Abstract

Weakly cemented soft rock goaf-side entry, as a typical extraction entry, faces the characteristics of low Surrounding Rock strength and water-induced softening. Under excavation and mining-induced disturbances, the entry experiences significant deformation dominated by floor heave, severely restricting safe and efficient working face extraction. Therefore, investigating the mechanism of floor heave in weakly cemented soft rock goaf-side entries and its control measures has become a critical issue for ensuring efficient production. This paper adopts a comprehensive research methodology integrating laboratory tests, theoretical analysis, field monitoring, and numerical simulation to systematically manuscript the water-softening behavior of weakly cemented soft rock and the evolution law of floor heave, establishing a mechanical model of floor heave throughout the mining process in goaf-side entries, revealing its disaster-causing mechanism, and proposing targeted prevention and control strategies. The main conclusions are as follows: (1) The cohesion of weakly cemented soft rock is relatively low, and its internal friction angle is significantly smaller than that of non-weakly cemented rocks. After water immersion, the weakly cemented soft rock exhibits a pronounced characteristic of reduced compressive strength.(2) Through field investigations, during the entry excavation period, the floor area near the solid coal side at the center of the entry is more prone to floor heave. During the extraction period, as the working face continuously advances, the heave magnitude on the pillar side gradually increases, and the heave peak dynamically shifts toward the pillar side.(3) By comparing the mechanical models of floor heave in the goaf-side entry during the excavation and extraction periods, it is evident that the stress levels on both sides of the entry remain asymmetric throughout both phases. This asymmetric stress on the entry sides is the primary cause of the resulting asymmetric floor heave.(4) The “floor corner bolt pile” technology is proposed to control floor heave during extraction. The 3DEC numerical simulation software was used to simulate the control effects of different floor bolt layout schemes on floor heave. When no floor support measures were implemented, the maximum floor heave in the entry was 780 mm. After installing floor bolts, the maximum reduction in heave magnitude reached 61.4%.(5) Based on simulation results, the “floor corner bolt pile” solution was field-tested. The entry’s floor heave magnitude decreased by 74.3% compared to the unsupported condition, demonstrating that implementing floor bolt reinforcement combined with floor grouting effectively mitigates floor heave in weakly cemented soft rock goaf-side entries.

Similar content being viewed by others

Introduction

In the mining areas of central and western China, the lithology of the coal seam roof and floor is predominantly composed of soft rocks such as silty mudstone, carbonaceous mudstone, and medium-fine sandstone. These rocks exhibit typical characteristics of weakly cemented soft rock, including low bearing capacity and high sensitivity to engineering excavation disturbances. Particularly under the influence of mining-induced stresses, floor heave in roadways occurs frequently. The floor heave reduces the cross-sectional area of the roadway, obstructing transportation, ventilation, and personnel movement. Instances of roadway abandonment due to severe floor heave are not uncommon. Intense floor heave not only significantly increases maintenance workload and costs but also severely impacts the safe and efficient production of coal mining faces1,2. Therefore, it is of paramount importance to investigate the mechanisms underlying severe floor heave in weakly cemented gob-side entries and develop corresponding control technologies.

At present, regarding the mechanism and control of roadway floor heave, numerous scholars have conducted extensive research from aspects such as theoretical analysis, numerical simulation, and field measurement. Yong Chen et al.3 research indicates that abutment pressure constitutes the primary driver of severe floor heave in gob-side entry retaining. Reinforcement of corner zones in the solid coal rib serves as the critical mitigation strategy for effective control. Wang, D et al.4 Based on the mechanism of asymmetric floor heave caused by uneven vertical stress distribution, a combined control scheme of floor leveling + cable bolting + concrete hardening was proposed. Shu Jian et al.5 proposed to control floor heave by strengthening the surrounding rock with grouting bolts. After on - site application, the floor heave phenomenon was well controlled. Zhu Lei et al.6 adopted the numerical simulation method. Through the analysis of the surface displacement and deep - layer displacement of the floor, it was concluded that increasing the thickness of the floor rock layer, enhancing the elastic modulus of the floor, and strengthening the surrounding rock can effectively control floor heave. Liu Quansheng et al.7 through the analysis of the floor heave mechanism, proposed a comprehensive treatment method for floor heave supported by technologies such as over - excavation of the floor, high - strength prestressed anchor cables, borehole grouting, floor - foot and arch - corner bolts, and backfilling, and verified the reliability of the method through numerical simulation. Ivan Sakhno et al.8 the research on the mechanism and control technologies of floor heave was conducted. Grouting reinforcement was proposed to control floor deformation. Numerical simulations were employed to model the grouting reinforcement process, revealing that the plastic strain within the floor strata was effectively reduced after grouting.Y.M.Zhao et al.9 this manuscript proposed employing the ultimate load method to calculate the critical buckling load of U-shaped steel arches. Numerical simulations were conducted using the finite difference software FLAC3D. The simulation results demonstrated that closed U-shaped steel support can effectively control the floor heave of roadways.Sun et al.10 conducted a comprehensive assessment of floor heave and failure using synchronized infrared imaging, video documentation, and strain field monitoring. Analysis confirmed horizontal stress as a critical factor governing floor heave magnitude. Zhang Shoubao et al.11 aiming at the serious problem of roadway floor heave in Xinzhi Coal Mine, analyzed that the surrounding rock conditions, stress conditions, roadway spatial position, and support method are the main factors affecting floor heave, and proposed the inverted “T” - shaped pouring support of the inverted arch, which effectively controlled the deformation of the roadway floor. Liu Cheng et al.12 through theoretical derivation of the floor heave mechanism of large - section mining roadways with layered floors, proposed a prediction method for this type of floor heave, and proposed that installing floor bolts while strengthening the roadway side - corners and roof can better prevent and control floor heave. J.H.Zhang et al.13 A combined supporting scheme of whole section bolting and grouting was proposed.It is proved that this support plan can effectively control the deformation and plastic zone expansion of the roadway surrounding rock.Chen, A et al.14 an innovative “relief-retaining” control scheme of floor heave is proposed, which is the comprehensive measure of “cutting groove in floor + drilling for pressure relief at roadway side + setting retaining piles at the junction of roadway side and floor.“Then, the specific parameters suitable for floor heave control of no.Finally, the yield monitoring results show that both the deformation of surrounding rocks and the cable force are significantly reduced. Liu, HY et al.15 in the areas of fine and medium-fine sandstone, trackage crosscut is in shear dislocation under high horizontal stress. The slip-line field theory was used to manuscript the ultimate load and maximum failure depth of crosscut floor heave. According to the deformation characteristics of crosscut floor heave, a collaborative control technology enhancing the bearing structure of all-sided surrounding rocks was proposed, including filling of the U-shaped steel supports, shallow grouting in the all-sided surrounding rocks and deep grouting in the floor and inverted arches.Zhai, W et al.16 the horizontal stress distribution of the roadway floor within 20 m of the advanced working face is simulated and analyzed. Based on the performed analyses and the obtained results, a novel double-seal deep and shallow inverted bottom arch (DS-IBA) floor support strategy is proposed. Model tests by Shimamoto and Yashiro17 validated the operational mechanism of the novel CIB bolt (Combined Improvement and Bonding rock bolt) and its efficacy in mitigating long-term tunnel deformations.

This paper studies the difficult problem of floor heave control in the gob - side roadways of Hongqingliang Coal Mine affected by mining. Through in - depth on - site investigation of the floor heave failure characteristics, the variation law of floor heave during the mining process of weakly - cemented gob - side roadways is obtained. A mechanical model of floor heave in weakly - cemented soft - rock gob - side roadways is established, the causes of floor heave are analyzed, and a floor heave control method is proposed, providing a reference for the floor heave control of roadways under similar engineering geological conditions, improving the safe, efficient production and transportation of the mine, and providing a basis for the surrounding rock stability control of gob - side roadways in weakly - cemented soft - rock mines.

Floor heave characteristics of weakly cemented soft rock in gob-side roadways

Engineering geology and support conditions

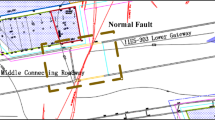

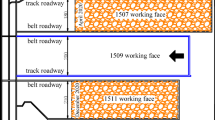

The 11,304 working face in Hongqingliang Coal Mine has a length of 275.5 m. The northern adjacent 11,303 working face has been mined out, while the southern 11,305 working face remains undeveloped. The 11,304 return airway is primarily composed of argillaceous sandstone, with main mineral constituents including quartz, kaolinite, muscovite, and others. Chlorite, constituting 20–38% of the total mineral content, serves as the dominant clay mineral, exhibiting water-induced argillization and low strength. The sandy mudstone exhibits an average uniaxial compressive strength of 17.45 MPa, categorizing it as typical weakly cemented soft rock. The working face layout and lithological characteristics of the roof and floor strata are illustrated in Figure 1.

The 11,304 tail entry has cross-sectional dimensions of 5.0 m × 3.6 m, with the roof supported by a combined rock bolt-cable system as shown in Fig. 2. The roof reinforcement employs Φ22 mm × 2600 mm yieldable rock bolts spaced at 0.7 m × 1.0 m intervals, complemented by Φ21.8 mm × 7300 mm shear-resistant cables arranged in a 4-4-4 pattern with a spacing of 1.3 m × 1.0 m. Rib bolts are installed in a rectangular configuration at 800 mm × 1000 mm spacing to stabilize the roadway walls.

Characteristics of weakly cemented soft rock

The roadway floor primarily consists of weakly cemented soft rock, whose distinct mechanical properties significantly influence floor deformation and failure, necessitating further investigation into its characteristics. Formed through sedimentary processes, weakly cemented soft rock exhibits typical layered structures and complex lithological combinations. The structural properties of floor strata determine their load-bearing capacity, which in turn governs stress propagation and deformation-failure patterns in surrounding rock masses18,19,20. Based on the Mohr-Coulomb strength theory, rock strength correlates closely with parameters such as cohesion and internal friction angle. A comparison between weakly cemented rocks and their non-weakly cemented counterparts (Figure 3) under identical stress conditions reveals that if both undergo simultaneous failure:

The relationship between their internal friction angles can be derived as:

Weakly cemented mudstone, characterized by high clay mineral content and fine crack development, exhibits lower cohesion and significantly smaller internal friction angles compared to non-weakly cemented rocks. Consequently, their Mohr-Coulomb failure envelopes are represented by lines AB and CD, respectively. Under constant confining pressure, reduced cohesion and internal friction angles lead to lower critical failure stresses (σ₁ << σ’₁), demonstrating the insufficient strength and heightened failure susceptibility of weakly cemented soft rock. In the 11,304 tail entry, the sandy mudstone floor’slow strength, combined with reinforced rib support preventing coal rib failure, causes abutment pressure to transfer prematurely to the floor, resulting in severe floor heave.

Schematic diagram of Mohr’s circle for weakly cemented soft rock21.

Weakly cemented soft rock exhibits poor cementation and is prone to argillization upon water exposure, with water significantly degrading its strength properties. Therefore, investigations into its strength characteristics must account for aqueous weakening effects.

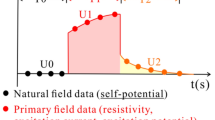

Standard specimens were immersed in water and weighed at 12-hour intervals, with a maximum immersion duration of 72 h. Uniaxial compression tests were conducted to determine the uniaxial compressive strength (UCS) of mudstone specimens under varying immersion times, as summarized in Table 1.

The experimental results indicate that mudstone specimens essentially reach saturation within 12 h of immersion, with their moisture content stabilizing thereafter. However, the relationship between compressive strength reduction and immersion duration lacks clear linearity. As shown in Fig. 4, the uniaxial compressive strength (UCS) of mudstone specimens demonstrates a progressive decline after water immersion. Specifically, after 12 h, 48 h, and 72 h of immersion, peak stresses decrease to 88.7%, 76.4%, and 69.5% of non-immersed specimens, respectively. Notably, higher water absorption correlates with greater UCS reductions. Concurrently, the strain values corresponding to peak stress exhibit significant increases. The interaction between mudstone and water, as illustrated in Fig. 5, reveals that the growth of microcrack dimensions within rock specimens and the dilation of joint surfaces lead to strength reduction. During loading, the opened joint surfaces gradually close under axial load, resulting in pronounced increases in strain values at peak stress.

The interaction between water and mudstone promotes microcrack propagation and joint surface dilation within the rock matrix, leading to strength degradation. During axial loading, the dilation of these joints gradually diminishes under compressive forces, resulting in pronounced strain accumulation at peak stress.

The marked UCS reduction in water-saturated weakly cemented soft rock significantly compromises the bearing capacity of roadway floors. Under superimposed stresses transferred from excavation or mining activities, this strength degradation exacerbates stress redistribution, ultimately triggering severe asymmetric floor heave.

Characteristics of roadway floor heave

The 11,304 tail entry, functioning as a gob-side entry adjacent to the 11,303 goaf, sustained varying degrees of surrounding rock damage during excavation due to overlying strata movement from the 11,303 goaf. As demonstrated in Fig. 6, the damage primarily manifested as floor heave and pavement cracking at the solid coal side of the roadway center section, where the floor stress reached the pavement’s ultimate bearing capacity, while the pillar-side floor maintained structural integrity.

As continuous mining advanced in the 11,304 working face, the dynamically evolving additional lateral abutment pressure disrupted the original equilibrium of the roadway’s stress field, triggering stress redistribution and further deteriorating the mechanical environment of the surrounding rock. Specifically, mining-induced advance abutment pressure transferred to the floor strata through roadway ribs. The weakly cemented laminated floor strata, with insufficient bearing capacity, underwent significant plastic deformation under asymmetric stress. The exposed surface of the floor strata provided free space for stress release and deformation development, intensifying floor uplift. Under the combined bolt-cable support system for the roof and ribs, the rib displacement remained notably smaller compared to the floor heave magnitude in unsupported floor zones.When the working face advanced to 120 m from the monitoring point, the roadway surrounding rock remained stable with no significant deformation due to minimal mining disturbance. As the face approached 70 m from the monitoring point, asymmetric floor heave initiated under advance abutment pressure. Proximity to the working face intensified mining disturbance, accelerating floor heave development. The deformation characteristics included migration of the heave peak toward the coal pillar side, accompanied by pronounced uplift on that side. The maximum uplift of 760 mm induced structural cracking in the floor, forming a typical asymmetric failure mode (as shown in Fig. 7).

Mechanical mechanism of floor heave in weakly cemented gob-side roadways

Based on comprehensive field measurements and analysis of Surrounding Rock deformation and failure characteristics, the floor of the 11,304 tailgate entry primarily exhibits deformation resulting from strength degradation, disintegration, and expansion of the Surrounding Rock under the coupling effect of intense stress disturbance and water-rock interaction. From the perspective of stress distribution, the original rock strata exist in a triaxial stress equilibrium system. When entry excavation disrupts the integrity of the geological structure, the Surrounding Rock system undergoes a complex stress redistribution process.

Stress redistribution during entry excavation and working face extraction follows the stress superposition principle in elasticity theory22. Based on the linear superposition principle, the stress distribution in the Surrounding Rock after entry excavation is linearly superimposed with the in-situ stress field, constructing a mechanical model of floor heave in the goaf-side entry with significant asymmetry, as illustrated in Fig. 8. Let the in-situ stress field be σr, Under the action of the secondary stress field formed by entry excavation, a composite stress field develops in specific zones of the Surrounding Rock: the solid coal side is subjected to the lateral additional stress σ2, induced by excavation disturbance, while the pillar side is subjected to both the lateral additional stress σ3 induced by overburden movement in the goaf and the lateral additional stress σ2 from excavation disturbance. According to the stress superposition principle:

As derived from Eq. (3) and Eq. (4), the pressure on the pillar-side floor σA exceeds that on the solid coal-side floor σB.

According to Rankine’s earth pressure theory, within a certain depth range of the entry floor, active sliding zones and passive sliding zones will develop. Specifically, ADB and A1D1B1 constitute the active sliding zones, while DBC and D1B1C1 form the passive sliding zones. Over time, the surfaces EC and E1C1 heave toward the free surface or extrude into the entry, generating vertically upward pressure. When this pressure exceeds the ultimate strength of the rock mass, floor failure occurs. The resultant deformation manifests as extrusion into the entry or heaving into the entry space, thereby causing floor heave. Due to the higher stress level on the pillar side compared to the solid coal side, the peak heave of the entry floor shifts toward the solid coal side.

During working face extraction, the lateral additional stress generated by face advance is linearly superimposed with the lateral abutment pressure from the excavation period, establishing a mechanical model of floor heave in the goaf-side entry during extraction, as illustrated in Fig. 9: Here, σ3 denotes the lateral additional stress caused by overlying strata movement in the goaf, σ2 represents the lateral additional stress from excavation disturbance, k1σ4 and k2σ4 are the lateral additional stresses induced by mining disturbances on the coal pillar side and solid coal side, respectively. σC indicates the peak lateral abutment pressure on the coal pillar side during mining, σD denotes the peak lateral abutment pressure on the solid coal side, and σr represents the in-situ stress.

As derived from Eq. (5) and Eq. (6), the pressure on the pillar-side floor σC is less than that on the solid coal-side floor σD.

During working face extraction, the Surrounding Rock on the pillar side enters a plastic state; the expansion of the plastic zone partially releases the stress concentration in the pillar rib, resulting in a relatively lower overall stress level induced by mining activities; in contrast, the solid coal side experiences concentrated vertical stress in the shallow coal mass due to front abutment pressure; the plastic zone remains shallow while the deeper region stays in the elastic zone, preventing effective stress release; consequently, the stress on the solid coal side caused by extraction far exceeds that on the pillar side. The stress on both sides of the entry floor remains persistently asymmetric, making the passive sliding zone D1B1C1 larger than DBC; this asymmetry causes higher susceptibility to failure in the pillar-side floor; the failure range on the pillar side is larger; under compression, the floor Surrounding Rock extrudes toward the pillar side; thus, the heave magnitude on the pillar side exceeds that on the solid coal side. Consequently, while floor heave intensifies, the peak heave location dynamically shifts from near the solid coal side at the entry center during excavation to the pillar side during extraction.

Control methods for floor heave in weakly cemented soft rock

Based on the mechanism analysis of the aforementioned floor heave, the floor heave in the 11,304 tail entry originates from the dual effects of external disturbance and Surrounding Rock degradation: on one hand, excavation and extraction activities induce stress redistribution in the Surrounding Rock, causing the floor to endure stress concentration due to lateral stress transfer; on the other hand, groundwater seepage triggers hydration of argillaceous strata, leading to continuous attenuation of rock mass strength; coupled with long-term lack of support constraints on the floor, these factors ultimately result in significant floor heave. Regarding the mechanism of floor heave in weakly cemented soft rock floors during extraction, controlling heave requires enhancing deformation resistance of the floor rock mass and applying active restraining forces through the “floor corner bolt pile” technology; for weakly cemented soft rock entries under high-stress conditions, the support principle lies in enhancing rock mass resistance to horizontal stress: on one hand, floor grouting effectively mitigates floor heave through two primary mechanisms: fracture filling/bonding and water ingress prevention. The pressurized injection of cementitious grout permeates bedding planes and discontinuities, creating a reinforced composite structure that enhances the overall stiffness of fractured floor strata while restoring cohesive strength along weakened interfaces through chemical bonding. Simultaneously, the grout acts as an impermeable barrier, sealing fluid migration pathways to prevent water infiltration that would otherwise contribute to rock softening, swelling, and stress corrosion in the floor strata. This dual-action intervention transforms the deformation behavior of the floor from discontinuous yielding to a more homogeneous, load-resistant medium, particularly crucial in weak or water-sensitive geological formations23,24,25,26,27,28; this approach achieves effective heave control through rock mass modification and mechanical equilibrium regulation, ultimately establishing dynamic balance between floor deformation resistance and Surrounding Rock stress environment.

As shown in Fig. 10, the floor corner bolt pile technology comprises drilling, grouting, and bolt installation: first, drilling is performed at the floor corners of the entry, where the borehole diameter is determined by the pile diameter of the floor pile; after partially relieving the stress in the floor Surrounding Rock, anchor bolts of specified dimensions are inserted into the boreholes; second, pressure grouting is conducted, allowing cement grout to penetrate rock fractures, enhancing the shear strength of structural planes while integrating the rock mass with the floor pile; following grouting, the floor corner bolt pile is formed; this grout-concrete composite requires no vibration and rapidly develops load-bearing capacity in the floor pile.

During grouting operations, the process control and parameter configuration for floor grouting are constrained by on-site construction conditions (e.g., geological environment, workspace limitations). While grouting material properties and mix ratios are typically predetermined through laboratory testing and remain relatively consistent, the determination of grouting procedures and critical parameters—such as grouting pressure, slurry water-cement ratio, and grout spread radius—is well-established. Conversely, variations in floor bolt parameters (e.g., length, spacing, installation angle) exert significant influence on floor deformation control, necessitating systematic investigation of floor bolt parameter optimization to achieve targeted reinforcement outcomes.

In response to the unique engineering conditions of the 11,304 tail entry (where the floor is subjected to differential lateral abutment pressures on both sides), four floor bolt parameter design schemes, as detailed in Table 2, have been formulated through field condition analysis. This design methodology holistically integrates asymmetric load distribution characteristics with roadway stability requirements, achieving holistic reinforcement efficacy of the floor structure by strategically matching differentiated anchoring parameters to region-specific stress states. The spatial distribution of floor bolts is explicitly illustrated in Fig. 11.

Using the 3DEC numerical software with the 11,304 tail entry as the engineering prototype, the model dimensions are: 170 m in the X-direction, 120 m in the Y-direction, and 85 m in the Z-direction. The upper boundary consists of conglomerate sandstone, while the lower boundary is siltstone; the strata sequence from top to bottom is conglomerate, siltstone, sandy mudstone, coal, sandy mudstone, and siltstone, with joint surfaces between layers permitted to slip. The entry cross-section is rectangular (5 m × 4 m). The in-situ entry burial depth is approximately 500 m. Model boundaries are defined as: displacement boundaries on the left/right, front/rear, and bottom; a stress boundary at the top with vertical loading (11.25 MPa calculated from 450 m overburden depth). The boundary conditions are illustrated in Fig. 12. Rock mechanical parameters in the numerical model were determined by laboratory tests on water-saturated rock samples (48 h immersion), with specific values listed in Table 3. After achieving initial geostatic equilibrium, the model first simulates extraction of the 11,303 working face; upon reaching a new stress equilibrium, it simulates excavation of the 11,304 tail entry; finally, after re-stabilization, it simulates extraction of the 11,304 working face. The floor bolts in the numerical model are established as shown in Fig. 13.

As shown in Fig. 14, the displacement contour map of the simulation results reveals that during panel retreat mining, the roadway floor heave exhibits significant asymmetric characteristics, with the heave magnitude on the solid coal side being notably smaller than that on the coal pillar side. Comparative analysis of the four support schemes demonstrates that the symmetrical floor bolts on both sides achieve the most effective suppression of floor heave by forming a bidirectional constraint system through enhanced floor support strength and coordinated surrounding rock deformation, reducing asymmetric displacement by up to 75%. In contrast, unilateral bolting on the solid coal side improves local deformation resistance but fails to balance support forces due to the lack of constraint on the coal pillar side, resulting in a 35% lower control efficiency compared to symmetrical bolting. Unilateral bolting on the coal pillar side further weakens control efficacy (20–25% heave reduction) as it cannot cover the deformation transfer path from the solid coal side, leading to incomplete systemic constraints. Under the no-bolting condition, the floor remains entirely passive under loading, accelerating asymmetric heave development with peak displacements exceeding 700 mm. These results conclusively indicate that the spatial symmetry and mechanical coordination of the support system are critical for controlling asymmetric floor heave, with symmetrical bolting optimizing stress redistribution and deformation compatibility to achieve dynamic equilibrium between the floor’s load-bearing capacity and mining-induced disturbances.

As shown in Fig. 15, a comparison of floor heave magnitudes before and after the implementation of floor support measures reveals that without support measures, the roadway exhibits significant floor heave with a maximum deformation of 780 mm, characterized by asymmetric distribution. After implementing support measures, the three bolt schemes—“symmetrically arranged floor bolts along roadway flanks”, “floor bolts on solid coal side”, and “floor bolts on coal pillar side”—reduce the maximum floor heave to 301 mm, 389 mm, and 503 mm, respectively. Compared to the unsupported condition, the reductions in floor heave are 61.4%, 54.0%, and 35.5%, demonstrating that floor bolt support significantly mitigates floor heave. Furthermore, the comparison of unilateral bolt arrangements shows that floor bolts on the solid coal side provide better control over floor heave than those on the coal pillar side, highlighting the influence of asymmetric stress distribution and deformation mechanisms in weak cemented soft rock.

Engineering application

Based on the simulation results, to address severe floor heave in the 11,304 tailgate entry, a symmetrical floor bolting + floor grouting solution is implemented, with specific procedures as follows: Commencing 100 m ahead of the working face, floor corner bolt holes are drilled on both sides; hole depth: 2400 mm; spacing: 1 m; collar position: 100 mm above floor; 60° angle to rib; spacing: 1.0 m; after drilling completion, cement-water slurry (ratio 1:0.5) is injected into holes; then ribbed steel bolts (2400 mm) are installed to form cement-mixed piles for floor reinforcement; the mix ratio for cement-mixed piles is typically cement: sand: water = 1:2:0.5. Implementation steps:

-

1.

Material preparation: Prepare cement and sand according to specified ratios, with clean water on standby.

-

2.

Material mixing: Mix cement, sand, and water at designated ratios for 5 min.

-

3.

Casting cement-mixed piles: Pour mixed concrete into pre-drilled holes; uniformly compact piles using tamping rods.

The field implementation is shown in Fig. 16.

As shown in Fig. 17, monitoring studies on floor heave in weakly cemented soft rock along-goaf roadways before and after implementing the “floor grouting + symmetrical floor bolts on both sides” scheme demonstrate significant control efficacy. Monitoring data indicate that unsupported monitoring points exhibited severe floor heave deformations of 760 mm and 720 mm, whereas the application of the combined grouting and bolting scheme effectively limited floor heave to 200 mm and 180 mm at corresponding points. Quantitative analysis reveals an average reduction of 74.3% in maximum floor heave magnitude post-implementation. These experimental results confirm that the synergistic interaction mechanism of grouting reinforcement and symmetrical floor bolting effectively improves the mechanical properties of surrounding rock, enhances the structural integrity of the floor, and significantly mitigates the sustained large deformations characteristic of soft rock roadways. This approach provides critical technical guidance for roadway support design under analogous geological conditions, particularly in weakly cemented strata subjected to asymmetric mining-induced stresses.

Discussion

This manuscript addresses severe floor heave in the 11,304 tailgate entry during both excavation and extraction phases. Based on Rankine’s earth pressure theory, mechanical models of the entry floor were established for these distinct stages, revealing stage-specific heave mechanisms and proposing corresponding control measures that yielded favorable engineering outcomes. However, the sole reliance on Rankine’s theory imposes limitations in explaining heave mechanisms across different mining periods; further investigation into control technologies for weakly cemented soft rock entries under varying extraction conditions remains necessary.

Main conclusions

-

1.

Uniaxial compression tests on mudstone specimens with different immersion durations revealed that after 12 h, 48 h, and 72 h of water immersion, the peak stresses decreased to 88.7%, 76.4%, and 72.5% of non-immersed specimens, respectively. The greater the water absorption of mudstone specimens, the larger the reduction in uniaxial compressive strength. The strain values corresponding to peak stresses showed significant increases. Weakly cemented soft rocks exhibited pronounced strength degradation after water immersion.

-

2.

During roadway excavation, the stress at the middle floor near the solid coal side reached the ultimate bearing capacity of the floor, inducing floor uplift and floor cracking. The heave peak appeared at the roadway center biased toward the solid coal side, while the floor on the coal pillar side remained relatively intact. Under mining-induced stresses, the peak heave position migrated toward the coal pillar side, with significant floor uplift observed on the coal pillar side. The maximum uplift caused structural cracking in the floor, forming a typical asymmetric failure mode.

-

3.

Comparative analysis of floor heave mechanical models during roadway excavation and mining periods demonstrated that during excavation, the lateral abutment pressure on the coal pillar side exceeded that on the solid coal side. During mining, mining-induced stresses reversed this pattern, making the lateral abutment pressure on the solid coal side greater. Based on slip-line theory, the Rankine passive zone induced by solid coal side stresses was larger than that on the coal pillar side, resulting in dynamic migration of the heave peak position from the excavation-phase location (mid-floor biased toward solid coal) to the coal pillar side during mining.

-

4.

A 3DEC numerical model of the 11,304 tail entry during mining simulated floor heave under four scenarios: “no floor bolts,” “symmetrical floor bolts on both sides,” “symmetrical floor bolts on the solid coal side,” and “symmetrical floor bolts on the coal pillar side.” Without support, maximum floor heave reached 780 mm. With bolt reinforcement, maximum heaves reduced to 301 mm, 359 mm, and 503 mm respectively, corresponding to reductions of 61.4%, 54.0%, and 35.5%. Floor bolts on the solid coal side demonstrated superior control effectiveness compared to those on the coal pillar side.

-

5.

Field testing of the “symmetrical floor bolts on both sides + floor grouting” scheme in the 11,304 tail entry showed 74.3% reduction in floor heave within a 100 m advance monitoring section as the working face progressed, confirming that floor bolt reinforcement effectively mitigates floor heave in weakly cemented soft rock roadways along goaf edges.

Data availability

The datasets generated and/or analysed during the current study are not publicly available due [REASON WHY DATA ARE NOT PUBLIC] but are available from the corresponding author on reasonable request.

References

Zhu, Y. Mechanism and Control Countermeasures of Floor Heave in Roadways with Weakly - Cemented Soft Rock Under Strong Mining in Meihuajing Mine (China University of Mining and Technology (Beijing), 2021).

Hua, X. Z. & Li, Y. Mechanical analysis of floor deformation and prevention and control of floor heave in Gob - Side entry retaining. J. China Coal Soc. 41(07), 1624–1631 (2016).

Chen, Y. et al. Control mechanism and technique of floor heave with reinforcing solid coal side and floor corner in gob-side coal entry retaining. Int. J. Min. Sci. Technol. 22(06), 841–845 (2012).

Wang, D. et al. Mechanism and control of asymmetric floor heave in the gob-side coal roadway under mining pressure in Extra-Thick coal seams. Energies 16, 4948 (2023).

Shu, J. et al. Floor heave control technology for roadways in weak surrounding rock. Saf. Coal Mines. 42(05), 52–54 (2011).

Zhu, L. et al. Research on floor heave mechanisms and control technology for deep dynamic pressure roadways. Processes. 11(2) (2023).

Liu, Q. S. et al. Research on characteristics and comprehensive control countermeasures of floor heave in high - geostress broken soft - rock roadways. Rock. Soil. Mech. 33(06), 1703–1710 (2012).

Sakhno, I. & Sakhno, S. Numerical studies of floor heave mechanism and the effectiveness of grouting reinforcement of roadway in soft rock containing the mine water. Int. J. Rock Mech. Min. Sci. 170, 105484 (2023).

Zhao, Y. M., Liu, N., Zheng, X. & Zhang, N. Mechanical model for con-trolling floor heave in deep roadways with U-shaped steel closed support. Int. J. Min. Sci. Technol. 25, 713–720 (2015).

Sun, X. M. et al. Physical modeling of floor heave for the deep-buried roadway excavated in ten degree inclined strata using infrared thermal imaging technology. Tunn. Undergr. Space Technol. 63, 228–243 (2017).

Zhang, S. B. et al. Mechanism and application of floor heave control in roadways in coal - mudstone chamber group areas. J. Basic. Sci. Eng. 25(04), 712–723 (2017).

Liu, C. et al. Mechanism and prevention countermeasures of floor heave in layered floor of large - section mining roadways. J. China Coal Soc. 39(06), 1049–1055 (2014).

Zhang, J. H., Wang, L. G., Li, Q. H. & Zhu, S. S. Plastic zone analysis and support optimization of shallow roadway with weakly cemented soft strata. Int. J. Min. Sci. Technol. 25(3), 395–400 (2015).

Chen, A. et al. Relief-Retaining Control Technology of Floor Heave in Mining Roadway with Soft Rock: A Case Manuscript, 1455052 (2021).

Li, X. L., Chen, S. J., Zhang, Q. M., Gao, X. & Feng, F. Research on theory, simulation and measurement of stress behavior under regenerated roof condition. Geomech. Eng. 26(1), 49–61 (2021).

Zhai, W. et al. Floor heave mechanism in water-rich soft rock roadways and a DS-IBA control approach. Geomatics Nat. Hazards Risk. 13(1), 2107–2123 (2022).

Shimamoto, K. & Yashiro, K. New rockbolting methods for reinforcing tunnels against deformationint. J. Rock. Mech. Min. 147, 104898 (2021).

Jiang, P. F. Research on the evolution of the comprehensive stress field of surrounding rock in opposite - mining and opposite - tunneling roadways in deep extra - thick coal seams. Coal Sci. Technol. 48(08), 26–36 (2020).

Ji, H. G. et al. Research progress on surrounding - rock stability control of engineering in weakly - cemented strata in western mining areas. Coal Sci. Technol. 51(01), 117–127 (2023).

Kang, Y. S. et al. Research progress on control technologies and methods for large - deformation disasters in soft rock in China. Rock. Soil. Mech. 43(08), 2035–2059 (2022).

Tan, Y. L. et al. Research on coordinated control method of bolt-cable and surrounding rock deformation in weakly cemented soft rock coal roadway. Coal Sci. Technol. 49(1), 198–207 (2021).

Liangke, X. et al. The evolution of fractures in deep, weakly cemented overlying strata and the characteristics of severe and mild fracture zones. Geomech. Geophys. Geo-Energy Geo-Resour. 10(1) (2024).

Tan, Y. L. et al. Research on the collaborative control method of bolt - anchor - surrounding rock deformation in coal roadways with weakly - cemented soft rock. Coal Sci. Technol. 49(01), 198–207 (2021).

Cheng, H. et al. Research on the mechanism and prevention technology of floor heave in mining roadways of close - distance coal seams. J. Cent. South. Univ. (Science Technology). 53(04), 1392–1405 (2022).

Yang, S. B. et al. Mechanism and application research of floor - corner bolts in controlling floor heave in deep soft - rock roadways. Chin. J. Rock Mechan. Eng.(S1), 2913–2920. (2008).

Chen, L. H. et al. Analysis and control of large deformation of water - rich expansive soft - rock floor. Coal Technol. 41(02), 48–52 (2022).

Zou, Y. D. & Yan, R. Y. Exploration and application of inverted - arch floor bolt and pouring floor heave control technology in deep soft - rock chambers. Coal Min. Technol. 19(03), 90–92 (2014).

Wang, P. et al. Accumulated damage failure mechanism of anchoring structures under cyclic impact disturbance. Int. J. Min. Sci. Technol. (2024).

Acknowledgements

This work was supported by the Shandong Provincial Natural Science Foundation General Project (No. ZR2022ME158).

Author information

Authors and Affiliations

Contributions

Fenghai Yu. and Jin Yang. were responsible for writing the first draft of the paper. Kai Zhou was responsible for the review of the paper. Baodeng Liu was responsible for the data analysis of the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yu, F., Yang, J., Zhou, K. et al. Mechanism and control measures for floor heave in gob-side entry of weakly cemented soft rock. Sci Rep 15, 33578 (2025). https://doi.org/10.1038/s41598-025-18701-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-18701-8