Abstract

Charge transport in two-dimensional crystals is critical for a large variety of future applications, and it is therefore highly desirable to get a better understanding of the underlying mechanisms. Here, we focus on the MXene Ti3C2Tx, which has recently garnered significant attention for its potential in printable electronics, energy storage and electromagnetic interference shielding, for which electrical properties play a leading role. To answer the need for experimental data on charge transport in Ti3C2Tx, we combine local-probe measurements (Conductive AFM), conventional four-contact measurements, finite element and ab initio simulations on individual few-layer flakes of Ti3C2Tx. This effort establishes new methods to study charge transport both in in-plane and out-of-plane directions and yields a consistent quantitative value of resistivity anisotropy in individual Ti3C2Tx flakes, an essential ingredient in the understanding and modeling of charge transport in MXenes, in particular considering the role of interlayer interactions and surface functionalization in these materials.

Similar content being viewed by others

Introduction

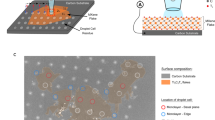

By nature, multilayer materials composed of stacks of two-dimensional (2D) crystals held together by van der Waals forces, such as graphene, exhibit anisotropic properties1,2. While some methods can be readily devised to characterize properties like electrical conductivity along different axes of a bulk multilayer material3,4, it is much more difficult to adapt such methods in the few-layer case as typical dimensions are in the μm (in-plane) and nm (out-of-plane) range. The common practice for electrical measurements on 2D flakes consists in the fabrication of devices with patterned contacts on the flakes, as shown in Fig. 1b–d, or transferring the 2D flakes on substrates with electrical contacts. Those techniques do not allow out-of-plane electrical measurements, making the study of anisotropic properties challenging for few-layer flakes. Yet, those properties are essential to characterize interlayer interactions, which are a key aspect in most applications using 2D crystals.

a Illustration of C-AFM measurement on an individual flake deposited on a metallic electrode, on a Si/SiO2 substrate. b Illustration of a conventional four-contact measurement on an individual flake. c 3D view of the AFM topography of a Ti3C2Tx flake deposited partially on an electrode, obtained in tapping mode. d 3D view of the AFM topography of patterned contacts on a Ti3C2Tx flake, obtained in tapping mode.

We focus here on MXenes, a family of 2D materials that garnered a lot of interest over the last few years. MXenes are 2D transition metal carbides, nitrides and carbonitrides, noted Mn+1XnTx, where n = 1, 2 or 3, ‘M’ is an early transition metal, ‘X’ is either C or N and Tx accounts for functional groups at the surface5,6. Their rich chemistry as well as surface terminations offer tunable electronic properties and surface engineering possibilities7,8. More specifically, functional groups can be controlled by the synthesis technique, making both the surface chemistry and the work function tunable9. For example, cation intercalation and physical delamination with solvent molecules used as intercalants have been studied towards intercalation- and termination-engineered MXenes to gain control on inter- and intra-flake transport mechanisms10,11. Structural and electronic modifications can also be induced in 2D MXenes by ion implantation12,13. On a larger scale, solution-processed films assembled from MXene nanosheets have numerous advantages, such as scalability, cost-effectiveness and compatibility with flexible substrates. In recent years, several strategies have been formulated to control the surface functional groups of MXene nanosheets to achieve the best balance between electron transport properties, atmospheric stability and dispersion in organic solvents14. Their versatility makes MXenes ideal for applications requiring specific chemical or electronic properties. Typically, they yielded breakthrough results in energy storage, electromagnetic interference shielding, sensing and printable electronics14,15,16,17,18,19.

In the vast majority of applications using MXenes, flakes are spin-coated, drop-casted, printed or sprayed on various substrates, yielding random networks of overlapping individual flakes20,21,22. Electronic transport in those 2D networks is still a matter of debate in the case of MXenes: the intra- and inter-flake transport should be studied separately, and there is a lack of extensive experimental investigation of electronic transport in individual flakes in order to characterize 2D networks of MXenes23,24. Several works report on 2- and 4-contact electrical characterization of monolayer and few-layer Ti3C2Tx flakes, using conventional measurements on patterned devices25,26,27,28,29. However, as emphasized above, those techniques are not concluding for the characterization of anisotropic properties of individual flakes. A strong anisotropy of electrical resistivity, defined as \(A=\frac{{\rho }_{{{\rm{z}}}}}{{\rho }_{{{\rm{xx}}}}}\), where ρz and ρxx are, respectively, the out-of-plane and in-plane resistivity, is reported in several MAX phases3,30. As MAX phases are the 3D precursors of MXenes, the study of anisotropy in their 2D counterpart is of utmost interest, in particular for 2D plasmonics31. Ab initio simulations have shown that the electronic conduction in Ti3C2(OH)2 is highly anisotropic, and an experimental result on a Ti3C2Tx particulate (i.e., a few μm-thick macroscopic aggregate of flakes) reports an estimated anisotropy of one order of magnitude32. No experimental reports have been published on anisotropy measurements on few-layer single-crystal individual flakes of MXenes, up to our knowledge.

In this context, advanced characterization at the nanoscale is needed to further explore charge transport in 2D MXenes. Scanning probe microscopy (SPM) tools are, in principle, the most adequate for this purpose, as the SPM probe size is typically in the few-nm range, much smaller than the lateral size of the flakes. Among the electrical SPM modes, Conductive Atomic Force Microscopy (C-AFM) offers high-resolution current maps and local current-voltage characterization at the nanoscale33. It is commonly used to study conduction mechanisms in 2D materials, current injection from contacts, and conductivity homogeneity34,35,36. Also, it allows for measuring out-of-plane current injection in 2D materials with the appropriate sample configuration, which makes it a method of choice to investigate the resistivity anisotropy in few-layer 2D crystals37,38,39. C-AFM is mostly used for qualitative measurements, as extracting quantitative data from SPM measurements is challenging. Indeed, as C-AFM is inherently a 2-contact technique, extrinsic electrical resistances come into play, whose relative contribution is not always straightforward to evaluate. Quantitative data can be extracted by combining the experimental results and an appropriate model, i.e., finite element simulations40,41. In the case of 2D crystals, electronic conductivity values were obtained from C-AFM measurements on electrochemically exfoliated graphene oxide and on monolayer CVD graphene using contact models42,43. In the case of MXenes, various SPM characterizations have been carried out, such as scanning thermal microscopy or Kelvin-probe force microscopy (KPFM), but are rather sparse when it comes to C-AFM measurements44. Nevertheless, a recent study on perovskite solar cells incorporating MXenes highlighted the powerful capabilities of C-AFM for the study of nanoscale photoconduction45.

In the present work, C-AFM measurements on flakes overlapping a metallic electrode and an insulating substrate are presented, as illustrated in Fig. 1a. A finite element model is used to simulate the electrostatics of a Ti3C2Tx individual flake and infer its electronic resistivity from C-AFM current maps. The result is then compared to values obtained with conventional four-contact measurements on individual flakes, as illustrated in Fig. 1b. Combining C-AFM and finite element simulation results, we provide a quantitative estimate of the out-of-plane resistivity and, in turn, of the MXene electrical resistivity anisotropy. Lastly, the obtained anisotropy value is consistent with results from ab initio simulations results obtained on large MXene supercells incorporating different types of functional groups.

Results and discussion

In-plane resistivity of individual flakes, measured by C-AFM

First of all, C-AFM measurements on few-layer Ti3C2Tx have been carried out in the configuration illustrated by Fig. 1a–c. In this case, an individual flake overlapping both the Au electrode and the SiO2 substrate was selected for the measurement. The obtained C-AFM current map is shown in Fig. 2a, using a logarithmic color scale representing electrical current values for better contrast visualization. A 3-D image of the measured topography of the flake of interest is shown in the inset of Fig. 2b and can be used to correlate topography and current maps. Here, the average flake thickness tz extracted from topography map is 12 nm, as shown in Supplementary Fig. 5. C-AFM current map allows to visualize the inhomogeneities in current distribution on the flake surface, which are partly related to tip-electrode distance and topography inhomogeneities. For example, one can notice in the current map of Fig. 2a that the flake edge exhibits less C-AFM current, which is directly linked to flake edge roughness that induces current inhomogeneities. Here, we focus on the current evolution with the tip-electrode distance. For this specific C-AFM measurement configuration, the different contributions to the total measured resistance RTOT can be expressed as follows:

In this expression, IAFM is the measured C-AFM current, ΔV is the C-AFM bias voltage, Rf,IN and Rf,OUT are the in-plane and out-of-plane resistances of the flake, respectively. RC,tip represents the contact resistance between the tip and the flake and RC,Au is the contact resistance between the flake and the Au electrode. All those contributions are illustrated by Fig. 3a. Rf,IN can be separated from other contributions to the total resistance thanks to its dependence on the tip-electrode distance, dt-e. The latter is illustrated in Fig. 2a and is defined as the distance between the tip and the edge of the electrode, on the flake surface. Tip-electrode distance-induced C-AFM current variations can be studied more quantitatively by extracting a profile in the current map along the length of the flake. Figure 2b shows the current profile extracted along the white dashed line displayed on Fig. 2a. The location of the profile was chosen in an area where the flake topography is rather flat and homogeneous, to avoid any artifact related to tip interaction with topographical features. A gradient is observed on the extracted profile, as C-AFM current increases as the tip approaches the electrode, corresponding approximately to a linear variation of the in-plane resistance Rf,IN as a function of dt-e. Additional C-AFM results obtained on flakes of various thicknesses are shown in Supplementary Figs. 7, 8, with several current profiles where the linear dependence of the C-AFM current with dt-e is also observed.

a Current map of a C-AFM measurement on a Ti3C2Tx flake overlapping a metallic electrode and an insulating substrate, obtained with a 5 mV bias. b Current values of the profile along the dashed line in (a). The inset shows a 3D view of the AFM topography of the flake and electrode. c Simulated potential distribution on the flake for C-AFM tip at 1.5 μm from the electrode, using C-AFM current at this location as input. d Comparison between the resistance profile extracted from the C-AFM measurements (orange line) and the resistance values on the flake as obtained from the simulation for different tip-electrode distances (stars).

a Equivalent circuit of the C-AFM measurement on an individual few-layer flake. b, c Simulated potential distribution within the flake below the conductive tip for two different anisotropy values. d Simulated potential distribution at the flake surface, for various anisotropy values. e Simulation of the equivalent radius req as a function of the anisotropy. req is defined as the radius corresponding to the area where 75% of the potential drop occurs at the flake surface.

Next, we detail how fitting the current profile of Fig. 2b allows to separate the in-plane resistance from the other contributions to the resistance. First, the C-AFM current can be written as IAFM = I0 + αdt-e, where α is the slope of the current profile of Fig. 2b and I0 is the C-AFM current measured for dt-e = 0. Then, the in-plane resistance can be rewritten \({R}_{{{\rm{f,IN}}}}({d}_{{{\rm{t}}}{\mbox{-}}{{\rm{e}}}})=\frac{\Delta V}{{I}_{0}+\alpha {d}_{{{\rm{t}}}{\mbox{-}}{{\rm{e}}}}}-({R}_{{{\rm{f,OUT}}}}+{R}_{{{\rm{C,tip}}}}+{R}_{{{\rm{C,Au}}}})=\frac{\Delta V}{{I}_{0}+\alpha {d}_{{{\rm{t}}}{\mbox{-}}{{\rm{e}}}}}\) - 10.85 kΩ. The goal is to extract the in-plane resistivity of the flake independently from contact resistances, as described in previous works on graphene43,46. First, we reproduce the geometry of the experiment, including the C-AFM tip, in a finite element simulation. This is necessary to capture the complexity of the electrostatics of a C-AFM measurement on a flake. Indeed, the simulated potential distribution in the flake, shown for dt-e = 1.5 μm in Fig. 2c, is clearly not trivial (see Supplementary Fig. 4 for potential maps corresponding to other tip positions). We then adjust the flake resistivity ρxx in the simulation until the best match is found between the simulated Rf,IN (at different dt-e), and the experimentally obtained Rf,IN(dt-e), as illustrated in Fig. 2d. The best fit was obtained for ρxx = 6.81 ± 0.91 Ω μm, yielding good agreement between simulation points and experimental data, as presented in Fig. 2d.

Comparison with conventional 4-contact measurements on individual flakes

Besides C-AFM measurements on individual flakes, the electrical resistivity of similar flakes has also been extracted through more conventional four-contact measurements. The devices used for those measurements consist in Ti3C2Tx flakes deposited on insulating substrate, with gold contacts patterned using lithography techniques, as illustrated by Fig. 1b–d. Several devices with at least four contacts on individual flakes have been fabricated and measured as described in the experimental section. Figure 4a shows optical micrographs of a Ti3C2Tx flake and the as-fabricated device. As expected for metallic flakes, the obtained I-V characteristics are linear, as presented in Fig. 4b. Resistivity values were extracted from these measurements for each device and fall in the range of [1–20] Ω μm. The obtained values are represented as a function of flake thickness on Fig. 4c along with resistivity values of Ti3C2Tx mono and few-layer flakes reported in the literature. The resistivity values obtained in the present work have been extracted taking into account flake geometry, and the error bars include the errors related to the geometry measurements from AFM topography as well as the noise of the resistance measurement. Note that the values reported by Lipatov et al. were acquired with two-contact measurements on MXenes synthesized by HF etching in one work25 and by the MILD method for two other works47,48. Sang et al. also present two-contact measurements on MXenes synthesized with MILD method27. By contrast, Hemmat et al. report four-contact measurements on MXenes, also synthesized with MILD method, which is the closest situation compared to the present work26. Lastly, Shekhirev et al. also reported a resistivity value which belongs to the aforementioned range, with a four-contact measurement on an individual Ti3C2Tx flake prepared via soft delamination49. It is interesting to note that even with different synthesis methods and when comparing measurements with two and four contacts, the resistivity values extracted are of the same order of magnitude. Consequently, contact resistance does not play a significant role in the measurements made on these devices, as Miranda et al. also indicated after control experiments28. It also proves that the resistivity of individual Ti3C2Tx flakes is fairly stable for different synthesis and processing methods.

a Optical microscope images of a Ti3C2Tx flake and Au contacts patterned on the same flake. b V–I characteristics obtained with four-contact measurements on individual Ti3C2Tx flakes. c In-plane resistivity values of Ti3C2Tx individual flakes, combining this work and literature25,26,27,47,48,49. The datapoints for this work gather values from four-contact measurements on patterned devices and the resistivity value obtained using finite element simulation combined with C-AFM results, as described in Fig. 2. The error bars include the errors related to the geometry measurements from AFM topography, as well as the noise of the resistance measurement.

Figure 4c displays the resistivity value (ρxx, deduced from the measured Rf,IN) obtained from the above-mentioned C-AFM measurement and simulation presented in Fig. 2. There is a remarkable agreement with the four-contact measurement approach, both in this work and in the literature. This, therefore, further validates the combined C-AFM and modeling approach for quantitative extraction of flake resistivity. As demonstrated in the present work, the C-AFM approach adds a degree of versatility that cannot be reached through conventional patterned contact measurements. One can indeed examine the local homogeneity of the flakes, as well as the decoupling between out-of-plane and in-plane components of the resistivity.

Resistivity anisotropy in Ti3C2Tx: from experimental results

Next, we focus on the extraction of Rf,OUT from the C-AFM measurement to obtain ρz. To do so, the extrinsic contributions to RTOT should be discussed. First, RC,Au is considered negligible compared to the total resistance, since it was shown by Makaryan et al. that the MXene-Au contact resistance does not exceed 10-Ω with the transfer length method50. Also, similar work based on C-AFM measurements performed on epitaxial graphene reported a 2-Ω contact resistance between Au and graphene35. Then, I–V characteristics have been acquired with C-AFM on various locations on the Au electrodes (See Supplementary Fig. 6b) to estimate RC,tip. The Au electrode is here considered as an ideal conductor and we assume that RC,tip stays in the same range whether the tip is located above the Au electrode or above Ti3C2Tx. This assumption is supported by the close values of work functions of both materials51,52. Indeed, KPFM measurements carried out in this work reveal that the work functions of Au and Ti3C2Tx are in the same range, suggesting that the band-alignment in Pt/Ir and Ti3C2Tx contact is comparable to the case of Pt/Ir and Au contact. Additional details can be found in Supplementary Fig. 9 and Supplementary Note 1. RC,tip is therefore estimated as 1390 ± 10 Ω. Using RC,tip estimation and neglecting RC,Au, Rf,OUT = 9.46 kΩ is obtained for the out-of-plane resistance of the flake.

Now that all the extrinsic contributions to the total resistance have been considered, the resistivity anisotropy can be written as follows:

where Sz is the equivalent contact area under the tip and tz is the flake thickness. Here, we use the value of ρxx = 6.81 ± 0.91 Ω μm found using C-AFM data combined with finite element simulations. To get an accurate view of the actual volume probed in this out-of-plane configuration, and hence an estimate of Sz, one has to rely again on a finite element simulation of the electrostatics of the vertical tip-MXene-contact geometry, as shown in Fig. 3d, e for different anisotropy values. Finite element simulations were proven to be well suited for quantitative interpretation of C-AFM measurements on isotropic dielectric or semiconductor samples40, but were never used with the same purpose in the case of metallic layered metals. Here, the model was established considering the 25-nm tip radius and equipotential layers of μm-range lateral length for the MXenes few-layer flakes. In this case, the simulated potential distribution shows that most of the potential drop occurs in the close vicinity of the tip apex, both for low and large anisotropy A, as shown on Fig. 3b, c. The equivalent contact area Sz is defined as the area where 75% of the potential drop occurs at the flake surface33, with a radius noted req. It has been simulated for a wide range of anisotropy values (1–105), and it appears that the evolution of req with A is relatively slow, as shown on the graph of Fig. 3e. Based on these results, a range of [40–70] nm can therefore be used for req as a first guess. As a consequence, we find from data in Fig. 2 that the obtained resistivity anisotropy range for this flake is A = [510–2050], which can be refined to A = 1400 ± 200 after several iterations to reduce req interval according to finite element simulations of Fig. 3b–e. Such large anisotropy values are expected. Indeed, one knows that several MAX phases—the 3D precursors of MXenes—exhibit high resistivity anisotropy3,4,30. After the etching step, MAX phases undergo delamination steps to form MXenes, which are expected to exhibit even higher anisotropic properties than their 3D counterparts. Besides, the functional groups and intercalation of water between the MXene layers at ambient conditions are also major factors explaining the high resistivity anisotropy. The anisotropy dependence on intercalated species can precisely be exploited in sensing applications, as shown in the work of Loes et al., which studies the layer-dependent sensing mechanism of Ti3C2Tx53.

To the best of our knowledge, no experimental data about resistivity anisotropy in Ti3C2Tx individual flakes have been reported, so we can only compare our data with those of a small number of experimental reports on more macroscopic samples, where disorder and defects are likely to play prominent roles. A previous work reported a resistivity anisotropy of about one order of magnitude in an individual μm-thick Ti3C2Tx particulate32, which confirms experimentally the presence of resistivity anisotropy in Ti3C2Tx. For the case of a Ti3C2Tx spray-coated layer, Makaryan et al. used impedance modeling to extract resistivity anisotropy, obtaining values between 105 and 10750. They also show a dependence of the anisotropy on the synthesis methods used to fabricate MXenes. While the aforementioned resistivity anisotropy values can not be directly compared to the specific case of individual flakes, they still indicate high resistivity anisotropy of Ti3C2Tx despite the different morphologies considered. The case of the layer of flake is expected to showcase higher resistivity anisotropy values, as it also includes junction resistances between the flakes that are contributing to electronic transport, mainly in the out-of-plane direction. The techniques used in the aforementioned studies are complementary, and C-AFM is a powerful addition to them as it allows for a more direct nanoscale measurement of the anisotropy at the individual flake level. It should also be noted that the resistivity anisotropy value obtained in this work is specific to few-layer flakes synthesized by the MILD method, measured under ambient conditions.

Resistivity anisotropy in Ti3C2Tx: from ab initio simulations

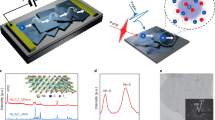

We provide another estimate of the electrical resistivity anisotropy through ab initio simulations. For this purpose, we consider the Ti3C2 supercell depicted in Fig. 5, which incorporates the main functional groups (-O, -OH, and -F) found in experimental samples. The resistivity anisotropy was estimated to be 440 as the ratio of the average out-of-plane resistivity to the average out-of-plane resistivity within an energy range of 1 eV at 300 K. One previous theoretical study shows that the electronic conduction in Ti3C2(OH)2 is highly anisotropic32. In the latter case, and in general for theoretical works related to the electronic conduction in MXenes, the simulations are usually carried out while considering no functional group or one at a time, given the complexity of the system54,55. Herein, the mixture of functional groups considered in the supercell brings the simulation closer to experimental conditions. More specifically, as functional groups have a significant role in the out-of-plane transport, the conductivity anisotropy value is expected to be dependent on the surface chemistry. Indeed, varying the functional group proportion in the ab initio simulation, one obtains values of A up to 3000 when the proportion between -F, -O, and -OH groups is modified (See Supplementary Fig. 10). A major difference remaining with experimental conditions is the presence of water or other species adsorbed between individual crystal planes56, which also influences the out-of-plane transport. Along with the uncertainty over the configuration of functional groups, water likely constitutes one of the main factors explaining the lower anisotropy value found in the simulation for similar proportions of functional groups in simulation and experiments. The value obtained in this ab initio simulation based on a realistic mixture of the main functional groups can therefore be safely used as a lower bound for resistivity anisotropy in Ti3C2Tx in ambient conditions.

In summary, charge transport was investigated in Ti3C2Tx individual flakes at the micro and nanoscale. To do so, conductive atomic force microscopy was performed on individual flakes overlapping a metallic electrode and an insulating substrate. The in-plane resistivity of a flake of interest could then be estimated to be around 7 ± 1 Ω μm thanks to an approach combining finite element simulations of the flake electrostatics with C-AFM data. Then, conventional four-contact measurements were performed on devices with contact patterns on top of individual Ti3C2Tx flakes. The resistivities obtained for several individual flakes are in good agreement with previous works, and with the in-plane resistivity computed from the C-AFM measurement. This validates the C-AFM and finite element simulation approach to extract quantitative data, and therefore also offers interesting prospects towards quantitative real-space mapping of resistivity in other 2D crystals. Lastly, the specific configuration used for C-AFM measurements also allows for estimating the MXene out-of-plane resistivity and therefore to provide a quantitative measurement of the resistivity anisotropy in Ti3C2Tx individual flakes around 103. Complementary ab initio simulations also allow to obtain an estimate of the high resistivity anisotropy in Ti3C2Tx, which is consistent with experiments. More generally, the study of charge transport at individual flake-scale provides invaluable insights to understand and model charge transport in a network of flakes more effectively and precisely. This work, therefore, paves the way for further investigations of the out-of-plane resistivity of different types of 2D crystals, which could prove important in various applications, such as understanding electrical contacts in all-2D-crystal transistors57 or characterizing the effect of intercalation or functionalization on out-of-plane transport in 2D flakes.

Methods

Ti3C2Tx synthesis

Ti3C2Tx was synthesized by the MILD (minimally intensive layer delamination) method from its MAX precursor, Ti3AlC258. First, 1.6 g of LiF salt (Sigma-Aldrich, 99%) was dissolved in 20 mL HCl 9M (Sigma-Aldrich, 37%) and stirred in a Teflon beaker at room temperature for 10 min to obtain in situ HF. Then, 1 g Ti3AlC2 was gradually added to the solution over the course of 10 min. The etching solution was heated at 40 ∘C in an oil bath under constant stirring for 24 h, during which the Teflon beaker was covered by a lid. After etching, the suspension was washed multiple times with DI water using cycles of centrifugation and vortex mixing. Centrifugation cycles were carried out at 6000 rpm for 5 min and repeated until the pH of the supernatant approached 7. A black supernatant was observed after seven washing cycles, indicating the start of the delamination. The Ti3C2Tx slurry was then carefully collected above the Ti3C2Tx/Ti3AlC2 sediment and vacuum filtered with a 0.22 μm membrane filter. The obtained MXene film was left to dry overnight at room temperature and stored under an inert atmosphere. More details about the morphology of the as-synthesized film are presented in Supplementary Figs. 1, 2, along with a Raman spectrum of the same film.

Samples fabrication

Ti3C2Tx flakes were deposited on two different substrates for this work. First, Ti3C2Tx was drop-cast onto interdigitated electrodes (IDEs) with a digit width of 2 μm and a spacing of 5 μm between the digits. The IDEs were fabricated by photolithography followed by the evaporation of 20 nm Ti and 200 nm Au, as described by Afyouni et al.59. After Ti3C2Tx drop casting and flake tracking, the 3 × 3 mm die was glued to a 1 cm2 gold-coated plate and wedge bonding was performed using a gold wire to connect the contact pads of the IDEs to the plate, as shown in Supplementary Fig. 3. Secondly, for the four-contact measurements, Ti3C2Tx flakes were drop-cast on a Si/SiO2 substrate with alignment marks. Flakes with the most homogeneous aspect in optical micrographs and the largest sizes were selected for contact patterning. The contact patterns were created with electron beam lithography after spin-coating a 200 nm-thick PMMA layer and its soft bake. After pattern writing and developing with MIBK:IPA 1:3, a 5 nm layer of Ti and a 55 nm layer of Au were deposited by thermal evaporation. Lift-off was carried out using acetone.

In both cases, the flake concentration on the substrates can be adjusted depending on the time that the droplet remains in contact with the substrate. It is also possible to rehydrate the solid films collected after the synthesis to disperse the flakes in any solvent, DI water in this work. A 1-min sonication is then required to ensure proper dispersion, followed by a 15-min rest to allow sedimentation of unwanted agglomerated species before drop casting.

C-AFM measurements

C-AFM measurements were conducted with a Bruker Icon Dimension equipped with C-AFM module. Metal-coated tips with a radius of 25 nm (SCM-PIT-V2, Bruker) were used for the measurements. Such tips have a Pt/Ir conductive coating, an elastic constant of 3 N m−1 and a resonance frequency of 75 kHz. The force applied on the tip was kept above 60 nN, as C-AFM current on Ti3C2Tx flakes is force-dependent (See Supplementary Fig. 6a) and becomes constant above 60 nN. All the measurements were performed in air at room temperature. Gwyddion and NanoScope Analysis were used for C-AFM data analysis, as well as the pySPM library60. The finite element simulations were carried out using COMSOL Multiphysics.

Four-contact measurements

The measurements were done on patterned devices using a PM8 probe station and a lock-in amplifier at low frequency (79 Hz), which is needed to measure highly conductive samples while keeping low current values to prevent local damage or overheating.

Ab initio simulations

In order to theoretically estimate the ratio between the in-plane and out-of-plane conductivity, numerical simulations were conducted using the VASP code61,62 within the density functional theory framework, employing the projector-augmented wave method and the PBE exchange-correlation functional63,64. Subsequently, a 4 × 4 × 2 supercell was constructed, and oxygen, fluorine, and hydroxyl groups were intercalated between the MXene layers using concentrations comparable with those reported in Benchakar et al. study for the case of the MILD method8, which is consistent with the Ti3C2Tx samples synthesized experimentally in this work. The structurally optimized atomistic model of Ti3C2 supercell incorporating various functional groups is shown in Fig. 5. After structural optimization, the in-plane and out-of-plane conductivity were calculated using the BoltzTraP2 code65.

Data availability

The data that support the findings of the current study are available from the corresponding authors on reasonable request.

References

Gao, Z.-d et al. Anisotropic mechanics of 2d materials. Adv. Eng. Mater. 24, 2200519 (2022).

Hermann, A., Somoano, R., Hadek, V. & Rembaum, A. Electrical resistivity of intercalated molybdenum disulfide. Solid State Commun. 13, 1065–1068 (1973).

Ouisse, T. et al. Magnetotransport properties of nearly-free electrons in two-dimensional hexagonal metals and application to the m n + 1 a x n phases. Phys. Rev. B 92, 045133 (2015).

Mauchamp, V. et al. Anisotropy of the resistivity and charge-carrier sign in nanolaminated Ti2AlC: experiment and ab initio calculations. Phys. Rev. B 87, 235105 (2013).

Naguib, M. et al. Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2. Adv. Mater. 23, 4248–53 (2011).

Naguib, M. et al. Two-dimensional transition metal carbides. ACS Nano 6 2, 1322–31 (2012).

Agresti, A. et al. Titanium-carbide MXenes for work function and interface engineering in perovskite solar cells. Nat. Mater. 18, 1–7 (2019).

Benchakar, M. et al. One max phase, different MXenes: a guideline to understand the crucial role of etching conditions on Ti3C2Tx surface chemistry. Appl. Surf. Sci. 530, 147209 (2020).

Caffrey, N. M. Effect of mixed surface terminations on the structural and electrochemical properties of two-dimensional ti 3 c 2 t 2 and v 2 ct 2 mxenes multilayers. Nanoscale 10, 13520–13530 (2018).

Hart, J. et al. Control of MXenes’ electronic properties through termination and intercalation. Nat. Commun. 10, 522 (2019).

Shi, S. et al. Recent advances in 2d mxenes: preparation, intercalation and applications in flexible devices. J. Mater. Chem. A 9, 14147–14171 (2021).

Pazniak, A. et al. Ion implantation as an approach for structural modifications and functionalization of Ti3C2Tx mxenes. ACS Nano 15, 4245–4255 (2021).

Obrȩbowski, S. et al. Ion-implanted MXene electrodes for selective VOC sensors. Appl. Mater. Today 39, 102343 (2024).

Ko, T. Y. et al. Functionalized MXene ink enables environmentally stable printed electronics. Nat. Commun. 15, 3459 (2024).

Iqbal, A., Hassan, T., Madad, S., Gogotsi, Y. & Koo, C. M. Mxenes for multispectral electromagnetic shielding. Nat. Rev. Electr. Eng. 1, 180–198 (2024).

Li, X. et al. Mxene chemistry, electrochemistry and energy storage applications. Nat. Rev. Chem. 6, 389–404 (2022).

Wan, S. et al. Scalable ultrastrong MXene films with superior osteogenesis. Nature 634, 1103–1110 (2024).

Iqbal, A., Hassan, T., Gao, Z., Shahzad, F. & Koo, C. M. Mxene-incorporated 1d/2d nano-carbons for electromagnetic shielding: a review. Carbon 203, 542–560 (2022).

Devaraj, M., Rajendran, S., Hoang, T. K. & Soto-Moscoso, M. A review on MXene and its nanocomposites for the detection of toxic inorganic gases. Chemosphere 302, 134933 (2022).

Jiang, X. et al. Inkjet-printed MXene micro-scale devices for integrated broadband ultrafast photonics. npj 2D Mater. Appl. 3, 34 (2019).

Herber, M., Lengle, D., Valandro, S. R., Wehrmeister, M. & Hill, E. H. Bubble printing of Ti3C2Tx MXene for patterning conductive and plasmonic nanostructures.Nano Lett. 23, 6308-6314 (2023).

Mojtabavi, M. et al. Wafer-scale lateral self-assembly of mosaic Ti3C2Tx mxene monolayer films. ACS Nano 15, 625–636 (2021).

Gabbett, C. et al. Understanding how junction resistances impact the conduction mechanism in nano-networks. Nat. Commun. 15, 4517 (2024).

Barsoum, M. W. & Gogotsi, Y. Removing roadblocks and opening new opportunities for MXenes. Ceram. Int. 49, 24112–24122 (2023). A selection of papers presented at CIMTEC 2022.

Lipatov, A. et al. High electrical conductivity and breakdown current density of individual monolayer Ti3C2Tx MXene flakes. Matter 4, 1413–1427 (2021).

Hemmat, Z. et al. Tuning thermal transport through atomically thin Ti3C2TZ MXene by current annealing in vacuum. Adv. Funct. Mater. 29, 1805693 (2019).

Sang, X. et al. Atomic defects in monolayer titanium carbide (Ti3C2Tx) mxene. ACS Nano 10, 9193–9200 (2016).

Miranda, A., Halim, J., Barsoum, M. & Lorke, A. Electronic properties of freestanding Ti3C2Tx MXene monolayers. Appl. Phys. Lett. 108, 033102 (2016).

Lipatov, A. & Sinitskii, A. Electronic and mechanical properties of MXenes derived from single-flake measurements. In: Anasori, B., Gogotsi, Y. (eds) 2D Metal Carbides and Nitrides (MXenes) 301–325 (Springer, 2019).

Ouisse, T. & Barsoum, M. Magnetotransport in the max phases and their 2D derivatives: MXenes. Mater. Res. Lett. 5, 1–14 (2017).

Raab, C., Rieger, J., Ghosh, A., Spellberg, J. L. & King, S. B. Surface plasmons in two-dimensional mxenes. J. Phys. Chem. Lett. 15, 11643–11656 (2024).

Hu, T. et al. Anisotropic electronic conduction in stacked two-dimensional titanium carbide. Sci. Rep. 5, 16329 (2015).

Rodenbücher, C., Wojtyniak, M. & Szot, K.Conductive AFM for Nanoscale Analysis of High-k Dielectric Metal Oxides, 29–70 (Springer, 2019).

Giannazzo, F., Greco, G., Roccaforte, F., Mahata, C. & Lanza, M. Conductive AFM of 2D Materials and Heterostructures for Nanoelectronics, 303–350 (Springer, 2019).

Giannazzo, F., Deretzis, I., La Magna, A., Roccaforte, F. & Yakimova, R. Electronic transport at monolayer-bilayer junctions in epitaxial graphene on SiC. Phys. Rev. B 86, 235422 (2012).

Giannazzo, F., Schilirò, E., Greco, G. & Roccaforte, F. Conductive atomic force microscopy of semiconducting transition metal dichalcogenides and heterostructures. Nanomaterials 10, 803 (2020).

Kubota, W., Utsunomiya, T., Ichii, T. & Sugimura, H. Local current mapping of electrochemically-exfoliated graphene oxide by conductive AFM. Jpn J. Appl. Phys. 59, SN1001 (2020).

Giannazzo, F., Fisichella, G., Piazza, A., Agnello, S. & Roccaforte, F. Nanoscale inhomogeneity of the Schottky barrier and resistivity in MoS2 multilayers. Phys. Rev. B 92, 081307 (2015).

Chen, Z. et al. Vertical conductivity and topography in electrostrictive germanium sulfide microribbon via conductive atomic force microscopy. Nano Lett. 22, 7636–7643 (2022).

Reid, O., Munechika, K. & Ginger, D. Space charge limited current measurements on conjugated polymer films using conductive atomic force microscopy. Nano Lett. 8, 1602–9 (2008).

Villeneuve-Faure, C., Makasheva, K., Boudou, L. & Teyssedre, G. Space Charge at Nanoscale: Probing Injection and Dynamic Phenomena Under Dark/Light Configurations by Using KPFM and C-AFM, 267–301. https://doi.org/10.1007/978-3-030-15612-1_9 (Springer International Publishing, 2019).

Tu, Y., Utsunomiya, T., Ichii, T. & Sugimura, H. Enhancing the electrical conductivity of vacuum-ultraviolet-reduced graphene oxide by multilayered stacking. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas., Phenom. 35, 03D110 (2017).

Lim, S., Park, H., Yamamoto, G., Lee, C. & Suk, J. W. Measurements of the electrical conductivity of monolayer graphene flakes using conductive atomic force microscopy. Nanomaterials 11, 2575 (2021). https://www.mdpi.com/2079-4991/11/10/2575.

Sahare, S. et al. An assessment of MXenes through scanning probe microscopy. Small Methods 6, 2101599 (2022).

Panigrahi, S. et al. Mxene-enhanced nanoscale photoconduction in perovskite solar cells revealed by conductive atomic force microscopy. ACS Appl. Mater. Interfaces 16, 1930–1940 (2023).

Nirmalraj, P., Lutz, T., Kumar, S., Duesberg, G. & Boland, J. Nanoscale mapping of electrical resistivity and connectivity in graphene strips and networks. Nano Lett. 11, 16–22 (2011).

Lipatov, A., Bagheri, S. & Sinitskii, A. Metallic conductivity of Ti3C2T x MXene confirmed by temperature-dependent electrical measurements. ACS Mater. Lett. 6, 298–307 (2023).

Lipatov, A. et al. Effect of synthesis on quality, electronic properties and environmental stability of individual monolayer Ti3C2 mxene flakes. Adv. Electron. Mater. 2, 1600255 (2016).

Shekhirev, M. et al. Ultralarge flakes of Ti3C2Tx MXene via soft delamination. ACS Nano 16, 13695–13703 (2022).

Makaryan, T., Okada, Y. & Suzuki, K. Impedance modeling for excluding contact resistance from cross-plane electronic conductivity measurement of anisotropic two-dimensional Ti3C2Tx MXenes. J. Appl. Phys. 133, 065304 (2023).

Kahn, A. Fermi level, work function and vacuum level. Mater. Horiz. 3, 7–10 (2016).

Schultz, T. et al. Work function and energy level alignment tuning at Ti3C2Tx mxene surfaces and interfaces using (metal-) organic donor/acceptor molecules. Phys. Rev. Mater. 7, 045002 (2023).

Loes, M. J., Bagheri, S. & Sinitskii, A. Layer-dependent gas sensing mechanism of 2d titanium carbide (Ti3C2Tx) mxene. ACS Nano 18, 26251–26260 (2024).

Boussadoune, N., Nadeau, O. & Antonius, G. Electronic transport in titanium carbide MXenes from first principles. Phys. Rev. B 108, 125124 (2023).

Khazaei, M. et al. Novel electronic and magnetic properties of two-dimensional transition metal carbides and nitrides. Adv. Funct. Mater. 23, 2185–2192 (2013).

Ghidiu, M. et al. Ion-exchange and cation solvation reactions in Ti3C2MXene. Chem. Mater. 28, 3507–3514 (2016).

Yuan, L. et al. Promises and prospects of two-dimensional transistors. Nature 591, 43–53 (2021).

Bärmann, P. et al. Scalable synthesis of max phase precursors toward titanium-based mxenes for lithium-ion batteries. ACS Appl. Mater. Interfaces 13, 26074–26083 (2021).

Afyouni, S., Enel, A., Hamoir, G. & Danlée, Y. An inkjet-printed rgo-pei composite for CO2 monitoring working at room temperature. In: Proc. IEEE International Symposium on Olfaction and Electronic Nose (ISOEN), 1–4 (IEEE, 2024).

Scholder, O. scholi/pyspm: pyspm v0.2.16 (version v0.2.16). https://doi.org/10.5281/zenodo.998575.

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Kresse, G., & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11–169 (1996).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. b 59, 1758 (1999).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865 (1996).

Madsen, G. K. & Singh, D. J. Boltztrap. A code for calculating band-structure dependent quantities. Comput. Phys. Commun. 175, 67–71 (2006).

Acknowledgements

B.H. (senior research associate) acknowledges support from the F.R.S.-FNRS. The authors are grateful to the Walloon region for funding this research through SIAHNA and ASPCIN projects. The authors also acknowledge financial support from the ARC project DREAMS (21/26.116). The technical support of Cécile D’Haese, Jean-François Statsyns and Miloud Zitout is sincerely acknowledged. We thank Jesus Gonzalez-Julian for providing MAX precursors used in one of the Ti3C2Tx syntheses of this work, and Thierry Ouisse for his fruitful collaboration. We thank VOCSens team for collaboration and technical support. The authors also acknowledge financial support by the EOS project “CONNECT" (40007563) and by the Belgium F.R.S.-FNRS through the research project (T.029.22F). Computational resources have been provided by the CISM supercomputing facilities of UCLouvain and the CÉCI consortium funded by F.R.S.-FNRS of Belgium (2.5020.11).

Author information

Authors and Affiliations

Contributions

O.D., F.M.F. and B.H. conceived and designed the experiments. O.D. and H.P. produced samples for analysis. O.D. and F.M.F. performed the experimental measurements. O.D., F.M.F. and S.A. carried out the data analysis and finite element simulations. L.C., A.P.F., V.N. and J.C. carried out ab initio simulations. O.D. and B.H. drafted the manuscript. F.M.F., S.A., L.C., A.P.F., V.N., H.P., B.N., J.C. and S.H. discussed the data, reviewed and edited the manuscript. B.H. supervised this study.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Materials thanks Filippo Giannazzo and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Primary Handling Editors: John Plummer. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

de Leuze, O., Fernandes, F.M., Arib, S. et al. Anisotropic charge transport in 2D single crystals of Ti3C2Tx MXenes. Commun Mater 6, 186 (2025). https://doi.org/10.1038/s43246-025-00902-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s43246-025-00902-3