Abstract

The demand for advanced applications in nanofiber technology has been increasing in recent years, one of which is in the field of particulate matter filtration. This review highlights the recent developments and applications of electrospun nanofibers as particulate matter filtration membranes. Electrospinning is chosen as a nanofiber fabrication method because of its high versatility, reliability, simplicity, and scalability. Besides adjustable fiber geometry affecting filtration efficiency, high surface hydrophobicity and high-temperature resistance have become the main attributes required by nanofibrous membranes for particulate matter filtration to enable their applications in harsh environments, such as industrial combustion and vehicle emission. Various organic and inorganic nanofiber materials are explored, in which their strengths and drawbacks are evaluated. Future research of nanofiber-based particulate matter filtration membranes is encouraged to overcome the currently faced challenges by exploring additional properties, for instance, antimicrobial and antifouling capabilities, optimizing nanofiber morphology, and employing environmentally friendly materials.

Similar content being viewed by others

Introduction

Rapid industrial expansion in recent years has not only led to scientific advancements but also had detrimental effects on human existence, one of which is emissions from industries that can lead to air pollution.1,2 One of the most common and widely recognized pollutants is particulate matter (PM). PM is commonly divided into three aerodynamic diameter levels of 2.5 − 10 µm, 0.3 − 2.5 µm, and < 0.3 µm, which are known as PM10, PM2.5, and PM0.3, respectively.3 The small size of PM has caused serious difficulties in controlling its spread in the air. In addition, PMs in harsh environments frequently possess high producing temperatures of up to 300 °C, which adds more complexity to environmental pollution management. The typical temperature ranges of PMs from vehicle exhaust,4,5,6 coal-burning furnaces,7 and metallurgical and cement plants8,9,10 are 30–80 °C, 70–180 °C, and 160–320 °C, respectively, as illustrated in Fig. 1.

Uncontrolled PM levels in the air can detrimentally affect the environment (e.g., air quality).11,12 Due to its low mass, PM can float in the air, creating pollution over time and, in some situations, decreasing visibility.13 Additionally, some PMs can absorb solar radiation,14 play a significant role in cloud formation,15,16 and induce weather and climatic instability,17,18 as well as the greenhouse effect.19,20 Moreover, both land-based and marine ecosystems may be negatively impacted by PM. Airborne PM can contaminate plants and prevent them from photosynthesizing.21,22,23 On the other hand, the ability of marine species to filter their food may be hampered by PM-polluted saltwater.24

Besides influencing the environment, the negative impacts of PM can also directly harm human health. PM, having a tiny size, can readily pass through the respiratory tract and reach the bronchi and alveoli, which can harm the respiratory system of humans.25,26,27 Moreover, when PM with a considerably smaller diameter dissolves in the blood, it can lead to cardiovascular problems.28,29,30 If this problem is not resolved, the adverse effect can worsen, given that, according to a 2019 USA report, 92% of people worldwide live in regions where air pollution levels are over the World Health Organization (WHO)-set safe thresholds.31

In addition, electronic devices can experience detrimental effects of PM. PM can clog their cooling systems because of its small size and ability to penetrate through vents. The obstruction may make it difficult for the device to lower its internal temperature, harming heat-sensitive electronic components in electronics (e.g., computers, laptops, and handphones). Moreover, some PMs have corrosive substances that can speed up corrosion and thereby may gradually harm the electronic components and shorten their lifespan.

Therefore, several airborne PM sensors based on microelectromechanical systems (MEMS)32,33,34,35,36,37,38 and microscale light-emitting diodes (microLEDs)39 have been developed attempting to be integrated into portable air quality monitoring platforms. As artificial intelligence has continuously advanced, machine learning algorithms can also be employed for the conversion of PM size distribution and effective density and PM mass-concentration calibration, enabling precise PM mass-concentration analysis in real-time.40 Nonetheless, real-time PM monitoring alone cannot directly solve the pollution problem. Here, filter media are required to trap and remove the airborne PMs from different sources, resulting in clean air products.

For industrial pollutants, one of the most widely used filter media is the filter bag. A filter bag comprises fabrics that can be used to remove PMs by collecting these particulates on the filtering material.41 Filter bags have been typically fabricated using natural fibers, chemical fibers, glass fibers, metal fibers, and other materials.42 Despite their widespread use, filter bags have several drawbacks (e.g., suboptimal efficiency, high-pressure drop, and low resistance to high temperatures),27 making their performance unsuitable for the filtration of high-temperature emissions from industry. In addition to filter bags, cyclone dust collectors have also been commonly utilized for PM filtration. A cyclone dust collector is a system able to collect dust in the air stream using centrifugal force.43,44 This method is very popular because of its simple structure, low production cost, and versatility.45,46,47 However, the ability of cyclone dust collectors to filtrate very fine dust is still questionable and has only been proven to effectively filter PM with sizes of >10 µm.6,48

The development of nanotechnologies in recent years has become a solution in various life aspects, including air filtration for PM removal.49,50 Among them, nanofibers are frequently utilized as PM filter media.51,52 Nanofibers typically have diameters of <1 µm and can be employed to form networks with high porosity and air permeability,53,54 making them appropriate for use as PM filtration membranes.

Various fabrication methods are available to produce nanofibers, such as electrospinning,55 CO2 laser supersonic multi-drawing,56,57 phase separation,58,59 and centrifugal spinning.60,61,62 Numerous researchers have chosen electrospinning as one of the most preferable fabrication techniques because of its numerous benefits (e.g., high versatility in creating nanofibers with different geometries and materials, affordable and simple setup, and industrial scalability).63 In addition, the electrospinning method has also been proven in several studies to enable the fabrication of nanofibers with small diameters, smoothness, continuity, high porosity, large surface area,53,64 and a huge variety of different materials.

Among these different materials, polymers are the most commonly used base materials for fabricating nanofibers in the electrospinning process.65,66 The selected polymer material thereby greatly affects the properties of the fabricated nanofibers, such as the hydrophobicity and temperature stability. For example, polyvinyl alcohol (PVA) is a hydrophilic polymer67,68 and therefore shows a high affinity to water. Nanofibers with hydrophilic properties (e.g., PVA) would be very appropriate if used as a microfilter or in other applications that require high water flux. On the other hand, polymers such as polyvinylidene fluoride (PVDF) are naturally highly hydrophobic69,70 and therefore act as water-repellent. Polymers with high hydrophobicity are suitable for oil-water separation71,72 and distillation-membrane applications73 and are beneficial for filter membrane applications as they make the membrane dirt- and water-resistant.74,75 Considering temperature stability, a polymer like polyvinylpyrrolidone (PVP) shows a low boiling point and is often used as a matrix in manufacturing metal oxide nanofibers as it can be easily removed through a calcination process.76 On the other hand, polymers such as polyimide (PI) inherit a high thermal resistance and can, therefore, be used in high-temperature applications (e.g., thermal insulation,77,78 air filter membranes,79 and device protection80).

Despite the attractive advantages of electrospun nanofibers as a PM filtration membrane, it is important to recognize its challenges during the electrospinning process (e.g., spinneret clogging, insufficient productivity, and ineffective fiber collection/transfer methods).81 Single-needle-based electrospinning is typically suitable only for laboratory-scale research because it has low productivity (<1 g·h−1), which does not meet the industry requirement. Thus, different strategies were proposed to scale up the electrospinning technology to reach high production rates for industrial applications, including the use of multi-needle electrospinning and free-surface electrospinning without needle/nozzle.81,82 Among them, needleless free-surface electrospinning is preferred because it can solve the spinneret clogging issue, has high productivity, and is suitable for mass production. In terms of fiber collection, the roll-to-roll process has been typically applied by industry.83,84,85 Wei et al. successfully designed a needleless electrospinning machine with an annular spinneret that can produce nanofibers as much as 4.5 g·h−1.86 In another study by Xiong et al., a needleless electrospinning setup having pre-Taylor cones with high curvature could demonstrate a nanofiber productivity of 13.7 g·h−1, which is a very significant result compared to conventional electrospinning machines.87

This review aims to provide an overview of the state-of-the-art and future challenges of electrospun nanofiber-based PM-filtration membranes, their applications, and the required properties of their used polymer materials (e.g., high-temperature stability, hydrophobicity, high filtration efficiency). Although several reviews on electrospun nanofibers for PM or air filtration membranes have been available in the literature, they are limited to face-mask applications,88,89 degradable membranes,90 two-dimensional (2D) materials,91 and polysaccharides.92 Moreover, they typically describe and discuss only nanofiber-based PM filter membranes that are used in normal ambient/temperatures. Thus, a comprehensive review of high-temperature-stable and hydrophobic nanofiber membranes for PM filtration is still missing. Moreover, their potential application in PM-generating sources has not been fully discussed. In addition, a detailed performance comparison between the nozzle and free-surface electrospinning technologies has been reviewed in a previous study,81 where the resulting nanofibers are, however, only applied in the pharmaceutical industry.

This review emerges as an essential guide for scientists and engineers to design and fabricate nanofiber-based PM filtration membranes, especially with properties of high thermal resistance and hydrophobicity, making them perform well in harsh environments and resulting in high PM removal efficiency. Among the established article reviews, a comprehensive discussion of these two properties (i.e., high-temperature resistance and hydrophobicity) on the filtration performance and potential use is still limited. This gap is an aspect that this review aims to address. It starts with an understanding of the working principle and important factors in PM filtration using nanofiber membranes, which then is followed by a detailed explanation of the electrospinning process and its key parameters. Here, we provide insights into fabrication processes, efficiency, limitations, scalability, cost considerations, potential technical barriers, and future perspectives. Various emerging applications of nanofiber-based PM filter membranes in industrial combustion and vehicle exhaust are also described, besides their recent use as personal masks. Finally, current challenges of the underlying electrospinning technology (e.g., spinneret clogging, insufficient productivity, ineffective fiber collection/transfer methods, and lack of scalability from laboratory-scale to industry-scale setups) are discussed, and future perspectives on this field of research are given. This review is expected to trigger future research and academia-industry collaboration toward advancing nanofiber and electrospinning technologies from a research state to an industry level.

Particulate matter (PM) filtration

Working principle of PM filtration

Nanofiber membranes typically comprise a very fine and highly porous network of nanofibers that allow a controlled through-flow of PM-containing fluids (e.g., air or liquids). The basic mechanisms that allow the nanofibers to filter and collect PM can be generally described by four different process scenarios (i.e., interception, inertial impaction, Brownian diffusion, and electrostatic effect), as illustrated in Fig. 2. In addition, the effect of high-temperature resistant and hydrophobic nanofiber membranes on the filtration mechanism will also be discussed.

The trapping of PMs on a nanofiber membrane is governed by several different mechanisms (i.e., interception, inertial impaction, Brownian diffusion, and electrostatic effect). PM and nanofiber are illustrated in red and gray colors, respectively. Filtration efficiency depends on the PM size for the different trapping mechanisms.

Interception

Interception occurs as the particulates tend to follow the airflow through the nanofiber pores and can thereby come into contact with the nanofibers. Upon the PMs’ contact with the nanofibers, they will be trapped on the nanofiber surface due to van der Waals interaction.93,94 This working principle efficiently filters particulates with sizes of 0.1 to 1 µm.95 Larger particulates tend to be more easily trapped on the nanofiber through this mechanism, as only comparatively large particles will come into contact with the nanofiber membrane (airflow drags the PM through the pores of the nanofiber membrane).

Inertial impaction

The chances of collecting large-sized and heavy particulates are enhanced in high-velocity airflow situations, where inertial forces affect the movement of the PMs in the airflow.96 At high-velocity airflows, heavy PMs cannot directly follow the direction changes of the airflow and, therefore, have a higher chance of colliding with the nanofibers. This mechanism, here called inertial impaction, particularly enhances the filtration efficiency for particulates with larger sizes (1–10 µm) at higher airflows.97,98,99,100,101

Brownian diffusion

Brownian diffusion tends to occur in particulates with small sizes, usually smaller than 1 µm.94 When air flows through the filtration membrane, small particulates tend to move in a random pattern generated by Brownian motion.102 Since these particulates are smaller than the membrane pores, they can, on the whole, follow the airflow. However, the random motion causes the particulates to come into contact with the nanofiber and subsequently be trapped. The impact of Brownian motion becomes notably more pronounced for particulates smaller than 0.1 µm in size.103

Electrostatic effect

Beyond van-der-Waals interaction-based collection mechanisms, the electrostatic attraction of particulates to the nanofibers enhances filtration efficiency. When the nanofibers are polarized with one type of electrical charge, particulates of the opposite charge are attracted to the nanofibers and may adhere to their surface.104 This working principle, however, only allows for the effective capture of electrically charged particulates.105

Effect of high-temperature resistance and hydrophobic properties of nanofiber membrane on filtration mechanism

The high-temperature resistance and hydrophobicity of the used materials greatly influence filtration performance. Exposure to high temperatures can affect the physical and chemical properties of the filter membrane and trapped PM. In the context of PM, high temperature can increase the kinetic energy of PM, resulting in an influence on several mechanisms, such as interception and inertial impaction, making PM more easily trapped.106,107 At the same time, nanofiber membranes used as filter media must be able to withstand exposure to high temperatures, as well as have mechanical resistance.

In addition to high-temperature resistance, the hydrophobic properties of the nanofiber membrane also play an important role in the filtration mechanism. Hydrophobic nanofiber membranes can prevent the absorption of water molecules, resulting in the avoidance of the formation of a water layer that can obstruct airflow, increase pressure drop, and reduce the filtration ability of the membrane.108,109 In addition, high hydrophobicity also can improve filtration performance, especially when applied to humid environments.

Evaluation parameters of PM filtration

In PM filtration, several key parameters have been normally used to evaluate the quality of the developed nanofiber membranes. Here, filtration efficiency, pressure drop, and quality factors are among the most important ones.

Filtration efficiency

The first and most important parameter in PM filtration is filtration efficiency, which quantifies the ability of the membrane to capture and retain PM of a defined range of particle sizes from passing through its pores.110,111 The filtration efficiency (η) can be expressed in Eq. (1):27,112,113

where C1 and C2 are the concentrations of the PM before and after filtration (mg·cm−3), respectively.

In addition to Eq. (1), the filtration efficiency can also be determined using the Kuwabara model, which is a more comprehensive method showing the relation between the filtration efficiency and the structure of the nanofiber membrane used in the PM filtration process. The filtration efficiency (η) based on the Kuwabara model is given by Eq. (2):30,94,114,115

where ηs denotes the filtration efficiency of a single fiber, α represents the fiber volume fraction, df stands for the average fiber diameter, and L represents the thickness of the membrane. The filtration efficiency of a single fiber can be calculated using Eq. (3):116

Electrospun nanofiber membranes are generally shown to achieve high PM filtration efficiencies for various particle sizes ranging from microscale down to nanoscale particulates.111,117,118 Several critical factors intricately influence the filtration efficiency of nanofiber membranes (e.g., the polymer type, the nanofiber diameter, and the membrane thickness), which can be adjusted or modified to increase filtration performance.93 Additionally, surface modifications, such as the addition of composite materials and thermal annealing,51,119,120,121 for specific interactions with PM also play crucial roles.122

Pressure drop

The pressure drop created by a PM filter represents a second key performance indicator. The pressure drop, denoted as ΔP, is the drop in pressure experienced when air is passing through a filtration membrane.123 Unlike the filtration efficiency, which underscores the membrane’s ability to capture particulates, pressure drop studies the resistance faced by the air as it passes through a PM filtration membrane. In other words, the pressure would decrease after filtration because of the resistance that airflow experiences when passing through the nanofiber membrane.116 Several factors contribute to the pressure drop across the nanofiber membrane (e.g., the density and arrangement of the nanofibers, the thickness of the membrane, and the porosity of the nanofibers), which collectively determine the resistance encountered by the air. Pressure drop is also a result of drag force acting on the air when it passes through the nanofiber PM filtration membrane, relating the pressure drop to the drag coefficient (CD), which mathematically can be expressed by Eq. (4):124,125,126,127

where k1 and k2 are the shape and orientation factors of the nanofiber, respectively, while µ is the dynamic viscosity of the gas. The velocity and density of the airflow are symbolized with v and ρ, respectively. L and db represent the length of the electrospun nanofibers given by the thickness of the filter membrane and the distance between adjacent fibers, respectively.

Based on drag theory, the pressure drop of a fiber-based PM filtration membrane can be formulated as Eq. (5):128,129

where U0 is the face velocity.

Quality factor

In the design and application of nanofiber as a PM filtration membrane, a trade-off has to be found between filtration efficiency and pressure drop.130,131 Although increasing the membrane thickness can enhance filtration efficiency, it will also simultaneously increase air resistance and pressure drop.132 Thus, a parameter called quality factor (QF) is introduced,133,134,135 which allows us to seek a balance between the ability of the filtration membrane to capture particulates and the pressure drop of air to traverse the filter. A high-QF filtration membrane implies a membrane that excels in effectively trapping particulate matter and has minimal pressure drop.134,135 The QF can be expressed in terms of the filtration efficiency and pressure drop as Eq. (6):124,125,131,136,137

The QF becomes a key criterion for selecting nanofibers for PM filtration membranes in practical applications. Environments where stringent air quality standards coexist with the imperative for energy efficiency, such as cleanrooms or ventilation systems in energy-efficient buildings, demand membranes with a high QF.138,139,140

Electrospinning technology

Electrospinning is a versatile technique for fabricating nanofibers that has attracted much attention among researchers due to its ease of use. The electrospinning process involves the usage of an electrical voltage to attract a polymer solution into the collector, resulting in nanofibers with a high specific surface area ratio, good mechanical strength, and various modified properties such as hydrophobicity and high-temperature resistance. In this section, we will explore the electrospinning process in detail, highlighting the advantages compared to other methods, main components, fabrication results, and parameters of the electrospinning process.

Electrospinning process

Electrospinning gained its recent popularity due to its minimal equipment requirements, ease of operation53,141 and capability to transform a diverse range of polymer materials into nanofibers, offering various applications in the fields of food packaging,142,143,144 supercapacitors,145 textiles,146,147 biomedical,148 sensors,64,149,150 air filtration membranes,31,116,139,151 and beyond.

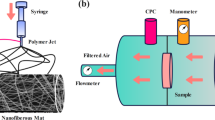

A typical nozzle-based electrospinning setup is depicted in Fig. 3a and consists purely of standard equipment available in most laboratories, namely a high-voltage power supply, a syringe pump, a nozzle, and a ground collector. During its operation, the syringe pump forces a controlled amount of an electrically charged polymer solution to be continuously ejected from the nozzle. A strong electrostatic field created by the high-voltage power supply then accelerates the ejected polymer solution towards the ground collector, where, depending on an interplay between the electrostatic driving force and surface tension of the polymer solution, nanofibers may be gathered.66,152 In order to create high-quality nanofibers via electrospinning, an ejection of the polymer solution in the form of a so-called Taylor cone is desirable. A Taylor cone, as illustrated in Fig. 3b, is typically formed when the electrostatic driving force (attractive force) is equal to or greater than the surface tension of the polymer solution. When forming a Taylor cone, the polymer solution droplets become highly elongated and form a continuous jet of very thin diameter when approaching the ground collector.153 As the polymer solvent will evaporate while traveling towards the ground collector, high-quality and very thin nanofibers are gathered on the ground collector.154 Naturally, the amount of applied voltage to form the desired Taylor cones in the electrospinning process varies for different polymer materials,152 e.g., polymers with high viscosity and molecular weight tend to require higher voltage to overcome their surface tension.155,156

a The electrospinning setup for nanofiber fabrication. An electrospinner comprises a high-voltage supply, syringe pump, nozzle, and ground collector. b The formation of Taylor cone. When an attractive force generated from the applied high voltage can compensate for the surface tension of the polymer solution, a Taylor cone will form at the edge of the nozzle.

To form the highest quality nanofibers, the previously named components of an electrospinning setup are subject to optimization, which is outlined here shortly. The polymer solution is typically contained in syringes, while a syringe pump controls the flow rate of the polymer solution out of the syringe. High-quality syringe pumps thereby play a key role in state-of-the-art electrospinning setups154,157 to provide a well-defined, constant, and continuous flow rate of the polymer, which allows researchers to define and adjust nanofiber properties (e.g., fiber diameter and morphology).158,159,160

The nozzle, also known as the spinneret, is where the polymer solution is ejected from during the electrospinning process. Generally, the spinneret used in the electrospinning process is made of metal.54,55 Hence, it can be connected to the positive pole of the high voltage in the electrospinning setup. The nozzle may be further modified to fabricate more complex nanofiber types such as coaxial nanofibers, where two or more polymer solutions are electrospun simultaneously using a coaxial spinneret. The resulting core-shell or hollow nanofibers161 are of high interest because the shell layer covering the core may provide advantageous properties, such as controlled release,162,163 enhanced mechanical strength,164,165 or targeted delivery.166 Figure 4a shows an example of a coaxial nanofiber that is used for drug-controlled release. This nanofiber is made of ampicillin-loaded polycaprolactone (PCL), which is encased within a PCL shield.167 Another implementation of coaxial electrospinning is to fabricate polyacrylamide (PAAm) nanofibers covered by a shell composed of L-Arginine (L-Arg) and keratin (AloKr) for wound dressing168 (see Fig. 4b). Fabricated wound-dressing nanofibers exhibit a small diameter, a heightened surface-area-to-volume ratio, a high water holding capacity, and better L-Arginine release.

a Nanofiber fabrication process and scanning electron microscopy (SEM) images of ampicillin-loaded polycaprolactone (PCL) nanofibers with various flow rates and concentrations (wt%). The fabricated nanofibers are denoted as CR (core nanofiber), CS1 (core-shell nanofiber 1), and CS2 (core-shell nanofiber 2). The diameter of the fabricated nanofibers is in the range of 400–700 nm. (reproduced with permission from,167 copyright (Elsevier B.V., 2016)). b The nanofiber fabrication process and SEM images of coaxial nanofibers comprising polyacrylamide (PAAm) as a core and L-Arginine (L-Arg)-combined keratin (AloKr) as a shell. (reproduced with permission from,168 copyright (Elsevier B.V., 2024)).

Another component allowing the optimization of an electrospinning setup is the ground collector, which is an electrode placed opposite to the spinneret. Its purpose is to collect the electrospun fibers and to prevent excess charge accumulation in them due to, e.g., non-uniform deposition or fiber whipping.169 There are several types of ground collectors described in the literature that can be used in electrospinning machines (e.g., flat plate,170,171 rotating drum,158 edge type,172 dual ring,159 rotational wire,160 steel sheet,173 mandrel,174 and blade placed inline collectors175). The most widely used among researchers are flat plate and rotating drum collectors. Flat plate collectors are the simplest collectors and are commonly utilized in academic laboratories. They have a flat surface that is placed parallel to the spinneret, resulting in uniform deposition of nanofibers on its entire surface.55,176,177

In comparison, the rotating drum collector is cylindrical, placed perpendicular to the spinneret, and rotated continuously during electrospinning.175 The rotating motion helps to collect the aligned fibers along the drum.178,179 Kiselev and Rosell-Llompart fabricated aligned nanofibers utilizing a collector drum with adjustments in rotational speed.179 The polymers investigated in their study were poly(ethylene oxide) (PEO) and polystyrene (PS). The findings demonstrated the successful acquisition of aligned nanofibers at specific rotational speeds (i.e., 4.71 m·s−1 and 6.5 m·s−1 for PEO and PS, respectively). In addition to fabricating aligned nanofibers, a rotating drum collector can produce nanofibers in larger quantities and areas than a flat plate collector.180

Besides electrospinning, there are several methods for fabricating nanofibers, such as wet spinning,181,182,183,184 centrifugal spinning,60,61,62,185,186 extrusion,187,188 and sol-gel methods.189,190 However, these methods have shortcomings in their efficiency and versatility in fabricating nanofibers. For example, the wet spinning and centrifugal spinning methods often produce fibers with larger diameters and less uniformity, thus reducing their advantage for fabricating nanofibers with small diameters or applications that require uniform size. On the other hand, although the extrusion methods can produce large amounts of fiber in a short period, they tend to produce nanofibers of larger sizes and require additional processing to obtain the desired fiber size. Meanwhile, sol-gel methods can produce better nanofibers, but the process tends to be more complicated and takes a longer time to achieve the desired fiber. Thus, electrospinning offers a combination of ease of fabrication and simple setup to produce nanofibers with small and uniform diameters, making it superior to other methods.

Key electrospinning parameters

To achieve the desired morphology of the nanofibers via electrospinning, optimum control and co-optimization of several machine and material parameters are of importance.191,192 Machine parameters include setup-related parameters such as the applied high voltage, the flow rate of the polymer solution, and the distance between the electrospinning nozzle and the collector (tip-to-collector distance). Material parameters comprise the concentration and viscosity of the polymer solution. These parameters are typically systematically varied and optimized through iterative experimental processes to ensure that the resulting nanofibers exhibit the desired characteristics (e.g., smooth, continuous, bead-less, small, and porous).193

Applied high voltage

In the electrospinning machine, a high voltage is applied and connected to the nozzle, causing the polymer solution to be ejected in the form of a Taylor cone, forming very fine nanofibers on the ground collector.194,195 As previously mentioned, the critical voltage required to form a Taylor cone differs for each polymer solution196,197 and, therefore, typically has to be experimentally quantified. Moreover, studies reported a relation between the voltage and the fiber diameter, in which increasing the applied voltage causes an increase in the charge-repulsive force on the polymer jet, resulting in nanofiber with a smaller diameter.155,198,199 For example, Mohraz and co-workers used polyurethane/chitosan (PU/Cs) nanofibers by varying several parameters (i.e., Cs weight ratio, applied voltage, tip-to-collector distance, and polymer flow rate).200 When other parameters were kept fixed, the diameter of the fabricated nanofiber decreased as the applied voltage increased (i.e., 387.44 nm, 324.66 nm, and 207.51 nm for voltages of 9.5 kV, 14.5 kV, and 19.5 kV, respectively). In another study, Bakar et al. investigated the effect of applied voltage, tip-to-collector distance, and flow rate on the fabricated fiber diameter.201 The polymer used was 10 wt% of PAN. When the flow rate and tip-to-collector distance were kept fixed at 20 µL·min−1 and 10 cm, the fiber decreased in diameter as the applied voltage increased, which was 1.27 µm and 1.21 µm for 10 kV and 15 kV, respectively. Likewise, when the flow rate and tip-to-collector distance were kept fixed at 10 µL·min−1 and 10 cm, the fiber diameters were 1.81 µm and 1.33 µm for 10 kV and 15 kV, respectively.

However, some studies have also reported an increase in diameter when higher voltage is applied. Using ethyl cyanoethyl cellulose (E-CEC) as a base material to create the nanofibers, Zhao and co-workers obtained nanofibers with diameters of 5.6 µm, 6.2 µm, 9.2 µm, and 10.7 µm while applying high voltages of 20 kV, 30 kV, 40 kV, and 50 kV, respectively.202 Scheidt et al. also reported a similar phenomenon with Cs/PEO.203 When the ratio of Cs:PEO and the tip-to-collector distance is kept fixed, the nanofiber diameter tends to increase along with increasing applied voltage. In another study, Dhanalakshmi et al. fabricated nanofibers using electrospinning by varying the voltage and concentration of Nylon11 (w/v%).204 At the same time, the tip-to-collector distance was kept fixed at 10 cm. At each observed concentration of Nylon11 (i.e., 5 w/v%, 10 w/v%, 15 w/v%, and 20 w/v%), the nanofiber diameter increased when the applied voltage was increased. The phenomenon of increasing nanofiber diameter with higher applied voltage is attributed to the increased speed in the solution jet. As the applied voltage rises, the speed of the jet increases, resulting in a shorter duration for the polymer to reach the collector. Consequently, this decrease in time reduces the jet’s ability to split and elongate effectively, making it less probable to obtain nanofibers with smaller diameters.205,206,207

It is worth noting that increasing the applied voltage beyond a critical value tends to cause undesired properties in the nanofibers, such as the formation of beads.155 This phenomenon is due to a decrease in Taylor cone size and an increase in jet speed for the same flow rate, contributing to the enlargement in diameter and the formation of bead-containing nanofibers.205,208

Flow rate

The second important fabrication parameter affecting the properties of the electrospun nanofibers is the flow rate of the polymer solution, which is determined by the syringe pump. Maintaining an appropriate and constant flow rate of the polymer solution is essential to fabricate bead-less nanofibers. The appropriate flow rate ensures that the polymer jet has sufficient time to stabilize, allowing the polymer solution to form a well-defined Taylor cone. Increasing the flow rate above the appropriate point enlarges the nanofiber diameter and fosters the appearance of beads.155 The increase in diameter is due to insufficient time for the nanofiber jet to dry from the needle tip to the collector, hindering complete fiber formation.209 Low stretching force may also contribute to bead formation.198

Moreover, the flow rate was also shown to influence the diameter of the fabricated nanofibers. For example, Hoseyni et al. conducted a catechin-based electrospinning process loaded from Azivash (Corchorusolitorius. L) gum-polyvinyl alcohol by varying several parameters such as voltage, tip-to-collector distance, and flow rate.210 At a fixed voltage and distance of 16 kV and 14 cm, respectively, the nanofiber diameter increased from 161 nm at a flow rate of 0.5 mL·h−1 to 185 nm at 0.9 mL·h−1. A similar trend of diameter increase with flow rate was observed under different voltage and distance settings (i.e., 20 kV and 10 cm, 20 kV and 14 cm, and 16 kV and 10 cm). Another example is found in the research on cyclodextrin nanofiber fabrication conducted by Topuz and Uyar.211 In their study, the applied voltage and tip-to-collector distance were kept at 17.5 kV and 15 cm, employing various flow rates of 0.1 mL·h−1, 0.25 mL·h−1, 0.75 mL·h−1, and 1 mL·h−1 resulting in different fiber diameters of 440 nm, 520 nm, 700 nm, and 740 nm, respectively.

Tip-to-collector distance

The tip-to-collector distance emerges as a third important setup parameter that researchers try to optimize in the electrospinning process. On the one hand, the distance between the tip and the collector greatly affects deposition time, evaporation rate, and whipping or instability interval.155,212 Therefore, setting the tip-to-collector at the right point is crucial to fabricating nanofibers with the desired morphology (e.g., smooth, continuous, and bead-less). On the other hand, again, a correlation between tip-to-collector distance and nanofiber diameter was reported in the literature. For small tip-to-collector distances, the fabricated nanofibers tended to have enlarged average diameters.213,214 Angel et al. conducted a study utilizing cellulose acetate to produce nanofibers using an electrospinning machine.215 The results showed that when the voltage and cellulose acetate concentration were fixed, the nanofiber decreased in average diameter as the tip-to-collector distance increased. Similar results were observed in another study using ethyl–cyanoethyl cellulose/tetrahydrofuran solutions.202 However, although many studies have indicated that tip-to-collector distance significantly affects nanofiber size (diameter), a few other reports showed contrary results, which might be caused by coupling with other parameters.216,217

Polymer concentration and solution viscosity

Beyond setup-related parameters, the nanofiber shape and morphology can be optimized via the concentration of the polymer in its solvent218 and the viscosity of the resulting polymer solution.219 Typically, both of these parameters are interdependent. The higher the polymer concentration, the higher the viscosity of the solution, and vice versa.155,207

In electrospinning, both parameters are very important to be controlled, as they determine the formation of a Taylor cone and the corresponding uniaxial stretching of the charged polymer-solution jets.220,221,222 If the concentration of the polymer solution is too low (causing the viscosity to be low as well), the solution has an infirm spinnability. In this case, surface tension dominates over the electrostatic driving force,155,223 which can cause entangled polymer chains to disconnect and tend to form fragments and beads157,207.224,225,226 In extreme cases, where the concentration is too low, the process rather emerges towards electrospraying than electrospinning, as it is then even more likely to form polymer droplets than beaded nanofibers.227,228,229,230

On the other hand, for very high concentrations of the polymer in the solution, the flow becomes inhibited at the needle tip, which may cause the polymer solution to dry out and block the tip.157,231 In addition, the increased surface tension derived from the increased solution concentration can inhibit the separation of the charged solution jets during electrospinning, which increases the average fiber diameter and widens the diameter distribution in the fabricated nanofiber.157,226 Moreover, studies revealed the formation of helical-shaped fibers and various morphologies at very high concentrations, including curly and wavy shapes.232,233

Research targets are, therefore, to find optimum concentration and viscosity values. Hence, bead-free, smooth, and continuous nanofiber can be obtained198,234 for all different kinds of polymer materials (e.g., polyvinyl acetate (PVAc),53,54,55,171 PVA,176,235,236 PAN,177,237,238 PI,239,240 PVP,241 polyacrylamide (PAM),242 and other composite nanofibers150,243,244,245).

Nanofiber for PM filtration

Besides the required adjustments on the main fiber properties (i.e., nanofiber size and porosity, high thermal resistance, and hydrophobicity), material selection is also crucial to obtain the desired performance of PM filtration membranes. Polymers are the most commonly used materials in nanofiber-based PM filtration membranes.246 In their development, both pure and composite polymers are used. In addition, post-treatments are also carried out on the nanofibers to improve their performance, especially in increasing the mechanical strength of the membranes. Not limited to polymer-based nanofibers, many studies have been conducted using nanofibers composed of inorganic materials to obtain heat/thermal resistance. A summary of the filtration key performance data is provided in Table 1.

Required properties of nanofibers for PM filtration

Several properties play a crucial role in the application of PM filtration membranes, significantly affecting the membrane quality in terms of efficiency and pressure drop. Among the influential properties, nanofiber size and porosity, high thermal resistance, and hydrophobicity are paramount factors. Aligning nanofibers with these properties can yield PM filtration membranes with the desired performance.

Nanofiber size and porosity

It has been previously explained that several factors from both machine and material parameters can influence the properties of the fabricated nanofibers using the electrospinning method. The size and porosity of the nanofibers are the most affected by these parameters. In its performance as a PM filtration membrane, the size and porosity of the nanofiber play an important role, especially in the efficiency and pressure drop of the membrane.94,114,115,129

The effect of nanofiber size or diameter on PM filtration performance, especially efficiency, can be seen from the Kuwabara model (see Eq. (2)).30,94,114,115 Eq. (2) shows that the average diameter of the nanofiber (df) is inversely proportional to its efficiency. Thus, smaller nanofiber diameters correspond to higher efficiency values, while larger diameters result in reduced efficiency. Numerous studies have corroborated this phenomenon. For example, Bian et al. used 25 nylon electrospun nanofibers as PM filtration membranes and then observed the effects of several parameters (e.g., fiber diameter, filter thickness, and packing density) on their efficiency against PM2.5.247 The results showed that the larger the diameter of the fabricated nanofiber, the less the efficiency value. Nanofibers with a diameter of 123.2 nm have an efficiency of 98.61%, while nanofibers with a diameter of 245.5 nm only possess an efficiency of 60.06%. Similar findings were reported in the study conducted by Liu et al., who utilized PAN nanofibers as PM2.5 membranes.248 Increasing the nanofiber diameter from ~200 nm to 1 µm with the same transmittance of 70% has lowered the filtration efficiency from 98.11% to 48.21%. Liu and co-workers also observed a similar effect on efficiency when increasing the diameter of PAN nanofibers.249 There was a decrease in filtration efficiency against PM10 as the nanofiber diameter increased from 0.57 µm to 1.31 µm.

In addition to efficiency, the pressure drop can be influenced by the average diameter of the fabricated nanofiber. This statement is corroborated by Eq. (5), where the pressure drop is inversely proportional to the average diameter of the fabricated nanofiber media.128,129 This phenomenon occurs because smaller nanofibers also result in reduced porosity, leading to increased air resistance as it passes through the nanofiber membrane, consequently elevating the pressure drop. Indeed, there exists a trade-off between the diameter of the nanofiber and its performance as a PM filtration membrane. Smaller nanofiber diameters correspond to reduced porosity, enhancing filtration efficiency. However, this reduction in porosity also decreases air permeability, leading to an increase in pressure drop.

High thermal resistance

Numerous PM filtration membranes have been typically developed and used at room temperature. Nonetheless, the importance of PM filtration membranes capable of withstanding high temperatures cannot be ignored. Many sources of PM are generated from high-temperature environments, such as vehicle exhausts (30–80 °C), metallurgical and cement plants (160–320 °C), biomass burning (30–120 °C), and coal furnaces (>80 °C) (see Fig. 1). Therefore, in addition to the size and porosity of the nanofiber, its resistance to high temperatures must also be a special concern. Here, the performance of the PM filtration membrane has to be maintained despite operating at high temperatures.

Previous studies have successfully fabricated nanofibers with excellent heat resistance capabilities while maintaining their PM filtration performance at high temperatures. For example, Yang et al. used electrospun polysulfonamide/polyacrylonitrile-boehmite (PSA/PAN-B) nanofiber for high-temperature dust removal.250 The fabricated membrane has a PM2.5 filtration efficiency of 99.52% with a low-pressure drop of 45.16 Pa and is resistant to temperatures of 300 °C. Another study conducted by Xie et al. demonstrated electrospun PI nanofibers made using thermally induced phase separation (TIPS) with PAN as a template.251 PI nanofiber membranes show a special wrinkled porous structure with a high specific surface area of 304.77 m2·g−1 and a PM2.5 filtration efficiency of 95.55% at 280 °C. Su et al. fabricated PM filtration membranes using multilayer polyarylene sulfide sulfone (M-PASS) by electrospinning.252 The fabricated filtration membrane has a very high filtration efficiency against PM2.5 at room temperature, reaching 99.97% with a very small air resistance of 44.3 Pa, while at high temperature (200 °C), the efficiency is still 95.2%. Kang et al. used thermally-oxidized polyacrylonitrile/polyvinylpyrrolidone/SnO2 (OPAN/PVP/SnO2) nanofibers.27 The fabricated membranes could filtrate PM2.5 with efficiency values of 99.98% and 98.51% at room temperature and 350 °C, respectively.

Those mentioned reports have demonstrated the feasibility of acquiring PM filtration membranes that sustain their efficiency at high temperatures, surpassing 200 °C. This underscores the valuable heat-resistant attributes of nanofiber-based PM filtration membranes, particularly in their practical applications across industrial sectors, notably those reliant on furnaces and harsh environments. At present, some industries still use glass fiber-based filters due to their resistance to high temperatures and availability.253 However, glass fibers have several drawbacks, such as inflexible properties that limit them to applications that do not require filters with high flexibility.254 On the other hand, besides being able to be modified to withstand high temperatures, nanofibers also offer high filtration efficiency for ultrafine PM, even to the extent of filtering PM0.3.255,256 In addition, the high flexibility of nanofiber membranes makes them suitable for several applications that require a flexible shape.257,258 The combination of heat resistance, high filtration efficiency against fine particles, and high flexibility makes nanofiber suitable for several applications, such as air filtration in medical environments, pharmaceutical industry, and water purification, which require high efficiency and resistance to certain contaminants.

Hydrophobicity

In addition to the two previously mentioned properties (i.e., nanofiber diameter and high thermal resistance), water resistance also influences the performance of PM filtration membranes.259 Membranes with high hydrophobicity indicate that they can repel water, which is important to keep the membrane from moisture.260,261 This ability is very influential on the lifetime of the membrane. With its water-repelling properties, it avoids degradation. Furthermore, the ability of the membrane to resist fouling also increases as hydrophobicity increases because the membrane does not absorb water. Thus, the membrane surface remains dry and is difficult to inhabit by contaminants.

The ability of a hydrophobic-based PM filtration membrane is very helpful in maintaining its performance in unideal conditions. In the previous section, the heat-resistance ability of the membrane gives it an advantage when applied at extreme temperatures, as evidenced by a high efficiency value when tested at high temperatures. Then, the hydrophobicity of the membrane will be very useful when applied in high-humidity areas. Furthermore, having good efficiency at high humidity can be a distinct advantage for PM filtration membranes. Liu et al. used electrospun PVA nanofibers, which were then electrosprayed with ethyl cellulose (EC) and added with eugenol to produce a superhydrophobic and high humidity-resistant air filtration membrane.259 At 60 RH%, the fabricated membrane has efficiencies of 99.69, 99.73, 99.74, 99.77, and 99.85% toward PM0.3, PM0.5, PM1, PM2.5, and PM5, respectively. At 90 RH%, efficiency is still very high, with 99.67% against PM2.5. Another study was conducted by Zhou et al. using electrospun polyetherimide (PEI)/zeolitic imidazolate framework-67 (PEI/ZIF-67) nanofibers.262 The fabricated membranes have a good ability to withstand not only high temperatures but also high relative humidity. The measurement results showed that PEI/ZIF-67 nanofiber has an efficiency of 98.68% for PM2.5 and 99.09% for PM10, which is maintained at a temperature of 200 °C and humidity of 90 RH%.

Organic nanofiber materials

Polyimide (PI)

Polyimide (PI) nanofibers fabricated using electrospinning machines are widely used in various applications, including for PM filtration membranes. PI has good characteristics, such as high-temperature resistance, small nanofiber diameter, high porosity, and adequate mechanical resistance.263,264 In addition, the hydrophobicity of PI also attracts the attention of researchers.265,266 These parameters ultimately make PI nanofibers a superior candidate for PM filtration membranes. Zhang et al. conducted research on PM2.5 filtration membranes employing PI nanofibers reinforced with a copper mesh.10 The fabricated nanofibers have a smooth and continuous morphology with an average diameter of about ~300 nm (see Fig. 5a). Besides demonstrating a high filtration efficiency of >99.5% (see Fig. 5b), the PI nanofiber membrane also exhibits excellent stability against high temperatures and can maintain its efficiency and good structure up to 370 °C. However, it starts to break at 380 °C, as shown in Fig. 5c.

a SEM images of PI nanofibers reinforced with a copper mesh. The nanofibers have a smooth, continuous, and bead-less morphology and (b) a high filtration efficiency of more than 99.5% for particulate sizes of 0.3–10 µm. c Heat resistance tests of PI nanofibers within temperatures of 25–380 °C show that the nanofiber still has a good structure at 370 °C and starts to break at 380 °C. (reproduced with permission from,10 copyright (American Chemical Society, 2016)).

Polytetrafluoroethylene (PTFE)

Polytetrafluoroethylene (PTFE) is considered one of the polymers with very wide applications due to its excellent properties (i.e., anti-stiction, low-friction, high thermal resistance, high chemical stability, and high hydrophobicity), beneficial for a high-temperature PM filtration membrane.267,268,269 PTFE has a melting point of about 327 °C,270,271 and it starts to decompose at 350 °C.272,273 Despite its advantageous characteristics, PTFE nanofibers contain fluorinated organic chemicals. Therefore, it is included in the list of per-and poly-fluoroalkyl substances (PFAS), which may be restricted in the near future for being used in various products by many regulatory initiatives across different countries in the world.274,275,276 Wang et al. used ultrafine PTFE porous fibrous membranes (UPPFM) for PM filtration. As a result, the membrane exhibits a very low-pressure drop of 89.9 Pa, with an efficiency reaching 99.72%.267 Another study conducted by Kim et al. used PTFE composite filters comprising a glass fiber mat with a thickness of ~800 μm at the bottom, a PTFE foam structure with a thickness of ~100 μm in the middle, and a PTFE nanofiber layer at the top.277 These filter membranes possess water and oil contact angles of 150.8° and 116.1°, respectively. In terms of the PM filtration performance, they demonstrate a high filtration efficiency value (above 90%). Still using PTFE, Ahn et al. fabricated a composite nanofiber of PTFE, poly(vinyl alcohol) (PVA), polyethylene oxide (PEO), and sodium alginate as a coating for glass fabric filters.278 The fabricated filters can operate from room temperature to 320 °C. Although the membrane has a fairly high-pressure drop, especially at high face velocity, the membrane has good efficiency and still maintains its performance at a test temperature of 320 °C.

Polyacrylonitrile (PAN)

Polyacrylonitrile (PAN) is known for its versatility and ease of processing, including the fabrication of nanofibers. PAN nanofibers are applied in many fields, such as sensors,177,279,280 wound dressings,281 and PM filtration.6,27,282,283 The PAN nanofiber is particularly advantageous in its application as a PM filtration membrane because it allows the fabrication of nanofibers with easily controllable diameter and structures. For example, Cheng et al. conducted a study using well-ordered PAN nanofibers and observed their efficiency as an air filtration membrane.31 The nanofiber was fabricated by varying the electrospinning voltage, environment humidity, and rotational speed of the drum collector. The optimum PAN nanofibers were obtained with a voltage of 8.5 kV, relative humidity of 40 RH%, and rotational speed of 20 rotation·min−1. The fabricated well-ordered PAN nanofibers have a much lower pressure drop of 62 Pa compared to conventional PAN nanofibers (disordered), which is 709 Pa. In addition, well-ordered PAN nanofibers have a high filtration efficiency of 99.60%.

Polyvinylidene fluoride (PVDF)

Another polymer that is widely used in PM filtration membranes is polyvinylidene fluoride (PVDF). PVDF is a polymer with excellent hydrophobicity for operation in high-humidity conditions. It prevents dirt and moisture from sticking to the membrane, thus extending its lifetime.260,261 Bui et al. developed PVDF nanofibers with various diameters of 70, 120, and 250 nm (see Fig. 6a) and investigated their efficiency towards PM0.3.284 Nanofibers with larger diameters tend to have a lower pressure drop. For example, PVDF nanofibers with a diameter of 250 nm only have a pressure drop of 30 Pa at an airflow of 5.3 cm·s−1, while PVDF nanofibers with a diameter of 70 nm possess a larger pressure drop of 51 Pa. However, the smaller the diameters of the nanofiber, the higher the efficiency values, which are 46.4%, 74.7%, and 97.4% for PVDF nanofibers with diameters of 250 nm, 120 nm, and 70 nm, respectively, as shown in Fig. 6b. In addition to normal (room temperature) conditions, the PVDF nanofibers with a diameter of 70 nm were also tested in two different scenarios (i.e., in a heating treatment at 120 °C for 24 h and in isopropanol immersion for 1 h), where after those robustness tests they could still demonstrate high filtration efficiencies of 95.99% and 87.90%, with pressure drop values of 55 Pa and 65 Pa, respectively. Again, similar to PTFE nanofibers, the real applications of PVDF nanofibers in the market are now becoming questionable because they are included in the list of PFAS.

a Piezoresponse force microscopy (PFM) images of PVDF nanofibers with various diameters of 70 nm, 120 nm, and 250 nm and (b) filtration efficiency towards PM0.3 of correspondingly fabricated PVDF nanofiber membranes. Membranes with smaller diameters tend to have higher efficiency, but on the other hand, the pressure drop of small-diameter nanofiber is increased. c The efficiency and quality factor (QF) of the 70 nm PVDF membrane toward PM0.3 under different temperatures dropped at a temperature of 100 °C but, surprisingly, increased again at a temperature of 120 °C. (reproduced with permission from,284 copyright (Elsevier B.V., 2022)).

Polymer composites

Nanofiber fabrication is not limited to using a single polymer. In several studies, polymer composites derived from adding other materials to the polymer are employed. The added materials can be other polymers or inorganic materials to improve filtration performance or obtain specific nanofiber characteristics. Polymer composites on nanofibers are widely used in various fields because single polymers still have shortcomings. Thus, the added material is expected to overcome these shortcomings. For example, Zhao and co-workers conducted research using polyacrylonitrile-reinforced polyimide (PAN/PI) nanofiber composite aerogels with fiber-pore interpenetrating structures in their application as sound absorption, air filtration, and thermal insulation product.285 The PI composite on PAN nanofiber aims to improve the heat resistance of the fabricated nanofiber while maintaining good filtration efficiency and Young’s modulus originating from the PAN nanofiber. The Young’s modulus of nanofiber with a PAN concentration of 10 wt% is 3.95 times higher than that with pure PI aerogels. In addition, the incorporation of 15 wt% of PAN into the nanofiber composite can reduce the pressure drop to 86.6 Pa. The filtration performance towards PM10 also shows an excellent efficiency of 99.4%. Moreover, the 15 wt% PAN/PI nanofiber is shown to be heat resistant with a heat resistance index temperature (THRI) value of 241.0 °C, close to the THRI of the pure PI nanofiber (i.e., 274.6 °C).

Another research study was conducted by Tian et al. using polycaprolactone (PCL) nanofibers modified with halloysite nanotubes (HNTs) and ZnO for anti-bacterial and air filtration membranes.286 The SEM images of the PCL nanofibers before and after the addition of HNTs-ZnO are shown in Fig. 7a. The addition of HNTs and ZnO to PCL aims to improve the anti-bacterial ability and filtration performance at the same time. By observing bacterial reduction of E. coli and S. aureus during a 24-hour incubation period (see Fig. 7b), the HNT/ZnO/PCL composite nanofibers exhibit a higher E. coli reduction level of 95.9% compared to that of single PCL nanofibers (i.e., 54.0%). Similar results were obtained in the case of S. aureus bacteria, in which the composite and single bare nanofibers yielded a bacterial reduction of 97.9% and 38.7%, respectively. The increase in bacterial reduction ability occurs because halloysite has hydroxyl groups on its surface, making it bind to bacteria through covalent or hydrogen bonding.287,288 Moreover, the addition of ZnO to the PCL nanofibers also plays an important role because ZnO releases Zn2+, which can effectively inhibit bacterial activity. Figure 7c shows the PM2.5 filtration performance. Single PCL and HNT/ZnO/PCL composite nanofibers have efficiency values of 89.78% and 92.10%, respectively. The increase in efficiency occurs because the HNTs are negatively charged to absorb positively charged dust.286 In addition, the fine structure from incorporating HNTs and ZnO causes an increase in air permeability, allowing for an increase in filtration efficiency and simultaneously maintaining a low-pressure drop, as shown in Fig. 7d.

a SEM images of polycaprolactone (PCL) nanofibers before and after the addition of halloysite nanotubes (HNTs) and ZnO and (b) their colony counting tests toward E. coli and S. aureus. After the addition of HNTs-7 wt%, the E. coli and S. aureus reduction levels increased to 95.9% and 97.9%, respectively. c The filtration efficiency towards PM2.5 increased after the addition of HNTs-7 wt% and ZnO from 89.78% to 92.10%. d Both membranes exhibit an ultra-low pressure drop of about 46 Pa. (reproduced with permission from,286 copyright (Elsevier B.V., 2022)).

Inorganic nanofiber materials

Besides being fabricated from organic materials, many nanofibers for PM filtration membranes are produced from inorganic materials (e.g., ceramic fibers). Inorganic nanofiber materials have several advantages over their polymer or organic polymer composite counterparts. Inorganic nanofibers have higher mechanical resistance, making them more suitable if applied as a PM filtration membrane because they are pressure-resistant. In addition, inorganic materials have higher thermal resistance, making them superior if applied as a PM filtration membrane with high-temperature airflow. For example, SiO2 has a melting point of 1710 °C. Other inorganic metal oxide-based materials also have melting points above 1000 °C. Here, SnO2 and TiO2 possess melting points of 1630 °C and 1850 °C, respectively. These values are much higher than those of polymers, which are mostly below 400 °C (e.g., PAN at 300–320 °C, PTFE at 327–342 °C, and PI at 260–400 °C).

Osorio and coworkers used the electrospinning method to fabricate SiO2 as a nanofiber base material for a PM filtration membrane.289 In that membrane, polyvinylpyrrolidone (PVP) was employed as the nanofiber matrix, which was then removed through calcination at 600 °C for 1 h. The fabricated nanofiber has a diameter of ~300 nm with a flexible quartz crystalline phase and high mechanical strength. In addition, the nanofiber also has a good thermal resistance up to 1000 °C. In its application as an air filtration membrane, the fabricated nanofiber has a pressure drop of 271.5 Pa with efficiencies of 99.57% for most penetrating particle size (MPPS) (166 nm) and 99.88% for PM0.3, thus having quality-factor values of 0.020 and 0.025 Pa−1, respectively.

Another report by Zhu et al.290 suggested that a mullite fiber porous ceramic filter (MFPCF) can be realized using vacuum filtration, in which a solution of mullite fiber was spun as the matrix material, and silica sol was used as a binder at high temperature. MFPCF was fabricated with various mass ratios of Si and MF, having a light mass (density of 0.58 g·cm−3) and high porosity (78.11%) for a mass ratio of Si to MF of 10:1. In addition, MFPCF also has high compressive strength (1.79 MPa) and low thermal conductivity (0.095 W·m−1K−1). The fabricated MFPCF filters have filtration efficiencies of 99.53% and 98.85% for PM2.5 and PM10 when the airflow is 2 L·min−1 (see Fig. 8a). This indicates that the MFPCF can effectively capture PMs, as shown in Fig. 8b. However, when the air flow is increased, the pressure drop also increases for all variations. This phenomenon affects the quality factor (QF). The lower airflow has a higher QF value, as shown in Fig. 8c.

a PM filter efficiency of a mullite fiber porous ceramic filter (MFPCF) with various mass ratios of Si and MF. Its efficiency values are 99.53% and 98.85% for PM2.5 and PM10, respectively, when the airflow is 2 L·min−1. b SEM image of MFPCF after the efficiency test revealing PM trapped on the surface of the MFPCF (see red box). c Quality factor (QF) of the MFPCF at airflows of 2 L·min-1 and 6 L·min−1. (reproduced with permission from,290 copyright (Elsevier B.V., 2023)). d Design of a SiC/SiC-TiO2 membrane and SEM image showing the total thickness of 100 µm of a membrane with 6 wt% SiC content. e Pressure drop and rejection rate (filter efficiency) of a SiC/SiC-TiO2 membrane at 500 °C. Even though it operates at high temperatures, the membrane still has a high efficiency of 99.93% with a pressure drop of 0.82 kPa. (reproduced with permission from,291 copyright (Elsevier B.V., 2023)).

Zhou et al. conducted research using a membrane made from SiC/SiC-TiO2 (see Fig. 8d and e).291 Silicon carbide (SiC) is used to increase gas permeability because it has a highly porous structure. Vertical growth of TiO2 nanowires was performed in situ on the surface of a SiC buffer (SiC-TiO2). At a SiC content of 6 wt%, the fabricated membrane has a total thickness of 100 µm, a porosity of 91%, a pore diameter of ~6.8 µm, and a gas permeability of 440 m3⋅m⋅h−1⋅kPa−1. In filtration test performance, SiO2 particulates of ~300 nm were used. The efficiency was 99.93% with a pressure drop of 0.82 kPa. The membrane was superior because the filtration process took place at 500 °C.

Advanced emerging applications

Industrial combustion

In modern society, industrial combustion continuously releases large amounts of dust and particulates into the atmosphere.98 Dangerous air pollution arises from various sources, including biomass burning, industrial emissions, soil dust, aerosols, and coal combustion.292 Industrial combustion contributes to PM pollution, which impacts ecological disruption, climate change, and increased global health (respiratory and cardiovascular diseases).293 High-thermal-resistant electrospun PM filtration membranes emerge as a superior choice for capturing various PM emitted from industrial combustion processes. The employed membranes typically comprise polymer composites.

Sentril et al. introduced an electrospun filtration membrane to prevent the presence of PM2.5 and PM10 from industrial combustion.294 The materials used to create a composite nanofiber membrane, a so-called functionalized nanofibrous air filter (FNA) with a dimension of 60 × 60 mm2, were poly-(vinyl) alcohol (PVA), carbon nanoparticle (CNP), and tea leaf extract (TLE). Membrane filters with different material combinations could be realized (e.g., PVA:CNP:TLE, PVA:CNP, and only PVA filters). FNA showed an excellent low-pressure drop (110 Pa), which is a promising characteristic for air purification. PVA:CNP:TLE FNA has demonstrated higher PM filtration performance compared to PVA:CNP and PVA filters. It exhibited high PM2.5 and PM10 removal efficiency values of 99.25% and 99.29%, respectively. PVA alone decomposes by side chain breaking at approximately 290 °C. The breakdown of CNP caused the greatest weight loss at temperatures of 320 °C and 480 °C. The O-H and COOH groups in the polymer chain enable CNP to interact with TLE and PVA. The occurrence of this interaction results in the formation of weak intermolecular cross-links between the polymer chains. The results of TGA show that the combination of PVA:CNP:TLE produces the greatest weight reduction among the other compositions. Also, the functionalization of the nanofibrous air filter (FNA) has good durability, with the highest is own after 10 h.

Li et al. developed a high-temperature PM0.3 filter membrane, which is intended for industrial combustion applications (burning fossil fuels).295 The PM0.3 nanofiber filter membrane was made of polyimide (PI), which was modified with zeolitic imidazolate framework-8 (ZIF-8) to increase the PM filtration efficiency. Compared to the pure PI membrane, which provides an efficiency of 96.38%, the ZIF-8/PI multifunctional nanofiber membrane achieves super-high filtration efficiency of 100% for ultrafine particulates (PM0.3) with a pressure drop of 63 Pa and an airflow of 6 L·min−1. The positive charge on the surface of ZIF-8 nanoparticles can polarize the surface of the particulates, making it easier for them to interact with the nanofibers, thus improving the ability of the membrane to capture PMs. The high specific surface area of ZIF-8 nanoparticles has improved the specific surface area of the PI nanofiber membrane, which helps to enhance the surface energy of the membrane and increases its adsorption efficiency.

The advantage of the PI nanofiber membrane is that it can be used in high-temperature applications. The trend of membrane changes between PI and ZIF-8/PI from room temperature to 800 °C. ZIF-8/PI pyrolysis starts at 450 °C, while PI pyrolysis starts at 500 °C. In practical filtration applications, the membrane is heat treated at temperatures of 100 °C, 200 °C, and 300 °C for 2 h, then the PM filtration efficiency is tested. The results showed that the filtration efficiency of PI and ZIF-8/PI against PM0.3 did not change after heat treatment. The morphology of the ZIF-8/PI nanofiber membrane remained unchanged after heat treatment up to 300 °C, proving that the ZIF-8/PI nanofiber membrane was thermally stable.

In conclusion, nanofiber membranes for industrial combustion filtration require a combination of high filtration efficiency, low-pressure drop, high-temperature resistance, and chemical resistance. By incorporating materials like PI, ZIFs, and functionalized nanofibers, researchers have made significant progress in developing membranes that meet these criteria.

Vehicles

In most urban areas, vehicle emissions have been a problem for air pollution and human health. All combustion engine vehicles produce COx, NOx, and PM. In Europe, the Euro 6 regulations have limited each vehicle’s emission amount, e.g., a maximum PM of 0.005 g·km−1. Gasoline particulate filters (GPFs) and three-way catalysts (TWCs) are commonly used in the exhaust line to filter the PM emission and convert NOx to N2. However, producing these filters requires expensive metals such as platinum, rhodium, and palladium. Besides, these filters are not sustainable. Nanofiber-based filtration membranes fabricated by electrospinning methods are being developed as an alternative. In applications of vehicle filters, the materials are required to resist high temperatures of 50–500 °C.296

Due to its high-temperature resistance, polyimide (PI) is a prospective organic nanofiber that can be applied to vehicle exhaust. Zhang et al. synthesized electrospun PI nanofibers for this application.10 The PI nanofibers of various optical transmittance have been tested directly in vehicle exhaust (see Fig. 9a). They can resist temperatures up to 350 °C and filter PM2.5 with a high efficiency of above 99.98% and a pressure drop of 73 Pa for PI nanofibers with an optical transmittance of 45% (see Fig. 9b). Mass and efficiency decrease rapidly at a temperature higher than 370 °C. In contrast, PI nanofibrous membranes fabricated from polyamic acid (PAA) have a higher maximum working temperature of 420 °C and a PM filtration efficiency of 99.73% with a pressure drop of 83.3 Pa.7

a PI nanofiber for vehicle exhaust filtration. The nanofiber membrane has various values of optical transmittance of 45%, 58%, 64%, 71%, 89%, and 95%, denoted as PI-45, PI-58, PI-64, PI-71, PI-89, and PI-95, respectively. b The PM2.5 filtering efficiency of PI nanofibers. PI nanofibers with optical transmittance of 45% have the highest efficiency of 99.98% at 350 °C. However, at 370 °C, the efficiency decreases significantly. (reproduced with permission from ref.10 copyright (American Chemical Society, 2016)). c The fabrication process of wrinkled PI nanofibers, including the SEM and TEM images of fabricated nanofibers. Wrinkled PI nanofibers are obtained by adding 20 wt% of PAN to PI (denoted as PI-20). d The efficiency of PM filtering with various particle sizes at room temperature of fabricated nanofibers (PI-0, PI-5, PI-10, and PI-20 nanofibers). The PI-20 has the highest efficiency for all PM sizes, with even a PM0.3 efficiency of 99.99%. e TGA curves of fabricated nanofibers. The mass of the pure PI nanofibers starts to decrease significantly at 505 °C. (reproduced with permission from,251 copyright (American Chemical Society, 2020)).

Further approaches have been developed to attain higher efficiency and temperature robustness. Using PAN in the PAA solution as a nanofiber precursor, a wrinkled porous PI nanofiber can be fabricated (see Fig. 9c). The wrinkled PI with 20 wt% of PAN (PI-20) membrane has the highest filtration efficiency of 99.99% against PM0.3 with a pressure drop of 43.35 Pa at room temperature, as shown in Fig. 9d. The wrinkled structures increase the capture of the particulates because of the effects of interception, inertia, diffusion, gravity, and electrostatic adsorption. Despite having high thermal stability, the mass of pure PI nanofibers starts to decrease at a critical temperature of 505 °C (see Fig. 9e).251 Besides, a combination of PI and polyethersulfone (PES) nanofibers can filtrate PM with an efficiency of 99.54% but with a much lower pressure drop of only 0.98 Pa.297

In contrast to organics, inorganic materials can work at much higher temperatures (>400 °C). Polyvinylpyrrolidone (PVP) is used as the carrier for the electrospinning process to fabricate inorganic nanofibers such as Ni,298 yttria-stabilized zirconia (YSZ),299 and SiO2.289 The electrospun membranes are then heated in an oven at 500–600 °C to remove all organic compounds. These inorganic nanofibers have been proven to result in a high PM filtration performance in high working temperatures. Nickel nanofibers not only capture PM but also show a catalytic ability to transform NO into N2 gas. The catalytic process reaches saturation at 300 °C. Although Ni will be oxidized in this process, it can be recycled at 500 °C.298 To synthesize foldable SiO2 membranes, tetraethyl orthosilicate (TEOS) is used as the SiO2 precursor and combined with PVP to be electrospun on a roll-to-roll collector. Lastly, the SiO2/PVP nanofiber membranes can filter PM0.3 with a high efficiency of 99.86%.289 A summary of the use of nanofiber-based filtration membranes in their application at high temperatures can be seen in Table 2.

Other applications

Besides industrial combustion and vehicle exhaust, nanofiber-based PM filtration membranes have normally been applied as masks in personal protective equipment against airborne pathogens to protect the human respiratory system.300 The first example is electrospun polyimide (PI)/polyethersulfone (PES) nanofiber mask with low-pressure drop and high biocompatibility for high-efficiency bacteria, viruses, and nano-aerosol removal.300 The nano-sized PI/PES membrane shows a high filtration efficiency of 99.74% against PMs having sizes of 50–500 nm, a high QF of 3.27 Pa−1, and a non-toxic effect on the human body (107% cell viability).

Another study was conducted by Yang et al.,301 where they developed a self-powered air filter mask with a simple structure that utilizes fiber membrane adhesion and separation driven by respiration. The wind energy generated by breathing will cause an upper arch structure to come into contact with a lower part, which contributes to generating friction charges and improves the filtration efficiency of the nanofiber membrane. A self-powered filter with a micro-nano composite structure consisting of a polybutanediol succinate (PBS) nanofiber membrane and polyacrylonitrile (PAN) nanofiber/polystyrene (PS) microfiber hybrid mats was prepared by electrospinning. PAN combined with PS achieves a balance between pressure drop and filtration efficiency. The membrane filtration efficiency for PM0.3 reached 99.4% for 48 h in an environment containing PM2.5 with a mass concentration of 23,000 µg·m−3 and a pressure drop of around 50 Pa. Oily particulates are successfully captured by the thin PAN/PS fiber combination. This proves that PS microfibers help to increase the air permeability of the filter, and PAN nanofibers assist in capturing PM. Yang et al. introduced a facial mask with thermal management to increase user comfort.302 A system of nanofibers on nanoporous polyethylene (fiber/nanoPE) has been developed, where the nanofibers have strong PM adhesion to ensure high PM capture efficiency (99.6% for PM2.5) with low-pressure drop. The nanoPE substrate with high infrared (IR) transparency (92.1% weighted based on human body radiation) results in effective radiative cooling. Using nanoPE coated with an Ag layer, the fiber/Ag/nanoPE mask shows high IR reflectance (87%), which can control the user’s thermal comfort.

PM filtration applications can be used in various ways, either independently or in combination with other filtration media. The high-efficiency particulate air filter (HEPA) is widely used to protect humans from harmful gases.303 HEPA production uses an environmentally friendly method for the generation of multifunctional poly (vinyl alcohol)/poly(acrylic acid) (PVA-PAA) composite membranes via green electrospinning and thermal crosslinking, as shown in Fig. 10. Superhydrophobic silica nanoparticles are inserted into the fiber to produce a rough surface, where the AgNO3 is subsequently added, forming Ag nanoparticles through UV reduction. The PVA-PAA-SiO2-Ag NP membrane with an area of 100 cm2 has a high PM2.5 filtration performance of 98% and a high tensile strength of more than 8.5 MPa. The materials of the membrane are environmentally friendly. Apart from that, the membrane avoids using dangerous organic solvents, which may cause an enlargement of toxic organic solvent residues in the human body. HEPA coated with a PVA-PAA-SiO2-Ag NP nanofiber membrane has the advantages of high efficiency, good resistance to low airflow (improving the breathability of HEPA), biological compatibility, and antibacterial properties. These advantages allow HEPA to combat air pollution and become one of the solutions for air filtration systems.

Schematic diagram of the process for making PVA-PAA-SiO2-Ag NP nanofiber membranes using a combination of electrospinning, UV reduction, and thermal cross-linking. Silver nitrate (AgNO3) is doped into a PVA-PAA-SiO2 NP filtration membrane, and Ag+ is reduced to Ag nanoparticles (AgNPs) via UV reduction to provide better antibacterial/antiviral activity. PVA-PAA-SiO2-Ag NP membranes are applied for air filtration, especially PM2.5, and have an antibacterial/antiviral effect. The electrospun PVA-PAA nanofiber membrane was carefully separated from the collector and thermally cross-linked at 140 ˚C for 2 h via an esterification reaction. (reproduced with permission from,303 copyright (Elsevier B.V., 2023)).

Air pollution occurs not only outdoors but also indoors. For example, the use of additional chemicals in building materials can cause an increase in the concentration of volatile organic compound (VOC) in a room that has been renovated recently, even if the concentration exceeds the industrial zone.304 For example, the VOC formaldehyde, when combined with certain environmental and occupational conditions, can cause sensory irritation. Electrospun nanofiber membranes can be used as an indoor air filtration solution to prevent contaminants, especially for hospitals that require an aseptic and dust-free environment.305 They emerge as an alternative filter media with high filtration efficiency and low air resistance to reduce air contamination.

Current challenges

The performance of fabricated nanofibers by electrospinning has attracted much attention from researchers and industrial providers. With such compelling performance, the demand for nanofibers has increased to a large scale in the industry. However, a transition from small-scale laboratory experiments to large-scale industrial fabrication with wider and more dynamic applications still has some obstacles. Conventional electrospinning machines widely available in laboratories are still single-nozzle machines,53,55,177 making the fabrication process take a long time. Accelerating nanofiber fabrication can be done using multi-jets, needleless electrospinning, or using electrospinning machines in large quantities.