Abstract

Glycoside Hydrolase Family 57 (GH57) amylopullulanase is a thermophilic endoamylase capable of hydrolyzing both α-1,4 and α-1,6-glycosidic bonds, demonstrating significant potential for one-step starch saccharification in industrial applications. However, the mechanisms underlying the dual catalytic activities of GH57 family amylopullulanase remain poorly understood. In this study, we report the first crystal structures of a GH57 amylopullulanase from Aquifex aeolicus (AaApu) in complex with oligosaccharides containing both α-1,4 and α-1,6 glycosidic bonds. Our structural analysis reveals that GH57 amylopullulanase features dual binding pockets arranged in a “Y”-shaped configuration, which accommodates branched-chain starches. The dual binding pockets share a common catalytic dyad composed of Glu256 and Asp352. Notably, unlike the typical retaining mechanism observed in many glycoside hydrolases, the distance between the catalytic residues in GH57 amylopullulanase is significantly larger (approximately 7 Å). This study provides critical insights into the structural basis of GH57 amylopullulanase activity and offers a foundation for the rational engineering of these enzymes for industrial applications.

Similar content being viewed by others

Introduction

Glycoside hydrolases (GHs), found in nearly all living organisms1, play crucial roles in regulation2, carbohydrate metabolism3, and industrial applications4,5. GHs are classified into numerous families based on sequence similarity, a classification system first established in 19916,7,8. To date, over 180 GH families have been identified (http://www.cazy.org/Glycoside-Hydrolases.html).

Amylopullulanases are classified into either the GH13 or GH57 families, depending on their sequence diversity. Mesophilic amylopullulanases are typically classified within the GH13 family, while thermophilic amylopullulanases may belong to either GH13 or GH579. The GH13 family is one of the most extensively studied and abundant amylase families, whereas GH57 is a relatively newer family, first delineated in 19968. To date, only a few GH57 enzymes have been characterized10,11, and the three-dimensional structures of seven GH57 enzymes have been experimentally determined12: four glucan branching enzymes (EC 2.4.1.18)13,14,15,16,17,18, one 4-α-glucanotransferase (EC 2.4.1.25)19, one glucan 1,4-α-maltohydrolase (EC 3.2.1.133)20 and one low resolution amylopullulanase (PDB ID: 7E1Y). Most GH57 family enzymes originate from extremophilic microorganisms, such as thermophilic bacteria and archaea11,21, which exhibit high optimal temperatures and exceptional thermal stability, making them highly valuable for industrial applications. Thermophilic enzymes enable higher reactant concentrations, reduced reaction times, and improved product conversion rates, which are critical for industrial processes22,23. The GH57 enzymes feature five conserved regions (CSRs) in their amino acid sequences, first reported in 200424. Their catalytic domain features an incomplete core TIM barrel, specifically a (β/α)7-barrel25,26, along with additional α-helices. Due to the presence of additional domains, such as carbohydrate-binding modules (CBMs) and surface layer homology domains (SLHs)11,27, GH57 enzymes exhibit significant sequence diversity, with amino acid lengths ranging from fewer than 400 residues to over 1500 residues28. Among the published three-dimensional structures of GH57 family enzymes, the only enzyme-ligand complex structures reported are those of a 4-α-glucanotransferase with the inhibitor acarbose19 and a glucan branching enzyme with glucose15. However, structures of enzyme-substrate complexes remain scarce.

There are two mechanisms of GHs to catalyze glycosidic bond hydrolysis: inverting and retaining7,29,30. In the inverting mechanism, one carboxylic acid acts as a general base, abstracting a proton from a nucleophilic water molecule. This activation water molecule then attacks the anomeric carbon of the aglycone, cleaving the glycosidic bond, resulting in the inversion of the α-anomeric carbon to the β-anomeric carbon. Simultaneously, another carboxylic acid functions as a general acid, donating a proton to the departing sugar31. In contrast, the retaining mechanism involves two steps, utilizing two residues with a carboxylic acid side chain, one of them as an acid/base catalyst and the other as a nucleophile. First, a nucleophilic residue attacks the anomeric center, displacing the aglycon and forming a covalent α-D-glycosyl-enzyme intermediate. Concurrently, an acid/base catalyst acts as an acid, protonating the glycosidic oxygen as the bond cleaves. In the second step, the deprotonated acid/base catalyst serves as a base, deprotonating a water molecule that attacks the glycosyl-enzyme intermediate, restoring the original anomeric configuration32,33. Typically, the carboxyl groups of the nucleophile and the acid/base catalyst are approximately 5 Å apart in retaining enzymes, while the base and acid catalyst in inverting enzymes are about 9 Å34,35. Although these distances provide initial clues about the catalytic mechanism, they are not always definitive. Current evidence suggests that GH57 enzymes follow a retaining mechanism, similar to GH13 enzymes, with Glu and Asp serving as the nucleophilic and acid/base catalyst, respectively36.

Starch hydrolysis is a critical process in the food, pharmaceutical, and biofuel industries37. In industrial applications, multiple GH enzymes often work synergistically to achieve complete glycan hydrolysis22,38,39. For example, a typical starch hydrolysis process involves three steps: gelatinization, liquefaction, and saccharification22. Gelatinization involves heating starch at 85–120 °C under slightly acidic conditions. Liquefaction employs endo-enzymes such as α-amylase to randomly hydrolyze α-1,4 glycosidic bonds at 95–105 °C, producing glucose, oligosaccharides, polysaccharides, and maltodextrin. Saccharification involves the hydrolysis of α-1,4 and α-1,6 bonds in amylopectin by exo-enzymes such as glucoamylase or pullulanase. However, debranching enzymes are typically active at lower temperatures (e.g., 60 °C)22,37,40, necessitating a cooling step before saccharification. Amylopullulanase (EC 3.2.1.41/1) is a debranching amylase that hydrolyzes both α-1,4 and α-1,6 glycosidic bonds in starch or pullulan, making it a promising candidate for one-step starch saccharification in industrial applications41.

Currently, various amylopullulanases from different sources have been characterized42,43,44, and their modification, as well as their use in the production of resistant starch45, maltose syrup46, and dextrin47, have been reported. GH57 amylopullulanases not only catalyze the cleavage of both α-1,4 and α-1,6 glycosidic bonds but also exhibit remarkable thermal stability36,48. Their application in the starch industry can streamline processes by eliminating the cooling step, thereby enabling one-step syrup production. This approach reduces contamination risks, allows for higher substrate concentration, minimizes by-product formation, and enhances overall productivity and economic efficiency9,27. However, few amylopullulanases meet the stringent demands of industrial applications49. The limited understanding of their structure and mechanism hinders efficient enzyme modification.

Here, we report an amylopullulanase from Aquifex aeolicus45 (AaApu) and co-crystallized wild-type (wt) AaApu with acarbose and maltopentaose (G5), as well as nucleophile mutants (E256L and E256Q) and an acid/base catalyst mutant (D352N) were co-crystallized with G5, maltohexaose (G6), maltooctaose (G8), and 6-α-D-maltotriosyl-maltotriose (G3G3’). Additionally, we analyzed the hydrolysis of G5, pullulan, soluble starch, glycogen, and potato starch by AaApu using thin layer chromatography (TLC). Moreover, we determined the crystal structures of AaApu targeting α-1,6 and α-1,4 glycosidic bonds. We observed two linear oligosaccharides bound separately in two adjacent binding pockets. These crystal structures suggest a model for branched polysaccharides binding in the active site of AaApu. revealing a dual-binding pocket architecture that shares a common catalytic dyad to hydrolyze both α-1,4 and α-1,6 glycosidic bonds. This study elucidates the catalytic mechanism of the GH57 family amylopullulanase, providing critical insights for the modification and serving as a valuable reference for the structure-function analysis of debranching amylases.

Results

Sequence analysis

The GH57 family expands their activities beyond α-amylase, featuring unrelated amino acid sequences. According to the CAZy database (http://www.cazy.org/GH57.html), the GH57 family is divided into seven functional clusters: α-1,4-glucan branching enzyme, 4-α-glucanotransferase, α-amylase, glucan 1,4-α-maltohydrolase, α-galactosidase, cyclomaltodextrinase, and amylopullulanase.

As a member of the GH57 family, the amino acid sequence of AaApu was compared with other GH57 family members, including 4-α-glucanotransferase from Thermococcus litoralis DSM 5473 (BAA22063.1), α-1,4-glucan branching enzyme from Thermococcus kodakarensis KOD1 (BAD85625.1), Pyrococcus horikoshii (BAA30492.1) and Thermus thermophilus HB8 (BAD71725.1), amylopullulanase from Thermococcus hydrothermalisas (AAD28552.1) and Thermococcus litoralis (BAC10983.1). The results indicate that AaApu contains the five CSRs typical of the GH57 (Fig. 1a), including 11-HMHQP-15, 187-GKGSV-191, 253-WPPEAS-258, 352-DGENCW-357, and 442-LVAEGSDW-449. In AaApu, Glu256 and Asp352 correspond to the catalytic nucleophile and the acid/base catalyst, respectively, suggesting they form the catalytic dyad. Notably, AaApu has a significantly shorter sequence (477 amino acids) compared to other GH57 amylopullulanases, attributed to the absence of additional domains and the presence of only the catalytic domain of the GH57 enzymes. The substantial sequence length divergence observed in GH57 family enzymes (ranging from fewer than 400 to over 1500 residues), arising from their diverse multi-domain architectures. Sequence alignment is more accurate when additional domains are excluded, making AaApu an ideal representative of GH57 amylopullulanase.

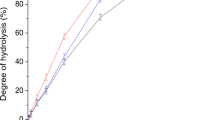

a Five conserve regions of GH57 from different strains, AaApu is amylopullulanase from Aquifex aeolicus; BAA22063.1 is the 4-α-glucanotransferase from Thermococcus litoralis DSM 5473; BAD71725.1, BAA30492.1 and BAD85625.1 are the α-1,4-glucan branching enzyme from Thermococcus kodakarensis KOD1, Pyrococcus horikoshii and Thermus thermophilus HB8, respectively. AAD28552.1 and BAC10983.1 are amylopullulanases from Thermococcus hydrothermalis and Thermococcus litoralis, respectively. Catalytic residues are highlighted with red boxes. b Effect of pH on the enzyme activity of AaApu. c Effect of temperature on the enzyme activity of AaApu wild-type (black), E256Q (blue), E256L (green), and D352N (purple). Data are expressed as mean ± SEM (n = 3).

Enzyme activity and product analysis of AaApu

The activity of AaApu was assessed using the 3′5-dinitrosalicylic acid (DNS) method and TLC to analyze hydrolysis products. AaApu retained more than 50% of its maximum activity within a pH range of 4.0–7.0 (Fig. 1b) and a temperature range of 100–110 °C (Fig. 1c). Activity assays of mutants targeting Glu256 and Asp352 confirmed these as the active residues (Fig. 1c). Kinetic parameters (Km and kcat) are presented in Table S1. Pullulan, a linear polysaccharide composed of G3 units linked by α-1,6 glycosidic bonds, undergoes hydrolysis to yield characteristic trisaccharide products: G3, panose, and isopanose. In the TLC analysis, the distance traveled by panose and isopanose was shorter than that of G350, as verified in Fig. 2a The TLC analysis of the products of pullulan revealed a significant presence of G3, rather than panose or isopanose (Fig. 2a). This suggests that AaApu catalyzes the hydrolysis of α-1,6 glycosidic bonds. Furthermore, AaApu hydrolyzed polysaccharides such as glycogen (Fig. 2a), soluble starch, and raw starch from potatoes (Fig. 2a), as well as oligosaccharides such as G5 (Fig. 2b). These results demonstrate that AaApu is an endoamylase capable of randomly hydrolyzing both α-1,6 and α-1,4 glycosidic bonds, exhibiting broad substrate specificity.

Overall structure of AaApu

To elucidate the catalytic mechanism of GH57 amylopullulanase, we successfully determined the crystal structure of AaApu in its apo form at a resolution of 1.79 Å (P2 space group). This represents the first high-resolution crystal structure of GH57 family amylopullulanase. As shown in Fig. 3a, the overall structure of AaApu is compact, consisting solely of the GH57 catalytic domain without additional domains, and features a predominance of α-helices, with only 10 β-sheets (Fig. 3b). The core structure comprises a twisted (β/α)7 barrel formed by β1, β2, β3, β4, β5, β7, and β8, surrounded by multiple α-helices (Fig. 3b). The catalytic dyad residues, Glu256 and Asp352, are located in the loop between β4 and α13, and at the end of β8, respectively. Structural comparisons with other GH57 enzymes revealed root-mean square deviations (RMSD) is 7.22 Å (290 Cα atoms) for the α-1,4-glucan branching enzymes from Thermococcus kodakarensis KOD1 (PDB ID: 3N8T)15, 7.60 Å (274 Cα atoms) for the branching enzymes from Pyrococcus horikoshii (PDB ID: 5WU7)16, 3.35 Å (270 Cα atoms) for the branching enzymes from Thermus thermophilus HB8 (PDB ID: 3P0B)13, 6.91 Å (287 Cα atoms) for the branching enzymes from Thermotoga maritima MSB8 (PDB ID: 2B5D)17. Comparisons with the 4-α-glucanotransferase from Thermococcus litoralis DSM 5473 (PDB ID: 1K1X)19, maltohydrolase from Pyrococcus sp. ST04 (PDB ID: 4CMR)20 and amylopullulanase from Staphylothermus marinus F1 (PDB ID: 7E1Y) yielded RMSDs of 2.09 Å (214 Cα atoms), 19.98 Å (260 Cα atoms), and 2.06 Å (223 Cα atoms), respectively. A comparison of the crystal structures of AaApu and the aforementioned enzymes from the GH57 family is presented in Fig. S1, where residues 75–175 are significantly non-conserved. Additionally, the C-terminal of AaApu features a three-helix bundle motif (residues 407–477) that is involved in substrate binding.

a Overall structure of AaApu depicted in cartoon representation, highlighting the catalytic dyad (shown as sphere) and β-sheet (colored in green). b A 90° clockwise rotation of panel (a) around the y-axis. c Crystal structure of AaApuwt complexed with acarbose shown in cartoon representation, with the five conserved regions displayed as surface and relevant residues shown as sticks. d The 2Fo-Fc electron density map (contoured at 1.0σ) showing acarbose bound to the active center of AaApu. e Binding of acarbose to the −4 to −1 subsites of the AaApu active pocket.

Active center of AaApu

Acarbose, a maltotetraose analog and glycoside hydrolase inhibitor, was used to model oligosaccharide binding51. The structure of AaApuwt and acarbose complex was determined at 1.69 Å resolution (Fig. 3c, d), which allowed us to identify the active center of AaApu. Acarbose binds deeply into the active pocket (Fig. 3e). Four of the five CSVs in AaApu contribute to the formation of its active pocket, with the exception of CSV-II (Lys188-Val191) (Fig. 3c). Following the naming convention of subsite by Davies et al.52, the non-reducing end of the glycan is assigned a negative value, while the reducing end is assigned a positive value, with cleavage occurring between the -1 and +1 subsites. In this work, the subsites occupied by acarbose were −4, −3, −2, and −1 (Fig. 3e), which do not cross the catalytic residues to occupy the positive subsites. The subsites occupied in all the complex crystal structures mentioned in this paper are summarized in Table 1. Additionally, the distance between the carboxylate -OH group of the nucleophile Glu256 and the acid/base catalyst Asp352 is 6.9 Å (Fig. 3d). Two α-1,4 bond-linked glucosyl groups adopt a 4C1 chair conformation, with an intramolecular hydrogen bond between the C2 and C3 hydroxyl groups (Fig. 3d).

Additionally, AaApuwt co-crystallized with G5 yielded a complex structure, though only three glycosyl groups were visible due to partial hydrolysis at the crystallization temperature (65 °C) (Fig. 4a).

a AaApuwt co-crystallized with maltopentaose (G5). b E256L mutant co-crystallized with maltohexaose (G6). c D352N mutant co-crystallized with 6-α-D-maltotriosyl-maltotriose (G3G3’). d D352N mutant co-crystallized with maltooctaose (G8). e D352N mutant co-crystallized with G5. f E256Q mutant co-crystallized with G5. g D352N mutant co-crystallized with G6. h E256Q mutant co-crystallized with G6.

Crystal structure of AaApu targeting α-1,6 glycosidic bond

As mentioned above, we have identified the active center of AaApu through the use of acarbose. To investigate the binding mode of substrates containing α-1,6 glycosidic bonds, the D352N mutant was co-crystallized with G3G3’. The substrate, G3G3’, consists of two G3 linked by an α-1,6 glycosidic bond, which is derived from the hydrolysis of pullulan by pullulanase. The resulting structure (1.66 Å resolution) revealed G3G3’ bound at subsites −3, −2, −1, +1, and +2, with the α-1,6 bond located between -1 and +1 subsites (Fig. 4c). Additionally, the glycosyl groups of G3G3’ adopt a 4C1 chair conformation. The conformations of the glycosyl groups on either side of the α-1,6 glycosidic bond are very similar, which can be seen from the torsion angles φ (O5-C1-O4’-C4’) and ψ (C1-O4’-C4’-C5’) (Table S2), respectively. The α-1,6 glycosidic oxygen is 3.4 Å from Asn352 (D352N), and the anomeric carbon at −1 subsites is 3.3 Å from Glu256 (Fig. 4c and Table S2).

Crystal structure of AaApu targeting α-1,4 glycosidic bonds

AaApu also targets α-1,4 glycosidic bonds, as demonstrated by co-crystallization with oligosaccharides containing only α-1,4 glycosidic bonds. Seven subsites (−5 to +2) were identified. In the D352N-G5 complex, all five glycosyl groups occupied on the same side of Glu256 and Asp352 (subsites −5 to −1) (Fig. 4e). When the number of the glycosyl groups is increased to six, the complete glucan chain crosses the catalytic dyad (Glu256 and Asp352), occupying the subsites −4 to +2 (Fig. 4g). If the number of glycosyl groups is further increased to eight, only seven subsites will be occupied (Fig. 4d). In short, we found that the binding subsite of AaApu is limited. At the primary binding site, there are seven visible subsites, two of which are distributed at the reducing end, while five subsites are distributed at the non-reducing end. The non-reducing ends of the glucan chain adopt a 4C1 chair conformation at subsites −5 to −1. However, the oligosaccharide between the −1 and +1 subsites is bent, disrupting hydrogen bond between the O2 of the −1 subsite glycosyl and the O3’ of the +1 subsite glycosyl (interatomic distance is 4.9 Å) (Fig. 4d). The torsion angles φ (O5-C1-O4’-C4’) was 51.6° (Fig. 4d) and ψ (C1-O4’-C4’-C5’) was −171.9° (Fig. 4d) for the glycosyl groups between the -1 and +1 subsites. The values are 54.3° less than the average torsion angle φ between subsites −5 to −1, and 41.6° less than the average dihedral angle ψ, respectively (Table S2). The torsion angles of glycosidic bonds at other subsites exhibit regularity.(Table S2). A sharp bend in the oligosaccharide at the −1 and +1 subsites was previously reported53. This sharp bend likely facilitates the cleavage of the departing glycosyl group51. The α-1,4-glycosidic bond between the −1 and +1 subsites is 3.2 Å from Asn352 (D352N), and 3.4 Å from Glu256 (Fig. 4d and Table S2).

Two oligosaccharides bind in AaApu

Co-crystallization of catalytic nucleophile mutants (E256Q and E256L) with oligosaccharides revealed two independent binding pockets: a primary active pocket (deep and narrow) and a secondary active pocket (shallow and wide). In the E256L-G6 (Fig. 4b), E256Q-G5 (Fig. 4f), and E256Q-G6 (Fig. 4h) complexes, up to five glycosyl groups are visible in the primary binding pocket (−5 to −1 subsites), although the electron density of the glycosyl group at the −5 subsite is weak. In the secondary binding pocket, four to six glycosyl groups are visible. The electron density in the secondary binding pocket was weaker in E256Q-G5 and E256L-G6 complexes, with higher B-factors (34.4 Å2 and 38.6 Å2) of the ligand in these two structures, which are significantly higher than the average overall B-factors. Additionally, the number of visible glycosyl groups in the secondary binding pocket was not uniform across each chain of asymmetric units.

The stereo representations of glycosyl groups bound at the active center in multiple complex structures are presented in Fig. S2.

C-terminal region in substrate binding

The C-terminal region (residues 407–477) of AaApu plays a critical role in substrate binding. The active site of AaApu is surrounded by multiple aromatic residues (predominantly Trp and Phe), whose hydrophobic aromatic rings collectively form a hydrophobic platform. This structural feature constitutes substrate-binding subsites critical for ligand stabilization and molecular recognition (Fig. 5a, b). Figure 5b highlights 12 aromatic residues encircling the active pocket, with 9 clustered in the C-terminal region. Notable examples include Trp449 and Trp451, located within the CSV-V. Additionally, Fig. 6c summarizes the π-π and π-cation interactions around the enzyme’s active site, which contribute to the formation of the hydrophobic platform at the binding site. A flexible loop (453-QGEEKAPFV-461) near the active center adjusts its position based on the length of substrates; which B-factors for this loop are the highest in the structure (Fig. 5b). Moreover, we identified significant conformational changes in the side chains of Phe409 (Fig. 6d), located on the egress side of the active pocket act as gate-keepers. Phe409 likely mediates substrate binding by forming stable hydrophobic interactions through side chain conformational adjustments.

Comparison of complex structures

Oligosaccharides bound at the active pocket are shown in Fig. 6a, b. Comparison of the D352N-G3G3’ and D352N-G8 complexes revealed distinct binding modes for α-1,6 and α-1,4 glycosidic bonds. Their positions at the +2 and +1 subsites do not completely overlap, although they are very close (Fig. 6b, c). The +1 subsite in D352N-G3G3’ highly overlaps with the +1 subsite in E256L-G6 (Fig. 6d), suggesting a potential binding model for branched oligosaccharides. However, there are no commercialized branched oligosaccharides available, and the experimental structure of AaApu and the branched oligosaccharide is unavailable, too. The introduction of new structural linkages during this merging process may induce subtle conformational adjustments in either the protein or ligands. To rigorously characterize these structural perturbations, we performed 200 ns molecular dynamics simulations based on the structures of the D352N-G3G3’ and E256L-G6 complexes, selecting the lowest-energy conformation from the equilibrated trajectory for structural representation (Fig. 7a, b). The RMSD of main chain Cα atoms relative to the initial structure was calculated based on the obtained MD trajectories to confirm the convergence of the simulations. The RMSD values for protein and ligand did not exceed 1.7 Å and 3.5 Å, respectively, and overall fluctuations were minimal (Fig. 7c). The lowest-energy conformation closely aligns with the experimental structures in Fig. 7d.

a Lowest-energy conformation obtained from MD simulation. b Detailed view of the structure shown in panel (a). c Time-dependent of root-mean-square deviations (RMSD) analysis of the modeled branched G7-AaApu complex structure during the ~200 ns MD simulation (upper panel: Cα of AaApu residues; lower panel: branched G7 substrate). d Structural comparison between the MD simulation model and the crystallographic structures of D352N-G3G3’ and E256L-G6 complex.

The interaction of oligosaccharides binding at the active center

The interaction schematic of the oligosaccharides at the active center in the structures of the D352N-G3G3’ and D352N-G8 complexes is illustrated in Fig. 8a, b and Fig. S3a, b, respectively. The glycosyl groups are stably bound through an extensive network of hydrogen bonds and hydrophobic interactions. The conserved residues near the catalytic site are primarily distributed around the −2, −1, and +1 subsites, forming hydrogen bonds exclusively with glycosyl groups at these positions. Furthermore, the glycosyl groups are also stabilized by numerous water-mediated hydrogen bonds. Although the interacting residues are relatively conserved, there are significant differences in the glycosidic conformations at the +2 and +1 subsites, leading to the involvement of different atoms from the ligands in the formation of hydrogen bonds. In the D352N-G3G3’ complex, the O2 and O3 atoms of the +2 subsite’s glycosyl form hydrogen bonds with Arg306 and Lys308. Conversely, in the D352N-G8 complex, the O1, O2, and O5 atoms of the +2 subsite’s glycosyl form hydrogen bonds with Arg306 and Lys308. The glycosyl groups from the +2 to −2 subsites are primarily stabilized through hydrogen bonds, whereas those from the -3 to −5 subsites are stabilized through a combination of hydrogen bonds and hydrophobic interactions. When two oligosaccharides bind separately at the active center, the number of residues near the secondary binding pocket is limited, resulting in weaker interactions. The residues involved in forming hydrogen bonds in this region include Arg306, Lys308, Ser311, Asp312, and Cys356 (Fig. 8c and Fig. S3c). The binding affinity of the ligands in the secondary binding pocket is weaker than that in the primary binding pocket, leading to lower electron density for the ligands in this area. In the primary binding pocket, the O6, O2, and O3 atoms of the glycosyl groups form hydrogen bonds with the enzyme, while in the secondary binding pocket, the binding is primarily stabilized by hydrogen bonds between the O2 and O3 atoms of the glycosyl groups and the enzyme.

Discussion

Amylopullulanase, due to its ability to catalyze both α-1,4 and α-1,6 glycosidic bonds and its exceptional thermostability, holds significant potential for one-step syrup production in industry applications. However, no amylopullulanase currently meets the stringent requirements for industrial use. A detailed study of the structure and mechanism of amylopullulanase is essential to guide the engineering of enzymes tailored to industrial needs. In this work, we present high-resolution crystal structures of amylopullulanase targeting α-1,4 and α-1,6 glycosidic bonds, determined through high-temperature crystallization54. These structures elucidate the molecular mechanism underlying the dual glycosidic bond activity of amylopullulanase.

Based on homologous sequence comparison (Fig. 1a), we identified Glu256 as the catalytic nucleophile and Asp352 as the acid/base catalyst in AaApu. This assignment was further confirmed by activity assays of AaApu mutants (Fig. 1c). AaApu is exclusively composed of the GH57 catalytic domain, lacking CBMs or SLHs. Its structure consists of three regions: a (β/α)7 barrel, an unconserved region that inserts into the (β/α)7 barrel, and a C-terminal region made up of α-helices. This architecture is consistent with other reported GH57 enzymes13,17,55. The inability of acarbose to span catalytic residues in AaApu is likely attributable to its limited chain length. Our systematic analysis revealed that only substrates with a degree of polymerization of at least six span the catalytic residues. Notably, the AaApu wild-type demonstrated substrate hydrolysis activity under crystallization temperature (60 °C). We aimed to determine the structure of the inactive enzyme complexed with substrate. This will allow us to analyze the catalytic molecular mechanism of AaApu hydrolyzes both α-1,4 and α-1,6 glycosidic bonds.

When targeting the α-1,4 glycosidic bonds (Fig. 4d, e, g), we can understand the molecular mechanism of amylopullulanase in catalyzing linear polysaccharides. When targeting α-1,6 glycosidic bond (Fig. 4c), we can comprehend the molecular mechanism of amylopullulanase in catalyzing the hydrolysis of pullulan. The results indicate that the α-1,4 bond-linked oligosaccharide exhibits a twist at the cleavage site (Fig. 4d), which lowers the energy barrier and facilitates hydrolysis. This sharp bend is a common feature in hydrolase-substrate complexes51,56,57. In contrast, when targeting α-1,6 bond linked substrates, no such sharp bend is observed, due to their extra carbon, α-1,6 glycosidic bonds are less restricted and more flexible than α-1,4. (Fig. 4c). Unlike the GH13 family, where catalytic residues are more parallel58,59, the catalytic residues in GH57 enzymes are positioned at a relative angle, resulting in an unusually large distance of 6.8 Å between them (Fig. 4c, d). This distance exceeds the conventional ~5 Å observed in the retaining mechanism and may reflect the spatial requirements for accommodating both α-1,4 and α-1,6 bonds.

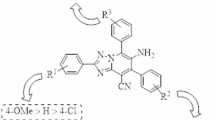

As a debranching enzyme, AaApu also hydrolyzes branched polysaccharides. Dual oligosaccharide binding at the active center has also been reported in other starch debranching enzymes58,59,60,61, which we suggest is characteristic of starch debranching enzymes. However, in AaApu, this phenomenon is only observed in nucleophilic residue mutants, likely due to the inability to form a glycosyl-enzyme intermediate, which creates sufficient space to accommodate a second oligosaccharide. Interestingly, the structural comparison of D352N-G3G3’ and E256L-G6 complex (Fig. 6d) suggests a model for the hydrolysis of the branched polysaccharides. AaApu utilizes a single catalytic site to hydrolyze both types of glycosidic bonds, facilitated by its unique dual-binding pockets. When the substrate is a linear polysaccharide, it preferentially binds to the primary binding pocket; when the substrate is a branched polysaccharide, the branched chain binds to the primary binding pocket, while the main chain binds to the secondary binding pocket. The two binding pockets share the same catalytic dyad (Glu256 and Asp352), forming a distorted “Y” shaped structure that facilitates the binding of both linear and branched polysaccharides. This arrangement highlights the enzyme’s versatility and efficiency.

In summary, whether hydrolyzing pullulan, linear polysaccharides, or branched polysaccharides, GH57 amylopullulanase employs two binding pockets that share the same catalytic residues to cleave both α-1,4 and α-1,6 glycosidic bonds. A residue, Phe409, acts as gate-keeper at the egress side of active pocket55. Additionally, a flexible loop (453-QGEEKAPFV-461) at the entrance with weak electron density adjusts its position relative to the active center depending on substrate length. A similar loop has been observed in β-amylase56. We propose that this gate-keeper and this flexible loop may play a role in substrate movement and binding. This study not only provides structural insights for the engineering of amylopullulanase but also serves as a valuable reference for the structural and functional analysis of debranching enzymes. In the future, we will also conduct research on other types of enzymes in the GH57 family to enhance our understanding of GH57 family enzymes.

Materials and methods

Materials

Pullulan was purchased from TCI (Japan). Soluble starch, glycogen, potato starch, glucose, maltose, and N-(1-Naphthyl)-ethylenediamine, dihydrochloride were purchased from Sangon Biotech (Shanghai, China). G5, G6, and G7 were purchased from HuicH (Shanghai, China). G8 and DNS were purchased from Yuanye Bio (Shanghai, China). G3G3’ was purchased from BIOSYNTH (Switzerland).

Sequence synthesis and plasmid construction

The synthesis of amylopullulanase from Aquifex aeolicus VF5 cDNA was based on GenBank WP_010880432.1, and codon usage was optimized for the Escherichia coli (E. coli) expression system. The full-length AaApu cDNA sequence was constructed into the pET-22b vector using NdeI/XhoI restriction endonuclease sites (pET22b-AaApu), which produced a C-terminal His-tagged protein.

Protein purification

Wild-type AaApu gene was translated into E. coli BL21(DE3) cells and protein were induced using LB broth with 0.5 mM IPTG. Bacteria were centrifuged at 8000 × g for 10 min after 18 h of induction at 18 °C. The resulting cell pellet was resuspended in buffer A (500 mM NaCl, 30 mM Tris-HCl pH 8.0, and 5% glycerol), and then lysed by passing through a microfluidizer (800 bar). The lysate was centrifuged at 30,000 × g for 60 min. The supernatant was subjected to immobilized metal affinity chromatography using a 5 mL Ni-NTA column pre-equilibrated with buffer A. Contaminants were removed through a stepwise imidazole gradient (15 mM and 30 mM in Buffer A) prior to target protein elution with buffer B (500 mM NaCl, 30 mM Tris-HCl pH 8.0, 500 mM imidazole, and 5% glycerol). AaApu can remain stable at high temperatures, so the initially purified sample is further purified by heating at 65 °C for 10 min and then centrifuged at 10,000 × g for 10 min to remove precipitated proteins. AaApu was loaded onto a Superdex 200 16/60 column, which was equilibrated with buffer C (30 mM Tris-HCl, pH 8.0, 100 mM NaCl, and 5% glycerol). Finally, the purity of the protein was detected using SDS-PAGE, and the concentration of the protein was detected using a nanodrop.

The purification method of AaApu mutants is similar to that of the wild type.

Protein crystallization

Before crystallization, CaCl2 was added to the protein solution to 1 mM final concentration. The initial crystal hits were obtained in the PEGRx (HR2-082) at 65 °C. Finally, high-quality apo-AaApu crystals were obtained after 15 mg/mL protein solution was mixed with equal volumes of the reservoir solution containing 100 mM sodium citrate, pH 4.2, 25% PEG3350 at 65 °C. AaApu and various oligosaccharide complex crystals were obtained by co-crystallization with the reservoir solution containing 100 mM sodium citrate, pH 3.6–4.8, 18%–30% PEG3350 at 65 °C.

Data collection and structure determination

Crystals were cryoprotected by the addition of 20% (v/v) glycerol before flash-cooling in liquid nitrogen. X-ray diffraction data were collected at beamlines BL02U162 and BL10U263 of the Shanghai Synchrotron Radiation Facility. Data processing, including indexing and integration, was performed using XDS or DIALS software packages. The structures were determined by molecular replacement using Phaser, utilizing an AlphaFold-predicted structure as the initial search model64. Subsequent refinement of the atomic coordinates and temperature factors was carried out using phenix.refine with maximum-likelihood target functions65. Iterative model building and adjustment were performed in Coot66. The stereochemical quality of the final model was validated using MolProbity67. Detailed crystallographic statistics are provided in Supplement Table 1. PyMOL is an invaluable tool for creating figures (https://github.com/schrodinger/pymol-open-source). LigPlot+ is a useful 2D intermolecular interaction diagram drawing software68.

Site-directed mutagenesis

The E256Q (AaApu-E256Q), E256L (AaApu-E256L), and D352N (AaApu-D352N) mutants were produced by applying mutagenic PCR to the pET22b-AaApu plasmid according to the QuikChange protocol. In order to confirm the desired mutants, all mutant plasmids need to be sequenced. Plasmids containing the confirmed AaApu mutants were then transformed into E. coli BL21(DE3) cells, and the corresponding overexpressed recombinant mutant proteins were purified as described for the wild-type enzyme.

Activity analysis

Reducing sugars were determined using the DNS method. Enzyme activity reaction was carried out using 2 mL centrifuge tubes. Enzyme activities were determined at 100 °C in 100 mM sodium citrate buffer (pH 5.0) using pullulan and soluble starch as substrates (1%, w/v). The optimal pH of AaApu was determined at 105 °C for 10 min using pullulan 1%, w/v) as the substrate in 100 mM sodium citrate buffer (pH 3.0–6.0) and HEPES buffer (pH 7.0–8.0). The optimal temperature was determined using pullulan (1%, w/v) as a substrate using conditions for the enzyme activity assay, and the reaction temperature was in a range of 90–110 °C. Each reaction tube of the reaction included 15 μg of purified AaApu. In addition, 500 μL of the reaction system contained 0.1 M buffer reagent, and the substrate and enzyme were separately incubated at different temperatures for 3 min and then mixed to react for 10 min. The accumulated heat from high-temperature heating may cause the centrifuge tube cover to open, and sealing it with a Parafilm® M sealing film can prevent liquid from splashing out. After hydrolysis, the reaction was ended by ice cooling. Then add 500 μL of DNS, and heat at 100 °C for 10 min. The concentration of the reducing sugars liberated from the enzymatic reaction mixture was spectrophotometrically quantified at OD = 540 nm in a microplate reader. One unit of enzyme was defined as the amount of the enzyme that liberated one micromole of reducing sugars per minute under the assay conditions. The kinetic parameters were measured for the pullulan substrates at 105 °C, pH 5.0. The enzyme activity data measured at different concentrations of the substrate were regressed nonlinearly using the Michaelis-Menten equation, and Km was obtained from the fitted equation.

Statistics and reproducibility

Each individual experiment included one control group and three experimental groups, and each experiment was repeated three times. The lower limit of relative activity is set to 0%. Data are expressed as mean ± SEM.

TLC analysis of hydrolysis products

The hydrolysis products of AaApu were analyzed using TLC. The reaction substrates were 1.5 mM of G5 and 0.5% of pullulan, glycogen, soluble starch, and potato starch, respectively. Each reaction group contains 0.1 M sodium citrate buffer and a total volume of 500 μL, in which 15 μg of AaApu was added to each reaction tube. Hydrolysis activities were carried out at 100 °C in 100 mM sodium citrate buffer (pH 5.0). Samples were taken at regular time intervals (0 h, 0.5 h, 2 h, 4 h, and 6 h). Here, n-butanol: anhydrous ethanol: water = 5:5:3 as the mobile phase. After separation, the silica gel plates were dried. After dryness, the silica gel plates were sprayed with the Methanol solution containing 0.3% of N-(1-naphthyl)-ethylenediamine, dihydrochloride, and 5% H2SO4, and then heated at 105 °C for 10 min to make sugar coloration.

Molecular dynamics simulation

To set-up the model structure of branched maltoheptaose (G7)-bound AaApu complex, a conventional molecular dynamics (MD) simulation was performed to evaluate the RMSD of the starting model with respect to the simulated one, lasting ~200 ns at constant temperature of 300 K and constant pressure of 1 atm. The atomic coordinates of the branched G7-bound AaApu were retrieved from the crystal structures were determined by us (PDB ID: 8ZYI and 9II1) with a resolution of 1.66 Å and 1.50 Å, with all residue mutants recovered to the wild-type ones. All crystal water was kept, and the solvated molecules (glycerol) were removed. Meanwhile, the substrate branched maltoheptaose (G7) was modified for the simulation. The protein termini remained freely charged (uncapped). The protonation states of all titratable residues at pH 7.5 were evaluated. All residues were found in their standard protonation states.

The protein system was solvated in a cubic box filled with a total of 18,855 water molecules, in which multiple Na+/Cl− ions were added to neutralize the protein charges. The AMBER 18 suite of programs69 was employed for simulations with the underlying force fields of the FF14SB force field70 for protein and the TIP3P model71 for water molecules. The glucan molecule was modeled using a GLYCAM06j force field72 implemented in AMBER 18. Finally, the conventional MD simulations were performed on the equilibrated system using the conventional MD module implemented in the GPU version of AMBER 18, lasting ~200 ns at a constant temperature of 300 K and a constant pressure of 1 atm.

Reporting summary

Further information on research design is available in the Nature Portfolio Reporting Summary linked to this article.

Data availability

The structure coordinates and structure factors have deposited to Protein Data Bank, and accession code are 9IHU, 9IHV, 9IHW, 9IHT, 9IHX, 9K7C, 9K7D, 9II0, 9II1 and 8ZYI. Source data and MD simulation files are provided with this paper.

References

Davies, G. J., Gloster, T. M. & Henrissat, B. Recent structural insights into the expanding world of carbohydrate-active enzymes. Curr. Opin. Struct. Biol. 15, 637–645 (2005).

Baker, P. et al. Exopolysaccharide biosynthetic glycoside hydrolases can be utilized to disrupt and prevent Pseudomonas aeruginosa biofilms. Sci. Adv. 2, e1501632 (2016).

Minic, Z. Physiological roles of plant glycoside hydrolases. Planta 227, 723–740 (2008).

Vieille, C. & Zeikus, G. J. Hyperthermophilic enzymes: sources, uses, and molecular mechanisms for thermostability. Microbiol. Mol. Biol. Rev. 65, 1–43 (2001).

Sundarram, A., Murthy, T. & Krishna, P. α-amylase production and applications: a review. J. Appl. Environ. Microbiol. 2, 166–175 (2014).

Henrissat, B. A classification of glycosyl hydrolases based on amino acid sequence similarities. Biochem. J. 280, 309–316 (1991).

Henrissat, B. & Davies, G. Structural and sequence-based classification of glycoside hydrolases. Curr. Opin. Struct. Biol. 7, 637–644 (1997).

Henrissat, B. & Bairoch, A. Updating the sequence-based classification of glycosyl hydrolases. Biochem. J. 316, 695–696 (1996).

Lin, H.-Y., Chuang, H.-H. & Lin, F.-P. Biochemical characterization of engineered amylopullulanase from Thermoanaerobacter ethanolicus 39E-implicating the non-necessity of its 100 C-terminal amino acid residues. Extremophiles Life Extrem. Cond. 12, 641–650 (2008).

Janeček, Š Amylolytic families of glycoside hydrolases: focus on the family GH-57. Biologia 60, 177–184 (2005).

Blesák, K. & Janeček, S. Sequence fingerprints of enzyme specificities from the glycoside hydrolase family GH57. Extremophiles Life Extrem. Cond. 16, 497–506 (2012).

Cifuente, J. O., Colleoni, C., Kalscheuer, R. & Guerin, M. E. Architecture, function, regulation, and evolution of α-glucans metabolic enzymes in prokaryotes. Chem. Rev. 124, 4863–4934 (2024).

Palomo, M. et al. Thermus thermophilus glycoside hydrolase family 57 branching enzyme: crystal structure, mechanism of action, and products formed. J. Biol. Chem. 286, 3520–3530 (2011).

Murakami, T., Kanai, T., Takata, H., Kuriki, T. & Imanaka, T. A novel branching enzyme of the GH-57 family in the hyperthermophilic archaeon Thermococcus kodakaraensis KOD1. J. Bacteriol. 188, 5915–5924 (2006).

Santos, C. R. et al. Structural basis for branching-enzyme activity of glycoside hydrolase family 57: structure and stability studies of a novel branching enzyme from the hyperthermophilic archaeon Thermococcus kodakaraensis KOD1. Proteins Struct. Funct. Bioinforma. 79, 547–557 (2011).

Na, S., Park, M., Jo, I., Cha, J. & Ha, N.-C. Structural basis for the transglycosylase activity of a GH57-type glycogen branching enzyme from Pyrococcus horikoshii. Biochem. Biophys. Res. Commun. 484, 850–856 (2017).

Dickmanns, A., Ballschmiter, M., Liebl, W. & Ficner, R. Structure of the novel alpha-amylase AmyC from Thermotoga maritima. Acta Crystallogr. Sect. D. Biol. Crystallogr. 62, 262–270 (2006).

Zhang, X. et al. Identification of Thermotoga maritima MSB8 GH57 α-amylase AmyC as a glycogen-branching enzyme with high hydrolytic activity. Appl. Microbiol. Biotechnol. 103, 6141–6151 (2019).

Imamura, H. et al. Crystal structures of 4-alpha-glucanotransferase from Thermococcus litoralis and its complex with an inhibitor. J. Biol. Chem. 278, 19378–19386 (2003).

Park, K. H. et al. Structural features underlying the selective cleavage of a novel exo-type maltose-forming amylase from Pyrococcus sp. ST04. Acta Crystallogr. Sect. D. Biol. Crystallogr. 70, 1659–1668 (2014).

Blesák, K. & Janeček, Š Two potentially novel amylolytic enzyme specificities in the prokaryotic glycoside hydrolase α-amylase family GH57. Microbiology 159, 2584–2593 (2013).

de Miguel Bouzas, T., Barros-Velázquez, J. & Gonzalez Villa, T. Industrial applications of hyperthermophilic enzymes: a review. Protein Pept. Lett. 13, 645–651 (2006).

Zeikus J. G. in Progress in Biotechnology). (Elsevier, 1996).

Zona, R., Chang-Pi-Hin, F., O’Donohue, M. J. & Janeček, Š. Bioinformatics of the glycoside hydrolase family 57 and identification of catalytic residues in amylopullulanase from Thermococcus hydrothermalis. Eur. J. Biochem. 271, 2863–2872 (2004).

Jeon, E. J. et al. Bioinformatic and biochemical analysis of a novel maltose-forming α-amylase of the GH57 family in the hyperthermophilic archaeon Thermococcus sp. CL1. Enzym. Microb. Technol. 60, 9–15 (2014).

Janeček, Š & Martinovičová, M. New groups of protein homologues in the α-amylase family GH57 closely related to α-glucan branching enzymes and 4-α-glucanotransferases. Genetica 148, 77–86 (2020).

Satyanarayana, T. & Nisha, M. Archaeal and bacterial thermostable amylopullulanases: characteristic features and biotechnological applications. Amylase 2, 44–57 (2018).

Zona, R., Chang-Pi-Hin, F., O’Donohue, M. J. & Janecek, S. Bioinformatics of the glycoside hydrolase family 57 and identification of catalytic residues in amylopullulanase from Thermococcus hydrothermalis. Eur. J. Biochem. 271, 2863–2872 (2004).

Vuong, T. V. & Wilson, D. B. Glycoside hydrolases: catalytic base/nucleophile diversity. Biotechnol. Bioeng. 107, 195–205 (2010).

Li, Z. et al. Understanding the pH-dependent reaction mechanism of a glycoside hydrolase using high-resolution X-ray and neutron crystallography. ACS Catal. 8, 8058–8069 (2018).

Davies, G. & Henrissat, B. Structures and mechanisms of glycosyl hydrolases. Structure 3, 853–859 (1995).

Wang, Q., Trimbur, D., Graham, R., Warren, R. A. J. & Withers, S. Identification of the acid/base catalyst in Agrobacterium faecalis beta.-glucosidase by kinetic analysis of mutants. Biochemistry 34, 14554–14562 (1995).

Henrissat, B. et al. Conserved catalytic machinery and the prediction of a common fold for several families of glycosyl hydrolases. Proc. Natl. Acad. Sci. USA 92, 7090–7094 (1995).

Wang, Q., Graham, R., Trimbur, D., Warren, R. & Withers, S. Changing enzymic reaction mechanisms by mutagenesis: conversion of a retaining glucosidase to an inverting enzyme. J. Am. Chem. Soc. 116, 11594–11595 (1994).

Zechel, D. L. & Withers, S. G. Dissection of nucleophilic and acid–base catalysis in glycosidases. Curr. Opin. Chem. Biol. 5, 643–649 (2001).

Nisha, M. & Satyanarayana, T. Recombinant bacterial amylopullulanases: developments and perspectives. Bioengineered 4, 388–400 (2013).

Olawoye, B., Jolayemi, O. S., Origbemisoye, B. A., Oluwajuyitan, T. D. & Popoola-Akinola, O. In Starch: Advances in Modifications, Technologies and Applications. (Springer International Publishing, 2023).

Bajpai P. In Developments and Applications of Enzymes from Thermophilic Microorganisms. (Academic Press, 2023).

Bertoldo, C. & Antranikian, G. Starch-hydrolyzing enzymes from thermophilic archaea and bacteria. Curr. Opin. Chem. Biol. 6, 151–160 (2002).

Wang, S., Li, C., Copeland, L., Niu, Q. & Wang, S. Starch retrogradation: a comprehensive review. Compr. Rev. Food Sci. Food Saf. 14, 568–585 (2015).

Hii, S. L., Tan, J. S., Ling, T. C. & Ariff, A. B. Pullulanase: role in starch hydrolysis and potential industrial applications. Enzym. Res. 2012, 921362 (2012).

Vishnu, C., Naveena, B., Altaf, M., Venkateshwar, M. & Reddy, G. Amylopullulanase—a novel enzyme of L. amylophilus GV6 in direct fermentation of starch to L (+) lactic acid. Enzym. Microb. Technol. 38, 545–550 (2006).

Li, X., Ji, H., Zhai, Y., Bai, Y. & Jin, Z. Characterizing a thermostable amylopullulanase from Caldisericum exile with wide pH adaptation and broad substrate specificity. Food Biosci. 41, 100952 (2021).

Jiao, Y. L. et al. A GH57 family amylopullulanase from deep-sea Thermococcus siculi: expression of the gene and characterization of the recombinant enzyme. Curr. Microbiol. 62, 222–228 (2011).

Peng, H. et al. Using a novel hyperthermophilic amylopullulanase to simplify resistant starch preparation from rice starches. J. Funct. Foods 80, 104429 (2021).

Nisha, M. & Satyanarayana, T. Characteristics and applications of recombinant thermostable amylopullulanase of Geobacillus thermoleovorans secreted by Pichia pastoris. Appl. Microbiol. Biotechnol. 101, 2357–2369 (2017).

Park, Y. U. et al. GH57 amylopullulanase from Desulfurococcus amylolyticus JCM 9188 can make highly branched cyclodextrin via its transglycosylation activity. Enzym. Microb. Technol. 114, 15–21 (2018).

Li, X., Li, D. & Park, K. H. An extremely thermostable amylopullulanase from Staphylothermus marinus displays both pullulan- and cyclodextrin-degrading activities. Appl. Microbiol. Biotechnol. 97, 5359–5369 (2013).

Xu, P. et al. Biotechnology and bioengineering of pullulanase: state of the art and perspectives. World J. Microbiol. Biotechnol. 37, 43 (2021).

Kuriki, T., Okada, S. & Imanaka, T. New type of pullulanase from Bacillus stearothermophilus and molecular cloning and expression of the gene in Bacillus subtilis. J. Bacteriol. 170, 1554–1559 (1988).

Strokopytov, B. et al. X-ray structure of cyclodextrin glycosyltransferase complexed with acarbose. Implications for the catalytic mechanism of glycosidases. Biochemistry 34, 2234–2240 (1995).

Davies, G. J., Wilson, K. S. & Henrissat, B. Nomenclature for sugar-binding subsites in glycosyl hydrolases. Biochem. J. 321, 557 (1997).

Przylas, I. et al. X-ray structure of acarbose bound to amylomaltase from Thermus aquaticus: implications for the synthesis of large cyclic glucans. Eur. J. Biochem. 267, 6903–6913 (2000).

Zhu, Z. et al. High-temperature crystallization method for the GH57 family hyperthermophilic amylopullulanase from Aquifex aeolicus. Cryst. Growth Des. 24, 10350–10357 (2024).

Santos, C. R. et al. Structural basis for branching-enzyme activity of glycoside hydrolase family 57: structure and stability studies of a novel branching enzyme from the hyperthermophilic archaeon Thermococcus kodakaraensis KOD1. Proteins 79, 547–557 (2011).

Vajravijayan, S. et al. Structural insights on starch hydrolysis by plant β-amylase and its evolutionary relationship with bacterial enzymes. Int. J. Biol. Macromol. 113, 329–337 (2018).

Fujimoto, Z. et al. Crystal structure of a catalytic-site mutant alpha-amylase from Bacillus subtilis complexed with maltopentaose. J. Mol. Biol. 277, 393–407 (1998).

Møller, M. S. et al. Oligosaccharide and substrate binding in the starch debranching enzyme barley limit dextrinase. J. Mol. Biol. 427, 1263–1277 (2015).

Huang, P., Wu, S., Yang, S., Yan, Q. & Jiang, Z. Structural basis of carbohydrate binding in domain C of a type I pullulanase from Paenibacillus barengoltzii. Acta Crystallogr. Sect. D. Struct. Biol. 76, 447–457 (2020).

Mikami, B. et al. Crystal structure of pullulanase: evidence for parallel binding of oligosaccharides in the active site. J. Mol. Biol. 359, 690–707 (2006).

Lammerts van Bueren, A. et al. The conformation and function of a multimodular glycogen-degrading pneumococcal virulence factor. Structure 19, 640–651 (2011).

Liu, K. et al. BL02U1: the relocated macromolecular crystallography beamline at the Shanghai Synchrotron Radiation Facility. Nucl. Sci. Tech. 34, 193 (2023).

Xu, Q. et al. The biosafety level-2 macromolecular crystallography beamline (BL10U2) at the Shanghai Synchrotron Radiation Facility. Nucl. Sci. Tech. 34, 202 (2023).

Jumper, J. et al. Highly accurate protein structure prediction with AlphaFold. Nature 596, 583–589 (2021).

Adams, P. D. et al. PHENIX: a comprehensive Python-based system for macromolecular structure solution. Acta Crystallogr. Sect. D. Biol. Crystallogr. 66, 213–221 (2010).

Emsley, P., Lohkamp, B., Scott, W. G. & Cowtan, K. Features and development of Coot. Acta Crystallogr. Sect. D. Biol. Crystallogr. 66, 486–501 (2010).

Chen, V. B. et al. MolProbity: all-atom structure validation for macromolecular crystallography. Acta Crystallogr. Sect. D., Biol. Crystallogr. 66, 12–21 (2010).

Laskowski, R. A. & Swindells, M. B. LigPlot+: multiple ligand-protein interaction diagrams for drug discovery. J. Chem. Inf. Modeling 51, 2778–2786 (2011).

Song, L. F., Lee, T.-S., Zhu, C., York, D. M. & Merz, K. M. Jr Using AMBER18 for relative free energy calculations. J. Chem. Inf. Modeling 59, 3128–3135 (2019).

Maier, J. A. et al. ff14SB: improving the accuracy of protein side chain and backbone parameters from ff99SB. J. Chem. Theory Comput. 11, 3696–3713 (2015).

Jorgensen, W. L., Chandrasekhar, J., Madura, J. D., Impey, R. W. & Klein, M. L. Comparison of simple potential functions for simulating liquid water. J. Chem. Phys. 79, 926–935 (1983).

Kirschner, K. N. et al. GLYCAM06: a generalizable biomolecular force field. Carbohydrates. J. Comput. Chem. 29, 622–655 (2008).

Acknowledgements

This research was supported by beamline BL10U2 and BL02U1 at the Shanghai Synchrotron Radiation Facility. We thank the Shanghai Synchrotron Radiation Facility of Experiment Assist System (https://cstr.cn/31124.02.SSRF.LAB) for the assistance on this work. This research was supported by the National Key Research and Development Program of China [grant No. 2021YFC2301405], the Natural Science Foundation of Shanghai (21ZR1471800), the National Natural Science Foundation of China [grant No. 32471251], and the National Key Research and Development Program of China [grant No. 2017YFA0504901]. We thank Professor Yechun Xu and Professor Qiang Shao at the Shanghai Institute of Materia Medica, Chinese Academy of Sciences, for their help in molecular dynamics simulations.

Author information

Authors and Affiliations

Contributions

Zhimin Zhu: formal analysis, investigation, methodology, writing—original draft. Weiwei Wang: methodology, supervision, writing—review & editing. Minjun Li: methodology, supervision, writing—review & editing. Qin Xu: resources, supervision. Huan Zhou: resources, supervision. Liqing Huang: methodology. Qisheng Wang: conceptualization, funding acquisition, resources, writing—review & editing. Yu Feng: conceptualization, funding acquisition, methodology, project administration, resources, writing—review & editing.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Biology thanks Tjaard Pijning, Christian Roth, and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Primary handling editors: Lei Zheng and Aylin Bircan.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhu, Z., Wang, W., Li, M. et al. The crystal structure of GH57 family amylopullulanase reveals its dual binding pockets sharing the same catalytic dyad. Commun Biol 8, 806 (2025). https://doi.org/10.1038/s42003-025-08192-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s42003-025-08192-8

This article is cited by

-

Transformation of Starch into an Equilibrium Pool of Glucose and Small Maltosaccharides by a Hyperthermophilic Enzyme Exhibiting Coupled (Exo)Amylase-Glucanotransferase Functions

Applied Biochemistry and Biotechnology (2025)