated by employing specific solvents and advanced techniques.

Acid saccharification of PPW

Saccharification was calculated at different time intervals after acid and acid plus steam hydrolysis. Results revealed that maximum sugars were released after 6 h of acid assisted autoclaved treatment with saccharification level of 40%, whereas minimum saccharification of 31.8% was occurred after 10 h. In case of acid treated substrate, maximum saccharification of 19% was calculated as shown in Fig. 7. Interestingly, it has been recorded that different food wastes including mango, orange, banana and pineapple peels have been utilized for liberation of various valuable products such as fermentable sugars, dextran and hydroxymethylfurfural (HMF) production employing different methods72,73,74,75. Such biowastes can also be processed through the acid/acid assisted steam treatments reported in this study for rendering the achievements cost-effective.

Conclusions

This study evaluated the effectiveness of dilute acid and acid assisted steam pre-treatment of potato peel waste. The extraction yields of total sugars and phenolic compounds was improved by combined acid and steam treatment. Statistical results of this study revealed maximum extraction of total and reducing sugars and phenolic compounds as 720.00, 660.62 and 38.66 mg/gds, respectively following the thermochemical treatment. The acid assisted autoclaved method proved to be very effective for the deconstruction of PPW and yielded the maximum release of both monomeric and oligomeric sugars. The cost-effective and simple strategy of dempolymerization of PPW into value added products is capable to provide various feedstocks to biotechnological processes with concomitant and sustainable management of solid food wastes.

Data availability

All the generated data is present in this manuscript.

References

Salam, M. et al. Exploring the role of Black Soldier Fly Larva technology for sustainable management of municipal solid waste in developing countries. Environ. Technol. Innov. 24, 101934–101987. https://doi.org/10.1016/j.eti.2021.101934 (2021).

Siddiqua, A., Hahladakis, J. N. & Al-Attiya, W. A. K. An overview of the environmental pollution and health effects associated with waste landfilling and open dumping. Environ. Sci. Pollut. Res. 29, 58514–58536. https://doi.org/10.1007/s11356-022-21578-z (2022).

Mushtaq, Q., Irfan, M., Tabssum, F. & IqbalQazi, J. Potato peels: A potential food waste for amylase production. J. of Food Process Eng. 40, e12512-12519. https://doi.org/10.1111/jfpe.12512 (2017).

Irfan, M., Mushtaq, Q., Tabssum, F., Shakir, H. A. & Qazi, J. I. Carboxymethylcellulase production optimization from newly isolated thermophilic Bacillus subtilis K-18 for saccharification using response surface methodology. AMB Express. 7, 1–9. https://doi.org/10.1186/s13568-017-0331-3 (2017).

Chohan, N. A., Aruwajoye, G. S., Sewsynker-Sukai, Y. & Kana, E. G. Valorisation of potato peel wastes for bioethanol production using simultaneous saccharification and fermentation: Process optimization and kinetic assessment. Renew. Energ. 146, 1031–1040. https://doi.org/10.1016/j.renene.2019.07.042 (2020).

Sawicka, B., Skiba, D. & Barbas, P. Food and Agricultural Byproducts as Important Source of Valuable Nutraceuticals 1st edn, 19–37 (Springer, 2022).

FAO, SAVE FOOD. Global initiative on food loss and waste reduction (2015). http://www.fao.org/3/ai4068e.pdf. 25, p. 2018.

FAO. Food Wastage Footprint: Impacts on Natural Resources: Summary Report (2013). http://site.ebrary.com/id/10815985

FAO (2013, 2016). Agriculture Organization of the United Nations Statistics Division. Economic and Social Development Department, Rome, Italy. http://faostat3.fao.org/home/E. Accessed 31 December 2016.

Schieber, A., Stintzing, F. C. & Carle, R. By-products of plant food processing as a source of functional compounds—Recent developments. Trends Food Sci. Technol. 2001(12), 401–413. https://doi.org/10.1016/S0924-2244(02)00012-2 (2001).

Arapoglou, D., Varzakas, T., Vlyssides, A. & Israilides, C. J. W. M. Ethanol production from potato peel waste (PPW). Waste Manag. 30, 1898–1902. https://doi.org/10.1016/j.wasman.2010.04.017 (2010).

Abeyrathne, E. D. N. S., Nam, K., Huang, X. & Ahn, D. U. Plant-and animal-based antioxidants’ structure, efficacy, mechanisms, and applications: a review. Antioxidants. 11, 1025–1043. https://doi.org/10.3390/antiox11051025 (2022).

El-Hadary, A. R. E., Sulieman, A. M. & El-Shorbagy, G. A. Comparative effects of hibiscus leaves and potato peel extracts on characteristics of fermented orange juice. J. Food Qual. Hazards Control. 2023(10), 39–50. https://doi.org/10.18502/jfqhc.10.1.11988 (2023).

Tlay, R. H., Abdul-Abbas, S. J., El-Maksoud, A. A. A., Altemimi, A. B. & Abedelmaksoud, T. G. Functional biscuits enriched with potato peel powder: Physical, chemical, rheological, and antioxidants properties. Food Syst. 6, 53–63. https://doi.org/10.21323/2618-9771-2023-6-1-53-63 (2023).

Brahmi, F. et al. Optimization of conventional extraction parameters for recovering phenolic compounds from potato (Solanumtuberosum L.) peels and their application as an antioxidant in yogurt formulation. Antioxidants 11, 1401–1422. https://doi.org/10.3390/antiox11071401 (2022).

de Andrade Lima, M., Andreou, R., Charalampopoulos, D. & Chatzifragkou, A. Supercritical carbon dioxide extraction of phenolic compounds from potato (Solanum tuberosum) peels. Appl. Sci. 11, 3410–3428. https://doi.org/10.3390/app11083410 (2021).

Jimenez-Champi, D., Romero-Orejon, F. L., Moran-Reyes, A., Muñoz, A. M. & Ramos-Escudero, F. Bioactive compounds in potato peels, extraction methods, and their applications in the food industry: A review. CyTA-J. Food 21, 418–432. https://doi.org/10.1080/19476337.2023.2213746 (2023).

Rodríguez-Martínez, B., Coelho, E., Gullón, B., Yáñez, R. & Domingues, L. Potato peels waste as a sustainable source for biotechnological production of biofuels: Process optimization. Waste Manag. 155, 320–328. https://doi.org/10.1016/j.wasman.2022.11.007 (2023).

Soltaninejad, A., Jazini, M. & Karimi, K. Sustainable bioconversion of potato peel wastes into ethanol and biogas using organosolv pretreatment. Chemosphere. 2022(291), 133003. https://doi.org/10.1016/j.chemosphere.2021.133003 (2022).

Sujeeta, K. M., Mehta, S. & Sihag, K. Optimization of conditions for bioethanol production from potato peel waste. Int. J. Chem. Stud. 6, 2021–2026 (2018).

Maldonado, A. F. S., Mudge, E., Ganzle, M. G. & Schieber, A. Extraction and fractionation of phenolic acids and glycoalkaloids from potato peels using acidified water/ethanol-based solvents. Food Res. Int. 65, 27–34 (2014).

Chen, M. S., Zhao, Y. & Yu, S. J. Optimisation of ultrasonic-assisted extraction of phenolic compounds, antioxidants, and anthocyanins from sugar beet molasses. Food Chem. 172, 543–550 (2015).

Singh, P. P. & Saldana, M. D. A. Subcritical water extraction of phenolic compounds from potato peel. Food Res. Int. 44, 2452–2458 (2011).

Alvarez, V. H., Cahyadi, J., Xu, D. Y. & Saldana, M. D. A. Optimization of phytochemicals production from potato peel using subcritical water: Experimental and dynamic modeling. J. Supercrit. Fluids. 90, 8–17 (2014).

Lantero, O. J., Li, M., & Shetty, J. K. Genencor International Inc. Process for conversion of granular starch to ethanol (2011). U.S. Patent 7968318 (filed September 15, 2011).

Betiku, E. & Taiwo, A. E. Modeling and optimization of bioethanol production from breadfruit starch hydrolyzatevis- a-vis response surface methodology and artificial neural network. Renew. Energy 74, 87–94. https://doi.org/10.1016/j.renene.2014.07.054 (2015).

Maiti, B., Rathore, A., Srivastava, S., Shekhawat, M. & Srivastava, P. Optimization of process parameters for ethanol production from sugar cane molasses by Zymomonas mobilis using response surface methodology and genetic algorithm. Appl. Microbiol. Biotechnol. 90, 385–395. https://doi.org/10.1007/s00253-011-3158-x (2011).

Abdulgader, M., Yu, J., Zinatizadeh, A. A., Williams, P. & Rahimi, Z. Process analysis and optimization of single stage flexible fibre biofilm reactor treating milk processing industrial wastewater using response surface methodology (RSM). Chem. Eng. Res. Des. 149, 169–181. https://doi.org/10.1016/j.cherd.2019.07.011 (2019).

Yılmaz, Ş & Şahan, T. Utilization of pumice for improving biogas production from poultry manure by anaerobic digestion: A modeling and process optimization study using response surface methodology. Biomass Bioenerg. 2020(138), 105601–105611. https://doi.org/10.1016/j.biombioe.2020.105601 (2020).

Chaudhary, A. et al. Pomegranate peels waste hydrolyzate optimization by Response Surface Methodology for Bioethanol production. Saudi J. Biol. Sci. 2021(28), 4867–4875. https://doi.org/10.1016/j.sjbs.2021.06.081 (2021).

Dahunsi, S. O. Liquefaction of pineapple peel: Pretreatment and process optimization. Energy 185, 1017–1031. https://doi.org/10.1016/j.energy.2019.07.123 (2019).

Saleem, A. et al. Acid hydrolysis optimization of pomegranate peels waste using response surface methodology for ethanol production. Biomass Convers. Biorefin. 12, 1513–1524. https://doi.org/10.1007/s13399-020-01117-x (2020).

Aissi, F. Z., El Hadi, D., Megateli, S. & Ketfi, S. Statistical optimization of pretreatment of orange processing waste using response surface methodology for bioethanol production. Energy Sources A: Recov. Util. Environ. Eff. 43, 1–15. https://doi.org/10.1080/15567036.2021.1967519 (2021).

Joly, N., Souidi, K., Depraetere, D., Wils, D. & Martin, P. Potato by-products as a source of natural Chlorogenic acids and phenolic compounds: Extraction, characterization, and antioxidant capacity. Molecules 26, 177–192. https://doi.org/10.3390/molecules26010177 (2020).

Rodríguez-Martínez, B., Gullón, B. & Yáñez, R. Identification and recovery of valuable bioactive compounds from potato peels: A comprehensive review. Antioxidants. 10, 1630. https://doi.org/10.3390/antiox10101630 (2021).

Salem, M. A. et al. Valorization of by-products Derived from Onions and Potato: Extraction Optimization, Metabolic Profile, Outstanding Bioactivities, and Industrial Applications. Waste Biomass Valorization 14, 1–36. https://doi.org/10.1007/s12649-022-02027-x (2023).

AOAC. Official Methods of Analysis Association of Official Analytical Chemists International 19th edn. (Maryland, 2005).

Miller, G. L. Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 31, 426–428 (1959).

DuBois, M., Gilles, K. A., Hamilton, J. K., Rebers, P. T. & Smith, F. Colorimetric method for determination of sugars and related substances. Anal. Chem. 28, 350–356 (1956).

Sanz, V. C., Mena, M. L., González-Cortés, A., Yanez-Sedeno, P. & Pingarrón, J. M. Development of a tyrosinase biosensor based on gold nanoparticles-modified glassy carbon electrodes: Application to the measurement of a bioelectrochemical polyphenols index in wines. Anal. Chim. Acta. 528, 1–8. https://doi.org/10.1016/j.aca.2004.10.007 (2005).

Irfan, M. et al. Statistical optimization of saccharification of alkali pretreated wheat straw for bioethanol production. Waste Biomass Valorization. 7, 1389–1396. https://doi.org/10.1007/s12649-016-9540-2 (2016).

Kpanja, E. J., Duru, S., Omage, J. J., Sekoni, A. A. & Gonjoh, P. T. Proximate composition, anti–nutritional factors and the effect of Irish potato (Solanum tuberosum L.) peels on the performance and carcass characteristics of broiler chickens. Niger. J. Anim. Sci. 21(2), 214–222 (2019).

Badr, S. A. & El-Waseif, M. A. Effect of dietary fiber in potato peels powder addition as fat replacer on quality char-acteristics and energy value of beef meatballs. J. Biol. Chem. Environ. Sci. 13(1), 145–160 (2018).

Adegunloye, D. V. & Oparinde, T. C. Effects of fermentation on the proximate composition of Irish (Solanum tuberosum) and sweet potato (Ipomoea batatas) peels. Adv. Microbiol. 7(7), 565–574 (2017).

Maxwell, O. I., Chinwuba, U. B. & Onyebuchukwu, M. G. Protein enrichment of potato peels using Saccharomyces cerevisiae via solid-state fermentation process. Adva. Chem. Eng. Sci. 9(1), 99–108 (2018).

Onuguh, I. C., Ikhuoria, E. U. & Obibuzo, J. U. Assessing the potentials of some agro-waste peels through proximate analysis. Int. J. Agric. Anim. Prod. 2(02), 1–6 (2022).

Rowayshed, G., Sharaf, A. M., El-Faham, S. Y., Ashour, M. & Zaky, A. A. Utilization of potato peels extract as source of phytochemicals in biscuits. J. Basic Appl. Res. Int. 8(3), 190–201 (2015).

Khawla, B. J. et al. Potato peel as feedstock for bioethanol production: A comparison of acidic and enzymatic hydrolysis. Ind. Crops Prod. 52, 144–149 (2014).

Xu, G. Y. et al. Evaluation of structural, functional, and anti-oxidant potential of differentially extracted polysaccharides from potatoes peels. Int. J. Biol. Macromol. 129, 778–785 (2019).

Malakar, B., Das, D. & Mohanty, K. Optimization of glucose yield from potato and sweet lime peel waste through different pre-treatment techniques along with enzyme assisted hydrolysis towards liquid biofuel. Renew. Energy 145, 2723–2732 (2020).

Atitallah, I. B. et al. On the evaluation of different saccharification schemes for enhanced bioethanol production from potato peels waste via a newly isolated yeast strain of Wickerhamomyces anomalus. Bioresour. Technol. 289, 121614 (2019).

Mushtaq, Q., Joly, N., Martin, P. & Qazi, J. I. Optimization of alkali treatment for production of fermentable sugars and phenolic compounds from potato peel waste using topographical characterization and FTIR spectroscopy. Molecules. 28, 7250–7269. https://doi.org/10.3390/molecules28217250 (2023).

Bhattacharyya, S., Chakraborty, S., Datta, S., Drioli, E. & Bhattacharjee, C. Production of total reducing sugar (TRS) from acid hydrolysed potato peels by sonication and its optimization. Environ. Technol. 34, 1077–1084. https://doi.org/10.1080/09593330.2012.733965 (2013).

Achinas, S., Li, Y., Achinas, V. & Euverink, G. J. W. Biogas potential from the anaerobic digestion of potato peels: Process performance and kinetics evaluation. Energies 12, 2311–2326. https://doi.org/10.3390/en12122311 (2019).

Ben Taher, I., Fickers, P., Chniti, S. & Hassouna, M. Optimization of enzymatic hydrolysis and fermentation conditions for improved bioethanol production from potato peel residues. Biotechnol. Prog. 33, 397–406. https://doi.org/10.1002/btpr.2427 (2017).

Rao, M. M., Ramesh, A., Rao, G. P. C. & Seshaiah, K. Removal of copper and cadmium from the aqueous solutions by activated carbon derived from Ceiba pentandra hulls. J. Hazard. Mater. 129(1–3), 123–129 (2006).

Ahmed, M. J. K., Ahmaruzzaman, M. & Reza, R. A. Lignocellulosic-derived modified agricultural waste: Development, characterisation and implementation in sequestering pyridine from aqueous solutions. J. Colloid Interface Sci. 428, 222–234 (2014).

Wibowo, N., Setyadhi, L., Wibowo, D., Setiawan, J. & Ismadji, S. Adsorption of benzene and toluene from aqueous solutions onto activated carbon and its acid and heat treated forms: Influence of surface chemistry on adsorption. J. Hazard. Mater. 146(1–2), 237–242 (2007).

Zheng, Y. et al. Luminescence and photocatalytic activity of ZnO nanocrystals: Correlation between structure and property. Inorg. Chem. 46(16), 6675–6682 (2007).

Bouhadjra, K., Lemlikchi, W. & Oubagha, N. Valorisation des pelures de pommes de terre pour le traitement d’une solution aqueuse contenant un colorant textile (Reactive Blue 72). J. Water Environ. Sci. 1, 219–229 (2017).

Chakraborty, M., Miao, C., McDonald, A. & Chen, S. Concomitant extraction of bio-oil and value added polysaccharides from Chlorella sorokiniana using a unique sequential hydrothermal extraction technology. Fuel 95, 63–70 (2012).

Kandhola, G. et al. Maximizing production of cellulose nanocrystals and nanofibers from pre-extracted loblolly pine kraft pulp: A response surface approach. Bioresour. Bioprocess. 7, 1–16 (2020).

Bouhadjra, K., Lemlikchi, W., Ferhati, A. & Mignard, S. Enhancing removal efficiency of anionic dye (Cibacron blue) using waste potato peels powder. Sci. Rep. 11, 2090–2099. https://doi.org/10.1038/s41598-020-79069-5 (2021).

El-Azazy, M. et al. Potato peels as an adsorbent for heavy metals from aqueous solutions: Eco-structuring of a green adsorbent operating Plackett-Burman design. J. Chem. 2019(2019), 1–14 (2019).

Hassan, M. L., Mathew, A. P., Hassan, E. A. & Oksman, K. Effect of pretreatment of bagasse pulp on properties of isolated nanofibers and nanopaper sheets. Wood Fiber Sci. 2010, 362–376 (2010).

Gong, J., Li, J., Xu, J., Xiang, Z. & Mo, L. Research on cellulose nanocrystals produced from cellulose sources with various polymorphs. RSC Adv. 7(53), 33486–33493 (2017).

Fang, W. et al. Effect of alkaline addition on anaerobic sludge digestion with combined pretreatment of alkaline and high pressure homogenization. Bioresour. Technol. 168, 167–172 (2014).

Wang, S., Lin, A. H. M., Han, Q. & Xu, Q. Evaluation of direct ultrasound-assisted extraction of phenolic compounds from potato peels. Processes. 8, 1665–1679. https://doi.org/10.3390/pr8121665 (2020).

Frontuto, D. et al. Optimization of pulsed electric fields-assisted extraction of polyphenols from potato peels using response surface methodology. Food Bioprocess Technol. 12, 1708–1720. https://doi.org/10.1007/s11947-019-02320-z (2019).

Sanusi, I. et al. A novel autoclave-assisted nanoparticle pre-treatment for improved sugar recovery from potato peel waste: process optimisation, nanoparticle recyclability and bioethanol production. Biomass Convers. Biorefin. 12, 1–13. https://doi.org/10.1007/s13399-022-03574-y (2022).

Atitallah, I., Antonopoulou, G., Ntaikou, I., Alexandropoulou, M., Nasri, M., Mechichi, T., Lyberatos, G. Potato peels waste as feedstock for bioethanol production: a comparison of chemical. Therm. Enzym. Pretreatm. 2021, 1–15. https://www.researchgate.net/publication/350801701.

Utekar, P. G., Kininge, M. M. & Gogate, P. R. Intensification of delignification and enzymatic hydrolysis of orange peel waste using ultrasound for enhanced fermentable sugar production. Chem. Eng. Process. Process Intensif. 168, 108556–108567. https://doi.org/10.1016/j.cep.2021.108556 (2021).

Dutta, A., Kininge, M. M. & Gogate, P. R. Intensification of delignification and subsequent hydrolysis of sustainable waste as banana peels for the HMF production using ultrasonic irradiation. Chem. Eng. Process. Process Intensif. 183, 109247. https://doi.org/10.1016/j.cep.2022.109247 (2023).

Jusoh, N. A., Karim, L., & Omar, S. R. Pretreatment and enzymatic saccharification of mango peel for sugar production. AJFAS. 1, 1–15 (2020).http://myjms.mohe.gov.my/index.php/ajfas

Tripathy, A., Patel, M. K. & Chakraborty, S. Microbial production of dextran using pineapple waste extract: a two-step statistical optimization of submerged fermentation conditions and structural characterization. Biotechnol. Bioprocess Eng. 2024, 1–17 (2024).

Author information

Authors and Affiliations

Contributions

Conceptualization, P.M. and J.I.Q.; Methodology, Q.M., U.I. and N.J.; Software, U.I.; Validation, Q.M., P.M. and J.I.Q.; Formal Analysis, N.J.; Investigation, Q.M.; Resources, P.M.; Data Curation, N.J.; Writing – Original Draft Preparation, U.I.; Writing – Review & Editing, P.M. and J.I.Q.; Visualization, J.I.Q.; Supervision, P.M. and J.I.Q.; Project Administration, J.I.Q.;

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mushtaq, Q., Ishtiaq, U., Joly, N. et al. Investigation and characterization of changes in potato peels by thermochemical acidic pre-treatment for extraction of various compounds. Sci Rep 14, 12655 (2024). https://doi.org/10.1038/s41598-024-63364-6

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-63364-6

Keywords

This article is cited by

-

Production of biodiesel and biolubricant via co-cultivation of Arthrospira platensis and Rhodosporidium babjevae using pulp-paper mill sludge hydrolysate

Scientific Reports (2025)

-

Contribution to the valorization of potato (Solanum tuberosum L) by-products in the broilers feed formulation: physicochemical characterization and nutritional value of potato peels

Tropical Animal Health and Production (2025)