Abstract

The dimensional optimization based on kinematic and dynamic performance indices is proven significant for improving the operational performance of parallel robots. As the pose-dependent performances vary with the dimensional parameters, there are still many challenges in the optimal design of parallel robots, such as the possible conflict amongst different performance indices and computational expensiveness. By considering a 4-DOF high-speed parallel robot as an illustrative example, this paper presents a framework for the optimal design of parallel robots by integrating skeleton modeling, CAD-CAE integration and multi-objective optimization techniques. In this approach, the models for kinematic and elasto-dynamic performance evaluation are first developed using the CAD and CAE techniques, respectively. After evaluating the performance distributions over the task workspace, several reference poses representative of multiple neighboring sample poses are determined to formulate corresponding local performance indices by using the Hard C-Means (HCM) clustering analysis algorithm. This consideration leads to the determination of the optimal dimensions by investigating the Pareto-optimal solutions of a multi-objective optimization problem, allowing the conflict amongst different performance indices to be appropriately handled and the computational time to be saved significantly. The results of the case study show that the proposed approach can significantly enhance the elastic dynamic performance while ensuring that the kinematic performance is not excessively compromised, when compared to the performance of existing physical prototype of the robot. A software package has been developed using the proposed framework, providing a highly accessible way for designing various types of parallel/hybrid robots based on CAD and CAE techniques.

Similar content being viewed by others

Introduction

The dimensional optimization is important for the development of parallel robots which are dedicated to high-speed and high accuracy industry applications. In this issue, a group of vital design parameters can be determined by developing single-objective or multi-objective optimization problems, depending on the specific performance requirements for particular applications1. Over the past decades, lots of investigations have been conducted on achieving optimal designs of parallel robots. The relevant performance aspects encompass the kinematic, rigid body dynamic, stiffness, and elasto-dynamic performance, et al. The optimal solutions can be determined using either the performance chart method or the objective-function method2.

The kinematic performance is often the first object to be concerned in the optimal design of parallel robots. The kinematic design approaches are commonly employed to optimize the dimensional parameters by incorporating the workspace/machine volume ratio3,4, algebraic characteristics of the Jacobian5,6 and the force/motion transmissibility7,8 as performance indices. For example, Miller9 proposed a kinematic design method of the Delta robot by constructing a weighted index that considers both the task workspace/reachable workspace volume ratio and the Jacobian condition number. Dastjerdi et al.10 proposed a dimensional optimization method for achieving the minimum length of limbs for a specified workspace. The result shows that the reciprocal of the Jacobian condition number is significantly improved for the suggested optimal design. Meng et al.11 used the force/motion transmissibility indices for kinematic analysis and dimensional synthesis of the TH-HR4 robot, leading to a good transmission and constraint workspace. Using the geometric algebra method, Li et al.12 identified the singular configurations and optimized the link parameters of a novel 1T2R parallel mechanism based on the input and output force/motion transmission indices. The performance analysis and experiment results show that the manipulator exhibits excellent kinematic, stiffness and dynamic performances within the optimized workspace.

The rigid body dynamic performance is another index to be concerned within the optimal design for achieving a lower driving torque while ensuring the kinematic performance, considering the desired acceleration capabilities of the robot13. Many methods and performance indices have been proposed for the rigid body dynamic design of the parallel robot. For instance, Liu et al.14,15 proposed an approach for the optimal design of high-speed parallel robots using kinematic and dynamic performance indices. In this method, the direct and indirect singularities of the robot are firstly evaluated using the pressure angles defined within a limb and between adjacent limbs, and then the optimized dimensional parameters are obtained by minimizing the normalized torque of the single motor shaft. Similarly, Liu et al.16 proposed a dynamic performance index ACI for the optimization of dimensional parameters of different types of parallel robots. It shows that the index is general and can be used for parallel robots having coupled translational and rotational motion capabilities. Zou et al.17 proposed two novel dynamic indices i.e., the BACI index and the VBCI index. By incorporating the CVI index and JRI index in Ref.18, a comprehensive comparison of the dynamic performance of two mechanisms is conducted, thus the two indices have the potential for the optimal design of parallel robots.

The stiffness and elasto-dynamic performance should also be concerned in the optimization of parallel robots because the elastic deformation affects the positional accuracy and contour accuracy of the robot when they undergoing high-acceleration movements. The precondition is to build an accurate stiffness model or elasto-dynamic model that can reveal the elastic deformation and lower-order dynamics efficiently. The approaches for building such a model include the analytical method19,20,21,22 and the Finite Element Analysis (FEA) method23,24. The analytical method can easily establish a mapping relationship between design variables and the performance indices, but it often poses challenges for engineers due to its reliance on advanced mathematical knowledge in dynamics theory. The FEA method depends on the modeling capabilities of commercial Finite Element (FE) software. It can well handle the complex three-dimensional geometry of components and joint contact characteristics, but optimizing a robot becomes challenging due to the need for repeated re-meshing of the FE model to much varying dimensions and poses. To tackle this issue, the authors have developed a feature-based CAD-CAE integration methodology for static and dynamic analysis25, which provides an alternative way for designing parallel robots based on stiffness and elasto-dynamic performances.

It is essential to emphasize that the aforementioned performances should be considered partially or completely based on specific application requirements. For instance, in the case of a robot dedicated to high-speed pick-and-place operations, the kinematic, rigid body dynamic and elasto-dynamic performance should be considered in order to achieve a compact, non-singular, lightweight and low-vibration design26,27. When the robot is intended for machining and forced assembly tasks, the elasto-static stiffness should also be taken into account to ensure that the robot can withstand deformation under external loads28,29,30. However, the possible coupling and conflict of multiple performance indices is a challenging issue in the dimensional optimization of parallel robots, e.g., the increase of kinematic performance may lead to the decline of static and dynamic performance. The methods for dealing with this issue can be classified into three categories, i.e., the weighted object method, the Pareto frontier method and the Principal Component Analysis (PCA) method.

The weighted object method is usually used to transform the multiple-objective problem into a single-objective problem by assigning weights or converting design objectives into constraints. For example, Zhao et al.31 proposed an approach for the optimal design of a 5-DOF hybrid machining robot in a hierarchical manner. In this method, a single performance index is defined by summing the weights of kinematic, rigid body dynamic and elasto-dynamic performances, and the weighted factors are expressed as the ratios of the average values of the performances. Nevertheless, the theoretical foundation for determining the weight coefficients still lacks clarity. Inappropriate weight coefficients can lead to a significant impact on the optimization results. Compared to the weighted object method, the Pareto frontier method effectively considers the interdependence and conflict among objectives, providing a more reasonable decision space for multi-objective optimization problems. Lara-Molina et al.32 optimized the dimensional parameters of a 5R planner parallel robot by considering the workspace, dynamic dexterity and control energy. The Pareto-optimal solutions obtained through multi-objective genetic algorithms are comprehensively discussed to achieve consensus among performance indices. Belkacem33 introduced a multi-objective optimization problem aimed at maximizing the workspace while taking into account the stiffness and dexterity across the workspace. The problem is addressed through evolutionary genetic algorithms to determine trade-offs among conflicting performances. Kelaiaia et al.34 reviewed the approaches utilized in the dimensional design of parallel robots, focusing on addressing difficulties encountered during the optimization process. They proposed an innovative optimal design approach that involves sequential implementation of task definition, topological structure selection, mechanical structure modeling, performance evaluation, multi-objective optimization, optimal solution determination and tolerance design. Using a 5R planner parallel robot as a case study, the final optimal solution is selected from a set of Pareto-optimal solutions based on the TOPSIS algorithm. With regard to the coupling relationship among performance indices, literature reveals that the PCA method can be used to combining several correlated indices into a smaller scale index set35, thereby reducing the decision-making workload. With the aforementioned methods, significant efforts have been made to address parameter uncertainties in the dimensional optimization of parallel robots36,37,38. This is because parameter disturbance due to machine and assembly errors, as well as wear and tear over time during operation, can indeed lead to deviations in the actual performance of the parallel robot prototype from the desired performance determined by optimal design. However, the benefits of these approaches need to be further verified through deep investigation in comparison with the two-stage design method, which involves initially determining the nominal values of dimensional parameters and subsequently determining geometric tolerances through tolerance synthesis39,40.

Another challenging issue is the computational expensiveness caused by the pose-depend kinematic and dynamic performances. In general, the global performance indices are often derived by computing the mean values of the local performance indices of some discrete nodes in the workspace. The optimization process requires the repeated calculation of each node within the whole workspace for different dimensions, which may reduce the efficiency of the optimization design, particularly in terms of elasto-dynamic performance evaluation. Though researchers use the Monte Carlo method41 and sensitivity analysis method42 to improve the efficiency of the optimization design of parallel robots, the selection of some reference poses representative of the performance at multiple neighboring sample poses would be more effective. During the past decades, clustering analysis algorithm has been successfully applied to the classification and selection of useful information in picture processing and task planning43,44. Through clustering analysis, the performance indices can be determined by a small number of discrete nodes (poses) in the workspace such that the workload of the optimization process can be reduced.

Moreover, with the rapid growth of demands for various types of robotized cells in industries, it is essential to develop specialized software that integrates robotics theory with digital prototyping technology to facilitate the rapid design of parallel robots. Tracking this issue, an integrated framework for the dimensional optimization of parallel robots is proposed in this paper based on our previous work on CAD-based kinematic performance analysis and CAD-CAE integrated dynamic performance evaluation. In comparison to existing approaches in the literatures, the models for kinematic and dynamic performance evaluation are formulated by CAD and CAE techniques. The local performance indices are defined by identifying a set of reference poses that represent the performance at multiple neighboring sample poses using the HCM clustering analysis algorithm, which significantly reduces the computational costs while considering the distribution laws of the performances over the workspace. The conflict among different performance indices is appropriately handled by finding the Pareto-optimal front derived from a multi-objective design problem. This allows for the selection of a reference solution that meets specific application requirements from the set of Pareto-optimal solutions. The proposed framework is utilized to develop a design software for designers in both academe and industry, making it well-suited for engineering applications.

After providing a concise overview of dimensional optimization for parallel robots in Sect. 1, the integrated framework for dimensional optimization is proposed in Sect. 2. Taking a 4-DOF parallel robot as an example, the models for kinematic and elasto-dynamic performance evaluation are built utilizing CAD and CAE technologies in Sect. 3. After evaluating the kinematic and elasto-dynamic performances of the robot, local performance indices and variations of dimensional parameters versus performance indices are determined in Sect. 4. In Sect. 5, the multi-objective optimal design problem is formulated and the optimal results are discussed. Finally, conclusions are summarized comprehensively in Sect. 6.

Framework for the dimensional optimization of parallel robots

The development of robotic systems represents a multifaceted engineering challenge that requires the synergistic integration of knowledge from various disciplines, including automatic control, computer science, sensor technology, as well as electronic and mechanical engineering. Over the years, scholars have developed a series of design frameworks targeted at different types of robots, respectively involving multiple aspects such as dimensional and structural optimization, intelligent control, state estimation, path planning and navigation, offline programming, equipment layout optimization, and driving system architecture. Table 1 presents the latest achievement of the relevant studies45,46,47,48,49,50,51,52,53,54. It is evident from Table 1 that the concerned performance indices and established objective-functions have significant differences for the design issues regarding different aspects of robots, but the design framework and process have many similarities. For example, performance analysis models are developed either through manual derivation or with the aid of computer-aided tools (e.g. CAD and CAE tools), while domain knowledge and associated rules are integrated either manually or acquired via knowledge bases and reasoning mechanisms. Although the research content of this paper focuses on the issue of dimensional optimization of parallel robots, especially those featured with high-speed and high-acceleration, the above mentioned design frameworks in different fields can provide adequate references for this study.

As clearly indicated in the introduction, the dimensional optimization of parallel robots is expected to be able to handle the conflict among different performance indices appropriately while significantly saving computational time. To meet this requirement, a framework is proposed for the dimensional optimization by integrating the skeleton modeling, CAD-CAE integration and multi-objective optimization techniques. The skeleton modeling and the CAD-CAE integration techniques are used to build the parameterized topological/mechanical structure model and FE model, respectively. The multi-objective optimization technique is employed to determine the standalone key dimensional parameters by sequentially implementing the clustering algorithm, Design of Experiments (DOE), Response Surface Method (RSM) and Pareto frontier method. The framework depicted in Fig. 1 comprises of three modules as follows:

The modeling module

In this module, three digital models of the robots, i.e., the topological structure model (conceptual model), the mechanical structure model and the FE model, are built by employing skeleton modeling and the CAD-CAE integration techniques. Referring to our previous work in Ref.55, the topological structure model comprises of a solid assembly and several skeleton elements56 for representing the dimensional and topological information. Using the algorithm proposed in7,14, the kinematic performance in terms of force/motion transmissibility and workspace/machine volume ratio can be evaluated conveniently. The mechanical structure model is also parametrized driven by its skeleton elements, and the dimensional, configuration and FE analysis features can be automatically transferred to the FE model by using the CAD-CAE integration technique25. This enables evaluation of rigidity and elasto-dynamic performances such as static stiffness and lower-order natural frequencies under different dimensions and poses.

The analysis module

In this module, the kinematic, static and elasto-dynamic performances are evaluated in the entire workspace by giving a set of initial dimensions. A group of reference poses representative of the performance at multiple neighboring sample poses can be determined by using the HCM clustering analysis algorithm, such that corresponding local performance indices can be defined for the optimization. In this way, the computational costs could be significantly reduced. Based on the RSM, the standalone key variables can be determined after revealing their influence on the performance indices, and the correlativity and priority between different performance indices can also be revealed.

The optimization module

In this module, the problem for the multi-objective optimal design, which has the characteristics of low complexity and fewer design variables, can be formulated thanks to the determined local performance indices, standalone vital variables, correlativity and priority between different performance indices. On this basis, the conflict among different performance indices can be dealt with appropriately by finding the Pareto-optimal solutions (also called Pareto front), and the reference solution that satisfies a particular application requirement can be selected from the Pareto-optimal solutions by minimizing the residual between the objective vector and the ideal values.

The dimensional optimization of a parallel robot can be implemented based on the proposed framework through the following steps.

Step 1: Build the parameterized topological structure model, mechanical structure model and FE model in the modeling module.

Step 2: Evaluate the kinematic, static and elasto-dynamic performance over the entire workspace for a given set of dimensional parameters.

Step 3: Determine a group of reference poses representative of the performance at multiple neighboring sample poses by using the HCM clustering analysis algorithm, and formulate local performance indices to replace global performance indices.

Step 4: Evaluate the impact of design variables on the local performance indices, and determine the standalone key variables and correlativity between performance indices.

Step 5: Formulate the experiment sets of standalone key variables in the design space by using the DOE, and establish a mapping relationship between local performance indices and independent key variables by using the RSM.

Step 6: Formulate the multi-objective design problem of the robot, and find the Pareto-optimal solutions to deal with the conflict among multiple performance indices.

Step 7: Select a reference solution that satisfies a particular application requirement from the Pareto-optimal solutions by minimizing the residual between the objective vector and the ideal values.

Step 8: Determine the parameters of the servomotors and the reducers by rigid body dynamic analysis.

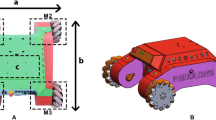

In the following sections, the proposed framework will be used for the dimensional optimization of a 4-DOF high-speed parallel robot created by Professor Huang in Tianjin university, which is a modified version of the Heli4 robot invented by Pierrot and Company57. Figure 2 shows the CAD model of the robot under consideration. In this robot, the base and the end-effector are connected by four identical R-(SS)2 limbs driven by an actuated revolute joint. The vertical rotational capability is generated by a screw-nut-guideway assembly that connects the two subparts of the end-effector, and the three-dimensional translation movement capabilities are achieved because a constraint couple perpendicular to the parallelogram is imposed on each R-(SS)2 limb.

The CAD model of the 4-DOF high-speed parallel robot (SolidWorks software58).

Topological structure and finite element modeling

In this section, the topological structure model for force/motion transmissibility and workspace analysis is formulated using the skeleton modeling technique, and the FE model for elasto-dynamic analysis is formulated using the CAD-CAE integration technique.

Topological structure modeling

As indicated in Ref.55, datum entities i.e., points, axes, planes and coordinate systems, are used to represent the topological and dimensional information of the topological structure model in the CAD system. These datum entities are called skeleton elements, which can be organized into three types of informative units termed as features for kinematic performance analysis in an automatic manner. The first one is the interface feature representative of assembly constraints between components, enabling automatic assembly of the topological structure model of a parallel robot within the CAD system. The second one is the joint axis feature representative of the position and orientation of the joint axes in the limb at a given pose, enabling generation of unit twists and wrenches of each limb by extracting the coordinates of corresponding datum points and axes. The third one is the coordinate system feature used for measuring the positional and orientational coordinate of joint axes.

As shown in Fig. 3, the skeleton elements of the 4-DOF robot are described detailly as follows: the datum points denoted by \({A_i}\), \({B_i}\) and \({C_i}\) are used to represent the position vectors (\({{\varvec{a}}_i}\), \({{\varvec{b}}_i}\) and \({{\varvec{c}}_i}\)) of the rotational axes of joints in the \(i\text{t}\text{h}\)(\(i=1\sim 4\)) limb, while the datum axis denoted by \({S_i}\) represents the unit orientation vector (\({{\varvec{s}}_i}\)) of the actuated revolute joint. e and \({\hat {{\varvec{e}}}_i}\) are the offset and unit vector from the origin of \(O - xyz\) to \({{\varvec{s}}_i}\), and \({l_1}\)(\({\hat {{\varvec{l}}}_{1,i}}\)) and \({l_2}\)(\({\hat {{\varvec{l}}}_{2,i}}\)) are the lengths (unit vectors) of the \(i\text{t}\text{h}\) forearm and connecting rod. \({P_1}\) and \({P_2}\) are the center of subpart 1 and subpart 2 of the end-effector, and they are coincident with each other when the rotation angle of the end-effector around the z-axis is set to zero. The position of the end-effector in the workspace is represented by the position vector of \({P_1}\)(\({P_2}\)) denoted by \({{\varvec{r}}_P}={\left( {\begin{array}{*{20}{c}} {{x_0}}&{{y_0}}&{{z_0}} \end{array}} \right)^\text{T}}\). All the vectors are all evaluated in the reference frame of the base denoted by \(O - xyz\) and can be expressed as

Based on the topological structure model, the kinematic performance of the robot can be analyzed by firstly extracting \({{\varvec{a}}_i}\), \({{\varvec{b}}_i}\), \({{\varvec{c}}_i}\) and \({{\varvec{s}}_i}\) from the model and then assigning them to the formulas packaged in an algorithm library in COM component format with the aid of the Builder NE capability of MATLAB.

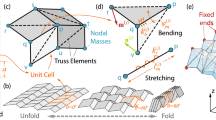

Finite element modeling

For the purpose of evaluation of the elasto-dynamic performance at any given dimension and configuration, the CAD-CAE integration technique is employed to build parameterized FE models of parallel or hybrid robots. Referring to our previous work in Refs.25,27, the geometric features, configuration features and FE analysis features have been defined to establish the information mapping relationship between the CAD model (SolidWorks) and the FE model (SAMCEF). As shown in Fig. 4, the process for building such an FE model and updating this model in the design space or task workspace are given as follows:

Step 1: Build a parameterized mechanical structure model by attaching the FE analysis features to related geometric entities as SolidWorks attributes. The FE analysis features include the material properties and element types of all components, and the joint features descripting the FE modeling information and parameters of mechanical joints between each two adjacent components. In addition, for the purpose of updating the mechanical structure model under different dimensional parameters in an automated manner, the dimensions of forearms and connecting rods are parameterized by using skeleton elements similar to the topological structure model.

Step 2: Transfer the solid models of components by the third-party interface to SAMCEF. In this step, all the solid models are at the global coordinate origin, and the orientation parameters are also set to be zero.

Step 3: Extract the geometrical features including the dimensional parameters from the mechanical structure model, and load the them into the Notebook in SAMCEF.

Step 4: Extract the configuration features including position and orientation parameters from the mechanical structure model, and load them into the Notebook.

Step 5: Using the extracted features in Step 3 and Step 4, the geometric model at a specified pose with the given dimensions is formulated in SAMCEF.

Step 6: Extract the FE analysis features from the mechanical structure model. The attributes of the features are loaded into the Notebook, and a command flow named Bacon is generated by compiling the FE analysis features, a preprocess for driving the FE solver.

Step 7: Load the Bacon commands into SAMCEF solver. In this way, the Bacon script is generated for formulating the FE model of the whole robot by assigning the element types, material properties and boundary conditions to the geometric model in SAMCEF.

On this basis, once the mechanical structure model in SolidWorks is modified by another set of dimensional parameters or driven to another pose, the FE model of the robot can be automatically updated by updating only the parameters necessary to specify geometric, configuration and FE analysis features, allowing the variations of dimensional and configuration parameters versus elasto-dynamic performance to be effectively evaluated.

Performance analysis

In this section, the workspace, kinematic performance, and elasto-dynamic performance will be evaluated to determine a set of reference poses representative of the performance at multiple neighboring sample poses using the HCM clustering analysis algorithm. The local performance indices will be formulated to reduce the computational cost of the optimal design.

Workspace analysis

Referring to Ref.14,59, the reachable workspace W of \({P_1}({P_2})\) of the robot is an enclosed space surrounded by eight spherical pieces constrained by the limitation of the rotation angles of the forearms. \({W_R}\) is the maximum inscribed cylinder of W, and \({W_T}\) is a cylindrical task workspace inside \({W_R}\) where R, h and H denote the radius, the height and the distance to the fixed platform, respectively.

For the purpose of achieving a compact design, the workspace/machine volume ratio is expressed as

As illustrated in Fig. 5, the dimensional relationship between the workspace and the robot can be easily obtained by solving a simple geometry problem in the plane spanned by the first and third forearms. The minimum and maximum distance (\({H_{\hbox{min} }}\) and \({H_{\hbox{max} }}\)) from O to the top plane of \({W_T}\) can be expressed as

where \([{\phi ^ - }]\) and \([{\phi ^+}]\) are the lower and upper boundaries of the range of the rotation angle of the forearms (\({\phi _i}\)). In this way, the distance from O to the top plane of \({W_T}\) satisfies with the following conditions

Equations (3) and (4) will be used to formulate geometrical constraints for the optimal design in Sect. 5.

Force/motion transmissibility analysis

As indicated in Ref.14, the force/motion transmission capabilities of high-speed parallel robots based on Jacobian matrix analysis are evaluated using two types of visualized pressure (or transmission) angles. The first one is the pressure angle \({\alpha _i}(i=1\sim 4)\) that describes the motion transmissibility between the actuated joints and passive joints within a limb, and the second one is the pressure angle \(\beta\) that describes the motion transmissibility between the end-effector and passive joints in other limbs when locking actuated joints. The two pressure angles can be expressed as

For a giving set of dimensional parameters with \({l_1}=0.375{\kern 1pt} {\kern 1pt} \text{m}\), \({l_2}=0.950{\kern 1pt} {\kern 1pt} \text{m}\), \(e=0.125{\kern 1pt} {\kern 1pt} \text{m}\), \(H=0.763{\kern 1pt} {\kern 1pt} \text{m}\), \(R=0.5{\kern 1pt} {\kern 1pt} \text{m}\) and \(h=0.025{\kern 1pt} {\kern 1pt} \text{m}\), which are those of the current physical prototype of the robot, the distributions of the complementary angles of \(\mathop {\hbox{max} }\limits_{i} ({\alpha _i})\) and \(\beta\) (transmission angles denoted by \({\theta _1}={90^ \circ } - \mathop {\hbox{max} }\limits_{i} ({\alpha _i})\) and \({\theta _2}={90^ \circ } - \beta\)) can be evaluated over the workspace by firstly extracting \({{\varvec{a}}_i}\), \({{\varvec{b}}_i}\), \({{\varvec{c}}_i}\) and \({{\varvec{s}}_i}\) from the topological structure model and then assigning them to the formulas (1) and (5). As shown in Fig. 6, \({\theta _1}\) and \({\theta _2}\) both take the maximum values at the center of the intermediate layer of the task workspace and decrease monotonically to the minimum value at the border of the intermediate layer of the task workspace (when \({z_0}=H+h/2\)). \({\theta _1}\) and \({\theta _2}\) will be used to formulate the local kinematic performance index after determining the reference poses representative of the performance at multiple neighboring sample poses.

Distributions of \({\theta _1}\) and \({\theta _2}\)in the intermediate layer of the task workspace (Matlab software60).

Elasto-dynamic performance analysis

As indicated in the introduction, the elasto-dynamic performance is also an crucial index in the design of parallel robot. Following the process given in Fig. 4, the modal analysis is performed using the feature-based CAD-CAE integration approach. Figure 7 presents the distributions of the first fourth natural frequencies of the robot in the intermediate layer of its task workspace when \({l_1}=0.375{\kern 1pt} {\kern 1pt} \text{m}\), \({l_2}=0.950{\kern 1pt} {\kern 1pt} \text{m}\), \(e=0.125{\kern 1pt} {\kern 1pt} \text{m}\), \(H=0.763{\kern 1pt} {\kern 1pt} \text{m}\), \(R=0.5{\kern 1pt} {\kern 1pt} \text{m}\) and \(h=0.025{\kern 1pt} {\kern 1pt} \text{m}\). It can be seen that the first fourth natural frequencies symmetrically distribute in the workspace. \({f_1}\) and \({f_2}\) takes the maximum values at the center pose, while \({f_3}\) takes the minimum value at this pose and \({f_4}\) keeps almost unchanged across the intermediate layer of the task workspace. It can also be seen from Fig. 8 that the first and second order mode shapes are vibrations along the y-direction and x-direction, respectively, which significantly influence the positioning accuracy. For this reason, \({f_1}\) and \({f_2}\)will be used to formulate the elasto-dynamic performance index.

Distributions of the first fourth natural frequencies in the intermediate layer of the task workspace (Matlab software60).

.

The first fourth mode shapes at the center point of the intermediate layer of the task workspace (SAMCEF software61).

Reference poses and performance indices

In the optimal design of robots, global performance indices and local performance indices are usually defined for revealing the variations of dimensional parameters versus performances. The former involves evaluating the performances within the whole workspace for different dimensions, which may result in substantial computational cost. The latter only involves evaluating the performances in one or more reference poses within the workspace, but the main issue is how to determine those reference poses reasonably. Considering the distribution laws of the performances of a parallel robot are usually with little difference for different dimensions, we can use the clustering algorithm to determine those reference poses at a specified dimension, such that the local performance indices can be used to replace the global performance indices in the optimal design.

Firstly, the intermediate layer of the task workspace \({W_T}\) is divided into a grid. The two transmission angles and the first second natural frequencies at the pose of the \(q{\text{th}}\) node in \({n_I}\) grid nodes are defined as sample transmission angle \({\theta _{k,q}}\left( {k=1\sim 2} \right)\) and sample natural frequency \({f_{j,q}}\left( {j=1\sim 2} \right)\), respectively. Here, the third and fourth order natural frequencies are not considered in the clustering analysis because they are much higher than the first second natural frequencies. Secondly, the weighted index \({\xi _q}\) for clustering analysis is formulated by \({\theta _{k,q}}\) and \({f_{j,q}}\), and it can be expressed as

where \({f_{j,\text{m}\text{i}\text{n}}}\) and \({f_{j,\text{m}\text{a}\text{x}}}\) are the minimum and maximum values of the jth order natural frequency, \({\theta _{k,\text{m}\text{i}\text{n}}}\) and \({\theta _{k,\text{m}\text{a}\text{x}}}\) are the minimum and maximum values of the kth transmission angle, \({\eta _1}\) and \({\eta _2}\) are the weighting factors satisfying \({\eta _1}+{\eta _2}=1\). Thirdly, the \({n_I}\) grid nodes are classified into \({c_I}\) groups according to the gradient of the distributions of \({\xi _q}\), and finally, the pth clustering center \({\xi _{c,p}}\left( {p=1\sim {c_I}} \right)\) are calculated for determining the reference poses representative of the performance at multiple neighboring sample poses. The membership degree \({\mu _{p,q}}\) of \({\xi _q}\) on \({\xi _{c,p}}\) are also calculated for representing the membership between the qth sample pose and the pth reference pose.

In this way, the above clustering problem can come down to the following nonlinear mathematical programming problem by using the HCM algorithm

where \(d_{{p,q}}^{{}}=\left\| {{\xi _q} - {\xi _{c,p}}} \right\|\) is the Euclidean distance between \({\xi _q}\) at the qth sample pose and \({\xi _{c,p}}\) at the pth reference pose, and

Let the partial derivative of Eq. (7) for be zero, then the formula for updating the pth clustering center is obtained

By using Eqs. (8) and (9), \({\mu _{p,q}}\) and \({\xi _{c,p}}\) are continuously updated until the \(l\text{t}\text{h}\) iteration satisfies \(\left\| {\xi _{{c,p}}^{{\left( l \right)}} - \xi _{{c,p}}^{{\left( {l - 1} \right)}}} \right\| \leqslant {\varepsilon _{\text{H}\text{C}\text{M}}}\), such that the clustering center vector \(\varvec{\xi}_{c}^{{{\text{HCM}}}}={\left( {\begin{array}{*{20}{c}} {\xi _{{c,1}}^{{(l)}}}&{\xi _{{c,2}}^{{(l)}}}& \cdots &{\xi _{{c,{c_I}}}^{{(l)}}} \end{array}} \right)^{\text{T}}}\) and the hard partition matrix \(\left[ {{\mu _{p,q}}} \right]_{{{c_I} \times {n_I}}}^{{{\text{HCM}}}}\) are determined. Here, \({\varepsilon _{{\text{HCM}}}}\) represents the iteration accuracy of the hard partition clustering centers. Since the clustering centers are the typical characteristic centers of the data of \({\xi _q}\), the poses corresponding to the components in \(\varvec{\xi}_{c}^{{{\text{HCM}}}}\) can be regarded as the reference poses for evaluating the performance of the robot with different dimensions, leading to the formulation of the local performance indices for the optimal design.

Figure 9 (a) illustrates the distribution of \({\xi _q}\) of the high-speed robot across its intermediate layer of the task workspace when \({l_1}=0.375{\kern 1pt} {\kern 1pt} \text{m}\), \({l_2}=0.950{\kern 1pt} {\kern 1pt} \text{m}\), \(e=0.125{\kern 1pt} {\kern 1pt} \text{m}\), \(H=0.763{\kern 1pt} {\kern 1pt} \text{m}\), \(R=0.5{\kern 1pt} {\kern 1pt} \text{m}\) and \(h=0.025{\kern 1pt} {\kern 1pt} \text{m}\). Based on the clustering algorithm mentioned above, the data of \({\xi _q}\) is divided into three groups (\({c_I}=3\)) with \(\varvec{\xi}_{c}^{{{\text{HCM}}}}={\left( {\begin{array}{*{20}{c}} {0.884}&{0.600}&{0.252} \end{array}} \right)^{\text{T}}}\)shown in Fig. 9 (b). Considering the symmetry of the distribution of \({\xi _q}\), four reference poses are determined along the x-direction with the coordinates in the intermediate layer of the task workspace shown in Table 2. It should be pointed out that the reference poses are assumed to be unchanged varying with the dimensional parameters, and this assumption will be verified by comparing the clustering centers of \({\xi _q}\) when the robot is with different dimensions in Sect. 5.

Based upon the determined reference poses, the local kinematic performance index \({F_1}\) and elasto-dynamic performance index \({F_2}\) can be expressed as

where \({\theta _{1,p}}\) and \({\theta _{2,p}}\) are the two transmission angles when the robot is at the pth reference pose, and \({f_{j,p}}\) is the jth order natural frequency when the robot is at the pth reference pose. The two local performance indices will be used for the optimal design of the robot in Sect. 5. Compared to our previous work in Ref.27, the global performance indices should be calculated in at least 36 poses within the workspace for a given dimension, while the local performance indices are calculated by only 4 poses determined by the HCM clustering algorithm, allowing the computational time to be significantly reduced while the distribution laws of the performances over the workspace to be considered.

Dimensional optimization

Equipped with the established models and the local performance indices, the dimensional optimization problem of the robot are described as follows: (1) to reveal the impact of standalone vital variables on the local performance indices (\({F_1}\) and \({F_2}\)) by response surface modeling; (2) to solve the Pareto-optimal solutions by formulating a multi-objective optimal design problem; (3) to select the reference solution that satisfies with a particular application requirement by minimizing the residual between the objective vector and the ideal values.

Response surface modeling

Response surface modeling uses a series of experiments to establish a polynomial surface function that accurately captures the relationships between variables and targeted performances62. As indicated in Sect. 4.1, let R and h for a specified \({W_T}\) be the given parameters ( \(R=0.5{\kern 1pt} {\kern 1pt} \text{m}\) and \(h=0.025{\kern 1pt} {\kern 1pt} \text{m}\)), e can be expressed as a function of \({l_1}\) according to Eq. (2), and H can be expressed as the function of \({l_1}\) and \({l_2}\) according to Eqs. (3) and (4), thus \({l_1}\) and \({l_2}\)are selected as the standalone key variables for the optimization. For reducing the number of experiments in the DOE, the Optimum Latin Hypercubes (OLH) method63 is used to formulate the experiment sets of \({l_1}\) and \({l_2}\) in the design space. The mapping relationship between the local performance indices (\({F_1}\) and \({F_2}\)) and the standalone key variables (\({l_1}\) and \({l_2}\)) is built using a quadratic polynomial surface function which can be expressed as

where \(\lambda _{0}^{{(k)}}\), \(\lambda _{i}^{{(k)}}\), \(\lambda _{{i+2}}^{{(k)}}\) and \(\lambda _{{i,j}}^{{(k)}}\) are the fitting coefficients of the polynomial surface function between \({F_k}\) and \({l_1}\), \({l_2}\). To ensure not exceeding the feasible region subject to constraints in the optimal design, the ranges of \({l_1}\) and \({l_2}\) are set to 0.2–0.5 m and 0.5–1.0 m based on the corresponding values of the existing physical prototype of the robot, respectively. The values of the fitting coefficients shown in Table 3 are calculated by the least square regression in MATLAB and Isight software. Let \(R=0.5{\kern 1pt} \text{m}\) and \(h=0.025{\kern 1pt} \text{m}\) for a desired task workspace. Figure 10 shows the response surfaces between \({F_1}\), \({F_2}\) and \({l_1}\), \({l_2}\) with the multiple determination coefficient \({R^2}\) being 0.963 and 0.975, respectively. Thus, sufficiently accuracy is ensured in the following dimensional optimization.

It can be seen from Fig. 10 that the variations of \({l_1}\) and \({l_2}\) versus the two indices are almost reversed. It means the robot can achieve higher elasto-dynamic performance but lower kinematic performance with the decrease of \({l_1}\) and \({l_2}\). It should be pointed out that the sectional parameters (e.g. diameter and thickness) of the forearms and connecting rods are considered to be the same when evaluating the elasto-dynamic performance, because they can be examined in the final design stage by evaluating their effects on the dynamic stress when the robot is undergoing a typical pick-and-place path.

The response surfaces between \({F_1}\), \({F_2}\) and \({l_1}\), \({l_2}\)(Matlab software60).

Formulation of the multi-objective design problem

Equipped with the response surfaces, the multi-objective design problem of the 4-DOF high-speed robot can be stated as: to determine \({l_1}\) and \({l_2}\) by maximizing \({F_1}\) and \({F_2}\) subject to the geometrical and kinematic performance constraints, i.e.,

where \({\kern 1pt} {\varvec{x}}={\left( {\begin{array}{*{20}{c}} {{l_1}}&{{l_2}} \end{array}} \right)^\text{T}}\)represents the vector of standalone key design variables, specifically the lengths of the forearm and connecting rod; \(\mathop {\text{m}\text{a}\text{x}}\limits_{{{\varvec{x}} \in {R^2}}} \left( {\begin{array}{*{20}{c}} {{F_1}({\varvec{x}})}&{{F_2}({\varvec{x}})} \end{array}} \right)\) is the objective function to maximizing both the local kinematic performance index \({F_1}\) and the elasto-dynamic performance index \({F_2}\), which are expressed as quadratic polynomial surface functions of \({l_1}\) and \({l_2}\); \({e_{\hbox{min} }}\) is the minimum value of e that can leave enough space for the servomotors and reducers; \(R{\text{-}}\left( {e+{l_1}} \right)=0\) is a constraint ensuring that the workspace/machine volume ratio \(\eta\) equals 1, thereby guaranteeing a compact design; \({H_{\hbox{min} }} - {H_{\hbox{max} }} \leqslant 0\)and \(H=\left( {{H_{\hbox{min} }}+{H_{\hbox{max} }}} \right)/2\) are constraints ensuring that the task workspace \({W_T}\) remains within the reachable workspace W; \(\mathop {\hbox{max} }\limits_{{p=1\sim 4}} \mathop {\hbox{max} }\limits_{{i=1\sim 4}} {\alpha _{i,p}} \leqslant \left[ \alpha \right]\) and \(\mathop {\hbox{max} }\limits_{{p=1\sim 4}} {\beta _p} \leqslant \left[ \beta \right]\) are constraints limiting the maximum values of the two pressure angles (\(\alpha\) and \(\beta\)) to their allowable values \(\left[ \alpha \right]\) and \(\left[ \beta \right]\)within the reference poses, and \({\alpha _{i,p}}\) is the value of \(\alpha\) in the ith limb when the robot is at the pth reference pose, \({\beta _p}\) is the value of \(\beta\) when the robot is at the pth reference pose.

The allowable design values of the geometrical and pressure angle constraints (i.e., \([{\phi ^ - }]\), \([{\phi ^{\text{+}}}]\), \([\alpha ]\), \([\beta ]\) and \({e_{\text{m}\text{i}\text{n}}}\)) are given in Table 4, and the feasible region of \({l_1}\) and \({l_2}\) subject to the constraints is illustrated in Fig. 11.

Using the particle swarm optimization algorithm with the settings given in Table 5, the Pareto-optimal solutions shown in Fig. 12 (a) are solved to deal with the conflict between \({F_1}\) and \({F_2}\). The distribution of the solutions in the feasible region can also be seen in Fig. 12 (b). To compare the design results for different requirements, three sets of reference solutions highlighted in Fig. 12 are selected from the Pareto-optimal solutions, i.e., one focusing on achieving higher kinematic performance, one focusing on achieving higher elasto-dynamic performance, and one focusing on balancing the kinematic and elasto-dynamic performance. The results of the three optimal solutions are listed in Table 6 and will be discussed in Sect. 5.3.

Result discussion

As indicated in Fig. 12, the three selected reference solutions are corresponded to different design requirements, i.e., whether the kinematic performance and elasto-dynamic performance are focused on. For thoroughly comparing the performances of the three solutions, the topological structure model and FE model of the robot are updated according to the dimensions given in Table 6, and the discussions of the simulated results are drawn as follows:

(1) Fig. 13 shows the distributions of \({\theta _1}\), \({\theta _2}\), \({f_1}\) and \({f_2}\) of the reference solutions in the intermediate layer of the task workspace, and Table 7 gives the comparison of statistical data of the simulated results. It can be seen that shortening the lengths of connecting rods can help improve the elasto-dynamic performance (\({f_1}\) and \({f_2}\)) but worsen the kinematic performance (\({\theta _1}\) and \({\theta _2}\)) when the dimensions of the task workspace (R and h) are specified. It can also be seen that the distributions of \({\theta _1}\), \({\theta _2}\), \({f_1}\) and \({f_2}\) of Case-1 are more homogeneous across the intermediate layer of the task workspace according to their standard deviations (\({\delta _{{\theta _1}}}\), \({\delta _{{\theta _2}}}\), \({\delta _{{f_1}}}\) and \({\delta _{{f_2}}}\)) listed in Table 7. Compared to the performances of the current physical prototype of the robot, it can also observed from Table 7 that the kinematic performance index \({F_1}\) increases by 3.88% for Case-1, decreases by 14.37% and 6.14% for Case-2 and Case-3, while the elasto-dynamic performance index \({F_2}\) decreases by 15.37% for case-1, increases by 18.32% and 8.20% for Case-2 and Case-3. Considering the dimensional parameters of current physical prototype have been optimized based on the kinematic performance before construction, the proposed optimization method can significantly improve the elastic dynamic performance while ensuring minimal compromise to kinematic performance, thus potentially reducing residual vibration during high-acceleration movements. The final design decision can be made by minimizing the residual between the objective vector and the expected values for specific application requirements.

(2) In Table 7, \({\bar {\theta }_1}\), \({\bar {\theta }_2}\), \({\bar {f}_1}\) and \({\bar {f}_2}\) are the mean values of \({\theta _1}\), \({\theta _2}\), \({f_1}\) and \({f_2}\) over the entire intermediate layer of the task workspace. It is easy to see that \({F_1}\) and \({F_2}\) are close to the mean values of \({\bar {\theta }_1}\) and \({\bar {\theta }_2}\), \({\bar {f}_1}\) and \({\bar {f}_2}\), respectively. Consequently, the local performance indices formulated by the reference poses in Table 2 are verified to be effective in replacing the global performance indices in the optimal design. Furthermore, Fig. 14 illustrates the distributions of \({\xi _q}\) and clustering centers of the three cases in the intermediate layer of the task workspace. Here, the clustering centers are determined by the HCM algorithm in Sect. 4.4, and the coordinates of the reference poses corresponding to the clustering centers are listed in Table 8. The data in Tables 2 and 8 verified the assumption in Sect. 4.4 that the coordinates of the reference poses are almost unchanged varying with the dimensions of the robot, such that the reference poses can be determined by any specified dimensions.

(3) Given the dimensional parameters in Table 6, the servomotor parameters in terms of torque and power are estimated using the Extended Adept Cycle. Figure 15illustrates the comparisons of torque and power versus time of the three cases when the robot is undergoing the path and motion rule proposed in Ref14. It can be seen that the maximum torque of Case-1 with longer connecting rods is higher than those of the other two cases, while the maximum power of Case-2 with shorter connecting rods is higher than those of the other two cases. The simulated results in Fig. 15 can be used for selecting the servomotors and the reducers in the final design stage.

(4) The performances are simulated using the CAD and CAE technologies proposed in our previous work24,25,55, which have been validated to be efficient and accurate through comparative simulations and experimental studies. Consequently, the optimal results could be trustworthy enough. Furthermore, the local performance indices are determined by only 4 poses using the HCM clustering algorithm, leading to a significant reduction in computational time while considering the distribution laws of performances over the workspace. A design software package has been developed by integrating the methodologies and techniques presented in this paper and our previous work, enhancing the efficiency and convenience of designing or simulating parallel robots.

Conclusion

The present study proposes a digital design framework for optimizing the dimensions of parallel robots based on the kinematic and elasto-dynamic performances. The modeling, analysis and optimization process is demonstrated using a 4-DOF parallel robot as an example. The conclusions are summarized as follows:

(1) The proposed framework integrates skeleton modeling, CAD-CAE integration and multi-objective optimization techniques, allowing the design procedure to be implemented by three closely connected modules, i.e., the modeling module, analysis module and optimization module. In comparison to existing methods, the models for evaluating kinematic and dynamic performance are formulated using CAD and CAE techniques, providing a convenient and effective way for both academic researchers and industry designers in the development of parallel/hybrid robots. A software package has been developed based on the proposed framework and our previous work, making it well-suited for engineering applications.

(2) After evaluating the kinematic and elasto-dynamic performances of the robot with specified dimensions, several reference poses representative of multiple neighboring sample poses are determined to formulate corresponding local performance indices using the HCM clustering analysis algorithm. Compared to the local performance indices only considering the home pose and the global indices considering all the poses within the workspace, the distribution laws of the performances over the workspace are considered and the computational time is significantly reduced.

(3) The possible conflict between performance indices is appropriately handled by finding the Pareto-optimal solutions derived from a multi-objective design problem, which is formulated to determine the standalone key dimensional parameters, aiming to maximize the local performance indices subject to the geometrical and kinematic constraints. Three reference solutions are selected to satisfy different design requirements, i.e., whether the emphasis is on kinematic performance or elasto-dynamic performance. A detailed comparison of these three reference solutions is provided to validate the effectiveness of the proposed framework. The results show that the proposed approach can significantly enhance the elastic dynamic performance while ensuring that the kinematic performance is not excessively compromised, when compared to the performance of existing physical prototype of the robot.

(4) The Pareto-optimal solutions are obtained using the particle swarm optimization method. Though this algorithm may exhibit suboptimal convergence performance for complex problems with high-dimensions, it is suitable for the problem in this paper because the standalone key variables in the optimization are not many and the global optimal solution is selected from the Pareto-optimal solutions by minimizing the residual between the objective vector and the expected values for specific application requirements. In future work, various intelligent optimization algorithms will be investigated and compared for designing parallel/hybrid robots, particularly those dedicated to high-speed machining.

(5) In comparison with existing studies, while the CAD-CAE integration technology can accurately predict the kinematic and dynamic performance of parallel robots, there is still a need to enhance the computational efficiency of the proposed approach by integrating principal component analysis, correlation modeling technology, and sensitivity analysis, particularly for parallel robots with complex mechanical structures and numerous design variables. Additional limitations of the proposed approach include the neglect of parameter uncertainties, as well as the exclusion of trajectory planning and residual vibration suppression control from the framework. Future work will be carried out to address these issues in order to further enhance the functionality and practicality of the developed software in the design and development of parallel robots.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author upon reasonable request.

Abbreviations

- \({A_i}\)(\({{\varvec{a}}_i}\)), \({B_i}\)(\({{\varvec{b}}_i}\)), \({C_i}\)(\({{\varvec{c}}_i}\)):

-

Datum points (position vectors) of rotational axes of joints in the \(i\text{t}\text{h}\) (\(i=1\sim 4\)) limb

- \({S_i}\)(\({{\varvec{s}}_i}\)):

-

Datum axis (unit orientation vector) of the actuated revolute joint in the \(i\text{t}\text{h}\) (\(i=1\sim 4\)) limb

- e (\({\hat {{\varvec{e}}}_i}\)):

-

Offset (unit vector) from the origin of \(O - xyz\) to \({{\varvec{s}}_i}\)

- \({l_1}\)(\({\hat {{\varvec{l}}}_{1,i}}\)), \({l_2}\)(\({\hat {{\varvec{l}}}_{2,i}}\)):

-

Lengths (unit vectors) of the \(i\text{t}\text{h}\) (\(i=1\sim 4\)) forearm and connecting rod.

- \({P_1}\), \({P_2}\) :

-

Center of subpart 1 and subpart 2 of the end-effector

- \({{\varvec{r}}_P}\) :

-

Position vector of \({P_1}\)(\({P_2}\))

- W, \({W_R}\), \({W_T}\) :

-

Reachable workspace, maximum inscribed cylinder of W, task workspace inside \({W_R}\)

- R, h, H :

-

Radius, height and distance to the fixed platform of \({W_T}\)

- \(\eta\) :

-

Workspace/machine volume ratio

- FSI :

-

Free swell index

- \({H_{\hbox{min} }}\), \({H_{\hbox{max} }}\) :

-

Minimum and maximum distance from O to the top plane of \({W_T}\)

- \({\phi _i}\) :

-

Rotation angle of the \(i\text{t}\text{h}\) (\(i=1\sim 4\))

- \([{\phi ^ - }]\), \([{\phi ^+}]\) :

-

Lower and upper boundaries of \({\phi _i}\)

- \({\alpha _i}\) :

-

Pressure angle within the \(i\text{t}\text{h}\) (\(i=1\sim 4\)) limb

- \(\beta\) :

-

Pressure angle amongst the limbs

- \({\theta _1}\), \({\theta _2}\) :

-

Transmission angle within the limbs and amongst the limbs

- \({f_1}\), \({f_2}\), \({f_3}\), \({f_4}\) :

-

The first fourth natural frequencies of the robot

- \({n_I}\) :

-

Number of the grid nodes of the intermediate layer of \({W_T}\)

- \({\theta _{k,q}}\) :

-

The \(k\text{t}\text{h}\) (\(k=1\sim 2\)) transmission angle at the pose of the \(q{\text{th}}\) node in \({n_I}\) grid nodes

- \({f_{j,q}}\) :

-

The first second natural frequencies (\(j=1\sim 2\)) at the pose of the \(q{\text{th}}\) node in \({n_I}\) grid nodes

- \({\xi _q}\) :

-

Weighted index for clustering analysis formulated by \({\theta _{k,q}}\) and \({f_{j,q}}\)

- \({\eta _1}\), \({\eta _2}\) :

-

Weighting factors for formulating \({\xi _q}\)

- \({f_{j,\text{m}\text{i}\text{n}}}\), \({f_{j,\text{m}\text{a}\text{x}}}\) :

-

Minimum and maximum values of \({f_{j,q}}\) in the intermediate layer of \({W_T}\)

- \({\theta _{k,\text{m}\text{i}\text{n}}}\), \({\theta _{k,\text{m}\text{a}\text{x}}}\) :

-

Minimum and maximum values of \({\theta _{k,q}}\) in the intermediate layer of \({W_T}\)

- \({f^{\prime}_{j,q}}\), \({\kern 1pt} {\kern 1pt} {\kern 1pt} \theta _{{k,q}}^{\prime }\) :

-

Normalized values of \({f_{j,q}}\) and \({\theta _{k,q}}\)

- \({c_I}\) :

-

Number of groups of the \({n_I}\) grid nodes

- \({\xi _{c,p}}\left( {p=1\sim {c_I}} \right)\) :

-

The pth (\(p=1\sim {c_I}\)) clustering center of \({\xi _q}\)

- \({\mu _{p,q}}\) :

-

Membership degree of \({\xi _q}\) on \({\xi _{c,p}}\)

- \(d_{{p,q}}^{{}}\) :

-

Euclidean distance between \({\xi _q}\) and \({\xi _{c,p}}\)

- \({\varGamma _{\text{H}\text{C}\text{M}}}\) :

-

Clustering loss function

- \(\xi _{{c,p}}^{{\left( l \right)}}\) :

-

Value of \({\xi _{c,p}}\) in the \(l\text{t}\text{h}\) iteration

- \({\varepsilon _{{\text{HCM}}}}\) :

-

Iteration accuracy of the hard partition clustering centers

- \(\left[ {{\mu _{p,q}}} \right]_{{{c_I} \times {n_I}}}^{{{\text{HCM}}}}\) :

-

Hard partition matrix

- \(\varvec{\xi}_{c}^{{{\text{HCM}}}}\) :

-

Clustering center vector

- \({F_1}\), \({F_2}\) :

-

Local kinematic performance and elasto-dynamic performance index at the reference poses

- \({\theta _{k,p}}\), \({f_{j,p}}\) :

-

The \(k\text{t}\text{h}\) (\(k=1\sim 2\)) transmission angle and the jth (\(j=1\sim 2\)) natural frequencies at the pth reference pose

- \(\lambda _{0}^{{(k)}}\), \(\lambda _{i}^{{(k)}}\), \(\lambda _{{i+2}}^{{(k)}}\), \(\lambda _{{i,j}}^{{(k)}}\) :

-

Fitting coefficients of the polynomial surface function between \({F_k}\) (\(k=1\sim 2\)) and \({l_1}\), \({l_2}\)

- \({R^2}\) :

-

Multiple determination coefficient of the polynomial surface function

- \({e_{\hbox{min} }}\) :

-

Minimum value of e

- \({\alpha _{i,p}}\), \({\beta _p}\) :

-

\({\alpha _i}\) and \(\beta\) at the pth reference pose

- \([\alpha ]\), \([\beta ]\) :

-

Allowable design values of \({\alpha _i}\) and \(\beta\)

- \(l_{1}^{*}\), \(l_{2}^{*}\), \({e^*}\), \({H^*}\), \({R^*}\), \({h^*}\) :

-

Results of reference optimal solutions

- \({\bar {\theta }_1}\), \({\bar {\theta }_2}\), \({\bar {f}_1}\), \({\bar {f}_2}\) :

-

Mean values of \({\theta _1}\), \({\theta _2}\), \({f_1}\) and \({f_2}\) over \({W_T}\)

- \({\delta _{{\theta _1}}}\), \({\delta _{{\theta _2}}}\), \({\delta _{{f_1}}}\), \({\delta _{{f_2}}}\) :

-

Standard deviations of \({\theta _1}\), \({\theta _2}\), \({f_1}\) and \({f_2}\) over \({W_T}\)

References

Yang, C., Ye, W. & Li, Q. Review of the performance optimization of parallel manipulators. Mech. Mach. Theory. 170, 104725 (2022).

Kelaiaia, R., Company, O. & Zaatri, A. Multiobjective optimization of a linear Delta parallel robot. Mech. Mach. Theory. 50, 159–178 (2012).

He, B., Hou, S., Deng, Z., Cao, J. & Liu, W. Workspace analysis of a novel underactuated robot wrist based on virtual prototyping. Int. J. Adv. Manuf. Tech. 72, 531–541 (2014).

Zhang, S. et al. Kinematics and workspace analysis of a 3-CR(Pa)(Pa)R parallel mechanism with an orthogonal layout. Mech. Mach. Theory. 195, 105616 (2024).

Joshi, S. A. & Tsai, L. W. Jacobian analysis of limited-DOF parallel manipulators. J. Mech. Des. 124 (2), 254–258 (2002).

Hoevenaars, A. G. L., Gosselin, C., Lambert, P. & Herder, J. L. A systematic approach for the jacobian analysis of parallel manipulators with two end-effectors. Mech. Mach. Theory. 109, 171–194 (2017).

Liu, H., Huang, T., Kecskeméthy, A. & Chetwynd, D. G. A generalized approach for computing the transmission index of parallel mechanisms. Mech. Mach. Theory. 74, 245–256 (2014).

Shen, X., Xu, L. & Li, Q. Motion/Force constraint indices of redundantly actuated parallel manipulators with over constraints. Mech. Mach. Theory. 165, 104427 (2021).

Miller, K. Optimal Design and modeling of spatial parallel manipulators. Int. J. Robot Res. 23 (2), 127–140 (2004).

Dastjerdi, A. H., Sheikhi, M. M. & Masouleh, M. T. A complete analytical solution for the dimensional synthesis of 3-DOF delta parallel robot for a prescribed workspace. Mech. Mach. Theory. 153, 103991 (2020).

Meng, Q., Liu, X. J. & Xie, F. Design and development of a Schönflies-motion parallel robot with articulated platforms and closed-loop passive limbs. Robot Cim-Int Manuf. 77, 102352 (2022).

Xu, L., Ye, W. & Li, Q. Design, analysis, and experiment of a new parallel manipulator with two rotational and one translational motion. Mech. Mach. Theory. 177, 105064 (2022).

Company, O., Marquet, F. & Pierrot, F. A new high-speed 4-DOF parallel robot synthesis and modeling issues. IEEE Robot Autom. Mag. 19 (3), 411–420 (2003).

Liu, S. et al. Optimal design of a 4-DOF SCARA type parallel robot using dynamic performance indices and angular constraints. J. Mech. Robot. 4, 031005 (2012).

Huang, T., Liu, S., Mei, J. & Chetwynd, D. G. Optimal design of a 2-DOF pick-and-place parallel robot using dynamic performance indices and angular constraints. Mech. Mach. Theory. 70, 246–253 (2013).

Liu, X., Han, G., Xie, F. & Meng, Q. A novel acceleration capacity index based on motion/force transmissibility for high-speed parallel robots. Mech. Mach. Theory. 126, 155–170 (2018).

Zou, Q., Zhang, D. & Huang, G. Dynamic performance evaluation of the parallel mechanism for a 3T2R hybrid robot. Mech. Mach. Theory. 172, 104794 (2022).

Mo, J., Shao, Z., Guan, L., Xie, F. & Tang, X. Dynamic performance analysis of the X4 high-speed pick-and-place parallel robot. Robot Cim-Int Manuf. 46, 48–57 (2017).

Kuo, Y. L. Mathematical modeling and analysis of the Delta robot with flexible links. Comput. Math. Appl. 71, 1973–1989 (2016).

Wu, L., Wang, G., Liu, H. & Huang, T. An approach for elastodynamic modeling of hybrid robots based on substructure synthesis technique. Mech. Mach. Theory. 123, 124–136 (2018).

Dong, C., Liu, H., Huang, T. & Chetwynd, D. G. A screw theory-based semi-analytical approach for elastodynamics of the Tricept robot. J. Mech. Robot. 11, 031005 (2019).

Wu, L., Dong, C., Wang, G., Liu, H. & Huang, T. An approach to predict lower-order dynamic behaviors of a 5-DOF hybrid robot using a minimum set of generalized coordinates. Robot Cim-Int Manuf. 67, 102024 (2021).

Pham, M., Champliaud, H., Liu, Z. & Bonev, I. A. Parameterized finite element modeling and experimental modal testing for vibration analysis of an industrial hexapod for machining. Mech. Mach. Theory. 167, 104502 (2022).

Ma, Y. et al. Elasto-dynamic performance evaluation of a 6-DOF hybrid polishing robot based on kinematic modeling and CAE technology. Mech. Mach. Theory. 176, 104983 (2022).

Ma, Y., Niu, W., Luo, Z., Yin, F. & Huang, T. Static and dynamic performance evaluation of a 3-DOF spindle head using CAD-CAE integration methodology. Robot Cim-Int Manuf. 41, 1–12 (2016).

Briot, S., Caro, S. & Germain, C. Design procedure for a fast and accurate parallel manipulator. J. Mech. Robot. 9, 061012 (2017).

Li, Y. H. et al. Integrated design of a 4-DOF high-speed pick-and-place parallel robot. CIRP Ann-Manuf Techn. 63 (1), 185–188 (2014).

Dong, C., Liu, H., Xiao, J. & Huang, T. Dynamic modeling and design of a 5-DOF hybrid robot for machining. Mech. Mach. Theory. 165, 104438 (2021).

Chen, K., Wang, M., Huo, X., Wang, P. & Sun, T. Topology and dimension synchronous optimization design of 5-DoF parallel robots for in-situ machining of large-scale steel components. Mech. Mach. Theory. 179, 105105 (2023).

Chi, Z., Zhang, D., Xia, L. & Gao, Z. Multi-objective optimization of stiffness and workspace for a parallel kinematic machine. Int. J. Mech. Mater. Des. 9, 281–293 (2013).

Zhao, Y., Mei, J., Jin, Y. & Niu, W. A new hierarchical approach for the optimal design of a 5-dof hybrid serial-parallel kinematic machine. Mech. Mach. Theory. 156, 104160 (2021).

Lara-Molina, F. A., Dumur, D. & Takano, K. A. Multi-objective optimal design of flexible-joint parallel robot. Eng. Comput. 35 (8), 2775–2801 (2018).

Belkacem, B. Multi-objective optimal design based kineto-elastostatic performance for the delta parallel mechanism parallel mechanism. Robotica 34 (2), 258–273 (2016).

Kelaiaia, R. et al. Optimal dimensional design of parallel manipulators with an illustrative case study: a review. Mech. Mach. Theory. 188, 105390 (2023).

Zeng, D. X., Wang, J. J., Sun, P., Xu, T. T. & Qin, S. Y. Parameter optimization of parallel mechanisms based on PCA. China Mech. Eng. 28 (24), 2899–2905 (2017).

Yang, Q., Sun, T. & Song, Y. Multi-objective optimization of parallel tracking mechanism considering parameter uncertainty. J. Mech. Robot. 10 (4), 041006 (2018).

Sun, T., Lian, B., Song, Y. & Lei, F. Elastodynamic optimization of a 5-DoF parallel kinematic machine considering parameter uncertainty. IEEE/ASME Trans. Mechatronics. 24 (1), 315–325 (2019).

Lara-Molina, F. A. & Dumur, D. Robust multi-objective optimization of parallel manipulators. Meccanica 56, 2843–2860 (2021).

Brahmia, A., Kelaiaia, R., Company, O. & Chemori, A. Kinematic sensitivity analysis of manipulators using a novel dimensionless index. Rob. Auton. Syst. 150, 104021 (2022).

Brahmia, A., Kerboua, A., Kelaiaia, R. & Latreche, A. Tolerance synthesis of Delta-like parallel robots using a nonlinear optimisation method. Appl. Sci. 13, 10703 (2023).

Tsai, L. W. & Joshi, S. Kinematics and optimization of a spatial 3-UPU parallel manipulator. J. Mech. Des. 112, 439–446 (2000).

Lian, B., Sun, T. & Song, Y. Parameter sensitivity analysis of a 5-DoF parallel manipulator. Robot Cim-Int Manuf. 46, 1–14 (2017).

Pan, X., Wang, Y. & Chin, K. S. Dynamic programming algorithm-based picture fuzzy clustering approach and its application to the large-scale group decision-making problem. Comput. Ind. Eng. 157, 107330 (2021).

Rashid, A., Frasca, M., Ali, A., Rizzo, A. & Fortuna, L. Multi-robot localization and orientation estimation using robotic cluster matching algorithm. Robot Auton. Syst. 63, 108–121 (2015).

Shi, Y. et al. Bioinspired attachment mechanism of dynastes hercules: vertical climbing for OnOrbit assembly legged robots. J. Bionic Eng. 21, 137–148 (2024).

Gao, J. et al. Design and optimization of a novel double-layer helmholtz coil for wirelessly powering a capsule robot. IEEE T Power Electr. 39 (1), 1826–1839 (2024).

Sun, Y., Peng, Z., Hu, J. & Ghosh, B. K. Event-triggered critic learning impedance control of lower limb exoskeleton robots in interactive environments. Neurocomputing 564, 126963 (2024).

Zheng, C. et al. Hybrid offfine programming method for robotic welding systems. Robot Cim-Int Manuf. 73, 102238 (2022).

Zhu, C. Intelligent robot path planning and navigation based on reinforcement learning and adaptive control. J. Logistics Inf. Service Sci. 10 (3), 235–248 (2023).

Sun, J., Zhou, L., Geng, B., Zhang, Y. & Li, Y. Leg state estimation for quadruped robot by using probabilistic model with proprioceptive feedback. IEEE-ASME T Mech. (2024).

Wang, Z. et al. Robot base position and spacecraft cabin angle optimization via homogeneous stiffness domain index with nonlinear stiffness characteristics. Robot Cim-Int Manuf. 90, 102793 (2024).

Tian, G., Tan, J., Li, B. & Duan, G. Optimal fully actuated system approach-based trajectory tracking control for robot manipulators. IEEE T Cybernetics (2024).

Li, R. et al. Simulation of residual stress and distortion evolution in dual-robot collaborative wire-arc additive manufactured Al-Cu alloys. Virtual Phys. Prototy. 19 (1), e2409390 (2024).

Zheng, C. et al. Knowledge-based engineering approach for defining robotic manufacturing system architectures. Int. J. Prod. Res. 61 (5), 1436–1454 (2023).

Ma, Y., Liu, Q., Zhang, M., Li, B. & Liu, Z. An approach for mobility and force/motion transmissibility analysis of parallel mechanisms based on screw theory and CAD technology. Adv. Mech. Eng. 13 (10), 1–22 (2021).

Mun, D., Hwang, J. & Han, S. Protection of intellectual property based on a skeleton model in product design collaboration. Comput. Aided Des. 41 (9), 641–648 (2009).

Krut, S., Company, O., Nabat, O. & Pierrot, F. Heli4: A parallel robot for scara motions with a very compact traveling plate and a symmetrical design. IEEE/RSJ International Conference on Intelligent Robots and Systems, Beijing, China, 1656–1661 (2006).

SolidWorks SolidWorks Corporation. (2021). SPS URL < http://www.solidworks.com (2024).

Zhang, L., Mei, J., Zhao, X. & Huang, T. Dimensional synthesis of the Delta robot using transmission angle constraints. Robotica 30, 343–349 (2012).

Matlab, R. MathWorks Corporation. URL < https://ww2.mathworks.cn>, (2024). (2014).

SAMCEFField V8.2-01. Simens Corporation. URL < (2024). https://www.siemens.com/.

Lian, B., Wang, L. & Wang, X. Elastodynamic modeling and parameter sensitivity analysis of a parallel manipulator with articulated traveling plate. Int. J. Adv. Manuf. Tech. 12, 1583–1599 (2019).

Fuerle, F. & Sienz, J. Formulation of the audze–eglais uniform Latin hypercube design of experiments for constrained design spaces. Adv. Eng. Softw. 42, 680–689 (2011).

Acknowledgements

Sincere thanks are given to Chenxing (Tianjin) Automation Equipment Co., Ltd. for applying the proposed methodology to the development of high-speed parallel robot cells, and many thanks are also given to the editors and the reviewers for their patient work and constructive suggestions.

Funding

This research is partially supported by the National Natural Science Foundation of China (Grant No. 52205030, 52205029, 52375026), the State Key Laboratory of Robotics and Systems (HIT) (SKLRS-2023-KF-07), the Natural Science Foundation of Tianjin (23JCQNJC00430), and the Beijing-Tianjin-Hebei Joint Research Collaboration Program for Basic Research (24JCZXJC00270).

Author information

Authors and Affiliations

Contributions

Yue Ma: Visualization, Investigation, Writing-original draft, Writing-review & editing. Weihua Sun: Simulation, Visualization, Supervision, Writing-review & editing. Hongye Wu: Investigation, Data Curation, Formal analysis, Writing-review & editing. Bin Li: Formal analysis, Writing-review & editing. Qi Liu: Formal analysis, Methodology, Writing-review & editing. Songtao Liu: Project administration, Supervision, Validation. Chenglin Dong: Project administration, Investigation, Writing-review & editing. Dun Peng: Visualization, Resources, Software.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ma, Y., Sun, W., Wu, H. et al. A digital design framework for the dimensional optimization of parallel robots based on kinematic and elasto-dynamic performance. Sci Rep 14, 29292 (2024). https://doi.org/10.1038/s41598-024-80413-2

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-80413-2