Abstract

This study offers a comprehensive techno-economic and environmental evaluation of a hybrid solar-natural gas combined cycle power plant designed for the Kirkuk region, taking advantage of its high solar irradiance. The proposed system incorporates advanced technologies to maximize efficiency and sustainability, including absorption refrigeration systems, steam Rankine cycles, and organic Rankine cycles. Two configurations were analyzed: Model 1 integrates a conventional gas turbine with a steam Rankine cycle driven by exhaust gases and solar energy collectors and an organic Rankine cycle; Model 2 combines all the components of Model 1 with the absorption refrigeration system (ARS) to enhance turbine efficiency through compressor inlet air cooling. The results indicate that Model 2 delivers a net power output between 235 MW and 245 MW, exceeding Model 1 by up to 12.7 MW. It offers significant 5–10% reductions, with electricity costs ranging from $70/MWh to $76.5/MWh, while also cutting CO₂ emissions by 0.7 to 2 kg CO2/MWh, particularly during hotter periods. In June, Model 2 achieved the lowest power cost of $70/MWh and a peak output of 245 MW, compared to $72/MWh and 235 MW for Model (1) During December, however, Model 1 shows slightly better performance due to cooler conditions, with costs of $78/MWh versus $76.5/MWh for Model (2) Exergy analysis highlights the combustion chamber as the main contributor to system losses, accounting for 46.07% of total exergy destruction. Nevertheless, Model 2 integrates solar energy and ARS effectively, achieving energy and exergy efficiencies of 59.25% and 57.21%, respectively, demonstrating its superior overall performance. These findings demonstrate that integrating gas turbines with renewable energy and advanced cooling technologies provides a scalable, economically viable solution to Iraq’s energy challenges. Additionally, this research establishes a replicable framework for regions with high solar potential, emphasizing the transformative potential of hybrid energy systems in achieving sustainable energy security while mitigating environmental impacts.

Similar content being viewed by others

Introduction

In today’s world, the extensive reliance on fossil fuels across various aspects of daily life and industrial sectors has significantly disrupted climate patterns, accelerating global warming1,2. Consequently, the urgent need to transition to sustainable and environmentally friendly fuels and energy sources has become increasingly paramount. Waste flue gases offer substantial potential for driving various thermal cycles, including steam and organic Rankine cycles. They can be utilized in applications such as desalination, absorption refrigeration, heating systems, and more. The concept of integrated multi-energy production is rapidly gaining prominence as a key area of research, attracting significant attention and recognition as a growing field3,4,5. Despite the recent surge in electricity demand, there has been a noticeable shift towards sustainability, driven by increased environmental awareness, concerns over global warming, natural resource depletion, and the pursuit of energy self-sufficiency6. In recent years, Iraq has faced numerous challenges, primarily stemming from its political and social environment, as well as ongoing military conflicts. These issues have hindered the country’s ability to achieve sustainable economic growth, which its people desire7. With its heavy reliance on oil and oil-related industries, Iraq boasts the fourth-largest economy in the Middle East. The country’s energy consumption is substantial, and demand continues to rise due to a growing population and external factors, such as higher temperatures. This has led to the widespread use of climate control systems, particularly air conditioning during the summer months. The rising demand for electricity threatens Iraq’s stability and poses significant risks to its economic growth and the well-being of its population. Addressing these challenges requires substantial investment in constructing new power plants, upgrading existing facilities, and modernizing the electricity infrastructure. Approaches such as re-powering, which focuses on retrofitting older plants, and leveraging advanced simulation tools for system optimization, play a pivotal role in improving efficiency and reducing operational costs. These initiatives have aligned with the country’s vision, addressing key environmental concerns and fostering greater awareness8. Inlet air cooling systems are widely recognized as an effective energy conservation method. Vapor Absorption Cooling technology stands out as a promising alternative for meeting cooling demands among energy-saving solutions. A 10 °C rise in ambient temperature can lead to a 6–10% reduction in output power, alongside an increase in specific heat consumption. Despite encouragement from the Iraqi Ministry of Electricity, there remains a significant gap in research to improve existing power plants and integrate renewable energy sources. A study of Iraq’s electricity sector shows that approximately 25% of the country’s electricity is generated by thermal power plants, operating at 40% efficiency, with the remaining 60% lost as waste heat. Gas turbines, which produce 47% of Iraq’s electricity, encounter efficiency issues due to high ambient temperatures. The use of inlet air cooling systems is widely recognized as an effective solution for significant energy savings, with Vapor Absorption Cooling technology offering promising potential in this area9.

Researchers in Iraq have conducted some studies to explore waste heat utilization from gas stations, aiming to reduce carbon emissions and increase production capacity and solar power plants. For example, Hassan et al.10 examined the feasibility of constructing solar photovoltaic (PV) power plants capable of generating 20 MW of energy, focusing their assessment on four major cities in Iraq. Talal et al.11,12 evaluated a polygeneration system integrating a solar-driven Rankine cycle with the Al-Qayyara gas turbine and absorption refrigeration. The system improves efficiency by utilizing exhaust gases and solar energy for steam generation and cooling. Shaheed et al.13 conducted an energy and exergy analysis of the 225 MW Al-Mosyab steam power plant, revealing a thermal efficiency of 39.91% and a second law (exergy) efficiency of 34.91%. The boiler was identified as the primary source of exergy destruction, accounting for 86.48% of the total losses. Kareem et al.14 conducted an analysis of the Taji power plant in Baghdad, integrating it with Rankine and Organic Rankine cycles to enhance waste heat recovery and reduce emissions. The integrated system generates 258.2 MW, achieving energy and exergy efficiencies of 44.37% and 42.84%, respectively, with a production cost of USD 9.03/MWh. Saeed et al.15 explored the potential of replacing fossil fuels in Iraq with renewable energy and nuclear power, assessing their practical viability. Their analysis showed that adopting alternative energy sources could help address the electricity deficit and significantly reduce greenhouse gas emissions from fossil fuel generators. Kazem and Chaichan16 investigated Iraq’s electricity shortages, finding that solar, wind, and biomass energy were underutilized but have significant potential to shape the country’s renewable energy future. Faisal et al.17 conducted an energy and exergy analysis on a GE gas turbine at the Shatt Al-Basra power plant in Basra, Iraq. Their findings revealed that thermal and exergy efficiencies peaked in February, making it the optimal month for efficiency. Ahmed et al.18 performed an energy and exergy analysis on a 150 MW gas turbine plant, using a data flow sheet and the Kirkuk unit, to assess efficiency losses in real-world settings. Similarly, Salah et al.19 conducted an energy and exergy analysis of the Kirkuk gas power plant to evaluate losses under actual operating conditions. Shukla and Singh20 examined how compressor inlet temperature and relative humidity affect gas turbine performance. They found that a 10 °C increase in inlet temperature can reduce efficiency and power output by up to 1.5%, while humidity levels above 60% can cause compressor fouling, decreasing performance by 3–5%. Effective management of these factors is crucial for maintaining efficiency and maximizing power generation. Oko and Njoku21 enhanced a 650 MW combined cycle power plant by integrating an Organic Rankine Cycle (ORC), using HFE7100 as the working fluid, to recover waste heat. This added 12.4 MW of power and improved energy and exergy efficiencies by 1.95% and 1.93%, respectively, with the highest exergy losses in the combustion chamber (59%) and ORC evaporator (62%). Yang et al.22 proposed a dual-pressure Kalina cycle-absorption refrigeration combined cooling and power system (DPKC-AR-CCP) efficiently recovers waste heat from internal combustion engines, significantly enhancing net power output, cooling capacity, and exergy efficiency while reducing payback period and CO2 emissions, though at a higher exergy cost rate, with optimal performance achieved at specific ammonia/water concentrations, temperatures, and pressures. Mubashir et al.23 proposed an innovative trigeneration system that integrates a supercritical CO₂ Brayton cycle, ORC, and ARS to recover waste heat from an internal combustion engine operating at 470 °C. After optimization, the system achieved an exergy efficiency of 59.21% and a levelized cost of electricity of 0.063 $/kWh, with the most efficient configuration utilizing a cascading setup where flue gas sequentially powers the Brayton cycle, ORC, and ARS. Chen et al.24 evaluated the performance of an integrated energy system combining absorption refrigeration and organic Rankine cycles. The system achieved a 22.53% reduction in natural gas consumption, a 50% increase in cold output, and improvements in energy and exergy efficiency by 12.90% and 1.99%, respectively, while also lowering total costs by 26.25% and environmental impact by 35.87%. Ren et al.25 proposed an innovative cogeneration system integrating biomass gasification with an externally fired gas turbine, organic Rankine cycle, and absorption refrigeration. The system achieved 66.36% thermal efficiency, 32.04% exergy efficiency, and a product cost of 8.71 USD/GJ, with optimization improving exergy efficiency by 9.7% and reducing product cost by 1.8%. Yang et al.26 proposed a biomass and solar-powered combined cooling, heating, and power (CCHP) system integrated with an organic Rankine cycle (ORC), achieving unit exergy costs ranging from 2.742 to 27.100 MW/MW, exergoeconomic costs between 41.11 and 507.10 USD/MWh, and environmental impact rates from 0.030 to 6.567 mPts/MJ. Yilmaz and Ozturk27 designed and analyzed a multigeneration plant integrating a gas turbine, Rankine cycle, desalination, hydrogen, and ammonia production. The system generates 12,835 kW of power, 0.0607 kg/s of hydrogen, and 4.89 kg/s of freshwater. The total cost rate is $1074/h, with energetic and exergetic efficiencies of 58.38% and 54.21%, respectively. Mousavi et al.28 propose a solar-driven cogeneration system using a PTC integrated with an organic Rankine cycle (ORC) and diffusion absorption refrigeration (DAR) for a village in Iran, delivering 10.76 kW of power and 44.55 kW of cooling, with exergy analysis showing 67.89% efficiency and environmental impact primarily from the EX-101 expander and E-102 heat exchanger, suggesting operational improvements. Yilmaz et al.29 examines a solar-assisted poly-generation system using a parabolic dish collector, integrating electricity, fresh-water, hot-water, heating-cooling, and hydrogen production. The system employs a Rankine cycle with three turbines for electricity, a membrane distillation unit for desalination using waste heat, and a PEM electrolyzer for hydrogen production during excess power generation. Additionally, a high-temperature cooling cycle supports hot-water production. The thermodynamic assessment reveals energy and exergy efficiencies of 58.43% and 54.18%. Nourpour et al.30 investigated the ISCCS in Yazd, Iran, through thermodynamic, exergy, exergoeconomic, exergoenvironmental, and emergy-based analyses, revealing a thermal efficiency of 48.25%, a net power generation of 419,600 kW, and less than 10% avoidable/endogenous exergy destruction, costs, and environmental impacts in most equipment. Adebayo et al.31 discussed A novel multigeneration system based on a solid oxide fuel cell (SOFC) fueled by biogas from agricultural waste (maize silage) produces electricity, domestic hot water, hydrogen, and cooling, achieving 789.7 kW net power, 317.3 kW cooling, and 69.86% and 47.4% energy and exergy efficiency, respectively, with a cascaded closed-loop ORC cycle. Yilmaz et al.32 evaluated an advanced geothermal power plant integrating ORCs, a PEM electrolyzer, ammonia synthesis, and reverse osmosis desalination. The system generates 2046 kW of electricity, 0.002367 kg/s of green hydrogen, and 0.009436 kg/s of ammonia. Exergy destruction totals 4945 kW, with energetic and exergetic performances of 26.31% and 33.09%, respectively. Assareh et al.33 proposed a system integrating a thermoelectric generator and an organic Rankine cycle with a gas turbine to reduce emissions and enhance production. The analysis shows that the combustion chamber, evaporator, gas turbine, and thermoelectric generator contribute most to exergy destruction. The thermodynamic and economic evaluations reveal that the system performs optimally in the cooler climate of Mashhad.

Recently, some researchers have proposed some techniques to reduce the air inlet temperature of gas turbines to improve the performance of turbines and increase their efficiency. Mohammadi et al.34 developed hybrid configurations based on GTCC for electricity, freshwater, and cooling, integrating double-effect absorption chillers (DEABC). Results show that DEABC is more economical than vapor compression chillers. Dizaji et al.35 introduced various techniques for reducing inlet air temperature to improve gas turbine power plant performance during hot seasons. Their approach involves an integrated cooling system that combines an indirect evaporative cooler (M-cycle), which avoids adding water droplets to the air stream, with absorption chillers. This configuration effectively decreases turbine inlet air temperature, significantly reducing the required chiller capacity and operational costs. Pourhedayat et al.36 introduced a hybrid pre-cooler using M-cycle and absorption cooling to cool air near dew-point temperature, enhancing gas turbine performance while minimizing energy consumption. Mohammadi et al.37 suggested a hybrid system combining a gas turbine, ORC, and absorption cooling cycle for residential use, achieving high efficiency and optimized performance under specific conditions. Zare38 applied an ammonia-water absorption cooling cycle for turbine inlet air cooling, improving energy efficiency by 30.1% and reducing electricity costs by 22.5%. Yang et al.39 developed two-stage hybrid coolers combining absorption and ejector cooling, achieving air temperatures below 10 °C, improving fuel efficiency, and reducing annual energy consumption by up to 50% in temperate climates.

Despite previous studies, significant research gaps remain. For instance, while the combined natural gas, Rankine cycle, and organic Rankine cycle integrates various subsystems and utilizes natural gas and solar energy as heat sources, numerical studies, and comprehensive economic and environmental analyses are still limited. This study offers two key innovations. First, unlike existing power plants in Iraq, which are either gas or steam-based, this plant is integrated with solar energy and absorption cooling systems. Second, while most studies focus solely on energy and exergy analysis, this research provides a comprehensive evaluation, incorporating energy, exergy, exergoeconomic, and environmental analyses.

System description

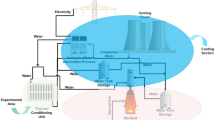

The layout of the current Kirkuk gas power plant, depicted in Fig. 1, offers a fascinating glimpse into the unique circumstances of this case study in Iraq. Three specific gas turbine types are within the configuration: K1, K2, and K3. It is worth mentioning that this study exclusively focuses on K1, which pertains exclusively to a unit from the Siemens V94.3 A gas turbine model. Normally, the electrical output capacity of this turbine is around 150 megawatts (MW).

This is a figure. Schemes follow the same formatting40.

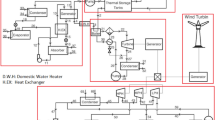

The system illustrated in Fig. 2 represents an integrated hybrid power generation cycle that combines the Bryton cycle BC, Steam Rankine cycle RC, organic Rankine cycle ORC, and a solar energy subsystem, which includes a solar field SF with thermal energy storage TES. This configuration is designed to maximize energy efficiency by effectively capturing and utilizing waste heat, as well as harnessing the potential solar energy available in Kirkuk. The cycle begins with the air compressor AC, which compresses incoming air. The compressed air then flows into the combustion chamber CC, where it mixes with fuel and undergoes combustion. This process generates high-temperature gases that flow through the gas turbine (GT), producing mechanical energy that is subsequently converted into electricity by the generator GEN. To further enhance efficiency, waste heat from the high-temperature exhaust gases is recovered using a Heat Recovery Steam Generator (HRSG). The HRSG directs the hot exhaust gases to convert water into steam, which then powers the Steam Rankine cycle, passing through high-pressure turbine (HP), intermediate-pressure (IP), and low-pressure (LP) turbines to generate additional power. The system also incorporates an Organic Rankine Cycle ORC that utilizes lower-temperature waste heat exiting the HRSG. The ORC employs a specific working fluid (R134), which evaporates at lower temperatures, allowing it to capture additional energy from the exhaust gases through an evaporator (EVAP) and a condenser (COND2). Additionally, the solar field SF supports the thermal power system by increasing the amount of steam produced within the hot steam generator, thereby enhancing energy production during sunlight hours. This combination of cycles, along with the solar subsystem, allows for the efficient use of all available heat, resulting in higher power output, reduced waste, and enhanced overall system performance. This integrated approach improves fuel utilization and minimizes environmental impact by reducing the release of high-temperature gases into the atmosphere.

Hybrid model 1 integrates a GT, RC, and ORC40.

Figure 3 shows how the Model 2 integrated power generation system is set up, with an Absorption Refrigeration Cycle (ARS) added, which is very important for making the system work better. In this setup, the ARS utilizes exhaust gases from the evaporator of the ORC unit as a heat source for its generator. By incorporating the ARS, the system manages to reduce the ambient air temperature entering the air compressors of the gas turbine units to 283 K. This cooling effect increases the density of the intake air, thereby boosting the gas turbine’s power output and overall efficiency. This integrated approach exemplifies a sophisticated hybrid system that not only leverages solar energy but also ensures optimal performance through effective waste heat recovery and air-cooling techniques, significantly improving the sustainability and environmental impact of the power plant.

System modeling

The following assumptions were applied in simulating the proposed system:

-

The system operates in a steady state.

-

Compressors, turbines, and pumps have consistent isentropic efficiencies.

-

Pressure drops in the connecting pipes are assumed to be negligible.

-

Kinetic and potential energy changes are negligible.

-

Exiting fluid from the condenser is saturated liquid.

-

Natural gas, with 100% methane, is used as the fuel for the combustion chamber, designed as an adiabatic system.

-

Ideal gas assumptions are used to determine the air and gas mixture properties at the combustion chamber outlet.

-

The pressure of the air and gas mixture flows in the heat exchangers is considered constant, and the heat exchangers operate with negligible pressure drop.

-

In the absorption system, the absorber and the generator temperatures are in equilibrium, matching the respective components.

-

The sun’s temperature is 5770 K40.

Thermodynamic analysis

The mass, energy, and exergy balance equations for each component within the system are defined as follows41:

Subscripts “i” and “e” denote the control volume inlet and exit, respectively. \(\:\dot{E}{x}_{\text{d}\text{e}\text{s}}\) represents the exergy destruction in each component, while “\(\:ex\)” refers to each stream’s exergy. \(\:\dot{E}{x}_{W}\:,\)and \(\:\dot{E}{x}_{Q}\) are the exergies associated with power and heat transfer, respectively that they are calculated using the following equations42:

The energy and exergy balance equations for all components of the Model 2 system are presented in Table 1.

The energy performance, represented as (\(\:{{\upeta\:}}_{\text{t}\text{h}}\)), can be approximated by utilizing the subsequent equation:

The heat input to the cycle (\(\:{\dot{\text{Q}}}_{\text{in\:}}\)) was calculated using:

Furthermore, the exergy efficiency (\(\:{{\upeta\:}}_{\text{e}\text{x}}\)) can be determined using the provided formula, which indicates the system’s quality:

Here, \(\:{\dot{\text{E}}}_{\text{3}}\) represents the exergy of the fuel supplied to the CC of the cycle.

Solar field modelling

In the current analysis, a Parabolic Trough Collector PTC is considered as the solar energy system, located at 35.47° N, 44.39° E in the Kirkuk region of Iraq, and a mathematical model has been developed for it. The solar collector absorbs solar irradiation, while the receiver reflects this radiation. Various heat losses occur throughout the process, impacting the solar energy efficiency of the PTC system. To determine the usable solar energy and quantify heat losses within the solar system, an energy analysis was conducted such as in the equations in Table 2.

Exergo-economic and environmental analysis

Cost balance equations for the exergy costing process can be formulated individually for each component of the system as follow45:

Based on the equation above, it can be inferred that the cost rates of exergy streams exiting each component are equivalent to the cost rates of entering exergy streams, along with the investment cost rate required to complete the process for each component. In Eq. (9), “c” denotes the unit cost of each exergy stream, while the capital investment cost rate, Z, is determined using Eq. (10)46:

Here, \(\:{\text{Z}}_{\text{k}}\) indicates the purchase cost of the k-th component, with ϕ representnting the maintenance factor. N refers to the system’s annual operating hours, and CRF denotes the Capital Recovery Factor, which is determined through Equation (11)47:

The interest rate and the operational lifespan of the system are set at i = 10%, and n = 20 years, respectively. Additionally, the maintenance factor ϕ is taken as 1.06, and the annual operating hours N are 7446 h48. The detailed cost balance equations for each component in the integrated system, along with their corresponding auxiliary equations and underlying assumptions, are presented in Table 3. Additionally, the capital investment cost functions for each component are derived from references12,26,49.

Lastly, the CO2 emission rate (\(\:{\epsilon\:}_{\text{C}\text{O}2}\)) is determined using the following equation50:

Results and discussion

The exergoeconomic findings of the integrated system are presented in three stages to ensure a comprehensive analysis. In the first stage, each system’s results are validated by comparing them with previous studies. The second stage involves operating the system under specific conditions to demonstrate its functionality practically. In the final stage, parametric experiments are conducted to evaluate the system’s performance across various scenarios. Table 4 presents the thermodynamic properties, including mass flow rate, pressure, temperature, enthalpy, and entropy, at different states within Model 2.

Validation of the model

To validate the developed model, simulation results were compared with related studies by Ahmed et al.18 for gas turbine cycle, Safarian and Aramoun51 for ORC, and Ren et al.52 for a LiBr-H2O system. In these comparisons, the input parameters (primarily component temperatures and refrigerant mass flow rate) in the examined cases were kept identical. For the BC, the input values were specified as: \(\:{T}_{amb}=19\:^\circ\:\text{C}\), \(\:{\dot{m}}_{air}=438\text{\:kg/s}\), PR = 12, and \(\:{T}_{25}=1100\:^\circ\:\text{C}\). The parameters used for the validation include PHRVG = 25 bar, PCOND=1 bar, PREG = 10 bar, \(\:{\dot{\text{Q}}}_{HRVG}\)=252 MW, ηs, T = 80%,ηs, P = 85%. In the LiBr-H₂O system, the input values were specified as: \(\:{T}_{Gen}=87.8\:^\circ\:\text{C}\), \(\:{T}_{abs}=37.8\:^\circ\:\text{C}\), \(\:{T}_{evap}=7.2\:^\circ\:\text{C}\), \(\:{\text{Ɛ}}_{SHE}=0.7\), and \(\:{\dot{m}}_{ref}=1\text{\:kg/s}\).

The validation results presented in Table 5 demonstrate a strong agreement between the simulation outcomes of this study and established literature values for the gas turbine cycle, ORC, and LiBr-H2O system. All performance parameters exhibit minimal relative errors, confirming the model’s reliability.

For the gas turbine cycle, key parameters fall within acceptable limits, including power output (0.87% error), thermal efficiency (0.59% error), fuel mass flow rate (0.45% error), and exhaust temperature (2.1% error). The validation of the ORC model against the literature51 also reveals a high degree of accuracy, with minimal deviations observed—power output error at 0.11%, thermal efficiency deviation at 0.42%, and exergy destruction error at 0.23%. These results reinforce the precision of the developed ORC model under specified operating conditions.

Similarly, the LiBr-H2O system validation confirms a close match with reference data, with heat capacity errors recorded at 0.04% for the generator, 0.107% for the condenser, − 0.092% for the absorber, and 0.085% for the evaporator. Additionally, the coefficient of performance (COP) deviation is minimal at − 0.023%, further demonstrating the robustness and accuracy of the developed model.

Base case

The system simulation employs the Engineering Equation Solver (EES) software, guaranteeing precise and dependable computations. This program was chosen for its strong capacity to manage intricate thermodynamic and engineering equations, delivering accurate results for the suggested model. Table 6 delineates the essential characteristics and simulation settings used in the model, providing a thorough description of the circumstances and assumptions applied to evaluate the system’s performance. These parameters are essential for ensuring that the simulation accurately represents genuine and practical operating conditions, hence improving the dependability of the findings.

Table 7 provides a detailed comparison of the key performance metrics for two integrated system models: Model 1 and Model 2. The results indicate that Model 1 consumes more air compressor power than Model 2, with a difference of 12.7 MW. This may suggest that Model 2 consumes less energy due to the use of the ARS system. The power output of the gas turbines is comparable across the two versions, with Model 1 delivering a slightly greater output of 0.5 MW. This little disparity indicates that the gas turbine performance is almost equivalent in both designs. Model 2 has a slightly higher output in the HPST by about 0.138 MW, and the LPST in Model 2 produces 0.296 MW more than in Model 1. Model 2 demonstrates a substantial improvement in network production, reflecting an increase of 12.7 MW. This indicates a more efficient overall system functioning, implying that Model 2 may derive more usable work from the integrated system with the ARS system. Model 1 shows slightly higher overall energy and exergy efficiency (both 0.1% more) than Model 2, despite Model 2’s better network output.

Table 8 focused on the exergy analysis of each component of Model 2. The results indicate that the combustion chamber exhibits the greatest exergy loss, comprising 46.07% of the overall exergy destruction. This is anticipated because of the characteristics of combustion processes, where considerable exergy losses arise from irreversibility. Nonetheless, its exergy efficiency is somewhat high at 74.79%, indicating a rather effective usage of available exergy despite significant losses. The PTC experiences substantial exergy destruction at 56.4 MW, nearly one-fifth of the system’s total destruction. Its exergy efficiency is relatively low at 53.31%. The HRSG demonstrates significant exergy degradation at 19.91 MW or 9.19% of total losses. Nonetheless, its exergy efficiency is notably high at 88.18%, indicating its efficacy in thermal energy recovery despite the inevitable loss of some exergy owing to irreversibility in heat transfer processes. The LPST contributes 6.37 MW to exergy destruction, which, while lower than other components, nonetheless positions it in the top four in exergy losses. The exergy efficiency of 90.52% signifies that, notwithstanding losses, it effectively transforms steam energy into mechanical effort. Table 8 also illustrates the c results of the model 2 system components. The analysis showed that the combustion chamber has the highest cost rate of exergy destruction at 7,291 $/h, which significantly contributes to the overall system costs. Its exergoeconomic factor is relatively low (f = 0.003%), indicating that a large portion of the cost is due to exergy destruction rather than component investment costs. This indicates the possibility of cost savings via enhanced efficiency. The AC ranks second with a cost rate of exergy destruction of 1,202 $/h. Its Exergoeconomic factor is slightly higher than the combustion chamber at 7.6%. The HRSG has an exergy destruction cost of 1,159 $/h, which is relatively lower than the previous two components but still among the top contributors, with an Exergoeconomic factor of 11.58%. The LPST shows a cost rate of exergy destruction at 465.9 $/h. Its exergy economic factor is 30.92%.

Results of parametric studies

Figures 4, 5, 6 and 7 compare two models of an ISCC system: Model 1, which integrates a gas turbine with a steam Rankine cycle and an ORC cycle, and Model 2, which includes all of Model 1’s components plus a refrigeration absorption system for cooling the compressor air inlet.

Figure 4 shows a graph plotting the \(\:{\dot{W}}_{net}\), Overall efficiencies and electricity costs are compared against the pressure ratio (PR) for two different models. In Fig. 4a, both models show a clear negative linear relationship between the PR and the \(\:{\dot{W}}_{net}\) output. Model 2 consistently outperforms, providing a greater work output at any given pressure ratio. This could indicate that Model 2 has a more efficient design or operating mechanism, allowing it to extract more power across varying PR. Higher PR leads to a decrease in \(\:{\dot{W}}_{net}\) in both models, suggesting a direct relationship between PR and output power. This decline is attributed to the fact that at higher PRs, the compression work required increases significantly, reducing the \(\:{\dot{W}}_{net}\:\)output of the system. Within the graph, there is a depiction of pressure ratios, encompassing a range of approximately 6 to 15. In the range provided, the \(\:{\dot{W}}_{net}\:\)Model 1 fluctuates from around 210 MW to 240 MW, whereas Model 2 ranges from approximately 225 MW to 260 MW. Figure 4b compares the electricity cost against PR for two models. Both models display a U-shaped curve, with the electricity costs reaching their lowest point at around 8 bar. As the PR increases to 16 bar, the electricity cost for Model 1 rises to around $76/MWh, contrasting with the decrease to approximately $70/MWh at 8 bar. In contrast, Model 2 outperforms all PR’s, showcasing a gradual rise in electricity cost from approximately $69/MWh at 8 bar to $72/MWh at 16 bar. The ARS in Model 2 not only improves gas turbine efficiency but also helps reduce costs, especially at higher PR’s where Model 1’s cost efficiency declines. Figure 4c and d illustrate the relationship between thermal efficiency and exergy efficiency (%) with PR for Model 1 and Model 2. As the pressure ratio (PR) increases from 6 to 16 bar, both models noticeably improve overall efficiencies. However, Model 2 distinguishes itself by offering even greater efficiency, thanks to its innovative cooling mechanism. According to the findings, Model 2 consistently demonstrates superior \(\:{{\upeta\:}}_{ex}\) compared to Model 1. The ARS’s significant advantages are highlighted at lower and mid-range PR (6 to 12 bar). Nevertheless, when the PR surpasses 12 bar, both models showcase similar \(\:{{\upeta\:}}_{ex}\), implying that the cooling system’s effect becomes less pronounced at elevated pressures.

Figure 5 provides a visual representation of how \(\:{\dot{W}}_{net}\) overall efficiencies, and electricity cost vary with gas turbine inlet temperature (GTIT) for Model 1 and Model 2. Figure 5a illustrates a clear positive linear relationship between GTIT and \(\:{\dot{W}}_{net}\)for both models, showing that higher GTIT leads to increased power output. This rise in net work output occurs because higher inlet temperatures supply more thermal energy to the gas turbine (GT), enhancing the expansion process and boosting power generation within the Brayton Cycle (BC). Both models demonstrate that a substantial increase in GTIT leads to a significant improvement in network output, as higher temperatures enhance the \(\:{{\upeta\:}}_{\text{t}\text{h}}\) of the gas turbine. As GTIT rises, the difference in the network between Model 1 and Model 2 also increases, indicating that the Absorption Refrigeration System (ARS) becomes more effective at elevated temperatures. At lower GTITs, between 1100 K and 1300 K, the performance gap between the two models is approximately 20 to 25 MW. However, at higher GTITs, ranging from 1600 K to 1700 K, this difference expands to 40 MW. Figure 5b illustrates the relationship between electricity cost and GTIT for both models. Both models display a U-shaped curve, where the electricity cost decreases as GTIT increases up to a certain point (around 1500–1600 K), after which the cost begins to rise slightly again due to material limitations. The ARS in Model 2 significantly reduces electricity costs at all GTIT values compared to Model 1. For instance, at 1100 K, Model 1 has an electricity cost of about $100/MWh, whereas Model 2 is lower at around $95/MWh. The cost difference widens as the GTIT increases, with Model 2 maintaining lower costs throughout. Figure 5c and d show that thermal and exergy efficiencies increase with GTIT, following the trend of \(\:{\dot{W}}_{net}\). This improvement is driven by higher power output, better fuel utilization, and reduced energy losses. Across the entire range of GTIT values, Model 1 consistently shows a slight performance advantage over Model 2 in terms of \(\:{{\upeta\:}}_{\text{t}\text{h}}\) and \(\:{{\upeta\:}}_{ex}\) efficiency with a difference of around 0.1% at most points. The gap between the two models is small but persistent, indicating that while Model 2’s (ARS) provides some performance benefits, Model 1 remains slightly more efficient in converting available thermal energy into useful work.

In Fig. 6, the\(\:\:{\dot{W}}_{net}\), overall efficiencies, and electricity cost are depicted for two different models, showcasing the impact of \(\:{T}_{in,\:\text{H}\text{P}\text{S}\text{T}}\). Both Model 1 and Model 2 show an increase in \(\:{\dot{W}}_{net}\) as the \(\:{T}_{in,\:\text{H}\text{P}\text{S}\text{T}}\:\)increases, but Model 2 consistently outperforms Model 1 across the entire pressure range, as seen in Fig. 6a. The \(\:{\dot{W}}_{net}\) increases as \(\:{T}_{in,\:\text{H}\text{P}\text{S}\text{T}}\) rises, as higher inlet temperatures enhance the Rankine Cycle (RC) performance by increasing the thermal energy available for expansion in the steam turbine. At an inlet pressure of 60 bar, Model 1 starts at around 225 MW, while Model 2 achieves approximately 235 MW, giving Model 2 an initial advantage of about 10 MW. This gap between the models grows slightly as the pressure increases. By 150 bar, Model 1 reaches approximately 240 MW, while Model 2 generates around 250 MW, maintaining a 10 MW to 15 MW advantage across the entire range. Model 2 consistently delivers higher \(\:{\dot{W}}_{net}\) output compared to Model 1, maintaining a 10 MW to 15 MW advantage across all inlet pressure values. The consistent difference between the two models suggests that the ARS system in Model 2 provides a sustained performance advantage, enabling it to extract more work from the system under higher pressure conditions. Figure 6b shows the relationship between electricity cost ($/MWh) and \(\:{T}_{in,\:\text{H}\text{P}\text{S}\text{T}}\). The findings present that electricity cost decreases with rising \(\:{T}_{in,\:\text{H}\text{P}\text{S}\text{T}}\) because the increased work output leads to a lower specific cost of electricity production. As the system generates more power, the cost per unit of electricity declines, demonstrating the economic benefit of higher inlet steam temperatures. Both Model 1 and Model 2 show a decrease in electricity cost as the \(\:{T}_{in,\:\text{H}\text{P}\text{S}\text{T}}\:\)increases, but Model 2 consistently achieves lower costs at every temperature point. Model 2 begins with a lower electricity cost of about $72.5/MWh at 720 K and decreases to approximately $70.5/MWh at 820 K, maintaining a $2/MWh advantage over Model 1 throughout the entire temperature range, while Model 1 starts at approximately $74.5/MWh at an inlet temperature of 720 K and decreases to around $72.5/MWh at 820 K. Figure 6c and d depict the correlation between \(\:{{\upeta\:}}_{\text{t}\text{h}}\) and \(\:{{\upeta\:}}_{ex}\) efficiencies as influenced by the\(\:\:{T}_{in,\:\text{H}\text{P}\text{S}\text{T}}\). Both models show a clear positive linear relationship between the \(\:{T}_{in,\:\text{H}\text{P}\text{S}\text{T}}\) and both efficiencies. This improvement is a direct result of the enhanced power production in the Rankine Cycle (RC) at higher inlet temperatures, which optimizes energy utilization and reduces irreversibilities. As the temperature increases from 720 K to 820 K, the \(\:{{\upeta\:}}_{\text{t}\text{h}}\) and \(\:{{\upeta\:}}_{ex}\) improves for both models, reflecting the gains in system performance from operating at higher temperatures. The gap between the two models remains small but consistent, with Model 1 maintaining a slight advantage in inefficiency.

Figure 7 illustrates the network, overall efficiencies, and power costs for two distinct models, highlighting the influence of input pressure on the high-pressure steam turbine \(\:{P}_{in,\:\text{H}\text{P}\text{S}\text{T}}\). The results depicted in Fig. 7a compare the performance of Model 1 and Model 2, illustrating that \(\:{\dot{W}}_{net}\) increases with rising \(\:{P}_{in,\:\text{H}\text{P}\text{S}\text{T}}\). The \(\:{\dot{W}}_{net}\) increases as \(\:{P}_{in,\:\text{H}\text{P}\text{S}\text{T}}\) rises, as higher pressure improves the Rankine Cycle (RC) expansion process, allowing for greater power extraction. However, Model 2 consistently surpasses Model 1 across the entire pressure range. This superior performance of Model 2 is attributed to the ARS, which cools the compressor’s air intake, thereby increasing air density. As a result, Model 2 consistently delivers higher net power output than Model 1, irrespective of the \(\:{P}_{in,\:\text{H}\text{P}\text{S}\text{T}}.\) At 100 bar, Model 1 produces roughly 232 MW, but Model 2 generates around 245 MW, sustaining a steady 13 MW advantage. Figure 7b illustrates the relationship between electricity cost ($/MWh) and the \(\:{P}_{in,\:\text{H}\text{P}\text{S}\text{T}}\) for both models. The results indicate that electricity costs decreases with increasing \(\:{P}_{in,\:\text{H}\text{P}\text{S}\text{T}}\), as the higher work output results in a lower specific electricity cost. More efficient energy utilization leads to reduced operational costs. Both models benefit from higher input pressure, as seen by the declining cost trend; nevertheless, Model 2 is the more economical choice due to its superior cooling system, which lowers power expenses at all pressure levels. Model 2 continuously incurs lower power costs than Model 1 throughout all intake pressure values, beginning at $74/MWh at 60 bar and decreasing to $67.5/MWh at 150 bar, while Model 1 declines from $76/MWh to $69.5/MWh within the same pressure range. Figure 7c and d depicts the correlation between thermal and exergy efficiency and the input pressure of the high-pressure steam turbine for Model 1 and Model 2. The findings indicate that both models have a positive linear correlation in thermal and exergy efficiency with increasing input pressure, signifying enhanced energy conversion efficiency at elevated pressures. The disparity between the models is minimal; nonetheless, Model 1 consistently surpasses Model 2 over the full pressure spectrum. Model 1 regularly demonstrates marginally superior \(\:{{\upeta\:}}_{\text{t}\text{h}}\) and \(\:{{\upeta\:}}_{ex}\) efficiency relative to Model 2. Model 1 exhibits thermal efficiency ranging from 57.7% at 60 bar to 60.5% at 150 bar, whilst Model 2 demonstrates a range from 57.6 to 60.4% within the same pressure spectrum. In terms of \(\:{{\upeta\:}}_{ex}\), Model 1 exhibits a range of 56.5–58.5%, whilst Model 2 has a range of 56.4–58.4%. Despite Model 2’s ARS improving cooling and overall performance, Model 1 continuously exhibits a 0.1% superiority in both \(\:{{\upeta\:}}_{\text{t}\text{h}}\) and \(\:{{\upeta\:}}_{ex}\) efficiency.

Figure 8 presents a bar chart depicting the monthly cumulative power output of Model 1 and Model 2, indicating that Model 1 exhibits superior performance in the milder winter months. In contrast, Model 2 routinely surpasses it in the hot months. In March, Model 1 attains around 230 MW, while Model 2 achieves 225 MW, benefiting from reduced air temperatures that optimize its gas turbine cycle. As temperatures increase, Model 2 exceeds Model 1, reaching a maximum of 245 MW in July, while Model 1 peaks at 235 MW. This tendency persists throughout the summer owing to Model 2’s ARS technology, which enhances the intake air temperature and increases efficiency in elevated temperatures.

Figure 9 illustrates the monthly power costs ($/MWh) for both Model 1 and Model 2 over the year, highlighting the disparities in cost-effectiveness between the two systems under diverse climatic circumstances. The power expenses for both systems peak during the winter months. Model 1 incurs the greatest costs in January, roughly 78 $/MWh, while Model 2 is somewhat lower, at around 76.5 $/MWh. Colder weather leads to decreased power production efficiency for both models; however, Model 2 incurs reduced costs because of the supplementary cooling provided by the ARS system. As temps elevate and Direct Normal Irradiance (DNI) intensifies, power expenses diminish, especially for Model 2, which has advantages over the refrigeration absorption system (ARC). In June, Model 2 attained its minimum power cost of around 70 $/MWh, while Model 1 recorded its lowest cost at 72 $/MWh. This suggests that Model 2 is more economical in the warmer months, fully using its enhanced cooling capabilities.

Figure 10 compares the monthly carbon footprint (kg CO₂/kWh) of Model 1 and Model 2 throughout the year, showing how emissions vary between the two systems under different climatic conditions. Both models have their highest emissions in the colder months (January, November, and December) and lowest emissions during the summer (June and July), indicating that colder weather conditions impact the efficiency of both systems, leading to increased carbon output. Model 1 consistently has slightly higher emissions than Model 2 across all months, suggesting that Model 2 is marginally more efficient in reducing CO2 emissions. This efficiency in Model 2 could be attributed to enhanced cooling mechanisms or system optimizations that allow it to maintain lower emissions, particularly in warmer months. For instance, the lowest emission levels for both models are seen in June, with Model 1 at 332.4 kg CO₂/MWh and Model 2 at 331.7 kg CO2/MWh, demonstrating Model 2’s slight advantage. As temperatures decrease in the fall, emissions start to rise again, peaking in December with values of 379.4 kg CO2/MWh for Model 1 and 377.4 kg CO2/MWh for Model 2.

Conclusion

This study has evaluated a hybrid solar-natural gas combined cycle power plant tailored to Iraq’s specific energy needs, focusing on the Kirkuk region’s high solar potential. Two configurations were analyzed: Model 1, a conventional gas turbine with Rankine and organic Rankine cycles, and Model 2, an enhanced version incorporating an absorption refrigeration system (ARS). Model 2 demonstrated superior performance, achieving a net power output increase of 12.7 MW and a 5–10% reduction in electricity costs. These improvements were most pronounced during high-demand summer months, showcasing the effectiveness of the ARS in improving compressor inlet air density and turbine efficiency under high-temperature conditions.

The exergoeconomic analysis revealed the financial viability of Model 2, with significant cost savings during peak operation. At the same time, the combustion chamber was identified as the primary source of exergy destruction, contributing 46.07% of total system losses. Environmental analysis further demonstrated Model 2’s advantage in reducing CO₂ emissions compared to Model 1, particularly in warmer months, highlighting its alignment with global sustainability goals. Additionally, the system’s integration of solar energy and advanced waste heat recovery processes demonstrated the potential to reduce fossil fuel dependence and improve energy security in Iraq.

This research contributes to developing scalable, environmentally friendly energy systems, offering a replicable framework for integrating renewable and conventional energy technologies in regions with similar climatic conditions. The findings underscore the potential for hybrid systems to address electricity shortages while achieving cost-effective, sustainable, and environmentally responsible power generation. These insights pave the way for further optimization of energy systems, providing a robust solution to Iraq’s growing energy challenges and aligning with broader global energy transition efforts.

Data availability

The datasets used and analyzed during the current study are available from the corresponding author upon reasonable request.

Abbreviations

- Aa :

-

Solar collector area (m2)

- \(A_{r}\) :

-

Area of the receiver or absorber

- \({\dot{\text{C}}}\) :

-

Cost rate $/h

- \({\dot{\text{C}}}_{{\text{D}}}\) :

-

Cost rate of exergy destruction

- \({\dot{\text{E}}}_{{\text{d}}}\) :

-

Exergy destruction rate

- \({\dot{\text{E}}\text{x}}_{{{\text{dest}}}}\) :

-

Rate of exergy destruction (kW)

- \({\dot{\text{E}}\text{x}}\) :

-

Exergy (kW)

- \({\text{f}}_{{\text{k}}}\) :

-

Thermoeconomics factor (%)

- \({\text{F}}_{{\text{R}}}\) :

-

Collector heat gain factor

- h :

-

Enthalpy, (kJ/kg)

- \(h_{rr}\) :

-

Radiative heat transfer coefficient between absorber and \({ }T_{amb}\)

- \(h_{rc}\) :

-

Radiative heat transfer coefficient between absorber and the cover

- k:

-

Conductivity heat transfer (W/m. K)

- \({\dot{\text{m}}}\) :

-

Mass flow rate (kg/s)

- n:

-

Predicted life of the system’s (years)

- P:

-

Predicted life of the system’s (years)

- \(P_{{in, {\text{HPST}}}}\) :

-

High pressure steam turbine inlet pressure

- \({\dot{\text{Q}}}\) :

-

Heat rate (kW)

- \({\dot{\text{Q}}}_{{{\text{solar}}}}\) :

-

Solar energy input (kW)

- S:

-

Solar energy absorbed by PTC

- \(T_{amb}\) :

-

Ambient temperature

- \(T_{{in, {\text{HPST}}}}\) :

-

High pressure steam turbine inlet temperature

- \({\dot{\text{W}}}\) :

-

Work by the control volume per unit time (kW)

- \({\dot{\text{Z}}}_{{\text{k}}}\) :

-

Entire cost rate

- T:

-

Temperature (K)

- \({\upeta }_{{{\text{ex}}}}\) :

-

Exergy efficiency (%)

- \({\upeta }_{{{\text{th}}}}\) :

-

Thermal efficiency (%)

- α:

-

Receiver’s absorption coefficient

- \({\upgamma }\) :

-

Reflection coefficient

- τ:

-

Coefficient of the glass cover

- φ:

-

Total operating and maintenance cost

- \(\varepsilon_{{{\text{CO}}2}}\) :

-

Emission rate of CO₂ (kg CO₂/MWh)

- AC:

-

Air compressor

- ARS:

-

Absorption refrigeration system

- BC:

-

Brayton cycle

- CC:

-

Combustion chamber

- CCPP:

-

Combined cycle power plant

- Cond:

-

Condenser

- CRF:

-

Capital recovery factor

- DNI:

-

Direct normal irradiation (kWh/m2 day)

- EES:

-

Engineering Equation Solver

- EVAP:

-

Evaporator

- GEN:

-

Generator

- GT:

-

Gas turbine

- GTCC:

-

Gas turbine combined cycle

- GTIT:

-

Gas turbine inlet temperature

- HE:

-

Heat exchanger

- HPST:

-

High-pressure steam turbine

- HRSG:

-

Heat recovery steam generation

- HTF:

-

Heat transfer fluid

- IPST:

-

Intermediate-pressure steam turbine

- ISCC:

-

Integrated solar combined cycle

- LHV:

-

Fuel’s lower heating value

- LPST:

-

Low-pressure steam turbine

- NG:

-

Natural gas

- NGCC:

-

Natural gas combined cycle

- OFWH:

-

Open feed water heater

- ORC:

-

Organic Rankine cycle

- ORP:

-

Organic pump

- ORT:

-

Organic turbine

- PP:

-

Power plant

- PR:

-

Pressure ratio

- PTC:

-

Parabolic trough collector

- RC:

-

Rankine cycle

- RES:

-

Renewable energy source

- RH:

-

Relative humidity

- RP:

-

Renewable part

- SF:

-

Solar field

- ST:

-

Steam turbine

- TES:

-

Thermal energy storage

- PEC :

-

Purchase equipment cost

References

Abbass, K. et al. A review of the global climate change impacts, adaptation, and sustainable mitigation measures. Environ. Sci. Pollut. Res. 29, 42539–42559. https://doi.org/10.1007/s11356-022-19718-6 (2022).

Akroot, A., Almaktar, M. & Alasali, F. The integration of renewable energy into a fossil fuel power generation system in oil-producing countries: a Case study of an integrated solar combined cycle at the sarir power plant. Sustainability (Switzerland) 16, 820. https://doi.org/10.3390/su16114820 (2024).

Ibraheem, W. E. & Abdulraheem, A. A. Design of 5 MW PV power plant in Iraq in Al-Sharqiyah Diyala substation. In 4th International Conference on Electrical, Computer and Communication, Technologies, CECCT 2021. https://doi.org/10.1109/ICECCT52121.2021.9616717 (2021).

Khudhur, J., Akroot, A. & Al-samari, A. Experimental investigation of direct solar photovoltaics that drives absorption refrigeration system. J. Adv. Res. Fluid Mech. Therm. Sci. 1, 116–135. https://doi.org/10.37934/arfmts.106.1.116135 (2023).

Dawood, T. A., Raphael, R., Barwari, I. & Akroot, A. Solar energy and factors affecting the efficiency and performance of panels in Erbil/Kurdistan. Int. J. Heat Technol. 41, 304–312. https://doi.org/10.18280/ijht.410203 (2023).

Kabeyi, M. J. B. & Olanrewaju, O. A. Sustainable energy transition for renewable and low carbon grid electricity generation and supply. Front. Energy Res. 9, 114. https://doi.org/10.3389/fenrg.2021.743114 (2022).

Bdaiwi, M., Akroot, A., Wahhab, H. A. A. & Mahariq, I. Numerical Analysis of the Steam Turbine Performance in Power Station with a Low Power Cycle (2023).

Semenova, T. & Al-Dirawi, A. Economic development of the Iraqi gas sector in conjunction with the oil industry. Energies (Basel) 15, 306. https://doi.org/10.3390/en15072306 (2022).

Abusaibaa, G. Y., Al-Aasam, A. B., Alwaeli, A. H. A., Al-Fatlawi, A. W. A. & Bin Sopian, K. Performance analysis of solar absorption cooling systems in Iraq. Int. J. Renew. Energy Res. 10, 223–230. https://doi.org/10.20508/ijrer.v10i1.10472.g7857 (2020).

Hassan, Q., AbduHasanl, S., Hasan, A. & Jaszczur, M. Evaluation of energy generation in Iraqi territory by solar photovoltaic power plants with a capacity of 20 MW. Energy Harvest. Syst. 1, 1 (2022).

Talal, W. & Akroot, A. Exergoeconomic analysis of an integrated solar combined cycle in the Al-Qayara power plant in Iraq. Processes 11, 656. https://doi.org/10.3390/pr11030656 (2023).

Talal, W. & Akroot, A. An exergoeconomic evaluation of an innovative polygeneration system using a solar-driven rankine cycle integrated with the Al-Qayyara gas turbine power plant and the absorption refrigeration cycle. Machines 12, 133. https://doi.org/10.3390/machines12020133 (2024).

Shaheed, H. R., Mohammed, H. N. & Radhi, R. M. Evaluation performance of the steam power plant in Iraq based on energy and exergy analysis. Int. J. Heat Technol. 41, 253–258. https://doi.org/10.18280/ijht.410128 (2023).

Kareem, A. F. et al. Exergo–economic and parametric analysis of waste heat recovery from Taji gas turbines power plant using rankine cycle and organic rankine cycle. Sustainability (Switzerland) 15, 376. https://doi.org/10.3390/su15129376 (2023).

Saeed, I. M., Ramli, A. T. & Saleh, M. A. Assessment of sustainability in energy of Iraq, and achievable opportunities in the long run. Renew. Sustain. Energy Rev. 58, 1207–1215. https://doi.org/10.1016/j.rser.2015.12.302 (2016).

Kazem, H. A. & Chaichan, M. T. Status and future prospects of renewable energy in Iraq. Renew. Sustain. Energy Rev. 16, 6007–6012. https://doi.org/10.1016/j.rser.2012.03.058 (2012).

Faisal, S. H., Naeem, N. K. & Jassim, A. A. Energy and exergy study of Shatt Al-Basra gas turbine power plant. J. Phys. Conf. Ser. 1773, 1. https://doi.org/10.1088/1742-6596/1773/1/012020 (2021).

Ahmed, A. H., Ahmed, A. M. & Hamid, Q. Y. Exergy and energy analysis of 150 MW gas turbine unit: a case study. J. Adv. Res. Fluid Mech. Therm. Sci. 67, 186–192 (2020).

Salah, S. A. et al. Evaluation of the gas turbine unit in the Kirkuk gas power plant to analyse the energy and exergy using ChemCad simulation. Int. J. Low-Carbon Technol. 17, 603–610. https://doi.org/10.1093/ijlct/ctac034 (2022).

Shukla, A. K. & Singh, O. Effect of Compressor Inlet Temperature & Relative Humidity on Gas Turbine Cycle Performance vol. 5, 664–671 (2014).

Oko, C. O. C. & Njoku, I. H. Performance analysis of an integrated gas-, steam- and organic fluid-cycle thermal power plant. Energy 122, 431–443. https://doi.org/10.1016/J.ENERGY.2017.01.107 (2017).

Yang, X. et al. Energy, exergy, exergoeconomic, economic, and environmental analyses and multi-objective optimization of a novel combined cooling and power system with dual-pressure Kalina cycle-absorption refrigeration. Energy Convers. Manag. 315. https://doi.org/10.1016/j.enconman.2024.118781 (2024).

Mubashir, W. et al. Thermo-economic evaluation of supercritical CO2 Brayton cycle integrated with absorption refrigeration system and organic Rankine cycle for waste heat recovery. Therm. Sci. Eng. Prog. 44, 73. https://doi.org/10.1016/j.tsep.2023.102073 (2023).

Chen, L., Xiao, K., Hu, F. & Li, Y. Performance evaluation and optimization design of integrated energy system based on thermodynamic, exergoeconomic, and exergoenvironmental analyses. Appl. Energy 326, 987. https://doi.org/10.1016/j.apenergy.2022.119987 (2022).

Ren, J., Qian, Z., Wang, X., Huang, W. & Wang, B. Investigation of a biomass-driven cogeneration system integrated with an externally fired gas turbine, organic rankine cycle, and absorption refrigeration cycle: thermodynamic and exergoeconomic analyses and optimization. Sustain. (Switzerland) 16, 495. https://doi.org/10.3390/su16114495 (2024).

Yang, K. et al. Exergy, exergoeconomic, and exergoenvironmental analyses of novel solar- and biomass-driven trigeneration system integrated with organic Rankine cycle. Energy 301, 605. https://doi.org/10.1016/j.energy.2024.131605 (2024).

Yilmaz, F. & Ozturk, M. Thermodynamic and economic investigation of an innovative multigeneration plant integrated with the solar collector and combustion chamber. Int. J. Hydrogen Energy 47, 31786–31805. https://doi.org/10.1016/J.IJHYDENE.2022.02.204 (2022).

Mousavi, S. A., Mehrpooya, M. & Delpisheh, M. Development and life cycle assessment of a novel solar-based cogeneration configuration comprised of diffusion–absorption refrigeration and organic rankine cycle in remote areas. Process Saf. Environ. Prot. 159, 1019–1038. https://doi.org/10.1016/j.psep.2022.01.067 (2022).

Yilmaz, F., Ozturk, M. & Selbas, R. Thermodynamic investigation of a concentrating solar collector based combined plant for poly-generation. Int. J. Hydrogen Energy 45, 26138–26155. https://doi.org/10.1016/J.IJHYDENE.2019.10.187 (2020).

Nourpour, M., Khoshgoftar Manesh, M. H., Pirozfar, A. & Delpisheh, M. Exergy, exergoeconomic, exergoenvironmental, emergy-based assessment and advanced exergy-based analysis of an integrated solar combined cycle power plant. Energy Environ. 34, 379–406. https://doi.org/10.1177/0958305X211063558 (2023).

Adebayo, V., Abid, M., Adedeji, M. & Hussain Ratlamwala, T. A. Energy, exergy and exergo-environmental impact assessment of a solid oxide fuel cell coupled with absorption chiller & cascaded closed loop ORC for multi-generation. Int. J. Hydrogen Energy 47, 3248–3265. https://doi.org/10.1016/j.ijhydene.2021.02.222 (2022).

Yilmaz, F., Ozturk, M. & Selbas, R. A parametric examination of the energetic, exergetic, and environmental performances of the geothermal energy-based multigeneration plant for sustainable products. Int. J. Hydrogen Energy https://doi.org/10.1016/J.IJHYDENE.2024.12.236 (2024).

Assareh, E. et al. Energy, exergy, exergoeconomic, exergoenvironmental, and transient analysis of a gas-fired power plant-driven proposed system with combined Rankine cycle: thermoelectric for power production under different weather conditions. J. Therm. Anal. Calorim. 148, 8283–8307. https://doi.org/10.1007/s10973-022-11651-7 (2023).

Mohammadi, K., Khaledi, M. S. E., Saghafifar, M. & Powell, K. Hybrid systems based on gas turbine combined cycle for trigeneration of power, cooling, and freshwater: a comparative techno-economic assessment. Sustain. Energy Technol. Assess. 37, 632. https://doi.org/10.1016/j.seta.2020.100632 (2020).

Sadighi Dizaji, H., Hu, E. J., Chen, L. & Pourhedayat, S. Using novel integrated Maisotsenko cooler and absorption chiller for cooling of gas turbine inlet air. Energy Convers. Manag. 195, 1067–1078. https://doi.org/10.1016/j.enconman.2019.05.064 (2019).

Pourhedayat, S., Hu, E. & Chen, L. Simulation of innovative hybridizing M-cycle cooler and absorption-refrigeration for pre-cooling of gas turbine intake air: including a case study for Siemens SGT-750 gas turbine. Energy 247, 356. https://doi.org/10.1016/j.energy.2022.123356 (2022).

Mohammadi, A., Kasaeian, A., Pourfayaz, F. & Ahmadi, M. H. Thermodynamic analysis of a combined gas turbine, ORC cycle and absorption refrigeration for a CCHP system. Appl. Therm. Eng. 111, 397–406. https://doi.org/10.1016/j.applthermaleng.2016.09.098 (2017).

Zare, V. Performance improvement of biomass-fueled closed cycle gas turbine via compressor inlet cooling using absorption refrigeration; thermoeconomic analysis and multi-objective optimization. Energy Convers. Manag. 215, 946. https://doi.org/10.1016/j.enconman.2020.112946 (2020).

Yang, Z., Radchenko, M., Radchenko, A., Mikielewicz, D. & Radchenko, R. Gas turbine intake air hybrid cooling systems and a new approach to their rational designing. Energies (Basel) 15, 1474. https://doi.org/10.3390/en15041474 (2022).

Alfaris, A., Akroot, A. & Deniz, E. The exergo-economic and environmental evaluation of a hybrid solar–natural gas power system in Kirkuk. Appl. Sci. 14, 10113. https://doi.org/10.3390/app142210113 (2024).

Noroozian, A., Mohammadi, A., Bidi, M. & Ahmadi, M. H. Energy, exergy and economic analyses of a novel system to recover waste heat and water in steam power plants. Energy Convers. Manag. 144, 351–360. https://doi.org/10.1016/J.ENCONMAN.2017.04.067 (2017).

El-Emam, R. S. & Dincer, I. Exergy and exergoeconomic analyses and optimization of geothermal organic Rankine cycle. Appl. Therm. Eng. 59, 435–444. https://doi.org/10.1016/j.applthermaleng.2013.06.005 (2013).

Yüksel, Y. E. Thermodynamic assessment of modified organic Rankine cycle integrated with parabolic trough collector for hydrogen production. Int. J. Hydrogen Energy 43, 5832–5841. https://doi.org/10.1016/j.ijhydene.2017.09.164 (2018).

Al-Sulaiman, F. A., Hamdullahpur, F. & Dincer, I. Performance assessment of a novel system using parabolic trough solar collectors for combined cooling, heating, and power production. Renew. Energy 48, 161–172. https://doi.org/10.1016/j.renene.2012.04.034 (2012).

Gogoi, T. K., Lahon, D. & Nondy, J. Energy, exergy and exergoeconomic (3E) analyses of an organic rankine cycle integrated combined cycle power plant. Therm. Sci. Eng. Prog. 41, 849. https://doi.org/10.1016/j.tsep.2023.101849 (2023).

Bejan, A. & Tsatsaronis, M. M. Thermal Design and Optimization, vol. 21. https://doi.org/10.1016/s0360-5442(96)90000-6 (1996).

Souza, J. et al. Proposal and 3E (energy, exergy, and exergoeconomic) assessment of a cogeneration system using an organic Rankine cycle and an absorption refrigeration system in the Northeast Brazil: thermodynamic investigation of a facility case study. Energy Convers. Manag. 217, 113002. https://doi.org/10.1016/j.enconman.2020.113002 (2020).

Gogoi, T. K., Lahon, D. & Nondy, J. Energy, exergy and exergoeconomic (3E) analyses of an organic rankine cycle integrated combined cycle power plant. Therm. Sci. Eng. Progress 41, 101849. https://doi.org/10.1016/J.TSEP.2023.101849 (2023).

Wang, J., Li, S., Zhang, G. & Yang, Y. Performance investigation of a solar-assisted hybrid combined cooling, heating and power system based on energy, exergy, exergo-economic and exergo-environmental analyses. Energy Convers. Manag. 196, 227–241. https://doi.org/10.1016/j.enconman.2019.05.108 (2019).

Tian, H., Li, R., Salah, B. & Thinh, P. H. Bi-objective optimization and environmental assessment of SOFC-based cogeneration system: performance evaluation with various organic fluids. Process Saf. Environ. Prot. 178, 311–330. https://doi.org/10.1016/j.psep.2023.07.040 (2023).

Safarian, S. & Aramoun, F. Energy and exergy assessments of modified organic rankine cycles (ORCs). Energy Rep. 1, 1–7. https://doi.org/10.1016/J.EGYR.2014.10.003 (2015).

Ren, J., Qian, Z., Yao, Z., Gan, N. & Zhang, Y. Thermodynamic evaluation of LiCl-H2O and LiBr-H2O absorption refrigeration systems based on a novel model and algorithm. Energies (Basel) 12, 3037. https://doi.org/10.3390/en12153037 (2019).

Akroot, A. & Al Shammre, A. S. Techno-economic and environmental impact analysis of a 50 MW solar-powered rankine cycle system. Processes 12, 1059. https://doi.org/10.3390/pr12061059 (2024).

Sachdeva, J. & Singh, O. Thermodynamic analysis of solar powered triple combined Brayton, Rankine and organic Rankine cycle for carbon free power. Renew. Energy 139, 765–780. https://doi.org/10.1016/j.renene.2019.02.128 (2019).

Acknowledgements

The authors extend their appreciation to the Researchers Supporting Project number (RSP2025R515), King Saud University, Riyadh, Saudi Arabia for funding this research work.

Author information

Authors and Affiliations

Contributions

Author Contributions: Conceptualization, Abdulrazzak Akroot; Methodology, Ali Alfaris, Saeed Alqaed and Fahad Awjah Almehmadi; Software, Ali Alfaris and Abdulrazzak Akroot; Validation, Abdulrazzak Akroot; Formal analysis, Ali Alfaris; Investigation, Ali Alfaris, Abdulrazzak Akroot, Saeed Alqaed and Fahad Awjah Almehmadi; Writing—original draft, Ali Alfaris, Abdulrazzak Akroot; Writing—review & editing, Saeed Alqaed and Fahad Awjah Almehmadi.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Alfaris, A., Akroot, A., Alqaed, S. et al. Performance analysis of integrated solar and natural gas combined cycle power plants in high solar potential regions. Sci Rep 15, 9181 (2025). https://doi.org/10.1038/s41598-025-90377-6

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-90377-6

Keywords

This article is cited by

-

Solar-assisted tri-generation system with LCPV‑CPC and small-scale gas turbine for year-round clean energy in hot-dry climates

Scientific Reports (2025)

-

Technical and economic evaluation of combined cycle power plant with ET100 linear parabolic collectors

Journal of Thermal Analysis and Calorimetry (2025)