Abstract

The current study assessed the effectiveness of five conventional and three hermetic storage facilities for extended storage of wheat grains under ambient storage conditions during two storage seasons (2023 and 2024). The findings indicated that hermetic storage facilities outperformed conventional ones throughout the six-month storage period. For instance, GrainPro PHB exhibited the minimal increase in grain moisture contents (0.50 and 0.33%), resulting in the least grain damage (2.38 and 2.44%) and weight loss (0.93 and 0.93%) during both years, respectively. Additionally, GrainPro PHB recorded the highest seed germination (90.50 and 90.33%) for both years. Compared to conventional storage methods, GrainPro PHB exhibited a lower number of storage insects. The proximate composition analysis revealed significant nutritional differences between polypropylene bags and GrainPro PHB. GrainPro PHB successfully maintained proximate composition, with minimal decreases in protein (1.03 and 0.71%), fat (16.88 and 14.95%), and starch content (0.8 and 0.5%) and minimal increases in ash (25.00 and 23.33%) and fiber contents (18.33 and 16.80%) in both years. Moreover, results revealed a positive correlation between grain moisture contents and damage parameters, suggesting that the higher moisture contents may aggravate the percent grain damage and weight loss. There were also better rheological properties in flour made from grains stored in GrainPro PHB, like a lower minimum water absorption capacity (WAC), a longer dough development time (DDT), and a maximum dough stability time (DST). Furthermore, texture profile analysis (TPA) of bread made from flour of grains stored in GrainPro PHB showed improved texture, with higher chewiness, cohesiveness, springiness, and resilience, and lower hardness, resulting in superior overall quality compared to bread made from conventionally stored grains. Eventually, these findings underscore the effectiveness of hermetic storage facilities in maintaining grain moisture contents, reducing losses, preserving seed quality, and enhancing food and nutrition security.

Similar content being viewed by others

Introduction

Cereal grains are the significant component of global food security, providing a vital source of nutrition for human consumption and animal feed1,2. They are key sources of essential nutrients, including proteins, vitamins, and minerals like iron, zinc, and fiber3,4. Besides these, grains also play a vital role in the economic stability of a country by generating valuable revenue through domestic trade and global exports5. It is estimated that, the world population will increase significantly by 2050, requiring a 50–70% increase in food production to meet the growing demand6,7. Thus, sustainable agriculture not only involves increasing grain production for a growing population but also preserving the grains to ensure food and nutrition security2.

Postharvest losses constitute a significant global issue with approximately one-third of the global food production which is equivalent to 1.3 billion tons, lost every year8. These losses result from factors such as pest infestations, inadequate storage, and unfavorable environmental conditions, leading to significant damage to valuable agricultural products9. Usually, in smallholder systems, farmers let their grain dry in the field, which may result in insect infestation10,11. In most parts of the world, there is a gap of 7–8 months between harvest and new crop season, which requires the seed to be stored in adequate conditions to avoid quality losses12. From production to consumption, grains undergo multiple stages, including harvesting, threshing, transport, and storage, during which improper handling can result in significant losses10,13. One major factor contributing to storage losses is elevated moisture content in the seeds, which creates favorable conditions for the proliferation of insects and microorganisms, ultimately reducing seed viability and quality during storage14,15.

Postharvest management plays a significant role in preserving agricultural commodities from deterioration16. The knowledge of grain handling, safe storage, facility management, and quality control procedures can be used to mitigate quality loss in stored grains17. Moreover, different insect and mite species are responsible for grain damage in many stored products causing serious qualitative and quantitative losses18,19. Common stored grain insect pests i.e., the lesser grain borer, Rhyzopertha dominica (F.) (Coleoptera: Bostrichidae), the khapra beetle, Trogoderma granarium E. (Coleoptera: Dermestidae) and the red flour beetle, Tribolium castaneum (H.) (Coleoptera: Tenebrionidae), cause severe physical damage and contamination of grains20,21,22. Grain mites such as Acarus and Rhizoglyphus species, also cause damage in warm, humid conditions by causing clumping, fungal growth, and unpleasant odors19. Apart from the direct damage to grains, infestations by these biotic factors also impact the rheological and technological properties of wheat flour, particularly for bread making23,24. Moreover, infested grains often lead to reduced germination rates, increased moisture content, loss of nutritional quality, and the presence of extraneous matter in stored products, rendering the grain unfit for consumption or germination18,25.

Conventional storage facilities such as mud bins, steel bins, gunny bags, cotton cloth bags, and polypropylene (PP) bags are commonly used for grain storage26. Although these structures are cost-effective and readily available, they offer limited protection against stored grain pests, leading to significant post-harvest losses27. Use of chemical fumigants has been a prominent method of controlling pests and microorganisms in stored grain28. However, the reliance on chemical insecticides poses several hazardous effects on human health and the environment. Unwise and injudicious use of these chemicals can cause contamination of the grains, leading to food safety concerns for consumers29,30. Furthermore, major pests of stored grain are developing resistance against these pesticides31,32,33. The need for safer and more sustainable solutions has led the researcher to find environment-friendly alternatives that are safer for the environment and compatible with human health30,34.

Effective postharvest pest management through proper storage practices can significantly reduce postharvest losses and ensure the long-term preservation of grain quality35. In recent years, hermetic storage as an alternative to conventional and chemical control methods has gained considerable attention among farmers, the private sector, governments, and development agencies36. These technologies provide pesticide-free, effective grain protection against storage insect pests. Moreover, hermetic bags prevent insect entry, further reducing the risk of infestation and preserving grain quality over extended storage periods37. Hermetic storage facilities rely on the principle of oxygen depletion with a corresponding rise in carbon dioxide (CO2) which is lethal to many grain pests, without the use of harmful chemicals or pesticides38. Most of these studies have shown that hermetic bags are able to maintain a constant relative humidity inside bags regardless of the outside environment39.

Although various studies have demonstrated the effectiveness of hermetic storage in suppressing insect infestation, maintaining moisture content, and preserving grain quality; there is a lack of comprehensive comparative studies evaluating the long-term performance of hermetic and conventional storage structures under ambient storage conditions, particularly with respect to their combined effects on pest dynamics, grain quality, and the functional and technological properties of wheat flour and its suitability for bread production. This study addresses that gap by adopting a multidimensional approach that evaluate storage performance under realistic, ambient conditions over a two-year period and examines its impact on flour quality and final product rheology, including dough and bread characteristics. By integrating physical, chemical, and baking quality analyses, this research provides a comprehensive understanding of how storage practices influence the entire value chain from raw grain to finished bread, an area that remains underexplored in current literature. Therefore, the present investigations were carried out to assess the effectiveness of various conventional and hermetic storage facilities for the long-term preservation of wheat under natural conditions.

Materials and methods

Experimental details

Storage field trials were conducted for six months (from May 1st to October 31st) in farmer’s store-room during two grain storage seasons i.e., 2023 and 2024, at Bahawalpur (BWP), Pakistan; located at 29.3544° N, 71.6911° E and an elevation of 143 m above sea level. On the chosen experimental site, the storage room was rectangular, constructed from burnt clay bricks, floors and walls plastered with cement and had a concrete roof. The facility had one steel door (3 × 6 ft. W × H), which was always kept closed, and a window (3 × 3 ft. W × H) for proper ventilation. The overall environmental condition of BWP is hot and dry with mean minimum and maximum temperature of (min. 20.34; max. 31.58), 32.77% relative humidity (r.h.), and average precipitation of 143 mm. Temperature and relative humidity data were daily recorded during the experiment using a data logger (AcuRite Indoor Temperature and Humidity Monitor, Model; 00215CA) placed in a corner of the store room.

Description of evaluated storage facilities

Storage bins

Two types of grain storage bins, i.e., steel bins and mud bins (Fig. 1), were used in this study to evaluate the moisture content and damage patterns of different stored grain insect pests and mites in these storage facilities. Steel bins were prepared by local blacksmith; made up of 24-gauge galvanized steel sheets with removable lid closures at the top fixed with riveted hinges, each having 762 mm height, and 254 mm diameter contained approximately 10–12 kg of wheat. Mud bins (762 × 305 mm, H × D) were constructed manually by artisans from mud reinforcement using straws and covered with a mud-made lid with 10 kg storage capacity. These storage bins were placed in a non-climate controlled room, covered on all sides, and naturally ventilated.

Storage bags

Different types of conventional storage bags, i.e., cotton cloth bags, polypropylene (PP) bags and jute bags were purchased from the local grain market. Hermetic plastic bags e.g., GrainPro Premium Hermetic Bags (PHB); (five layers) and GrainPro Super Hermetic Bags (SHB); (triple layers) were provided by Haji Sons Pvt. Ltd., while University of Agriculture, Faisalabad (UAF) Hermetic Bags (HB); (five-layers) were purchased from the Department of Agronomy, UAF. The storage capacity of all these bags ranged from 50–60 kg. To reduce the cost of the study, resized bags (10 kg capacity) were used and the bags were cut into smaller size and sealed using an impulse sealer and a heat-sealing process for hermetic plastic bags, while the bags made up of cotton cloth, polypropylene and jute were reduced to the same size using machine-assisted needlework to ensure that there are no external holes. Before storage, each bag was thoroughly checked for holes and sealing defects40,41. The non-hermetic bags were sealed with jute twine while the hermetic bags were sealed with a plastic strip seal.

Wheat grains

All the storage structures including storage bins and bags, were filled with a freshly harvested Zn-biofortified wheat cultivar i.e., Akbar-2019. The selection of the grain cultivar for the study was based on common farming practices in the area. Wheat grains were purchased from the local grain market of BWP, and an initial moisture content (MC) of 17% was recorded using a moisture meter (MC-7821). Prior to storage, the grains were sun-dried to reduce the MC to 12%, which is an ideal MC for the storage of grains. Afterwards, grains were cleaned and screened using sieves with 2.5 to 5 mm mesh size, depending on grain size, to remove impurities, crop residues, and broken grain fragments. The wheat grains were then divided, on a plastic sheet, into 40 kg portions to enable 4 × 10 kg replicates per treatment to be set up in each storage structure.

Storage methodology and sampling

Eight different grain storage facilities replicated four times were set up under a Completely Randomized Design (CRD) without any chemical treatment or fumigation of wheat grain, and with no artificial infestation of insects. The storage bins and bags containing wheat seeds (10 kg each) were kept in the farmer’s store-room during both observation years for a period of six months (May to October) at ambient storage conditions. Sampling of the wheat grains was conducted at 30-day intervals. Samples were collected carefully using 1 m long stainless steel multi-compartmented sampling spears to avoid puncturing the hermetic liners. The sampling spears were disinfected between collections of samples from different treatments to avoid cross-contamination. At the end of the experiment, samples were taken in the stored product laboratory, Department of Entomology, FA&E, The Islamia University of Bahawalpur, to assess grain damage, weight loss, adult insects and mites count (live) and grain MC.

Determination of moisture content (%)

MC of grains was determined to investigate its correlation with the levels of insect infestation. For this purpose, MC of grains was measured before and after infestation. All the MC determinations in the study were made on wet basis using standard42 Method No. 930.15. For this purpose, 20 g grain samples from each treatment were ground using a hand-crank disc mill (SKU: V015.LC-80), then weighed on an analytical weighing balance (ELB 300, Shimadzu, Kyoto, Japan) and transferred to a pre dried covered dish. Each weighed sample was dried in an air oven at 100 ± 2 °C for 3 h. Dried samples were transferred to a desiccator, cooled to room temperature, and weighed. MC was measured as the loss in weight divided by the original wet sample weight. This process was repeated twice for each storage structure.

Grain damage (%) and weight loss (g)

For determination of percent grain damage and weight loss, 20 g grain samples from each replication of each treatment were collected for assessment. Numbers of grains per 20 g were counted and analyzed for grain damage by manually separating and counting the damaged and undamaged grains. Grains that had been pierced by insect pests were referred to as damaged grains. The process was repeated at 60-day intervals until the end of the experiment. The following formula was used to determine the percentage grain damage:

For assessment of weight loss, the number and weight of damaged and undamaged grains were recorded. Afterwards, these findings were put into a formula devised by43

where,

Nd = total number of damaged grains.

Nu = total number of undamaged grains.

Wu = weight of undamaged grains.

Wd = weight of damaged grains.

Frass weight (g)

While determining weight loss, the weight of exuviae, grain dust, dead as well as alive adult and immature stages of insect species and those of other excretions produced during infestation were measured and collectively termed as the frass weight of the respective sample of each treatment. Following this, insects produced dust was separated from the grain by passing the grain samples through a fine sieve (1–2 mm mesh) to allow frass and smaller dust particles to fall through and were weighed on an analytical weighing balance.

Germination test (%)

The percentage of damaged embryo seeds was assessed by analyzing the seed samples from four replications under a stereo microscope. The number of damaged seeds was recorded, and the percentage was calculated using the formula:

Seed germination was tested by placing four replications of 150 seeds, from randomly drawn seed samples from each treatment, in sterilized and moistened blotting paper, in a plant growth chamber (Panasonic Japan, MLR-352H-PE) at 25 °C, 90% r.h., and a photoperiod of 8: 16 (L: D) hrs44. The germination percentage reported indicates the proportion by number of seed which have produced normal seedlings assessed on the 5th and the 8th day after the test installation. Germination percentage was calculated by using the following formula:

Germination index (GI) was calculated as described by45 using formula:

Germination energy (%) was recorded by counting the number of seedlings germinated the fifth day after the start of germination.

Density of adult insects and mites

For counting live adults of insects and mites, 100 g composite grain samples were drawn at random from each storage facility and were put in bowls. Grain samples were sieved to separate grains and insects. Live insects were sorted by species and then counted manually for assessment of live insect populations. For evaluating the mite population, 100 g grain samples were collected from each storage treatment. All these samples were packed in Plastic Lid Bags and brought to the Insect Taxonomy Laboratory, Bahauddin Zakariya University, Multan for the identification of different mite species in stored grain samples.

Proximate composition analysis

All proximate composition components, i.e., crude ash, fiber, protein, fat and starch content were evaluated according to the standard procedures described in AACC International method46. The ash content was resolved as a whole inorganic material according to AACC International method46 method No. 08–01. Oven-dried 5 g sample was ignited in a muffle furnace at 550–600 ºC for 4–5 h until complete combustion occured. After incineration, the residue is cooled in a desiccator and weighed. Crude fiber contents were assessed according to AACC International method46 method No. 32–10, also known as Enzymatic–Gravimetric Method. In this process, 5 g samples were subjected to a series of enzymatic treatments (α-amylase, protease, and amylglucosidase) followed by filtration to separate soluble and insoluble fiber. Soluble fiber was precipitated with ethanol and the final fiber content was calculated.

The content of crude protein in grain specimens was evaluated by Kjeldahl method as described in AACC International method46 method No. 46–10. 5 g of grain samples from each treatment were digested in 25 ml conc. H2SO4 with a catalyst, K2SO4 till the material attained transparent or light green color. Following that, the solution was distilled with 40% NaOH solution with the help of distillation apparatus. The percentage of protein was computed by multiplying a factor of 5.7 with the amount of nitrogen. Crude fat was determined by solvent extraction method through Soxhlet mechanical assembly utilizing petroleum ether as a solvent for 2–3 h. by AACC International method46 method No. 30–10. The solvent was evaporated after the extraction, leaving behind only the extracted fat. Starch contents were evaluated using the glucoamylase technique according to the AACC International method46 method No. 76–13. The sample is gelatinized by heating in water and then treated with glucoamylase. The amount of glucose released is used to calculate the starch content.

Rheological properties of flour

Farinograph test

In the farinograph test, flours were analyzed using a Brabender Farinograph-Resistograph, which measures the dough’s consistency during mixing. This method is used for the determination of key parameters such as water absorption, development time, and mixing stability, which are crucial for evaluating the flour baking quality.

Water absorption capacity

Flours were evaluated for water absorption using the constant flour weight method, AACC International method46 (Method 54–21). Samples of 50 g flour from each treatment were weighed, and distilled water was gradually added while mixing until a dough of the desired consistency was formed. The water absorption was calculated as the percentage of water added relative to the flour weight. The dough consistency was visually assessed to ensure proper hydration without excess moisture.

Dough development time (DDT)

Dough development time was determined following the AACC International method46 Method 54–70 using a farinograph. A sample containing 50 g of flour was mixed with water, and the time taken for the dough to reach its maximum viscosity was recorded. The development time defined as the duration from the initiation of mixing to the point where the dough achieves maximum resistance to mixing, reflecting its optimal consistency and strength.

Dough stability time (DST)

Similarly, dough stability time was assessed using the AACC International method46 Method 54–70. Fifty grams of flour was mixed with water in a farinograph, and the dough resistance to mixing was continuously recorded. Dough stability time was determined by observing the length of time the dough maintained its peak viscosity and resist to deformation. This parameter was used to evaluate the dough’s ability to withstand the mixing process without significant breakdown, providing insights into the flour’s quality and suitability for baking applications.

Preparation and physical properties of bread

Bread preparation

The straight dough procedure was used to make bread following the AACC International method46. The dough formula included 100 g of flour, 4 g of dry yeast, 1 g of salt, 4 g of sugar, and 10 g of oil. The dough was then placed in a fermentation cabinet at 37 °C and 80–85% r.h., for 20 mins, after which the dough was divided into 125 g portions. The dough was left for proofing in the same cabinet for 30 mins, at controlled conditions, as mentioned above, followed by baking at 220 °C for 20 mins in an electric oven. The pan bread was then allowed to cool at room temperature for approximately 20 mins before being packaged in polyethylene bags.

Physical properties of bread

After cooling, the baked bread loaves were weighed. Bread loaf volumes (cm3) were then measured following the method described by AACC International46 by using the rapeseed displacement method, where the volume of rapeseeds displaced by the bread loaf was considered the loaf volume.

Texture profile analysis (TPA) of bread

Texture analysis of pan bread was performed according to47 using a Universal Testing Machine (Conetech, B type, Taiwan) equipped with software, following the standard procedure described in AACC Method 74–09.01. A cylindrical probe (25 mm diameter) was positioned at the center of the bread crumb and used to perform a double compression test to 50% of the original sample height at a crosshead speed of 1.0 mm/s. The parameters recorded from the TPA curve included hardness, chewiness, cohesiveness, springiness, and resilience.

Statistical analysis

The collected data were statistically analyzed by one-way analysis of variance (ANOVA) in CRD using GenStat 15th Edition. Each parameter was assessed with four replications. For live adult counts and grain damage parameters, data were submitted to a two-way ANOVA with treatment and time as main effects. The associated interaction of the main effects was taken into account in the analysis. Prior to analysis, the data were tested for normality and conformed to the requirements of ANOVA. Since the data were normally distributed, no data transformation was conducted. Means were compared and separated using the Tukey–Kramer HSD test at 1% significant level. The graphs were generated using Origin Lab software (Origin, 2024).

Results

Ambient conditions of store-room

Daily minimum and maximum temperature, and r.h. data were averaged on a monthly basis during both storage seasons, 2023 and 2024 (Fig. 2a, b). The average minimum temperature (30.10 °C and 29.00 °C) was recorded in October for both respective years. Contrarily, the average maximum temperature during 2023 was recorded in August (39.10 °C), while in 2024, it was recorded in July (37.42 °C). Similarly, average r.h. showed significant variations with a minimum of 65.12% in June, 2023, and 56.11% in May, 2024 while a maximum of 70.96% in October, 2023, and 71.10% in August, 2024 (Fig. 2a, b).

Grain moisture content (%)

The initial MC of grains was 12.00% during both observed years. After six months of storage, data collected for both observed years indicated a slight, non-significant increase in MC of grains stored in hermetic bags i.e., GrainPro PHB (0.50 and 0.33%), GrainPro SHB (0.92 and 0.75%), and UAF HB (0.66 and 0.58%), respectively for 2023 (F 7, 31 = 18649; p ≤ 0.01) and 2024 (F 7, 31 = 16412; p ≤ 0.01). In contrast, grains stored in conventional storage facilities showed a significant increase in MC, i.e., steel bins (11.33 and 10.42%), mud bins (18.33 and 17.33%), CC bags (31.08 and 30.08%), PP bags (35.17 and 34.42%), and jute bags (26.92 and 26.25%), respectively. Moisture content was recorded regularly at monthly intervals throughout the storage period to assess its impact on grain quality and pest infestation (Fig. 3).

Grain damage parameters and frass weight

Significant differences were observed in the main effects and interactions for percent grain damage, weight loss, and frass weight during both study years (Table 1). Similarly, grain damage and weight loss varied significantly among different storage facilities over the 180-day storage period. It was noted that, the conventional storage facilities exhibited the highest susceptibility towards grain damage, whereas hermetic bags displayed the highest resistance (Table 2 and 3). The maximum grain damage was recorded in PP bags i.e., 2.88, 8.68, and 17.25% in 2023 and 2.80, 8.18 and 17.18% in 2024 after 60, 120, and 180 days of storage, respectively. On the other hand, the minimum grain damage was recorded in GrainPro PHB after 60 days (0.31 and 0.34%), 120 days (1.34 and 1.36%) and 180 days (2.38 and 2.44%), for both years, respectively. Likewise, the highest weight loss was observed in PP bags (1.06, 3.22, and 6.64%) and (1.00, 3.11, and 6.45%) after 60, 120, and 180 days of storage, respectively in both years. Contrarily, GrainPro PHB exhibited the lowest weight loss after 60 days (0.12 and 0.13%), 120 days (0.53 and 0.52%), and 180 days (0.93 and 0.93%), respectively for both years (Table 2 and 3). In the case of frass weight, grains stored in conventional storage facilities had the highest frass weight as compared to those in hermetic storage. The maximum frass weight was recorded in grains stored in PP bags (0.20, 0.71, and 1.62 g) and (0.19, 0.72, and 1.64 g), after 60, 120, and 180 days of storage, respectively during both concerned years. The minimum frass weight was recorded in GrainPro PHB after 60 days (0.02 and 0.02 g), 120 days (0.08 and 0.08 g) and 180 days (0.15 and 0.16 g), respectively (Table 2 and 3).

Germination test

The germination attributes of wheat seeds revealed significant variations (p ≤ 0.01) in damaged embryo seeds, germination percentage, germination index and energy in different storage facilities after 6 months of storage during both observation years. The percentage of damaged embryo seeds was maximum in seeds stored in PP bags (21.75 and 19.50%) in both years, respectively. In contrast, seeds stored in GrainPro PHB exhibited minimum damaged embryo seeds i.e., 1.75 and 2.00%, respectively. Germination percentage also varied significantly among the seeds stored in different storage facilities during both observed years, evaluated on the 5th and the 8th day after the test installation (GT5 and GT8). The seeds stored in PP bags had the lowest germination percentages, i.e., 67.00 and 67.67%, followed by CC bags with 69.50 and 70.00%, respectively (Table 4). On the other hand, seeds stored in GrainPro PHB exhibited highest germination rates (90.50 and 90.33%), respectively. Likewise, germination index and energy of seeds stored in hermetic bags were significantly higher than those stored in conventional storage facilities. The minimum germination index and energy were calculated in PP bags i.e., 15.89 and 44.01, respectively in 2023 while 16.16 and 45.50, respectively in 2024, whereas maximum was calculated in GrainPro PHB (2023; 23.40 and 63.18, respectively) and (2024; 23.33 and 62.94, respectively) as shown in Table 4.

Adult insects and mites density

Significant differences were observed in the main effects and interactions for density of live adult insects and mites (Table 1). In both years, infestation by six insect pest species, including R. dominica, T. granarium, T. castaneum, Liposcelis paeta (Psocoptera: Liposcelididae), Cryptolestes ferrugineus (Coleoptera: Laemophloeidae), and Sitophilus granarius (Coleoptera: Curculionidae), was recorded during six months of storage period. Among these, first four were common while the remaining were rarely observed. In addition to these insects, two mite species, Acarus and Rhizoglyphus, were also detected in conventional storage facilities. Significant differences in insects and mites population were noted between different storage facilities i.e., conventional and hermetic, in 250 g of grains. In insect pests, the highest populations of R. dominica (2023; 19.75, 40.50, and 91.25; 2024; 18.00, 39.00, and 83.50), T. granarium (2023; 9.25, 19.25, and 43.50; 2024; 8.00, 17.25, and 38.75), T. castaneum (2023; 17.25, 36.00, and 84.00; 2024; 15.50, 34.25, and 75.50), and L. paeta (2023; 24.00, 50.50, and 117.50; 2024; 22.50, 49.00, and 106.00) were recorded in PP bags after 60, 120, and 180 days of storage, respectively. In contrast, the lowest populations of R. dominica (2023; 2.00, 4.75, and 14.25; 2024; 1.75, 5.00, and 8.50), T. granarium (2023; 1.00, 3.00, and 8.75; 2024; 1.25, 3.50, and 5.50), T. castaneum (2023; 1.75, 4.75, and 12.25; 2024; 2.00, 5.00, and 7.00), and L. paeta (2023; 3.75, 7.00, and 19.00; 2024; 4.25, 10.00, and 18.00) were recorded in GrainPro PHB respectively, for all intervals (Table 5 and 6).

In case of mites, the highest population of Acarus and Rhizoglyphus was recorded in PP bags. Acarus populations were 0.00, 64.75 and 142.25 in 2023, and 0.00, 65.00 and 136.00 in 2024, after 60, 120 and 180 days, respectively. Similarly Rhizoglyphus populations were 0.00, 59.75, and 123.50 in 2023, and 0.00, 57.25, and 117.00 in 2024 at the same intervals. No mite specie was detected in hermetic bags, as the MC of grains in hermetic bags was low (≈12.13%), which creates an unfavorable environment for mite survival and reproduction (Table 7).

Proximate composition analysis (%)

The proximate composition analysis of milled wheat grains revealed significant variability among grains stored in different storage facilities during both study years (Fig. 4). Initially, the grains had the highest ash content of 2.12 and 2.10% in 2023 and 2024, respectively. The ash content showed a significant increase, i.e., 2.65 and 2.59% in grains stored in PP bags during both years, respectively. Contrarily, grains stored in GrainPro PHB exhibited a slight increase, up to 2.17 and 2.16%, followed by UAF HB i.e., 2.18 and 2.17%, respectively during 2023 (F 7, 31 = 208; p ≤ 0.01) and 2024 (F 7, 31 = 66; p ≤ 0.01) (Fig. 4a). A similar trend was observed for fiber content. The initial fiber content of grains was 2.51 and 2.50% during both years, respectively. After a 180-day storage period, fiber content increased significantly in grains stored in PP bags i.e., 2.97% during 2023 (F 7, 31 = 112; p ≤ 0.01) and 2.92% during 2024 (F 7, 31 = 65.9; p ≤ 0.01). In contrast, a minimal increase in fiber content was noted in grains stored in GrainPro PHB and UAF HB (2.57 and 2.56%), followed by GrainPro SHB (2.59 and 2.57%) during both years as shown in (Fig. 4b).

Mean (± SE) proximate composition analysis (%) i.e., ash (a), fiber (b), protein (c), fat (d), and starch contents (e) of milled wheat grains stored in different storage facilities during both years. Different letters above the bars show significant differences among the genotypes (Tukey’s HSD test, p < 0.01).

On the other hand, a decreasing pattern was observed in the protein, fat, and starch content among all storage facilities. Initially, the protein content in the grains were recorded at 12.64 and 12.61% during both years respectively. After storage, grains stored in PP bags showed a significant decrease, with protein contents decreasing to 11.49% in 2023 (F 7, 31 = 707; p ≤ 0.01) and 11.54% during 2024 (F 7, 31 = 397; p ≤ 0.01). In comparison, grains stored in GrainPro PHB retained higher protein content i.e., 12.51 and 12.52% during both concerned years (Fig. 4c). Likewise, the initial fat content was 1.54% during both years, decreased to 1.28% and 1.31% in 2023 (F 7, 31 = 38.9; p ≤ 0.01) and 2024 (F 7, 31 = 34.1; p ≤ 0.01), respectively in grains stored in PP bags. In contrast, grains in GrainPro PHB had the highest fat contents of 1.52% and 1.53%, during both years respectively (Fig. 4d). Starch content also decreased significantly, from 66.40 to 53.03% in 2023 (F 7, 31 = 1314; p ≤ 0.01) while 66.44 to 55.23% in 2024 (F 7, 31 = 76.1; p ≤ 0.01) in PP bags, whereas GrainPro PHB preserved higher starch contents of 63.53 and 64.10% during both respective years (Fig. 4e).

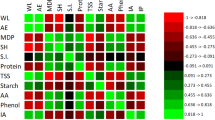

Correlation between grain moisture content and insect damage parameters

A simple correlation between grain MC and the damage parameters revealed a positive and highly significant correlation. Percent grain damage showed a positive and highly significant correlation (R2 ≥ 0.97 and 0.97, respectively) with MC of grain during both observed years (Fig. 5a, b). Similarly, percent weight loss also exhibited a positive and highly significant correlation (R2 ≥ 0.98 and 0.97, respectively) with the grain moisture contents (Fig. 5c, d). Minimum grain damage was observed in GrainPro PHB (2023: 2.38% and 2024: 2.44%) with a moisture content of 12.06 and 12.04%, respectively, while the maximum percent grain damage was recorded in PP bags (2023: 17.24% and 2024: 17.17%) with a moisture content of 16.22 and 16.13%, respectively. Likewise, minimum percent weight loss was recorded in GrainPro PHB (0.93 and 0.93%) with a moisture content of 12.06 and 12.04%, respectively, while the maximum percent weight loss was recorded in PP bags (6.64 and 6.45%) with a moisture content of 16.22 and 16.13%, respectively.

Rheological properties of flour

A farinograph analysis revealed that flour derived from infested wheat grains exhibited a notable increase in water absorption capacity (WAC). The highest WAC was observed in flours made from grains stored in PP bags (75.33 and 72.18%, respectively) and the lowest WAC for flours made from grains stored in GrainPro PHB (59.40 and 59.25%, respectively) for both years. In contrast, dough development time (DDT) and dough stability time (DST) exhibited an opposite trend. The lowest DDT (2023; 3.00 mins, and 2024; 3.25 mins) and DST (2023; 5.25 mins and 2024; 5.45 mins) were recorded for flour milled from grains stored in PP bags, whereas the highest DDT (2023; 6.45 min and 2024; 6.25 min) and DST (2023; 8.50 min and 2024; 8.45 min) were observed in flour from grains stored in GrainPro PHB (Table 9).

Physical properties of bread

The bread made from various flours derived from the grains in various storage facilities are presented in Fig. 6. Regarding the physical properties of bread i.e., loaf volume (LV) and loaf weight (LW), the lowest LV and LW was recorded in loaves prepared from flour of grains stored in PP bags i.e., 956.15cm3 and 333.38 g, respectively in 2023 while 971.13cm3 and 337.68 g respectively in 2024. On the other hand, the highest values were observed in loaves prepared from flour of grains stored in GrainPro PHB, with LV of 1150.60cm3 and LW of 414.95 g in 2023, while 1159.90cm3 and of 422.38 g, respectively in 2024 (Table 8).

Texture profile analysis (TPA) of bread

The textural profile analysis (TPA) of bread made from milled grains (flour) stored in different storage facilities, are presented in Table 9.

The highest hardness (75.10 and 72.80 g) was recorded for bread made from grains stored in PP bags, while the lowest (59.20 and 59.45 g) was observed in bread from grains stored in GrainPro PHB for both years, respectively. On the other hand, the maximum chewiness (6.50 and 6.27 g), cohesiveness (8.52 and 8.50), springiness (1151.90 and 1159.70 mm), and resilience (414.57 and 418.90) were found in the bread made from grains stored in GrainPro PHB, respectively. Contrarily, the lowest values for these parameters were associated with bread made from grain stored in PP bags, with chewiness (3.00 and 3.26 g), cohesiveness (5.28 and 5.51), springiness (967.72 and 958.42 mm), and resilience (333.25 and 336.78), for both respective years (Table 9).

Discussion

The present study evaluated the performance of different conventional and hermetic storage facilities based on physical damage, seed germination, live adult pest population, nutritional qualities, and changes in moisture content of wheat seeds during prolonged storage. The results indicated that, the MC of grains stored in conventional storage facilities significantly increased throughout the storage period, whereas in hermetic bags, a slight increase in grains MC was observed. This can be attributed to the sealed, low-permeability of hermetic bags, which limits the exchange of air and moisture between the internal and external environment. Our results confirmed other studies48,49,50,51 that hermetic bags provide an effective barrier and prevent the absorption of moisture from the environment into the seeds stored inside the bag. Kamel et al. (2024)52 also evaluated three hermetic and one non-hermetic bags for the storage of maize seeds over 12 months. They reported that the moisture content in hermetic bags was < 14% throughout the storage period, whereas it exceeded 14% in non-hermetic bags.

Regarding damage parameters of insects and mites, our findings showed that grain damage and weight loss were significantly higher in conventional storage facilities as compared to hermetic bags. The frass weight was also maximum in the storage facility with high grain damage. Notably, maximum insect activity and damage were observed during the monsoon season in conventional storage facilities. The higher grain damage and weight loss in conventional storage facilities result from their inability to control MC and oxygen levels, which creates favorable conditions for pest growth and development. In contrast, hermetic bags are designed to create a low O2 and high CO2 environment, which restricts the growth and survival of pests and inhibits their metabolic and respiratory processes53. The results were in accordance with those of Atta et al. (2020)54, who assessed the damage potential of T. castaneum in wheat grains stored in different hermetic and conventional storage bags. They observed that, the insect growth rate, grain damage, weight loss, and frass weight were maximum in grains stored in conventional bags and minimum in grains stored in hermetic bags. Likewise, Mutambuki and Likhayo (2021)55 also checked the performance of different grain storage bags (conventional and hermetic) for the storage of maize seeds over a 36 week storage period and reported that grain damage remained below 4% and weight loss below 3% in all hermetic bags while in the untreated PP bags, it increased to 81.1 and 25.5%, respectively.

As for the germination attributes, seeds stored in hermetic bags exhibited higher seed germination percentage as compared to the conventional storage facilities. The same trend was observed for germination index and germination energy. Germination losses in seeds stored in conventional storage systems were due to increased MC under prevailing high RH storage conditions. It is well known that every 1% increase in seed moisture content reduces seed shelf life by 50%56. Our results confirmed the findings of Bewley et al. (2013)57 and Tubbs et al. (2016)58, who demonstrated that increased grain MC is detrimental to seed viability and germination. The results were also in line with that of Mutambuki and Likhayo (2021)55 who evaluated the performance of different grain storage bags (conventional and hermetic) for the storage of maize seeds over a 9-months storage period and reported that seed germination was higher (up to 60%) in hermetic bags while in untreated PP bags, it was lowest (4.7%). In the case of live adult insect and mite populations, our findings revealed that, there were a higher number of insects and mites in grains stored in conventional storage facilities throughout the storage period, with the highest population density recorded in PP bags, followed by cloth CC bags. Conversely, there were no mites detected in hermetic bags, and insect populations were significantly lower. Better performance of hermetic bags such as GrainPro PHB, UAF HB, and GrainPro SHB, in protecting grains against insect pests is well documented59,60. As discussed earlier, low O2 and high CO2 in hermetic bags restrict the growth and survival of pests and inhibit their metabolic and respiratory processes61. This increased level of CO2 at low levels of O2 has proved fatal for the insect pests62. This could be the result of a disrupted water supply caused by O2 deficiency, as insects and mites obtain the majority of their water requirements through aerobic respiration14,63. The results were also in accordance with those of Yewle et al. (2021)64, who assessed the efficacy of hermetic and traditional storage bags for their effect on the postharvest storage of turmeric and determined that, the number of live insects was significantly higher in traditional storage facilities as compared to the hermetic storage.

MC in stored grain is a critical factor that affects its quality, safety, and market value65. When moisture levels in stored grains are high, it attracts more pests, leading to increased grain damage and weight loss66,67. In our case, a positive correlation of grain moisture content with grain damage and weight loss was observed. It might be attributed to the fact that higher moisture content in wheat genotypes creates favorable conditions for storage pests and correlates positively with grain damage and weight loss68. Current findings are in accordance with Chatha et al. (2021)69 and Wang et al. (2020)70, who noted the highest weight loss in rice genotypes due to high moisture content. Similarly, Yousuf et al. (2025)22 also reported high weight loss in wheat grain due to high moisture content and temperature.

Furthermore, the present study also determined the proximate composition analysis of milled grains including crude protein, crude fat, ash, fiber, and starch. The results of our findings showed that ash and fiber content were significantly increased in grains stored in conventional facilities (PP bags) after six months of storage, whereas grains stored in hermetic bags (GrainPro PHB) exhibited a slight increase over the same storage period. The increase in ash and fiber content in grains stored in PP bags, may be due to the degradation of grain components by insect activity, which leads to the release of compounds, enhancing ash and fiber content71,72. On the other hand, protein, fat, and starch contents were significantly decreased in grains stored in conventional storage, while only a slight decrease was observed in grains stored in hermetic bags. Losses in nutritional values, such as protein, fat, and starch content, are mainly attributed to storage insect pests, which preferentially feed on grain embryos71,72. These results confirm the findings of Mahmood et al. (2013)73, who observed changes in the nutritional value of wheat grains (Lasani-08) when infested with varying population levels of the acarid mite, Rhizoglyphus tritici (Acari: Acaridae), over one and three-month periods. They concluded that fiber and ash contents increased significantly in infested grains compared to untreated control, while protein, fat and starch contents were significantly decreased over the same storage intervals. Likewise, Chattha et al. (2015)74 also observed a decrease in fat, protein and starch content of wheat grains during storage in a straw-clay bin for one year.

In relation to the rheological properties of wheat flour, the outcomes revealed a notable increase in water absorption capacity (WAC) of flour derived from grain stored in conventional storage facilities as compared to the hermetic ones. The increase in WAC of infested grain flour may result from structural changes in the grain caused by insect activity, leading to higher porosity allowing the flour to absorb more water75. Contrarily, the lowest DDT and DST were recorded in flour derived from grains stored in conventional facilities, whereas the highest DDT and DST were observed in flour from grains stored in hermetic storage. The lowest DDT and DST in flour from grains stored in conventional facilities may be attributed to the deterioration of grain quality due to insect activity which can negatively affect gluten formation. On the other hand, the higher DDT and DST in flour from grains stored in hermetic conditions possibly reflect better grain preservation, leading to improved dough properties76. Our findings align with those of Mohammad et al. (2012)77, who observed a significant decrease in DDT and DST in flour derived from grains infested by T. confusum compared to uninfested grains. The results also correspond to those of Bodroža-Solarov et al. (2012)78, who reported an increase in farinograph water absorption in infested samples.

Among the physical parameters of flour i.e., loaf volume (LV) and loaf weight (LW), the lowest LV and LW were recorded in loaves prepared from flour of grains stored in conventional bags. On the other hand, the highest values were observed in loaves prepared from grains stored in hermetic bags. As discussed earlier, the lowest LV and LW in conventional storage can be attributed to grain degradation by insects, while the highest values in hermetic storage reflect better grain preservation and flour quality. Our findings confirmed the results of Abdelfattah et al. (2023)76 and Keskin and Ozkaya (2015)79, who also observed the lowest LV and LW in infested grain flour and vice versa. The textural profile analysis (TPA) revealed significant differences based on storage conditions. Bread made of flour derived from grains stored in PP bags had the maximum hardness and the minimum values for chewiness, cohesiveness, springiness, and resilience, likely due to grain degradation and gluten deterioration from insect infestation. In contrast, bread from grains stored in GrainPro PHB exhibited the minimum hardness and the maximum values for these parameters, reflecting better grain preservation and flour quality under hermetic conditions. These findings are consistent with Abdelfattah et al. (2023)76, who also observed the variations in texture profile analysis of bread prepared from flour of infested and ozone-treated wheat grain. Bonet et al. (2007)80 also determined that the disrupted gluten structure of infested wheat flours leads to low-quality doughs, affecting bread characteristics such as hardness, chewiness, cohesiveness, springiness, and resilience, rendering it unsuitable for bread-making processes.

Finally, this study highlights the significant impact of storage conditions on various quality parameters of grains and their subsequent impact on flour and bread properties. Conventional storage facilities were associated with significant pest damage, leading to grain degradation and reduced nutritional and functional quality. In contrast, hermetic storage effectively preserved grain quality, minimizing insect damage and maintaining better nutritional and rheological properties of flour, consequently improved the textural qualities of bread. These findings emphasize that, hermetic storage facilities are more effective than conventional in maintaining grain MC, preserving grain quality, reducing losses, and ensuring better nutritional qualities of flour and bread.

In contrast to previous studies that primarily focused on either pest infestation or grain quality parameters, the present study offers a comprehensive evaluation of conventional and hermetic storage systems by integrating assessments of insect dynamics, physicochemical grain quality, and the functional performance of wheat flour in bread-making applications. These findings offer valuable insights into the long-term effectiveness of storage technologies and contribute to evidence-based recommendations for improving postharvest grain management practices. Future research should assess the long-term effects of hermetic storage on flour functionality and bread quality across various wheat genotypes. Additionally, evaluating the economic viability of hermetic storage under farm and store-roo conditions will be essential to support its broader implementation in sustainable grain storage systems.

Conclusion

In conclusion, hermetic storage proved to be more effective in protecting grain from insect and mite infestation under smallholder farming conditions by maintaining low grain MC. These storage facilities significantly reduce insect pest numbers, grain damage, and weight loss, resulting in a higher proportion of healthy and edible grains. Based on these findings, we recommend the use of hermetic bags as part of an integrated postharvest management approach. Although hermetic storage requires higher initial investment, its ability to significantly reduce pest-related losses and maintain grain quality results in greater economic benefits over time compared to conventional storage. Promoting hermetic storage can help in reducing post-harvest losses, enhancing farmer’s incomes, and strengthening food and nutrition security, thereby contributing to mitigate malnutrition. Moreover, hermetic storage facilities can replace the use of pesticides in storage, reducing the associated health risks. Future research should focus on evaluating the long-term efficacy of hermetic storage beyond six months, assessing its impact on grain quality, nutritional composition, and milling properties. Economic feasibility studies are needed to compare costs and benefits with traditional storage methods and identify barriers to adoption among smallholder producers. Further investigation is required to determine the effectiveness of hermetic storage against a broader range of storage pests under varying environmental conditions. Additionally, exploring the integration of hermetic storage with other non-chemical postharvest management strategies, such as biological control or modified atmospheres, could enhance its effectiveness and sustainability. Addressing these research gaps will help optimize hermetic storage for widespread adoption, contributing to improved food security and postharvest grain management.

Data availability

The datasets used in the current study available from the corresponding author on reasonable request.

Abbreviations

- WAC:

-

Water absorption capacity

- DDT:

-

Dough development time

- DST:

-

Dough stability time

- TPA:

-

Texture profile analysis

- PP:

-

Polypropylene

- CO2 :

-

Carbon dioxide

- BWP:

-

Bahawalpur

- r.h.:

-

Relative humidity

- PHB:

-

Premium hermetic bags

- SHB:

-

Super hermetic bags

- UAF:

-

University of agriculture, Faisalabad

- MC:

-

Moisture content

- CRD:

-

Completely randomized design

References

Grote, U., Fasse, A., Nguyen, T. T. & Erenstein, O. Food security and the dynamics of wheat and maize value chains in Africa and Asia. Front. Sustain. Food Syst. 4, 617009 (2021).

Albahri, G. et al. Enhancing essential grains yield for sustainable food security and bio-safe agriculture through latest innovative approaches. Agronomy 13, 1709 (2023).

Poutanen, K. S. et al. Grains–a major source of sustainable protein for health. Nutr. Rev. 80, 1648–1663 (2022).

Zaib, S., Hayat, A. & Khan, I. Nutritional and health benefits of cereals and grains. Curr. Nutr. Food Sci. 20, 1205–1221 (2024).

Anteneh, A. & Asrat, D. Wheat production and marketing in Ethiopia: Review study. Cogent Food Agric. 6, 1778893 (2020).

Tian, X. et al. Will reaching the maximum achievable yield potential meet future global food demand?. J. Clean. Prod. 294, 126285 (2021).

Fao, I. & Unicef, W. Repurposing food and agricultural policies to make healthy diets more affordable. The state of food security and nutrition in the world (2022).

Yigezu, Y. A. et al. Food losses and wastage along the wheat value chain in Egypt and their implications on food and energy security, natural resources, and the environment. Sustainability 13, 10011 (2021).

Abdullahi, N. & Dandago, M. A. Postharvest losses in food grains–A Review. Turkish J. Food Agric. Sci. 3, 25–36 (2021).

Kumar, D. & Kalita, P. Reducing postharvest losses during storage of grain crops to strengthen food security in developing countries. Foods 6, 8 (2017).

Manandhar, A., Milindi, P. & Shah, A. An overview of the post-harvest grain storage practices of smallholder farmers in developing countries. Agriculture 8, 57 (2018).

Win, M. T., Maredia, M. K. & Boughton, D. Farmer demand for certified legume seeds and the viability of farmer seed enterprises: Evidence from Myanmar. Food Security 15, 555–569 (2023).

Bradford, K. J. et al. in Food industry wastes 375–389 (Elsevier, 2020).

Murdock, L. L., Margam, V., Baoua, I., Balfe, S. & Shade, R. E. Death by desiccation: effects of hermetic storage on cowpea bruchids. J. Stored Prod. Res. 49, 166–170 (2012).

Bradford, K. J., Dahal, P. & Bello, P. Using relative humidity indicator paper to measure seed and commodity moisture contents. Agric. Environ. Lett. 1, 160018 (2016).

Muroyiwa, B., Shokopa, L., Likoetla, P. & Rantlo, M. Integration of post-harvest management in agricultural policy and strategies to minimise post harvest losses in Lesotho. J. Dev. Agric. Econ. 12, 84–94 (2020).

Bellochio, S. D. C. & Coradi, P. C. Occupational hazards at grain pre-processing and storage facilities: A review. J. Stored Prod. Res. 106, 102288 (2024).

Ahmad, R. et al. Stored grain pests and current advances for their management. Postharvest technology-recent advances, new perspectives and applications (2021).

Maheswari, S. Effect of Biotic and abiotic factors on mites infestation under grain storage-A review. Flora Fauna 29, 99–103 (2023).

Gad, H. A., Al-Ayat, A. A. & Abdelgaleil, S. A. Management of khapra beetle, Trogoderma granarium everts, using binary combinations of chitin synthesis inhibitors and inert dusts. J. Stored Prod. Res. 104, 102194 (2023).

Hassan, M. W. et al. Damage assessment of stored grain pests against rice grains types and wheat. Int. J. Trop. Insect Sci. 43, 35–41 (2023).

Yousuf, H. M. B. et al. Assessment of different conventional and biofortified wheat genotypes based on biology and damage pattern of Rhyzopertha dominica and Trogoderma granarium. Insects 16, 66 (2025).

Carvalho, M. O., Geirinhas, H., Duarte, S., Graça, C. & de Sousa, I. Impact of red flour beetle infestations in wheat flour and their effects on dough and bread physical, chemical, and color properties. J. Stored Prod. Res. 102, 102095 (2023).

Stathas, I. G. et al. The effects of insect infestation on stored agricultural products and the quality of food. Foods 12, 2046 (2023).

Rosentrater, K. A. in Storage of cereal grains and their products 443–501 (Elsevier, 2022).

Kiran Babu, P. & Rampal. in Addressing the Climate Crisis in the Indian Himalayas: Can Traditional Ecological Knowledge Help? 53–93 (Springer, 2024).

Tadesse, M. Post-harvest loss of stored grain, its causes and reduction strategies. Food Sci. Qual. Manage. 96, 26–35 (2020).

Srivastava, S. & Mishra, H. N. Ecofriendly nonchemical/nonthermal methods for disinfestation and control of pest/fungal infestation during storage of major important cereal grains: A review. Food Front. 2, 93–105 (2021).

Malalgoda, M. & Simsek, S. Pesticide residue in grain-based food: Effects on health, grain quality, and chemical properties of biomacromolecules. Cereal Chem. 98, 8–16 (2021).

Yousuf, H. M. B. et al. Evaluation of different Kabuli chickpea genotypes against Helicoverpa armigera (Hübner)(Lepidoptera: Noctuidae) in relation to biotic and abiotic factors. PeerJ 12, e16944 (2024).

Nayak, M. K., Collins, P. J., Pavic, H. & Kopittke, R. A. Inhibition of egg development by phosphine in the cosmopolitan pest of stored products Liposcelis bostrychophila (Psocoptera: Liposcelididae). Pest Manage. Sci. Formerly Pesticide Sci. 59, 1191–1196 (2003).

Collins, P. J., Daglish, G. J., Pavic, H. & Kopittke, R. A. Response of mixed-age cultures of phosphine-resistant and susceptible strains of lesser grain borer, Rhyzopertha dominica, to phosphine at a range of concentrations and exposure periods. J. Stored Prod. Res. 41, 373–385 (2005).

Lorini, I., Collins, P. J., Daglish, G. J., Nayak, M. K. & Pavic, H. Detection and characterisation of strong resistance to phosphine in Brazilian Rhyzopertha dominica (F.)(Coleoptera: Bostrychidae). Pest Manage. Sci. Formerly Pesticide Sci. 63, 358–364 (2007).

Nawaz, H., Zhang, X., Chen, S., You, T. & Xu, F. Recent studies on cellulose-based fluorescent smart materials and their applications: A comprehensive review. Carbohyd. Polym. 267, 118135 (2021).

Berhe, M. et al. Post-harvest insect pests and their management practices for major food and export crops in East Africa: An Ethiopian case study. Insects 13, 1068 (2022).

Baributsa, D. & Concepcion Ignacio, M. C. Developments in the use of hermetic bags for grain storage. (2020).

Attia, M. A. et al. Stored grain pest prevalence and insecticide resistance in Egyptian populations of the red flour beetle Tribolium castaneum (Herbst) and the rice weevil Sitophilus oryzae (L.). J. Stored Prod. Res. 87, 101611 (2020).

Okolo, C., Chukwu, O., Adejumo, B. & Haruna, S. Hermetic storage technology: The way forward in solving numerous cereal grains storage challenges in developing countries. Int. J. Eng. Res. Technol. 6(7), 682–692 (2017).

Rizwan, M. et al. The comparison of interstitial relative humidity and temperatures of hermetic and polypropylene bag for wheat grain storage under different agro-climatic conditions of rice-wheat ecosystem of Pakistan: Effect on seed quality and protection against insect pests. J. Stored Prod. Res. 96, 101936 (2022).

Sanon, A., Dabiré-Binso, L. & Ba, N. Triple-bagging of cowpeas within high density polyethylene bags to control the cowpea beetle Callosobruchus maculatus F. (Coleoptera: Bruchidae). J. Stored Prod. Res. 47, 210–215 (2011).

Vales, M., Rao, G. R., Sudini, H., Patil, S. & Murdock, L. Effective and economic storage of pigeonpea seed in triple layer plastic bags. J. Stored Prod. Res. 58, 29–38 (2014).

International, A. & Group, G. W. AOAC INTERNATIONAL guidelines for validation of botanical identification methods. J. AOAC Int. 95, 268–272 (2012).

Adams, J., Schulten, G., Harris, K. & Lindblad, C. Postharvest grain loss assessment methods. American Assoc. Cereal Chem. 193 (1978).

Allen, E. & Alvarez, S. International rules for seed testing 2020. The International Seed Testing Association: Bassersdorf, Switzerland (2020).

Analysts, A. O. S. in Association of Official Seed Analysts.

Committee, A. A. o. C. C. A. M. Approved methods of the American association of cereal chemists. Vol. 1 (American Association of Cereal Chemists, 2000).

Bourne, M. C. Texture profile analysis. Food Technol. 32, 62–66 (1978).

Afzal, I., Bakhtavar, M. A., Ishfaq, M., Sagheer, M. & Baributsa, D. Maintaining dryness during storage contributes to higher maize seed quality. J. Stored Prod. Res. 72, 49–53 (2017).

Bakhtavar, M. A., Afzal, I. & Basra, S. M. A. Moisture adsorption isotherms and quality of seeds stored in conventional packaging materials and hermetic Super Bag. PLoS ONE 14, e0207569 (2019).

Baributsa, D. & Baoua, I. B. Hermetic bags maintain soybean seed quality under high relative humidity environments. J. Stored Prod. Res. 96, 101952 (2022).

Tharwat, A., Matouk, A. & El-Kholy, M. Safe storage of corn using different types of hermetic bags. J. Soil Sci. Agric. Eng. 14, 399–406 (2023).

Kamel, R. M., Assaha, D. V., El-kholy, M. & Elsawy, H. I. Influence of maize (Zea mays L.) moisture content stored in various compacted multi-layer hermetic bags on seed quality and mycotoxins contamination. J. Stored Prod. Res. 107, 102319 (2024).

Obeng-Akrofi, G. et al. Effectiveness of hermetic bag storage technology to preserve physical quality attributes of shea nuts. J. Stored Prod. Res. 101, 102086 (2023).

Atta, B., Rizwan, M., Sabir, A. M., Gogi, M. D. & Ali, K. Damage potential of Tribolium castaneum (Herbst)(Coleoptera: Tenebrionidae) on wheat grains stored in hermetic and non-hermetic storage bags. Int. J. Trop. Insect Sci. 40, 27–37 (2020).

Mutambuki, K. & Likhayo, P. Efficacy of different hermetic bag storage technologies against insect pests and aflatoxin incidence in stored maize grain. Bull. Entomol. Res. 111, 499–510 (2021).

Harrington, J. F. & Kozlowski, T. Seed storage and longevity. Seed Biol. 3, 145–245 (1972).

Bewley, J. D. et al. Longevity, storage, and deterioration. Seeds: Physiology of Development, Germination and Dormancy, 3rd Edition, 341–376 (2013).

Tubbs, T., Baributsa, D. & Woloshuk, C. Impact of opening hermetic storage bags on grain quality, fungal growth and aflatoxin accumulation. J. Stored Prod. Res. 69, 276–281 (2016).

Baoua, I. B., Margam, V., Amadou, L. & Murdock, L. L. Performance of triple bagging hermetic technology for postharvest storage of cowpea grain in Niger. J. Stored Prod. Res. 51, 81–85 (2012).

Baoua, I., Amadou, L., Baributsa, D. & Murdock, L. Triple bag hermetic technology for post-harvest preservation of Bambara groundnut (Vigna subterranea (L.) Verdc.). J. Stored Prod. Res. 58, 48–52 (2014).

Murdock, L. & Baoua, I. On Purdue Improved Cowpea Storage (PICS) technology: background, mode of action, future prospects. J. Stored Prod. Res. 58, 3–11 (2014).

Navarro, S. The use of modified and controlled atmospheres for the disinfestation of stored products. J. Pest. Sci. 85, 301–322 (2012).

Navarro, S., Navarro, H., de Bruin, T. & Inbari, N. in Control and Management of Pests in Stored Products 74–120 (CRC Press, 2024).

Yewle, N. R., Swain, K. C., Mann, S. & Dhakre, D. S. Evaluating of hermetic bags for long-term storage of turmeric (Curcuma longa L.) rhizomes. J. Stored Prod. Res. 92, 101806 (2021).

Tushar, S. R. et al. Analysis of the factors influencing the stability of stored grains: implications for agricultural sustainability and food security. Sustain. Oper. Comput. 4, 40–52 (2023).

Majeed, M. Z. et al. Biology and management of stored products’ insect pest Rhyzopertha dominica (Fab.)(Coleoptera: Bostrichidae). Int. J. Biosci. 7, 78–93 (2015).

Athanassiou, C. G., Phillips, T. W. & Wakil, W. Biology and control of the khapra beetle, Trogoderma granarium, a major quarantine threat to global food security. Annu. Rev. Entomol. 64, 131–148 (2019).

Ahmedani, M. S. et al. Quantitative losses and physical damage caused to wheat kernel (Triticum aestivum L.) by khapra beetle infestation. Pak. J. Botany 43, 659–668 (2011).

Chatha, A. A., Asrar, M., Hussain, S. M., Zahoor, M. K. & Koehler, P. G. Appraisal of quantitative and qualitative losses in six rice genotypes caused by Trogoderma granarium (Everts) and Rhyzopertha dominica (F.). Pakistan J. Agric. Sci. 58 (2021).

Wang, R., Liu, L., Guo, Y., He, X. & Lu, Q. Effects of deterioration and mildewing on the quality of wheat seeds with different moisture contents during storage. RSC Adv. 10, 14581–14594 (2020).

Mali, P. & Vir, S. Quantitative and qualitative losses in green gram stored in different containers and temperatures. Ann. Arid Zone 39(1), 57–64 (2000).

Mali, P. & Satyavir, S. Effect of storage environment and storage material on qualitative and quantitative losses in pearl millet. Ann. Arid Zone 44, 177–184 (2005).

Mahmood, S. U., Bashir, M. H., Muhammad Abrar, M. A., Sabri, M. A. & Khan, M. A. Appraising the changes in the nutritional value of stored wheat, Triticum aestivum L. infested with acarid mite, Rhizoglyphus tritici (Acari: Acaridae). (2013).

Chattha, S. H., Hasfalina, C. M., Lee, T. S., Nawaz, B. & Mirani, M. R. M. A study on the quality of wheat grain stored in straw-clay bin. J. Biodivers. Environ. Sci. 6, 428–437 (2015).

Obadi, M. et al. Effects of ozone treatment on the physicochemical and functional properties of whole grain flour. J. Cereal Sci. 81, 127–132 (2018).

Abdelfattah, N. A., Marie, A. M. & Fawki, S. The effect of ozone on Rhyzopertha dominica Tribolium castaneum and technological properties of wheat flour. Ozone Sci. Eng. 45, 488–502 (2023).

Mohammad, O. S., Ali, W. K. & Al-Hulitan, A. M. The effect of infestation by the confused flour beetle (Tribolium confusum Duv.) on specifications of wheat flour. J. Agric. Sci. Technol. A 2(5A), 696 (2012).

Bodroža-Solarov, M., Kljajić, P., Andrić, G., Filipčev, B. & Dokić, L. Quality parameters of wheat grain and flour as influenced by treatments with natural zeolite and diatomaceous earth formulations, grain infestation status and endosperm vitreousness. J. Stored Prod. Res. 51, 61–68 (2012).

Keskin, S. & Ozkaya, H. Effect of storage and insect infestation on the technological properties of wheat. CyTA-J. Food 13, 134–139 (2015).

Bonet, A., Rosell, C. M., Pérez-Munuera, I. & Hernando, I. Rebuilding gluten network of damaged wheat by means of glucose oxidase treatment. J. Sci. Food Agric. 87, 1301–1307 (2007).

Acknowledgements

Authors would like to thank Researchers Supporting Project number (ORF-2025-107), King Saud University, Riyadh, Saudi Arabia for providing financial support for the present work. This paper has been supported by the RUDN University Strategic Academic Leadership Program.

Funding

Authors would like to thank Researchers Supporting Project number (ORF-2025–107), King Saud University, Riyadh, Saudi Arabia for providing financial support for the present work. This paper has been supported by the RUDN University Strategic Academic Leadership Program.

Author information

Authors and Affiliations

Contributions

Conceptualization, H.M.B.Y. and M.Y.; methodology, N.Y.R, H.M.B.Y. and U.A.; software, H.M.B.Y., M.Y., K.A.U.R. and A.S.A.; validation, M.Y. and H.M.B.Y; formal analysis, H.M.B.Y. and N.Y.R; investigation, U.A. and A.S.A.; resources, M.Y., A.S.A., H.M.B.Y. and K.A.R.; data curation, U.A. and N.Y.R; writing, original draft preparation, H.M.B.Y.., M.Y. and A.S.A.; writing, review, and editing, M.Y., U.A. and K.A.R; visualization, M.Y., U.A. and K.A.R; supervision, M.Y.; project administration, U.A. and K.A.R.; funding acquisition, M.Y. and A.S.A.; All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yousuf, H.M.B., Yasin, M., Rebouh, N.Y. et al. Comparative assessment of conventional and hermetic storage facilities on wheat grain quality, pest infestation, and bread development. Sci Rep 15, 34725 (2025). https://doi.org/10.1038/s41598-025-18340-z

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-18340-z