Abstract

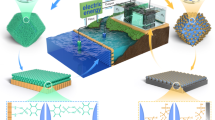

Serving as a clean energy carrier, green hydrogen — hydrogen produced by the electrolysis of water — enables low-carbon transportation and facilitates the large-scale integration of intermittent renewable energy sources into the power grid, thereby enhancing system flexibility and decarbonization. Hydrogen fuel cell vehicles (HFCVs) are key to the integration of green hydrogen into the energy and transport systems. The adoption of HFCVs is being supported by advances in hydrogen production and fuel cell technologies, coupled with the development of hydrogen refuelling infrastructure. However, technological, economic and regulatory barriers to the growth of the hydrogen economy remain. This Review examines the progress and challenges in the integration of HFCVs into the energy and transport systems. We also consider challenges in scaling green hydrogen production using renewable energy and highlight the role of HFCVs in facilitating the integration of green hydrogen and renewable energy into the energy and transport systems. Finally, we provide a roadmap that outlines directions for research, policy and investment to overcome the obstacles to growing the hydrogen economy and harnessing hydrogen as a cornerstone of sustainable energy and transport systems.

Key points

-

Hydrogen fuel cell vehicles (HFCVs) serve as a key link between green hydrogen production and zero-emission transport, while also contributing to energy system flexibility by enabling renewable energy storage, grid balancing and coupling across the energy and mobility domains.

-

Realizing safe and high-performance HFCVs requires durable and efficient fuel cells and their real-time safety monitoring and smart operation control.

-

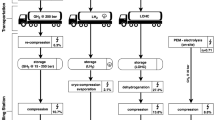

Hydrogen refuelling stations act as hubs that connect green hydrogen production, storage and end-use in transport, ensuring a convenient and reliable fuel supply for HFCVs; the expansion of hydrogen refuelling infrastructure is essential for increasing HFCV adoption and fostering a fully integrated hydrogen economy.

-

Addressing the challenges of scaling green hydrogen requires not only advances in electrolyser technology and the development of large-scale renewable energy-powered hydrogen hubs, but also strategies to align hydrogen production with variable demand across the energy and transport systems to ensure reliable, cost-effective and sustainable integration.

-

The next stages of HFCV integration into the energy and transport systems require coordinated policy support, investment in infrastructure, a reduction in the cost of fuel cells and green hydrogen production, technological advances for performance and safety, and alignment with renewable energy development.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

International Energy Agency. CO2 emissions in 2022 (IEA, 2023).

Hydrogen Council. Hydrogen insights 2023 (Hydrogen Council, McKinsey & Company, 2023).

International Energy Agency. Global EV outlook 2023 (IEA, 2023).

Schlapbach, L. Hydrogen-fuelled vehicles. Nature 460, 809–811 (2009).

Yoo, E., Kim, M. & Song, H. H. Well-to-wheel analysis of hydrogen fuel-cell electric vehicle in Korea. Int. J. Hydrog. Energy 43, 19267–19278 (2018).

Ugurlu, A. An emission analysis study of hydrogen powered vehicles. Int. J. Hydrog. Energy 45, 26522–26535 (2020).

van Renssen, S. The hydrogen solution? Nat. Clim. Change 10, 799–801 (2020).

Han, J. et al. Hydrogen‐powered smart grid resilience. Energy Convers. Econ. 4, 89–104 (2023).

Wang, Y. et al. Current understanding and challenges of solar-driven hydrogen generation using polymeric photocatalysts. Nat. Energy 4, 746–760 (2019).

Jaunatre, M. Renewable Hydrogen (Springer, 2021).

Glenk, G. & Reichelstein, S. Economics of converting renewable power to hydrogen. Nat. Energy 4, 216–222 (2019).

Yang, X., Nielsen, C. P., Song, S. & McElroy, M. B. Breaking the hard-to-abate bottleneck in China’s path to carbon neutrality with clean hydrogen. Nat. Energy 7, 955–965 (2022).

Allendorf, M. D. et al. Challenges to developing materials for the transport and storage of hydrogen. Nat. Chem. 14, 1214–1223 (2022).

Yazdi, M., Moradi, R., Pirbalouti, R. G., Zarei, E. & Li, H. Enabling safe and sustainable hydrogen mobility: circular economy-driven management of hydrogen vehicle safety. Processes 11, 2730 (2023).

Zhou, J., Du, P., Liang, G., Chang, H. & Liu, S. Hydrogen station location optimization coupling hydrogen sources and transportation along the expressway. Int. J. Hydrog. Energy 54, 1094–1109 (2024).

Jones, J., Genovese, A. & Tob-Ogu, A. Hydrogen vehicles in urban logistics: a total cost of ownership analysis and some policy implications. Renew. Sustain. Energy Rev. 119, 109595 (2020).

Wang, X. X., Swihart, M. T. & Wu, G. Achievements, challenges and perspectives on cathode catalysts in proton exchange membrane fuel cells for transportation. Nat. Catal. 2, 578–589 (2019).

Jiao, K. et al. Designing the next generation of proton-exchange membrane fuel cells. Nature 595, 361–369 (2021).

Moghaddam, S. et al. An inorganic–organic proton exchange membrane for fuel cells with a controlled nanoscale pore structure. Nat. Nanotechnol. 5, 230–236 (2010).

Shen, G. et al. Multi-functional anodes boost the transient power and durability of proton exchange membrane fuel cells. Nat. Commun. 11, 1191 (2020).

Xiao, F. et al. Atomically dispersed Pt and Fe sites and Pt–Fe nanoparticles for durable proton exchange membrane fuel cells. Nat. Catal. 5, 503–512 (2022).

Wang, H. et al. Cathode design for proton exchange membrane fuel cells in automotive applications. Automot. Innov. 4, 144–164 (2021).

Zhan, G., Li, P. & Zeng, H. C. Architectural designs and synthetic strategies of advanced nanocatalysts. Adv. Mater. 30, 1802094 (2018).

Bae, G. et al. Unravelling the complex causality behind Fe–N–C degradation in fuel cells. Nat. Catal. 6, 1140–1150 (2023).

Adabi, H. et al. High-performing commercial Fe–N–C cathode electrocatalyst for anion-exchange membrane fuel cells. Nat. Energy 6, 834–843 (2021).

Malko, D., Kucernak, A. & Lopes, T. In situ electrochemical quantification of active sites in Fe–N/C non-precious metal catalysts. Nat. Commun. 7, 13285 (2016).

Mehmood, A. et al. High loading of single atomic iron sites in Fe–NC oxygen reduction catalysts for proton exchange membrane fuel cells. Nat. Catal. 5, 311–323 (2022).

Choi, S. H. et al. Experimental study on non-uniform arrangement of 3D printed structure for cathodic flow channel in PEMFC. Int. J. Hydrog. Energy 47, 1192–1201 (2022).

Zhao, Z. et al. Graphene-nanopocket-encaged PtCo nanocatalysts for highly durable fuel cell operation under demanding ultralow-Pt-loading conditions. Nat. Nanotechnol. 17, 968–975 (2022).

Wee, J.-H., Lee, K.-Y. & Kim, S. H. Fabrication methods for low-Pt-loading electrocatalysts in proton exchange membrane fuel cell systems. J. Power Sources 165, 667–677 (2007).

Zhang, T., Wang, P., Chen, H. & Pei, P. A review of automotive proton exchange membrane fuel cell degradation under start-stop operating condition. Appl. Energy 223, 249–262 (2018).

Sutharssan, T. et al. A review on prognostics and health monitoring of proton exchange membrane fuel cell. Renew. Sustain. Energy Rev. 75, 440–450 (2017).

Zhang, C. et al. A health management review of proton exchange membrane fuel cell for electric vehicles: failure mechanisms, diagnosis techniques and mitigation measures. Renew. Sustain. Energy Rev. 182, 113369 (2023).

Pan, R., Yang, D., Wang, Y. & Chen, Z. Health degradation assessment of proton exchange membrane fuel cell based on an analytical equivalent circuit model. Energy 207, 118185 (2020).

Van Der Linden, F., Pahon, E., Morando, S. & Bouquain, D. A review on the proton-exchange membrane fuel cell break-in physical principles, activation procedures, and characterization methods. J. Power Sources 575, 233168 (2023).

He, W., Tang, F., Li, X., Zhang, C. & Ming, P. Quantification and evolution on degradation mechanisms of proton exchange membrane fuel cell catalyst layer under dynamic testing conditions. Int. J. Hydrog. Energy 48, 18032–18040 (2023).

Ao, Y., Laghrouche, S., Depernet, D. & Chen, K. Lifetime prediction for proton exchange membrane fuel cell under real driving cycles based on platinum particle dissolve model. Int. J. Hydrog. Energy 45, 32388–32401 (2020).

Ren, P. et al. Degradation mechanisms of proton exchange membrane fuel cell under typical automotive operating conditions. Prog. Energy Combust. Sci. 80, 100859 (2020).

Benaggoune, K., Yue, M., Jemei, S. & Zerhouni, N. A data-driven method for multi-step-ahead prediction and long-term prognostics of proton exchange membrane fuel cell. Appl. Energy 313, 118835 (2022).

Yuan, H., Dai, H., Wei, X. & Ming, P. Model-based observers for internal states estimation and control of proton exchange membrane fuel cell system: a review. J. Power Sources 468, 228376 (2020).

Nagulapati, V. M., Kumar, S. S., Annadurai, V. & Lim, H. Machine learning based fault detection and state of health estimation of proton exchange membrane fuel cells. Energy AI 12, 100237 (2023).

Chen, K., Laghrouche, S. & Djerdir, A. Degradation model of proton exchange membrane fuel cell based on a novel hybrid method. Appl. Energy 252, 113439 (2019).

Meraghni, S. et al. A data-driven digital-twin prognostics method for proton exchange membrane fuel cell remaining useful life prediction. Int. J. Hydrog. Energy 46, 2555–2564 (2021).

Pan, R., Yang, D., Wang, Y. & Chen, Z. Performance degradation prediction of proton exchange membrane fuel cell using a hybrid prognostic approach. Int. J. Hydrog. Energy 45, 30994–31008 (2020).

Quan, S. et al. Health-aware model predictive energy management for fuel cell electric vehicle based on hybrid modeling method. Energy 278, 127919 (2023).

Liu, Y., Amin, M. T., Khan, F. & Pistikopoulos, E. N. Safety analysis of proton exchange membrane water electrolysis system. J. Environ. Chem. Eng. 11, 110772 (2023).

Wang, J. et al. Recent advances and summarization of fault diagnosis techniques for proton exchange membrane fuel cell systems: a critical overview. J. Power Sources 500, 229932 (2021).

Zhang, G. & Jiao, K. Multi-phase models for water and thermal management of proton exchange membrane fuel cell: a review. J. Power Sources 391, 120–133 (2018).

Yang, L. et al. A review on thermal management in proton exchange membrane fuel cells: temperature distribution and control. Renew. Sustain. Energy Rev. 187, 113737 (2023).

Jullian, G. et al. Fault detection and isolation for proton exchange membrane fuel cell using impedance measurements and multiphysics modeling. Fuel Cell 20, 558–569 (2020).

Dijoux, E., Steiner, N. Y., Benne, M., Péra, M.-C. & Pérez, B. G. A review of fault tolerant control strategies applied to proton exchange membrane fuel cell systems. J. Power Sources 359, 119–133 (2017).

Zuo, B. et al. Data-driven flooding fault diagnosis method for proton-exchange membrane fuel cells using deep learning technologies. Energy Convers. Manag. 251, 115004 (2022).

Zhou, S. et al. Real-time data-driven fault diagnosis of proton exchange membrane fuel cell system based on binary encoding convolutional neural network. Int. J. Hydrog. Energy 47, 10976–10989 (2022).

Li, Z. et al. Fault diagnosis for fuel cell systems: a data-driven approach using high-precise voltage sensors. Renew. Energy 135, 1435–1444 (2019).

Xu, J.-H. et al. Fault diagnosis of PEMFC based on fatal and recoverable failures using multi-scale convolutional neural networks. Int. J. Hydrog. Energy 80, 916–925 (2024).

Cooper, N. J., Santamaria, A. D., Becton, M. K. & Park, J. W. Neutron radiography measurements of in-situ PEMFC liquid water saturation in 2D & 3D morphology gas diffusion layers. Int. J. Hydrog. Energy 42, 16269–16278 (2017).

Chaparro, A. M. et al. Thermal neutron radiography of a passive proton exchange membrane fuel cell for portable hydrogen energy systems. J. Power Sources 480, 228668 (2020).

Stöhr, T. et al. Hydrogen quality in used natural gas pipelines: an experimental investigation of contaminants according to ISO 14687:2019 standard. Int. J. Hydrog. Energy 67, 1136–1147 (2024).

Mousa, G., Golnaraghi, F., DeVaal, J. & Young, A. Detecting proton exchange membrane fuel cell hydrogen leak using electrochemical impedance spectroscopy method. J. Power Sources 246, 110–116 (2014).

Koo, W.-T. et al. Chemiresistive hydrogen sensors: fundamentals, recent advances, and challenges. ACS Nano 14, 14284–14322 (2020).

Ning, F. et al. High safety fuel cells based on gas diffusion layer suppressed uneven current and thermal runaway. Adv. Funct. Mater. 35, 2414081 (2024).

Hong, J. et al. Review on proton exchange membrane fuel cells: safety analysis and fault diagnosis. J. Power Sources 617, 235118 (2024).

Tang, X., Zhou, H., Wang, F., Wang, W. & Lin, X. Longevity-conscious energy management strategy of fuel cell hybrid electric vehicle based on deep reinforcement learning. Energy 238, 121593 (2022).

Li, M. et al. Review on the research of hydrogen storage system fast refueling in fuel cell vehicle. Int. J. Hydrog. Energy 44, 10677–10693 (2019).

Ghahari, S., Assi, L., Carter, K. & Ghotbi, S. The future of hydrogen fueling systems for fully automated vehicles. In International Conference on Transportation and Development 2019: Innovation and Sustainability in Smart Mobility and Smart Cities 66–76 (American Society of Civil Engineers, 2019).

Bourgeois, T. et al. Optimization of hydrogen vehicle refuelling requirements. Int. J. Hydrog. Energy 42, 13789–13809 (2017).

Prokop, M., Drakselova, M. & Bouzek, K. Review of the experimental study and prediction of Pt-based catalyst degradation during PEM fuel cell operation. Curr. Opin. Electrochem. 20, 20–27 (2020).

Borup, R. L. et al. Recent developments in catalyst-related PEM fuel cell durability. Curr. Opin. Electrochem. 21, 192–200 (2020).

Talukdar, K. et al. Experimental and numerical study on catalyst layer of polymer electrolyte membrane fuel cell prepared with diverse drying methods. J. Power Sources 461, 228169 (2020).

Jung, J. et al. Electrochemical degradation of Pt3Co nanoparticles investigated by off-lattice kinetic Monte Carlo simulations with machine-learned potentials. ACS Catal. 13, 16078–16087 (2023).

Piras, M., De Bellis, V., Malfi, E., Novella, R. & Lopez-Juarez, M. Hydrogen consumption and durability assessment of fuel cell vehicles in realistic driving. Appl. Energy 358, 122559 (2024).

Kurtz, J. M., Sprik, S., Saur, G. & Onorato, S. Fuel Cell Electric Vehicle Durability and Fuel Cell Performance. Report no. NREL/TP-5400-73011 (National Renewable Energy Laboratory, 2019).

Hahn, S., Braun, J., Kemmer, H. & Reuss, H.-C. Adaptive operation strategy of a polymer electrolyte membrane fuel cell air system based on model predictive control. Int. J. Hydrog. Energy 46, 17306–17321 (2021).

Sasmito, A. P., Shamim, T. & Mujumdar, A. S. Passive thermal management for PEM fuel cell stack under cold weather condition using phase change materials (PCM). Appl. Therm. Eng. 58, 615–625 (2013).

Xu, J. et al. Progress and perspectives of integrated thermal management systems in PEM fuel cell vehicles: a review. Renew. Sustain. Energy Rev. 155, 111908 (2022).

Ríos, G. M., Schirmer, J., Gentner, C. & Kallo, J. Efficient thermal management strategies for cold starts of a proton exchange membrane fuel cell system. Appl. Energy 279, 115813 (2020).

Chen, Q. et al. Thermal management of polymer electrolyte membrane fuel cells: a review of cooling methods, material properties, and durability. Appl. Energy 286, 116496 (2021).

Liu, Z. et al. Adaptive look-ahead model predictive control strategy of vehicular PEMFC thermal management. Energy 285, 129176 (2023).

Su, Q. et al. An intelligent control method for PEMFC air supply subsystem to optimize dynamic response performance. Fuel 361, 130697 (2024).

Venkatasatish, R. & Dhanamjayulu, C. Reinforcement learning based energy management systems and hydrogen refuelling stations for fuel cell electric vehicles: an overview. Int. J. Hydrog. Energy 47, 27646–27670 (2022).

Wang, X. et al. Review on water management methods for proton exchange membrane fuel cells. Int. J. Hydrog. Energy 46, 12206–12229 (2021).

Stogiannis, I. A., Mouza, A. A. & Paras, S. V. Study of a micro-structured PHE for the thermal management of a fuel cell. Appl. Therm. Eng. 59, 717–724 (2013).

Genovese, M. & Fragiacomo, P. Hydrogen refueling station: overview of the technological status and research enhancement. J. Energy Storage 61, 106758 (2023).

Xu, Z., Dong, W., Yang, K., Zhao, Y. & He, G. Development of efficient hydrogen refueling station by process optimization and control. Int. J. Hydrog. Energy 47, 23721–23730 (2022).

Li, M. et al. Experimental and numerical study of the temperature evolution in hydrogen cylinder under fast-refueling process. Int. J. Heat Mass Transf. 211, 124220 (2023).

Bauer, A., Mayer, T., Semmel, M., Morales, M. A. G. & Wind, J. Energetic evaluation of hydrogen refueling stations with liquid or gaseous stored hydrogen. Int. J. Hydrog. Energy 44, 6795–6812 (2019).

Hu, D., Xiang, C., Lu, D. & Wang, J. Characterization of hydrogen refueling temperature rise of the on-board hydrogen system under different failure modes. Appl. Therm. Eng. 247, 123026 (2024).

Apostolou, D. & Xydis, G. A literature review on hydrogen refuelling stations and infrastructure. Current status and future prospects. Renew. Sustain. Energy Rev. 113, 109292 (2019).

Li, Y., Wang, Z., Shi, X. & Fan, R. Numerical investigation of the dispersion features of hydrogen gas under various leakage source conditions in a mobile hydrogen refueling station. Int. J. Hydrog. Energy 48, 9498–9511 (2023).

Byun, Y.-S. A study on safety improvement for mobile hydrogen refueling station by HAZOP analysis. Trans. Korean Hydrog. N. Energy Soc. 32, 299–307 (2021).

Zeng, B. & Yan, W. in Resilient and Adaptive Tokyo: Towards Sustainable Urbanization in Perspective of Food-Energy-Water Nexus 211–230 (Springer, 2024).

Samsun, R. C., Rex, M., Antoni, L. & Stolten, D. Deployment of fuel cell vehicles and hydrogen refueling station infrastructure: a global overview and perspectives. Energies 15, 4975 (2022).

Long, J., Yang, J., Li, S. & Xiao, J. Research on demand analysis and path planning of mobile hydrogen refueling station. In 2021 3rd International Academic Exchange Conference on Science and Technology Innovation (IAECST) 1268–1274 (IEEE, 2021).

Lahnaoui, A., Wulf, C., Heinrichs, H. & Dalmazzone, D. Optimizing hydrogen transportation system for mobility via compressed hydrogen trucks. Int. J. Hydrog. Energy 44, 19302–19312 (2019).

Kim, P., Kang, S., Yoo, M. & Huh, Y. A study on safety analysis of stationary LPG-mobile hydrogen complex refueling station. J. Energy Eng. 28, 48–60 (2019).

Huertas Gaja, P. & Llompart Jaume, M. d. M. Standards, Codes and Regulations of Hydrogen Refueling Stations and Hydrogen Fuel Cell Vehicles. BSc thesis, Univ. Politècnica de Catalunya (2014).

Minutillo, M., Perna, A., Forcina, A., Di Micco, S. & Jannelli, E. Analyzing the levelized cost of hydrogen in refueling stations with on-site hydrogen production via water electrolysis in the Italian scenario. Int. J. Hydrog. Energy 46, 13667–13677 (2021).

Wang, K., Huang, J., Chen, H., Wang, Y. & Song, S. Recent advances in electrochemical 2e oxygen reduction reaction for on-site hydrogen peroxide production and beyond. Chem. Commun. 56, 12109–12121 (2020).

Zhang, C., Song, P., Sui, Y., Hou, J. & Wang, X. Economic competitiveness of compact steam methane reforming technology for on-site hydrogen supply: a Foshan case study. Int. J. Hydrog. Energy 47, 32359–32371 (2022).

Bukar, A. L., Chaitusaney, S. & Kawabe, K. Optimal design of on-site PV-based battery grid-tied green hydrogen production system. Energy Convers. Manag. 307, 118378 (2024).

Harrison, K., Martin, G., Ramsden, T., Kramer, W. & Novachek, F. Wind-to-Hydrogen Project: Operational Experience, Performance Testing, and Systems Integration. Report No. NREL/TP-550-44082 (National Renewable Energy Laboratory, 2009).

Saur, G. Wind-to-Hydrogen Project: Electrolyzer Capital Cost Study. Report no. NREL/TP-550-44103 (National Renewable Energy Laboratory, 2008).

Hansen, T. NREL, Xcel energy partner on wind-to-hydrogen project. Power Eng. 111, 10–11 (2007).

Clifton, A., Schreck, S., Scott, G., Kelley, N. & Lundquist, J. K. Turbine inflow characterization at the National Wind Technology Center. J. Sol. Energy Eng. 135, 031017 (2013).

Yang, C. & Ogden, J. Determining the lowest-cost hydrogen delivery mode. Int. J. Hydrog. Energy 32, 268–286 (2007).

Heerema, K. Strategic Niche Management for Hydrogen: Analysing the Hydrogen Hub Twente. MSc thesis, Univ. of Twente (2021).

Covarrubias, M. Post-2020 visions and national plans for sustainable transport (European Biofuels Technology Platform, 2015).

Neumann, F., Zeyen, E., Victoria, M. & Brown, T. The potential role of a hydrogen network in Europe. Joule 7, 1793–1817 (2023).

Rasul, M., Hazrat, M., Sattar, M., Jahirul, M. & Shearer, M. The future of hydrogen: challenges on production, storage and applications. Energy Convers. Manag. 272, 116326 (2022).

Dou, Y., Sun, L., Ren, J. & Dong, L. in Hydrogen Economy 537–569 (Elsevier, 2023).

Crowl, D. A. & Jo, Y.-D. The hazards and risks of hydrogen. J. Loss Prev. Process Ind. 20, 158–164 (2007).

Yang, N., Deng, J., Wang, C., Bai, Z. & Qu, J. High pressure hydrogen leakage diffusion: research progress. Int. J. Hydrog. Energy 50, 1029–1046 (2024).

Qian, J.-y, Li, X.-j, Gao, Z.-x & Jin, Z.-j A numerical study of hydrogen leakage and diffusion in a hydrogen refueling station. Int. J. Hydrog. Energy 45, 14428–14439 (2020).

Wang, H. et al. Research and demonstration on hydrogen compatibility of pipelines: a review of current status and challenges. Int. J. Hydrog. Energy 47, 28585–28604 (2022).

Hugo, A., Rutter, P., Pistikopoulos, S., Amorelli, A. & Zoia, G. Hydrogen infrastructure strategic planning using multi-objective optimization. Int. J. Hydrog. Energy 30, 1523–1534 (2005).

Stephens-Romero, S. D., Brown, T. M., Kang, J. E., Recker, W. W. & Samuelsen, G. S. Systematic planning to optimize investments in hydrogen infrastructure deployment. Int. J. Hydrog. Energy 35, 4652–4667 (2010).

Dayhim, M., Jafari, M. A. & Mazurek, M. Planning sustainable hydrogen supply chain infrastructure with uncertain demand. Int. J. Hydrog. Energy 39, 6789–6801 (2014).

Greene, D. L., Ogden, J. M. & Lin, Z. Challenges in the designing, planning and deployment of hydrogen refueling infrastructure for fuel cell electric vehicles. ETransportation 6, 100086 (2020).

Zhang, J., Li, C., Chen, G. & Dong, Z. Planning of hydrogen refueling stations in urban setting while considering hydrogen redistribution. IEEE Trans. Ind. Appl. 58, 2898–2908 (2021).

Kim, H., Eom, M. & Kim, B.-I. Development of strategic hydrogen refueling station deployment plan for Korea. Int. J. Hydrog. Energy 45, 19900–19911 (2020).

Geçici, E., Güler, M. G. & Bilgiç, T. Multi-period planning of hydrogen refuelling stations using flow data: a case study for Istanbul. Int. J. Hydrog. Energy 47, 40138–40155 (2022).

Fu-jin, N., Tie-ju, M., Ying, L., Jun, C. & Chun-jie, C. An agent-based hydrogen vehicle system simulation. In 2010 International Conference on Management Science & Engineering 17th Annual Conference Proceedings 156–161 (IEEE, 2010).

Zhang, Q., Chen, J. & Ihara, T. Assessing regional variations in hydrogen fuel cell vehicle adoption: an integrative approach using real-world data and analytic hierarchy process in Tokyo. Appl. Energy 363, 123014 (2024).

Chen, J. et al. Roadmap to hydrogen society of Tokyo: locating priority of hydrogen facilities based on multiple big data fusion. Appl. Energy 313, 118688 (2022).

Gan, W. et al. Multi-network coordinated hydrogen supply infrastructure planning for the integration of hydrogen vehicles and renewable energy. IEEE Trans. Ind. Appl. 58, 2875–2886 (2022).

Yang, C. & Hu, Q. Quantifying fuel cell vehicles and hydrogen refueling station networks in China based on roadmap. Energy Sustain. Dev. 76, 101265 (2023).

Ziyu, L. & Yan, W. in Resilient and Adaptive Tokyo: Towards Sustainable Urbanization in Perspective of Food-Energy-Water Nexus 231–251 (Springer, 2024).

Suzuki, T. et al. Quantitative risk assessment using a Japanese hydrogen refueling station model. Int. J. Hydrog. Energy 46, 8329–8343 (2021).

Behling, N., Williams, M. C. & Managi, S. Fuel cells and the hydrogen revolution: analysis of a strategic plan in Japan. Economic Anal. Policy 48, 204–221 (2015).

Hara, D. Toward a hydrogen society — introduction of representative projects in Japan. ECS Trans. 91, 3 (2019).

Iida, S. & Sakata, K. Hydrogen technologies and developments in Japan. Clean Energy 3, 105–113 (2019).

Kawatsu, K. et al. Dynamic physical model of Japanese hydrogen refueling stations for quantitative trade-off study between benefit and risk. Int. J. Hydrog. Energy 52, 1208–1219 (2022).

Caponi, R., Ferrario, A. M., Del Zotto, L. & Bocci, E. Hydrogen refueling stations and fuel cell buses four year operational analysis under real-world conditions. Int. J. Hydrog. Energy 48, 20957–20970 (2023).

Speers, P. Hydrogen Mobility Europe (H2ME): vehicle and hydrogen refuelling station deployment results. World Electr. Veh. J. 9, 2 (2018).

Viesi, D., Crema, L. & Testi, M. The Italian hydrogen mobility scenario implementing the European Directive on Alternative Fuels Infrastructure (DAFI 2014/94/EU). Int. J. Hydrog. Energy 42, 27354–27373 (2017).

Kim, J. & Yoo, J. Science and technology policy research in the EU: from framework programme to HORIZON 2020. Soc. Sci. 8, 153 (2019).

Yartys, V. A. et al. HYDRIDE4MOBILITY: an EU HORIZON 2020 project on hydrogen powered fuel cell utility vehicles using metal hydrides in hydrogen storage and refuelling systems. Int. J. Hydrog. Energy 46, 35896–35909 (2021).

Li, Y. & Taghizadeh-Hesary, F. The economic feasibility of green hydrogen and fuel cell electric vehicles for road transport in China. Energy Policy 160, 112703 (2022).

Tsuchiya, H. Innovative renewable energy solutions for hydrogen vehicles. Int. J. Energy Res. 32, 427–435 (2008).

Shao, C. et al. Optimal stochastic operation of integrated electric power and renewable energy with vehicle-based hydrogen energy system. IEEE Trans. Power Syst. 36, 4310–4321 (2021).

Fukushima hydrogen energy research field in Japan ready for green hydrogen production. Fuel Cells Bull. https://doi.org/10.1016/S1464-2859(20)30089-4 (2020).

Shell to start building Europe’s largest renewable hydrogen plant. Shell https://go.nature.com/4kq7GYV (2022).

Long, Y. et al. Pyrolyzed iron–nitrogen–carbon hybrids for efficient contaminant decomposition via periodate activation: active site and degradation mechanism. Sep. Purif. Technol. 317, 123945 (2023).

Hassan, Q. et al. Renewable energy-to-green hydrogen: a review of main resources routes, processes and evaluation. Int. J. Hydrog. Energy 48, 17383–17408 (2023).

Zhang, X. et al. A win-win strategy of wastewater recycling and treatment: synchronous hydrogen production and norfloxacin degradation. Mater. Today Sustain. 22, 100346 (2023).

Liu, H., Yu, M., Tong, X., Wang, Q. & Chen, M. High temperature solid oxide electrolysis for green hydrogen production. Chem. Rev. 124, 10509–10576 (2024).

Odenweller, A., Ueckerdt, F., Nemet, G. F., Jensterle, M. & Luderer, G. Probabilistic feasibility space of scaling up green hydrogen supply. Nat. Energy 7, 854–865 (2022).

Zhao, H. et al. Raw biomass electroreforming coupled to green hydrogen generation. Nat. Commun. 12, 2008 (2021).

Kendall, K. Green hydrogen in the UK: progress and prospects. Clean Technol. 4, 345–355 (2022).

Perez, R. J., Brent, A. C. & Hinkley, J. Assessment of the potential for green hydrogen fuelling of very heavy vehicles in New Zealand. Energies 14, 2636 (2021).

Zheng, W., Zhang, M., Li, Y., Shao, Z. & Wang, X. Optimal dispatch for reversible solid oxide cell-based hydrogen/electric vehicle aggregator via stimuli-responsive charging decision estimation. Int. J. Hydrog. Energy 47, 8502–8513 (2022).

Vechkinzova, E., Steblyakova, L. P., Roslyakova, N. & Omarova, B. Prospects for the development of hydrogen energy: overview of global trends and the Russian market state. Energies 15, 8503 (2022).

Hydrogen Council. Path to hydrogen competitiveness: a cost perspective (Hydrogen Council, 2020).

Hydrogen Council. Hydrogen certification 101 (Hydrogen Council, 2023).

Hydrogen Council. Hydrogen for net zero — a critical cost-competitive energy vector (Hydrogen Council, 2021).

Yang, Z., Li, H. & Zhang, H. Dynamic collaborative pricing for managing refueling demand of hydrogen fuel cell vehicles. IEEE Trans. Transp. Electrif. 10, 10349–10360 (2024).

Zepter, J. M., Engelhardt, J. & Marinelli, M. Optimal expansion of a multi-domain virtual power plant for green hydrogen production to decarbonise seaborne passenger transportation. Sustain. Energy Grids Netw. 36, 101236 (2023).

Robledo, C. B., Oldenbroek, V., Abbruzzese, F. & van Wijk, A. J. Integrating a hydrogen fuel cell electric vehicle with vehicle-to-grid technology, photovoltaic power and a residential building. Appl. Energy 215, 615–629 (2018).

Lin, R.-H., Zhao, Y.-Y. & Wu, B.-D. Toward a hydrogen society: hydrogen and smart grid integration. Int. J. Hydrog. Energy 45, 20164–20175 (2020).

Oladosu, T. L., Pasupuleti, J., Kiong, T. S., Koh, S. P. J. & Yusaf, T. Energy management strategies, control systems, and artificial intelligence-based algorithms development for hydrogen fuel cell-powered vehicles: a review. Int. J. Hydrog. Energy 61, 1380–1404 (2024).

Moura, L. et al. Evaluation of technological development of hydrogen fuel cells based on patent analysis. AIMS Energy 12, 190–213 (2024).

Phan, T. S., Minh, D. P., Espitalier, F., Nzihou, A. & Grouset, D. Hydrogen production from biogas: process optimization using ASPEN Plus®. Int. J. Hydrog. Energy 47, 42027–42039 (2022).

Chu, K. H., Lim, J., Mang, J. S. & Hwang, M.-H. Evaluation of strategic directions for supply and demand of green hydrogen in South Korea. Int. J. Hydrog. Energy 47, 1409–1424 (2022).

Muratori, M., Bush, B., Hunter, C. & Melaina, M. W. Modeling hydrogen refueling infrastructure to support passenger vehicles. Energies 11, 1171 (2018).

Brey, J. J., Brey, R. & Carazo, A. F. Eliciting preferences on the design of hydrogen refueling infrastructure. Int. J. Hydrog. Energy 42, 13382–13388 (2017).

Kobashi, T. et al. in Urban Systems Design 289–333 (Elsevier, 2020).

Dispenza, G., Antonucci, V., Sergi, F., Napoli, G. & Andaloro, L. Development of a multi-purpose infrastructure for sustainable mobility. A case study in a smart cities application. Energy Procedia 143, 39–46 (2017).

Kim, J., Boo, K., Cho, J. & Moon, I. in Advances in Hydrogen Production, Storage and Distribution 3–31 (Elsevier, 2014).

Zhang, C. et al. Flexible grid-based electrolysis hydrogen production for fuel cell vehicles reduces costs and greenhouse gas emissions. Appl. Energy 278, 115651 (2020).

Liu, J., Chen, X., Yang, H. & Shan, K. Hybrid renewable energy applications in zero-energy buildings and communities integrating battery and hydrogen vehicle storage. Appl. Energy 290, 116733 (2021).

Fragiacomo, P. & Piraino, F. Vehicle-to-grid application with hydrogen-based tram. Energy Convers. Manag. 250, 114915 (2021).

İnci, M., Büyük, M. & Özbek, N. S. Sliding mode control for fuel cell supported battery charger in vehicle-to-vehicle interaction. Fuel Cell 22, 212–226 (2022).

İnci, M. & Bayındır, K. Ç. Single-stage vehicular fuel cell system with harmonic elimination capability to suppress distortion effects of electric vehicle parking lots. J. Power Sources 597, 234175 (2024).

Fayaz, H. et al. An overview of hydrogen as a vehicle fuel. Renew. Sustain. Energy Rev. 16, 5511–5528 (2012).

Fayyazi, M. et al. Artificial intelligence/machine learning in energy management systems, control, and optimization of hydrogen fuel cell vehicles. Sustainability 15, 5249 (2023).

Rothuizen, E., Mérida, W., Rokni, M. & Wistoft-Ibsen, M. Optimization of hydrogen vehicle refueling via dynamic simulation. Int. J. Hydrog. Energy 38, 4221–4231 (2013).

Zeng, B. et al. Optimal configuration planning of vehicle sharing station-based electro-hydrogen micro-energy systems for transportation decarbonization. J. Clean Prod. 387, 135906 (2023).

Lin, R., Ye, Z., Guo, Z. & Wu, B. Hydrogen station location optimization based on multiple data sources. Int. J. Hydrog. Energy 45, 10270–10279 (2020).

Ochoa Bique, A., Maia, L. K., Grossmann, I. E. & Zondervan, E. Design of hydrogen supply chains under demand uncertainty — a case study of passenger transport in Germany. Phys. Sci. Rev. 8, 741–762 (2023).

Dyson, R. G. & Shale, E. A. Data envelopment analysis, operational research and uncertainty. J. Oper. Res. Soc. 61, 25–34 (2010).

Lu, M. & Shen, Z. J. M. A review of robust operations management under model uncertainty. Prod. Oper. Manag. 30, 1927–1943 (2021).

Sadeghi, S., Amiri, M. & Mooseloo, F. M. in Data Mining — Concepts and Applications (eds Han, J. et al.) Ch. 8 (2021).

El-Taweel, N. A., Khani, H. & Farag, H. E. Z. Hydrogen storage optimal scheduling for fuel supply and capacity-based demand response program under dynamic hydrogen pricing. IEEE Trans. Smart Grid 10, 4531–4542 (2019).

Guo, H., Gong, D., Zhang, L., Wang, F. & Du, D. Hierarchical game for low-carbon energy and transportation systems under dynamic hydrogen pricing. IEEE Trans. Ind. Inform. 19, 2008–2018 (2022).

Maghami, M. R. et al. Hybrid energy management with respect to a hydrogen energy system and demand response. Int. J. Hydrog. Energy 45, 1499–1509 (2020).

Trapp, C. T., Kanbach, D. K. & Kraus, S. Sector coupling and business models towards sustainability: the case of the hydrogen vehicle industry. Sustain. Technol. Entrep. 1, 100014 (2022).

Zhang, H., Yuan, T. & Tan, J. Business model and planning approach for hydrogen energy systems at three application scenarios. J. Renew. Sustain. Energy 13, 044101 (2021).

Ben-Menachem, M. A business model for hydrogen fuel and hydrogen cars infrastructure. J. Bus. Financ. Aff. 7, 1000313 (2018).

Apostolou, D. & Welcher, S. N. Prospects of the hydrogen-based mobility in the private vehicle market. A social perspective in Denmark. Int. J. Hydrog. Energy 46, 6885–6900 (2021).

Jun, E., Jeong, Y. H. & Chang, S. H. Simulation of the market penetration of hydrogen fuel cell vehicles in Korea. Int. J. Energy Res. 32, 318–327 (2008).

Sartory, M. et al. Modular Concept of a Cost-Effective and Efficient On-site Hydrogen Production Solution. Report No. 0148-7191 (SAE, 2017).

Debe, M. K., Schmoeckel, A. K., Vernstrom, G. D. & Atanasoski, R. High voltage stability of nanostructured thin film catalysts for PEM fuel cells. J. Power Sources 161, 1002–1011 (2006).

Zhuang, Z. et al. Three-dimensional open nano-netcage electrocatalysts for efficient pH-universal overall water splitting. Nat. Commun. 10, 4875 (2019).

Ott, S. et al. Ionomer distribution control in porous carbon-supported catalyst layers for high-power and low Pt-loaded proton exchange membrane fuel cells. Nat. Mater. 19, 77–85 (2020).

Isaac, N. & Saha, A. Analysis of refueling behavior of hydrogen fuel vehicles through a stochastic model using Markov chain process. Renew. Sustain. Energy Rev. 141, 110761 (2021).

AlHumaidan, F. S., Halabi, M. A., Rana, M. S. & Vinoba, M. Blue hydrogen: current status and future technologies. Energy Convers. Manag. 283, 116840 (2023).

Cho, S., Noh, W. & Lee, I. Hybrid systems design for blue and green hydrogen co-production: integration of autothermal reforming with solid oxide electrolysis. Energy Convers. Manag. 300, 117969 (2024).

Ahn, S.-Y. et al. From gray to blue hydrogen: trends and forecasts of catalysts and sorbents for unit process. Renew. Sustain. Energy Rev. 186, 113635 (2023).

Patel, G. H., Havukainen, J., Horttanainen, M., Soukka, R. & Tuomaala, M. Climate change performance of hydrogen production based on life cycle assessment. Green Chem. 26, 992–1006 (2024).

Walsh, S. D., Easton, L., Wang, C. & Feitz, A. J. Evaluating the economic potential for geological hydrogen storage in Australia. Earth Sci. Syst. Soc. 3, 10074 (2023).

Ehlig-Economides, C. A. Geologic carbon dioxide sequestration methods, opportunities, and impacts. Curr. Opin. Chem. Eng. 42, 100957 (2023).

Deng, W., Xie, X., Guo, Y. & Hu, G. Breakthroughs in CH4 capture technologies: key to reducing fugitive methane emissions in the energy sector. Carbon Capture Sci. Technol. 13, 100316 (2024).

Massarweh, O., Al-khuzaei, M., Al-Shafi, M., Bicer, Y. & Abushaikha, A. S. Blue hydrogen production from natural gas reservoirs: a review of application and feasibility. J. CO2 Util. 70, 102438 (2023).

Noussan, M., Raimondi, P. P., Scita, R. & Hafner, M. The role of green and blue hydrogen in the energy transition — a technological and geopolitical perspective. Sustainability 13, 298 (2020).

Bauer, C. et al. On the climate impacts of blue hydrogen production. Sustain. Energy Fuels 6, 66–75 (2022).

Khan, M. H. A. et al. A framework for assessing economics of blue hydrogen production from steam methane reforming using carbon capture storage & utilisation. Int. J. Hydrog. Energy 46, 22685–22706 (2021).

Zapantis, A. Blue hydrogen (Global CCS Institute, 2021).

Svendsmark, E., Straus, J. & del Granado, P. C. Developing hydrogen energy hubs: the role of H2 prices, wind power and infrastructure investments in Northern Norway. Appl. Energy 376, 124130 (2024).

Ji, J., Chi, Y. & Yin, X. The blue treasure of hydrogen energy: a research of offshore wind power industry policy in China. Int. J. Hydrog. Energy 62, 99–108 (2024).

Wu, W., Zhai, H. & Holubnyak, E. Technological evolution of large-scale blue hydrogen production toward the US hydrogen energy earthshot. Nat. Commun. 15, 5684 (2024).

Gurz, M., Baltacioglu, E., Hames, Y. & Kaya, K. The meeting of hydrogen and automotive: a review. Int. J. Hydrog. Energy 42, 23334–23346 (2017).

Poullikkas, A. Sustainable options for electric vehicle technologies. Renew. Sustain. Energy Rev. 41, 1277–1287 (2015).

Zhao, A. P. et al. Electric vehicle charging planning: a complex systems perspective. IEEE Trans. Smart Grid https://doi.org/10.1109/TSG.2024.3446859 (2024).

Bicer, Y. & Dincer, I. Life cycle environmental impact assessments and comparisons of alternative fuels for clean vehicles. Resour. Conserv. Recycl. 132, 141–157 (2018).

Nowotny, J. & Veziroglu, T. N. Impact of hydrogen on the environment. Int. J. Hydrog. Energy 36, 13218–13224 (2011).

Yuan, X., Li, L., Gou, H. & Dong, T. Energy and environmental impact of battery electric vehicle range in China. Appl. Energy 157, 75–84 (2015).

Li, S. et al. Online battery-protective vehicle to grid behavior management. Energy 243, 123083 (2022).

Song, B., Wang, X., Kang, Y. & Li, H. Research on hydrogen leakage diffusion and safety analysis in hydrogen fuel cell vehicles with regard to leakage location and ventilation ports. Int. J. Hydrog. Energy 83, 173–187 (2024).

Levinson, R. S. & West, T. H. Impact of public electric vehicle charging infrastructure. Transp. Res. D Trans. Environ. 64, 158–177 (2018).

Manoharan, P. & Vishnupriyan, J. Designing a comprehensive charging infrastructure for environmentally friendly transportation: a proposal for evaluating viability and uncertainty modeling. Energy Convers. Manag. 322, 119185 (2024).

Zhao, P. et al. A social computing method for energy safety. J. Saf. Sci. Resil. https://doi.org/10.1016/j.jnlssr.2023.12.001 (2024).

Li, S. & Zhao, P. Big data driven vehicle battery management method: a novel cyber-physical system perspective. J. Energy Storage 33, 102064 (2021).

Author information

Authors and Affiliations

Contributions

A.P.Z. researched data for the article. A.P.Z., S.L. and Y.W. contributed substantially to the discussion of the content. A.P.Z., S.L., D.X., Y.W. and Z.L. wrote the article. D.X., Z.L., P.J.-H.H. and Q.Z. reviewed and/or edited the manuscript before submission.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Reviews Electrical Engineering thanks Mustafa İnci and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Related links

Germany’s National Hydrogen Strategy: https://www.bundesregierung.de/breg-en/issues/hydrogen-technology-2204238#:~:Text=What%20is%20the%20National%20Hydrogen,its%20derivatives%20in%20all%20sectors

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, A.P., Li, S., Xie, D. et al. Hydrogen as the nexus of future sustainable transport and energy systems. Nat Rev Electr Eng 2, 447–466 (2025). https://doi.org/10.1038/s44287-025-00178-2

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s44287-025-00178-2

This article is cited by

-

A distributionally robust bilevel optimization model for wholesale–retail electricity market design

Scientific Reports (2026)

-

Optimizing virtual power plant coordination through locational marginal flexibility under network constraints

Scientific Reports (2026)

-

Rethinking hydrogen mobility at a strategic crossroads

npj Sustainable Mobility and Transport (2026)

-

Ranking-oriented machine learning framework for probabilistic wind power forecasting with temporal reliability constraints

Scientific Reports (2025)

-

Federated reinforcement learning with constrained markov decision processes and graph neural networks for fair and grid-constrained coordination of large-scale electric vehicle charging networks

Scientific Reports (2025)