Abstract

Fluorinated or fluoroalkylated alcohols are common structural motifs in biologically active molecules, natural products, and pharmaceuticals. However, pentafluorosulfanyl (SF5) alcohols, a unique class of SF5 compounds that serve as synthetically valuable building blocks, are difficult to prepare with current methodologies. In this article, we present a single-step, metal-free, and photo-induced hydroxypentafluorosulfanylation of styrenes or α,β-unsaturated esters/amide, producing a series of structurally diverse pentafluorosulfanyl alcohols with up to 89% yields. This reaction is mild and operationally simple, using molecular oxygen as the hydroxy source. The protocol is suitable for a wide range of alkenes, including natural products and drug molecule derivatives. The formed SF5 alcohol units can be readily converted into diverse functionalized SF5 compounds, such as α-SF5 ketones, SF5 diols, and SF5 cyclic carbonates. The potential applications of these SF5 compounds in pharmaceutical and material sciences are vast, making this research a step forward in the field.

Similar content being viewed by others

Introduction

Recently, the pentafluorosulfanyl (SF5) group1,2,3,4,5,6,7,8, an emerging organic fluorinated functional group, has attracted significant attention in the fields of medicine, pesticides and materials9,10,11,12,13,14,15. Compared with its structurally analogous CF3 group, SF5 group has higher lipophilicity (similar to t-Bu group) and electron-absorbing properties (similar to nitro group)16,17. Therefore, the installation of an SF5 group to an organic molecule significantly affects its physical and chemical properties. Consequently, molecules bearing an SF5 functional group could potentially be excellent pharmaceutical compounds1,4,18. Despite the similarity between SF5 and CF3, there are still a limited number of reactions to introduce SF5 group, in contrast to the well-established chemistry of CF3. For aromatic or heteroaromatic SF5 compounds, the methods include the direct fluorination of aryl disulfides in the presence of an alkali metal fluoride, as well as the chlorine to fluorine exchange of pre-synthesized chlorotetrafluorosulfanyl intermediates using a fluoride source such as AgF, IF5, HgO/HF or PPHF, KHF2, Ag2CO3, AgBF4 etc19,20,21,22,23,24,25,26,27,28,29. In the case of aliphatic SF5 compounds, the predominant strategy involves the addition of SF5Cl or SF5Br to alkenes and alkynes under mild free radical conditions30,31,32,33. However, the synthesis and storage of SF5Cl reagents have long been challenging due to their high reactivity and low boiling point; it wasn’t until 2019 that Togni and Pitts et al. discovered a gas-free method for synthesizing SF5Cl using molecular sulfur, trichloroisocyanuric acid (TCICA), and potassium fluoride (KF)34. Based upon it, the Qing group in 2021 developed a more practical approach to produce an easy-to-handle solution of SF5Cl in n-hexane35. Accordingly, SF5Cl has been emerging as a popular SF5 donor in a variety of radical pentafluorosulfanylation reactions36,37,38,39,40. For instance, Qing’s group reports hydro(chloro)pentafluoro-sulfanylation of diazo compounds35, iodopentafluorosulfanylation of [1.1.1]propellane as well as three-component radical addition reaction of SF5Cl41, alkene and diazo compounds42. Shortly thereafter, they developed a one-step method to synthesize SF5-substituted alkynes from ethynylbenziodoxolones (EBX)43. Pitts et al. synthesized structurally diversified SF5-bicyclopentanes (SF5-BCPs) and SF5-cyclobutanes (SF5-CBs) via a strain-release pentafluorosulfanylated process36,38. Champagne and Paquin et al. discover photoinitiated anti-hydropentafluorosulfanylation of terminal alkynes44. Cahard and co-workers utilized a combination of SF5Cl, KI, and 18-crown-6 ether to produce SF5I and successfully synthesized (E)−1-iodo-2-(pentafluoro-λ6-sulfanyl) alkenes45. Moreover, the direct activation of the highly inert sulfur hexafluoride (SF6) as a pentafluorosulfanylating reagent offers an alternative source of SF5• for photoredox catalysis46,47,48. However, to date, this method has been limited to reactions with styrene derivatives. Concurrently, the synthetic applications and derivatizations of SF5-substituted building blocks facilitate the efficient construction of complex SF5-containing molecules that are otherwise challenging to synthesize49,50,51. Despite these advancements, the formation of Cl radicals during the radical chemistry of SF5Cl with alkenes often leads to the production of chlorinated SF5-products, limiting the development of SF5Cl as a reagent33,42,52,53,54,55,56,57,58,59,60,61. Therefore, developing a more practical and efficient method for synthesizing novel SF5-substituted compounds is highly desirable.

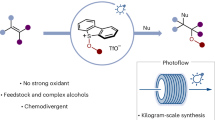

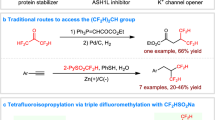

Alkenes are key building blocks in organic chemistry. The radical bifunctionalization of alkenes is an efficient and practical synthetic protocol, enabling the simultaneous introduction of two pivotal functional groups. Fluorinated alkyl radicals, renowned for their robust electrophilic nature, readily engage in radical addition reactions with alkenes. Additionally, the hydroxyl functional group, as a valuable synthetic building block, could be introduced by oxygen gas and enable further diverse functionalizations62,63. To date, such a strategy has been widely utilized in various fluorinated functional groups, including CF364,65,66,67,68,69,70,71,72,73,74,75, CnF2n+176,77,78,79,80,81,82,83,84, CF2H85,86,87,88, F89,90,91,92 and SCF393 (Fig. 1a). However, the single-step method for the simultaneous introduction of SF5 and hydroxyl groups to alkenes has only been reported by the Wagenknecht group47. More commonly, the currently existing methods to synthesize pentafluorosulfanyl alcohols utilize indirect methods via multi-step reactions94, or direct methods but using alcohol-containing starting materials52,59. Nevertheless, current reactions generally lack broad substrate scopes, with only a few reports of pentafluorosulfanyl alcohols. We hypothesize that a direct method where two functional groups could be introduced would have great potential in late-stage drug development, especially in complex and bioactive complex molecules. However, recent synthetic progress has significant limitations. For instance, in an oxidizing environment, alcohols are prone to further oxidation, forming their ketone derivatives66,68. Moreover, other radical additions, such as the chlorohydroxylation95,96 and chloropentafluorosulfanylation33,42,52,53,54,55,56,57,58,59,60,61 of olefins, can occur, leading to uncontrollable and undesired products (Fig. 1b). Herein, through our meticulous design, we present the photo-induced hydroxypentafluorosulfanylation of alkenes using SF5Cl and oxygen gas as the oxidant. Importantly, we demonstrate that these SF5-alcohol scaffolds not only serve as suitable platforms for synthesizing α-SF5-ketones, SF5-diols, SF5-cyclic carbonates, but also hold promise for the development of potential SF5-substituted medicinal drugs (Fig. 1c).

Results

Method optimization

To optimize reaction conditions, α,β-unsaturated ester 1a was chosen as the template alkene substrate to react with SF5Cl. Under optimal conditions, 0.1 M DCM was used as the solvent, and 1a (0.05 mmol) and SF5Cl (0.1 mmol) were exposed to oxygen gas in the presence of 1 equivalent of H2O and 0.2 equivalents of 1-hexene for 4 h at room temperature under 365 nm LEDs light. Product 3a was produced with an 89% isolated yield (Table 1, entry 1). We found that the addition of 1-hexene significantly increased the yield by inhibiting the formation of chlorinated byproducts (entry 2 and vide infra). Additionally, oxygen gas was critical for the transformation; no reaction was detected in its absence (entry 4). When halogenated solvents such as CHCl3 and CCl4 were used for the reaction (entries 5 and 6), diminishing yields were observed. Non-chlorinated solvents, including THF and acetonitrile, also resulted in much lower yields (entries 7 and 8). Additionally, using 427 nm or 390 nm LEDs as the excitation light source led to sluggish reactions and lower yields (entries 9 and 10). Using less than two equivalents of SF5Cl or increasing the reaction concentration resulted in reduced yields (entries 11 and 12).

Substrate scope

With the optimized reaction conditions in hand, we examined the functional group tolerance of olefinic substrates. We were pleased to find that a variety of electron-donating and electron-withdrawing functional groups on the aryl ring were well tolerated in this transformation (3a-3p, Fig. 2). Electron-withdrawing groups such as cyano, ester, trifluoromethoxy, trifluoromethylthio and acetyl were well tolerated, furnishing products 3b-3f in 52–81% yield. Furthermore, trifluoromethyl groups on aryl ring were tolerated under the reaction conditions with positional insignificance (3j-3l). Additionally, the transformation also tolerated electron-neutral and electron-donating groups. Products with phenyl (3g), methyl (3h), and tert-butyl (3i) groups were obtained in 60–83% yield. Substrates with halogen groups on the aromatic rings also performed well, delivering products 3n and 3o in 62% and 60% yields, respectively, which are more conducive to subsequent coupling derivatization. The nitro group (3p) with strong polarity was also well tolerated, yielding 76%. When the ester group is attached to aliphatic groups (3q-3s), the hydroxypentafluorosulfanylation of the alkene achieved yields of 44–76%. It was gratifying to observe that a tertiary alcohol featuring the SF5 motif (3t) could be generated in 77% yield, indicating the potential of our strategy to overcome steric hindrance in substrates. Further exploration revealed that both single substituted (3c) and multiple substituted (3m) substrates are suitable for this transformation, with the desired products obtained in moderate yields. To further demonstrate the synthetic applications of this protocol, we explored the late-stage elaboration of natural product derivatives and pharmaceutical molecules, achieving synthetically useful yields. For example, the amino acid derivative tyrosine methyl ester (3v) was produced in 50% yield. The corresponding product 3w was also obtained in the reaction with the natural androgen estrone. We unequivocally verified the desired hydroxypentafluorosulfanylation product 3x from an acetovanillone-based olefin via X-ray crystallographic analysis. Additionally, the androgen receptor antagonist Ru58841 (3y) participated in the reaction with a yield of 58%. Selected pharmaceutically active compounds, including carvacrol (3z), 4-tert-octylphenol (3aa), and raspberry ketone (3ab), smoothly proceeded to deliver the corresponding products, highlighting the capacity for late-stage modification of complex natural or pharmaceutical molecules. These experimental results further demonstrate the advantages of our strategy in late-stage transformations to derive biologically relevant pentafluorosulfanylated molecules. Due to the lipophilic properties of the SF5 group, these molecules could potentially have unique biological activities in medicinal development, even with the protected alcohol functional groups of bioactive compounds.

We next sought to broaden the substrate scope of the transformation to include styrenes (Fig. 3). To our delight, the target product 4a was obtained in 65% yield when styrene was used. However, when electron-donating groups were attached to the phenyl rings, almost no products were generated under standard conditions. Further investigation indicated that the formation of an electron-donor-acceptor (EDA) complex between the electron-donating group substrates and pentafluorothiochloride resulted in the consumption of the substrate, as evidenced by UV-visible spectroscopy experiments (see Supporting Information Section 2.5.1 for details). We hypothesized that an increased amount of substrate would be necessary for an effective reaction. To our delight, switching the ratio of electron-donating substrates to SF5Cl to 2:1 uneventfully furnished 4b, 4c, and 4h albeit somewhat diminished yields, showcasing the generality of the reaction. We then tested substrates with electron-withdrawing groups. In the case of using a substrate with an ester motif, the reaction occurred smoothly, with the ester remaining intact (4d). Halogen atom (F, Br) substituents on the aryl ring (4g and 4i) had little influence on the reaction efficiency. The effect of substituents at different positions was determined using trifluoromethyl substrates (4f, 4j and 4k). Even in cases with the trifluoromethyl group in the ortho position, the reaction yield was still good (4k). For substrates with multiple halogens, the corresponding products (4l and 4m) were obtained with good yields of 76% and 78%. Unfortunately, further examination of styrene derivatives revealed that based-derived structures, such as pyridine or aniline (See Supporting Information Section 2.3 for details), still remained unsuitable for this reaction.

aCondition A: 1 (0.05 mmol), 2 (0.1 mmol, ~0.3 M in n-hexane), H2O (0.05 mmol), O2 (0.09 mmol), 1-hexene (0.01 mmol), DCM (0.5 mL), 365 nm LEDs, r.t., 4 h, N2 atmosphere, isolated yields; bCondition B: 1 (0.1 mmol), 2 (0.05 mmol), H2O (0.05 mmol), O2 (0.09 mmol), 1-hexene (0.01 mmol), DCM (0.5 mL), 365 nm LEDs, r.t., 4 h, N2 atmosphere, isolated yields.

Further derivatization

The synthetic utility of this approach has also been demonstrated by the transformations of the resulting hydroxypentafluorosulfanylated compounds. First, as described in previous literature, the SF5-substituted ketone is significant35,50,55,97. As shown in Fig. 4, oxidation of pentafluorosulfanyl alcohol 4f using PCC reagent afforded ketone 5 in 85% yield. We can also use NaBH4 to reduce 3h to give the desired diol 6 in 78% yield. The resulting diol product 6 can be further transformed. For example, when reacting with CDI and DMAP, it could be converted to SF5-substituted cyclic carbonate 10 in 92% yield. In addition, the diol product 6 could undergo selective protection of alcohols to give product 11. Gratifyingly, the resulting SF5-substituted α-hydroxy acids (AHAs), as the potential cosmetics, were obtained under the acidity condition. In addition, 3h could be transformed into 8 in the presence of acetyl chloride, which also demonstrated the utility of our method. Treatment of product 3h with aniline afforded acylation product 9 successfully in 78% yield. Moreover, cross-coupling transformations are among the most common and powerful reactions in the synthesis and development of SF5 compounds97,98,99, the bromo-substituted SF5 alcohols 4i could function as a coupling reagent to generate the desired arylation or animation products (12 and 13) through either Suzuki or Buchwald-Hartwig cross-coupling reaction, without any protecting groups on the substrates. Our strategy to develop hydroxypentafluorosulfanyl products would be synthetically valuable and powerful to expand the pharmaceutical drug pools containing the SF5 group.

Reaction conditions: See the Supporting Information Section 2.6 for full experimental details, isolated yields. aYield was determined by 19F NMR spectroscopy using trifluoroacetic acid as the internal standard.

Mechanistic investigations

Control experiments were conducted to gain mechanistic insights into the reaction. Under standard conditions, the reaction was entirely suppressed by 2,2,6,6-tetramethyl-1-piperidinyloxy (TEMPO), and no products were formed, suggesting the involvement of a radical process (Fig. 5a). Subsequently, in the absence of oxygen, the reaction with alkenes, whether acrylic acid ester or styrene, failed to produce the desired product 3a or 4b, instead yielding the chloropentafluorosulfanylated products 14 or 15 (Fig. 5b). Notably, when the chloropentafluorosulfanylated product 15 was directly subjected to the standard conditions, almost no hydroxypentafluorosulfanylated product 4b were obtained, with the starting material largely unreacted. Therefore, formation of chloropentafluorosulfanylated product is not the primary pathway in the overall mechanism (vide infra; Path II). To further clarify the source of hydrogen at the hydroxyl site of the product, control experiments were performed under the standard conditions while using d2-DCM as the reaction solvent and D2O as proton reagents respectively (Fig. 5c, Supporting Information Section 2.5.2). When d2-DCM were used, 3a-d could be obtained in 62% D. By contrast, when D2O was used, only 39% D was observed. This result clearly demonstrated that the proton of H2O and solvent (DCM) were transferred to the product. As shown in Fig. 5d, the unactivated olefin (4-phenyl-1-butene 16) instead of 1-hexene was used to react with two equivalents of SF5Cl, and dichlorinated addition product 17 was successfully obtained as the main product and a few hydroxypentafluorosulfanylated product 18, which demonstrated that aliphatic alkene (1-hexene) used in this experiment was a favorable chlorine radical trapping agent. However, when 4-phenyl-1-butene and an acrylic acid ester were used as substrates, a competition reaction occurred, resulting in a mixture of the corresponding hydroxypentafluorosulfanylated products (3a and 18), also along with the formation of a dichlorinated addition product of 4-phenyl-1-butene. Based on our control experiments and previous studies, we propose the following reaction mechanism (Fig. 5e). The reaction is initiated by the excitation of SF5Cl using a 365 nm UV lamp. The S-Cl bond undergoes homolytic cleavage to form a Cl radical and an SF5 radical, with the Cl radical being trapped by 1-hexene to afford 1,2-dichlorohexane. Of note, the quantum yield studies100 indicate that this is a radical-chain process as evidenced by the calculation (Φ = 11, see Supporting Information Section 2.5.3 for details). Therefore, an alternative pathway involves the trapping of SF5Cl by the C6H13 radical or CHCl2 radical, derived from the solvent (hexane or DCM), leading to the formation of the corresponding aliphatic chlorides, C6H13Cl or CHCl3. These products were confirmed by HRMS (Supporting Information Section 2.5.3 for details) and are consistent with previous literature35. The generated SF5 radicals are added to the olefin substrate 1, resulting in the formation of radical intermediate A (Path I), which is immediately trapped by oxygen gas to generate peroxide radical B. In contrast, Path II, which proposes chloropentafluorosulfanylated product C as the intermediate, is not supported by the control experiments presented in Fig. 5b. When C was employed under standard conditions, the desired product 4 was scarcely obtained. The peroxide radical B is then converted into the desired product via two distinct pathways. In one pathway, the hydrogen is extracted from water or solvent, followed by cleavage of the peroxide bond to yield product 3 or 4. Alternatively, the peroxide radical B undergoes direct radical-radical coupling to produce the dimer D. Subsequent homolysis of dimer D forms radical intermediate E, ultimately affording the desired hydroxypentafluorosulfanylation product 3 or 4.

a Radical capture experiment. b Control experiment of chloropentafluorosulfanylated product. c Deuteration experiment. d Control experiment of aliphatic alkene. e Proposed mechanism. Reaction conditions: 1 (0.05 mmol), 2 (0.1 mmol, ~0.3 M in n-hexane), H2O (0.05 mmol), O2 (0.09 mmol), 1-hexene (0.01 mmol), DCM (0.5 mL), 365 nm LEDs, r.t., 4 h, N2 atmosphere, isolated yields. N. D. denotes not detected.

Discussion

In summary, we have disclosed an efficient and practical methodology for the hydroxypentafluorosulfanylation of olefins, which occurs under mild conditions and has been successfully applied to both styrene and electron-withdrawing alkenes. Using the widely available reagent SF5Cl, this method enables the rapid synthesis of β-pentafluorosulfanyl alcohols. Of note, the reaction substrates are highly universal, rendering them suitable for the synthesis of complex SF5-substituted molecules. Furthermore, the post-functionalization reactions of β-pentafluorosulfanyl alcohols could provide rapid avenues to construct complex molecules containing the SF5 group. We believe that this hydroxypentafluorosulfanylation protocol will provide opportunities for applications in medicinal chemistry.

Methods

In a N2 glovebox, to alkene 1 (0.05 mmol, 1.0 equiv.) was added 1-hexene (0.01 mmol, 0.20 equiv.) in a 10 mL sealed vial tube. Seal the bottle cap and then transfer it out of the glovebox. DCM (0.5 mL, 0.1 M), H2O (0.05 mmol, 1.0 equiv.), O2 (2 mL) and SF5Cl (dissolved in n-hexane, ~0.3 M, 0.1 mmol, 2.0 equiv.) were injected through a syringe into the reaction, and the resulting mixture was stirred for 4 h at room temperature under the 365 nm LEDs. Then, the reaction was diluted with DCM. The filtrate was concentrated in vacuo and the residue was purified by flash column chromatography with developing agent of petroleum ether and ethyl acetate to afford product 3 or 4.

Data availability

Data relating to the characterization data of materials and products, general methods, optimization studies, experimental procedures, mechanistic studies and NMR spectra are available in the Supplementary Information. All data are also available from the corresponding author upon request. Crystallographic data for the structures reported in this Article have been deposited at the Cambridge Crystallographic Data Centre, under deposition numbers 2354865 (3x). This data can be obtained free of charge via www.ccdc.cam.ac.uk/structures/. Source data are provided with this paper.

References

Altomonte, S. & Zanda, M. Synthetic Chemistry and Biological Activity of Pentafluorosulphanyl (SF5) Organic Molecules. J. Fluor. Chem. 143, 57–93 (2012).

Haufe, G. Synthesis and Application of Pentafluorosulfanylation Reagents and Derived Aliphatic SF5-containing Building Blocks. Tetrahedron 109, 132656 (2022).

Kordnezhadian, R. et al. Chemistry of Pentafluorosulfanyl Derivatives and Related Analogs: From Synthesis to Applications. Chem. Eur. J. 28, e202201491 (2022).

Magre, M., Ni, S. & Cornella, J. (Hetero)aryl‐SVI Fluorides: Synthetic Development and Opportunities. Angew. Chem. Int. Ed. 61, e202200904 (2022).

Sani, M. & Zanda, M. Recent Advances in the Synthesis and Medicinal Chemistry of SF5 and SF4Cl Compounds. Synthesis 54, 4184–4209 (2022).

Sheldon, D. J. & Crimmin, M. R. Repurposing of F-gases: Challenges and Opportunities in Fluorine Chemistry. Chem. Soc. Rev. 51, 4977–4995 (2022).

Wagenknecht, H.-A. & Rombach, D. Photochemical Activation of Sulfur Hexafluoride: A Tool for Fluorination and Pentafluorosulfanylation Reactions. Synthesis 54, 4883–4894 (2022).

Zou, Z. et al. Recent Advances in Conversion and Use of Inert Fluorinated Greenhouse Gases. Chinese J. Org. Chem. 44, 1831–1852 (2024).

Welch, J. T. & Lim, D. S. The Synthesis and Biological Activity of Pentafluorosulfanyl Analogs of Fluoxetine, Fenfluramine, and Norfenfluramine. Bioorg. Med. Chem. 15, 6659–6666 (2007).

Stump, B. et al. Pentafluorosulfanyl as a Novel Building Block for Enzyme Inhibitors: Trypanothione Reductase Inhibition and Antiprotozoal Activities of Diarylamines. ChemBioChem 10, 79–83 (2008).

Sowaileh, M. F., Hazlitt, R. A. & Colby, D. A. Application of the Pentafluorosulfanyl Group as a Bioisosteric Replacement. ChemMedChem 12, 1481–1490 (2017).

Meanwell, N. A. Fluorine and Fluorinated Motifs in the Design and Application of Bioisosteres for Drug Design. J. Med. Chem. 61, 5822–5880 (2018).

Lim, D. S., Choi, J. S., Pak, C. S. & Welch, J. T. Synthesis and Herbicidal Activity of a Pentafluorosulfanyl Analog of Trifluralin. J. Pestic. Sci. 32, 255–259 (2007).

Kirsch, P. Fluorine in Liquid Crystal Design for Display Applications. J. Fluor. Chem. 177, 29–36 (2015).

Chan, J. M. W. Pentafluorosulfanyl Group: An Emerging Tool in Optoelectronic Materials. J. Mater. Chem. C. 7, 12822–12834 (2019).

Sheppard, W. A. The Electrical Effect of the Sulfur Pentafluoride Group. J. Am. Chem. Soc. 84, 3072–3076 (1962).

Corwin. Hansch, C. et al. The Correlation of Biological Activity of Plant Growth Regulators and Chloromycetin Derivatives with Hammett Constants and Partition Coefficients. J. Am. Chem. Soc. 85, 2817–2824 (1963).

Savoie, P. R. & Welch, J. T. Preparation and Utility of Organic Pentafluorosulfanyl-Containing Compounds. Chem. Rev. 115, 1130–1190 (2014).

Kanishchev, O. S. & Dolbier, W. R. Jr. Synthesis and Characterization of 2-Pyridylsulfur Pentafluorides. Angew. Chem. Int. Ed. 54, 280–284 (2015).

Kanishchev, O. S., William, R. & Dolbier, J. Generation of ortho-SF5-Benzyne and Its Diels–Alder Reactions with Furans: Synthesis of 1-SF5-Naphthalene, Its Derivatives, and 1,6(1,7)-Bis-SF5-naphthalenes. J. Org. Chem. 81, 11305–11311 (2016).

Kosobokov, M. et al. Importance of a Fluorine Substituent for the Preparation of meta- and para-Pentafluoro-λ6-sulfanyl-Substituted Pyridines. Angew. Chem. Int. Ed. 55, 10781–10785 (2016).

Cui, B., Jia, S., Tokunaga, E., Saito, N. & Shibata, N. Silver-induced Self-immolative Cl–F Exchange Fluorination of Arylsulfur Chlorotetrafluorides: Synthesis of Arylsulfur Pentafluorides. Chem. Commun. 53, 12738–12741 (2017).

Cui, B., Kosobokov, M., Matsuzaki, K., Tokunaga, E. & Shibata, N. IF5 Affects the Final Stage of the Cl–F Exchange Fluorination in the Synthesis of Pentafluoro-λ6-sulfanyl-pyridines, Pyrimidines and Benzenes with Electron-withdrawing Substituents. Chem. Commun. 53, 5997–6000 (2017).

Das, P., Takada, M., Matsuzaki, K., Saitob, N. & Shibata, N. SF5-Pyridylaryl-λ3-iodonium Salts and Their Utility as Electrophilic Reagents to Access SF5-pyridine Derivatives in the Late-stage of Synthesis. Chem. Commun. 53, 3850–3853 (2017).

Pitts, C. R., Bornemann, D., Liebing, P., Santschi, N. & Togni, A. Making the SF5 Group More Accessible: A Gas‐Reagent‐Free Approach to Aryl Tetrafluoro-λ6-sulfanyl Chlorides. Angew. Chem. Int. Ed. 58, 1950–1954 (2019).

Saidalimu, I. et al. Synthesis of Aryl and Heteroaryl Tetrafluoro-λ6-sulfanyl Chlorides from Diaryl Disulfides Using Trichloroisocyanuric Acid and Potassium Fluoride. Org. Chem. Front. 6, 1157–1161 (2019).

Guzyr, O. I. et al. Enhanced Preparation of Aryl and Heteryl Sulfur Pentafluorides Using Mercury (II) Oxide - hydrogen Fluoride Media as a Fluorinating Reagent. J. Fluor. Chem. 239, 109635 (2020).

Tanagawa, K., Zhao, Z., Saito, N. & Shibata, N. AgBF4-Mediated Chlorine-Fluorine Exchange Fluorination for the Synthesis of Pentafluorosulfanyl (Hetero)arenes. Bull. Chem. Soc. Jpn. 94, 1682–1684 (2021).

Wang, L., Ni, S. & Cornella, J. Validation of Arylphosphorothiolates as Convergent Substrates for Ar-SF4Cl and Ar-SF5 Synthesis. Synthesis 53, 4308–4312 (2021).

Roberts, H. L. & Ray, N. H. Sulphur Chloride Pentafluoride: Preparation and Some Properties. J. Chem. Soc., 665–667 (1960).

Sheppard, W. A. Arylsulfur Trifluorides Andpentafluorides. J. Am. Chem. Soc. 82, 4751–4752 (1960).

Case, J. R., Ray, N. H. & Roberts, H. L. Sulphur Chloride Pentafluoride: Reaction with Unsaturated Hydrocarbons. J. Chem. Soc. 2066–2070 (1961).

Aϊt-Mohand, S., William, R. & Dolbier, J. New and Convenient Method for Incorporation of Pentafluorosulfanyl (SF5) Substituents Into Aliphatic Organic Compounds. Org. Lett. 4, 3013–3015 (2002).

Pitts, C. R. S., Nico; Togni, Antonio. Method for preparing polyfluorinated compound. WO2019229103 (2019).

Shou, J. Y., Xu, X. H. & Qing, F. L. Chemoselective Hydro(Chloro)pentafluorosulfanylation of Diazo Compounds with Pentafluorosulfanyl Chloride. Angew. Chem. Int. Ed. 60, 15271–15275 (2021).

Kraemer, Y. et al. Strain‐Release Pentafluorosulfanylation and Tetrafluoro(aryl)sulfanylation of [1.1.1]Propellane: Reactivity and Structural Insight. Angew. Chem. Int. Ed. 61, e202211892 (2022).

Kordnezhadian, R. et al. An Extrusion Strategy for On-Demand SF5Cl Gas Generation from a Commercial Disulfide. Org. Lett. 25, 8947–8951 (2023).

Kraemer, Y. et al. Overcoming a Radical Polarity Mismatch in Strain‐Release Pentafluorosulfanylation of [1.1.0]Bicyclobutanes: An Entryway to Sulfone‐ and Carbonyl‐Containing SF5‐Cyclobutanes. Angew. Chem. Int. Ed. 63, e202319930 (2024).

Kucher, H., Wenzel, J. O. & Rombach, D. Hydrothiolation of Triisopropylsilyl Acetylene Sulfur Pentafluoride – Charting the Chemical Space of β‐SF5 Vinyl Sulfides. ChemPlusChem 89, e202400168 (2024).

Matchavariani, D. et al. Ambiphilic Reactivity of SF5‐Alkynes Applied to Regioselective and Stereodivergent Halogenation Reactions: An Experimental and Theoretical Case Study. Advanced Synthesis Catal. 366, 3481–3493 (2024).

Zhao, X., Shou, J.-Y. & Qing, F.-L. Iodopentafluorosulfanylation of [1.1.1]propellane and Further Functionalizations. Sci. Chi. Chem. 66, 2871–2877 (2023).

Shou, J. Y. & Qing, F. L. Three‐Component Reaction of Pentafluorosulfanyl Chloride, Alkenes and Diazo Compounds and Synthesis of Pentafluorosulfanylfurans. Angew. Chem. Int. Ed. 61, e202208860 (2022).

Shou, J.-Y., Xu, X.-H. & Qing, F.-L. The Radical Reaction of Ethynylbenziodoxolone (EBX) Reagents with Pentafluorosulfanyl Chloride: New Approach to SF5-substituted Alkynes. J. Fluor. Chem. 261-262, 110018 (2022).

Birepinte, M., Champagne, P. A. & Paquin, J. F. Photoinitiated anti‐Hydropentafluorosulfanylation of Terminal Alkynes. Angew. Chem. Int. Ed. 61, e202112575 (2021).

Nguyen, T. M., Legault, C. Y., Blanchard, N., Bizet, V. & Cahard, D. Tracking SF5I in the Iodopentafluorosulfanylation of Alkynes. Chem. Eur. J. 29, e202302914 (2023).

Rombach, D. & Wagenknecht, H. A. Photoredox Catalytic Activation of Sulfur Hexafluoride for Pentafluorosulfanylation of α‐Methyl‐ and α‐Phenyl Styrene. ChemCatChem 10, 2955–2961 (2018).

Rombach, D. & Wagenknecht, H. A. Photoredox Catalytic α‐Alkoxypentafluorosulfanylation of α‐Methyl‐ and α‐Phenylstyrene Using SF6. Angew. Chem. Int. Ed. 59, 300–303 (2020).

Rombach, D., Birenheide, B. & Wagenknecht, H. A. Photoredox Catalytic Pentafluorosulfanylative Domino Cyclization of α‐Substituted Alkenes to Oxaheterocycles by Using SF6. Chem. Eur. J. 27, 8088–8093 (2021).

Debrauwer, V. et al. Synthesis and Physicochemical Properties of 2-SF5-(Aza)Indoles, a New Family of SF5 Heterocycles. ACS Org. Inorg. Au 1, 43–50 (2021).

Popek, L. et al. Regio‐ and Stereoselective Hydroelementation of SF5‐Alkynes and Further Functionalizations. Angew. Chem. Int. Ed. 62, e202300685 (2023).

Wenzel, J. O., Jester, F., Togni, A. & Rombach, D. Hydroamination of Triisopropylsilyl Acetylene Sulfur Pentafluoride – a Bench‐top Route to Pentafluorosulfanylated Enamines. Chem. Eur. J. 30, e202304015 (2024).

Dolbier, W. R. et al. A Convenient and Efficient Method for Incorporation of Pentafluorosulfanyl (SF5) Substituents into Aliphatic Compounds. J. Fluor. Chem. 127, 1302–1310 (2006).

Gilbert, A. & Paquin, J.-F. Evaluation of the Compatibility of Pentafluorosulfanyl Chloride with Various Solvents and Additives. J. Fluor. Chem. 221, 70–74 (2019).

Gilbert, A. et al. Amine–borane Complex-initiated SF5Cl Radical Addition on Alkenes and Alkynes. Beilstein J. Org. Chem. 16, 3069–3077 (2020).

Feng, F.-F., Ma, J.-A. & Cahard, D. Radical 1,5-Chloropentafluorosulfanylation of Unactivated Vinylcyclopropanes and Transformation into α-SF5 Ketones. J. Org. Chem. 86, 13808–13816 (2021).

Gilbert, A., Birepinte, M. & Paquin, J.-F. Electron Donor-acceptor (EDA)-complex Enabled SF5Cl Addition on Alkenes and Alkynes. J. Fluor. Chem. 243, 109734 (2021).

Lefebvre, G., Charron, O., Cossy, J. & Meyer, C. Radical Addition of SF5Cl to Cyclopropenes: Synthesis of (Pentafluorosulfanyl)cyclopropanes. Org. Lett. 23, 5491–5495 (2021).

Taponard, A. et al. Metal‐Free SF6 Activation: A New SF5‐Based Reagent Enables Deoxyfluorination and Pentafluorosulfanylation Reactions. Angew. Chem. Int. Ed. 61, e202204623 (2022).

Ouellet-Du Berger, M.-R., Boucher, M. & Paquin, J.-F. Light-activation of SF5Cl for the Atom Transfer Radical Addition onto Alkenes and Alkynes. J. Fluor. Chem. 268, 110131 (2023).

Nguyen, T. M. et al. Expanding Radical Chloropentafluorosulfanylation of Alkynes. Org. Lett. 26, 365–369 (2024).

Wang, L. & Qin, W. Copper-Initiated Regiodivergent Chloropentafluorosulfanylation of 1,3-Enynes under Substrate Control. Org. Lett. 26, 5049–5054 (2024).

Smith, M. B. & March, J. Advanced Organic Chemistry: Reactions, Mechanisms, and Structure, 6th ed. (Wiley-Interscience, 2007).

Chang, L., An, Q., Duan, L., Feng, K. & Zuo, Z. Alkoxy Radicals See the Light: New Paradigms of Photochemical Synthesis. Chem. Rev. 122, 2429–2486 (2021).

Li, Y. & Studer, A. Transition‐Metal‐Free Trifluoromethylaminoxylation of Alkenes. Angew. Chem. Int. Ed. 51, 8221–8224 (2012).

Yasu, Y., Koike, T. & Akita, M. Three‐component Oxytrifluoromethylation of Alkenes: Highly Efficient and Regioselective Difunctionalization of C=C Bonds Mediated by Photoredox Catalysts. Angew. Chem. Int. Ed. 51, 9567–9571 (2012).

Luo, X.-Z., Luo, H.-Q., Zhang, Z.-P. & Dong, W. A Practical Method for Metal-Free Radical Trifluoromethylation of Styrenes with NaSO2CF3. Synlett 25, 1307–1311 (2014).

Liu, C. et al. NMP and O2 as Radical Initiator: Trifluoromethylation of Alkenes to Tertiary β-Trifluoromethyl Alcohols at Room Temperature. Org. Lett. 17, 6034–6037 (2015).

Yang, Y., Liu, Y., Jiang, Y., Zhang, Y. & Vicic, D. A. Manganese-Catalyzed Aerobic Oxytrifluoromethylation of Styrene Derivatives Using CF3SO2Na as the Trifluoromethyl Source. J. Org. Chem. 80, 6639–6648 (2015).

Yang, X., He, L. & Tsui, G. C. Hydroxytrifluoromethylation of Alkenes Using Fluoroform-Derived CuCF3. Org. Lett. 19, 2446–2449 (2017).

Shen, W.-G., Wu, Q.-Y., Gong, X.-Y., Ao, G.-Z. & Liu, F. A Facile Method for Hydroxytrifluoromethylation of Alkenes with Langlois Reagent and DMSO. Green. Chem. 21, 2983–2987 (2019).

Su, Z., Guo, Y., Chen, Q. Y., Zhao, Z. G. & Nian, B. Y. Catalyst‐Free Hydroxytrifluoromethylation of Alkenes UsingIodotrifluoromethane. Chin. J. Chem. 37, 597–604 (2019).

Li, Q. et al. Cobalt–Tertiary-Amine-Mediated Hydroxytrifluoromethylation of Alkenes with CF3Br and Atmospheric Oxygen. Acs. Catal. 10, 4012–4018 (2020).

Long, W., Lian, P., Li, J. & Wan, X. Mn-Catalysed Photoredox Hydroxytrifluoromethylation of Aliphatic Alkenes Using CF3SO2Na. Org. Biomol. Chem. 18, 6483–6486 (2020).

Zheng, P. et al. Fe-catalyzed Hydroxytrifluoromethylation of α-(trifluoromethyl)styrenes with CF3SO2Na: Facile Access to α,β-bistrifluoromethyl Tertiary Alcohols. Org. Biomol. Chem. 20, 9302–9306 (2022).

Kundu, B. K. et al. Trifluoromethylative Bifunctionalization of Alkenes via a Bibenzothiazole-Derived Photocatalyst under Both Visible- and Near-Infrared-Light Irradiation. Acs. Catal. 13, 8119–8127 (2023).

Yoshida, M., Ohkoshi, M., Aoki, N., Ohnuma, Y. & Iyoda, M. Photochemical Oxyfluoroalkylation of Styrenes by the Addition of Perfluoroalkyl Radicals in an Atmosphere of Oxygen. Tetrahedron Lett. 40, 5731–5734 (1999).

Yoshida, M., Ohkoshi, M., Muraoka, T., Matsuyama, H. & Iyoda, M. Oxygenative Perfluoroalkylation of Olefinic Compounds Using Perfluoroalkyl Iodide in the Presence of Oxygen. Bull. Chem. Soc. Jpn. 75, 1833–1842 (2002).

Chen, T. et al. Photoinduced Hydroxylperfluoroalkylation of Styrenes. Org. Chem. Front. 5, 1045–1048 (2018).

Geng, X., Lin, F., Wang, X. & Jiao, N. Photoredox-catalyzed Hydroxyfluoroalkylation of Alkene with Simple Fluoroalkyl Iodides. J. Photoch. Photobio. A 355, 194–201 (2018).

Gryaznova, T. V. et al. Palladium Nanoparticles–Polypyrrole Composite as Effective Catalyst for Fluoroalkylation of Alkenes. Cata. Lett. 148, 3119–3125 (2018).

Li, Q. et al. Cobalt-Catalyzed Hydroxyperfluoroalkylation of Alkenes with Perfluoroalkyl Bromides and Atmospheric Oxygen. Synthesis 54, 1353–1364 (2021).

Tagami, K., Ofuji, Y., Kanbara, T. & Yajima, T. Metal-free Visible-light-induced Hydroxy-perfluoroalkylation of Conjugated Olefins Using Enamine Catalyst. RSC Adv. 12, 32790–32795 (2022).

Tagami, K. & Yajima, T. Halogen‐Bond‐Promoted Hydroxyperfluoroalkylation of Olefins with Molecular Oxygen under Visible‐Light Irradiation. Asian J. Org. Chem. 12, e202300273 (2023).

Tang, L., Feng, C., Yang, F. & Wu, Y. Copper-Catalyzed Hydroxyperfluoroalkylation of Unactivated Alkenes: Access to β-Perfluoroalkyl Alcohols. Org. Lett. 25, 2782–2787 (2023).

Arai, Y., Tomita, R., Ando, G., Koike, T. & Akita, M. Oxydifluoromethylation of Alkenes by Photoredox Catalysis: Simple Synthesis of CF2H‐Containing Alcohols. Chem. Eur. J. 22, 1262–1265 (2015).

Xu, H.-H., Song, J.-S. & Xu, H.-C. Electrochemical Difluoromethylation of Electron‐Deficient Alkenes. ChemSusChem 12, 3060–3063 (2019).

Xie, Z.-Z. et al. Visible-Light-Promoted Hydroxydifluoroalkylation of Alkenes Enabled by Electron Donor–Acceptor Complex. Org. Lett. 23, 9474–9479 (2021).

Luan, S., Castanheiro, T. & Poisson, T. Electrochemical Difluoromethylation of Electron-Rich Olefins. Org. Lett. 25, 1678–1682 (2023).

Li, Y. et al. Silver-Catalyzed Anti-Markovnikov Hydroxyfluorination of Styrenes. Acs. Catal. 7, 1606–1609 (2017).

Sedgwick, D. M. et al. Metal-Free and User-Friendly Regioselective Hydroxyfluorination of Olefins. Org. Lett. 20, 2338–2341 (2018).

Zhou, J., Fang, Y., Wang, F. & Li, J. Catalyst-free Regioselective Hydroxyfluorination and Aminofluorination of α,β-unsaturated Ketones. Org. Biomol. Chem. 17, 4470–4474 (2019).

Dai, L. et al. Fluorohydroxylation and Hydration Reactions of para-Quinone Methides Promoted by Selectfluor. J. Org. Chem. 88, 1352–1363 (2023).

Zhu, Z., Luo, J. & Zhao, X. Combination of Lewis Basic Selenium Catalysis and Redox Selenium Chemistry: Synthesis of Trifluoromethylthiolated Tertiary Alcohols with Alkenes. Org. Lett. 19, 4940–4943 (2017).

Joliton, A., Plancher, J. M. & Carreira, E. M. Formation of α‐SF5‐Enolate Enables Preparation of 3‐SF5‐Quinolin‐2‐ones, 3‐SF5‐Quinolines, and 3‐SF5‐Pyridin‐2‐ones: Evaluation of their Physicochemical Properties. Angew. Chem. Int. Ed. 55, 2113–2117 (2016).

Kato, T., Okada, Y., Fujii, Y., Uyanik, M. & Ishihara, K. Oxidative Ritter-type Chloroamidation of Alkenes Using NaCl and Oxone. Asian J. Org. Chem. 10, 2907–2910 (2021).

Shen, D. et al. Additive-free oxychlorination of unsaturated C–C bonds with tert-butyl hypochlorite and water. Org. Biomol. Chem. 22, 3080–3085 (2024).

Cloutier, M., Roudias, M. & Paquin, J.-F. Regioselective Gold-Catalyzed Hydration of CF3- and SF5-alkynes. Org. Lett. 21, 3866–3870 (2019).

Gauthier, R., Mamone, M. & Paquin, J.-F. Gold-Catalyzed Hydrofluorination of Internal Alkynes Using Aqueous HF. Org. Lett. 21, 9024–9027 (2019).

Popek, L., Cihan, M., Blanchard, N. & Bizet, V. Palladium‐Catalyzed Regioselective Synthesis of 2‐SF5‐Indenols and Further Derivatizations. Angew. Chem. Int. Ed. 63, e202315909 (2024).

Reiß, B., Hu, Q., Riedle, E. & Wagenknecht, H. A. The Dependence of Chemical Quantum Yields of Visible Light Photoredox Catalysis on the Irradiation Power. ChemPhotoChem 5, 1009–1019 (2021).

Acknowledgements

S. Guo gratefully acknowledge National Natural Science Foundation of China (22261037), the Program for Young Talents of Science and Technology in Universities of Inner Mongolia Autonomous Region (NJYT22091), Young science and technology talents cultivation project of Inner Mongolia University (No. 21221505), the Central Guidance on Local Science and Technology Development Fund of Inner Mongolia Autonomous Region (2023ZY0016), Program for Innovative Research Team in Universities of Inner Mongolia Autonomous Region (NMGIRT2324) for financial support.

Author information

Authors and Affiliations

Contributions

S. Guo conceived the project. Y. Y. Jiang, X. L. Meng, J. S. Zhang, G. Wu and X. J. Lin performed the experiments and analyzed the experimental data. All the authors discussed the results and contributed to the preparation of the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Jiang, Y., Meng, X., Zhang, J. et al. Photo-induced hydroxypentafluorosulfanylation of alkenes with SF5Cl and oxygen gas and their further derivatization. Nat Commun 15, 9705 (2024). https://doi.org/10.1038/s41467-024-54015-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-024-54015-5

This article is cited by

-

Applying alternating current in paired photo-electrocatalysis for asymmetric cross-coupling of alcohols

Nature Synthesis (2025)

-

Bench-stable reagents for modular access to persulfuranyl scaffolds

Nature Communications (2025)