Abstract

Piezoresistive pressure sensors offer high accuracy, high sensitivity, and a compact form factor, making them widely adopted in aerospace applications. However, conventional designs are constrained by sensing materials and structural limitations, hindering pressure monitoring at temperatures exceeding 600 °C. Stable and repeatable pressure measurement over a wide temperature and frequency range remains a significant challenge. In this work, a ceramic-based nitrogen-doped ITO (ITON) piezoresistive pressure sensor is proposed. By utilizing an Al2O3 ceramic structure and ITO material, the issue of operational temperature limitations is effectively addressed, thereby enabling stable sensor output at high temperatures. Results show that the sensitivity of the sensor reaches 236 mV/mA/MPa at 900 °C. The linearity of the sensor is less than 3.74%FS in the range from 25 °C to 900 °C. The frequency response of the sensor exceeds 409 kHz across temperatures spanning 25 °C to 1000 °C, with an ultra-fast response time of 12µs. In addition, the resistance of the sensor chip increased by only 2.4% and 0.8% after being immersed in H2SO4 and NaOH solutions for 70 hours, respectively. Thus, the developed sensor demonstrates significant potential for pressure measurement in high-temperature and wide frequency domain environments.

Similar content being viewed by others

Introduction

With the advancement of the aerospace field1,2,3, higher requirements have been placed on the real-time, in-situ acquisition of pressure parameters for key components operating in harsh environments, including high-temperature and high-pressure conditions. For instance, aero-engine turbine blades are exposed to extreme operating conditions, including ultra-high temperatures, high Mach-number airflow impacts, and severe oxidative ablation, which may result in blade deformation. Furthermore, the maintenance of turbine blades is both very difficult and expensive4,5. Therefore, the accurate measurement of pressure parameters in high-temperature and high-pressure environments is essential for the structural design and safe operation of critical components. The stability and selectivity of pressure sensors are determined by the physical, electrical, and mechanical properties of the sensing materials utilized in sensor fabrication6. Pressure sensors that have been widely utilized include piezoresistive, capacitive, piezoelectric, and optical types7,8,9,10,11,12. Among these, capacitive pressure sensors typically demonstrate relatively low temperature dependence, high sensitivity, and high resolution. However, their outputs exhibit nonlinearities, and the presence of parasitic and distributed capacitances adversely affects both sensitivity and measurement accuracy. Addressing these issues requires compensation circuits for nonlinear correction, which presents significant challenges in high-temperature environments13,14,15. Optical pressure sensors offer superior operational stability in extreme environments, owing to the use of optical fibers as the sensing medium16. However, their operating range is relatively limited, and the demodulation of temperature-pressure parameters at high temperatures is challenging17,18,19. Piezoelectric pressure sensors are passive sensing devices that exhibit a high signal-to-noise ratio, a simple structural design, and excellent sensitivity20,21. However, material selection and preparation are challenging, and these sensors are not suitable for low-frequency or quasi-static pressure measurements. Its operating temperature is constrained by the Curie temperature, and the material is prone to depolarization at elevated temperatures, which can lead to sensor performance degradation or even failure22. In contrast, piezoresistive pressure sensors are characterized by a relatively simple structure, ease of miniaturization, large output signals, high accuracy, rapid frequency response, good reproducibility, excellent linearity, and an extensive operating temperature range23,24,25,26,27. These advantages render them highly suitable for the detection of pressure parameters under harsh conditions.

Typical piezoresistive pressure sensors are fabricated using silicon (Si) materials28,29,30,31. Commercially available silicon pressure sensors are mature, compact, and exhibit excellent performance within the 100 °C temperature range. However, when the operating temperature exceeds 120 °C, leakage currents may occur at internal P-N junctions, leading to performance degradation. Moreover, silicon undergoes plastic deformation at temperatures between 500 °C and 600 °C, and is susceptible to oxidation and corrosion, which significantly limits its application in extreme environments32,33. With the development of new high-temperature-resistant materials such as silicon carbide (SiC) and low-temperature co-fired ceramics (LTCC), researchers both domestically and internationally have commenced investigating the feasibility of fabricating high-sensitivity sensors utilizing these materials. Silicon carbide (SiC) is a semiconductor material characterized by a wide bandgap, excellent mechanical properties, chemical stability, and radiation resistance34,35. Since the 1990s, silicon carbide (SiC) materials have been employed in pressure sensor applications. There are three commonly used SiC crystal structures in engineering: 3C-SiC, 4H-SiC, and 6H-SiC. 3C-SiC offers the advantage of high electron mobility, making it suitable for high-frequency devices. However, lattice mismatch between 3C-SiC and silicon substrates affects device performance. 6H-SiC and 4H-SiC exhibit superior performance compared to 3C-SiC, with fewer crystal defects, and have therefore attracted increasing attention. Although SiC holds great promise for sensor applications, its widespread adoption is hindered by complex fabrication processes and high production costs36,37,38. In addition, the high-temperature stability of SiC-based piezoresistive sensors remains limited, with typical operating temperatures not exceeding 600 °C, which restricts their practical use in high-temperature engineering applications.

The operating temperature of a high-temperature sensor is determined by the thermal tolerance of both the sensor structure and the sensing material. Accordingly, this study explores the feasibility of developing high-temperature pressure sensors based on heat-resistant materials. ITO, a ceramic material, possesses advantages such as high-temperature resistance, oxidation resistance, and a high gauge factor. It is frequently utilized in environments with temperatures exceeding 1000 °C and does not experience any phase transitions during the heating process. Gregory et al39. fabricated ITO thin-film strain gauges on Al₂O₃ substrates by magnetron sputtering. Tests showed that the resulting strain gauges could operate at temperatures up to 1400 °C, with a gauge factor of 4.2 and a resistance drift rate of 0.203/h. Luo et al40. fabricated ITO thin-film strain gauges on aluminum nitride and alumina ceramic substrates using magnetron sputtering. At 1200 °C, the maximum gauge factor of the ITO-based thin film reached 20.9. Yang et al. fabricated ITO strain gauges by sputtering in a mixed oxygen-argon atmosphere, followed by annealing the films in a nitrogen environment. The study demonstrated that thermal treatment significantly improved the piezoresistive stability of the ITO films at 1200 °C41,42. In our previous study, we showed the effect of different nitrogen partial pressures on the temperature coefficient of resistance (TCR) of ITO films within the range from 500 °C to 1200 °C. The test showed that the TCR stability was effectively improved at 20% nitrogen partial pressure43,44. Therefore, the excellent high-temperature performance of ITO materials is of great significance for the application of pressure sensors in high-temperature environments.

This study proposes a pressure sensor based on ITON thin films. First, the piezoresistive effect of the ITON film was investigated over a wide temperature range. The transverse and longitudinal piezoresistive coefficients were measured using an equal-strain beam structure, and the dynamic frequency response characteristics of the ITON films were analyzed. Subsequently, the optimal dimensional parameters of the sensor chip were determined through a combination of theoretical calculations and simulation modeling. The sensor chips were then batch-fabricated using MEMS technology. Finally, the pressure sensor was packaged, and its output performance was evaluated across a temperature range from 25 °C to 900 °C, exhibiting high output sensitivity and excellent linearity. In addition, experiments confirmed the sensor’s wide-frequency response capability and rapid response characteristics within the temperature range from 25 °C to 1000 °C, as well as its survivability in harsh environments, including strong acids and alkalis. The proposed pressure sensor is capable of meeting the requirements for pressure measurement of high-temperature components across wide temperature and frequency ranges.

Structure Design

Piezoresistive property analysis of ITON

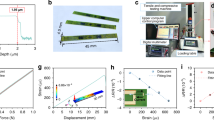

The piezoresistive structure is a key factor in the fabrication of high-temperature pressure sensor chips. Therefore, to design a MEMS pressure sensor chip using ITON as the sensing material, it is essential to study the piezoresistive properties of ITON. As an n-type semiconductor, ITON exhibits a change in resistivity when subjected to pressure loading, which consequently alters its resistance. Crucially, the extent of this strain-induced resistivity change directly determines the magnitude of the sensor’s gauge facto (GF)39,40. To investigate the piezoresistive properties of the ITON thin film, as shown in Fig. 1a, the film was deposited on the surface of an alumina ceramic equal-strength beam. The bending technique of the equal-strength beam was employed43,44, where one end of the sample was fixed while a specified displacement was applied to the other end. The bending of the beam induced changes in the measured resistance, from which the GF was calculated. To ensure maximum sensor sensitivity, three different sizes of ITO piezoresistors (800 × 20 μm, 800 × 30 μm, and 800 × 40 μm) were designed to investigate the piezoresistive effect. As shown in Fig. 1a, the ITO piezoresistors were positioned within the constant-strain region of the equal-strength beam. To further calculate the GF of ITO, a piezoresistive model based on an equal-strength beam was established using the multiphysics simulation software COMSOL Multiphysics to analyze the piezoresistive behavior of ITO. In the simulation, the distribution of ITO piezoresistors was consistent with that in the experimental samples, and the same loading and boundary conditions were applied to the cantilever structure. Finally, the strain in the piezoresistor is extracted and plotted in Fig. 1b. When the voltage V and strain ε are parallel, the longitudinal gauge factor (GFl) is used to characterize the resistance variation of the ITO. When V and ε are perpendicular, the transverse gauge factor (GFt) is used instead. The analysis and calculation of GFl and GFt are critical for sensor chip design and are essential for the development of ITO-based piezoresistive pressure sensors. As illustrated in Fig. 1b, the simulation results indicate that when the length of the ITO piezoresistor remains constant, increasing its width leads to a decrease in the GF. However, considering the limitations of standard photolithographic fabrication processes, excessively narrow resistor widths may introduce large resistance deviations due to process variation, resulting in greater bridge offset. Conversely, overly wide resistor designs require longer lengths to achieve the same resistance value, which can negatively affect the uniformity of the piezoresistors45,46,47. In consideration of fabrication feasibility, a piezoresistor width of 30μm was determined. Subsequently, ITON piezoresistors were deposited on the surface of the equal-strength beam using magnetron sputtering (JCP600, Technol, Beijing), and the beam was tested accordingly. For ITO thin film deposition, 20% nitrogen gas was passed in and the power was set to 200 W. The introduction of nitrogen during the deposition of ITO films can stabilize the concentration of oxygen vacancies, improve the stability of carrier concentration, and result in the most stable chemical composition and microstructure at high temperatures, thereby enhancing the high-temperature stability of the ITO films43,44. The measured results, shown in Fig. 1c, indicate that the GFl is 1.42, and GFt is 0.96.

ITON piezoresistive effect test. a Schematic diagram of the equal strain beam test principle, b GF curves of ITO with different line widths, c GF curves of ITON with 30 µm line widths, d–h Frequency response curves of ITON resistors at 25 °C, 200 °C, 500 °C, 800 °C, and 1000 °C, respectively, i Response time curve of ITON resistor

The dynamic performance of the ITON sensing material determines the frequency response characteristics of the pressure sensor. High-frequency pressure sensors offer excellent response speed, wide bandwidth, and high sensitivity, enabling the detection of rapid pressure fluctuations, making them critical devices for pressure measurement in highly dynamic environments. The ITON piezoresistive samples shown in Fig. 1a were subjected to dynamic testing using an impact method48,49,50. During testing, the samples were placed in a high-temperature furnace, with the temperature set to room temperature, 200 °C, 500 °C, 800 °C, and 1000 °C, respectively. An 6 mm diameter ball was released from a fixed height to freely fall and impact the equal-strength beam. A source meter (IT2805, ITECH, China) was used to provide a constant current excitation, while the output signal was recorded using a digital multimeter (DMM6500, KEITHLEY, China). The collected data were processed using the Fast Fourier Transform (FFT) method. As shown in Fig. 1d-h, the frequency response of the ITON piezoresistors exceeded 409 kHz in all cases. The response time was determined by measuring the time required for the output voltage of the ITON piezoresistor to reach 63% of its steady-state value, as illustrated in Fig. 1i. The piezoresistor achieved 63% of its final output within 169 µs, demonstrating its rapid response capability. Therefore, the use of ITON as a piezoresistive material provides a feasible approach for the development of wide-bandwidth pressure sensors.

Pressure chip structure design and principle

As the sensing element in the pressure sensor chip, the ITON piezoresistor exhibits resistance changes due to the piezoresistive effect when the applied pressure on the chip varies. These resistance changes are positively correlated with the magnitude of the applied pressure. The ITON-based pressure sensing chip adopts the principle of a Wheatstone bridge, in which four ITON piezoresistors are connected via metal electrodes to form the bridge circuit. Variations in resistance caused by pressure are thereby converted into output voltage signals. The design parameters of the pressure sensor chip include the material, dimensions, and geometry of the elastic diaphragm, as well as the size, shape, and placement of the ITON piezoresistors. Therefore, it is critical to establish the relationship between the strain distribution on the diaphragm and the applied pressure. The elastic diaphragm is selected from alumina ceramic sheet with similar coefficient of thermal expansion (CTE) to ITO (Al2O3:7.8 × 10-6/ °C, ITO:5 × 10-6/ °C) to further reduce the effect of thermal stress caused by different CTE. The pressure chip is set to be circular, due to the more uniform stress distribution and lower stress concentration of the circular diaphragm51. To achieve maximum deflection of the pressure chip while ensuring structural reliability, the maximum stress on the diaphragm must remain below the material’s fracture strength, and the pressure-bearing capacity of the diaphragm must exceed the upper limit of the sensor’s intended pressure range. According to the small deflection theory of circular plates, when the edge of the elastic diaphragm is clamped and a uniform pressure is applied to its surface, the deflection equation of the diaphragm can be derived as follows52:

Where W is the bending deflection of the sheet; D is the elastic stiffness of the diaphragm, P is the pressure acting on the diaphragm, R is the radius of the diaphragm, r is the distance of the points on the diaphragm to the axis, E is the Young’s modulus of the Al2O3, h is the thickness of the diaphragm, v is the Poisson’s ratio of the Al2O3. To ensure linear output performance of the sensor, the maximum deflection of the elastic diaphragm under full-scale pressure (\({W}_{\max }\)) must be less than one-fifth of the diaphragm thickness(H), so that the diaphragm undergoes pure bending without membrane stretching. To meet overload protection requirements, the maximum equivalent stress on the diaphragm surface (\({\sigma }_{\max }\)) should be less than half of the material’s yield strength (\({\sigma }_{m}\)). Taking these constraints into account, the diaphragm design is formulated as follows52:

Based on the aforementioned calculation results and fabrication feasibility, the diaphragm of the sensor was designed with a radius of 4.5 mm and a thickness of 0.25 mm. The overall dimensions of the sensor chip are 10 × 10 × 0.25 mm. As shown in Fig. 2a, R1–R4 represent the ITON piezoresistors. To achieve maximum sensitivity, the piezoresistors were positioned in the regions of maximum strain on the elastic diaphragm. A finite element simulation model was developed using COMSOL Multiphysics to analyze the elastic diaphragm. First, a simulation model of the sensor’s sensing element was constructed. The material properties of alumina were defined, and the underside of the diaphragm’s supporting region was fixed. A uniformly distributed pressure load of 1 MPa was applied to the top surface of the diaphragm for simulation. The results are shown in Fig. 2b. It was observed that stress was concentrated along the edge and center of the circular diaphragm. The stress distribution along the line connecting the center points of opposing edges is illustrated in Fig. 2c. The simulation results indicate that the maximum full-scale deflection of the diaphragm is 14.9 μm, which is less than one-fifth of the diaphragm thickness, thereby satisfying the linear output requirement of the sensing element. The maximum positive strain was 340 με at the diaphragm center, while the maximum negative strain was −675 με at the diaphragm edge. Therefore, piezoresistors R1–R4 were placed in the high-strain regions at the center and edge of the diaphragm. To facilitate the measurement of individual resistor values, four ITON piezoresistors were connected into a semi-open Wheatstone bridge using platinum (Pt) metal electrodes, as illustrated in Fig. 2a, d. To accurately design the sensing grid of the pressure sensor chip, the sensitivity of chips with different sensitive grid widths (20, 30, and 40 μm) was analyze. The pressure chip model is shown in Fig. 2e, and the simulation results are presented in Fig. 2f, g. The simulation results are consistent with the previously obtained piezoresistive performance simulations of ITO. When a uniformly distributed pressure of 1 MPa is applied to the chip surface, the output sensitivity of the chip decreases as the line width of the ITO sensitive grid increases. The chip with a sensing grid width of 30 μm exhibits a linear relationship between output voltage and applied pressure. Under uniform pressure loading, the resistance of R1 and R3 increases, while that of R2 and R4 decreases, resulting in an output voltage from the Wheatstone bridge that varies proportionally with the applied pressure. Ideally, when the applied pressure P = 0, the four piezoresistors have identical resistance values, the bridge is balanced, and the output voltage is 0 V. When pressure is applied to the diaphragm surface, the resistance values of the piezoresistors change. Assuming all four resistors experience the same amount of change, the bridge output voltage is proportional to the resistance change and the constant current supplied by the excitation source. Therefore, the sensor output depends on both the magnitude and precision of the constant current source. The bridge output is independent of temperature and the Wheatstone bridge somewhat eliminates the effect of temperature on the sensor output53. As the output of the Wheatstone bridge is inherently independent of temperature, the bridge structure effectively reduces the influence of temperature variations on the sensor output53. Considering that the excitation current may cause self-heating effects in the ITON pressure sensor bridge and connecting wires, it is noted that the resistance of the employed Pt wire is much lower than that of the bridge arms, accounting for only 0.4% of the bridge arm resistance. In addition, as shown in Figure S1 of the supplementary information, a constant current of 1 mA was continuously applied to the ITON chip at room temperature using a current source, and the surface temperature of the ITON chip was measured with an infrared thermometer (YT50AS, Yutu, China). The temperature variation was only 2 °C. Therefore, compared to the sensor’s operating temperature range (25–900 °C), the self-heating effect caused by the wire and bridge resistances can be considered negligible. When powered by a constant current source I0, the output voltage Uout of the Wheatstone bridge is given by:

Pressure chip simulation analysis. a Model diagram of pressure chip, b Stress cloud of pressure chip, c Stress distribution curve of pressure chip, d Schematic diagram of pressure chip, e Sensitivity simulation model of pressure chip, f Pressure chip sensitivity for different sensitive gate widths, g Pressure chip output with 30 µm sensitive gate width

Sensor chip preparation and characterisation

The pressure sensing chip was fabricated using standard MEMS processes and consists of two main components: an ITON sensitive layer and Pt electrodes. The fabrication process is illustrated in Fig. 3a. Fabrication of ITON piezoresistors: (1) As shown in Fig. 3b, a 3 inch diameter, 0.25 mm thick Al2O3 substrate was used as the base material. The substrate was sequentially ultrasonically cleaned in acetone, anhydrous ethanol, and deionized water for 15 minutes to remove organic contaminants from the surface, and then dried on a hot plate. (2) As shown in Fig. 3c, a 10 μm thick AZ50XT positive photoresist was spin-coated onto the substrate using a spin coater. The coated substrate was then baked on a hot plate for hardening. (3) As shown in Fig. 3d, the ITON piezoresistor mask plate was covered on the substrate and exposed using a SUSS MA/BA6 lithography machine with a mercury lamp UV light to uniformly irradiate the AZ50XT photoresist film. (4) After exposure, as shown in Fig. 3e, the substrate was immediately immersed in a developer solution composed of AZ400k and deionized water in a 1:3 ratio to develop the exposed pattern. (5) ITON piezoresistors were then deposited using a magnetron sputtering process, yielding a film thickness of approximately 3 μm, as shown in Fig. 3f. (6) Following sputtering, the substrate was soaked in acetone to lift off the unwanted material and release the patterned piezoresistors. It was subsequently cleaned with anhydrous ethanol and deionized water to obtain the final ITON structures consistent with the mask pattern. The completed samples were then annealed in a muffle furnace at 1000 °C for 2 h. The resulting ITON piezoresistor structure is shown in Fig. 3g. Fabrication of Pt electrodes: The above process steps were repeated for substrate cleaning. A 3 μm-thick BP212 positive photoresist was spin-coated onto the alumina substrate, followed by hot plate baking for hardening. The Pt electrode mask was aligned and placed on the substrate, and the photoresist was exposed using the same mask aligner with UV illumination from a mercury lamp. After exposure, the substrate was developed in a 0.5% NaOH solution. Then, Pt metal electrodes were prepared by magnetron sputtering process with a thickness of about 1 μm. Following sputtering, the substrate was soaked in acetone to lift off excess material and release the electrode pattern, followed by cleaning in anhydrous ethanol and deionized water to obtain a Pt electrode structure matching the mask design. Finally, the samples were annealed in a muffle furnace at 600 °C for 30 min. The fabricated sensor chip array was observed under a microscope, as shown in Fig. 3h. The ITON piezoresistors had a uniform line width of 30 μm, with smooth edges and intact patterns.

The sensor chip array was diced into individual chips using a dicing machine, as shown in Fig. 4a. The surface morphology of the fabricated thin films was observed using a scanning electron microscope (SEM, SU8220, Japan), as shown in Fig. 4b–e. The results indicate that both the ITON sensitive films and Pt electrode lines exhibit uniform line widths. The film surfaces are dense and free from pores and cracks. X-ray diffraction (XRD, SmartLab 9, Japan) was used to analyze the crystalline phases of the Pt and ITON thin films, and the results are presented in Fig. 4f. Within the diffraction angle range of 20 °–65 °, a distinct (111) orientation of Pt crystals is observed. The ITO film is polycrystalline, with crystal orientations corresponding to (211), (222), (400), (431), (440), and (622). All five characteristic peaks of the ITON film match those in the ICDD database entry In₂O₃ No.06-0416, indicating that the films are fully crystallized54. The current–voltage (I–V) characteristics between contact pads were measured using a semiconductor parameter analyzer. As shown in Fig. 4g, the I–V curve of the corresponding resistance between the pads confirms that good ohmic contact was formed between the Pt electrodes and the ITON films.

Sensor Testing Device

The packaging quality of the pressure sensing chip has a direct impact on the stability of the sensor’s performance. To enable in-situ pressure measurement under high-temperature environments, a flip-chip flush-mount packaging structure was designed, as shown in Fig. 5a. This packaging method effectively protects and isolates the sensing elements from harsh environmental conditions. The sensor housing is made of die-cast alumina ceramic columns, which are capable of withstanding test temperatures up to 1500 °C while minimizing the thermal stress exerted on the pressure chip. The pressure chip is mounted upside down on the alumina ceramic base, with its central sensing region aligned with a circular groove to form a sealed deformable cavity. High-temperature Pt wires are used as leads, which pass through the lead holes to contact the Pt electrodes on the pressure chip and are bonded using high-temperature Pt paste, ensuring reliable electrical connectivity. A high-temperature glass frit is employed to seal both the pressure chip and the lead holes. The CTE of the glass frit is close to that of alumina, which helps reduce the effects of thermal mismatch. Finally, the glass-filled pressure sensor assembly is placed in a high-temperature furnace for sintering, completing the packaging process.

To verify the high-temperature performance of the ITON high-temperature pressure sensor, it is necessary not only to ensure the reliability of the pressure sensing chip but also to establish a static calibration platform. The platform must withstand a wide range of pressure loads, and all materials and equipment used in testing must be capable of withstanding high-temperature conditions (>600 °C). To address this challenge, a high-temperature pressure testing system, as shown in Fig. 5b, was established, featuring a pressure range of 0–3.5 MPa and a temperature range of 25 °C–1600 °C. The testing system consists of a pressure gauge (ALKC400, AILEIKE, China), an air compressor, stainless steel sealing tube, a high-temperature furnace, a source meter (IT2805, ITECH, China), and a digital multimeter (DMM6500, KEITHLEY, China). During testing, the packaged pressure sensor is placed inside stainless steel tube sleeve, with the lead wires drawn out and sealed to create an enclosed pressure environment, as shown in Fig. 5c. The system is then connected to the pressure controller via a pressure guide tube to form a pressure circulation pathway. Pressure load is applied to the ITON thin-film pressure sensor through the pressure controller. The stainless steel sleeve is placed inside the high-temperature furnace to provide the elevated temperature environment. The voltage signal output from the sensor chip is collected using the digital multimeter, and the Wheatstone bridge of the sensor is powered by the source meter with a constant current of 1 mA.

Results and Discussion

Temperature effects of pressure chips

The resistive temperature effect refers to the change in semiconductor resistance with temperature, which is quantitatively evaluated using the Temperature Coefficient of Resistance (TCR). Therefore, by measuring the resistance of the material at elevated temperatures, the relationship between the resistance variation of the ITON pressure sensing chip and temperature was determined. To investigate the effect of temperature on the pressure sensing chip, Fig. 6a shows the resistance variations of the chip under different temperatures. As illustrated in the inset, the chip electrodes are numbered from 1 to 4. In the closed-loop Wheatstone bridge configuration, there are six resistances between these metal electrodes, namely R12, R13, R14, R23, R24, and R34. The variations of the six resistance values with temperature were recorded. The results show that, within the temperature range from 25 °C to 1000 °C, all resistances exhibit a consistent trend, with inflection points observed around 600 °C and 800 °C. The resistance-temperature curves are therefore divided into three stages for analysis43,44. In the first stage, all resistances exhibit a negative TCR. This indicates that, within this temperature range, the rate of electron release from Sn⁴⁺ into the conduction band increases with temperature, and the number of electrons thermally excited from oxygen vacancies also rises. As a result, the film’s resistance decreases with increasing temperature. In the second stage, a positive TCR is observed with increasing temperature. This suggests, on the one hand, that the ITON film undergoes further crystallization, leading to larger grain sizes. On the other hand, more oxygen from the ambient atmosphere diffuses into the film at elevated temperatures, causing a sharp increase in the resistance of the ITON film. In the third stage, the resistance once again exhibits a negative TCR. This behavior is similar to that in the first stage and reflects the intrinsic nature of n-type semiconductors under high temperatures. The nonlinear resistance variation reveals the microscopic changes in the ITON semiconductor at high temperatures, which may result in variations in the sensor’s output sensitivity. For sensor performance evaluation, the Temperature Coefficient of Resistance (TCR) is defined as:

The TCR reflects the trend and magnitude of resistance variation with temperature. According to the series-parallel configuration of the Wheatstone bridge, the resistance values of R13 and R24 theoretically equal to the values of individual pressure-sensitive bridge arms. As shown in Fig. 6b, all resistances of the pressure sensing chip exhibit negative TCR values, with variation trends consistent with those in Fig. 6a. The maximum negative TCR occurs at 600 °C, reaching approximately -938.53 ppm/ °C. At 1000 °C, the average TCR is -644.32 ppm/ °C. Notably, R13 and R24 show high consistency, with a maximum difference of only 4.88 ppm/ °C. This indicates that the ITON resistors fabricated via MEMS processes have excellent consistency, which effectively enhances the stability of the pressure sensor under high-temperature conditions. When operating in extreme environments, pressure sensors face not only high-temperature challenges but also corrosive atmospheres containing acidic or alkaline gases, which can react with water to create harsh chemical environments. To evaluate the sensor’s resistance to such corrosive conditions, the pressure sensor chip was immersed in H₂SO₄ and NaOH solutions for 70 h, respectively, and the changes in resistance were recorded, as shown in Fig. 7c, d. The results indicate varying degrees of resistance change with increasing immersion time. After 60 h, the resistance value increased by 2.4% in the H₂SO₄ solution and by 0.8% in the NaOH solution. These results demonstrate that the chip exhibits high tolerance to corrosive environments. Overall, these experimental results verify that the ITON-based pressure sensor is capable not only of measuring pressure in high-temperature conditions but also of withstanding corrosive environments.

Pressure sensor chip output characteristics

Repeatable and stable output is critical for pressure sensor performance evaluation. With conventional pressure sensors, it is rare to make multiple repeatable measurements above 300 °C. In order to verify the output performance of the pressure sensor, ITON high temperature pressure sensors were tested for repeatability over a wide temperature range. The results can prove the repeatability of the ITON pressure sensor at high temperatures. Experimental investigations were carried out to examine the sensor’s static pressure output within the range of 0.1–0.6 MPa at ten key temperature points between 25 °C and 900 °C (25 °C, 100 °C, 200 °C, 300 °C, 400 °C, 500 °C, 600 °C, 700 °C, 800 °C, and 900 °C). At each temperature point, the sensor was held at a constant temperature for one hour to allow the output voltage to stabilize before testing. During testing, a source meter was used to provide a constant current input, and a digital multimeter was employed to collect output data. The high-temperature test data of the sensor were recorded accordingly. By calculating the sensor’s output characteristics, the results affirm the practical value of the sensor in engineering applications.

Figure 7a illustrates the full-scale output characteristics of the pressure sensor. During the testing procedure, the sensor was subjected to a full-scale load for a duration of 2 minutes. Subsequently, after unloading, it was maintained under zero load for an additional 2 minutes. At each temperature point, three test cycles were conducted. From the output curves, it can be observed that the sensor exhibits relatively stable sensitivity within the temperature range from 25 °C to 400 °C, with an approximate value of 10 mV/MPa/mA. In the higher temperature range from 500 °C to 900 °C, the sensitivity increases linearly with temperature. At 700 °C, the sensitivity reaches 21.6 mV/MPa/mA, and when the temperature rises to 900 °C, the sensitivity peaks at 236 mV/MPa/mA. Notably, the sensitivity shows significant variation between 800 °C and 900 °C, which may be attributed to agglomeration of the Pt electrodes, resulting in increased output55. As shown in the SEM image of the Pt electrode in Figure S2 of the supplementary information, agglomeration of the Pt electrode film leads to the formation of voids on the film surface. This phenomenon results in increased resistance variation of the Pt electrode. The nonlinear variation in sensitivity is closely related to the intrinsic nonlinearity of the ITO material. In addition to full-scale output characteristics, Fig. 7b presents the sensor’s response during forward loading and reverse unloading. The pressure was increased incrementally in steps of 0.1 MPa, with each step maintained for 1 minute. Three test cycles were conducted at each temperature point. Table 1 summarizes the key performance characteristics of the sensor across the temperature range of 25 °C–900 °C.

The sensor exhibits good repeatability and stability across different temperature points. Within the range of 25 °C–500 °C, the sensor’s linearity remains below 1%FS, and the hysteresis remains below 0.5%FS, and the repeatability remains below 0.4%FS. As shown in Fig. 7a, a noticeable inflection point appears at 600 °C, where the sensor linearity slightly decreases to 1.1%FS. As the temperature continues to rise, the overall sensor output exhibits drift and fluctuations, resulting in progressively poorer linearity, hysteresis and repeatability. At a temperature of 900 °C, the linearity is 3.74%FS, the hysteresis is 2.6%FS, and the repeatability is 3.13%FS. The reasons for this phenomenon are manifold. On one hand, due to manual operation of the pressure controller, the inconsistency in pressure step size and control speed during loading and unloading leads to fluctuations in the sensor output. On the other hand, agglomeration of Pt electrodes reduces the output stability of the pressure-sensing chip55. Additionally, the test apparatus is constructed using metal components, which may experience reduced reliability at elevated temperatures, causing pressure fluctuations during loading and affecting output stability. Dynamic impact testing was carried out on the ITON pressure sensor. The test setup is shown in Fig. S3 of the supplementary information, and the test principle is illustrated in Fig. S4. During testing, the sample was placed inside a high-temperature furnace with temperatures set between 25 °C and 1000 °C. An 6 mm-diameter steel ball was dropped from a fixed height to impact the pressure-sensing chip freely. A source meter provided a constant current excitation, while a digital multimeter recorded the output signal. The collected data were processed using the Fast Fourier Transform (FFT) method. The sensor’s frequency response results, shown in Fig. S5a–k, consistently exceed 409 kHz. The response time of the ITON pressure sensor is shown in Figure S5l. The sensor reaches 63% of its steady-state output within 12µs, highlighting its rapid response capability. Therefore, the ITON pressure sensor demonstrates excellent response speed, wide bandwidth, and high sensitivity, making it a viable solution for pressure measurements in high-temperature and dynamic environments.

A detailed comparison of the performance parameters of our ITON pressure sensor with those of similar sensors reported in the literature is listed in Table.S1. Although extensive research has been conducted on piezoresistive pressure sensors with significant breakthroughs, most of these sensors operate at temperatures below 600 °C. Typical silicon-based pressure sensors have a maximum operating temperature of around 120 °C, beyond which excessive heat can cause leakage currents at internal P-N junctions. Moreover, the fabrication processes of 4H-SiC and 6H-SiC pressure sensors are complex, and prolonged exposure to high temperatures tends to induce lattice defects, which limits their application in extreme environments. Therefore, the ITON pressure sensor developed in this study successfully overcomes the above limitations, enabling repeatable and stable measurements over a wide temperature range from 25 °C to 900 °C, and achieving wide frequency bandwidth and fast response.

Conclusion

In this study, a high-temperature pressure sensor was proposed using ITON as the sensing material. The piezoresistive effect of ITON resistors with three different sizes was investigated over a wide temperature range. The GF of the ITON thin films was measured using an equal-strain beam setup, and COMSOL simulations were conducted to determine the optimal width of the piezoresistor as 30 μm. The dynamic frequency response characteristics of the ITON films were analyzed, showing frequency responses exceeding 409 kHz across the entire temperature range from 25 °C to 1000 °C. The piezoresistor reached 63% of its steady-state output within 169 μs. By integrating theoretical calculations with simulation results, the optimal dimensions of the sensor chip were determined to be 10 × 10 × 0.25 mm. The sensor chips were fabricated in batches using MEMS processes, and SEM images revealed that the surface of the sensitive film was dense and defect-free. Subsequently, the temperature effect on the pressure chip was evaluated, indicating good consistency in the sensing resistors, with a maximum difference in the TCR of 4.88 ppm/ °C. Moreover, the pressure chip exhibited excellent acid/alkali corrosion resistance. After immersion in H₂SO₄ and NaOH solutions for 70 h, the resistance increased by only 2.4% and 0.8%, respectively. Finally, the pressure sensors were packaged and tested over a temperature range from 25 °C to 900 °C, demonstrating high output sensitivity and linearity. The sensor showed a sensitivity of approximately 10 mV/mA/MPa between 25 °C and 400 °C. At 700 °C, the sensitivity increased to 21.6 mV/mA/MPa, and at 900 °C, it reached 236 mV/mA/MPa. The linearity was maintained below 1%FS up to 500 °C and was 3.74%FS at 900 °C. The dynamic response characteristics of the pressure sensor were further analyzed, revealing frequency responses greater than 409 kHz and a response time as fast as 12µs within the temperature range of 25 °C to 1000 °C. These results demonstrate that the proposed ITON pressure sensor enables wide temperature range, broadband, and high-sensitivity pressure measurements up to 1000 °C, offering a feasible solution for accurate pressure monitoring in high-temperature components of aerospace vehicles.

References

H. S. Kahveci, Investigation of a rotor blade with tip cooling subject to a nonuniform temperature profile, J. Turbomach. 143, 071002 (2021).

Liu, H., Sun, J., Lei, S. & Ning, S. In-service aircraft engines turbine blades life prediction based on multi-modal operation and maintenance data. Propuls. Power Res. 10, 360–373 (2021).

Mambro, A., Congiu, F. & Galloni, E. Influence of the snubber on temperature distribution at last stage blade exit of a steam turbine during low volume flow operations. Appl. Therm. Eng. 150, 937–952 (2019).

J. Błachnio, J. Spychała and D. Zasada. Analysis of structural changes in a gas turbine blade as a result of high temperature and stress. Eng. Failure Anal. 127, 105554 (2021).

Kukla, D. et al. A novel method for high temperature fatigue testing of nickel superalloy turbine blades with additional NDT diagnostics. Materials 14, 1392 (2021).

Song, P. et al. Recent progress of miniature MEMS pressure sensors. Micromachines 11, 56 (2020).

Ha, K.-H., Huh, H., Li, Z. & Lu, N. Soft capacitive pressure sensors: trends challenges and perspectives. ACS Nano 16, 3442–3448 (2022).

D. A. Mills, D. Alexander, G. Subhashb and M. Sheplak, Development of a sapphire optical pressure sensor for high-temperature applications Proc. SPIE, vol. 9113 (SPIE, 2014).

Liang, H., Wang, J., Zhang, L., Liu, J. & Wang, S. Review of optical fiber sensors for temperature salinity and pressure sensing and measurement in seawater. Sensors 22, 5363 (2022).

Kumar, S. S. & Pant, B. D. Design principles and considerations for the ‘ideal’ silicon piezoresistive pressure sensor: a focused review. Microsyst. Technol. 20, 1213–1247 (2014).

Phan, H.-P., Dao, D. V., Nakamura, K., Dimitrijev, S. & Nguyen, N.-T. The piezoresistive effect of SiC for MEMS sensors at high temperatures: a review. J. Microelectromech. Syst. 24, 1663–1677 (2015).

Jiang, X., Kim, K., Zhang, S., Johnson, J. & Salazar, G. High-temperature piezoelectric sensing. Sensors 14, 144–169 (2013).

Ren, S. et al. Investigation of strain gauges based on interdigitated Ba0.5Sr0.5TiO3 thin film capacitors. Sens Actuators A Phys. 236, 159–163 (2015).

Do, C. uong & Seshia, A. A. Active Temperature compensation for MEMS capacitive sensor. IEEE Sens J. PP.99, 1–1 (2021).

Shirhatti, V. et al. High-range noise immune supersensitive graphene-electrolyte capacitive strain sensor for biomedical applications. Nanotechnology 30, 47 (2019).

Shao, Z. Q. et al. All-sapphire fiber-optic pressure sensors for extreme harsh environments. Opt. Exp. 30, 3665–3674 (2022).

B. W. A, Y. N. A, X. Q. A, Y. Y. B, and M. D. A, Review of high temperature measurement technology based on sapphire optical fiber. Measurement 184, 109868 (2021).

Zhang et al. Characterization of a fiber Bragg grating in pure-silica-core and Ge-doped-core optical fiber under high-temperature strain, Meas. Sci. Technol. 29, 035102 (2018).

Yang, T., Qiao, X., Rong, Q. & Bao, W. Fiber Bragg gratings inscriptions in multimode fiber using 800 nm femtosecond laser for high-temperature strain measurement. Opt. Laser Technol. 93, 138–142 (2017).

C. Yu et al. High-performance multifunctional piezoresistive/piezoelectric pressure sensor with thermochromic function for wearable monitoring. Chem. Eng. J. 459, 141648 (2023).

S. C. Moulzolf, R. Behanan, R. J. Lad and M. P. da Cunha, Langasite SAW pressure sensor for harsh environments, Proc. IEEE Int. Ultrason. Symp. pp. 1224-1227, (IEEE, 2012).

N.-I. Kim et al. Piezoelectric pressure sensor based on flexible gallium nitride thin film for harsh-environment and high-temperature applications. Sens. Actuators A Phys. 305, 111940 (2020).

Ayerdi, I., Casta no, E., García-Alonso, A. & Gracia, J. High-temperature ceramic pressure sensor. Sens Actuators A Phys. 60, 72–75 (1997).

Wu, C. et al. Ohmic contact characteristics of silicon carbide-based MEMS devices. In Proc. IEEE 16th International Conference on Nano/Micro Engineered and Molecular Systems (NEMS) 334–338 (IEEE, 2021).

Y. Chen, Q. Xu, X. Zhang and M. Kuang. Materials and sensing mechanisms for high-temperature pressure sensors: a review. IEEE Sens. J. 23, 26910–26924 (2023).

Yijie Xia, Pengju Huang, Xinming Lin, et al. The piezoresistive pressure sensors based on ITO nanocrystalline-plant fiber composite. Sci. China Mater. 66, 3922–3930 (2023).

Mala S., Latha H. K. E., Udayakumar A. Design and Fabrication of indium tin oxide based thin film piezoresistive pressure sensor. Exp. Techn. 48, 761–773 (2024).

Li, X. et al. High-temperature piezoresistive pressure sensor based on implantation of oxygen into silicon wafer. Sens Actuators A Phys. 179, 277–282 (2012).

Li, S. et al. A novel SOI pressure sensor for high temperature application. J. Semiconductors 36, 1 (2015).

H.-D. Ngo et al., Liquid-free piezoresistive SOI-based pressure sensor for high temperature measurements up to 400 °C, Proc. IEEE Sensors, pp. 1-4, (IEEE, 2012).

Ngo, H.-D., Ehrmann, O., Schneider-Ramelow, M. & Lang, K.-D. Piezoresistive pressure sensors for applications in harsh environments-A roadmap. Mod. Sens Technol. 29, 231–251 (2018).

Sarro, P. M. Silicon carbide as a new MEMS technology. Sens Actuators A Phys. 82, 210–218 (2000).

Sheeparamatti B. G., Balavalad K. B. Fabrication and characterization of polysilicon-on-insulator (PolySOI) and a-SOI based micro piezoresistive pressure sensor for harsh environment applications. Microsyst. Technol. 25, 1–15 (2019).

R. S. Okojie, R. D. Meredith, C. T. Chang and E. Savrun, High temperature dynamic pressure measurements using silicon carbide pressure sensors, Int. Conf. High Temp. Electron. (HiTEC, 2014).

Liu, J. et al. MgO single crystals MEMS-based fiber-optic Fabry–Pérot pressure sensor for harsh monitoring. IEEE Sens J. 21, 4272–4279 (2021).

A. Ned, A. Kurtz, G. Beheim, F. Masheeb and S. Stefanescu. Improved SiC leadless pressure sensors for high temperature low and high pressure applications. (Kulite, 2004).

Riza, N. A., Ghauri, F. N. & Perez, F. Wireless pressure sensor using laser targeting of silicon carbide. Opt. Eng. 46, 014401 (2007).

Pecholt, B., Gupta, S. & Molian, P. Review of laser microscale processing of silicon carbide. J. Laser Appl 23, 1 (2011).

Gregory, O. J., Luo, Q. & Crisman, E. E. High temperature stability of indium tin oxide thin films[J]. Thin Solid films 406, 286–293 (2002).

Luo Q. Indium tin oxide thin film strain gages for use at elevated temperatures. (University of Rhode Island, 2001).

Yang, S. et al. Effect of heat treatment atmosphere on the piezoresistivity of indium tin oxide ceramic strain sensor. Ceram. Int 45, 17048–17053 (2019).

Yang, S. et al. Effect of nitrogen doping temperature on the resistance stability of ITO thin films. J. Alloy Compd. 778, 90–96 (2019).

Liu, Z. et al. Effect of nitrogen partial pressure on the TCR of magnetron sputtered indium tin oxide thin films at high temperatures. Ceram. Int 48, 12924–12931 (2022).

Z. Liu et al., Effect of nitrogen partial pressure on the piezoresistivity of magnetron sputtered ITO thin films at high temperatures, Appl. Surf. Sci., 2023.

Tan M. Development and calibration of high temperature pressure sensor. DEStech Trans. Comp. Sci. Eng. 10, 3561137 (2017).

Tulaev, A. T. et al. MEMS pressure sensors design, simulation, manufacturing, interface circuits: a review, in. IEEE Sens J. 24, 7395–7405 (2024).

Farhath, M. & Samad, M. F. Design and simulation of a high sensitive stripped-shaped piezoresistive pressure sensor. J. Comput Electron 19, 310–320 (2020).

Abas, Z., Yang, D. H., Kim, H. S., Kwak, M. K. & Kim, J. Characterization of electro-active paper vibration sensor by impact testing and random excitation. Int J. Appl Mech. 07, 1550065 (2015).

Yusaku, F. ujii Optical method for accurate force measurement: dynamic response evaluation of an impact hammer. Opt. Eng. 45, 023002 (2006).

Bruns, T., Kumme, R., Kobusch, M. & Peters, M. From oscillation to impact: the design of a new force calibration device at PTB. Measurement 32, 85–92 (2002).

Wu, C. et al. Exploring the nonlinear piezoresistive effect of 4H-SiC and developing MEMS pressure sensors for extreme environments. Microsyst. Nanoeng. 9, 41 (2023).

Timoshenko, S.; Woinowsky-Krieger, S. Theory of Plates and Shells, 2nd ed. (McGraw-Hill, 1987.

Dalola, S., V. Ferrari, and D. Marioli. A MEMS piezoresistive inclination sensor with a CMOS ASIC front-end interface. Proc. Sensors and Microsystems (AISM, 2010).

Mei, F., Yuan, T. & Li, R. Effects of second-phase particles and elemental distributions of ITO targets on the properties of deposited ITO films. Ceram. Int 43, 8866–8872 (2017).

Wang, H. et al. Stability Enhancement of the Platinum Thin-Film Temperature Detector up to 1400 °C by Printing Al₂O₃ Protective Layer. IEEE Sens J. 24, 17433–17440 (2024).

Acknowledgements

This work was supported in part by the Aviation Science Fund under Grant 20230012063001 and Grant 2019ZD063001, and in part by the Science & Technology Program of Liaoning Province Fund under Grant 2023JH1/10400044.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, H., Xu, R., Wang, B. et al. A ceramic-based ITON piezoresistive pressure sensor with wide temperature range (RT-900 °C) and broad frequency response. Microsyst Nanoeng 11, 251 (2025). https://doi.org/10.1038/s41378-025-01100-4

Received:

Revised:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41378-025-01100-4