Abstract

Cecropin A is a potent antimicrobial peptide with broad-spectrum activity; however, its clinical application is limited by poor stability, solubility, and bioavailability. In this study, an engineered analog of Cecropin A was developed by incorporating an M cell-targeting peptide (MTP) at the N-terminus, a self-assembling EAK16-II sequence at the C-terminus, and a rigid EAAAK linker to preserve domain integrity. This engineered peptide (Pep A) exhibited significantly improved physicochemical properties, including enhanced solubility (0.930), a higher extinction coefficient (8480 M− 1cm− 1), and a more favorable net positive charge (+ 7), all of which may support stronger interactions with microbial membranes and enhanced therapeutic potential. Despite a slightly elevated instability index, the peptide remained within the stable range. The engineered peptide was predicted to be non-toxic, in contrast to its native form, which was identified as toxic. Furthermore, its high solubility upon overexpression facilitates large-scale recombinant production in bacterial systems. Computational modeling using AlphaFold and Robetta confirmed the structural accuracy of the design, with Pep A outperforming other models in compactness and favorable folding. Molecular dynamics simulations further validated the improved stability of Pep A, demonstrating reduced flexibility, consistent hydrogen bonding, and lower solvent exposure. Point mutations at surface-accessible, flexible, and non-critical residues further enhanced its stability. Collectively, these modifications produced a multifunctional Cecropin A analog with improved structural stability, solubility, and bioavailability, establishing Pep A as a promising candidate for advanced antimicrobial and mucosal delivery applications. However, in vitro and in vivo validations are critical for confirming its final applications.

Similar content being viewed by others

Introduction

Antimicrobial peptides (AMPs) are a diverse class of molecules that play a crucial role in the innate immune response. They defend against a wide range of diseases and hold significant promise as alternatives or adjuncts to conventional antibiotics, particularly in the fight against multidrug-resistant (MDR) bacterial strains1,2,3. Their structural diversity offers advantages over traditional small-molecules, recent advances in peptide engineering have improved their bioavailability, stability, and pharmacokinetic properties4,5. Among the various classes of AMPs, cecropins have emerged as particularly promising candidates due to their potent antimicrobial activity, though their clinical application still requires improvements in stability and physicochemical properties6.

Cecropins are categorized into three principal types‒Cecropin A, B, and D‒and have been isolated from various insect families, including Diptera, Lepidoptera, and Coleoptera7. They exert their antimicrobial effects mainly by interacting with microbial membranes, leading to cell disruption. Several mechanisms have been proposed, including the carpet model, which suggests that high concentrations of Cecropins destabilize membranes via micelle-like aggregate formation8. Additionally, post-translational modifications such as amidation can enhance their activity9,10.

Among the three types, Cecropin A has demonstrated broad antibacterial and antifungal activities8,11. However, its clinical application is limited by poor stability, rapid proteolysis, and low bioavailability12. To overcome these challenges, peptide engineering strategies—including sequence modifications, stability-enhancing substitutions, and domain fusion—are widely employed13,14.

Functional domains are especially useful for improving therapeutic properties. For example, M cell-targeting peptides (MTPs) facilitate mucosal delivery15while self-assembling domains like EAK16-II can protect peptides from enzymatic degradation and enhance delivery efficiency16,17,18,19,20. Strategies such as L-to-D isomerization and site-directed mutagenesis (SDM) also improve protease resistance and antimicrobial activity. The L-to-D isomerization of AMPs, which increases resistance to degradation by host and microbial proteases, as peptides composed of L-amino acids are generally more susceptible to enzymatic breakdown21. Additionally, SDM is used to precisely modify specific amino acids within a peptide or protein sequence. This approach can produce mutant variants with improved stability, enhanced antimicrobial activity, and other favorable functional properties22.

Computational techniques are routinely employed to complement traditional experimental approaches and facilitate the systematic design of peptides and proteins. These tools enable the redesign and optimization of peptide structures, prediction of binding free energies, and exploration of conformational dynamics with greater efficiency and accuracy23,24. Among these methods, molecular dynamics (MD) simulations offer significant advantages by providing atomic-level insights into the flexibility, stability, and interaction patterns of peptides in various environments25. This allows for predicting structural behavior over time, identifying favorable modifications, and rationalizing peptides with enhanced therapeutic properties.

In this study, we present a novel peptide engineering approach to optimize Cecropin A by simultaneously integrating three distinct strategies that, to our knowledge, have not been combined before. Specifically, we incorporated an M cell-targeting peptide (MTP) at the N-terminus to facilitate targeted delivery, and the self-assembling peptide EAK16-II at the C-terminus to improve structural stability—an approach not previously reported for Cecropin A or similar antimicrobial peptides. Furthermore, we applied site-directed point mutations to fine-tune structural integrity and enhance bioactivity. This unique combination of domain fusion and rational mutagenesis provides a new framework for designing antimicrobial peptides with improved solubility, stability, and therapeutic potential, thereby addressing key limitations that have hindered their clinical translation.

Materials and methods

Retrieval of cecropin A sequence and construction design

The primary sequence and 3D structure of Cecropin A were retrieved from the UniProt database (https://www.uniprot.org/) with an accession number of P01507 and from the RCSB Protein Data Bank (https://www.rcsb.org/) with a PDB code of 2LA2, respectively. Three peptide sequences were used in designing the engineered variant of Cecropin A: MTP with the sequence FYPSYHSTPQRP, an EAAAK linker, and the self-assembling peptide EAK16-II. The MTP was fused to the N-terminus of Cecropin A using the linker, while EAK16-II was attached to the C-terminus using the same linker.

Predicting toxicity, physicochemical properties, and solubility

Peptide toxicity was predicted using the CSM-Toxin server26which employs a deep learning-based natural language model to interpret protein sequences in the context of their biological relevance. Physicochemical properties of the peptides, including length, molecular weight (MW), theoretical isoelectric point (pI), charge, estimated half-life in the mammalian reticulocytes, grand average of hydropathicity (GRAVY), extinction coefficient, aliphatic index, and instability index, were computed using the ProtParam tool27. The solubility upon overexpression was evaluated using the SOLpro server28which applies a machine learning algorithm based on features such as hydrophobicity, amino acid composition, secondary structure, solvent accessibility, and charge distribution29.

Evaluating secondary structure and helical wheel

The secondary structure of peptides was analyzed using the JPred tool30which utilizes the Jnet al.gorithm to provide predictions of secondary structure elements, solvent accessibility, and coil regions within protein sequences. Hydrophobic and hydrophilic interfaces within the secondary structure of the peptides were further analyzed using the NetWheels tool31 to generate helical wheel projections, aiding in the visualization of amphipathic α-helices.

Modeling and validating the 3D structure of peptides

The 3D structure of the engineered peptide was modeled using two widely recognized servers for comparative modeling to identify the most accurate structure. The Robetta32 and AlphaFold233 servers were employed for initial model generation. Subsequently, the peptide model was refined using the GalaxyRefine server34. The GalaxyRefine server begins by reconstructing all side-chain conformations, followed by iterative structural relaxation through localized molecular dynamics simulations after side-chain repacking, thereby improving the quality of the initial model35.

Following refinement, the resulting 3D structures were compared, and the final model quality was assessed using several validation tools, i.e. ERRAT, PROCHECK, and ProSA-web. The ERRAT server36 evaluated non-bonded atomic interactions by comparing them to a database of well-refined crystallographic structures, helping to identify potential errors or irregularities in atomic contacts. The PROCHECK server37 was employed to analyze the Ramachandran plot, which evaluates the stereochemical quality of the model by examining the distribution of backbone dihedral angles (ϕ and ψ) for each residue. The plot categorizes residues into favored, allowed, and disallowed regions, providing insight into the model’s structural integrity37. Additionally, the ProSA-web server38 was utilized to assess the overall quality of the model by calculating a Z-score that reflects the deviation of the total energy of the structure from values typical of experimentally determined protein structures in the RCSB Protein Data Bank (RCSB PDB).

Molecular dynamics (MD) simulations

MD simulations were conducted using the GROMACS 2022 package39 to analyze the dynamic behavior of the studied peptides in an aqueous environment. The topologies of the peptides, designed for viral proteins, were generated using the OPLS-AA force field40. Simulation boxes were solvated with SPC/E water molecules, and appropriate counterions were added to neutralize the system. Subsequently, energy minimization was performed using the steepest descent algorithm until the maximum force dropped below 10 kJ/mol40. Periodic boundary conditions were employed in all directions. The simulations were conducted under NPT and NVT ensembles, maintaining a temperature of 310.15 K and a pressure of 1.0 bar. Temperature and pressure were controlled using the V-rescale thermostat and the Parrinello-Rahman barostat, respectively. Intermolecular interactions were calculated using a 1.0 nm cut-off for both short-range electrostatic and van der Waals interactions, while long-range electrostatic interactions were handled using the Particle Mesh Ewald (PME) method. Bond constraints involving heavy atoms were applied using the LINCS algorithm. A 100 ns production simulation was carried out using the leapfrog integration algorithm41. Molecular interactions and structural trajectories were visualized and analyzed using Discovery Studio software (v. 4.5) and the gmx tools, respectively.

Applying in Silico mutagenesis for residual modifications

Amino acid modifications are a fundamental strategy in peptide design42. Research has shown that specific amino acid substitutions can significantly influence the functional and structural properties of peptides20. To assess the effect of point mutations on peptide stability, two computational tools, including CUPSAT and MuPro, were employed43. CUPSAT is a web-based tool that predicts protein or peptide structural stability changes caused by single-point mutations. It generates stability predictions based on solvent accessibility and torsion angle distributions. Users can upload a 3D structure of the protein or peptide in PDB format and specify the mutation site. CUPSAT evaluates whether a mutation stabilizes or destabilizes by calculating the change in Gibbs free energy (ΔΔG). MuPro is an advanced machine learning-based tool to predict stability changes resulting from point mutations44. Users can input an amino acid sequence or a structure in PDB format. MuPro provides a ΔΔG value, indicating whether the mutation will likely enhance or reduce protein stability. Its high prediction accuracy stems from integrating support vector machines and neural networks into its algorithm. Together, these tools offer valuable insights into how specific mutations may affect the overall structural stability of peptides.

Results

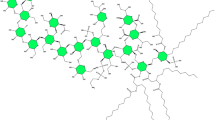

Designing a modified version of Cecropin A

To design engineered Cecropin A, the selected sequences were strategically combined with the peptide to enhance its stability and solubility. The N-terminal domain was modified by adding the sequence FYPSYHSTPQRPE (MTP). Additionally, the C-terminal segment featured a repetitive AEAEAKAK motif (EAK16-II), characteristic of synthetic peptides designed for self-assembly. The schematic representation of the engineered peptide based on the cecropin A template is shown in Fig. 1.

Evaluation of toxicity, physicochemical, and solubility properties of peptides

The toxicity, solubility, and physicochemical properties of both the native and engineered peptides are summarized in Table 1. Toxicity analysis using the CSM-Toxin server predicted the native peptide to be toxic, whereas the engineered peptide was identified as non-toxic, underscoring its improved safety profile and potential for therapeutic applications. Physicochemical properties were further evaluated using the ProtParam tool. The engineered peptide exhibited a lower isoelectric point compared to the native peptide (9.82 vs. 10.39) and carried a higher net positive charge (+ 7 vs. +6), changes that may enhance electrostatic interactions with negatively charged microbial membranes and potentially improve antimicrobial efficacy. Its predicted half-life in mammalian reticulocytes was slightly shorter (1.1 h vs. 1.3 h), which could modestly reduce systemic persistence but may also lower the risk of prolonged off-target effects. The engineered peptide also demonstrated a higher predicted absorbance, with an extinction coefficient of 8480 M− 1 cm− 1 compared to the native peptide, which could facilitate more sensitive detection and quantification in analytical assays. Hydropathicity analysis showed a more hydrophilic profile for the engineered peptide, as reflected by a lower GRAVY index (-0.533 vs. -0.073), potentially improving solubility and reducing aggregation propensity. The aliphatic index was lower for the engineered peptide (72.00 vs. 108.11), which may indicate reduced thermostability; however, this is less critical for in vivo applications where physiological temperatures are maintained. The instability index increased (30.88 vs. 16.52); however, it remains well below the threshold of 40 defined by Guruprasad et al. (1990) for unstable proteins, thus still falling within the ideal stability range. In peptide engineering, stability is assessed by considering multiple parameters in parallel, such as hydrophobicity, GRAVY score, estimated half-life, and predicted protease resistance; and the observed increase likely reflects a trade-off from sequence modifications aimed at enhancing other critical attributes, including reduced susceptibility to degradation, while maintaining overall stability. Solubility upon overexpression was also slightly lower for the engineered peptide (0.930) compared to the native (0.988), yet still within a favorable range for recombinant production. While these in silico values provide valuable preliminary insights, we acknowledge that solubility, stability, and functional activity under serum-mimicking conditions, physiological pH, and physiological ionic strength can differ from computational predictions. Therefore, future work will experimentally evaluate these properties under biologically relevant conditions to confirm the in silico findings and assess their implications for therapeutic deployment.

Secondary structure, solvent accessibility, and helical wheel prediction

Prediction of the secondary structure of engineered peptide was evaluated using the JPred tool. The analysis revealed a structure composed of alpha-helical (H) and coil (-) regions, with three to four distinct helical segments interspersed among coil regions (Fig. 2). No extended beta-sheet (E) structures were predicted.

JPred secondary structure prediction. The JNETCONF track displays confidence scores (ranging from 0 to 9), with taller black bars indicating high confidence in the assigned structural predictions. Secondary structure predictions from JNETSOL25, JNETSOL0, JNETHMM, JNETPSSM, and JNETJURY identify regions assigned as coils (C), alpha helices (H), and beta strands (B). Alpha-helical areas are highlighted with red horizontal bars, while coils and beta-strands are denoted by the letter’s ‘C’ and ‘B’, accompanied by underlined dashes, respectively. Dashed and dotted lines represent unstructured regions. Black bars indicate predicted solvent accessibility; JNETSOL25 and JNETSOL0 distinguish between buried, exposed, or buried residues within the structure.

As illustrated in Fig. 3, the Schiffer-Edmundson helical wheel model and secondary structure prediction demonstrate that the hydrophobic and hydrophilic residues are arranged on opposite faces of the engineered peptide structure.

From prediction to refinement of 3D structures

The 3D structures of the engineered peptide were modeled using AlphaFold and Robetta servers. Subsequently, all generated models were refined using the Galaxy Refine tool to enhance the quality of the 3D structures. Validation results are presented in Table S1. According to the findings, AlphaFold models displayed high predictive accuracy, while Robetta models demonstrated excellent structural quality. For the AlphaFold predictions, refined model 1 was chosen as the final structure, showing a ProSA Z-score of -1.34 (Fig. 4C) and an ERRAT quality score of 98.46% (Fig. 4E). The Ramachandran plot analysis revealed that 98.5% of residues were in favored regions, 1.5% in allowed regions, and none in outlier regions (Fig. 4A).

A similar validation process was applied to the Robetta models (Table S1), where model 2 was selected based on its superior evaluation metrics, including a ProSA Z-score of -1.66 (Fig. 4D) and an ERRAT quality score of 100% (Fig. 4F). The Ramachandran plot for this model indicated that 98.1% of residues were in favored regions, 1.9% in allowed regions, and 0% in outlier regions (Fig. 4B). These two high-quality 3D models were subsequently selected for MD simulations and comparative analysis with the native Cecropin A template.

Molecular dynamics (MD) simulations

MD simulations were performed using the GROMACS tool to evaluate the engineered peptides’ structural stability. Figure 5 illustrates the optimized 3D structure representations of Cecropin A, Pep A (AlphaFold), and Pep B (Robetta) after MD simulations. A 100 ns MD simulation was conducted to investigate their dynamic behavior in an aqueous environment.

As shown in Fig. 6A, the root means square deviation (RMSD) values for the native peptide exhibited consistent fluctuations during the first 30 ns, followed by a gradual increase to approximately 10 Å, stabilizing around 70 ns. Notably, the RMSD values for Pep A increased significantly during the initial 20 ns, reaching around 25 Å, and then stabilized with minimal fluctuations. In contrast, the RMSD profile for Pep B showed upward fluctuations during the first ~ 40 ns, reaching 20 Å, and remained stable at this level until the end of the simulation.

In addition, root mean square fluctuation (RMSF) analysis was performed to evaluate residue fluctuations. As illustrated in Fig. 6B, the RMSF plot for Pep A generally displayed lower average fluctuations compared to Pep B, particularly around the linker regions (residues 13–17 and 55–59) and the engineered segment (residues 60–75). These findings are consistent with the RMSD results, suggesting that Pep A exhibits higher overall structural stability. Notably, the template segment (residues 18–54) in Pep A exhibited lower RMSF values than in both Pep B and the original Cecropin template, indicating better preservation of the native core structure. In contrast, Pep B showed greater flexibility in its linker and engineered regions, which may contribute to its comparatively higher overall RMSD and potentially less stable conformation.

The Rg plot was analyzed to assess the overall size and shape of the peptides throughout the simulation. According to the results, the Rg value of Pep B decreased from approximately 3 nm to 1.5 nm during the first 36 ns (Fig. 6C) and remained stable at this level until the end of the simulation, indicating that the peptide adopted a more compact conformation. A similar compaction process was observed for both Pep A and the native form, but they achieved compactness more rapidly, within the first 10 and 5 ns, respectively (Fig. 6C). However, the Rg plot of the native form displayed moderate fluctuations over time. Overall, the native form exhibited greater compaction by the end of the simulation compared to Pep A and Pep B. This can be attributed to the absence of additional peptide sequences, such as the linker, EAK16-II, and MTP sequences, present in the engineered peptides, resulting in a smaller overall size and simpler structure. Since Rg and SASA analyses are positively correlated, the native form exhibited the lowest solvent-accessible surface area, consistent with its more compact structure (Fig. 6D).

As shown in Fig. 7A, the native Cecropin exhibited relatively limited motion, ranging from − 2 to 2 on the PC1 axis (range = 4) and from − 1.2 to ~ 0.8 on the PC2 axis (range = 2). The PCA analysis of Pep A indicates that it undergoes minimal large-scale motion or conformational changes, whereas Pep B displays greater dynamic behavior with more pronounced structural fluctuations (Fig. 7B, C). Based on the Rg and SASA analyses, Pep A demonstrated greater compactness and reduced structural fluctuations compared to Pep B.

Principal component analysis (PCA) of native Cecropin (A), Pep A (B), and Pep B (C). The PCA results show that Pep A’s motion range closely aligns with Cecropin’s, indicating structural stability, while Pep B exhibits broader ranges along the first two principal components, reflecting greater conformational flexibility. Pep A demonstrates superior structural integrity compared to Pep B.

These findings indicated that Pep A exhibits greater structural stability and reduced solvent exposure compared to Pep B, making it the most stable among the engineered peptides. Time-resolved plots of hydrogen bonds were generated for the native and the two engineered peptides. The native peptide consistently formed fewer hydrogen bonds, averaging around 20 throughout the simulation. In contrast, both Pep A and Pep B formed approximately twice as many hydrogen bonds as in the native (Fig. 8).

Evaluating the effect of in silico mutagenesis on cecropin A

Application of the CUPSAT server

To evaluate the effect of point mutations on the structure and stability of Cecropin A, the CUPSAT server was used to introduce point mutations within the mature peptide sequence. Mutation sites within three distinct regions of Cecropin A, i.e., surface-accessible residues, flexible residues, and non-critical residues, were identified based on key structural and functional features. The sequence segment analyzed was KWKLFKKIEKVGQNIRDGIIKAGPAVAVVGQATQIAK.

As detailed in Table 2, mutations were introduced at the surface-accessible lysine residues at positions 3 (K3) and 10 (K10). These residues exhibited high solvent accessibility and are positioned within the helical regions of the peptide, as supported by torsion angles consistent with alpha-helical structures. K3 displayed a high solvent accessibility of 89.45%, with torsion angles of -53.9° and − 67.1°, indicating it is highly flexible and surface-exposed. Mutational analysis predicted substituting K3 with leucine or glutamine would significantly improve the peptide’s stability. Similarly, K10 exhibited a solvent accessibility of 63.2% and torsion angles of -65.4° and − 58.7°, supporting its location within a helical region. Mutations at K10, particularly to isoleucine, also enhanced stability, suggesting favorable energetic changes (Table 2). These results collectively demonstrate that selective mutation of surface-exposed lysine residues, particularly those in helical segments like K3 and K10, can improve the structural stability of Cecropin A. The findings highlight the importance of solvent accessibility and torsional flexibility in guiding mutation strategies for stability enhancement.

Mutations introduced at flexible residues, specifically glycine at positions 12 (G12) and 18 (G18), were also evaluated to assess their impact on peptide stability (Table 2). Glycine’s inherent flexibility contributes to the dynamic nature of the peptide, and modifying these sites was aimed at enhancing structural stability. Substituting glycine with more rigid and Stabilizing residues such as alanine, valine, or leucine is predicted to improve the peptide’s structural robustness while potentially modulating its dynamic behavior. These results suggest that targeted replacement of flexible residues with stabilizing amino acids may enhance overall peptide stability without significantly impairing necessary conformational flexibility.

Alanine residues at positions 22 (A22) and 25 (A25) were identified as non-critical for maintaining the core structure of the peptide (Table 2). These sites could accommodate non-disruptive mutations without compromising overall peptide stability. As a result, substitutions at these positions were expected to have minimal structural impact, enabling functional modifications. Additionally, the solvent accessibility of wild-type alanine at position 25 was 81.67%, indicating that it is likely surface-accessible and flexible, further supporting its suitability for mutation without significant structural consequences.

Application of MUpro server

To investigate the impact of specific residues on the stability and structural flexibility of cecropin, we introduced point mutations at four positions using the MUpro server. The substitution of lysine (K) at position 10 with valine (V) resulted in a ΔΔG value of 0.036 kcal/mol, indicating a slight increase in protein stability, with a confidence score of 0.00783. Similarly, replacing glycine (G) at position 12 with leucine (L) yielded a more substantial ΔΔG value of 0.306 kcal/mol, suggesting increased stability, supported by a confidence score of 0.542. These findings demonstrated the potential Stabilizing effects of specific amino acid substitutions in the peptide sequence. At position 22, substituting alanine (A) with isoleucine (I) resulted in a ΔΔG value of 0.147 kcal/mol, indicating a moderate increase in stability with a confidence score of 0.132. Likewise, at position 25, replacing alanine (A) with valine (V) produced a ΔΔG value of 0.163 kcal/mol, reflecting an increase in stability supported by a higher confidence score of 0.57. Collectively, these results highlight the Stabilizing potential of these specific mutations, as predicted by support vector machine (SVM) models based on sequence data.

Discussion

Cecropin A is a promising antimicrobial peptide, but its application is limited by stability, solubility, and bioavailability issues. To address this, different functional segments were incorporated: self-assembling EAK16-II at the C-terminal, MTP sequences at the N-terminal, and a rigid EAAAK linker between domains. The linker forms a stable alpha-helix that separates domains, preventing steric interference and maintaining function45. By keeping domains apart, it helps ensure that each domain folds correctly without being sterically hindered or disrupted by neighboring domains46.The engineered peptide showed improved physicochemical properties, including predicted non-toxicity, enhanced solubility, and higher net positive charge, which may strengthen interactions with bacterial membranes. Although the instability index increased (30.88), it remained within the stable range (< 40). Notably, the solubility of the engineered peptide upon overexpression was significantly improved, which not only facilitates its formulation for medical use but also supports its efficient production in bacterial systems. The lower aliphatic index (72.00 vs. 108.11) still indicated structural rigidity and adaptability47while higher solubility supports recombinant production and eco-friendly large-scale applications48.

In peptide engineering, modifying solubility and half-life is key for optimizing pharmacological performance. Short half-life reduces systemic accumulation and toxicity49,50whereas poor solubility promotes aggregation—sometimes desirable for hydrogel formation but usually detrimental to bioavailability51. Balancing these properties without compromising activity or inducing immunogenicity remains a major challenge52,53. The Schiffer-Edmundson helical wheel confirmed an amphipathic structure, supporting interactions with membranes and aqueous environments. In addition to improved physicochemical properties and lack of predicted toxicity, the appended segments may further enhance stability and delivery potential. Previously, it has been reported that MTPs facilitate intestinal transcytosis and mucosal immune responses54,55,56. Furthermore, EAK16-II, known for its amphiphilic and self-assembling properties, stabilizes therapeutic agents by forming nanostructures that protect against degradation and enable sustained release. For example, EAK16-II has been used to encapsulate ellipticine, improving its stability, therapeutic efficacy, and cellular uptake57,58. Additionally, the inclusion of a rigid EAAAK linker maintains structural separation between functional domains, ensuring optimal biological activity59.

AMPs such as Cecropin A provide versatile scaffolds for developing multifunctional agents34,35. Structural modifications (e.g., glycine substitutions, amidation, or D-amino acid incorporation) improve protease resistance and bioactivity13while MTPs are widely used in drug delivery and vaccine design due to their potential to target M cells and exploit immune surveillance mechanisms55,60.

Here, 3D models generated by AlphaFold and Robetta confirmed high structural quality, with most residues in favored Ramachandran regions, ERRAT scores > 90, and acceptable ProSA Z-scores. AlphaFold-derived Pep A was superior across evaluations. MD simulations confirmed structural stability of Pep A and Pep B, with Pep A equilibrating faster, displaying lower residue fluctuations, more stable hydrogen bonding, and compact folding (Rg ~ 14.5Å). Its SASA stabilized after initial rearrangement, while Pep B showed greater fluctuations, indicating reduced stability. PCA further demonstrated Pep A maintained stability comparable to native Cecropin, with limited flexibility and the highest average hydrogen bond count. Collectively, these results identify Pep A as the most stable construct. However, this work has focused on improving peptide solubility and stability through rational sequence modifications. While membrane interaction modelling (e.g., lipid bilayer simulations) would be valuable for confirming retention of membrane-disruptive activity, future studies can incorporate membrane-binding and disruption modelling, as well as experimental assays, to evaluate whether the engineered modifications affect the peptide’s membrane-targeting properties.

To further optimize performance, point mutations were introduced at surface-accessible residues, enhancing stability through favorable energetic contributions. Previous studies support such strategies: tryptophan or phenylalanine substitutions increase protease resistance and membrane affinity61,62; D-amino acid replacement enhances serum and in vivo stability63; and non-natural amino acids improve cell penetration while reducing cytotoxicity64. Charge modifications with lysine or arginine strengthened electrostatic interactions65while hydrophobic substitutions optimized amphipathic helices for selectivity and membrane disruption66.

In summary, integration of MTP, EAK16-II, and EAAAK into Cecropin A produced Pep A, a multifunctional analog with significantly enhanced solubility, folding, and structural stability, confirmed by computational analyses. These improvements make Pep A as a strong candidate for advanced antimicrobial applications. While this work focused on computational modeling, future studies will incorporate membrane-binding simulations and experimental validation (e.g., TEM, DLS) to confirm biological activity.

Conclusion

This study presents a rationally engineered version of Cecropin A by incorporating M cell-targeting sequences (MTP), a self-assembling EAK16-II domain, and a rigid EAAAK linker to possibly enhance its antimicrobial efficacy, stability, and mucosal delivery. Bioinformatic and molecular dynamics analyses demonstrated improved physicochemical properties, structural stability, and solubility, with Pep A showing the most favorable profile. Structural modeling confirmed proper folding and amphipathic nature, while targeted amino acid substitutions further enhanced protease resistance and functional performance. These results highlight the potential of peptide engineering in improving therapeutic peptides; however, experimental validation is necessary to confirm the computational predictions.

Data availability

All the data generated or analyzed during this study are available in the manuscript.

Abbreviations

- AMPs:

-

Antimicrobial peptides

- Pep A:

-

Peptide A

- Pep B:

-

Peptide B

- MDR:

-

Multidrug-resistant

- MTP:

-

M cell-targeting peptides

- SDM:

-

Site-directed mutagenesis

- MD:

-

Molecular dynamics

- PME:

-

Particle Mesh Ewald

- ΔΔG:

-

Gibbs free energy

- RMSD:

-

Root means square deviation

- RMSF:

-

Root means square fluctuation

- SVM:

-

Support vector machine

- CPE:

-

Claudin-4-specific peptides

- SASA:

-

Solvent-accessible surface area

- PCA:

-

Principal component analysis

- MW:

-

Molecular weight

- pI:

-

Theoretical isoelectric point

- GRAVY:

-

Grand average of hydropathicity

- PDB:

-

Protein Data Bank

References

Taghizadeh, M. S. et al. Discovery of the cyclotide Caripe 11 as a ligand of the cholecystokinin-2 receptor. Sci. Rep. 12, 9215 (2022).

Taghizadeh, M. S., Niazi, A., Retzl, B. & Gruber, C. W. Unveiling the insecticidal efficiency of Viola ignobilis against Macrosiphum rosae and Agonoscena pistaciae: from chemical composition to cytotoxicity analysis. Heliyon 10 (2024).

Bucataru, C. & Ciobanasu, C. Antimicrobial peptides: opportunities and challenges in overcoming resistance. Microbiol. Res. 286, 127822 (2024).

Gholami, A. A. et al. Applying RSM for optimization of ferula assafoetida protein hydrolysis to enhance bioactivity and functional properties. Appl. Food Res. 100915 (2025).

Luo, X. et al. Advancements, challenges and future perspectives on peptide-based drugs: focus on antimicrobial peptides. Eur. J. Pharm. Sci. 181, 106363 (2023).

Brady, D., Grapputo, A., Romoli, O. & Sandrelli, F. Insect cecropins, antimicrobial peptides with potential therapeutic applications. Int. J. Mol. Sci. 20, 5862 (2019).

Yi, H. Y., Chowdhury, M., Huang, Y. D. & Yu, X. Q. Insect antimicrobial peptides and their applications. Appl. Microbiol. Biotechnol. 98, 5807–5822 (2014).

Shaik Mohideen, H. & Louis, H. P. Insect antimicrobial peptides–therapeutic and agriculture perspective. J. Appl. Biotechnol. Rep. 8, 193–202 (2021).

Dho, M., Candian, V. & Tedeschi, R. Insect antimicrobial peptides: advancements, enhancements and new challenges. Antibiotics 12, 952 (2023).

Manniello, M. et al. Insect antimicrobial peptides: potential weapons to counteract the antibiotic resistance. Cell. Mol. Life Sci. 78, 4259–4282 (2021).

Hashemi, S., Niazi, A., Baghizadeh, A. & Taghizadeh, M. S. Successful use of Nicotiana tabacum hairy roots for the recombinant production of Cecropin A peptide. Biotechnol. Appl. Chem. 69, 876–886 (2022).

Wang, C., Hong, T., Cui, P., Wang, J. & Xia, J. Antimicrobial peptides towards clinical application: delivery and formulation. Adv. Drug Deliv. Rev. 175, 113818 (2021).

Torres, M. D., Sothiselvam, S., Lu, T. K. & de la Fuente-Nunez, C. Peptide design principles for antimicrobial applications. J. Mol. Biol. 431, 3547–3567 (2019).

Lin, C. Y. & Liu, J. C. Modular protein domains: an engineering approach toward functional biomaterials. Curr. Opin. Biotechnol. 40, 56–63 (2016).

Guo, L. et al. Oral immunization with a M cell-targeting recombinant L. lactis vaccine LL-plSAM-FVpE stimulate protective immunity against H. pylori in mice. Front. Immunol. 13, 918160 (2022).

Mirzapour-Kouhdasht, A., McClements, D. J., Taghizadeh, M. S., Niazi, A. & Garcia-Vaquero, M. Strategies for oral delivery of bioactive peptides with focus on debittering and masking. Npj Sci. Food. 7, 22 (2023).

Abbasi, A. et al. A comprehensive insight into ultrasound-assisted protein extraction from camelina sativa and de-bittering of resulting hydrolysates with emphasis on their structural, physicochemical, sensory, and biological properties. Food Chem. 492, 145435 (2025).

Armen, J. M. et al. Chemically-induced cross‐linking of peptidic fibrils for scaffolding polymeric particles and macrophages. Macromol. Biosci. 21, 2000350 (2021).

La Manna, S., Di Natale, C., Onesto, V. & Marasco, D. Self-assembling peptides: from design to biomedical applications. Int. J. Mol. Sci. 22, 12662 (2021).

Moghadam, A. et al. Exploring novel insights: Methyl jasmonate treatment reveals novel lncRNA-mediated regulation of secondary metabolite biosynthesis pathways in Echinacea purpurea. Food Bioscience. 57, 103457 (2024).

Zhang, Q. Y. et al. Antimicrobial peptides: mechanism of action, activity and clinical potential. Military Med. Res. 8, 1–25 (2021).

Watanabe, S., Ito, M. & Kigawa, T. DiRect: Site-directed mutagenesis method for protein engineering by rational design. Biochem. Biophys. Res. Commun. 551, 107–113 (2021).

Chang, L., Mondal, A. & Perez, A. Towards rational computational peptide design. Front. Bioinf. 2, 1046493 (2022).

Lotfi, M. et al. Optimizing camelina sativa oil extraction and its cytotoxicity using RSM by emphasis on antioxidant properties, physical characteristics, and molecular docking insights. Ind. Crops Prod. 224, 120334 (2025).

Taghizadeh, M. S., Niazi, A., Moghadam, A. & Afsharifar, A. Experimental, molecular docking and molecular dynamic studies of natural products targeting overexpressed receptors in breast cancer. PloS One. 17, e0267961 (2022).

Morozov, V., Rodrigues, C. H. & Ascher, D. B. CSM-toxin: a web-server for predicting protein toxicity. Pharmaceutics 15, 431 (2023).

Gasteiger, E. et al. ExPASy: the proteomics server for in-depth protein knowledge and analysis. Nucleic Acids Res. 31, 3784–3788 (2003).

Magnan, C. N., Randall, A. & Baldi, P. SOLpro: accurate sequence-based prediction of protein solubility. Bioinformatics 25, 2200–2207 (2009).

Magnan, C. N. & Baldi, P. SSpro/ACCpro 5: almost perfect prediction of protein secondary structure and relative solvent accessibility using profiles, machine learning and structural similarity. Bioinformatics 30, 2592–2597 (2014).

Cole, C., Barber, J. D. & Barton, G. J. The Jpred 3 secondary structure prediction server. Nucleic Acids Res. 36, W197–W201 (2008).

Mol, A. R., Castro, M. S. & Fontes, W. NetWheels: A web application to create high quality peptide helical wheel and net projections. BioRxiv, 416347 (2018).

Kim, D. E., Chivian, D. & Baker, D. Protein structure prediction and analysis using the Robetta server. Nucleic Acids Res. 32, W526–W531 (2004).

Bryant, P., Pozzati, G. & Elofsson, A. Improved prediction of protein-protein interactions using AlphaFold2. Nat. Commun. 13, 1265 (2022).

Lee, G. R., Won, J., Heo, L. & Seok, C. GalaxyRefine2: simultaneous refinement of inaccurate local regions and overall protein structure. Nucleic Acids Res. 47, W451–W455 (2019).

Heo, L., Park, H. & Seok, C. GalaxyRefine: Protein structure refinement driven by side-chain repacking. Nucleic Acids Res. 41, W384–W388 (2013).

Colovos, C. & Yeates, T. O. Verification of protein structures: patterns of nonbonded atomic interactions. Protein Sci. 2, 1511–1519 (1993).

Laskowski, R. A., MacArthur, M. W., Moss, D. S. & Thornton, J. M. PROCHECK: a program to check the stereochemical quality of protein structures. Appl. Crystallogr. 26, 283–291 (1993).

Wiederstein, M. & Sippl, M. J. ProSA-web: interactive web service for the recognition of errors in three-dimensional structures of proteins. Nucleic Acids Res. 35, W407–W410 (2007).

Taghizadeh, M. S., Taherishirazi, M., Niazi, A., Afsharifar, A. & Moghadam, A. Structure-guided design and cloning of peptide inhibitors targeting CDK9/cyclin T1 protein-protein interaction. Front. Pharmacol. 15, 1327820 (2024).

Kaminski, G. A., Friesner, R. A., Tirado-Rives, J. & Jorgensen, W. L. Evaluation and reparametrization of the OPLS-AA force field for proteins via comparison with accurate quantum chemical calculations on peptides. J. Phys. Chem. B. 105, 6474–6487 (2001).

Shahraki, Z., Taghizadeh, M. S., Niazi, A., Rowshan, V. & Moghadam, A. Enhancing bioactive compound production in salvia Mirzayanii through elicitor application: insights from in vitro and in Silico studies. Food Bioscience. 60, 104185 (2024).

Li, X., Chen, S., Zhang, W. D. & Hu, H. G. Stapled helical peptides bearing different anchoring residues. Chem. Rev. 120, 10079–10144 (2020).

Parthiban, V., Gromiha, M. M. & Schomburg, D. CUPSAT: prediction of protein stability upon point mutations. Nucleic Acids Res. 34, W239–W242 (2006).

Cheng, J., Randall, A. & Baldi, P. Prediction of protein stability changes for single-site mutations using support vector machines. Proteins Struct. Funct. Bioinform. 62, 1125–1132 (2006).

Lee, T. et al. Engineering of long-acting human growth hormone-Fc fusion proteins: effects of valency, fusion position, and linker design on pharmacokinetics and efficacy. PLoS One. 20, e0323791 (2025).

George, R. A. & Heringa, J. An analysis of protein domain linkers: their classification and role in protein folding. Protein Eng. 15, 871–879 (2002).

Singh, S., Biswas, S., Srivastava, A., Mishra, Y. & Chaturvedi, T. P. In silico characterization and structural modeling of a homeobox protein MSX1 from homo sapiens. Inf. Med. Unlocked. 22, 100497 (2021).

Taghizadeh, M. S., Niazi, A., Mirzapour-Kouhdasht, A., Pereira, E. C. & Garcia-Vaquero, M. Enhancing cyclotide bioproduction: Harnessing biological synthesis methods and various expression systems for large-scale manufacturing. Crit. Rev. Biotechnol. 1–23 (2024).

Lee, M. F. & Poh, C. L. Strategies to improve the physicochemical properties of peptide-based drugs. Pharm. Res. 40, 617–632 (2023).

Al Musaimi, O., Lombardi, L., Williams, D. R. & Albericio, F. Strategies for improving peptide stability and delivery. Pharmaceuticals 15, 1283 (2022).

Sarma, R., Wong, K. Y., Lynch, G. C. & Pettitt, B. M. Peptide solubility limits: backbone and side-chain interactions. J. Phys. Chem. B. 122, 3528–3539 (2018).

Baumann, T. et al. Prospects of in vivo incorporation of non-canonical amino acids for the chemical diversification of antimicrobial peptides. Front. Microbiol. 8, 124 (2017).

Kim, S. et al. Discovery of a novel potent peptide agonist to adiponectin receptor 1. PLoS One. 13, e0199256 (2018).

Kim, S. H., Lee, K. Y. & Jang, Y. S. Mucosal immune system and M cell-targeting strategies for oral mucosal vaccination. Immune Netw. 12, 165 (2012).

Singh, B. et al. Combinatorial approach of antigen delivery using M cell-homing peptide and mucoadhesive vehicle to enhance the efficacy of oral vaccine. Mol. Pharm. 12, 3816–3828 (2015).

Lo, D. D., Ling, J. & Holly Eckelhoefer A. M cell targeting by a Claudin 4 targeting peptide can enhance mucosal IgA responses. BMC Biotechnol. 12, 1–9 (2012).

Wu, Y. et al. Self-assembling peptide-based nanoparticles enhance anticancer effect of ellipticine in vitro and in vivo. Int. J. Nanomed. 3221–3233 (2012).

Lee, S. et al. Self-assembling peptides and their application in the treatment of diseases. Int. J. Mol. Sci. 20, 5850 (2019).

Imon, R. R. et al. Computational formulation of a multiepitope vaccine unveils an exceptional prophylactic candidate against Merkel cell polyomavirus. Front. Immunol. 14, 1160260 (2023).

Surwase, S. S. et al. Engineered nanoparticles inside a microparticle oral system for enhanced mucosal and systemic immunity. ACS Appl. Mater. Interfaces. 14, 11124–11143 (2022).

Ji, S., Li, W., Zhang, L., Zhang, Y. & Cao, B. Cecropin A–melittin mutant with improved proteolytic stability and enhanced antimicrobial activity against bacteria and fungi associated with gastroenteritis in vitro. Biochem. Biophys. Res. Commun. 451, 650–655 (2014).

Hitchner, M. A., Necelis, M. R., Shirley, D. & Caputo, G. A. Effect of non-natural hydrophobic amino acids on the efficacy and properties of the antimicrobial peptide C18G. Probiotics Antimicrob. Proteins. 13, 527–541 (2021).

Lu, J. et al. D-and unnatural amino acid substituted antimicrobial peptides with improved proteolytic resistance and their proteolytic degradation characteristics. Front. Microbiol. 11, 563030 (2020).

Sang, M., Zhang, J. & Zhuge, Q. Selective cytotoxicity of the antibacterial peptide ABP-dHC-Cecropin A and its analog towards leukemia cells. Eur. J. Pharmacol. 803, 138–147 (2017).

Arias, M., Piga, K. B., Hyndman, M. E. & Vogel, H. J. Improving the activity of Trp-rich antimicrobial peptides by arg/lys substitutions and changing the length of cationic residues. Biomolecules 8, 19 (2018).

Ablan, F. D., Spaller, B. L., Abdo, K. I. & Almeida, P. F. Charge distribution fine-tunes the translocation of α-helical amphipathic peptides across membranes. Biophys. J. 111, 1738–1749 (2016).

Acknowledgements

The authors express their gratitude to Shiraz University of Medical Sciences for providing support for the execution of this research.

Author information

Authors and Affiliations

Contributions

Navid Nezafat, Cambyz Irajie, contributed to the conception, design, and interpretation of literature data. Samaneh Hashemia, wrote the manuscript. Armin Zarei, and Mohammad Sadegh Taghizadeh, Molecular dynamics analysis. Amir Savardashtaki prepared the figures and tables.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Hashemi, S., Zarei, A., Taghizadeh, M.S. et al. Structure-guided design of a novel, stable, and soluble Cecropin A variant for antimicrobial therapeutic applications. Sci Rep 15, 32836 (2025). https://doi.org/10.1038/s41598-025-18067-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-18067-x