Abstract

In this study, the inductively coupled plasma (ICP) etching process for patterning single-crystal diamond was experimentally investigated using O₂/Ar as the etching gas. The influence of various etching parameters on the process was analyzed via laser confocal microscopy. Taking etching rate and surface roughness as the primary evaluation metrics, the optimal etching parameters were determined as follows: an O₂/Ar gas flow ratio of 50/50 sccm, an ICP power of 600 W, a bias (RF) power of 120 W, and a chamber pressure of 20 mTorr.The experimental results indicate that the etching rate increases significantly with higher RF power and ICP power. Additionally, the etching rate exhibits a gradual increase with a higher oxygen content in the O₂/Ar ratio, while the influence of chamber pressure on the etching rate follows an increasing-then-decreasing trend. Moreover, the O₂/Ar gas flow ratio and chamber pressure have minimal impact on surface roughness, whereas increasing ICP and RF power leads to a pronounced rise in surface roughness, particularly under high-power conditions. Finally, by calculating the ratio of diamond etching depth to mask depletion thickness, the etch selectivity of this process was determined to be 1:46.

Similar content being viewed by others

Introduction

Diamond exhibits a unique combination of outstanding physical, chemical, optical, mechanical, and electrical properties, including the highest thermal conductivity, lowest compressibility, exceptionally high Young’s modulus, wide bandgap, extreme chemical inertness, ultra-low coefficient of friction, and the broadest optical transparency range among known materials. These exceptional characteristics make diamond highly versatile for a wide range of applications, particularly in semiconductor devices1,2,3,4,5.

Despite these advantages, the high cost of diamond and the challenges associated with shaping it into specific profiles have historically constrained its industrial applications. However, advancements in diamond growth technology have facilitated the commercialization of high-quality diamond, which is now available in precisely controlled sizes, typically within the range of a few square millimeters6. Concurrently, the cost of high-quality diamond has been significantly reduced7, leading to a growing body of research focused on its applications across various fields. In particular, diamond has shown great potential in microelectromechanical systems (MEMS)8, where its unique properties offer promising opportunities for innovation.

However, due to the extreme hardness of diamond, conventional processing methods are challenging to apply directly to this material. Micro-nano processing technology9,10 has emerged as a key approach for diamond machining due to its advantages, including high precision, flexibility, low power consumption, and broad applicability. This technology enables precise structural control of materials and devices, leading many researchers to introduce micro-nano processing techniques into diamond fabrication. Currently, the primary technologies for diamond processing include laser processing11,12,13, reactive ion etching (RIE)14, electron cyclotron resonance (ECR) etching15, focused ion beam (FIB) milling16, and inductively coupled plasma (ICP) etching17,18,19.However, each of these techniques presents certain limitations in surface micromachining. For instance, conventional laser processing struggles to achieve dimensionally accurate microtextures and is prone to crack formation. While focused ion beam milling offers high precision, it suffers from low efficiency, high cost, and sidewall tilting issues. Among these techniques, ICP etching stands out for its high processing efficiency and precision, enabling nanoscale, size-controllable microstructure fabrication. This method supports the fabrication of a wide range of nano- and micron-scale structures, including conventional stripe and hole arrays, as well as more complex polygonal and composite array structures. Consequently, ICP etching significantly enhances the diversity of surface morphologies in micro- and nanofabrication.Although ICP technology has been applied in microfabrication processes for diamond20,21,22, research on the influence of etching parameters on patterned diamond surface etching remains limited. Therefore, investigating the effects of etching parameters on patterned diamond etching presents a valuable and relevant research direction.

Inductively coupled plasma (ICP) etching technology distinguishes itself from other micro- and nanofabrication techniques due to its wide range of controllable processing dimensions, high precision, high efficiency, and superior processing quality. At the same time, diamond has gained significant research interest in recent years because of its exceptional physical, chemical, and mechanical properties23,24, making ICP etching one of the mainstream techniques for diamond micromachining.In this study, an experimental investigation of ICP etching for single-crystal diamond was conducted to systematically analyze the effects of various etching parameters on the patterned etching process. By considering etching rate and surface roughness as the primary evaluation metrics, the optimal etching parameters were determined, providing a valuable experimental foundation for the fabrication of diamond micro- and nanostructures.

Experimentation and Preparation

Experimental equipment and methods

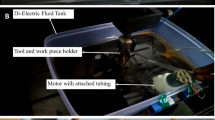

The single-crystal diamond etching experiments were conducted using an inductively coupled plasma (ICP) etching system (model ICP-S-150) developed by Beijing Zhongke Tailong Electronic Technology Co., Ltd. The structural configuration of the system is shown in Fig. 1. In this system, a high-frequency power supply (13.56 MHz) delivers energy to an inductive coil, exciting electrons in the process gas. These high-energy electrons collide with gas molecules, producing ions, electrons, and neutral species, which collectively form a high-density plasma. Under the influence of an electric field, the generated ions are accelerated toward the sample surface, where they transfer kinetic energy and trigger a series of physical and chemical reactions. Specifically, ion bombardment facilitates material removal through sputtering, while reactive species in the plasma chemically interact with the surface, forming volatile by-products that further enhance the etching process.

In this experiment, the combination of oxygen and argon gas is selected as the etching gas, and the combination of Ar/O₂ gas can promote the oxidation reaction through ion bombardment to realize more efficient and cleaner diamond etching25. Oxygen atoms and free radicals react with the diamond surface, which is mainly composed of carbon, to generate volatile compounds such as carbon dioxide (CO₂) and carbon monoxide (CO), which effectively removes carbon atoms from the surface and accelerates the etching process. At the same time, the accelerated argon ions in the plasma collide with the diamond surface, sputtering out carbon atoms or oxidized by-products to further enhance the oxygen etching effect. The specific chemical reaction equations for the etching process are shown in (1) and (2):

A sequential univariate optimization method was employed to determine the optimal ICP etching parameters. In this approach, one variable was varied at a time while the others were held constant, allowing the independent effect of each parameter on the diamond etching characteristics to be assessed. This method, also adopted by Mu Chenliang et al.26, has proven effective in analyzing the influence of ICP parameters on cemented carbide etching. To ensure consistent etching conditions, the diamond samples were positioned at the center of the silicon substrate stage, corresponding to the region of highest plasma density. Additionally, temperature variations during the etching process were strictly controlled to maintain uniform processing conditions, thereby enhancing the reproducibility and reliability of the experimental results.

Sample preparation

A 3 × 3 × 0.5 mm³ double-sided polished single crystal diamond (SCD) made of CVD was used in the experiments, and the initial roughness of the samples ranged from 5 to 10 nm. Prior to etching, the diamond substrate underwent a series of chemical cleaning steps to ensure surface purity. It was first immersed in a boiling piranha solution composed of 95–98% sulfuric acid and 30% hydrogen peroxide (H₂SO₄:H₂O₂ = 7:3) for 8 h. This was followed by sequential cleaning in acetone and anhydrous ethanol, and finally purged with nitrogen gas to remove residual contaminants.An aluminum mask was subsequently deposited on the diamond surface via magnetron sputtering. A layer of S1813 positive photoresist was spin-coated, pre-baked, UV-exposed for pattern transfer, and developed. The resulting pattern was transferred onto the aluminum layer by wet etching, and the remaining photoresist was removed using acetone and deionized water.The patterned substrate was then etched using Inductively Coupled Plasma (ICP) technology, as shown in Fig. 2, which illustrates the complete fabrication process. After 30 min of etching, the surface roughness and etching depth of the patterned areas were measured using a VK-X1000 laser confocal microscope (Keyence, Japan). For the etch depth, measurements were taken at five different points at the four corners as well as the center of the pattern after etching, and the mean and standard deviation were calculated for graphical representation and analysis.

Gas flow ratio experiment

Four etching experiments with different O₂/Ar gas flow ratios (25/50, 50/50, 75/50, and 100/50 sccm) were conducted under fixed conditions: ICP power of 600 W, RF power of 120 W, and chamber pressure of 20 mTorr. This set of tests was designated as Experiment 1. Detailed parameters are listed in Table 1.

ICP power experiments

Based on the optimal gas flow ratio identified in Experiment 1, the effect of ICP power on the diamond plasma etching process was further investigated. Five etching experiments were conducted with ICP powers of 200 W, 400 W, 600 W, 800 W, and 1000 W, while keeping the O₂/Ar gas flow ratio (50/50 sccm), RF power (120 W), and chamber pressure (20 mTorr) constant. This set of experiments was designated as Experiment 2. The detailed parameters are provided in Table 2.

RF power experiment

Building on the previously optimized gas flow ratio and ICP power, the effect of bias (RF) power on the diamond plasma etching process was further investigated. Five experiments were conducted with RF power levels of 40 W, 80 W, 120 W, 160 W, and 200 W, while keeping the O₂/Ar gas flow ratio (50/50 sccm), ICP power (600 W), and chamber pressure (20 mTorr) constant. This set of tests was designated as Experiment 3, and the detailed parameters are provided in Table 3.

Chamber air pressure experiment

Building on the previously optimized gas flow ratio, ICP power, and RF power, the effect of chamber pressure on the diamond plasma etching process was further examined. Five experiments were conducted at chamber pressures of 10, 15, 20, 25, and 30 mTorr, while maintaining constant O₂/Ar gas flow ratio (50/50 sccm), ICP power (600 W), and RF power (120 W). This series was designated as Experiment 4. Detailed parameters are presented in Table 4.

Results and discussion

Effect of gas flow rate ratio on plasma etching of diamonds

In Experiment 1, the relationship between the etching rate and different gas flow ratios is illustrated in Fig. 3(a). The results indicate that the etching rate of diamond increases as the oxygen ratio increases, reaching a maximum value of 250.6 nm/min at an O₂/Ar gas flow ratio of 100/50 sccm. As the oxygen flow rate increases, the intensity of the chemical reaction on the diamond surface increases, which helps to enhance the etching rate. However, if the oxygen flow rate continues to be increased, the total gas flow rate in the chamber is too high, and too many neutral molecules will scatter with the electrons in the plasma, reducing the electron energy and ionization efficiency, which inhibits the further enhancement of the plasma density and leads to a decrease in the etching rate. At the same time, high oxygen concentration will also trigger plasma instability27, affecting the controllability and repeatability of the etching process, thus reducing the accuracy and reliability of the experimental results. This suggests that oxygen plays a dominant role in the diamond etching process, with its increased flux significantly enhancing the etching reaction. The enhancement of the etching rate is primarily attributed to the oxidation reaction between oxygen and the carbon atoms on the diamond surface, forming volatile byproducts such as carbon monoxide (CO) and carbon dioxide (CO₂), which facilitate material removal. Additionally, a higher oxygen flow rate increases the concentration of reactive oxygen radicals in the plasma, further amplifying the chemical etching effect.

The variation in etched surface roughness with different gas flow rate ratios is illustrated in Fig. 3(b), while the three-dimensional morphology of the etched surface is shown in Fig. 4. As depicted in Fig. 3(b), the surface roughness gradually increases with an increasing oxygen flow rate. This is attributed to the localized uneven etching that occurs as oxygen concentration increases, leading to different etching rates across various crystal orientations, ultimately contributing to higher surface roughness.The lowest surface roughness (Ra = 47.57 nm) was observed at an O₂/Ar gas flow ratio of 25/50 sccm. As shown in Fig. 4, the surface roughness for the other three gas flow ratios was slightly higher than that of the O₂/Ar = 25/50 sccm condition, further confirming that lower oxygen flow contributes to a smoother etched surface.

Combining the combined effect of gas flow ratio on the etching rate and etching surface roughness during the etching process, an O2/Ar ratio of 50/50 sccm was selected as the condition for further study, as it maintained a lower surface roughness (52.52 nm) at a higher etching rate (239.88 nm/min).

Effect of ICP power on plasma-etched diamonds

In Experiment 2, the relationship between etching rate and ICP power is illustrated in Fig. 5(a). The results clearly show that the etching rate increases significantly with increasing ICP power. This is primarily due to the enhanced dissociation of O₂/Ar gas at higher ICP power, which generates a greater number of reactive oxygen radicals in the reaction chamber, thereby accelerating the oxidative etching reaction. Additionally, higher ICP power increases ion energy, leading to stronger physical bombardment of the diamond surface, which further promotes material removal. The combined effects of these mechanisms contribute to the observed increase in etching rate with increasing ICP power. Specifically, at 200 W ICP power, the etching rate was 93.8 nm/min, whereas at 1000 W ICP power, it increased to 309.32 nm/min, representing a 229.8% increase compared to the 200 W condition. This result demonstrates that high ICP power is an effective means of enhancing the etching rate in the diamond etching process.

The effect of ICP power on diamond surface roughness is illustrated in Fig. 5(b), while Fig. 6 presents the three-dimensional morphology of the etched surface. As shown in Fig. 5(b), the surface roughness of the etched diamond remains relatively stable when the ICP power is 200 W, 400 W, and 600 W. However, when the ICP power increases to 800 W and 1000 W, the surface roughness rises sharply.This phenomenon can be attributed to the increase in plasma density and ion energy at higher ICP power levels, which leads to more intense ion bombardment of the diamond surface. High-energy ion impact induces localized uneven etching, creating surface irregularities. Additionally, the increased ICP power raises the concentration of reactive oxygen radicals, further intensifying the chemical etching reaction. This combined effect amplifies surface inhomogeneity, resulting in a substantial increase in surface roughness.When the ICP power increased from 200 W to 1000 W, the surface roughness Ra rose from 42.29 nm to 111.93 nm, representing a 164.7% increase. These results indicate that while higher ICP power enhances the etching rate, it also deteriorates surface quality by significantly increasing roughness, especially at elevated power levels. As seen in Fig. 6, higher ICP power leads to greater surface roughness and degraded etching quality, highlighting the need for optimizing ICP power to balance etching efficiency and surface smoothness.

In conclusion, the etching rate increases significantly with increasing ICP power, whereas the surface roughness of the etched pattern rises sharply at high power levels. Considering both etching rate and surface roughness, an optimal balance is necessary, as low surface roughness is crucial for enhancing the optical, mechanical, electronic, and medical performance of diamond-based applications28. To achieve a high etching rate while maintaining acceptable surface quality, an ICP power of 600 W was selected for subsequent experiments in this study. This choice ensures efficient etching without excessively compromising surface smoothness.

Effect of RF power on plasma-etched diamonds

In Experiment 3, the relationship between etching rate and RF power is shown in Fig. 7(a). The results indicate that the etching rate increases significantly with increasing RF power, demonstrating a strong upward trend.This can be attributed to the fact that higher RF power enhances the electric field strength at the substrate surface, which accelerates ion motion toward the diamond surface. The increase in ion kinetic energy improves both the bombardment effect and the sputtering effect, leading to a higher material removal rate. Consequently, the etching rate rises substantially as RF power increases.Specifically, when RF power increases from 40 W to 200 W, the etching rate increases from 112.86 nm/min to 362.98 nm/min, representing a 221.6% increase compared to the 40 W condition. This result clearly demonstrates that RF power plays a critical role in enhancing the etching rate during the diamond etching process.

The variation in etched surface roughness with different RF power levels is shown in Fig. 7(b), while the 3D morphology of the etched surface is presented in Fig. 8. The results indicate that surface roughness gradually increases as RF power rises from 40 W to 120 W, but when RF power exceeds 120 W and increases to 200 W, the roughness rises sharply.During ICP etching of diamond, RF power directly influences ion kinetic energy and bombardment intensity. In the 40 W to 120 W range, the plasma ion velocity remains relatively low, resulting in moderate ion bombardment on the diamond surface. This leads to a more uniform material removal, maintaining higher surface quality and a relatively smooth etched surface.However, when RF power increases beyond 120 W, the ion velocity and energy increase significantly, causing intense ion bombardment. This leads to a stronger sputtering effect, which disrupts the surface structure and results in a sharp increase in surface roughness. The findings suggest that while higher RF power enhances the etching rate, it also substantially increases surface roughness, particularly at high power levels.As seen in Fig. 8, when RF power is ≤ 120 W, the etched surface remains relatively smooth with low roughness. However, when RF power exceeds 120 W, the etched surface quality deteriorates, leading to a marked increase in roughness. This underscores the importance of optimizing RF power to balance etching efficiency and surface quality.

In summary, the optimal RF bias power for the etching process is determined to be 120 W. At this power level, a better balance between etching rate and surface roughness is achieved. The lower surface roughness ensures improved optical performance and enhances the suitability of diamond for applications in optics and other related fields, while the higher etching rate significantly improves fabrication efficiency, reducing both processing time and costs.Thus, selecting 120 W RF power provides an optimal trade-off between surface quality and etching speed, making it the preferred setting for high-quality diamond micro- and nanostructure fabrication.

Effect of chamber air pressure on plasma-etched diamonds

As shown in Fig. 9(a), the etching rate in Experiment 4 follows an increasing-then-decreasing trend with varying chamber gas pressure. At lower gas pressures, the reaction gas density and plasma density increase as pressure rises, leading to a higher etching rate. This occurs because, at lower pressures, the plasma density increases, which enhances the etching reaction and promotes material removal.However, when the gas pressure exceeds 20 mTorr, the frequency of gas collisions increases, causing a shortening of the ion mean free path and a reduction in ion energy. As a result, the etching rate begins to decrease due to weaker ion bombardment and reduced material removal efficiency.Thus, the etching rate initially rises with increasing pressure but declines beyond a critical threshold. The highest etching rate of 239.88 nm/min is observed at 20 mTorr, indicating that optimal chamber pressure can enhance the etching efficiency of diamond.

The relationship between etched surface roughness and chamber air pressure is illustrated in Fig. 9(b), while Fig. 10 presents the three-dimensional morphology of the patterned etched surface. As seen in Fig. 9(b), the surface roughness exhibits a trend of first increasing and then decreasing as chamber air pressure rises, although the overall roughness variation among samples remains relatively small.This phenomenon can be attributed to the influence of chamber air pressure on ion bombardment and chemical reaction uniformity during ICP etching of diamond. At low air pressure, etching is highly anisotropic, leading to a smoother surface due to directional ion bombardment. As air pressure increases, lateral etching becomes more pronounced, resulting in etching inhomogeneity and an increase in surface roughness. However, when chamber pressure exceeds 20 mTorr, the mean free path of ions shortens, reducing ion energy and leading to a more uniform etching process, which ultimately lowers the surface roughness. At chamber pressures of 10 mTorr and 25 mTorr, the etching rate and post-etch surface roughness show relatively minor differences. This can be attributed to the fact that, under both conditions, the plasma remains in a stable operational state. The concentration of reactive oxygen radicals and the energy of ion bombardment are relatively balanced and do not vary significantly across this pressure range. As a result, both the physical sputtering and chemical reaction processes operate in a near-equilibrium regime, leading to comparable etching performance. From Fig. 10, it is evident that at low pressure (10 mTorr), the etched surface quality is optimal, with a roughness value of only 41.2 nm. As air pressure increases, etching becomes less uniform, and roughness peaks at 20 mTorr. However, at higher pressures, improved etching homogeneity due to reduced ion energy and collision effects leads to a subsequent decrease in roughness.These findings highlight the importance of optimizing chamber air pressure to balance etching uniformity and surface quality, ensuring effective diamond ICP etching.

In summary, based on the consideration of etching rate and roughness, the selected chamber air pressure is 20 mTorr. Although the roughness of the pattern-etched surface is not optimal at this chamber air pressure, the etching rate is the highest, which is conducive to the improvement of the etching efficiency of diamond and the saving of time cost.

Results of etching parameter optimization and microstructure Preparation

Considering both etching rate and surface roughness, the optimal etching parameters were determined as follows: O₂/Ar gas flow ratio of 50/50 sccm, ICP power of 600 W, RF power of 120 W, and chamber pressure of 20 mTorr. Using these parameters, a square array structure was successfully fabricated via Inductively Coupled Plasma (ICP) etching, as shown in Fig. 11(a). The laser confocal 3D image in Fig. 11(b) confirms that the optimized process achieves a high-quality etched structure with reduced surface roughness, measured at 49.7 nm. The SEM magnified image in Fig. 11(c) further reveals that plasma bombardment during etching leads to a minor deposition of mask particles on the etched surface. The etching depth of the diamond, measured using laser confocal microscopy, is 7.60 μm, as shown in Fig. 11(e). The thickness change of the aluminum mask before and after etching, illustrated in Figs. 11(d) and (f), indicates an average mask thickness of 827.6 nm before etching and 662.6 nm after etching, corresponding to an overall depletion of 165 nm. By optimizing the etching parameters and calculating the ratio of diamond etch depth to mask consumption, this study achieved both low surface roughness and a substantial etch depth, yielding an etch selectivity of 1:46. While slightly lower than the 1:56 selectivity reported by D.T. Tran et al.29 using an aluminum mask, the present work demonstrates a more balanced trade-off between etch precision and surface quality, highlighting the effectiveness and practical advantage of the developed process. In addition, among the multiple etching parameters studied in this experiment, chamber air pressure is a key factor affecting the mask selectivity30. While ICP and RF power mainly affect the etching rate and surface morphology of diamond, changes in air pressure directly affect the etching rate of the mask by acting on the ionic energy and the mean free range of radicals. Under appropriate air pressure conditions, the overconsumption of the mask can be better suppressed while maintaining a high etching efficiency, resulting in a high selectivity ratio.

To further explain the changes in the deep etching of diamond, it is important to note that as the etching depth increases, the longer path of the argon and oxygen radical plasma during the etching process leads to a decrease in the concentration of free radicals when etching deeper arrays of diamond grooves thereby leading to a decrease in the rate of the chemical reaction at deeper arrays of diamond grooves, thus altering the localized etching mechanism of the diamond grooves. At this time, the physical bombardment of argon ions during etching is relatively enhanced and becomes the primary removal mechanism. This change can lead to problems such as reduced etching rates, the emergence of high depth-to-width ratio structure-dependent effects, and the etching pattern becoming irregular, which is a common technical challenge in high depth-to-width ratio ICP etching.

Conclusion

In this experiment, a systematic study on inductively coupled plasma (ICP) etching for single-crystal diamond patterning was conducted, with a focus on analyzing the effects of key etching parameters on the etching process. By comprehensively evaluating the etching rate and etched surface roughness, the optimal etching process parameters were determined. The main conclusions of this study are as follows:

-

(1)

The optimal process parameters for inductively coupled plasma etching of patterned single crystal diamond were: O2/Ar gas flow ratio of 50/50 sccm, ICP power of 600 W, RF power of 120 W, and gas pressure of 20 mTorr.

-

(2)

With the increase of RF power and ICP power, the etching rate increases significantly. Meanwhile, in the O2/Ar gas flow, the etching rate increases but more slowly with the increase of oxygen flow rate, while the effect of air pressure on the etching rate shows a tendency of increasing and then decreasing.

-

(3)

The O2/Ar gas flow ratio and chamber air pressure had a small effect on the diamond patterned etching surface roughness. However, the etching surface roughness increased with increasing ICP power and RF power, and the increase in roughness was significant at high power.

-

(4)

By calculating the ratio of diamond etching depth to mask depletion thickness after etching the diamond pattern for the optimized process, the Etching selectivity ratio for the process was obtained as 1:46.

Data availability

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding authors.

References

AmaratungaGA Applied physics. A dawn for carbon electronics? Science 297, 1657–1658 (2002).

Isberg, J., Hammersberg, J., Twitchen, D. J. & Whitehead, A. J. Single crystal diamond for electronic applications. Diam. Relat. Mater. 13, 320–324 (2004).

Liao, M. & Koide, Y. High-performance metal-semiconductor-metal deep-ultraviolet photodetectors based on homoepitaxial diamond thin film. Appl. Phys. Lett. 89, 113509 (2006).

Liu, J. et al. Low on-resistance diamond field effect transistor with high-k ZrO2 as dielectric. Sci. Rep. 4, 6395 (2014).

MayPW Materials science. The new diamond age? Science 319, 1490–1491 (2008).

Liang, Q. et al. Developments in synthesis, characterization, and application of large, high-quality CVD single crystal diamond. J. Superhard Mater. 35, 195–213 (2013).

Prelas, M. A. P. G. & Bigelow, L. K. Handbook of industrial diamonds and diamond films (2018).

Luo, J. K. et al. Diamond and diamond-like carbon MEMS. J. Micromech. Microeng. 17, S147–S63 (2007).

Auciello, O. & Aslam, D. M. Review on advances in microcrystalline, nanocrystalline and ultrananocrystalline diamond films-based micro/nano-electromechanical systems technologies. J. Mater. Sci. 56, 7171–7230 (2021).

Brousseau, E. B., Dimov, S. S. & Pham, D. T. Some recent advances in multi-material micro- and nano-manufacturing. Int. J. Adv. Manuf. Technol. 47, 161–180 (2009).

Zhang, Y., Xu, S., Cui, E. N., Yu, L. & Wang, Z. Research and Application Progress of Laser-Processing Technology in Diamond Micro-Fabrication. Micromachines 15 (2024).

Odake, S. et al. Pulsed laser processing of nano-polycrystalline diamond: A comparative study with single crystal diamond. Diam. Relat. Mater. 18, 877–880 (2009).

Wei, C. et al. Study on femtosecond laser processing characteristics of Nano-Crystalline CVD diamond coating. Appl. Sci. 9, 4273 (2019).

Lee, C. L., Choi, H. W., Gu, E., Dawson, M. D. & Murphy, H. Fabrication and characterization of diamond micro-optics. Diam. Relat. Mater. 15, 725–728 (2006).

Aiello, G. et al. Diamond window technology for Electron cyclotron heating and current drive: state of the Art. Fusion Sci. Technol. 75, 719–729 (2019).

Babinec, T. M., Choy, J. T., Smith, K. J. M., Khan, M. & Lončar, M. Design and focused ion beam fabrication of single crystal diamond nanobeam cavities. Journal of Vacuum Science & Technology B, Nanotechnology and Microelectronics: Materials, Processing, Measurement, and Phenomena 29 (2011).

Ren, Z., Heard, P. J., Marshall, J. M., Thomas, P. A. & Yu, S. Etching characteristics of LiNbO3 in reactive ion etching and inductively coupled plasma. J. Appl. Phys. 103, 034109 (2008).

Welch, C. C., Goodyear, A. L., Wahlbrink, T., Lemme, M. C. & Mollenhauer, T. Silicon etch process options for micro- and nanotechnology using inductively coupled plasmas. Microelectron. Eng. 83, 1170–1173 (2006).

Zhang, Z. et al. A Morphology Control Method of Submicron SiO2 Arrays in CHF3/Ar Inductively Coupled Plasma Etching. IEEE International Conference on Manipulation, Manufacturing and Measurement on the Nanoscale (3 M-NANO) pp. 272-5. (2023).

Xin, Q. et al. Surface roughening of ground fused silica processed by atmospheric inductively coupled plasma. Appl. Surf. Sci. 341, 142–148 (2015).

Yang, C-M., Zeng, W-Y., Chen, C-H., Chen, Y-P. & Chen, T-C. Spatial resolution and 2D chemical image of light-addressable potentiometric sensor improved by inductively coupled-plasma reactive-ion etching. Sens. Actuators B. 258, 1295–1301 (2018).

Lee, C. L., Gu, E., Dawson, M. D., Friel, I. & Scarsbrook, G. A. Etching and micro-optics fabrication in diamond using chlorine-based inductively-coupled plasma. Diam. Relat. Mater. 17, 1292–1296 (2008).

Donato, N., Rouger, N., Pernot, J., Longobardi, G. & Udrea, F. Diamond power devices: state of the art, modelling, figures of merit and future perspective. J. Phys. D 53, 093001 (2019).

Lu, J., Xu, D., Huang, N., Jiang, X. & Yang, B. One-dimensional diamond nanostructures: fabrication, properties and applications. Carbon 223, 119020 (2024).

Reeves Ah, G. K. Reactive ion etching of diamond in CF4,O2,O2 and Ar-based mixtures. J. Mater. Sci., 36, 3453–3459 (2001).

Lian, Y., Mu, C., Xie, C. & Yao, B. Experimental investigation of inductively coupled plasma etching on cemented carbides. Vacuum 162, 101–109 (2019).

Yin, Y., Bilek, M. M. M., McKenzie, D. R., Boswell, R. W. & Charles, C. Micro-arcing in radio frequency plasmas. J. Phys. D. 37, 2871–2875 (2004).

Tong, W. et al. Fabrication of planarised conductively patterned diamond for bio-applications. Mater. Sci. Engineering: C. 43, 135–144 (2014).

Tran, D. T., Fansler, C., Grotjohn, T. A., Reinhard, D. K. & Asmussen, J. Investigation of mask selectivities and diamond etching using microwave plasma-assisted etching. Diam. Relat. Mater. 19, 778–782 (2010).

Booker, K., Mayon, Y. O., Jones, C., Stocks, M. & Blakers, A. Deep, vertical etching for GaAs using inductively coupled plasma/reactive ion etching. Journal of Vacuum Science & Technology B, Nanotechnology and Microelectronics: Materials, Processing, Measurement, and Phenomena 38 (2020).

Funding

This research was funded by Science and Technology Major Project of Ningbo, grant number 2021ZDYF020196, 2021ZDYF020198.

Author information

Authors and Affiliations

Contributions

Author Contributions Conceptualization, J.Y. and S.F.; methodology, L.Z.; investigation, L.Z.; writing—original draft preparation, L.Z.; writing—review and editing, S.F., J.Y., X.W. and N.K.; visualization, L.Z.; supervision, X.W.; funding acquisition, N.J. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhao, L., Wang, X., Jiang, N. et al. Experimental study of inductively coupled plasma etching of patterned single crystal diamonds. Sci Rep 15, 21062 (2025). https://doi.org/10.1038/s41598-025-08066-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-08066-3